Page 1

J48 2½”- 6”

Commissioning Instructions

OPERATING INSTRUCTIONS

• Ensure that this product is suitable for the chosen application.

• Installation, adjustment and maintenance by authorised, trained personnel only.

• When being fitted to an appliance, refer to the appliance manufacturers

instructions.

Warning! Incorrect installation, adjustment, modification, operation and maintenance may

cause injury or damage.

Read the instructions before use. This control must be installed in accordance with the rules in

force.

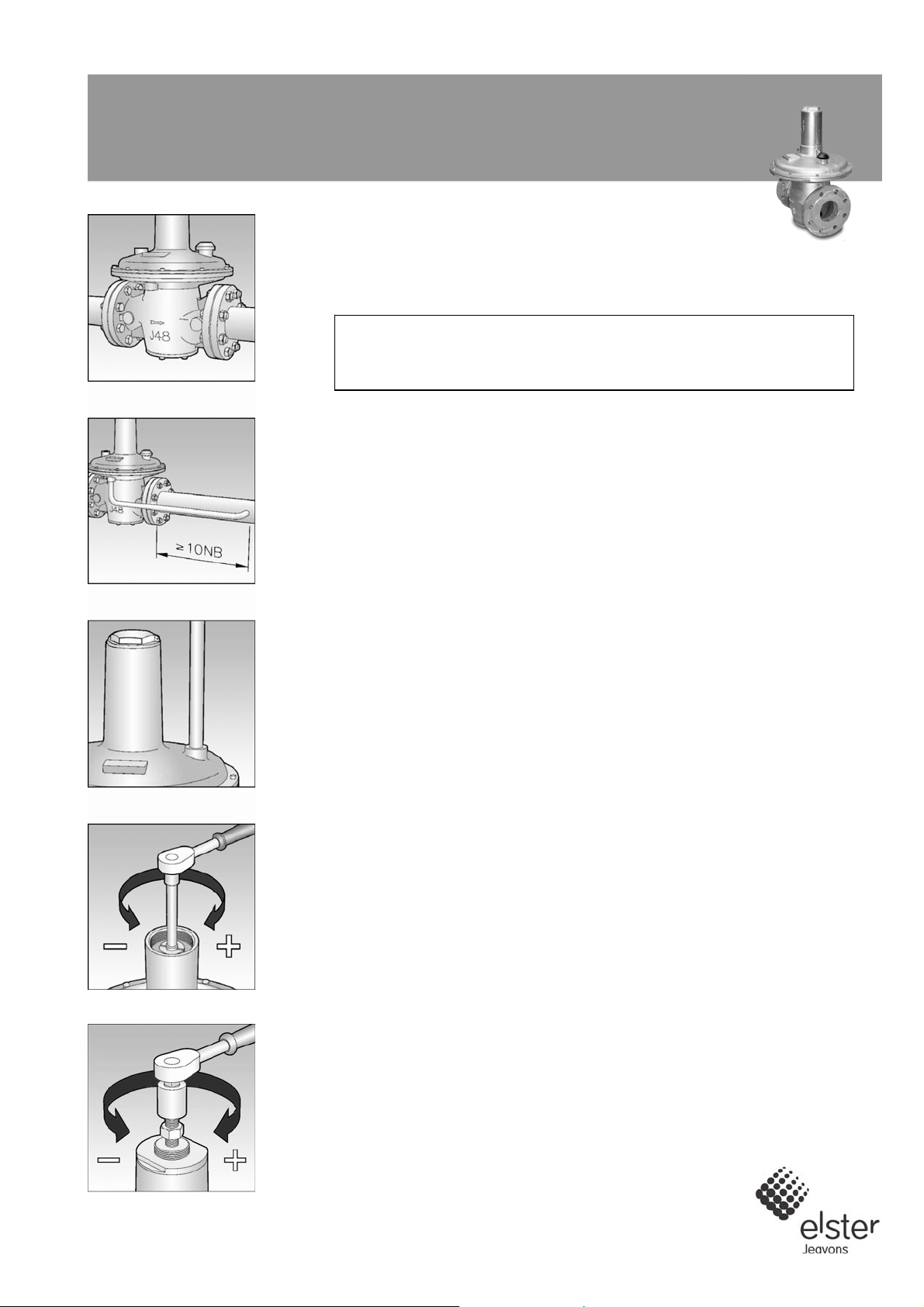

Fig. 1

Fig. 2

Fig. 3

Fig. 4

FITTING UNITS INTO PIPEWORK

1. Remove the protection from the inlet and outlet ports.

2. Ensure that the installation pipework is thoroughly clean.

3. The direction of gas flow must be the same as the arrows on the regulator body.

See Fig. 1.

4. Install regulator into pipework.

INSTALLATION OF EXTERNAL IMPULSE LINE (IF REQUIRED)

1. Remove the plastic protection plug.

2. Connect the impulse line (½"), using a jointing compound approved to national

standards, and lead to a point downstream not less than ten times the nominal

pipe diameter from the outlet. See Fig. 2.

INSTALLATION OF VENT LINE (IF REQUIRED)

1. Remove breather cover from regulator top case / cover.

2. Connect the vent line (½"), using a jointing compound approved to national

standards, and lead to atmosphere in accordance with national standards.

Ensure that no water can penetrate vent pipe. See Fig. 3.

3. If vent connection is to be used for top loading or other similar use refer to your

own installation instructions.

SETTING OF OUTLET PRESSURE

1. Turn off inlet and outlet valves.

2. Remove top cap.

3. For L.P. 65mm and 80mm unit insert ½" square socket extension piece into

square hole, or flat blade screwdriver into slot in spring adjuster. See Fig. 4.

4. For H.P. 65mm and 80mm unit and L.P. 100mm and 150mm unit, slacken

locknut on spring adjusting stem and connect suitable spanner (24mm A/F) to

hexagon of spring adjusting stem. See Fig. 5.

5. For 100mm and 150mm H.P. unit connect suitable spanner (27mm A/F) to

hexagon of spring adjusting nut. See Fig. 6.

6. Turn spring adjustment anticlockwise to reduce pressure on loading spring.

7. Slowly turn on inlet supply.

8. Increase loading on spring by turning spring adjustment clockwise until the

required outlet pressure, plus approximately 2.5mbar, is obtained).

9. Commission downstream appliance(s).

10. Trim the outlet pressure of the regulator, if necessary, when normal working flow

rates have been achieved.

11. Replace the top cap.

Fig. 5

Page 2

J48: 2½” – 6” Commissioning Instructions

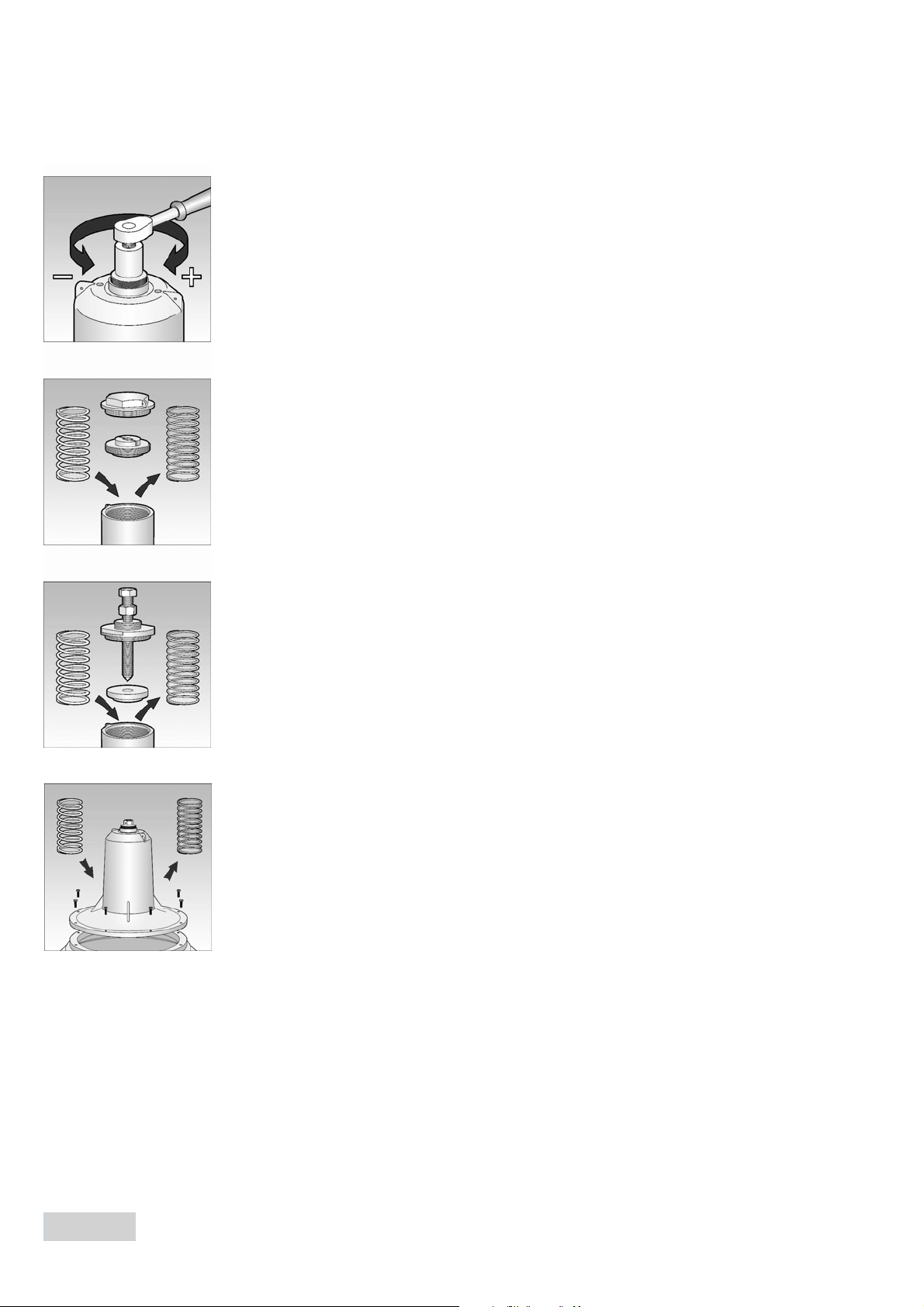

IF THE REQUIRED OUTLET PRESSURE CAN NOT BE ACHIEVED WITH

THE SPRING FITTED.

1. Choose a loading spring from the catalogue that will give the required outlet

pressure range.

For L.P. 65mm and 80mm units: See Fig. 7.

2. Remove top cap.

3. Fully unscrew and remove the spring holder.

4. Remove loading spring.

Fig. 6

5. Insert new loading spring.

6. Screw spring holder back in place ensuring that spigot is located in loading

spring.

7. Adjust the outlet pressure, as described earlier, until the required setting is

achieved.

8. Replace top cap.

For H.P. 50mm and 80mm & L.P. 100mm and 150mm units: See Fig. 8.

9. Remove top cap.

10. Slacken locknut on spring adjusting stem.

Fig. 7

11. Turn spring adjuster anticlockwise to reduce loading on spring.

12. Unscrew spring adjusting bush.

13. Remove top spring holder and loading spring.

14. Insert new loading spring.

15. Place top spring holder over spring ensuring that spigot is located in loading

spring.

16. Screw spring adjusting bush into top cover making sure that the end of the stem

is located in the recess in the top spring holder.

17. Adjust the outlet pressure, as described earlier, until the required setting is

achieved.

Fig. 8

18. Tighten locknut.

19. Replace top cap.

For H.P. 100mm and 150mm units: See Fig. 9.

20. Remove top cap.

21. Turn spring adjusting nut anticlockwise to reduce loading on spring.

22. Remove 8 hexagon head screws that secure top cover to top diaphragm case.

Carefully lift off top cover assembly and gasket.

23. Remove loading spring.

24. Install new loading spring over spring location washer in centre of diaphragm.

Fig. 9

25. Replace gasket and top cover assembly and secure with 8 hexagon head

screws.

26. Adjust the outlet pressure, as described on earlier, until the required setting is

found.

27. Replace top cap.

Contacts

United Kingdom Germany USA

Elster Jeavons Elster GmbH Elster American Meter

Tollgate Business Park, Beaconside Steinern Str. 19 - 21 2221 Industrial Road

Stafford, Staffordshire ST16 3HS 55252 Mainz-Kastel Nebraska City, NE 68410-6889

T +44 1785 275200 T +49 6134 605 0 T +1 402 873 8200

F +44 1785 275305 F +49 6134 605 223 F +1 402 873 7616

www.jeavonsltd.co.uk www.elster-instromet.com www.elster-meterservices.com

info.jeavons@gb.elster.com info@elster-instromet.com

C483EN01

A25.1.2008

Subject to change without prior notice All rights reserved

Subject to change without prior notice All rights reserved

Loading...

Loading...