Page 1

Gas quality analyser Q1

Technical documentation

Function, operation,

commissioning and maintenance

FCQ1-BAShort-EN a 19.3.2013

2013 Elster GmbH Edition a 19.3.2013

Page 2

Copyright

2013 Elster GmbH

GAS-WORKS, Z1, gas-lab Q1, and FLOW COMP are German

registered trademarks of Elster.

Microsoft, Windows and Windows NT are registered trademarks

of Microsoft Corporation.

HART is a registered trademark of HART Communication

Foundation.

Elster GmbH

Schlossstraße 95a

D - 44357 Dortmund, Germany

Tel.: +49 231 937110-0

Fax: +49 231 937110-99

E-mail: info@elster-instromet.com

Page ii gas-lab Q1

Page 3

Contents

Safety and warning notes ................................................................................. v

1 Introduction ............................................................................................... 1

1.1 The gas-net system idea ...................................................................... 1

1.2 The measuring principle ....................................................................... 1

2 Device view and design ............................................................................ 5

2.1 Sensor system ..................................................................................... 5

2.2 Evaluation computer ............................................................................ 7

3 Operating gas-net devices ..................................................................... 11

3.1 The keypad ........................................................................................ 11

3.2 Other operating elements: status LED, calibration switch .................. 12

3.3 Display ............................................................................................... 14

3.4 Displays / Menus / Dialogs ................................................................. 14

4 Primer for impatient operators: What do I have to do to …? ............. 25

4.1 ... view the gas quality error listing? ................................................... 25

4.2 … accept the gas quality measurement errors? ................................. 26

4.3 … check all parameter settings? ........................................................ 27

4.4 … check the input values? ................................................................. 28

4.5 … view and check the outputs? ......................................................... 28

4.6 … view the archives? ......................................................................... 28

5 Functional description ............................................................................ 29

5.1 Gas quality module ............................................................................ 29

5.2 Data logging module .......................................................................... 53

5.3 Monitoring module ............................................................................. 59

5.4 System module ................................................................ .................. 78

5.5 Integrated RDT module ...................................................................... 87

5.6 DSfG module, Data exchange module ............................................... 89

6 GAS-WORKS / GW-GNET+ ..................................................................... 97

6.1 Compiling and exporting a parameterisation: Brief description .......... 98

6.2 Importing and editing a parameterisation: Brief description ............. 101

6.3 Extras: GW-GNET+ service programs ............................................. 103

6.4 Optional: GW-Remote+ for downloading archives ........................... 105

gas-lab Q1 Page iii

Page 4

7 Installation ............................................................................................. 107

7.1 Mounting the gas-net Q1 ................................................................. 107

7.2 Connecting the lines ........................................................................ 107

7.3 Mounting the sensor system ............................................................ 117

8 Commissioning ..................................................................................... 121

8.1 Parameter protection against unauthorised access ......................... 121

8.2 Parameterisation ............................................................................. 122

8.3 Sealing of the device (if applicable/when required) ......................... 122

8.4 Commissioning of Integrated RDT module ..................................... 122

8.5 Commissioning the sensor system .................................................. 123

9 Maintenance .......................................................................................... 125

9.1 Maintaining the gas-net Q1 evaluation computer ............................ 125

9.2 Maintaining the gas-lab Q1 sensor system ...................................... 128

10 Technical data: Q1 ................................................................................ 129

10.1 Device type ...................................................................................... 129

10.2 Sensor technology details (gas-lab Q1) ........................................... 129

10.3 Evaluation computer details (gas-net Q1)........................................ 131

11 Annex ..................................................................................................... 135

11.1 Error listing of the gas-lab Q1 .......................................................... 135

11.2 Menue structure of the Q1 ............................................................... 145

12 Index ...................................................................................................... 147

Page iv gas-lab Q1

Page 5

Safety and warning notes

To ensure a safe and faultless operation of the device the instructions and

notes contained in the documentation on hand must be observed.

The device must be used as prescribed and connected according to the

connection diagram. The national and local regulations for electrical

installations must be observed.

The mounting, electrical installation, commissioning and maintenance of

the entire measuring system must be performed by qualified staff who

have been trained in the field of explosion protection and have read and

understood all parts of the operating instructions necessary for the

actions to be carried out.

Please refer to the corresponding technical regulations (DIN, DIN EN, VDE,

VDI, and DVGW) for general information on mounting, commissioning,

taking out of service and maintaining. Below, we have listed the standards

and guidelines that must be observed:

DIN EN 60079-14, Publication date: 1998-08, Electrical apparatus for

explosive gas atmospheres – Part 14: Electrical installations in hazardous

areas (other than mines)

DIN EN 50110-1, Publication date: 1997-10, Operation of electrical

installations

DIN EN 60079-17, Publication date: 1999-08, Electrical apparatus for

explosive gas atmospheres – Part 17: Inspection and maintenance of

electrical installations in hazardous areas (other than mines)

DIN VDE 0100-610, Publication date: 1994-04, Erection of power

installations with nominal voltages up to 1000 V; initial verification

gas-lab Q1 Page v

Page 6

gas-lab Q1 sensor system (sensor technology):

The sensor system must neither be stored at temperatures below

-20°C nor above +55°C.

Connect the electrical cables only to the EEx-e approved junction box!

This junction box is located on the mounting plate of the gas-lab Q1.

The sensor system is supplied by 24 V DC and must be secured

externally by 2.5 A.

Include the housing and mounting plate in the local earthing system.

A temperature between +5 deg. C and +40 deg. C must be guaranteed

during the operation of the sensor system (-x to +40 deg. C with

additional heater, -x to +55 deg. C with cooling unit; the lower

temperature limit depends on the heat output).

Only gases of the second gas family according to DIN DVGW 460 or

approved calibration gases are permissible. The oxygen content in the

natural gas must not be higher than 2.0 percent by volume.

The ventilation must be connected to the exhaust gas manifold via a

stainless steel tube with a minimum inside diameter of 4 mm.

After a voltage failure the measuring system automatically purges

with process gas before it activates the sensors. After a new gas

cylinder with flammable contents has been connected, the system

must be purged manually before the normal measurement can be

continued. This also applies if air may have got into a gas pipeline

connected to the sensor system (see also Chapter 5.1.4).

The user must ensure by means of high-pressure reduction and safety

devices that all gases injected into the measuring system do not

exceed an inlet pressure of 1,250 mbars absolute!

The opening of the housing as well as inspection and maintenance

must be carried out by specialists authorised by Elster!

Page vi gas-lab Q1

Page 7

Only if the atmosphere is not explosive or in de-energised conditions

after a delay of 5 minutes after the electrical supply has been

disconnected, the cover of the housing may be opened!

The cable entries for the electrical connections of the EEx d housing

of the measuring system must never be loosened if the atmosphere is

explosive!

The loosening or unscrewing of the breather is prohibited!

Only authorised personnel is allowed to exchange the breather, if

need be. In this case, the breather as a whole must be exchanged!

Only authorised personnel are allowed to exchange a cable entry

gland, if necessary.

The sensor system may only be switched on before or together with

the gas-net Q1 evaluation computer. It will result in an error (alarm) if

you switch on the sensor system after having switched on the

evaluation computer.

gas-lab Q1 Page vii

Page 8

gas-net Q1 evaluation computer:

The gas-net Q1 evaluation computer must neither be stored at

temperatures below -20°C nor above +55°C.

A temperature between 0 deg. C and +40 deg. C must be guaranteed

during operation.

The gas-net Q1 must be installed outside ex-zone 2.

The gas-net Q1 evaluation computer may contain subassemblies that

are approved as associated electrical apparatus of the ib category

according to DIN EN 50020 with intrinsically safe circuits. This renders

the electronic evaluation computer Q1 suitable for connection to

sensors and pulse generators located in hazardous areas (e.g.

zone 1).

A mixed connection of intrinsically safe and not intrinsically safe

circuits is not permitted in case of these subassemblies.

The evaluation computer is supplied by 24 V DC and must be secured

externally by 1 A.

The earthing is connected to PE of the power supply connector for

equipotential bonding.

Observe the regulations of the relevant standards, in particular of DIN

EN 50014, DIN EN 50020, and DIN EN 50029.

Observe the limit values stated in the respective certificates of

conformity of the boards to be connected.

Warning: The evaluation computer of the Q1 measuring system is a class

A device that may cause interferences in living areas; in this case, the

user may be asked for appropriate measures at his expense.

Page viii gas-lab Q1

Page 9

Introduction 1

1 Introduction

1.1 The gas-net system idea

is the generic term for an Elster device family. The evaluation

computer of the gas-lab Q1, too, is based on the gas-net device

family. All gas-net devices, including future device types, are characterised by

uniformity in appearance, operation and parameterisation.

Each Elster device always covers a multitude of measurement and control

functionalities.

gas-net devices also provide this functional variety. To keep the operation and

parameterisation of the devices well structured and user-friendly, the gas-net

series is based on a modular concept. A module corresponds to a special

functionality. Each module has its own main display within the device’s menu

assistance, and each module has its own group of settings within the parameter

data record.

A particular module can be employed in different device types. This yields a

modular system that is advantageous to the user as a particular module can

always be operated and adjusted in the same way, no matter in which device

type it has been installed.

1.2 The measuring principle

The gas-lab Q1 measuring system is a gas quality analyser that performs

infrared absorption and thermal conductivity measurements. The primary target

variables are the gross calorific value, standard density and CO2 content of the

natural gas being measured.

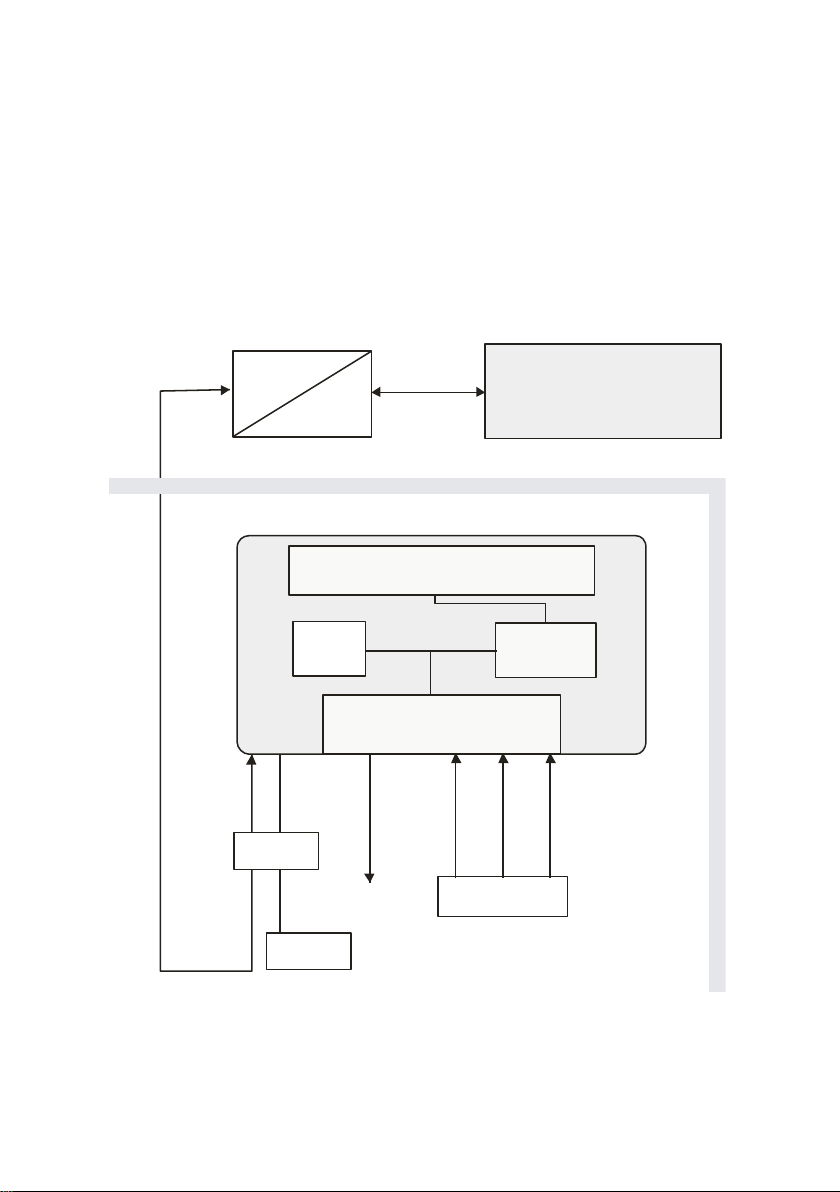

The entire measuring system consists of two components:

1. gas-lab Q1 sensor system

The actual sensor technology is located in an explosion-proof housing,

which can be installed in a hazardous environment.

2. gas-net Q1 evaluation computer

The evaluation computer of the Q1 measuring system is located in a nonhazardous environment. The main tasks of the evaluation computer are

controlling and monitoring the measuring process, evaluating the sensor

measurements, calculating the target variables and supporting the user

during calibration. Furthermore, the evaluation computer contains an

gas-lab Q1 Page 1

Page 10

1 Introduction

gas-lab Q1 sensor system

Vent gas line

RS422,

4-wire

Hazardous

area

Non-hazardous

area

Gas supply

24 VDC

Sensor unit

Sensor

elektronics

Double-block&bleed

valve set

RS422 / optical fibre

converter

gas-net

Q1

evaluation computer

optical fibre

EEX-e

Communi-

cations

PTB

integrated data logging function, mainly for interval- and event-controlled

data logging of analysis data as well as of error listing and logbook. The

signal and message processing provides some digital and analogue output

possibilities. The evaluation computer also controls the measuring process

and calculates the target variables.

Page 2 gas-lab Q1

Page 11

Introduction 1

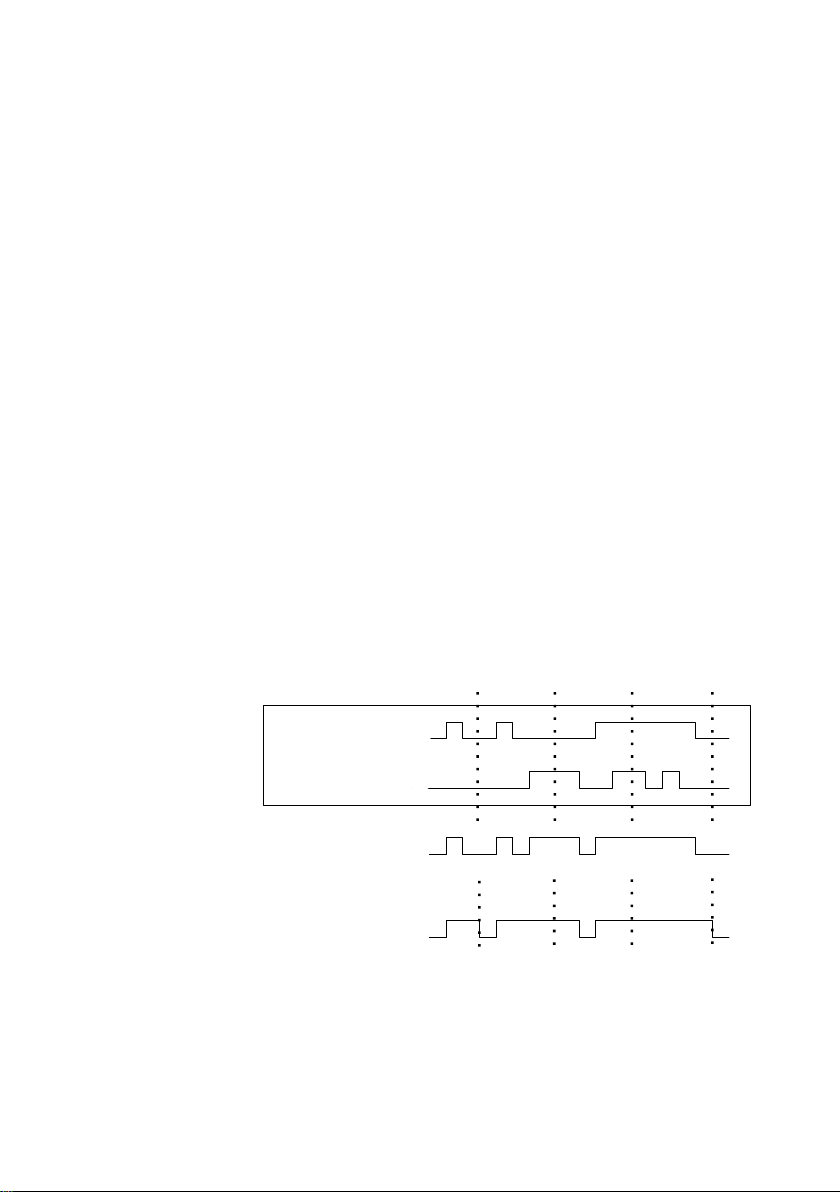

The connection between sensor system and evaluation computer is

implemented via interface cable, RS422/optical fibre-converter and fibre-optics

cable, as illustrated above.

The sensor system contains two infrared sensors for measuring the absorption

of the hydrocarbons and carbon dioxide contained in the natural gas. Another

sensor additionally determines the thermal conductivity of the natural gas and

thus also measures gas components such as nitrogen, for instance, which

cannot absorb infrared light. Afterwards the evaluation computer evaluates all

three measurements. As a result, these measurements supply the gross calorific

value, standard density and CO2 content of the natural gas. These variables are

sufficient to establish with a flow computer the compressibility ratio k (real gas

dependence) according to SGERG and the energy content of the natural gas.

Besides, other variables such as the Wobbe and methane numbers are also

determined. Other than that mentioned, the system provides also a noncalibratable sample analysis of the natural gas. The underlying algorithm is

based on the systematic of the composition of natural gases. In case of nontypical gases a major deviation in the measured value of a single component

can occur.

The device measures continually and determines new measurements every

second. It can therefore also be used for fast closed-loop control tasks.

The manufacturer calibrates the gas-lab Q1 before delivery, i.e. he performs a

zero point adjustment with nitrogen and afterwards a 3-point calibration with

ultra-pure methane and two calibration gases. The correction values are saved

in the sensor unit. This basic calibration is usually repeated during the

commissioning and on the occasion of a recalibration.

The evaluation computer automatically performs a 1-point calibration with ultrapure methane after a mains failure and after each switching on of the measuring

sensor technology.

Moreover, the gas-net Q1 offers a wealth of additional functions for monitoring

tasks and data communications. The gas-net Q1 also always includes a data

logging function that logs important measurements at defined intervals and

when errors occur. See Chapter 5.2 for a detailed description of the archive

structure.

gas-lab Q1 Page 3

Page 12

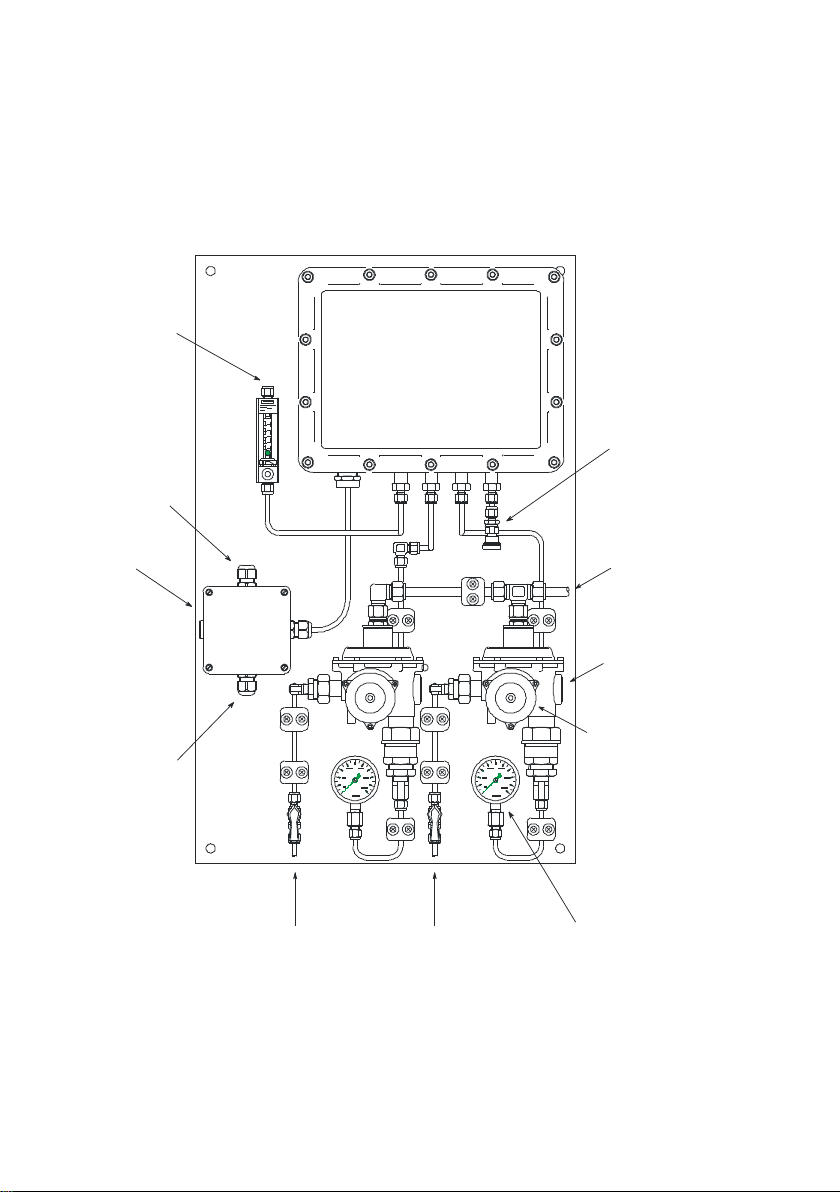

Page 13

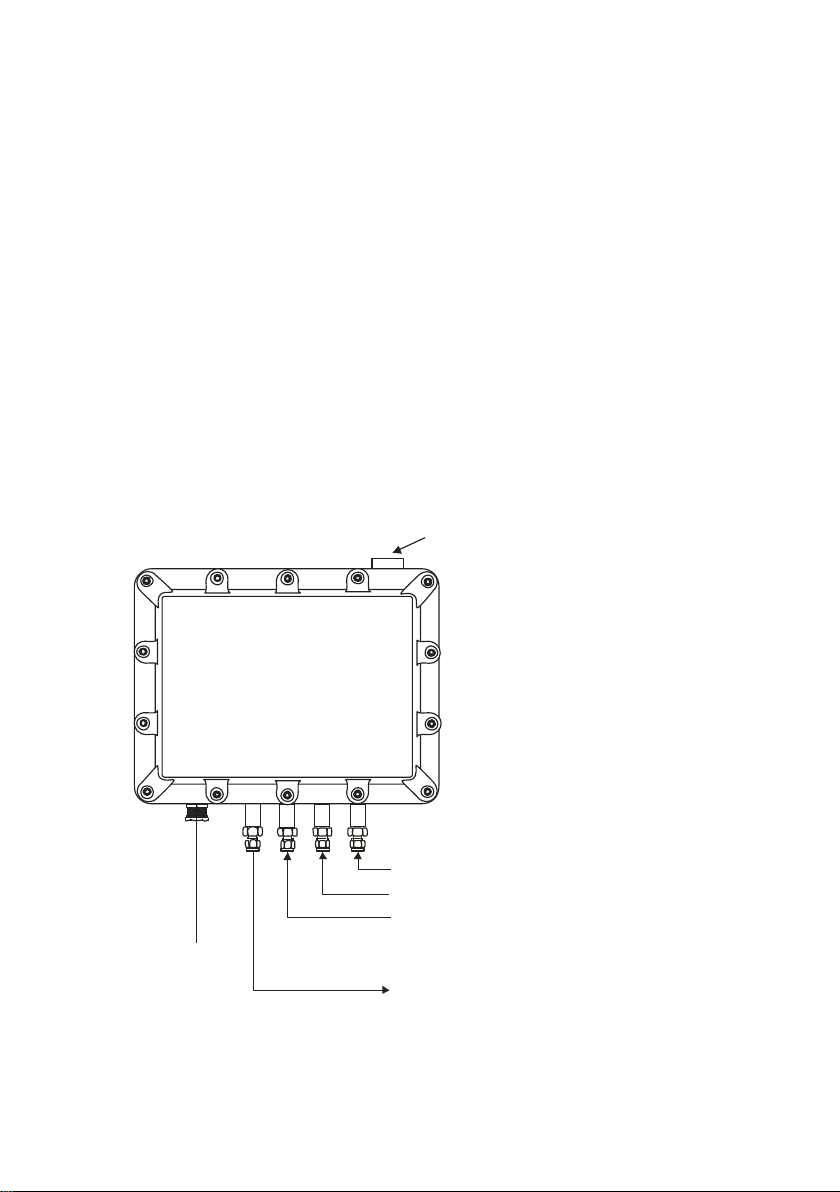

View and design 2

breather

EEx-d junction

(voltage supply,

data connection)

3: Calibration gas connection (i.e. N2, H2-11K, L1-8K)

2: Calibration gas connection (methane)

1: Process gas connection

Vent gas line

2 Device view and design

2.1 Sensor system

The actual sensor technology of the gas-lab Q1, the sensor system, is mounted

in an explosion-proof housing. The gas is supplied at approximately 80 mbars

overpressure and via a double block & bleed solenoid valve set, which is also

located inside the housing. There are a total of three gas inlets for different

gases, one connection for the process gas and two connections for calibration

gases. The out flowing gas is led via a vent gas line.

The housing is mounted on a mounting plate in such a way that the gas and

other process connections point downwards. In order to ensure that the housing

withstands the maximum permissible inside pressure of 1,100 mbars, a breather

is led out of the housing at the top. The following illustration shows the front of

the sensor housing:

gas-lab Q1 Page 5

Page 14

2 View and design

gas-lab Q1

exhaust gas

connection of

safety relief valve

power supply

connection

exhaust gas

connection of

gas-lab Q1

pressure controller

with integrated

safety relief and

safety shut-off valve

data line

connection

pressure gauge of

inlet pressure for gas-lab Q1

calibration gas 1

connection

process gas

connection

calibration gas 2

connection

release button of

safety shut-off valve

ex-junction box

The parameterisation of the evaluation computer defines which gas has to be

connected to which inlet. The process gas is assigned to path 1 and the internal

calibration gas (ultra-pure methane) to path 2. Nitrogen and further calibration

gases are injected via path 3 for performing the basic calibration. The test gas

can either be injected via path 1 or 3.

Not only the sensor housing is installed on the mounting plate, but also

regulators for the inlet pressure of the different gases to be injected, safety shutoff and safety relief valves as well as the EEx-e junction box for the

interconnecting cables (voltage supply, data link to the evaluation computer).

Page 6 gas-lab Q1

Page 15

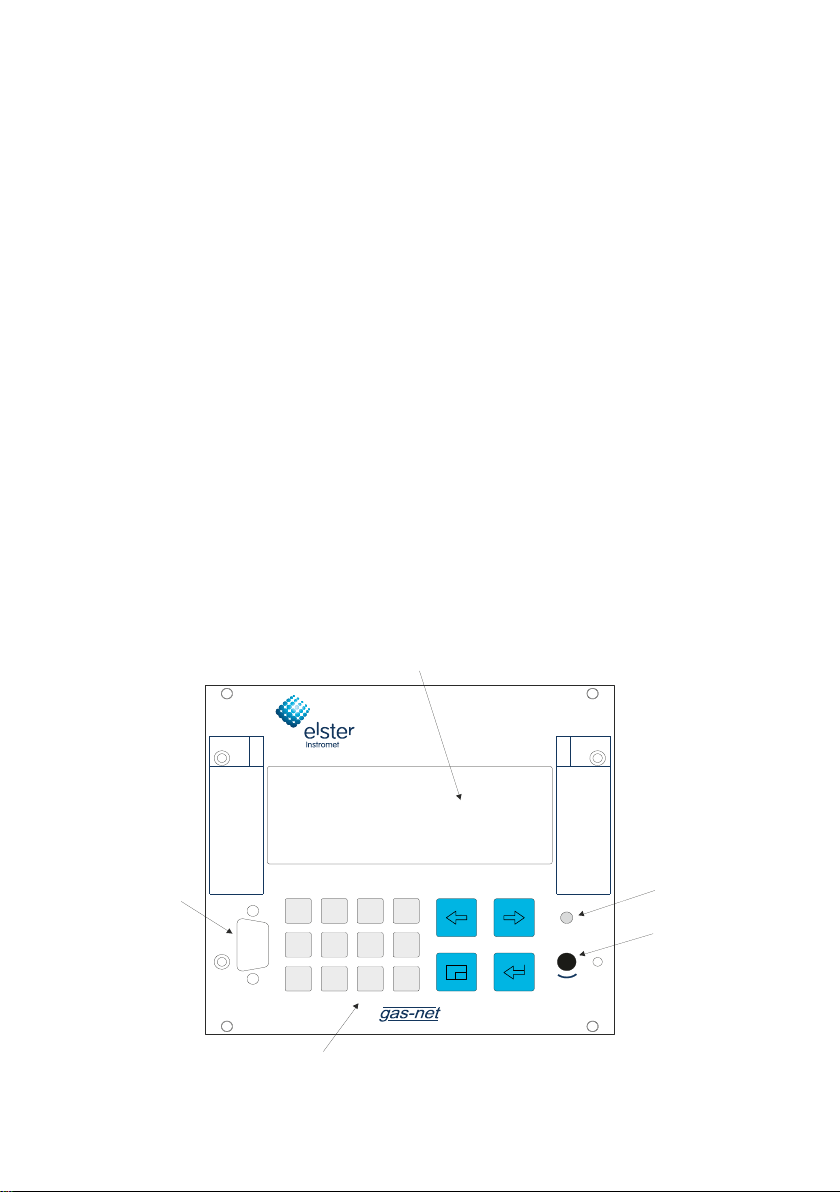

View and design 2

0987

,

6

5

4

_

3

2

1

Q1

gas-lab

Status

Cal.-

switch

close open

DSS

Gas Quality Meter

Data

interface

Key pad

Calibration

switch

Status LED

Display

The pressure regulators with integrated safety shut-off/pressure relief valves for

the process and calibration gases are necessary, as the maximum absolute inlet

pressure of the gases must never exceed 1,250 mbars. The pressure regulators

have been set by the manufacturer to a control pressure of 80 mbars (gauge).

The integrated pressure relief valve starts to vent at an overpressure of about

110 mbars and above. The safety shut-off valve has been set to a tripping

pressure of 142 mbars (gauge) by the manufacturer.

2.2 Evaluation computer

The housing of the gas-net Q1 evaluation computer is designed as plug-in unit

for a 19”-frame and is available in two housing sizes, i.e. with a mounting width

of 1/3 for up to three process boards or a mounting width of 1/2 for up to six

process boards.

The device front includes one 8x32 characters-LCD, one keypad with 16 keys,

one status LED and the calibration switch. The DSS data interface is also

located on the device front. It serves the connection of a PC or laptop for

servicing purposes.

The following illustration shows, as an example, the front view of a gas-net Q1 in

the narrow design with a mounting width of 1/3:

gas-lab Q1 Page 7

Page 16

2 View and design

Most of the connection possibilities are located on the back of the device. The

following interfaces are always available:

fibre-optics connection for the sensor system

DSfG bus connection

COM2 interface: serial interface according to RS232. In case of devices

with an integrated RDT, the modem is connected to COM2. A different

software variant offers gateway functionality for interfacing a host protocol

instead. In this case, the COM2 interface can be used as protocol channel.

DCF77 interface for connecting a radio clock

24 V DC power supply connection

HSB bus connection (not used)

All process connections are implemented via process boards installed in the

housing. The exact composition of the I/O boards depends on the tasks of each

individual device (number of required output signals, etc.).

The name of the software variant, the version’s number and the checksum for

the identification of the software version can be invoked directly at the device via

the main display of the System module.

The main functionality of the Q1 is measuring the gas quality. The sensor

system is connected via an LMFA1-type process board, which provides 3 digital

and 4 analogue outputs in addition to the fibre-optics connection for the sensor

system.

Furthermore, the following boards can be used:

A multi-functional EXMFE4 input board for the connection of a pressure and

a temperature sensor (PT100) and two digital inputs (NAMUR). All channels

are intrinsically safe (EX-i).

An MSER2 board with 2 serial channels (RS232, RS422 or RS485) for

interfacing communication protocols (e.g. MODBUS).

An MFE11 input board with 8 digital and 3 analogue inputs.

An MFA6 output board with 4 digital and 2 analogue outputs.

Page 8 gas-lab Q1

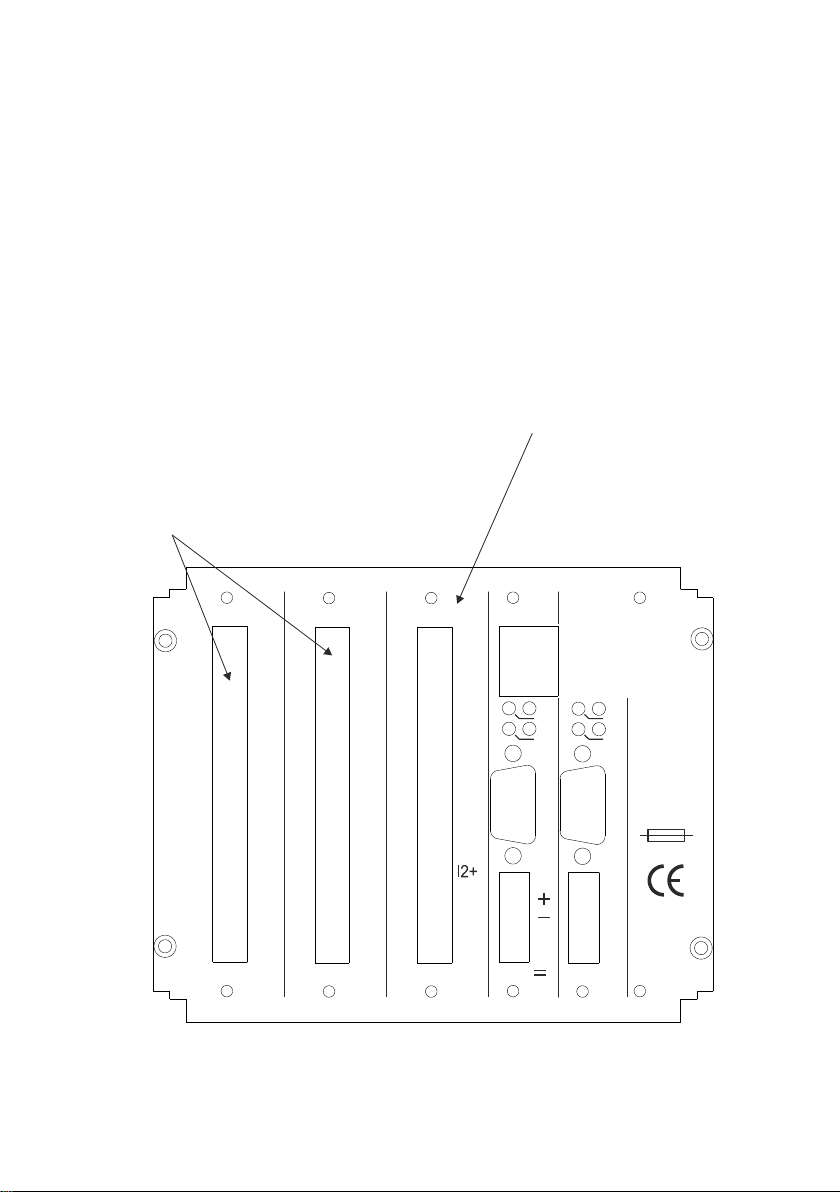

Page 17

View and design 2

0,63 ATT

LE

LA

D1

D2

D3

I1+

I3+

ISH

DC

LMFA7

SH

GD

DT

VN

VP

PE

DCF7724V

HS-Bus

2

M

O

C

G

f

S

D

CD

RI

TX

RX

SD

DD

SH

DH

internal

Board 3Board 2Board 1

Output board LMFA7 (digital/analog)

LA/LE:

D1-D3:Three digital outputs for digital signals / pulses.

I1-I3: Three analog outputs for measurement output.

optical fibre connection for external I/O expansion

(sensor system connection)

Any input or output board can

be assigned to board locations 1 or 2.

gas-net

All in all, up to 6 process boards can be mounted in the broader housing and up

to 3 boards in the narrow design. Please see Section Fehler! Verweisquelle

konnte nicht gefunden werden. or the Technical Data Section in Chapter 10

for a description of the currently available boards.

The following illustration shows, as an example, a device in the narrow design

with the always existing LMFA7 board.

gas-lab Q1 Page 9

gas-net Q1 rear view (example)

Page 18

Page 19

Operation 3

3 Operating gas-net devices

This chapter’s objective is to give you an understanding of the basic operating

and menu structures of gas-net devices.

As already mentioned, all devices of the gas-net family have a uniform

appearance and a comparable menu structure.

This means for the user: If you have operated a gas-net device once, you will

also be able to operate all other device types without any problems.

According to our philosophy of how to parameterise gas-net devices, they are

adjusted by means of a PC or laptop and not via the operator panel. The device

operation via the operator panel mainly serves the indication of the most

important information on the display. The content of the operator interface on

the display depends on the individual gas-net device type.

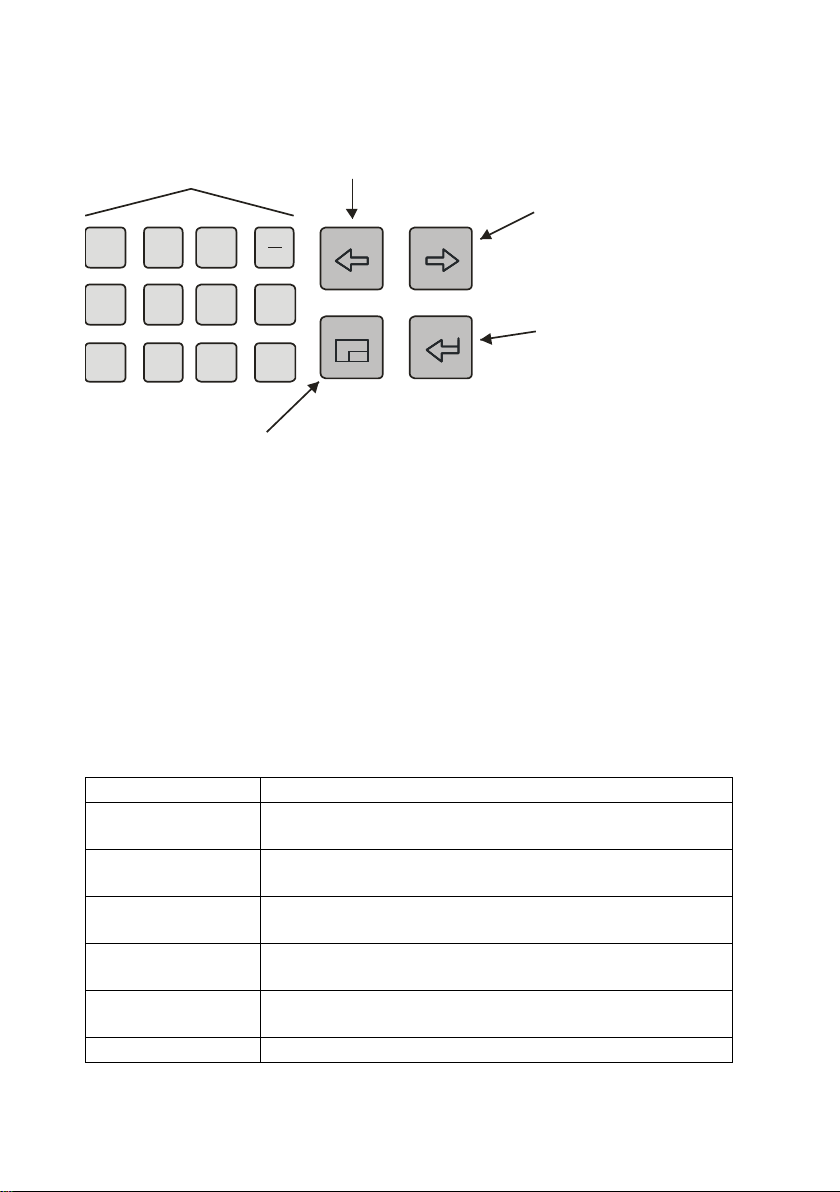

3.1 The keypad

The keypad of gas-net devices consists of a numeric keypad for the entry of

numbers, minus sign and decimal point keys and a group of four navigation

keys. With these keys, you may move within the menu structure and invoke

menus and displays. In some cases you may also trigger actions or change

values via the navigation keys.

The illustration below shows an overview of the keys’ meanings. The exact

context-related meaning of each navigation key will be explained in connection

with the menu structure in Section 3.4.

gas-lab Q1 Page 11

Page 20

3 Operation

1 2 3

4 5 6

,

7 8 9 0

Menu key:

Opens/closes a menu.

When starting from a display this means:

Pressing once opens the current display's submenu listing.

Pressing twice opens the menu listing for branching to other modules.

Pressing three times closes the menu.

Arrow key left:

Previous entry.

Input mode: delete previous character

Enter.

Menu selection.

Enter input mode.

Within input mode:

Accept new value.

Numeric key pad

incl. minus sign

and decimal point

Arrow key right:

Next entry.

Input mode:

Quit input mode without

changing values.

LED status

Meaning

red, blinking

An alarm is pending, i.e. an error has occurred that

influences the gas quality measurement.

yellow, blinking

A warning is pending. That is, an event has occurred

without affecting the gas quality measurement.

green, blinking

A green blinking light appears in the start-up phase after

a mains failure.

red, steady light

An alarm has been pending but is no longer relevant.

It can be removed from the error listing by accepting it.

yellow, steady light

A warning has been pending but is no longer relevant.

It can be removed from the error listing by accepting it.

green, steady light

The device runs error-free.

3.2 Other operating elements: status LED, calibration

switch

The status LED on the front of the device is a three-colour light emitting diode.

The status of this LED indicates whether an error of the gas quality

measurement is pending or has been pending.

Please refer to the table below for the meaning of the individual colours:

Page 12 gas-lab Q1

Page 21

Operation 3

The sequence of the LED status in the above table corresponds to the

sequence the error management keeps to: The system always indicates the

error with the highest priority. A pending error always takes precedence over an

error that is no longer relevant.

The exact meaning of the terms alarm, warning and hint is explained in Chapter

5.3.1.

The calibration switch is on the lower right side of the front panel.

All gas-net devices are furnished with a two-level safety concept: All parameters

being protected by the calibration switch can only be changed if the calibration

switch is open. Such parameters are always modified with a PC or laptop and

the associated parameterisation software GW-GNET+.

Open the calibration switch by turning it anticlockwise as far as it will go. This

first level of the safety concept is important for devices used for legal metrology

and custody transfer. In this case, a seal may officially secure the calibration

switch.

The basic display of the device will automatically be invoked when you close the

calibration switch.

Note: The User lock as the safety concept’s second level consists of one

numerical lock for each of the two contract parties. The user lock is, in contrast

to the calibration switch, implemented via the device software. This means that

the locks are defined via the device parameterisation and opened or closed via

the operator panel. Open locks allow the user to access certain parameters or

actions. All parameters being subject to the user locks can be changed when

both locks are or the calibration switch is open. .

gas-lab Q1 Page 13

Page 22

3 Operation

3.3 Display

The display is an illuminated LCD consisting of 8 lines with 32 characters each.

After approximately 30 minutes without a keystroke, the display’s background

illumination switches off automatically.

3.4 Displays / Menus / Dialogs

One note at the outset:

The following section describes the menu assistance and operation of all gas-

net devices in general.

Where appropriate, individual subjects have been illustrated with examples.

These examples refer to currently available device types. Therefore, it may

happen that a special menu illustrated in an example does not exist in your gas-

net device type.

In accordance with the gas-net concept, however, the operating mechanisms

generally described here function in all devices in the same way.

Each module has a main display in which all important current values are

indicated.

For example: Among others, the gas-net Q1 contains the gas-lab Q1 and

Monitoring modules. The main display of the gas-lab Q1 module shows

the current measurements, whereas the main display of the Monitoring

module indicates the error listing.

The main display of the first module is also the basic display of the device, i.e.

the display that is invoked automatically if there has been no keystroke for about

30 minutes.

For example: The basic display of the gas-net Q1 is the main display of

the gas-lab Q1 module.

A display serves to present values.

If there are more entries than can be made visible at once, little scroll arrows on

the right side indicate whether or not you may scroll upwards or downwards.

Page 14 gas-lab Q1

Page 23

Operation 3

1

“Down” scroll arrow pointing

downwards: Scroll downwards with the rightward

arrow key.

„Up“ scroll arrow pointing

upwards: Scroll upwards

with the leftward arrow key.

Each display which can be shown belongs to a module within the device

software, therefore to a closed functionality. If you see the display of any

module, there are two entirely different targets in the menu structure of the

device. On the one hand a subordinated display / dialogue1 of the shown

module and on the other hand the main display of any module.

To make the navigation within the menu structure as easy and fast as possible,

the menu key is configured as follows:

Unique pressing of the menu key opens up the list of submenues, wich is

provided by the actual module display.

Pressing the menu key again opens up the menu list to branch to any module.

Repeated pressing closes the menu.

The list of submenus of a module is provided according to the current

parameterisation: Menu items that relate to functionalities which are not

parameterised, are not offered at all.

Submenus of a module are either calling other displays or dialogs, in which the

user can manipulate values via control panel.

The menu structure is aborescent:

A subordinated menu item of a module can offer subordinated menu items by

himself.

A Dialog is a display window indicating values that can be changed by the operator.

gas-lab Q1 Page 15

Page 24

3 Operation

Start:

Basic display Gas quality

Menu list of the module Gas

quality.

The hyphen in front of the menu

descriptions indicates that the list

refers to subordinated menus.

In lower levels of the menu structure following contextual menu items are

offered to return to the next upper level:

Menu item Back in a display

Menu items OK / Cancel in a dialog

(OK means acceptance of the changed values too, Cancel means to reject

the changes)

Independent of the menu level which is shown at the moment, with the arrow

keys you can move for- and backward within every menu list and select a menu

item. The selected target is presented in an inverted way, i.e. with green writing

on a black background. Activate the menu item belonging to the selected entry

by pressing the Enter key.

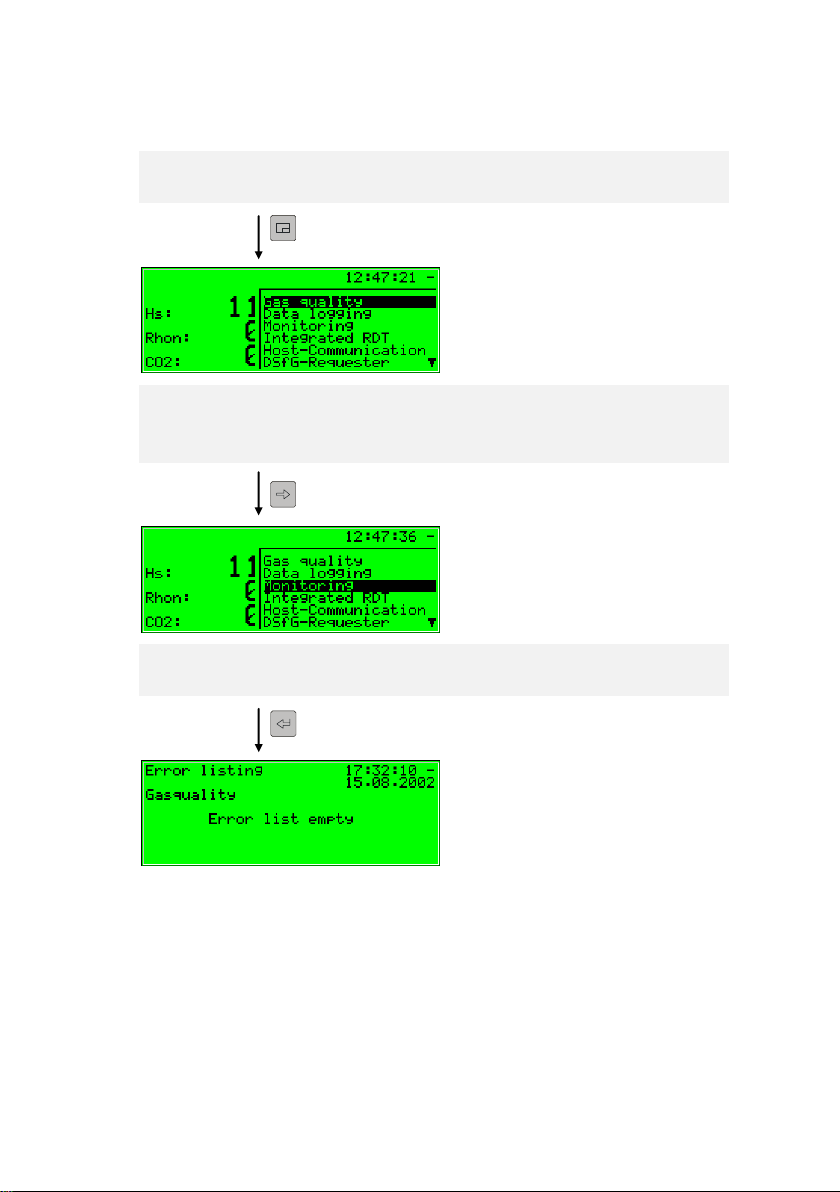

For example: We assume you want to change from the basic display of

the Q1 to the main display of the Monitoring module.

For this, press the menu key first to open the menu window. The first

entry of the appearing listing is selected, i.e. it is backlit in black:

Page 16 gas-lab Q1

Page 25

Operation 3

Module list:

Without hyphens in front

of the menu descriptions

Module list:

Monitoring module

is selected

Since we won’t activate a gas quality menu in our example, but branch to

another module, please press the menu key again.

Now the menu shows a list of all modules the device software contains.

Press the rightward arrow key several times until the module is selected,

that you want to see. In our example it’s the Monitoring module.

Then press the Enter key and the display of the just selected module will

be invoked.

gas-lab Q1 Page 17

Page 26

3 Operation

Tips:

If you have pressed the rightward arrow key too often and went too far

down in the menu selection list, move upwards again by pressing the

leftward arrow key.

If you want to quit an invoked menu selection window without having made

a selection, just press the Menu key as often, until the menu window is

closed.

The selection of some menu items invokes a dialog. These dialogs are displays

in which values can be modified. However, only a few values can be modified

via the operator panel.

In such input dialogs you move from one parameter to another by using the

arrow keys. If a parameter must not be changed (for instance, because it is a

parameter that is subject to the calibration lock, which is closed at that moment),

it will be crossed out in the display.

If you have selected a parameter that can be changed, you may switch into the

edit mode via the Enter key.

In order to render the operation more comfortable, there are different methods of

defining a new value, depending on the type of the value to be changed:

Direct entry of a new numerical value

If you would like to replace individual characters only, delete the characters step

by step from the right using the leftward arrow key. Then enter the new

characters via the numerical keys including decimal point and minus sign.

If it is easier to replace the entire value by a new one, just start with your entry

right away: As soon as you press any numerical key the preset value will be

deleted and overwritten by the new entry.

Quit the edit mode via the Enter key. This initiates a test for consistency: If you

have entered a value that does not make sense in the present context or is not

permissible, you will not be able to quit the edit mode. This way, the user is

forced to correct the value he has entered.

Page 18 gas-lab Q1

Page 27

Operation 3

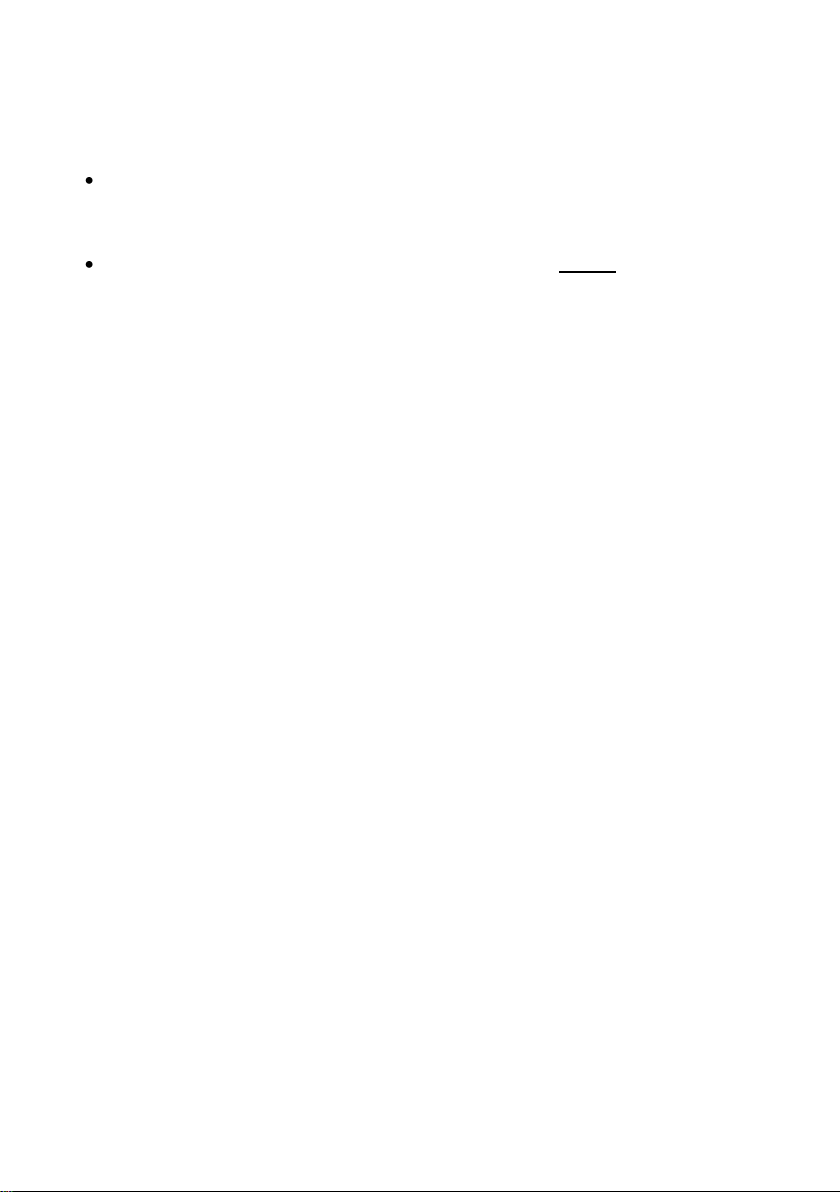

Start:

Display Single message

Value to be modified is selected.

Edit mode:

The insertion mark is now blinking

behind the value.

In order to quit the edit mode without accepting the change, for instance after an

erroneous entry, just press the rightward arrow key.

In order to quit the entire dialog, invoke the menu and select either OK (the new

values will be accepted) or Cancel (the values will be rejected).

For example:

Change of the lower hint limit for the GCV in the Monitoring module of

the gas-net Q1. After you have invoked the associated menu item, the

following display is visible:

The currently set value is indicated.

Switch to the edit mode via the Enter key.

gas-lab Q1 Page 19

Page 28

3 Operation

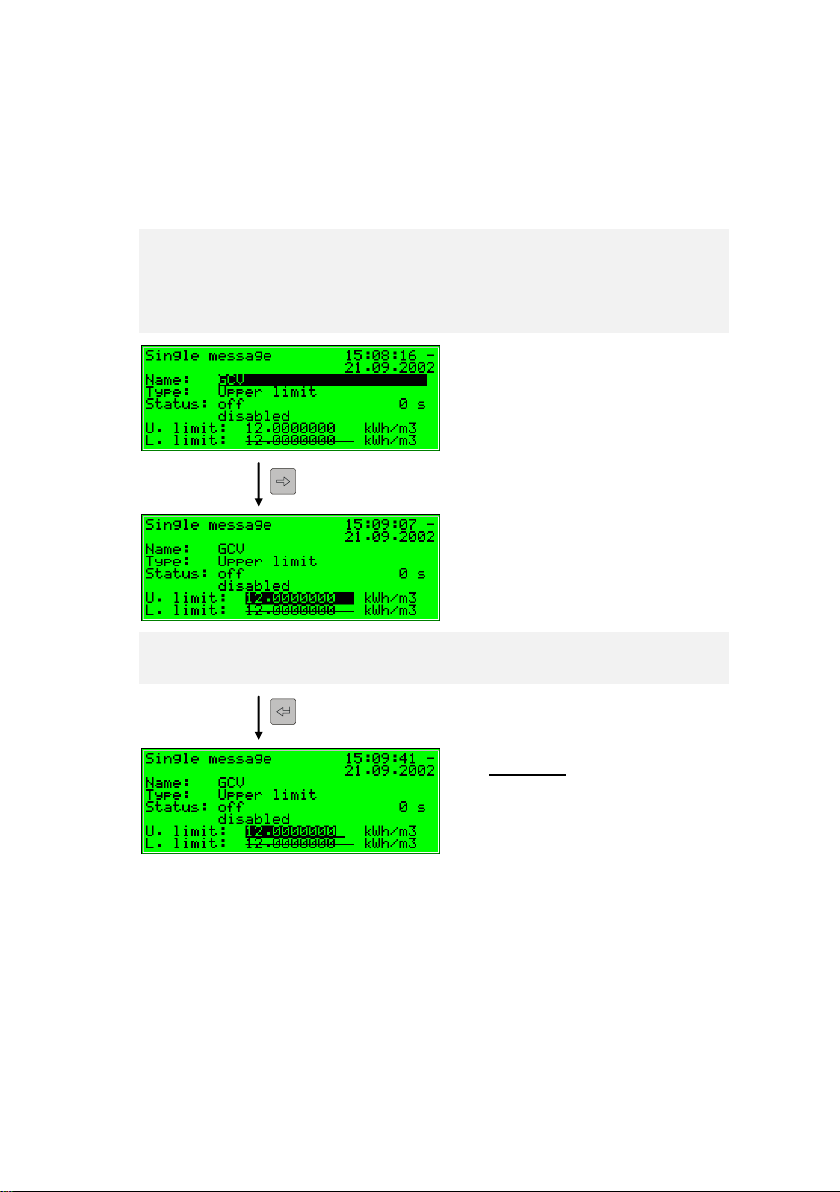

1

,2,3,4,5,6,

7,8

,9,0,,,

Options on leaving

Acceptance or rejection of the

changed values.

Enter a new value now:

Either directly via the numerical keypad or by deleting individual numbers

from the right using the leftward arrow key and by entering new numbers.

Quit the edit mode by pressing the Enter key. Thereby the new value will

be accepted. If you don’t want that, you should leave the edit mode via

the rightward arrow key.

Invoke the menu now.

If you confirm OK by pressing the Enter key, the new value will be

accepted. To reject the modification, go to Cancel by pressing the

rightward arrow key and afterwards the Enter key.

You will quit the dialog in both cases.

Page 20 gas-lab Q1

Page 29

Operation 3

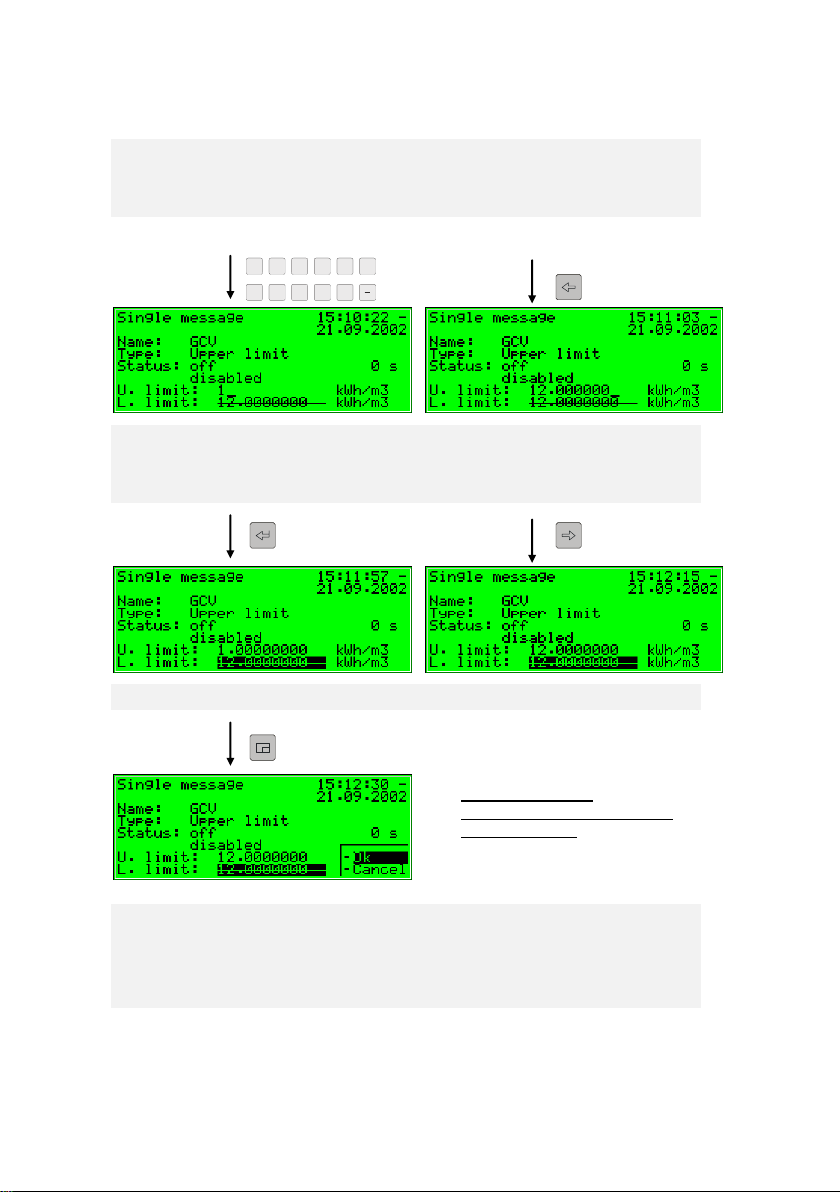

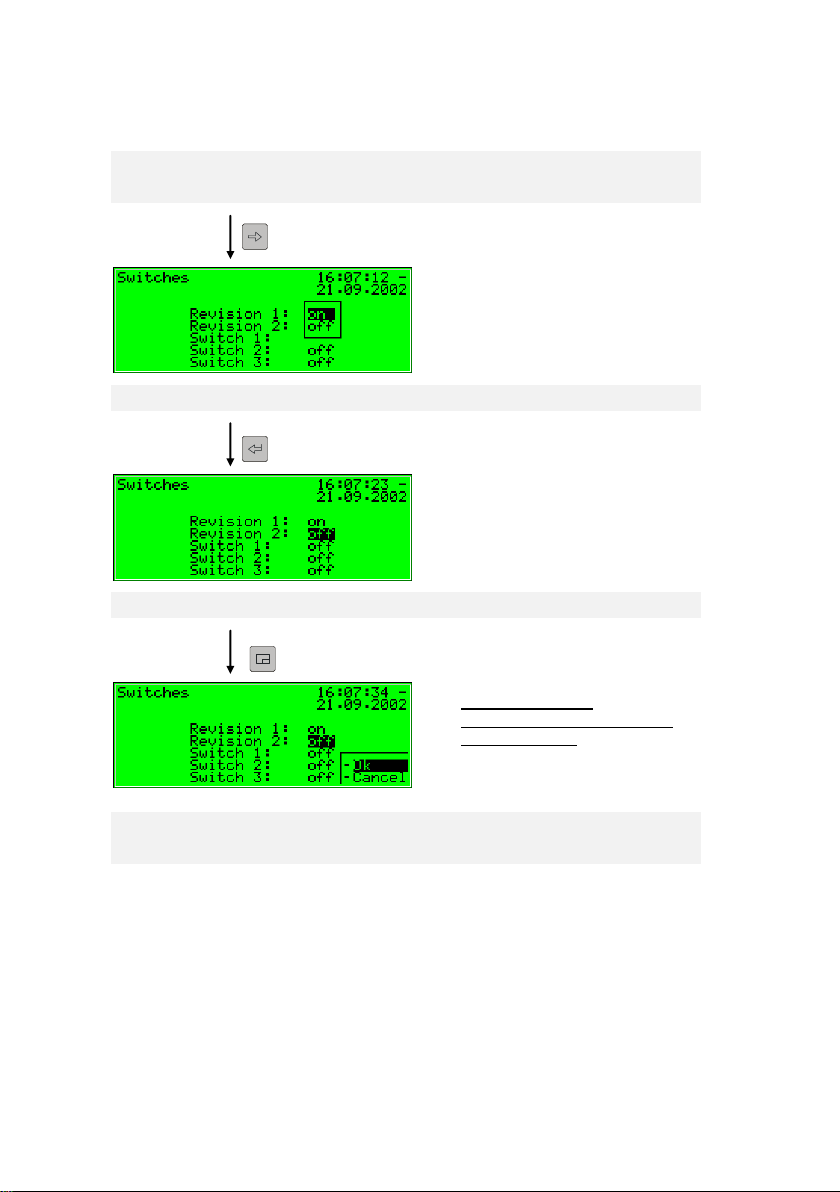

Start:

Monitoring - Switches

Selective list:

All applicable values are offered.

(Here: off and on)

New value by selection from a list

The device software offers a list of possible values in case of editable values the

range of which is restricted to a fixed number of selectable values. Choose a

suitable value from the list via the arrow keys and accept it by pressing the Enter

key.

Example: Opening of the revision switch (Hint: Only possible with user

locks opened!). The state of the revision switches can be changed in the

submenu Switches of the Monitoring module. Therefore go to the related

dialog via the menu items Monitoring - Switches.

In the above illustration the revision switch for both streams is shown as

closed (Revision 1 = off, Revision 2 = off). Let’s assume that you want to

activate the revision switch for the first stream. On entering the display

this switch is already activated, so you can press the Enter key right now

to switch to the edit mode.

gas-lab Q1 Page 21

Page 30

3 Operation

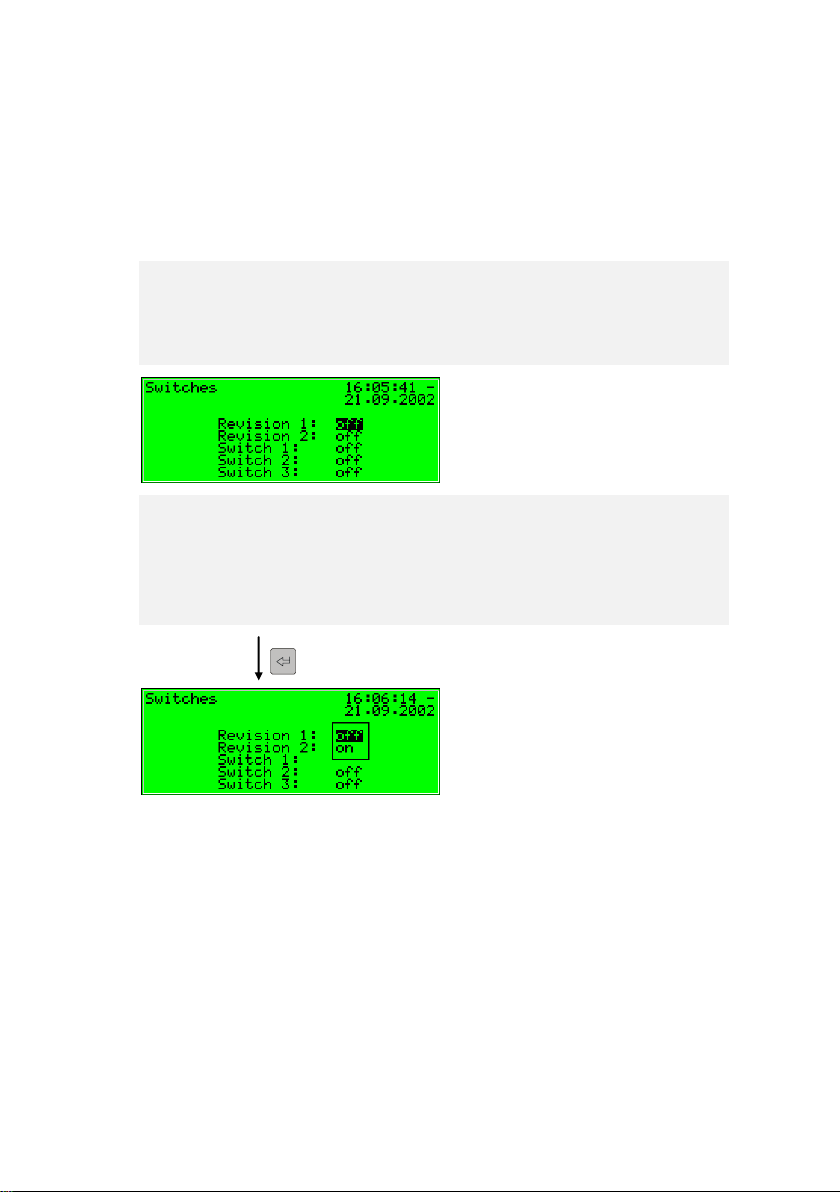

Selective list:

On is selected.

Revision switch 1 is opened now.

Options on leaving

Acceptance or rejection of the

changed values.

Select the desired value via the arrow keys, in our example select on.

The display looks as follows:

Then press the Enter key to leave the edit mode.

Invoke the menu now:

If you confirm OK the new value will be accepted. To reject the

modification, go to Cancel and press the Enter key afterwards.

Page 22 gas-lab Q1

Page 31

Operation 3

Modifying several values at once

Most of the dialogs don’t offer individual values but whole sets of values for

being modified. In such a case, edit the first selected value first. Switch to the

edit mode by pressing the Enter key.

Move to the next value by pressing the Enter key.

Tip: If you don’t want to modify an offered value, skip it by pressing the

rightward arrow key.

Change the value either by directly entering the new value via the numerical

keypad or by selecting a new value from a list.

After having edited all values, press the Menu key. The invoked menu contains

the menu items OK and Cancel. Selecting OK means accepting the modified

values. Selecting Cancel means rejecting the changes. In both cases you will

return to the display you invoked last.

gas-lab Q1 Page 23

Page 32

Page 33

Primer 4

Gas quality error listing

Monitoring error listing

Next listing

4 Primer for impatient operators:

What do I have to do to …?

Notice: The following instructions are based on the assumption that you are in

the basic device menu.

4.1 ... view the gas quality error listing?

If the status LED blinks red or yellow or is steadily illuminated, the error listing

contains alarm or warning entries.

Proceed as described below to view the error listing:

1) Invoke the menu (subordinated items) via the Menu key.

2) Invoke the next Menu (other modules) via the Menu key

3) Press the rightward arrow key until you have selected the Monitoring menu

item.

4) Press the Enter key.

The main display of the Monitoring module is invoked. The error with the

highest priority level is displayed. Scroll through the error listing using the

arrow keys.

5) Proceed to Chapter 5.3.2 should you need more detailed information. If you

would like to accept an error, proceed to the very next chapter.

There may be up to two error listings. In addition to the Gas quality error listing,

an error listing of the Monitoring module’s message processing is also available.

Always switch to the display of the next error listing via the Next listing menu

item. Please refer to Chapter 5.3 for further information on the error listing of the

message processing.

gas-lab Q1 Page 25

Page 34

4 Primer

4.2 … accept the gas quality measurement errors?

Errors can only be accepted and thus removed from the gas quality error listing

if they are no longer pending.

To accept an error, proceed as follows:

1) Open the error listing via the menu as described above in Chapter 4.1.

2) Select the error you want to accept via the rightward or leftward arrow key.

3) Press the Menu key. If the error indicated on the display cannot be

accepted, the first menu item appears as being crossed out: Accept. In this

case, press the Menu key again to quit the menu.

If the error can be accepted, just select Accept and press the Enter key.

The error disappears from the error listing, and the error with next lower

priority level will be indicated on the display.

4) Repeat the steps explained above to accept further errors.

Note: Accepting errors as described above only refers to errors in connection

with the device’s gas quality functions. How to accept messages of the general

message processing (Monitoring error listing) is explained in Chapter 5.3.

Page 26 gas-lab Q1

Page 35

Primer 4

4.3 … check all parameter settings?

The parameterisation of a gas-net device contains too many settings for them to

be conveniently displayed via the operator panel. It is much easer to get a

general idea of the device settings with the aid of the GW-GNET+

parameterisation program and a laptop.

Proceed as described below:

1. Connect the COM interface at the PC to the DSS interface of the Q1

evaluation computer using a parameterisation cable.

2. Start GAS-WORKS on your computer. Activate the communication program

by clicking the Import – Data interface tool in the GW-BASE toolbar.

3. After having successfully started the communication program, you are

linked with the connected device data technology-wise. The window

appearing on your display shows some important basic device information.

4. Select the Tools tab now.

Double-click the Change parameters or the Edit parameterisation entry.

The GW-GNET+ interface will appear on the screen. This is where you can

invoke and check the parameter listings of the individual modules.

Consult the GW-GNET+ online help for details on the operation of the user

interface of GW-GNET+.

Please note: The Change parameters or Edit parameterisation service

programs also offer the option of changing device settings. The current status of

the protection mechanisms (calibration switch / user lock) is of course taken into

consideration. Please refer to the GW-GNET+ comprehensive online help for

further information.

gas-lab Q1 Page 27

Page 36

4 Primer

4.4 … check the input values?

1) The input values are in the System module. Therefore, change to this

module: Press the Menu key twice, then move to the System entry using

the rightward error key and press the Enter key.

2) Then press the Menu key and select the Inputs entry via the rightward

arrow key.

3) Press the Enter key afterwards. The Inputs display will be invoked.

5) Please refer to Chapter 5.4.2 for information on how to proceed further.

4.5 … view and check the outputs?

1) The output values are in the System module. Therefore, change to this

module: Press the Menu key twice, then move to the System entry using

the rightward arrow key and press the Enter key.

2) Then press the Menu key and select the Outputs entry by means of the

rightward arrow key.

3) Press the Enter key afterwards.

The Outputs display will be invoked.

4) Please refer to chapter 5.4.2 for information on how to proceed further.

4.6 … view the archives?

1) Change to the display of the Data logging module: Press the Menu key

twice, move to the Data logging entry using the rightward error key and

press the Enter key.

2) Select exactly the archive information you want to view in the appearing

dialog. By the way it’s more comfortable to view the archives with the PCSoftware. Please refer to Chapter 5.2.2 for a detailed description of the

function.

Page 28 gas-lab Q1

Page 37

Functional description 5

5 Functional description

5.1 Gas quality module

The gas-lab Q1 measuring system is a device for measuring the gas quality of

natural gas. It measures the infrared absorption of hydrocarbons and carbon

dioxide (CO2) and also the thermal conductivity. The following variables are

directly determined based on these measurements:

Hs – Heating value superior, equal to GCV – gross calorific value

standard density Rhos

concentration xCO2 as mole fraction

Further variables are derived from these direct variables, such as:

Wobbe index superior Ws

Methane number MN

Composition of the natural gas consisting of 10 components from C1 to

C8+ as well as N2 and CO2.

Hi – Heating value inferior, equal to NCV – net calorific value

saturated Hs/GCV and Hi/NCV (gas with H2O saturation)

When the device is started, the evaluation computer reads the calibration data

out of the non-volatile memory of the sensor system and starts to measure.

Therefore, make sure to switch on the sensor system either before or together

with the evaluation computer. The measuring operation may only start after the

Q1 has been successfully calibrated (see 5.1.2) and if the process gas is

injected to path 1 with sufficient pressure. The sensor system is furnished with a

pressure switch that detects whether gas is flowing or not.

The sensor system must have reached its operating temperature of about 55 to

60 °C before the device is ready to operate. It may take up to one hour to heat

up a cold device. The evaluation computer waits until the operating temperature

has been reached before indicating valid measurements. View the temperature

of the sensor system in the Process values display (see 5.1.1.2).

gas-lab Q1 Page 29

Page 38

5 Functional description

Indication of the error with

the highest priority level

Time and date

Final values for

GCV – gross calorific value,

standard density,

CO

2

concentration

Important: After the commissioning has been completed, operate

the gas-net Q1 evaluation computer only with the calibration

switch being closed. The calibration switch (the rotary switch on

the front of the device) can be sealed for safety reasons. A closed

calibration switch ensures that actions to be performed by trained

and qualified staff, such as calibrating actions etc., cannot be

started from the device.

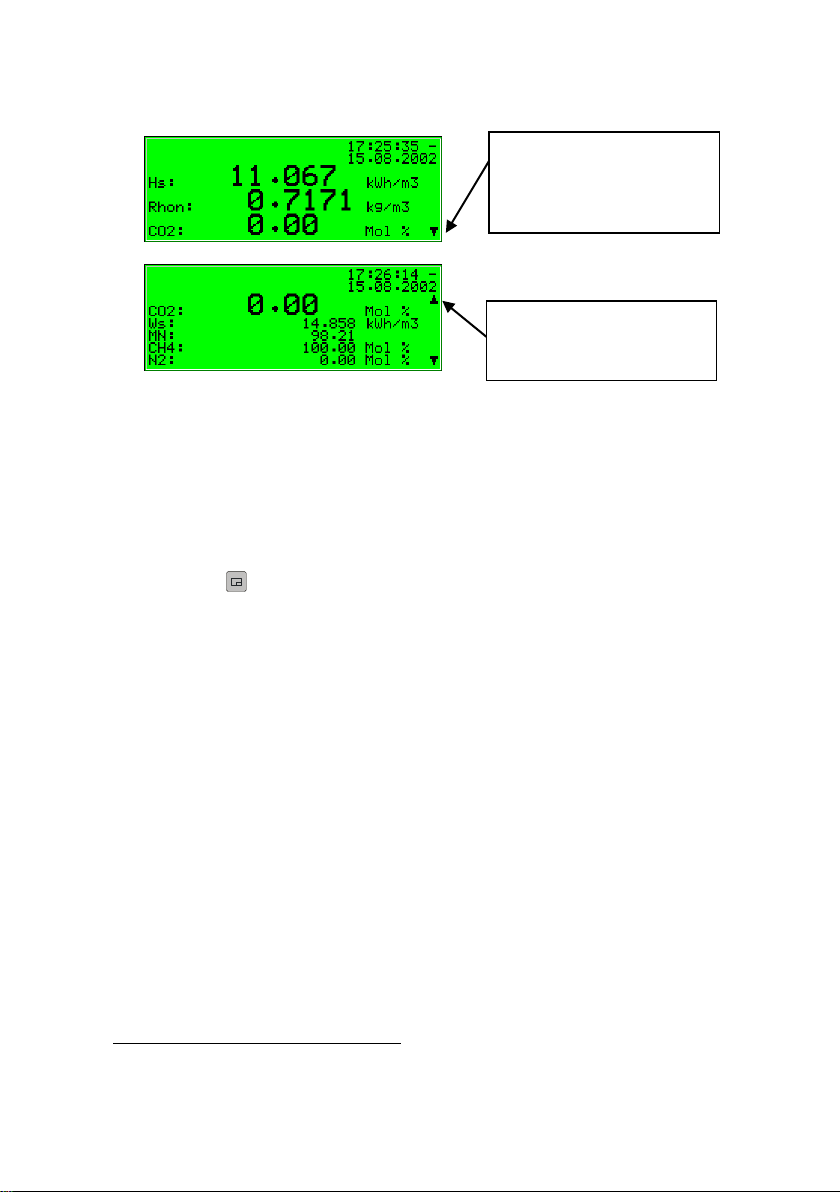

5.1.1 Display and operation

5.1.1.1 Main display Gas quality

The gas-lab system measures continuously during normal operation and

constantly calculates actual values for the target variables gross calorific value

GCV, standard density Rhon and CO2 content of the measured gas.

The basic display of the gas-net Q1 evaluation computer supplies a survey of

the measurement status and currently calculated values of the gas analysis.

The first two lines show the pending gas quality measurement error with the

highest priority level on the left as well as time and date on the right.

The last three lines of the basic display indicate the current gas analysis

values GCV, Rhon, and CO2, written in large numbers.

The values shown in the basic display are only current and valid if the

system operates normally in undisturbed conditions. This means that the

measurement is not in the alarm status and a calibration is not carried out.

Page 30 gas-lab Q1

Page 39

Functional description 5

„Down“ scroll arrow pointing

downwards: Scroll downwards with the rightward

arrow key.

The following illustration shows an example of the basic display in case of an

undisturbed operation:

If you scroll downwards in the main display, further derived values will be

indicated as illustrated by the following figures:

A calculated gas analysis with 10 components and the molar percentage of the

C2+ components are indicated in addition to the Wobbe (Ws) and methane

numbers (MN). Hi is the NCV – net calorific value. The variables Hs’, Rhon’ and

CO2’ are corrected values used in the automatic adjustment by means of a

process gas chromatograph (PGC). The values satHon and sat Hun are the

GCV and NCV in case of saturated concentration of H2O for the defined

reference condition. At last the density ratio is displayed.

gas-lab Q1 Page 31

Page 40

5 Functional description

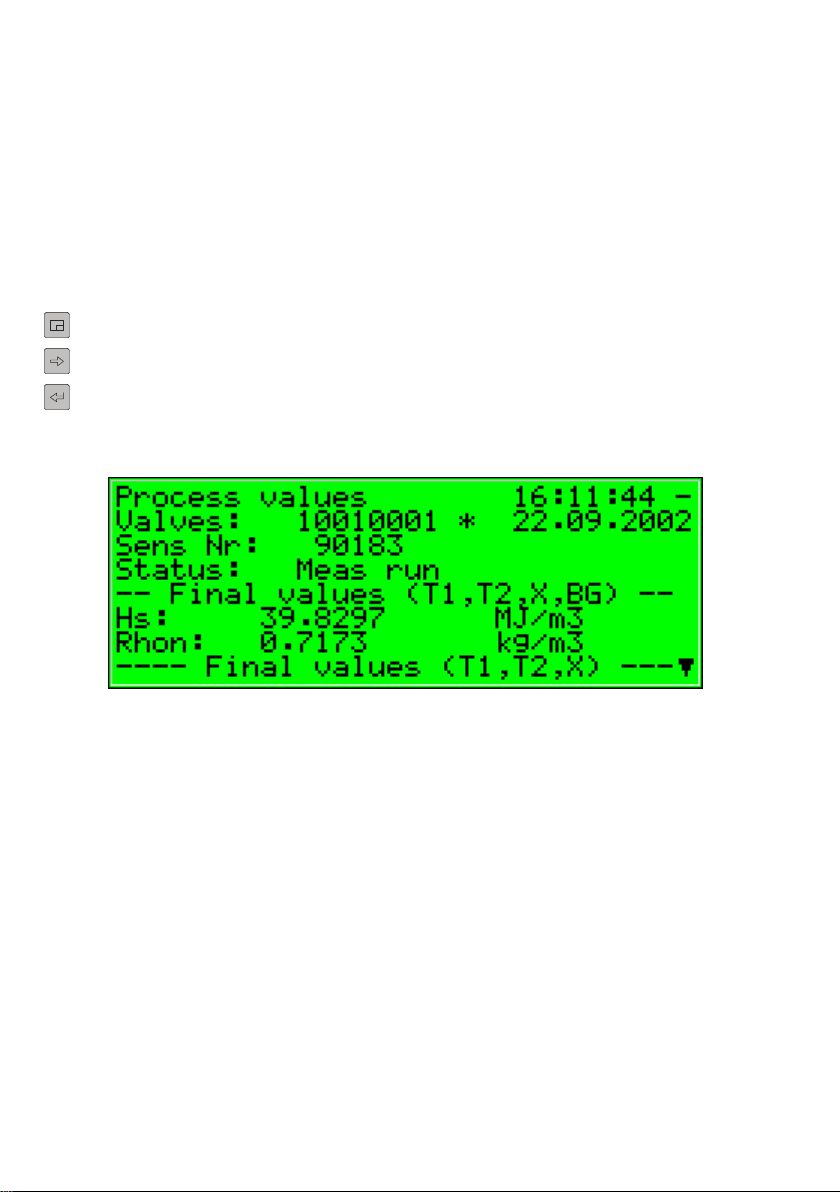

5.1.1.2 Process values display

The gas-net Q1 evaluation computer provides a special display to indicate the

source data measured by the sensor technology, the intermediate values that

have been calculated based on these source values and all determined final

values.

This display is called Process values and is invoked as described below:

1) Invoke the menu in the basic display.

2) Select the Process values entry by pressing the rightward arrow key. Press

the Enter key afterwards.

The Process values display contains too many values to be indicated all at

once. Scroll up or down the display with the arrow keys.

The upper part of the display shows the last valve positioning command sent by

the computer to the valve set as bit string (10010001). Also the number of the

current measurement is displayed, which is consecutively numbered. Furthermore the current state of measurement is indicated.

All other values are intended for service and maintenance purposes. If you have

questions for them please contact Elster.

Page 32 gas-lab Q1

Page 41

Functional description 5

5.1.2 Calibration

Each gas-lab Q1 measuring system has been calibrated when being delivered,

i.e. the device has been calibrated by the manufacturer. During operation an

automatic calibration with methane (1-point calibration) is carried out

periodically. During the routine testing of the device after one year, we

recommend to perform a manual basic calibration with nitrogen, methane and

two other calibration gases (3-point calibration).

5.1.2.1 1-point calibration / automatic calibration

Precondition for a successful completion of a 1-point calibration is that the

methane is properly connected on gas path 2 (see Cylinder change 5.1.4).

For this purpose the cylinder regulator must set be to approx 2 bars and the

precision pressure regulator (M2R) of the second gas path must be set to about

80 mbars. If the methane cylinder is not already opened, open it now and do a

purging right after it (see 5.1.5). Also the corresponding shut-off valve must be

opened.

It is not necessary to open the calibration switch at the gas-lab Q1 for this

calibration type.

An automatic 1-point calibration with methane can be carried out during normal

measuring in the following conditions:

In a fixed, configurable cycle every 1, 2, 3, 4, 5 or 6 days or 1, 2, 4, 8 or 12

weeks on a specified day at xx o’clock, typically every 7 days.

After a configurable time in hours after each switching on of the supply

voltage for the evaluation computer or sensor system, typically 12 hours

later.

After a configurable time in hours after each manual purge of a gas path,

typically 12 hours later.

After a configurable time in hours after errors that may affect the

measurement have been cleared, for instance Pressure disturbed

evaluation computer (A607), typically 12 hours later.

gas-lab Q1 Page 33

Page 42

5 Functional description

Manually by performing the 1P-cal. start command in the Calibration menu

what is described below.

By setting a parameterised digital input.

By means of a DSfG command.

The following reactions of the evaluation computer are indicating the status of

the 1-point calibration:

Via measurement outputs and on the controller’s basic display the last valid

gas quality values are maintained provided any values are available.

The basic display shows 1P-cal.

during calibration.

A Revision message will not be

generated.

If you want to abort the function prematurely, do so by keeping to the following

instruction sequences:

Invoke the menu from the basic display and select Calibration.

Confirm the selection and invoke the menu again.

Then select Cal. Cancel and confirm the selection

The gas-lab Q1 terminates the calibration process and returns to normal

operation.

Page 34 gas-lab Q1

Page 43

Functional description 5

The process will be aborted automatically if an alarm occurs during calibration.

Afterwards, the gas-lab Q1 uses the previous calibration data, provided such

data exists.

To manually start the 1-point calibration, do so by keeping to the following

instruction sequences:

Invoke the menu from the basic display select Calibration and confirm.

Measurement values of different sensors are displayed now.

By pressing the menu key again, the following submenu appears. Select the

menu item 1P-cal. start and confirm.

gas-lab Q1 Page 35

Page 44

5 Functional description

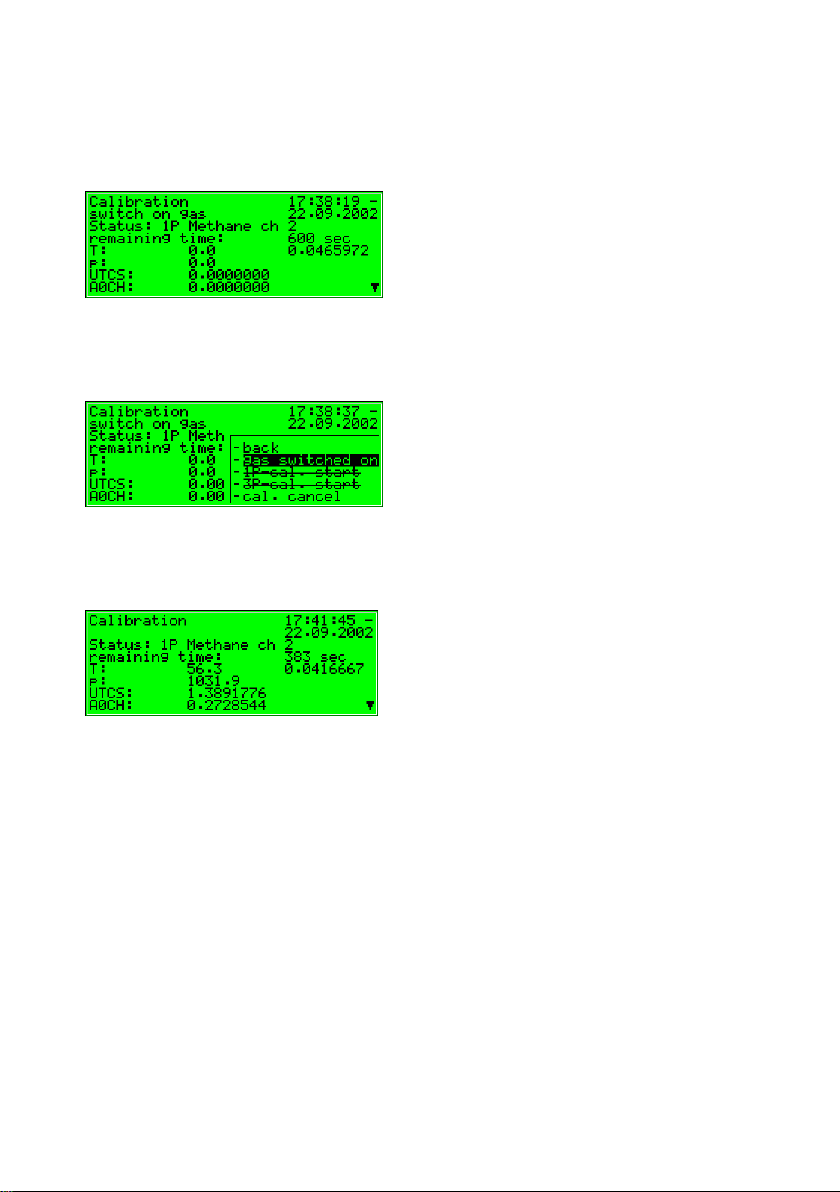

Now the actual status of the 1-point calibration is indicated on the display. Here

e.g. the required operation – switch on gas (methane gas path 2)

In case the methane is properly connected to gas path 2 (see beginning of

chapter), please invoke the menu and select the menu item gas switched on.

After confirming the calibration with methane proceeds automatically, whereas

the remaining time is displayed.

This process starts after approx. 2 minutes for purging and lasts for 10 minutes.

Page 36 gas-lab Q1

Page 45

Functional description 5

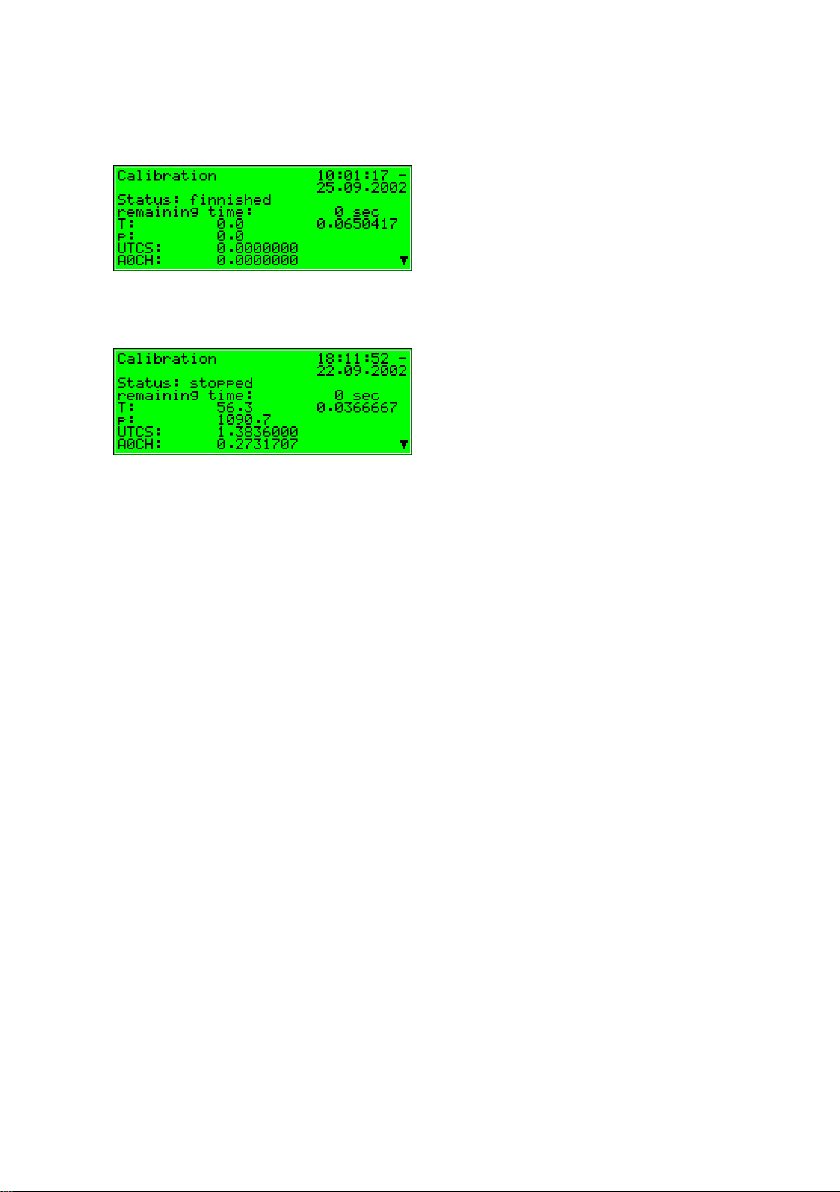

The end of calibration is indicated by the following display:

Then the display changes to the following condition (same as before starting):

After the 1-point calibration is finished, the sensor system automatically injects

the process gas and starts measuring.

The new correction values determined during the calibration are written to the

calibration archive.

We also recommend observing the deviations of the automatic 1-point

calibration in the quality archive.

If these values are getting too high, a new basic calibration should be

performed.

gas-lab Q1 Page 37

Page 46

5 Functional description

5.1.2.2 Basic calibration / 3-point calibration

Such a basic calibration is generally performed on the occasion of the yearly

routine testing. Trained and qualified staff must perform the basic calibration.

Although it runs automatically, the process steps are supported via the operator

panel of the evaluation computer.

The calibration switch at the gas-lab Q1 must be open to facilitate a basic

calibration.

The following reactions of the evaluation computer are indicating the status of

the 3-point calibration:

During the parameterisation of the gas-lab Q1 you may determine whether

or not the last valid gas quality values shall be maintained via measurement

outputs and on the basic display of the computer during this time.

The display shows 3P-cal. during

calibration.

A Revision message will be

generated.

If you want to abort the function prematurely, do so by keeping to the following

instruction sequences:

In case you are not in the Calibration module: Invoke the menu from the basic

display, select Calibration and confirm the selection.

Invoke the menu and then select Cal. Cancel.

Page 38 gas-lab Q1

Page 47

Functional description 5

By confirming the selection the gas-lab Q1 terminates the calibration process.

The process will be aborted automatically if an alarm occurs during calibration.

Afterwards, the gas-lab Q1 uses the same calibration data as before, provided

such data exists.

The basic calibration consists of the following steps:

1. Preparation

2. Zero point adjustment with nitrogen via path 3

3. Calibration with methane (1. calibration gas) via path 2

4. Calibration with H2-11K (2. calibration gas) via path 3

5. Calibration with L1-8K (3. calibration gas), via path 3

optional with a binary gas mixture (5% CO2 in methane)

1. Preparation

For successful completion of a 3-point calibration, the methane cylinder, also

used for the automatic calibration, has to be connected correctly to the second

gas path (see 5.1.4). The cylinder regulator must be set to approximately 2 bars

and the precision pressure regulator (M2R) of the second gas path to about

80 mbars.

If the methane cylinder has not been opened yet, open it and perform a purge

first (see 5.1.5).

Furthermore nitrogen and two other calibration gases (H2-11K, L1-8K or binary

mixture) will be connected one after another to the third gas path during the

calibration process. Since they are not needed for normal operation, they have

to be connected first.

The nitrogen is needed first, so his connection to the third gas path is described

next and stands also for the other two gases.

gas-lab Q1 Page 39

Page 48

5 Functional description

As no precision pressure regulator (M2R) has been installed on the mounting

plate for the third path normally, mount an additional precision pressure

regulator behind the cylinder regulator of the nitrogen cylinder for you to adjust

the operating pressure of the sensor system to approximately 80 mbars. This is

done in the following way:

Make sure that the nitrogen cylinder has been turned off and the cylinder

regulator is set to zero.

Connect a precision pressure regulator to the cylinder regulator of the

nitrogen cylinder and attach a high-pressure tube to the precision pressure

regulator.

Open the precision pressure regulator, so that some gas can flow off in the

next step, whereby the high-pressure tube is purged.

Open the nitrogen cylinder. The cylinder regulator must be set to about 2

bars.

Set the precision pressure regulator to approx. 80 mbars

Connect the high-pressure tube to the third gas path of the sensor system

finally

For performing a basic calibration the gas-lab Q1 needs to know the exact composition of the used calibration gases also.

For that purpose the gas analysis of the used calibration gases has to be

entered in the actual parameterization.

Support in changing an existing parameterization is given in chapter 6.2 and

regarding the affected parameters in chapter Fehler! Verweisquelle konnte

nicht gefunden werden. under periphery.

Page 40 gas-lab Q1

Page 49

Functional description 5

2. Zero point adjustment with nitrogen

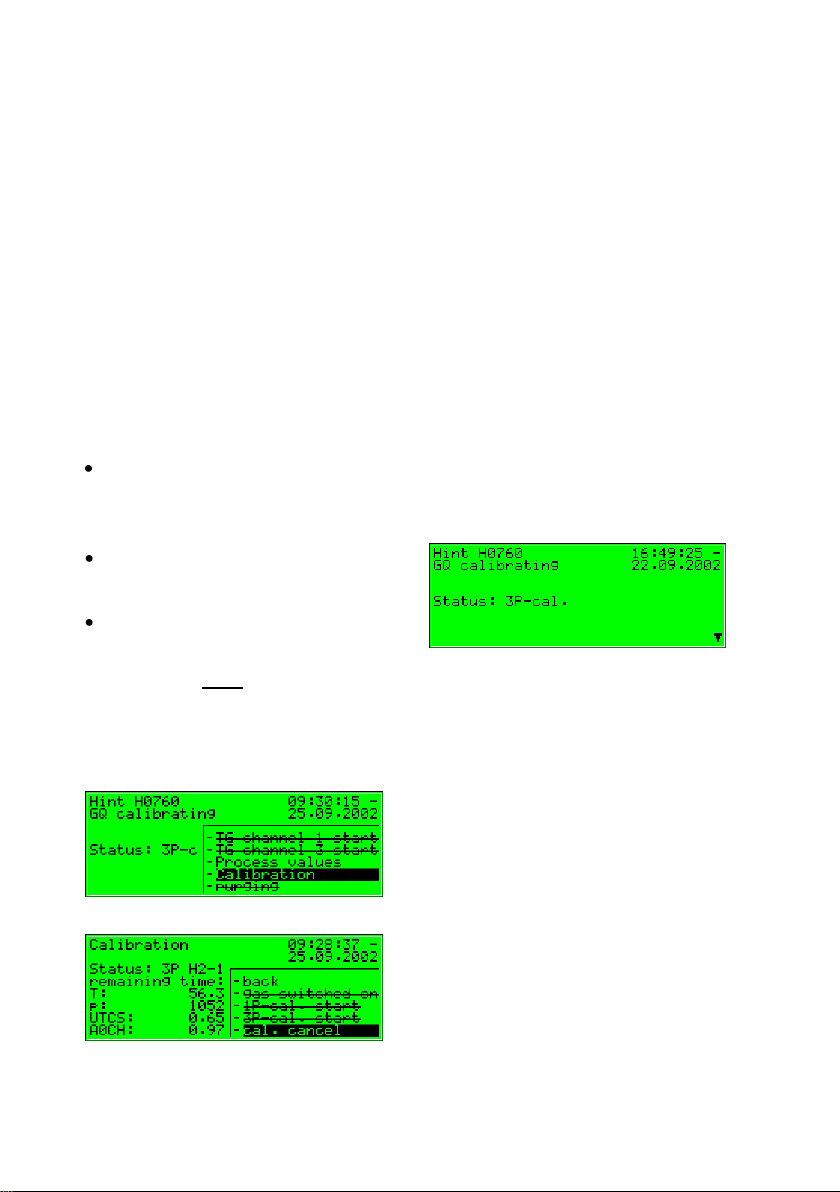

While being in the gas quality main display press the menu key and activate the

Calibration command in the invoked menu.

A display with measurements of the different sensors appears.

By pressing the menu key again, the following submenu appears.

Select the menu item 3P-cal. start and confirm.

Now the actual status of the 3-point calibration is indicated on the display. Here

e. g.: The required operation – switch on gas (nitrogen channel 3)

gas-lab Q1 Page 41

Page 50

5 Functional description

In case the nitrogen is properly connected to gas path 3 (see beginning of

chapter), please invoke the menu and select the menu item gas switched on.

After confirmation the zero point adjustment with nitrogen proceders

automatically.The process takes about 25 minutes. Meanwhile the display

shows the remaining time. It will not count down beforet 2 minutes of flushing

time.

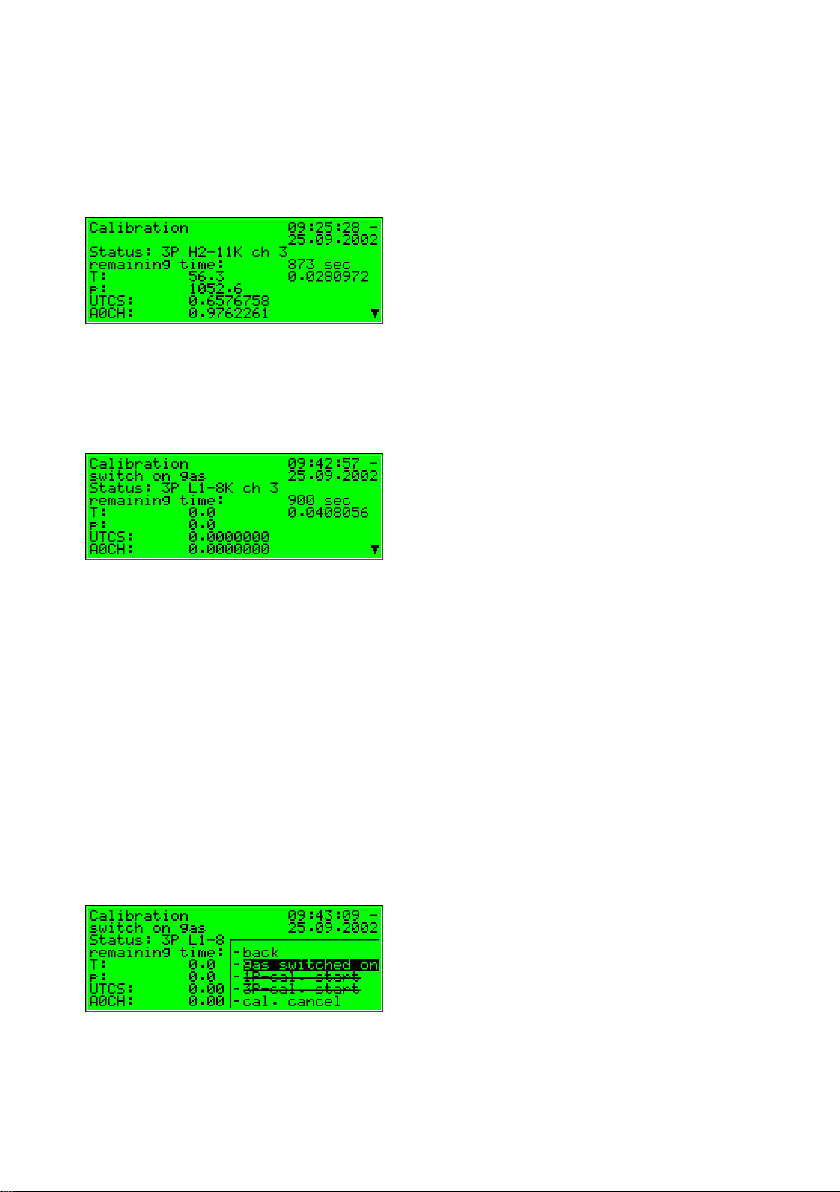

3. Calibration with methane (1. calibration gas)

Now the prepared methane has to be switched on, which the following display

indicates:

Please invoke the menu and select the menu item gas switched on.

Page 42 gas-lab Q1

Page 51

Functional description 5

After confirming the calibration with methane (1. calibration gas) runs

automatically. The adjustment starts after approx. 2 minutes for purging and

lasts for 15 minutes, whereas the remaining time is displayed.

Meanwhile turn off the nitrogen cylinder and remove the tube on both sides.

(Caution: Unpressurise the line first!).

Furthermore you can prepare the second calibration gas (H2-11K) on the third

gas path (see step 1. Preparation) When the calibration process with methane

(1. calibration gas) is finished, the following display appears:

4. Calibration with H2-11K (2. calibration gas)

Now the prepared H2-11K has to be switched on. Please invoke the menu and

select the menu item gas switched on.

gas-lab Q1 Page 43

Page 52

5 Functional description

After confirming the calibration with H2-11K (2. calibration gas) runs automatically, whereas the remaining time is displayed.

The adjustment starts after approx. 2 minutes for purging and lasts for 15

minutes. When the calibration process with H2-11K (2. calibration gas) is

finished, the following display appears:

Now turn off the H2-11K cylinder and remove the tube on both sides.

(Caution: Unpressurise the line first!).

5. Calibration with L1-8K or binary gas mixture (3. calibration gas)

Now the prepared L1-8K or binary gas mixture has to be connected. (see step 1.

Preparation)Then the prepared 3rd calibration gas is started by opening the

menu and selecting the menu item gas switched on.

Page 44 gas-lab Q1

Page 53

Functional description 5

After confirmation the calibration with the 3rd calibration gas (L1-8K or a binary

gas mixture) proceeds automatically. The remaining time is indicated on the

displayed. In any case “L1-8K” is shown on the display, even if you use a binary

gas mixture instead.

The adjustment starts after approx. 2 minutes for purging and lasts for 15

minutes, whereas the remaining time is displayed

The end of calibration is indicated by the following display:

Then the display changes to the following condition (same as before starting):

After the basic calibration is finished, the sensor system automatically switches

back to the process gas and starts measuring.

Now turn close the L1-8K or binary gas mixture cylinder and remove the tube on

both sides.

(Caution: Unpressurise the line first!)

gas-lab Q1 Page 45

Page 54

5 Functional description

5.1.3 Test gas injection

The injection of test gases serves to check the gas quality meter with a known

gas or to measure unknown gases on a non-routine basis.

The following reactions of the evaluation computer are indicating the status of

the test gas injection:

Via measurement outputs and on the controller’s basic display the last

valid gas quality values are maintained provided any values are

available.

A Revision message will be generated.

Please proceed as described below:

1. Decide whether you like to inject the test gas via gas path 1 or 3.

2. Make sure the test gas cylinder is closed and the cylinder regulator is set to

zero. Set the associated precision pressure regulator to zero. Connect the

outlet of the precision pressure regulator to the first or third gas path of the

sensor system using a high-pressure tube. When using gas path 1, make

sure the process gas, which is also connected to this path, has been shutoff tightly and thus is not able to affect the measurement by contaminating

the test gas.

3. Open the test gas cylinder. The cylinder regulator must be set to about

2 bars.

4. Set the precision pressure regulator to approx. 80 mbars.

5. Now purge the first or third gas path (see 5.1.5).

Page 46 gas-lab Q1

Page 55

Functional description 5

6. Press the Menu key while being in the gas quality main display and activate

the TG path 1 start or TG path 3 start command in the invoked menu.

7. Now, the sensor system will be purged with test gas for about 2 minutes.

Afterwards, the measurement begins. The measurement results are shown

in the main display.

8. To finish the test gas injection, press the Menu key and activate the TG

path 1 end or the TG path 3 end command.

9. Now please turn off the test gas cylinder and remove the tube on both

sides.

(Caution: Unpressurise the line first!).

A running test gas injection will be aborted automatically after 1 hour (which can

be parameterised), and process gas will be injected instead.

When gas path 1 was used, make sure that after the test gas injection the

process gas is reconnected and opened to this path. Otherwise the test gas is

handeled as process gas and the measurement results are mapped incorrectly.

gas-lab Q1 Page 47

Page 56

5 Functional description

5.1.4 Cylinder change

Different gases must be available in the plant for calibration and measurement

tasks. Therefore it might be necessary from time to time to connect another gas

cylinder to a gas supply connection of the gas-lab sensor housing; for instance,

if the pressure of the methane cylinder is insufficient for the 1-point calibration to

be carried out.

To remove an existing cylinder, proceed as follows:

1. Close the old cylinder at the main valve on top of the cylinder and

unpressurize the connected gas line. You possibly have to wait until the

remaining gas has been used up or use an available venting possibility

(preferably low pressure side).

2. Remove the cylinder connection from the cylinder and close the cylinder

with the corresponding nut.

3. Place the protective cap on the cylinder and fasten it..

4. Not until now detach the protection against falling down (safety chain or

clamp) and remove the cylinder.

Page 48 gas-lab Q1

Page 57

Functional description 5

To connect a new cylinder, proceed as follows:

5. Secure the new cylinder with a chain or clamp against falling down at first.

6. Remove the protective cap from the cylinder by unscrewing it.

7. Make sure that the main valve on top of the cylinder is closed.

8. Remove the nut from the valve connection now.

9. Make sure that the pressure reducing valve and the shut-off valve of the

high-pressure regulator or cylinder pressure regulator to be connected are

closed. Close the pressure reducing valve by unscrewing its setting screw.

10. Now connect the cylinder connection of the high-pressure regulator or

cylinder pressure regulator to the valve connection of the gas cylinder.

11. Open the main valve of the gas cylinder and adjust the outlet pressure of

the high-pressure regulator or cylinder pressure regulator to the operating

pressure needed by the sensor system for the gas stream you are

preparing just now. (i.e.: 1 – 5 bars if in front of an additional low pressure

regulator (M2R) or only 80 mbars if directly connected to gas path 3 of

sensor system)

To purge the high-pressure or cylinder pressure regulator, proceed as follows:

12. Close the main valve of the gas cylinder and wait until the high-pressure

regulatoror cylinder pressure regulator is almost drained, i.e. until the outlet

pressure has almost dropped down to 0 bar. Now open the gas cylinder

again.

13. Repeat this draining and filling of the high-pressure regulator or cylinder

pressure regulator twice to ensure that the regulator’s dead volume does

not contain gas from the previous use or air.

14. Pay attention to the fact that the gas cylinder must be open finally to make a

calibration or measurement possible.

gas-lab Q1 Page 49

Page 58

5 Functional description

5.1.5 Purging

After having exchanged a gas cylinder with a flammable content, always make

sure that no air gets into the sensor system. This is why a purge must be

initiated manually after each cylinder change. This also applies if air may have

entered in a gas path connected to the sensor system.

The following reactions of the evaluation

computer are indicating the status of the

test gas injection:

The last valid gas quality values are maintained via measurement outputs,

provided any values are available at all.

The Revision status will not be indicated.

Proceed as described below:

1. Connect the gas cylinder to the relevant gas path. Set the pressure of the

cylinder regulator output to 1 - 5 bars and the pressure of the downstream

precision pressure regulator to 80 mbars.

2. Press the key while menue being in

the main display, select the purging

command and confirm it by pressing

the key enter.

3. Gas-channel 1 appears on the

display.

Page 50 gas-lab Q1

Page 59

Functional description 5

4. Press the Enter key again. The

following selection list appears:

Select the gas path you would

like to purge via the arrow keys.

Confirm your selection by

pressing the enter key again.

5. Press the menu key now and start the purge with OK or quit the dialog via

Cancel.

6. The purge lasts for about 7

minutes. The display shows

purging.

After the purge has been finished automatically, the gas-lab Q1 starts

measuring the process gas again.

gas-lab Q1 Page 51

Page 60

5 Functional description

5.1.6 Revision

The gas-lab Q1 sets the revision status in case of a zero point adjustment, a 3point calibration or a test gas injection.

A set revision status means that the gas quality is not measured under normal

and proper operating conditions.

All entries in the interval archive are marked with the Revision status note.

Furthermore, the Revision switch open hint will be generated and entered in the

error listing and logbook.

The termination of the revision operation results in the ending of the Revision

switch open hint with an entry in the logbook and induces a last entry marked

Revision in the interval archive.

The gas quality measurement runs normally again.

Page 52 gas-lab Q1

Page 61

Functional description 5

5.2 Data logging module

5.2.1 Function

The gas-net Q1 evaluation computer is always equipped with an integrated data

logging function. The responsible Data logging module, however, provides only

the data logging service. The actual data to be logged is generated by other

modules of the module group.

When parameterising the Data logging module, you only have to define which of

the available archive groups shall actually be logged and which storage depth

shall be applicable. All archives defined in that way are designed as ring

storage. The data logging depth determines how many entries an archive is able

to write at most. If an archive is full, the respective oldest entry will be

overwritten by each new entry.

The following sections list the types of archive groups each gas-net Q1 module

provides:

Gas quality module:

The gas quality module provides 3 archive groups:

The PTB archive logs the billing-relevant data, which consists of the gross

calorific value GCV, CO2 content and status of the measurement system.

The data is recorded every 15 minutes. The PTB archive has a size of 180

days.

The Interval archive logs the gross calorific value GCV, the standard

density Rhon, the CO2 content and the status of the measuring system.

The data is logged at the full hour and when an error occurs. The Interval

archive has a size of about 60 days.

The Quality archive logs 6 quality factors during each 1-point calibration.

These factors provide information on the corrections that have been made

during the individual calibrations with methane. The Quality archive has a

depth of 365 entries.

gas-lab Q1 Page 53

Page 62

5 Functional description

Monitoring module:

The Monitoring module facilitates the compilation of process value archives

(archives with any measurements or count values). Moreover, it runs the gas

quality measurement’s error logbook. The beginning and ending of all error

types (alarm, warning, hint – see Chapter 5.3.1) are entered in the listing in clear

text and together with a time mark. There is an additional, separate error listing

for internal message processing, if this function is used. This error listing can

also be logged.

System module:

The System module runs a parameter change archive (changed settings

archive) ), in which changes of the parameterisation are logged.

If individual parameters are modified, the old and new values will be logged in

addition to the time mark. The module to which the changed parameter belongs

is also displayed.

A completely new parameterisation will be entered in the changed settings

archive as New parameterisation via the data interface when the calibration

switch is open. A change of the parameterisation’s operational part is marked as

New operational parameterisation.

Note: The archive depth, exact composition and order of archives can be

configured by the user via the parameterisation. However, when changing the

archive structure, you have to delete the old archives already existing in the

device.

The devices have already been provided with a pre-defined archive structure

corresponding to the common requirements before delivery.

Page 54 gas-lab Q1

Page 63

Functional description 5

Current calendar time

Input mask for selection of the

archive information to be

indicated in the next step.

}

5.2.2 Display and operation

Main display (Data logging module)

All existing archive entries can be made visible at the operator panel.

The main display of the Data logging module consists of a mask in which you

may choose the data you want to view more closely. The following illustration

shows an example:

After the main display of the Data logging module has been invoked, the most

recent entry of the first channel of the first archive group is always indicated first.

Choose the archive information you would like to view :

The archive type is selected at the

beginning, i.e. it is backlit in black.

Press the Enter key to get into the