Elster Kromschroder VMF 115, Kromschroder VMF 110, Kromschroder VMF 225, Kromschroder VMF 120, Kromschroder VMF 125 Technical Information

...Page 1

Filter module VMF

Technical Information · GB

3.1.0.20 Edition 02.11

• Safe gas cleaning using filter pad and strainer

• Easy installation into a system in conjunction with valVario valves and

regulators

• Installation in any position, even with optional pressure switch

www.kromschroeder.com

Page 2

Contents

Filter module VMF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Examples of application. . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.1 valVario double block valve with pressure regulator VCD

and VMF fitted to a forced draught burner . . . . . . . . . . . . . . . . . 4

1.1.2 valVario double block valve with variable air/gas ratio

control VCV and VMF fitted to a forced draught burner . . . . . . . 4

1.1.3 Industrial burner with staged control. . . . . . . . . . . . . . . . . . 4

1.1.4 Industrial burner with continuous control . . . . . . . . . . . . . . .5

2 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Calculating the nominal size . . . . . . . . . . . . . . . . . . . . . 7

4 Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Project planning information . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 Seal set VA 1 – 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 Filter pad set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.1.1 VMF..R. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.1.2 VMF..N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

7.1.3 VMF 240F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

8 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2

VMF · Edition 02.11

t

= To be continued

Page 3

Application

1 Application

VMF2..1-4 VMF2..R..M

The filter module VMF is designed for cleaning the gas and air

flow to gas burners or gas appliances. It is suitable for use in

gas control and safety systems in all sectors of the iron, steel,

glass and ceramics industries, and also in all areas of private

and commercial heat generation.

It can easily be adapted to different pipes thanks to various

flange shapes for the individual valVario valve sizes. Its modular design allows assembly with valVario valves or regulators

making it possible to construct space-saving gas systems.

3

Forced draught gas burner with valVario controls

VMF · Edition 02.11

Roller hearth furnace

Page 4

Application

4

1.1 Examples of application

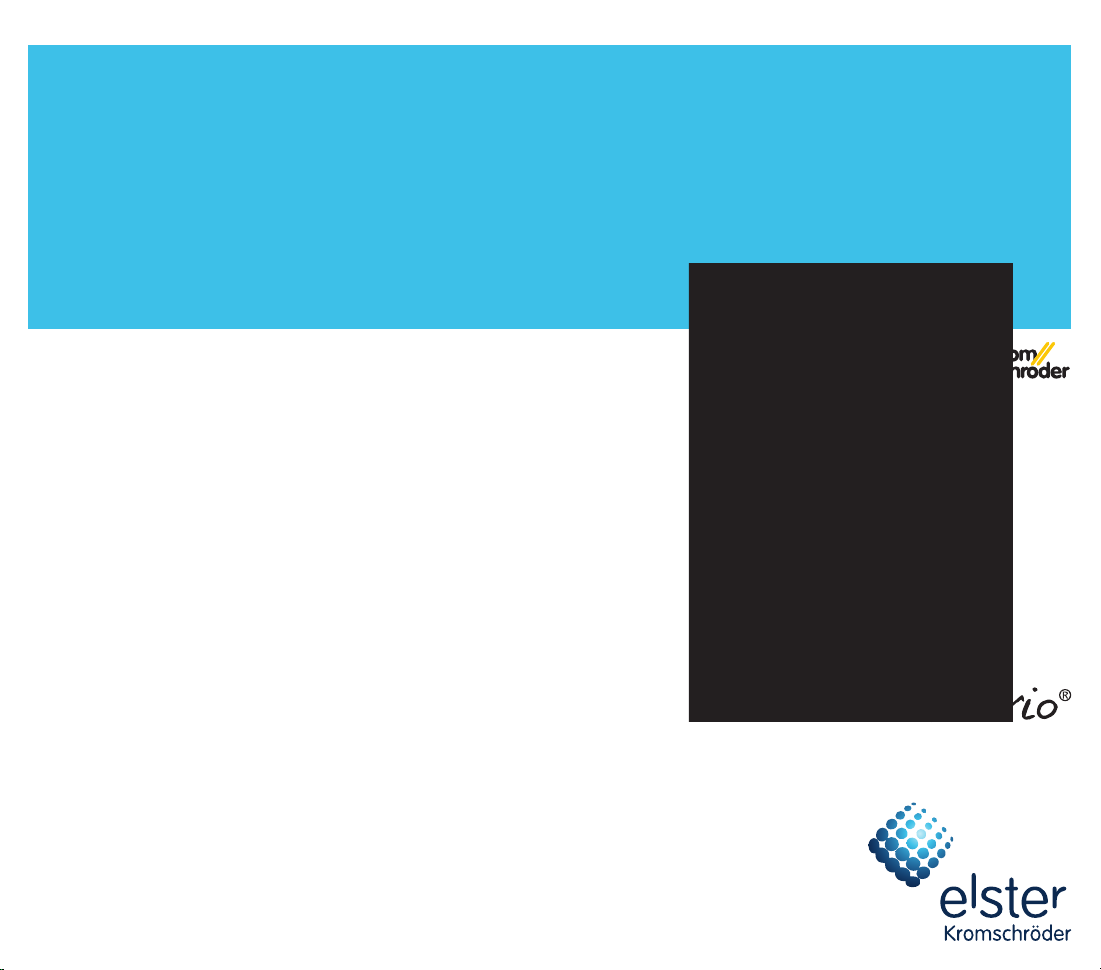

1.1.1

valVario double block valve with pressure regulator VCD

and VMF fitted to a forced draught burner

VCD

VMF

This type of control is used on one-stage forced draught burn-

ers or in one-stage boilers, it is also suitable for use with a

mechanical or electronic air/gas ratio control system.

1.1.2 valVario double block valve with variable air/gas ratio

control VCV and VMF fitted to a forced draught burner

VCV

VMF

p

F

1.1.3 Industrial burner with staged control

VAG

VMV

EKO

BIC

EKO

LEH

AKT

VMF

VAS

+VBY

IC 40 + BVA

M

The high output impulse at the burner generated by this type

of control produces a uniform temperature distribution and

good circulation of the furnace or kiln atmosphere, e.g. in heat

treatment furnaces in the iron and non-ferrous metal industries

or kilns for heavy clay and fine ceramics. The required lambda

value can be set using the fine-adjusting valve VMV and the

air adjusting cock LEH. Using the filter module VMF, the gas

flow upstream of the gas valve VAS is cleaned.

p

L

With this type of continuous control, the mixture setting is

maintained over a wide control range while at the same time

preventing air deficiency.

VMF · Edition 02.11

Page 5

Application > Examples of application

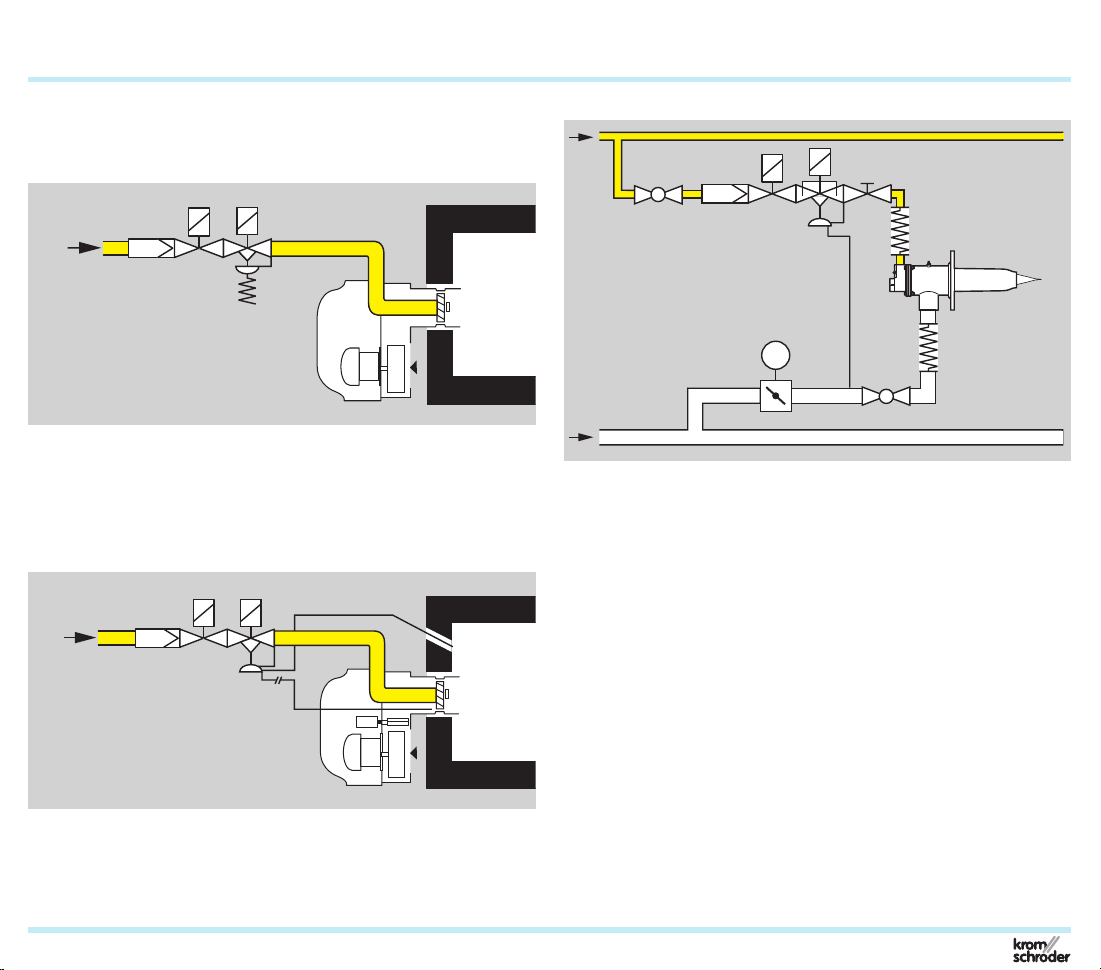

1.1.4 Industrial burner with continuous control

5

Three-

point

step

VMF

IC 20 + BVA

VAS

M

VAG

VMV

BVA

EKO

ZIO, BIO, BIOA

EKO

LEH

Using the filter module VMF, the gas flow upstream of the

gas valve VAS and the air/gas ratio control VAG is cleaned.

The gas/air mixture is set using the fine-adjusting valve VMV.

A constant mixture setting is maintained over a wide control

range while at the same time preventing air deficiency. This

type of control is used on boilers with multi-stage or infinitely

adjustable forced draught burners.

VMF · Edition 02.11

Page 6

2 Function

6

Pressure switch DG..VC

Pressure test point

Flange

Retaining frame

with strainer

Filter pad

Housing

Base plate

VMF..M with test points

There is a retaining frame with an integrated strainer and filter

pad in the housing of the VMF. The filter pad is supported by

the strainer. The filter pad and the strainer rid the gas of coarse

as well as fine impurities.

In order to replace the filter pad, the two retaining screws are

undone and the base plate removed. The retaining frame with

the filter pad is pulled out. The retaining frame is opened and

the filter pad can be taken out.

The VMF is delivered with two test points for pressure measure-

ment as standard. The VMF can also optionally be delivered

with two 1/8“ screw plugs.

COM

Pressure test point

NC

NO

Flange

Retaining frame

with strainer

Filter pad

Housing

Base plate

VMF..1 to 4 with pressure switch DG..VC

The VMF..1 to 4 is equipped with a pressure switch for moni-

toring minimum or maximum pressure. The pressure switch

monitors the outlet pressure downstream of the filter pad. In

addition, there is also a test point for measuring the pressure

directly.

VMF · Edition 02.11

Page 7

7

●

Natural gas

0.80

kg/m3

20.9

m3/h

400

10.0

mbar

mbar0°C

15.0

m3/h

[mbar]

[m/s]

VMF 110 | 9.2| 29

VMF 115 | 4.5| 18

VMF 120 | 1.3| 11

VMF 125 | 0.8| 7

VMF 225 | 0.4| 7

VMF 232 | 0.2| 4

VMF 240 | 0.1| 3

3 Flow rate

8

6

5

4

∆p [inch WC]

3

2

0,8

0,6

0,5

0,4

0,3

0,2

0,8

0,6

0,5

0,4

= natural gas (ρ = 0.80 kg/m3)

= propane (ρ = 2.01 kg/m3)

= air (ρ = 1.29 kg/m3)

The characteristic curves are measured at

15°C (59°F) with a measurement set-up in accordance with the standards EN 13611/EN 161.

VMF · Edition 02.11

20

∆p [mbar]

10

8

6

5

4

1

1

3

2

1

0,8

0,6

0,5

0,4

0,3

0,2

0,1

1

2

3

0,8 1 2 3 4 6 8 10 20 30 40

1

30 40 60 100 200 10000400 2000 300 0 5000600 1000

21 3 4 6 8 10 20 30 40

1 2 3 4 6 8 10 20 30

0,7

VMF 110

VMF 115

VMF 125

VMF 120

60 100

40 60

VMF 225

60 100

VMF 232

VMF 240

VMF 250

200 300 500

100 200 300

200 300

V' n [m3/h]

V' [SCFH]

This involves measuring the pressure 5 x DN

upstream and downstream of the unit under

test. The pressure drop of the pipe is also

measured but is not compensated for.

A pressure loss of 10 mbar must not be ex-

ceeded.

Reading instructions:

Should operating cubic metres (V

·

b) have

been used in the flow rate diagram, instead

of standard cubic metres (

V·

n), then the pres-

sure loss read must be multiplied by the

absolute inlet pressure in bar (1+positive

pressure in bar).

Example:

inlet pressure p

(positive pressure) = 0.4bar,

e

gas type: natural gas,

operating flow rate

V·

b = 15 m

3

/h,

selected filter module: VMF 120

∆p from diagram = 3.1 mbar,

∆p = 3.1 mbar x (1 + 0.4) = 4.5 mbar.

The VMF 120 has been selected correctly.

3.1 Calculating the nominal size

Standard T-product

Flow rate

Inlet pressure p

Medium temperature

Flow rate

Product

·

(V

n)

e

∆p

max.

·

(V

b)

∆p v

Page 8

4 Selection

* Specifi cation omitted, if the nominal diameter of the inlet and outlet fl anges is the same.

1)

* Specifi cation omitted, if the nominal diameter of the inlet and outlet

Type – 10 15 20 25 32 40 50 /–* /10* /15*

VMF 1

VMF 2

= standard, = available

Only available for VMF 240.

4.1 Type code

Code Description

VMF Filter module

1–2 Size

–

10–50

/–

/10–/50

R

N

F

05 p

M

P

1

With outlet pressure switch: DG 17/VC

2

3

4

Without inlet fl ange

Nominal inlet diameter

Without outlet fl ange*

Nominal outlet diameter

NPT internal thread

Flange to ISO 7005

With pressure test points

/20*/25*/32*/40*/50*

Rp internal thread

500 mbar

e max

With screw plugs

DG 40/VC

DG 110/VC

DG 400/VC

8

R N F 1) 05 M P 1 2 3 4

fl anges is the same.

VMF · Edition 02.11

Page 9

5 Project planning information

5.1 Installation

Installation position: VMF can be installed as required.

We recommend installation with the base plate pointing

downwards or sideways so that dirt can be removed from

the housing more easily.

Installation position when using valVario valves and regulators:

the VMF is fitted upstream of the valVario control.

The VMF can be installed as a standalone device in the pipe.

9

VMF · Edition 02.11

Page 10

10

6 Accessories

6.1 Seal set VA 1 – 3

A B

Scope of delivery:

A 1 x double block seal,

B 2 x O-rings (flange),

C 2 x O-rings (pressure switch),

D 2 x sealing rings (test point).

C

D

6.2 Filter pad set

A

Scope of delivery:

A 1 x retaining frame with strainer,

B 10 x filter pads,

C 10 x seals for the base plate,

D 2 x seals for 1/8” test points,

E 2 x screws for securing the base plate.

B

D

C

E

VMF · Edition 02.11

Page 11

7 Technical data

Gas types:

natural gas, LPG (gaseous), biologically produced methane

(max. 0.1 %-by-vol. H2S) or air; other gas types on request.

The gas must be dry in all conditions and must not contain

condensate.

Max. inlet pressure p

max. 500 mbar (7.25 psig).

Ambient temperature:

-20 to +60°C (-4 to +140°F),

no condensation permitted.

Storage temperature:

-20 to +40°C (-4 to 104°F).

Housing: aluminium.

Connection flanges:

with internal thread: Rp to ISO 7-1, NPT to ANSI/ASME,

with ISO flange: DN 40 to ISO 7005.

:

e

11

VMF · Edition 02.11

Page 12

* Without fl anges.

Technical data

7.1 Dimensions

12

H1

H2

VMF..R..M, VMR..R..P

D

L1

F

VMF..R..1-4

H3

H2

D

L1

F

7.1.1 VMF..R

Dimensions Weight

Type

Connection

L1 F D H1 H2 H3

Rp DN mm mm mm mm mm mm kg kg kg

VMF 110 3/8 10 30 15 62.7 65.1 44.6 99 0.34 0.49 0.07

VMF 115 1/2 15 30 15 62.7 65.1 44.6 99 0.34 0.49 0.06

VMF 120 3/4 20 30 23 62.7 65.1 44.6 99 0.34 0.49 0.11

VMF 125 1 25 30 23 62.7 65.1 44.6 99 0.34 0.49 0.09

VMF 225 1 25 34 29 88 81 65.2 114.6 0.76 0.91 0.29

VMF 232 11/4 32 34 29 88 81 65.2 114.6 0.76 0.91 0.26

VMF 240 11/2 40 34 29 88 81 65.2 114.6 0.76 0.91 0.29

VMF 250 2 50 34 29 88 81 65.2 114.6 0.76 0.91 0.22

VMF..R..P*,

VMF..R..M*

VMF..N..1-4* Flange

VMF · Edition 02.11

Page 13

* Without fl anges.

Technical data > Dimensions

H3

H1

H2

D

L1

F

VMF..N..M, VMR..R..P

VMF..N..1-4

7.1.2 VMF..N

Dimensions Weight

Type

VMF 110 3/8 10 1.18 0.59 2.46 2.56 1.76 3.89 0.75 1.08 0.15

VMF 115 1/2 15 1.18 0.59 2.46 2.56 1.76 3.89 0.75 1.08 0.14

VMF 120 3/4 20 1.18 0.91 2.46 2.56 1.76 3.89 0.75 1.08 0.23

VMF 125 1 25 1.18 0.91 2.46 2.56 1.76 3.89 0.75 1.08 0.20

VMF 225 1 25 1.34 1.14 3.46 3.19 2.57 4.51 1.66 2.01 0.64

VMF 232 11/4 32 1.34 1.14 3.46 3.19 2.57 4.51 1.66 2.01 0.57

VMF 240 11/2 40 1.34 1.14 3.46 3.19 2.57 4.51 1.66 2.01 0.65

VMF 250 2 50 1.34 1.14 3.46 3.19 2.57 4.51 1.66 2.01 0.49

Connection

L1 F D H1 H2 H3

NPT DN inch inch inch inch inch inch lbs lbs lbs

H2

D

F

VMF..N..P*.

VMF..N..M*

L1

VMF..N..1-4* Flange

13

VMF · Edition 02.11

Page 14

Technical data > Dimensions

* Without fl anges and connection parts.

H1

14

D

H3

H2

L1

F

VMF 240/40F..M, VMF 240/40F..P

H2

L1

F

VMF 240/40F..1-4

7.1.3 VMF 240F

Dimensions Weight

Type

Connection

L1 F D H1 H2 H3

DN mm mm mm mm mm mm kg kg kg

VMF 240 40 34 66 88 81 65.2 114.6 0.76 0.91 1.04

VMF · Edition 02.11

VMF..F..P*,

VMF..F..M*

VMF..F..1-4* Flange

Page 15

8 Maintenance

Check for external tightness at least once per annum, at least

twice per annum for operation with biologically produced

methane. Replace filter pad as required, see page 10 (Filter

pad set).

15

VMF · Edition 02.11

Page 16

16

Kromschröder AG

Michael Rehkamp

m.rehkamp@kromschroeder.com

Osnabrüc

k

Feedback

Feedback

Finally, we are offering you the opportunity to assess this “Technical Information (TI)” and to give us your opinion, so that we

can improve our documents further and suit them to your needs.

Clarity

Found information quickly

Searched for a long time

Didn’t find information

What is missing?

No answer

Use

To get to know the product

To choose a product

Planning

To look for information

Remarks

Contact

Contact

Elster GmbH

Postfach 2809 · 49018 Osnabrück

Strotheweg 1 · 49504 Lotte (Büren)

Germany

T +49 541 1214-0

F +49 541 1214-370

info@kromschroeder.com

www.kromschroeder.com

www.elster.com

VMF · Edition 02.11

Comprehension

Coherent

Too complicated

No answer

Navigation

I can find my way around

I got “lost”

No answer

The current addresses of our international

agents are available on the Internet:

www.kromschroeder.com Sales

Scope

Too little

Sufficient

Too wide

No answer

My scope of functions

Technical department

Sales

No answer

(Adobe Reader 7 or higher required)

We reserve the right to make technical

modifications in the interests of progress.

Copyright © 2007 – 2011 Elster Group

All rights reserved.

03250962

Loading...

Loading...