Page 1

Self recuperative burner ECOMAX® for gas

Technical Information · GB

Edition 02.11

• For direct and indirect heating equipment

• Economical, energy-saving operation by virtue of internal

air preheating up to 700°C

• Great flexibility due to its maintenance-friendly modular design

• Uniform distribution of temperature by means of a high burner impulse

• Low polluting level thanks to staged combustion

• Direct ignition and monitoring

• 7 sizes for a broad output range from 15–500kW

• Highly efficient with a ceramic burled tube recuperator, a cast steel ribbed

tube recuperator or a flat tube recuperator

www.lbe-online.de

Page 2

Contents

Self recuperative burner ECOMAX® for gas . . . . . . . . . . . . 1

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Indirect heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Direct heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Examples of application . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3.1 ECOMAX® in radiant tubes. . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.3.2 ECOMAX

2 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Approval for Russia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Mechanical construction. . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Burner housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Recuperator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Air guide tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Gas insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4.1 Versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Burner type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Burner design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Gas types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.4 Burner length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5 Connection for additional furnace cooling . . . . . . . . . 16

5.6 Differential air pressure measuring kit DA 1 . . . . . . . . 17

5.7 Differential air pressure measuring kit DA2 with

pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.8 Flue gas monitoring kit DW . . . . . . . . . . . . . . . . . . . . . 18

5.9 Selection table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.9.1 Type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6 Project planning information . . . . . . . . . . . . . . . . . . . . . 22

6.1 Flame control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Purging air and cooling air . . . . . . . . . . . . . . . . . . . . . 23

®

in direct heating systems . . . . . . . . . . . . . . . . . .7

2

6.3 Recommended burner control units . . . . . . . . . . . . . . 24

6.4 Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.1 Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.2 Operation with LPG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4.3 Air/gas ratio control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.5 Air connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.1 Indirect heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.2 Direct heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.6 Flue gas guide tube FGT for direct heating . . . . . . . . . 29

6.6.1 For ECOMAX..C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.6.2 For ECOMAX..M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.7 Radiant tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.7.1 Ceramic radiant tube SER-C for indirect heating . . . . . . . .31

6.7.2 Metallic radiant tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.7.3 Radiant tube distances . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.7.4 Eductor on burners with metallic single-ended

radiant tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.8 Flue gas channelling. . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.8.1 Indirect heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.8.2 Direct heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.9 Burner adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.9.1 Differential air pressure measuring kit DA2 with

pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

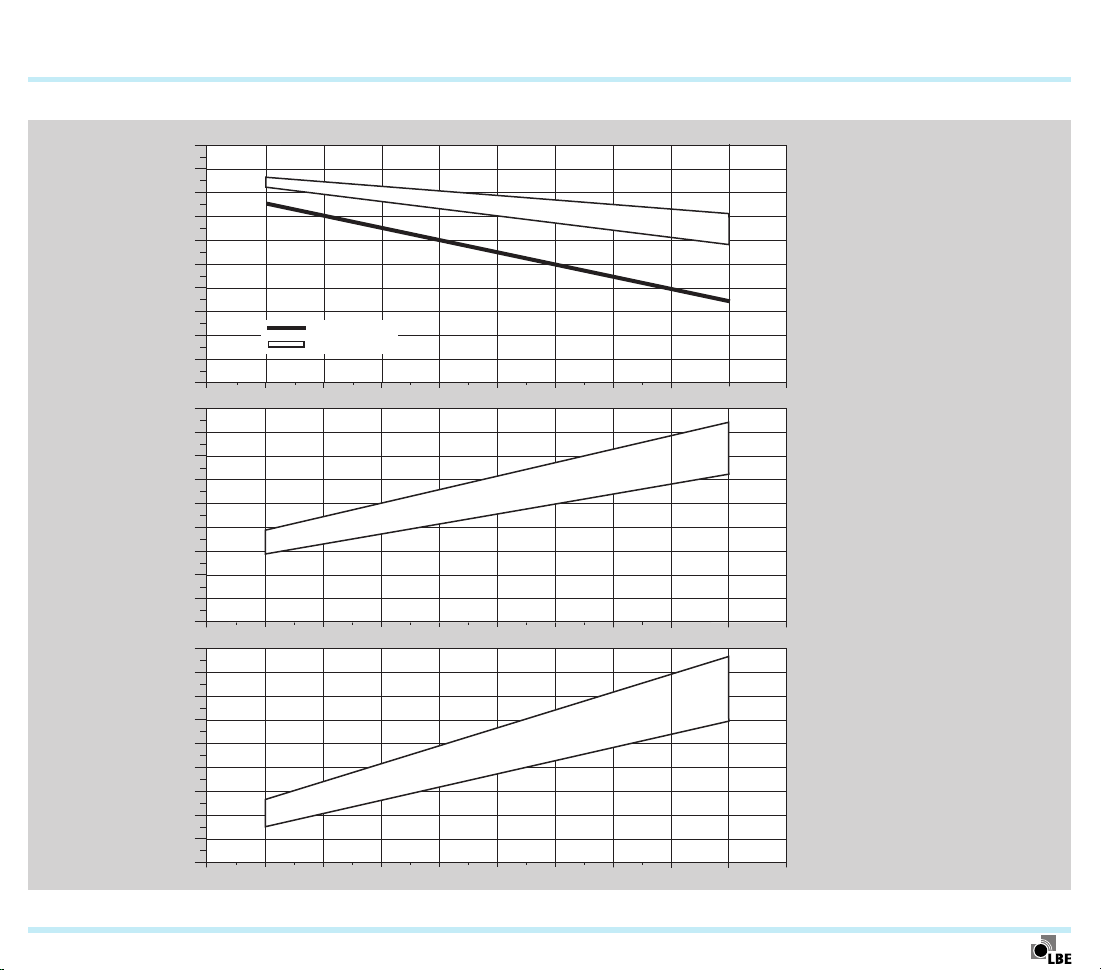

7.1 Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.1.1 ECOMAX..C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1.2 ECOMAX..M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1.3 ECOMAX..FTR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

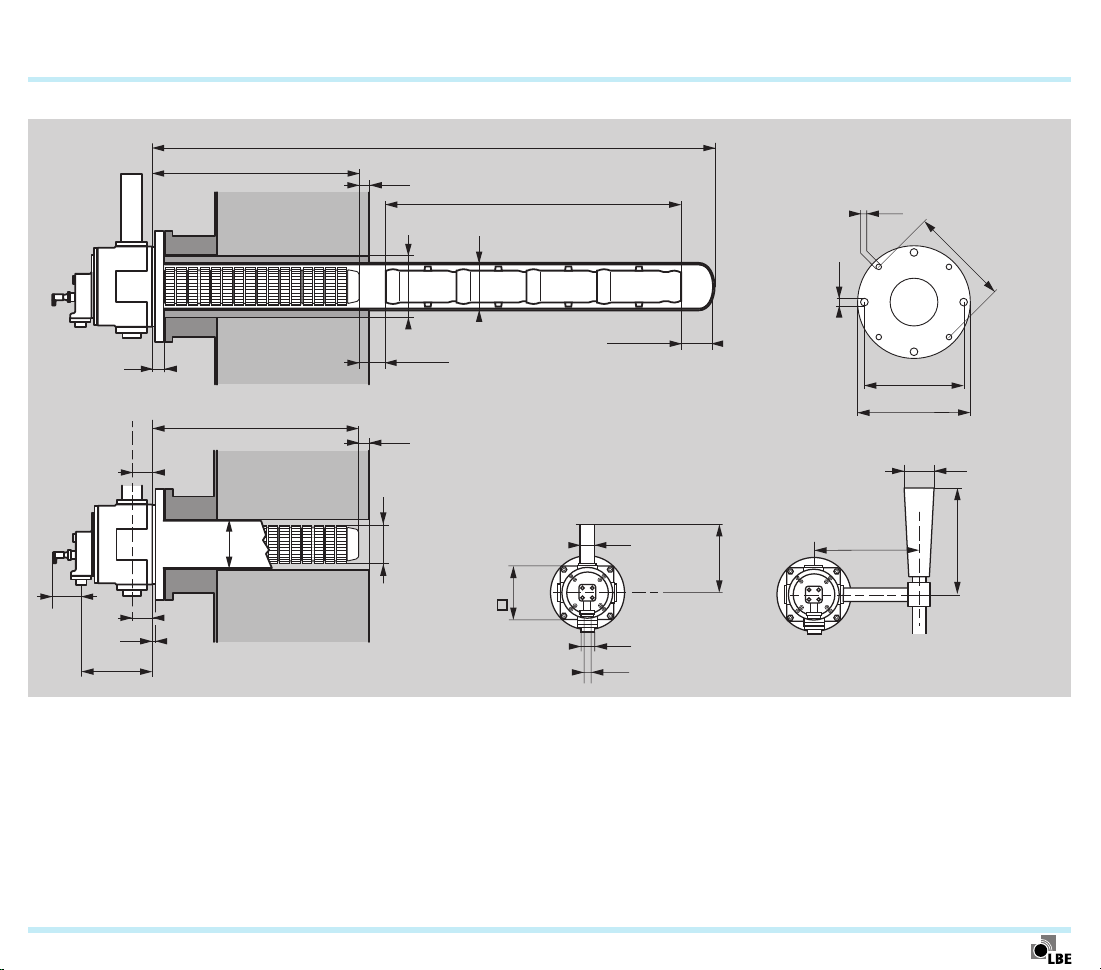

7.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.2.1 ECOMAX..C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.2.2 ECOMAX..M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2.3 ECOMAX..FTR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2.4 ECOMAX standard piping . . . . . . . . . . . . . . . . . . . . . . . . . .47

8 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

ECOMAX · Edition 02.11

t

= To be continued

Page 3

9 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1 Flue gas guide tube FGT kit . . . . . . . . . . . . . . . . . . . . . . 49

9.2 Flue gas eductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.3 Ceramic radiant tube SER-C . . . . . . . . . . . . . . . . . . . . . 50

®

9.4 SICAFLEX

segmented flame tube. . . . . . . . . . . . . . . . 50

9.5 P2/P3 set Eco. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3

ECOMAX · Edition 02.11

t

= To be continued

Page 4

ECOMAX..C ECOMAX..M ECOMAX..FTR

1 Application

The burners with integrated recuperator ECOMAX® are used

for heating on either direct or indirect furnace systems in intermittent mode.

1.1 Indirect heating

ECOMAX® self recuperative burners are used in conjunction

with metallic or ceramic radiant tubes and the segmented

ceramic flame tube SICAFLEX® as indirect heating equipment

whenever the combustion gases are to be separated from

the product.

4

1.2 Direct heating

In conjunction with an eductor to extract the flue gases, the

burner is used to save energy in a direct heating system. Applications include industrial furnaces and firing systems in the

iron and steel industry and in the non-ferrous metal industry.

ECOMAX · Edition 02.11

Page 5

Application

Roller hearth furnace Bogie hearth furnace Batch furnace

5

ECOMAX · Edition 02.11

Page 6

Application

6

1.3 Examples of application

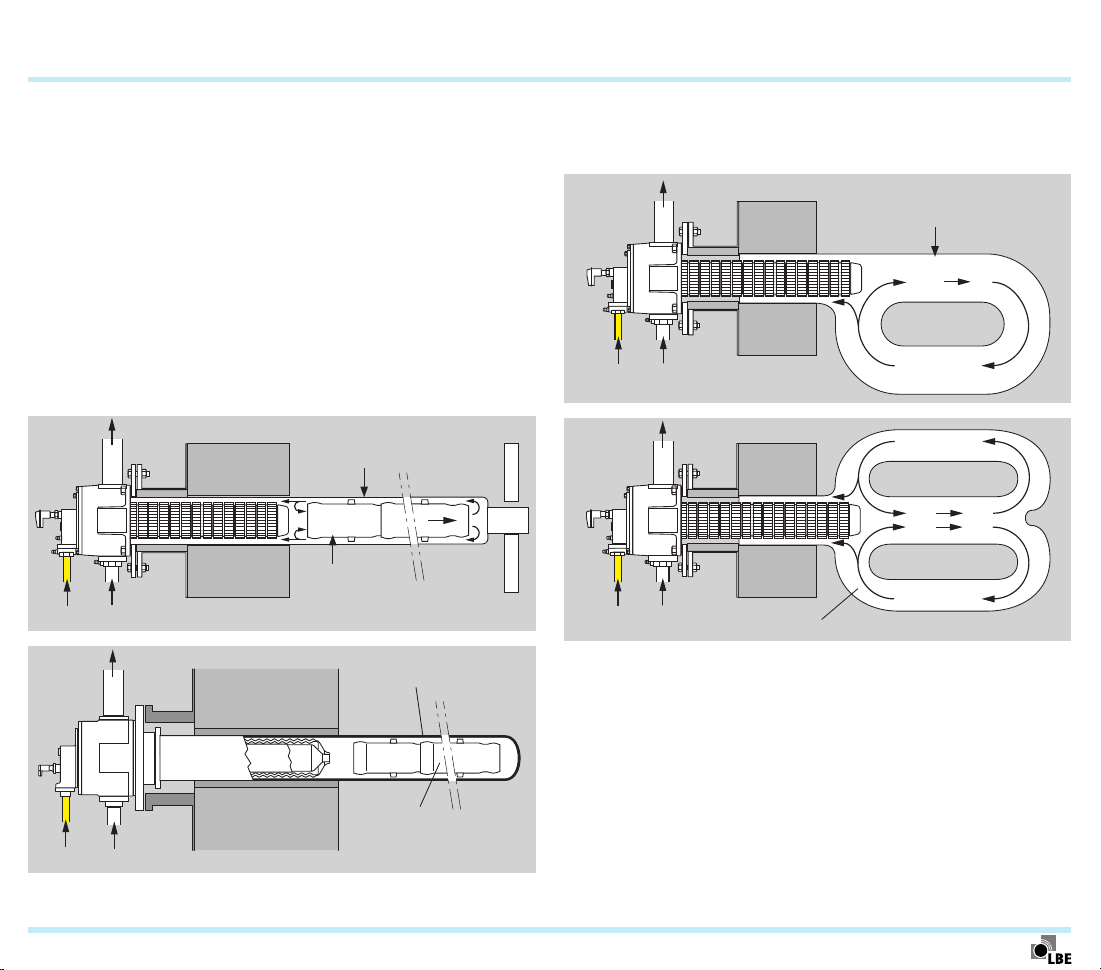

1.3.1 ECOMAX® in radiant tubes

The high outlet velocity of the combustion gases generates a

pressure at the outlet of the ceramic burner tube, resulting in

the recirculation of the flue gases. This leads to the following:

– a reduction in NOx emissions,

– a uniform radiant tube temperature.

The hot flue gases are fed through the ceramic or metallic heat

exchanger, heating the additional supply of cold combustion

air flowing in the opposite direction. The maximum achievable

air preheat temperature amounts to approx. 700°C, depending on the application.

Flue gas

Gas Cold air

Flue gas

Metallic radiant tube

®

Sicaflex

Ceramic radiant tube

SER-C

SICAFLEX® segmented flame tubes must be fitted in the singleended (metallic or ceramic) radiant tube to guide the hot flue

gases.

Flue gas

P radiant tube

Gas Cold air

Flue gas

Gas Cold air

Twin P

radiant tube

Gas Cold air

ECOMAX · Edition 02.11

Flame tube

Page 7

Application > Examples of application

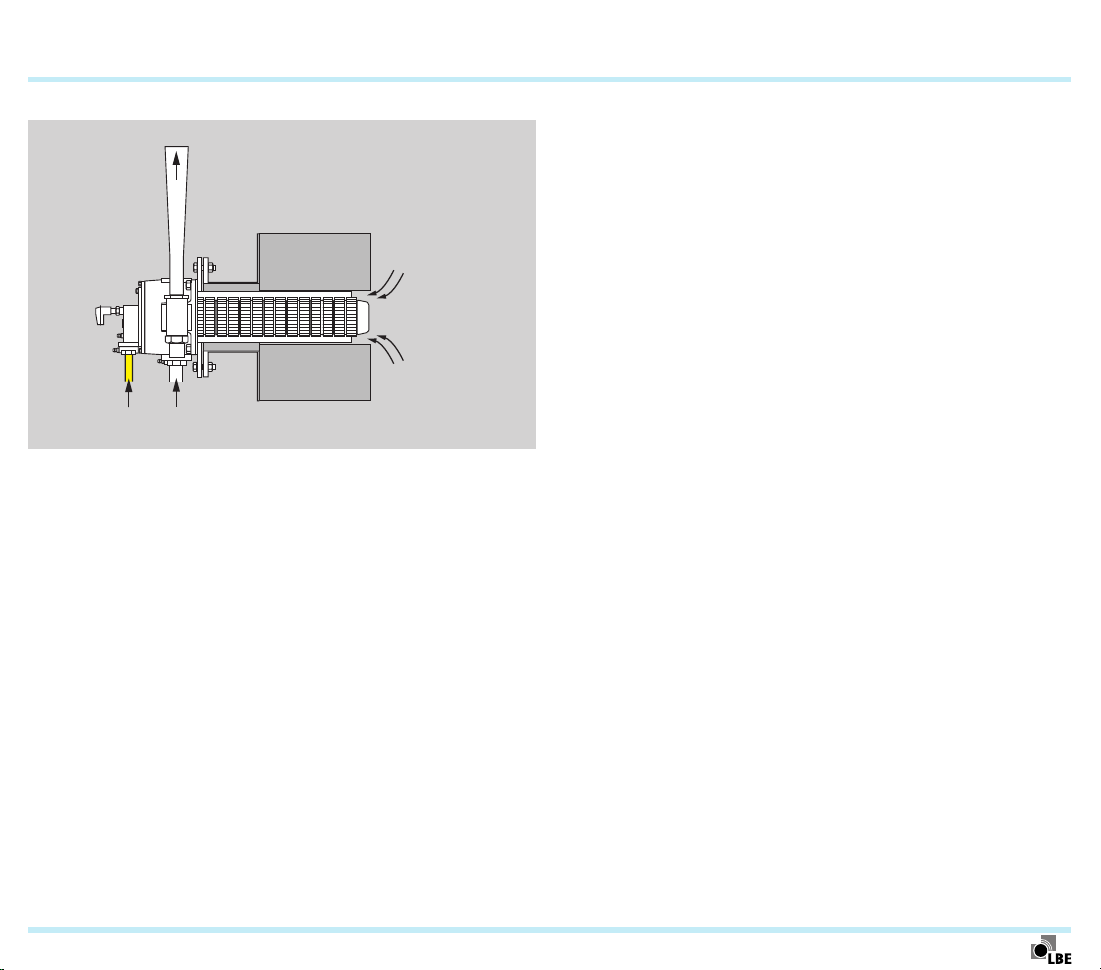

1.3.2 ECOMAX® in direct heating systems

Flue gas

Gas Cold air

ECOMAX® self recuperative burner in a direct heating system with an eductor for extracting the flue gases from the

furnace. The eductor generates a vacuum with a centrally

positioned nozzle and thus draws the flue gases out of the

furnace chamber through the burner’s heat exchanger. The

maximum achievable air preheat temperature amounts to

approx. 700°C, depending on the application.

7

ECOMAX · Edition 02.11

ECOMAX® with eductor and burner control unit BCU

Page 8

2 Certification

2.1 Approval for Russia

Certified by Gosstandart pursuant to GOST-R.

Approved by Rostekhnadzor (RTN).

8

ECOMAX · Edition 02.11

Page 9

9

3 Mechanical construction

The ECOMAX® burner unit is composed of four modules:

burner housing, recuperator, air guide tube and gas insert.

The modular design facilitates adapting the burners to the

respective application or integrating them into an existing

furnace system. Maintenance and repair times are reduced,

and existing furnace installations can easily be converted.

3.1 Burner housing

The burner housing accomodates the connections for the

combustion air, gas, cooling air and flue gas channelling. It

also secures the burner insert. It is made of cast aluminium,

which means it has a low weight. The housing has a doublewall design. The combustion air is fed into the burner via the

outer annular gap. This cools the burner housing und reduces

emissions.

3.2 Recuperator

All-ceramic

The surface of the all-ceramic recuperator, which is made

of SiSiC for high thermal stress, is burled in order to achieve

high efficiency.

Cast steel

The ribs on the cast steel recuperator offer a large surface area,

allowing it to achieve high efficiency even at low temperatures.

Flat tube

The flat tube recuperator has a smooth surface. It is a cost-

effective alternative at a lower efficiency level and is suitable

for lower application temperatures.

ECOMAX · Edition 02.11

Page 10

Mechanical construction

10

3.3 Air guide tube

Burners Ecomax..C have a ceramic air guide tube that for sizes

0 to 3 also serves as the combustion chamber.

Burners Ecomax..M and Ecomax..FTR have an air guide tube

made of heat-resistant steel.

3.4 Gas insert

The gas insert consists of the gas connection flange, the gas

lance with mixer unit and the ignition electrode (also serves

as monitoring electrode). For operation with LCV gas, the gas

insert is equipped with a special mixing system.

Gas insert with combustion chamber for Ecomax M and Ecomax FTR

ECOMAX · Edition 02.11

Gas insert without combustion chamber for Ecomax C (sizes 1 to 3)

Page 11

Mechanical construction > Gas insert

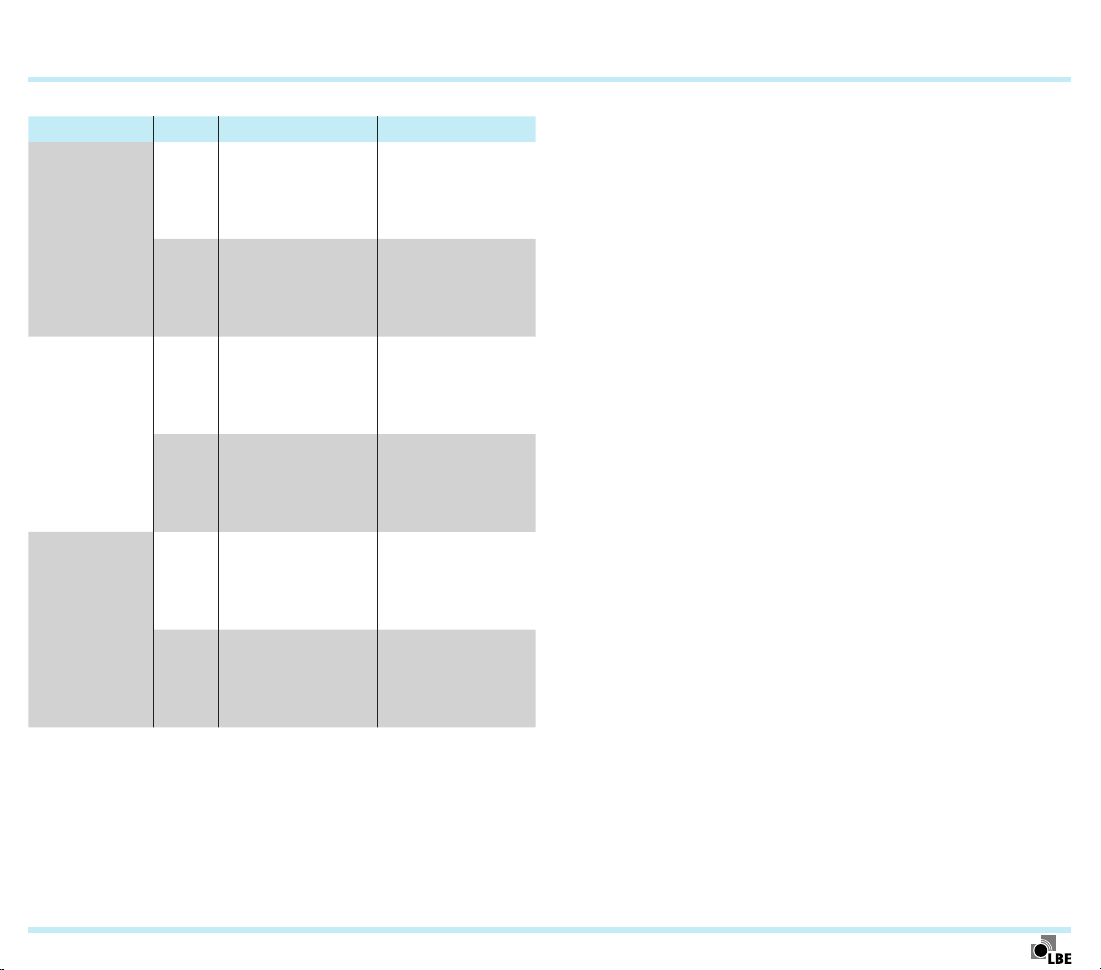

3.4.1 Versions

Burner Size Gas insert Air guide tube

Ceramic,

ECOMAX..C

ECOMAX..M

ECOMAX..FTR

0 – 3

4 – 5

1 – 3

4 – 6

1 – 3

4 – 5

With mixing

funnel

With swirl plate

and ceramic

combustion

chamber

With mixing funnel and ceramic

combustion

chamber

With swirl plate

and ceramic

combustion

chamber

With mixing funnel and ceramic

combustion

chamber

With swirl plate

and ceramic

combustion

chamber

with integrated

combustion

chamber

Ceramic

Metallic

Metallic

Metallic

Metallic

11

ECOMAX · Edition 02.11

Page 12

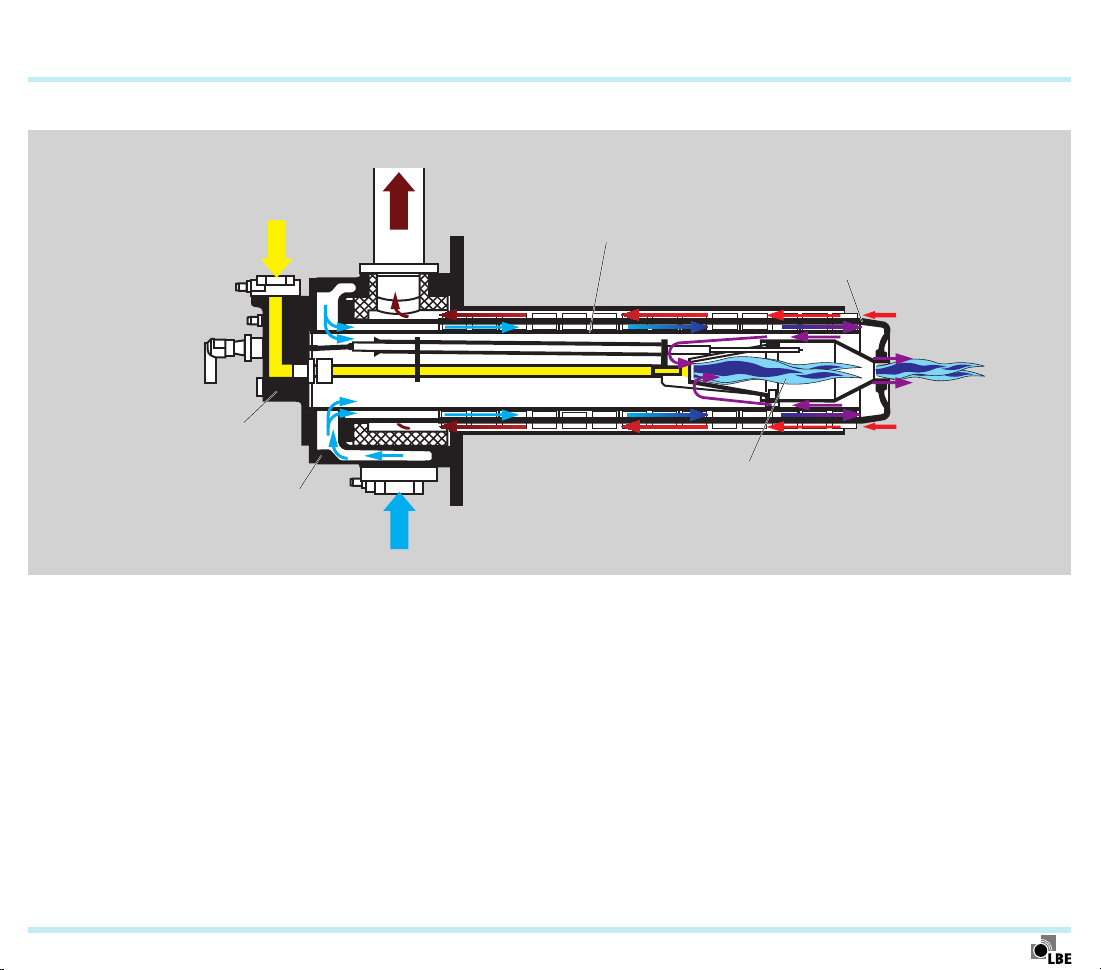

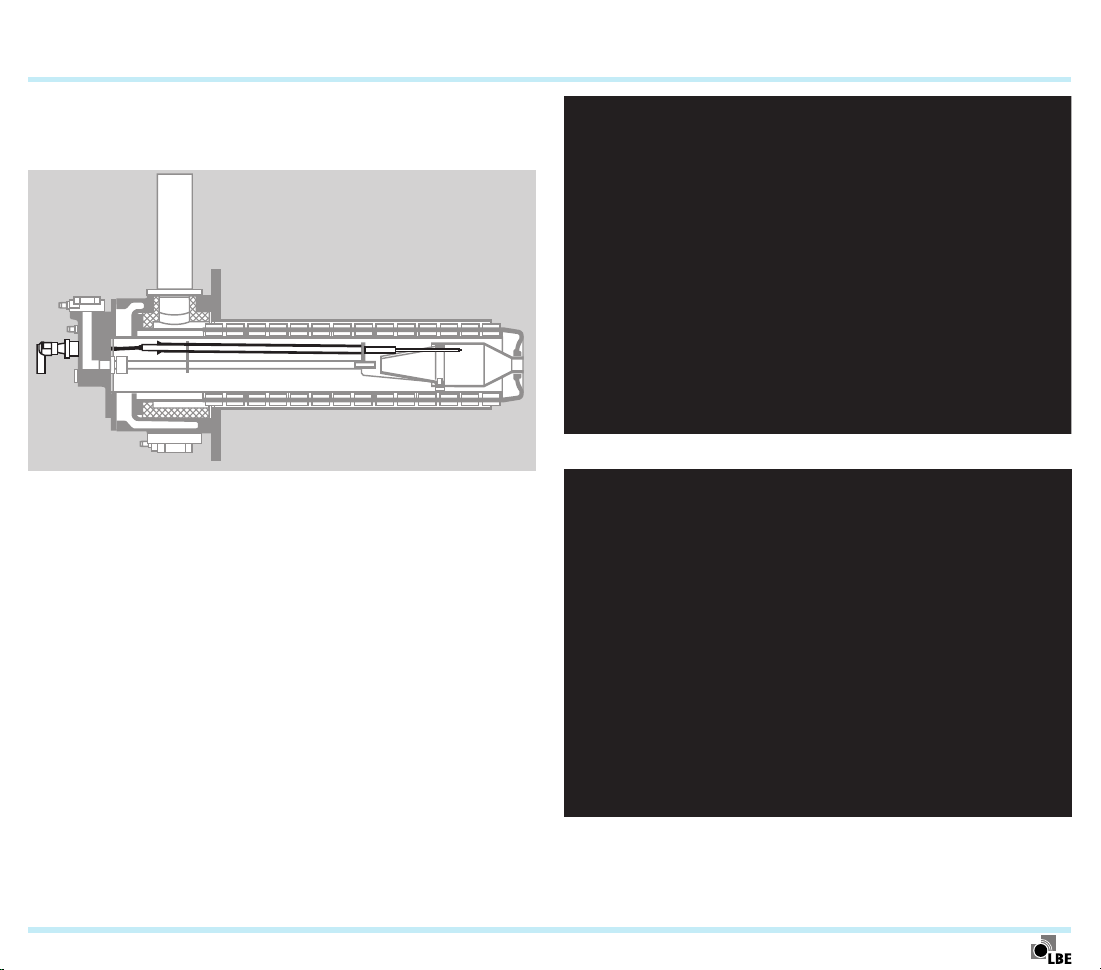

4 Function

Combustion air

12

Flue gas

Combustion gas

Air guide tube

Recuperator

Gas insert

Combustion chamber

Housing

The self recuperative burner ECOMAX® uses the heat from the

flue gases to preheat the combustion air. The heat exchanger

(recuperator) required for this is part of the burner.

After entering the burner, the combustion air flows in the gap

between the air guide tube and the inside of the recuperator

towards the tip of the burner. Some of this air is fed into the

inside of the burner, where it combusts in the first combustion

stage. The rest of the combustion air flows out through the gap

between the combustion chamber and the recuperator head

at high speed before combustion takes place in the second

combustion stage here. This process means that fewer pollutant emissions are produced.

ECOMAX · Edition 02.11

The hot flue gases, flowing in the opposite direction, leave the

furnace chamber on the outside of the recuperator. Heat is exchanged between the hot flue gases and the cold combustion

air through the recuperator wall. The burner is directly ignited.

Page 13

5 Selection

5.1 Burner type

The burner ECOMAX is available with a ceramic burled

tube recuperator (Ecomax..C), a cast steel ribbed tube recuperator (Ecomax..M) or a metallic flat tube recuperator

(Ecomax..FTR). Selection is dependent on the type of heating

and the furnace temperature.

Furnace temperature [°C]

Burner

direct indirect*

Ecomax..C 1300 approx. 1200

Ecomax..M 1150 approx. 1000

Ecomax..FTR 950 approx. 850

* The max. allowable temperature of the radiant tube must

be observed.

Heating

13

ECOMAX..C

ECOMAX..M

ECOMAX · Edition 02.11

ECOMAX..FTR

Page 14

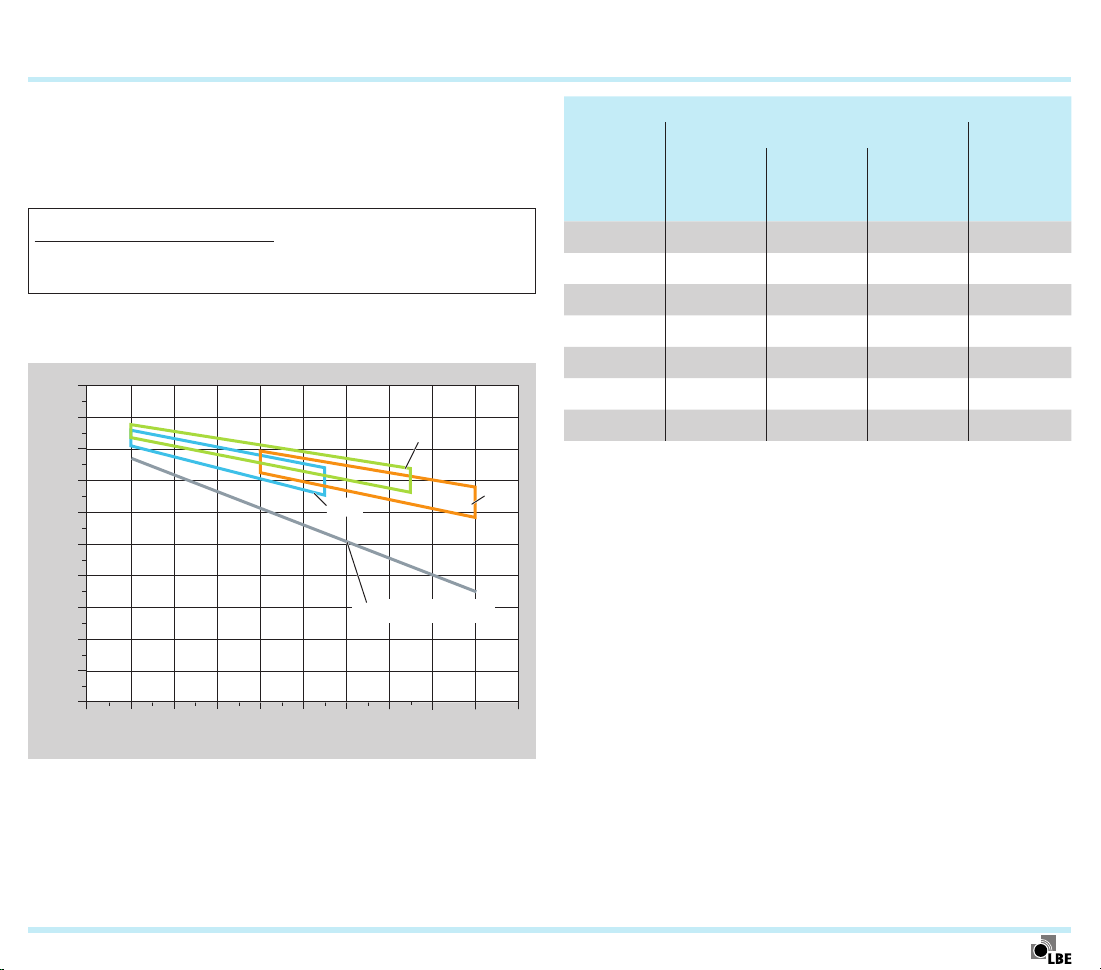

Firing efficiency η

Selection

14

5.2 Burner design

Selection of the burner size is dependent on the net heat output.

From this, the required burner output is calculated using the

firing efficiency value.

Net heat output [kW]

Firing

efficiency η

Determine the firing efficiency for the desired furnace temperature using the diagram.

1

0,9

0,8

0,7

0,6

0,5

0,4

0,3

0,2

0,1

0

400 500 600 700 800 900 1000 1100

Flue gas temperature on recuperator inlet [°C]

= Burner output [kW]

M

FTR

Cold air burner

1200

1300

C

1400

Burner

Recuperator Output*

Size

ceramic

C

Ecomax 0

Ecomax 1

Ecomax 2

Ecomax 3

Ecomax 4

Ecomax 5

Ecomax 6 –

= available.

* For operation with natural gas. For operation with coke oven gas,

the output is approx. 80%, for operation with LCV gas, approx.

65%.

metallic

M

metallic,

flat tube

FTR

– – 25

– 500

[kW]

36

60

100

180

250

Precise dimensioning is available on request using the

ECOMAX calculation tool. For this, the following information

is required:

– Type of heating

– Furnace temperature

– Required net heat output

– Gas type

– Geometric furnace data (wall thickness, furnace extension,

clear width)

ECOMAX · Edition 02.11

Page 15

Selection

15

5.3 Gas types

Calorific value

Gas type Code letter

Natural gas L

and H quality

Propane, propane/butane,

butane

Town gas,

coke oven

gas

LCV gas L 1.7 – 3.9 0.9 –1.15

The output of the burners – see page 14 (Burner design) – refers

to natural gas and LPG.

In the case of coke oven gas, the output of the burners is

reduced to about 80%; higher outputs are only possible with

higher supply pressure.

In the case of LCV gas, the output of the burners is reduced

to about 65% of the rated output.

B 8 – 12 0.7– 0.9

G 25 – 35 2.0 – 2.7

D 4 – 6 0.4 – 0.6

range

[kWh/m3(n)]

Density ρ

[kg/m3]

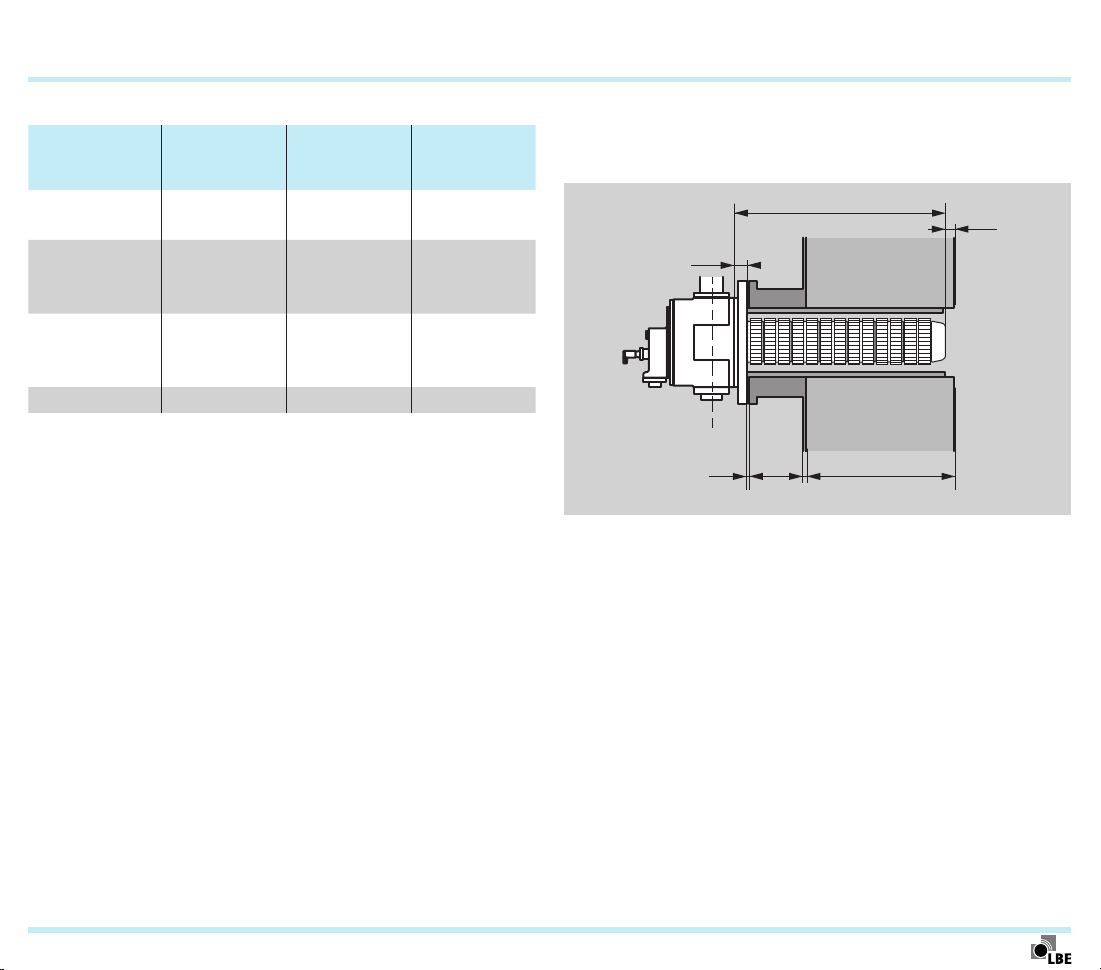

5.4 Burner length

The burner length G should be selected so that the burner is

flush with the inside edge of the furnace lining (S1 = 0 ± 20 mm).

P1

N1

M1

G

K1

L1

S1

ECOMAX · Edition 02.11

Page 16

Selection

16

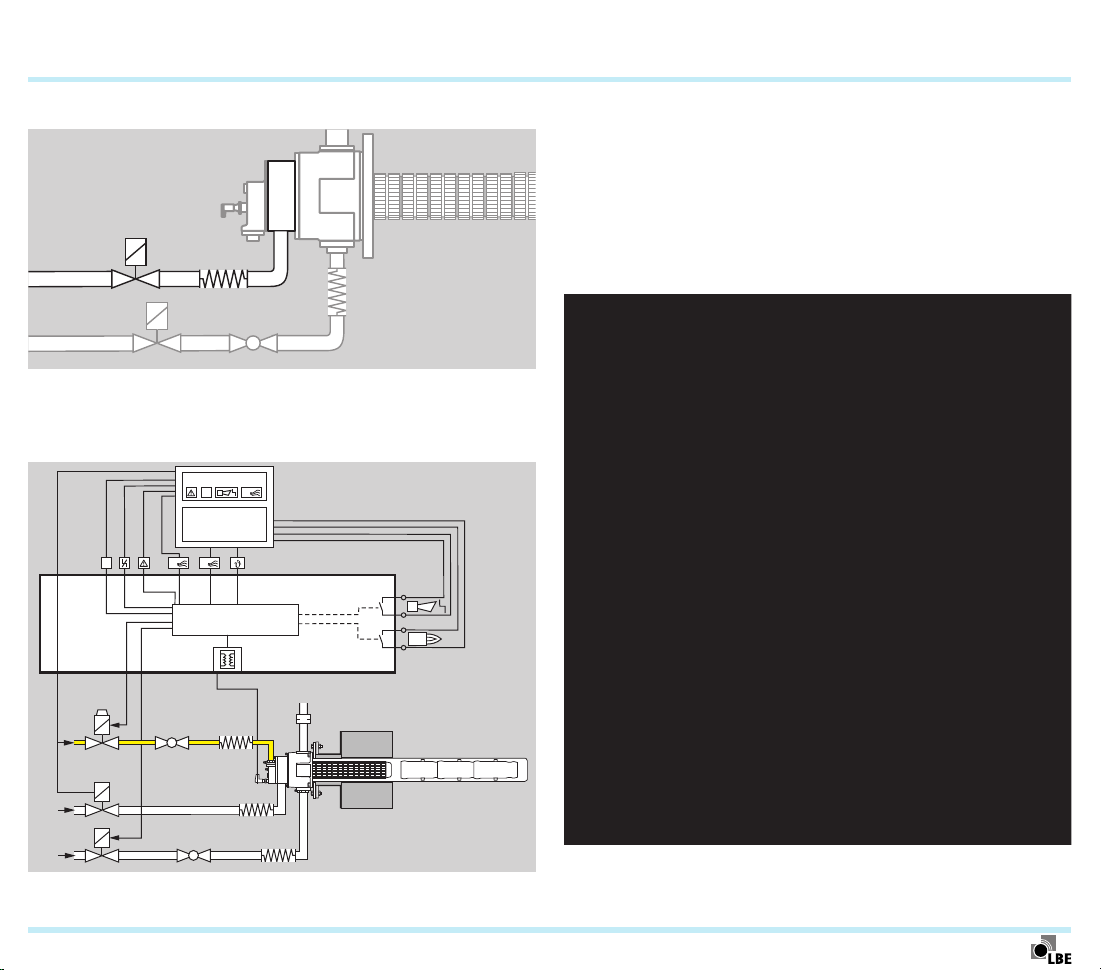

5.5 Connection for additional furnace cooling

The air volume supplied to the burner in cooling mode can

be increased using an optional intermediate flange with an

additional cooling air connection on the burner ECOMAX.

L1, N, PE

DI

P

PLC

DI

32

6

3

33

12

A

P

5

23

22 4

19

BCU 465..C

18

17

16

µC

26

Depending on the technical requirements for the process, cooling can be implemented in two stages. Actuating the air valve

for the burner (terminal 22) initiates “normal” cooling; actuating

a second air valve for the additional cooling air connection

initiates additional cooling. The additional cooling air valve is

actuated separately by the process control system. For wiring

on site, we recommend using a BCU..C with a supplementary

terminal strip (e.g. terminals 32/33 for additional air valve).

VG..L

GEH

VR..N

ECOMAX · Edition 02.11

EKO

Additional purging air connection on the ECOMAX® burner

Page 17

Selection

17

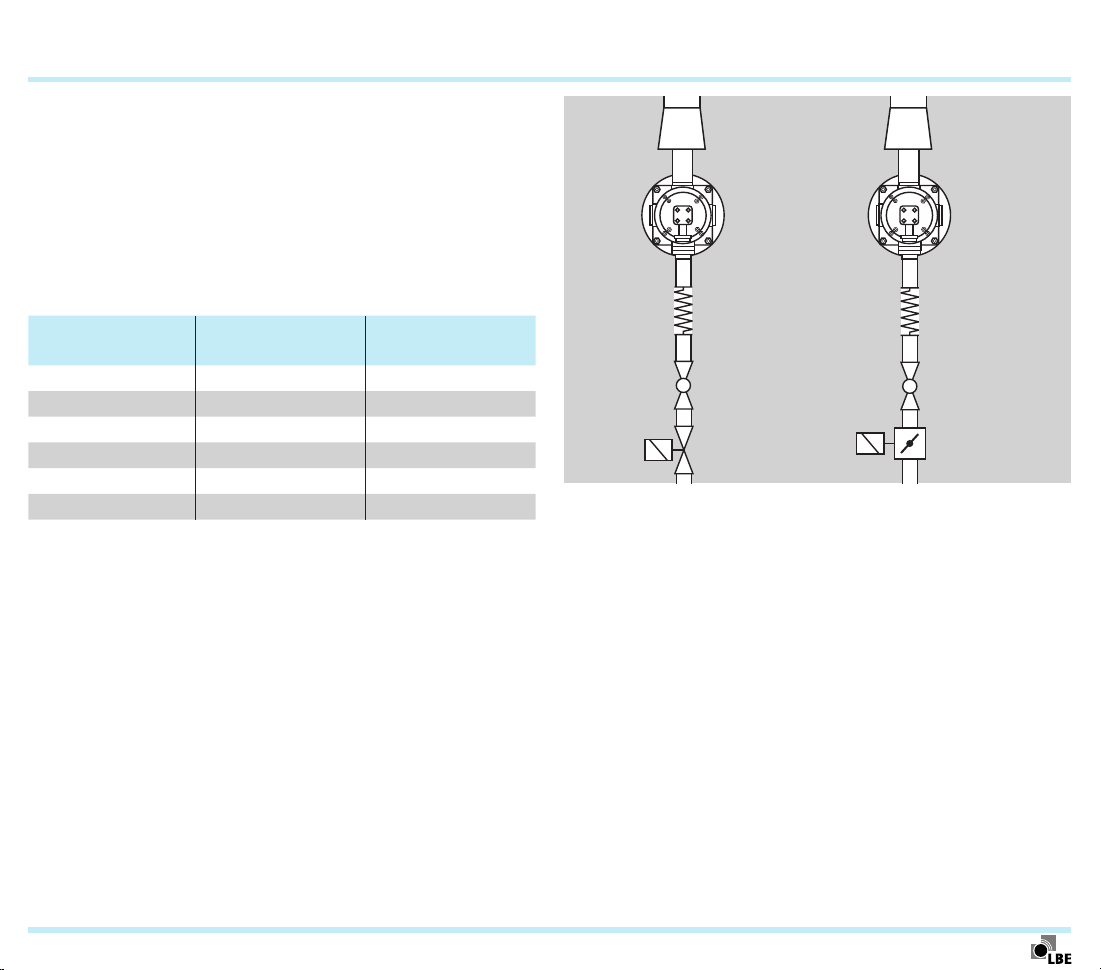

5.6 Differential air pressure measuring kit DA 1

For adjusting the air volume, especially for direct heating, we

recommend using the optional intermediate flange for differential pressure measurement.

The differential air pressure measuring kit DA1 is fitted at the

factory.

Order No. For burners

22800614 ECOMAX 1, 2

22800615 ECOMAX 3, 4, 5

22800666 ECOMAX 6

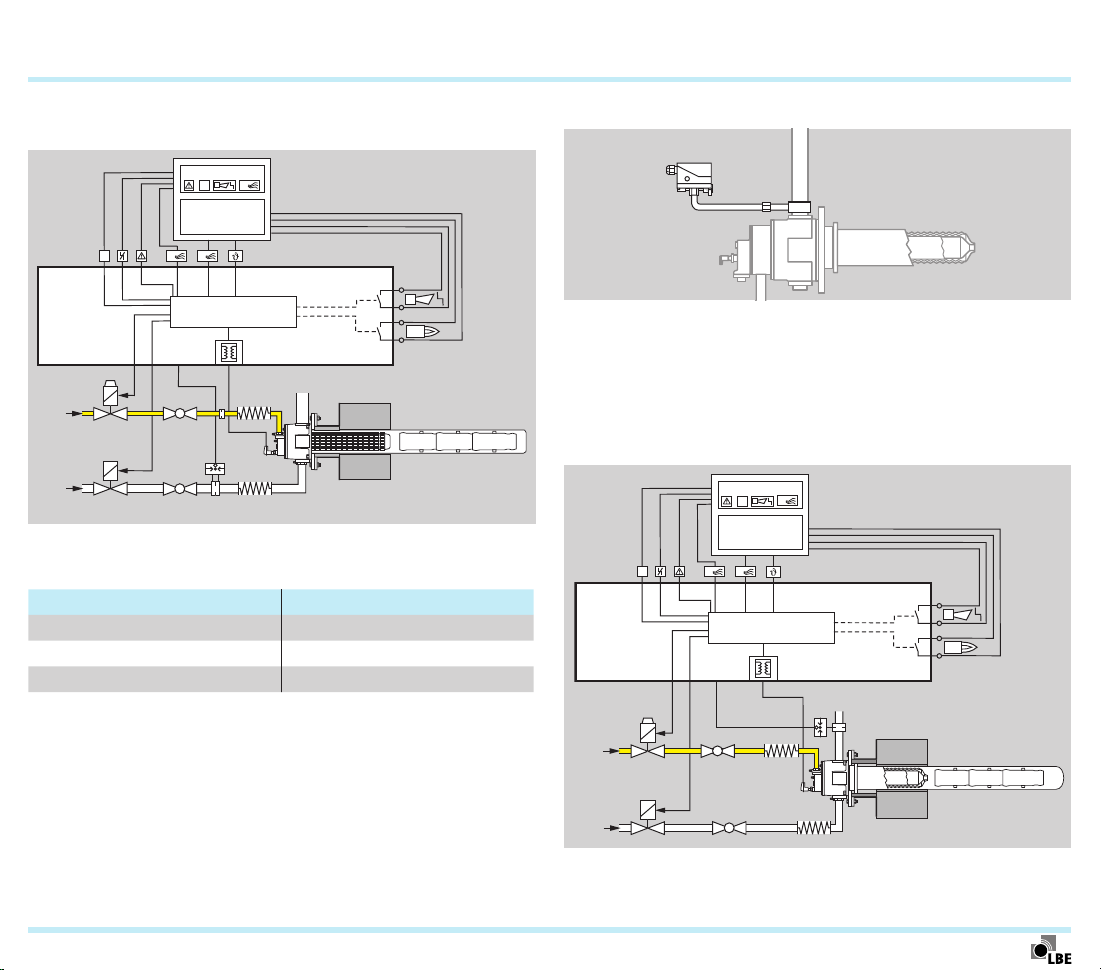

5.7 Differential air pressure measuring kit DA2 with

pressure switch

The differential air pressure measuring kit DA2 is used for the

automatic monitoring of the air flow on the burner ECOMAX® in

conjunction with the burner control unit BCU465– see page24

(Recommended burner control units) The pressure switch

monitors the air flow during pre-purge and burner operation.

If there is no air pressure, the burner is switched off via the

pressure switch, or the burner is not enabled.

Differential air pressure measuring kit DA 1 on the ECOMAX® burner

ECOMAX · Edition 02.11

Page 18

Selection

18

The pressure switch switching point should be set to approx.

80% of the differential pressure in normal operation.

L1, N, PE

DI

P

PLC

BCU 465..L

VG..L

VR..N

DI

6

3

12

A

P

5

23

22 4

19

ECOMAX

18

17

16

µC

26

21

EKO

GEH

The differential air pressure measuring kit DA2 is fitted at

the factory.

Order No. For burners

22800971 ECOMAX 1, 2

22800972 ECOMAX 3, 4, 5

22800973 ECOMAX 6

5.8 Flue gas monitoring kit DW

The flue gas monitoring kit DW with pressure switch is used in

conjunction with the burner control unit BCU465– see page24

(Recommended burner control units)– on ceramic radiant

tubes for automatically checking for ruptures. The pressure

switch monitors the flow rate of air and/or flue gas during

pre-purge and burner operation.

L1, N, PE

DI

P

PLC

BCU 465..L

DI

6

3

12

A

P

5

23

22 4

19

µC

26

21

18

17

16

ECOMAX · Edition 02.11

VG..L

VR..N

GEH

EKO

Page 19

Selection

When using the flue gas monitoring kit DW, the fan pressure

must be 10mbar higher, as the measuring orifice causes a

pressure loss in the flue gas pipe.

19

ECOMAX · Edition 02.11

Page 20

Selection

1)

2)

3)

t

5.9 Selection table

20

B D G L1)395 475 545 556 593 595 613 617 636 641 645 681 689 695

ECOMAX 0C

ECOMAX 1C

ECOMAX 2C

ECOMAX 3C

ECOMAX 4C

ECOMAX 5C

ECOMAX 1M

ECOMAX 2M

ECOMAX 3M

ECOMAX 4M

ECOMAX 5M

ECOMAX 6M

ECOMAX 1FTR

ECOMAX 2FTR

ECOMAX 3FTR

ECOMAX 4FTR

ECOMAX 5FTR

On request.

Orifi ce size on request.

If “none”, this specifi cation is omitted.

●

= standard, = available

● ● ● ● ● ● ● ● ●

● ● ● ● ● ● ● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ● ● ● ● ● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

●

●

●

●

●

● ●

●

●

●

●

Order example

ECOMAX 3MB545-100P0DA1

-22 to -5002)P03)K3)A3)DA13)DA23)DW3)T3)S3)Z

●

●

● ● ● ● ●

● ● ● ● ●

● ● ●

● ● ●

●

●

●

●

3)

● ● ● ● ● ●

● ● ● ● ● ●

● ● ● ● ● ●

● ● ● ●

●

●

●

●

●

● ●

●

●

●

●

●

ECOMAX · Edition 02.11

Page 21

Selection > Selection table

1)

2)

3)

4)

5.9.1 Type code

Code Description

ECOMAX Burner type

0

1

2

3

4

5

6

M

C

FTR

B

D

G

1)

L

395 to 695 Burner length in mm

-22 to -500

3)

P0

3)

K

3)

A

3)

DA1

3)

DA2

3)

DW

3)

T

3)

S

3)

Z

On request.

Orifi ce size on request.

If “none”, this specifi cation is omitted.

Other gas types on request.

Burner size (max. burner output with natural gas):

Recuperator: metallic

metallic, fl at tube variant

Gas type4): natural gas

coke oven gas

2)

Orifi ce for burner output in kW

Gas fl ange with purging air connection

Additional cooling air connection

Kanthal electrode

Differential air pressure measuring kit

Differential air pressure measuring kit with pres-

Flue gas monitoring kit with pressure switch

NPT connection

Spacer for SICAFLEX® fl ame tube

Special version

5 (250 kW)

6 (500 kW)

sure switch

21

0 (25 kW)

1 (36 kW)

2 (60 kW)

3 (100 kW)

4 (180 kW)

ceramic

LPG

LCV gas

2)

ECOMAX · Edition 02.11

Page 22

6 Project planning information

6.1 Flame control

The flame is monitored by a combined ignition/ionization

electrode as standard.

Flame control with UV sensor is only necessary if furnace

temperatures of 1050°C for direct heating or 950°C for indirect

heating are exceeded. Furthermore, we recommend using

bend-resistant Kanthal electrodes for ignition (standard with

ECOMAX..C) in this case.

We recommend the UV sensor UVS10D1 with integral purging

air connection (Order No.84315202) for burner length545.

For burner lengths greater than 545mm and for burner size

Ecomax0, the UV sensor UVS10L1 (Order No.84315203) with

lens is required. For attaching the UVS10, an adapter set EcoUVS10/E (Order No.22800079) is available.

22

ECOMAX® burner with ionization control

ECOMAX · Edition 02.11

ECOMAX® burner with UV control

Page 23

Project planning information

23

6.2 Purging air and cooling air

Purging air must be connected to the burner Ecomax in order

to ensure safe ignition and monitoring, and in order to avoid

problems caused by condensation and/or overheating:

– At temperatures above 950°C in the case of indirect heat-

ing and horizontal burner installation to prevent the ce-

ramic insulation of the ignition electrode from overheating.

Heating

horizontal –

Indirect

vertical

Direct

ECOMAX 0–6 ECOMAX 0–3 ECOMAX 4–5 ECOMAX 6

< 950°C > 950°C

Purging air on UV sensor,

P3 set Eco 2.5 /B

Purging air on electrode,

P2 set Eco 2.5 /E

Purging air on electrode,

P2 set Eco 2.5 /E

Purging air on UV sensor,

P3 set Eco 2.5 /B

Purging air on electrode,

P2 set Eco 2.5 /E

Purging air on UV sensor,

P3 set Eco 2.5 /B

– In the case of indirect heating and vertical burner installa-

tion, irrespective of temperature, in order to prevent condensation forming in the burner. Otherwise the flue gas

will enter the burner due to thermal lift.

– In the case of direct heating, irrespective of temperature,

in order to prevent condensation forming in the burner.

Otherwise, the flue gas will enter the burner, due to the

furnace pressure.

The required purging air volume is approx. 0.5 to 1.0% of the

3

air volume for rated output, or a minimum of 1 Nm

/h.

The purging air is connected to the purging air connection on

the gas flange next to the electrode, or in the case of UV control

to the purging air connection of the UV sensor. The purging air

is tapped upstream of the air control valve so that the purging

air continues to flow even if the burner is switched off.

In order to limit the volume of purging air, special nozzles can

be used which are adjusted to the required air supply pressure

for the ECOMAX– see page 51 (P2/P3 set Eco).

Furnace chamber temperature

Purging air on UV sensor,

P3 set Eco 4.0 /B

Purging air on UV sensor,

P3 set Eco 4.0 /B

950°C to 1050°C

Purging air on electrode,

P2 set Eco 2.5 /E

> 1050°C

Purging air on UV sensor,

P3 set Eco 4.0 /B

Purging air on electrode,

P2 set Eco 4.0 /E

Purging air on UV sensor,

P3 set Eco 4.0 /B

–

–

ECOMAX · Edition 02.11

Page 24

Project planning information

24

6.3 Recommended burner control units

ECOMAX burners, indirectly heated, with burner control unit

BCU465

Depending on the type of heating, we recommend operating

ECOMAX burners with the burner control units BCU460..L..8

or BCU465..L..8. When using burners ECOMAX..K with the

additional cooling air connection, we recommend operation

with a burner control unit BCU..C with additional circuit board

for signal distribution.

For ignition, the ECOMAX burners require an ignition transformer with 7.5kV high voltage and an output current of 20mA

at a duty cycle of 33%. An appropriate ignition transformer is

already integrated in burner control units BCU460..L..8 and

BCU465..L..8.

On request, we can also provide parameter lists for the programmable air supply and air post ventilation on the BCU465.

Heating

SER-C (ceramic radiant tube)

Metallic radiant tube

Direct

1)

Pre-purge is required following a false start in order to avoid

damage to the radiant tubes and flame tubes.

2)

In conjunction with an optional flue gas monitoring kit, see page

18 (Flue gas monitoring kit DW)

3)

In conjunction with a differential air pressure measuring kit, see

page .17 (Differential air pressure measuring kit DA2 with pressure switch)

4)

For burners with an additional cooling air connection

(ECOMAX..K), use burner control unit BCU460-3/1LW8AC.

5)

For burners with an additional cooling air connection

(ECOMAX..K), use burner control unit BCU465-3/1LW8AC.

Recommended burner control unit

BCU 460..L..8 BCU 465..L..8

1), 2), 5)

1), 5)

3), 5)

–

–

4)

ECOMAX · Edition 02.11

Page 25

Project planning information

25

6.4 Gas connection

®

ECOMAX

L = 3× – 5× DN

EKO

GEH

VG..L

VG..N

Approx. 60 to 80mbar gas pressure should be present at

the gas connection of the ECOMAX burner. Furthermore, the

pressure losses due to pipework and valves are to be taken

into consideration.

For adjusting the burners, we recommend measuring the

flow rate using the integrated orifice. The orifice is designed

according to the burner output and gas type.

To ensure accurate measurements of the pressure differential

on the integrated orifice, the following boundary conditions for

the design of the gas connection must be taken into account:

– A straight inlet section which is 3 to 5 times as long as

the nominal diameter of the connection must be provided

upstream of the orifice. The attachment of a coupling, a

bellows unit or a pipe bend directly upstream of the ori-

fice can cause turbulence in the gas flow resulting in the

burner being incorrectly adjusted.

– All valves and fittings should have the same nominal size.

– Use bends with the largest possible radii.

– The pressure loss of the integrated orifice is approximate-

ly 10mbar.

6.4.1 Valves

A slow opening and quick closing gas valve is to be used as

an automatic shut-off valve. A quick opening and quick closing gas valve is to be installed as a second automatic shut-off

valve, unless the relevant application standard allows using

a single valve.

For burners ECOMAX® 4, 5 and 6, as an alternative to two

individual valves VAS..L and VAS..N, a double solenoid valve

VCS can be used.

Burner 1st gas valve

1)

2nd gas valve

1)

Ecomax 0 VG 15..L VG 15..N

Ecomax 1 VG 15..L VG 15..N

Ecomax 2 VG 15..L VG 15..N

Ecomax 3 VG 15..L VG 15..N

Ecomax 4 VAS 120..L

Ecomax 5 VAS 125..L

Ecomax 6 VAS 225..L

1)

For operation with natural gas.

2)

Alternatively, double solenoid valve VCS 120RLNW.

3)

Alternatively, double solenoid valve VCS 125RLNW.

4)

Alternatively, double solenoid valve VCS 225RLNW.

2)

3)

4)

VAS 120..N

VAS 125..N

VAS 225..N

2)

3)

4)

Instead of the stainless steel bellows unit EKO, a stainless

steel flexible tube ES can also be used. In this case, a higher

pressure loss must be taken into account.

ECOMAX · Edition 02.11

Page 26

Project planning information > Gas connection

26

6.4.2 Operation with LPG

For operation with LPG, it is essential to cool the gas lance via

a central air lance in order to prevent the LPG from cracking in

the gas lance and soot formation during combustion.

6.4.3 Air/gas ratio control

In order to ensure the required air/gas ratio when equipping

the burners with only gas and air valves without a pneumatic

ratio control system, precise control of the gas and air pressures, as well as monitoring of these pressures is necessary

in accordance with the relevant standards (e.g. EN746-2).

For pneumatic air/gas ratio control, we recommend the variable air/gas ratio control GVRH, which prevents the lambda

value from varying due to changes in the furnace temperature.

The central air volume is approx. 3 to 5% of the combustion

air volume and must also flow while the burner is switched off.

ECOMAX · Edition 02.11

Page 27

Project planning information

6.5 Air connection

6.5.1 Indirect heating

Approx. 60 to 80mbar air pressure should be present at

the air connection of the ECOMAX burner. Furthermore, the

pressure losses due to pipework and valves are to be taken

into consideration.

A quick opening, quick closing air valve or solenoid actuator

should be used.

ECOMAX 0

…

ECOMAX 4

27

ECOMAX 5

Burner Air valve

Butterfly valve/so-

lenoid actuator

Ecomax 0 VR 20..N –

Ecomax 1 VR 25..N –

Ecomax 2 VR 40..N –

Ecomax 3 VR 50..N –

Ecomax 4 VR 65..N –

Ecomax 5 – BVHM 65/MB 7

VR..N

Other types of control on request.

+

MB 7

BVHM

ECOMAX · Edition 02.11

Page 28

BVHM

Project planning information > Air connection

28

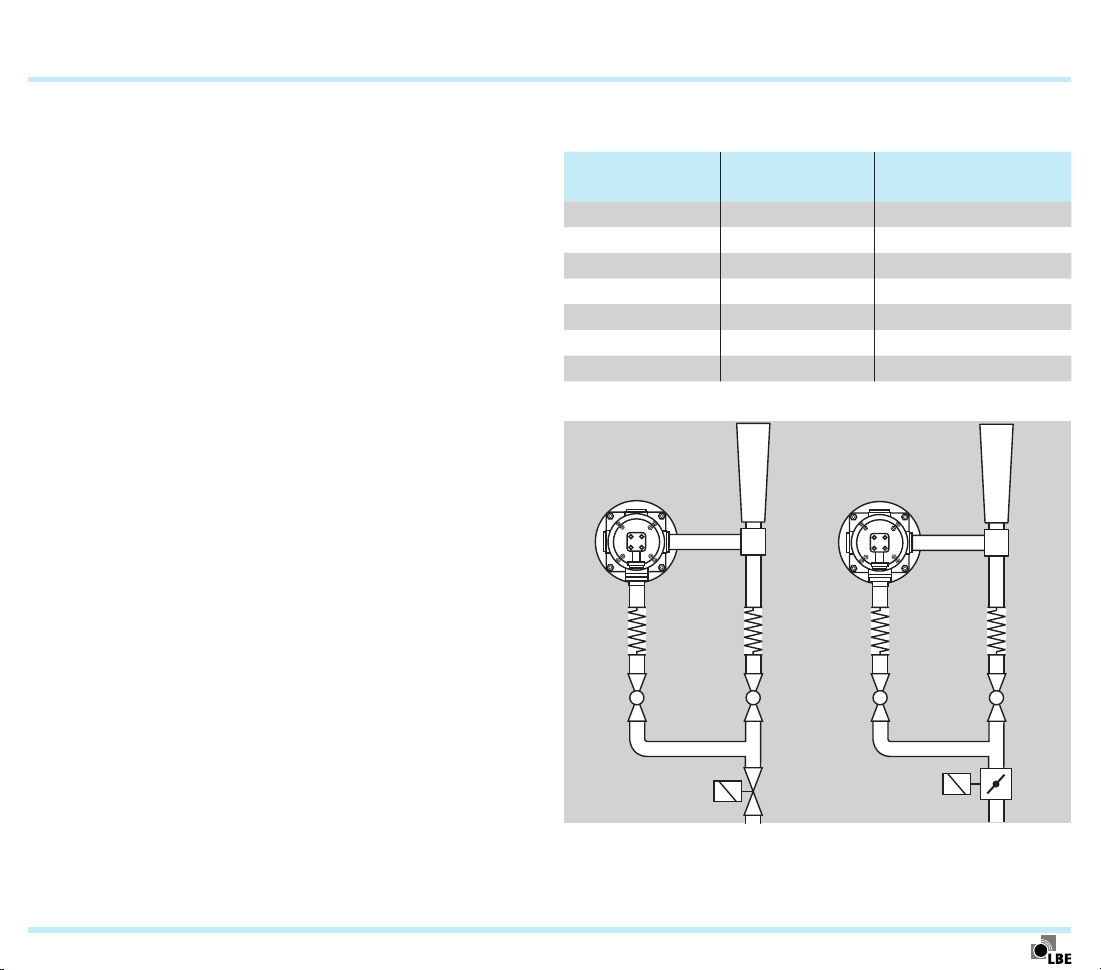

6.5.2 Direct heating

Approx. 90 to 100 mbar air pressure should be present at the

eductor. Furthermore, the pressure losses due to pipework

and valves are to be taken into consideration.

For burner adjustment, we recommend using the differential

air pressure measuring kit DA1– see page17 (Differential air

pressure measuring kit DA 1).

To ensure accurate measurement of the pressure differential,

the following boundary conditions for the design of the air

connection must be taken into account:

– A straight inlet section which is 3 to 5 times as long as the

nominal diameter of the connection must be provided up-

stream of the differential air pressure measuring kit DA1.

– All valves and fittings should have the same nominal size

and nominal connection diameter.

– Use bends with the largest possible radii.

– The pressure loss of the measuring orifice is approx.

6mbar.

A quick opening, quick closing air valve or solenoid actuator

should be used.

Burner Air valve

Butterfly valve/sole-

noid actuator

Ecomax 0 VR 40..N –

Ecomax 1 VR 50..N –

Ecomax 2 VR 65..N –

Ecomax 3 – BVHM 65/MB7NM3

Ecomax 4 – BVHM 80/MB7NM3

Ecomax 5 – BVHM 80/MB7NM3

Ecomax 6 BVHM 100/MB7NM3

ECOMAX 0

ECOMAX 1

ECOMAX 2

ECOMAX 3

…

ECOMAX 6

ECOMAX · Edition 02.11

VR..N

Other types of control on request.

+

MB 7

Page 29

P1

Project planning information

29

6.6 Flue gas guide tube FGT for direct heating

When using the ECOMAX® burners on direct heating installations, a flue gas guide tube FGT kit is required (see page) 49

(Flue gas guide tube FGT kit).

The flange thickness P1 of the flue gas guide tube is 15mm.

Plan the height of the furnace extension so that the front edge

of the recuperator is flush with the inside edge of the furnace

lining (S1= 0± 20mm).

The FGT is to be insulated with Cerablanket or similar mate-

rial, so that no hot furnace atmosphere reaches the furnace

extension.

6.6.1 For ECOMAX..C

Flue gas guide tube FGT

Furnace extension

Burner

FGT external ∅ A

in mm

ECOMAX 0C 140

ECOMAX 1C 180

ECOMAX 2C 200

ECOMAX 3C 236

ECOMAX 4C 300

ECOMAX 5C 336

S1

∅A

ECOMAX · Edition 02.11

Page 30

P1

Project planning information > Flue gas guide tube FGT for direct heating

6.6.2 For ECOMAX..M

Flue gas guide tube FGT

S1

∅A

Furnace extension

30

Burner

FGT external ∅ A

in mm

ECOMAX 1M 133

ECOMAX 2M 156

ECOMAX 3M 193

ECOMAX 4M 254

ECOMAX 5M 287

ECOMAX 6M 390

ECOMAX · Edition 02.11

Page 31

Project planning information

31

6.7 Radiant tubes

For indirect heating, different combinations of radiant tubes

and ECOMAX burners can be used.

The metallic burners Ecomax M or FTR are used in metallic

radiant tubes (single-ended radiant tube, P radiant tube or

twin P radiant tube). The ceramic burners EcomaxC are used

in ceramic single-ended radiant tubes, see page6 (ECOMAX®

in radiant tubes).

Depending on the geometry, flue gas guide tubes may be

needed for radiant tubes and additional adapter flanges may

be required for the metallic single-ended radiant tube.

In special cases, a ceramic burner EcomaxC can be installed

in a metallic radiant tube. Special flue gas guide tubes are

needed here in order to avoid damage to the ceramic burner

due to deformation of the metallic tube.

6.7.1 Ceramic radiant tube SER-C for indirect heating

Install the radiant tube free of mechanical stress.

Ensure that there are threaded bolts on the furnace flange to

attach the ceramic radiant tube to the furnace.

Ensure that there is an annular gap of ≥20mm between the

radiant tube and the furnace lining.

of the radiant tube SER-C is either 32 or 37mm, depending

on the size.

Plan the height of the furnace extension so that the front

edge of the recuperator is flush with the interior furnace wall

(S1 = 0 ± 20 mm).

Loosely wrap a Cerablanket mat or similar material around

the radiant tube before installing it in the furnace.

The flange thickness P1

Installation dimensions

P1

≥ 8 mm

B1

Furnace

extension

Compression fitting

SER-C com-

pression

Burner

fitting

∅ B1

in mm

SER-C 100/088

SER-C 142/128

SER-C 162/148

SER-C 202/188

160 100 140

200 142 180

220 162 200

260 202 240

Annular gap

Ceramic radiant tube ∅ X

in mm

S1

∅X

Lining

∅ Y

in mm

∅Y

ECOMAX · Edition 02.11

Page 32

Project planning information > Radiant tubes

32

6.7.2 Metallic radiant tube

Install the radiant tube free of mechanical stress.

Ensure that there is an annular gap of ≥20mm between the

radiant tube and the furnace lining.

Insulate the metallic radiant tube with a 20mm Cerablanket

mat or similar material.

Plan the height of the furnace extension so that the front edge

of the recuperator is flush with the interior furnace wall (S1=

0± 20mm).

The burner Ecomax M can be installed in different me-

tallic radiant tubes: single-ended radiant tubes SER-M,

P radiant tubes or twin P radiant tubes.

The metallic radiant tubes are available in a variety of dimen-

sions in either centrifugal casting or in welded form. The efficiency of the burner EcomaxM is determined by the internal

diameter di of the radiant tubes in the vicinity of the burner.

The following dimensions are recommended:

Burner

Radiant tube internal diameter d

[mm]

i

recommended min.

ECOMAX 1M 128 ≤ 127

ECOMAX 2M 148 ≤ 147

ECOMAX 3M 187 ≤ 184

ECOMAX 4M 250 ≤ 246

ECOMAX 5M 280 ≤ 280

6.7.3 Radiant tube distances

For furnace temperatures > 600°C:

∅X

1.2X

1.2X

2.5X

The centre to centre distance of the radiant tubes should be

≥ 2.5 d. The distance of the radiant tubes from the furnace

wall, from the furnace floor or from the material to be heated

should be ≥1.2 d.

For furnace temperatures < 600°C with air circulation of 15 m/s:

≥100

mm

≥100

mm

ECOMAX · Edition 02.11

≥100 mm

The distance of the radiant tubes from one another and from

the furnace wall should be ≥100mm.

Page 33

Project planning information > Radiant tubes

6.7.4 Eductor on burners with metallic single-ended radiant tubes

The eductor ensures negative pressure in the radiant tube.

This prevents the inert gas atmosphere in the furnace being

contaminated by flue gases from the burner in the event of

leakage from the single-ended radiant tube.

Flue gas

Metallic radiant tube

Gas Cold air

33

ECOMAX · Edition 02.11

Page 34

Project planning information

6.8 Flue gas channelling

A flue gas system must be fitted on the furnace as a means

of guiding the flue gas to the chimney.

In the flue gas system there should be a low negative pressure thanks to the draught of the chimney or an exhaust fan.

The eductor or the flue gas connector on the burner can be

equipped with protection against accidental contact, but they

must not be insulated.

6.8.1 Indirect heating

The flue gas system on the furnace should stop 10mm away

from the flue gas connector, or be fitted flush with the eductor.

For indirect heating with flue gas monitoring kit DW and

BCU465, excessive negative pressure in the flue gas system

or an excessively narrow flue gas pipe diameter on the furnace can cause problems with setting the switching point of

the pressure switch.

∅1.5Q

∅2Q

∅Q

M

∅1.5Q

∅2Q*

10 mm ±5

∅Q

0 mm

(±10 mm)

∅1.5P

10 mm ±5

M

M

* With flue gas monitoring kit DW; without flue gas monitoring kit

DW: 1.5Q to 2Q.

∅ Q ∅ P

ECOMAX 0 DN 32 43

ECOMAX 1 DN 50 43

ECOMAX 2 DN 50 73

ECOMAX 3 DN 65 79

ECOMAX 4 DN 100 98

ECOMAX 5 DN 100 98

34

∅P

ECOMAX · Edition 02.11

Page 35

Project planning information > Flue gas channelling

35

6.8.2 Direct heating

The eductors for flue gas extraction via the burner ECOMAX

cannot be used for furnace pressure control. For direct heating, we recommend discharging 10 to 15% of the flue gases

via an additional flue gas opening on the furnace fitted with

a furnace pressure control system.

In normal cases, for 90% of flue gas extraction, a low positive

pressure of between 0.1 and 0.3mbar can be maintained in

the furnace chamber. In the case of heavily leaking furnaces,

flue gas extraction must be reduced, where necessary, to

avoid pulling in cold air due to negative pressure in the furnace chamber.

For furnace temperatures ≥ 1000°C, it is recommended that

eductors with a mechanical flue gas valve (AGK) are used to

avoid these excessive temperatures.

The flue gas system on the furnace should be fitted flush with

the eductor (±10mm). The diameter of the flue gas pipe on the

furnace should be twice the eductor diameter P. If the diameter is

too small, even with the flue gas valve there is the danger of hot

flue gases creeping through the burner when it is switched off.

0 mm

(±10 mm)

∅2P

∅P

M

∅1.5P

∅2P

∅P

M

0 mm (±10 mm)

Flue gas extraction via the burner is adjusted based upon the

negative pressure measured on the eductor.

If the furnace temperature is too high, damage can occur

to burners which are switched off due to the flow of hot flue

gases over them.

ECOMAX · Edition 02.11

∅ P [mm]

ECOMAX 0 43

ECOMAX 1 43

ECOMAX 2 73

ECOMAX 3 79

ECOMAX 4 98

ECOMAX 5 98

ECOMAX 6 137

Page 36

Project planning information

6.9 Burner adjustment

Differential pressure curves are delivered with the burner documentation to enable adjustment of the air and gas volumes

thus changing the burner output accordingly.

6.9.1 Differential air pressure measuring kit DA2 with

pressure switch

The pressure switch should be set to approx. 80% of the pres-

sure differential in normal operation.

36

ECOMAX · Edition 02.11

Page 37

37

7 Technical data

Heating: direct with eductor or indirect in radiant tube.

Control type: On/Off.

Control range: approx. 1:3.

Flame velocity: approx. 120 to 150 m/s.

Flame control: direct ionization control (UV control as an

option).

Ignition: direct, electrical.

Recuperator:

ECOMAX..C:

ceramic (SiSiC), max. application temperature 1300°C,

ECOMAX..M:

cast steel, max. application temperature 1150°C,

ECOMAX..FTR:

metallic, max. application temperature 950°C.

Burner Output [kW] Flame length [mm]*

ECOMAX 0 25 250

ECOMAX 1 36 350

ECOMAX 2 60 450

ECOMAX 3 100 600

ECOMAX 4 180 800

ECOMAX 5 250 800

ECOMAX 6 500 800

* Visible range for natural gas operation in the open air,

max. connection rating and air index 1.15.

7.1 Efficiency

Heating: direct.

Flue gas extraction: 100%.

Lambda: 1.1.

Duty cycle: 80%.

Diagrams for efficiency, flue gas temperature and air preheat-

ing – see page 38 (ECOMAX..C), page39 (ECOMAX..M),

page 40 (ECOMAX..FTR).

For detailed information about the efficiency, contact us– see

page52 (Contact)

ECOMAX · Edition 02.11

Page 38

Technical data > Efficiency

7.1.1 ECOMAX..C

100

90

80

70

Efficiency [%]

60

50

40

30

20

10

0

900

800

700

600

500

400

300

200

100

Flue gas temperature [°C]

0

900

800

700

600

500

400

300

Air preheating [°C]

200

100

0

400 500 600 700 800 900 1000 1100

Cold air burner

ECOMAX..C

1200

1300

Temperature on

recuperator inlet

1400

[°C]

38

ECOMAX · Edition 02.11

Page 39

Technical data > Efficiency

7.1.2 ECOMAX..M

100

90

80

70

Efficiency [%]

60

50

40

30

20

10

0

900

800

700

600

500

400

300

200

100

Flue gas temperature [°C]

0

900

800

700

600

500

400

300

Air preheating [°C]

200

100

0

400 500 600 700 800 900 1000 1100

Cold air burner

ECOMAX..M

1200

1300

Temperature on

recuperator inlet

[°C]

1400

39

ECOMAX · Edition 02.11

Page 40

Technical data > Efficiency

7.1.3 ECOMAX..FTR

90

80

70

60

Efficiency [%]

50

40

30

20

10

0

900

800

700

600

500

400

300

200

100

Flue gas temperature [°C]

0

900

800

700

600

500

400

300

Air preheating [°C]

200

100

0

400 500 600 700 800 900 1000 1100

40

Cold air burner

ECOMAX..FTR

Temperature upstream

of recuperator

[°C]

ECOMAX · Edition 02.11

Page 41

M16

Technical data

t

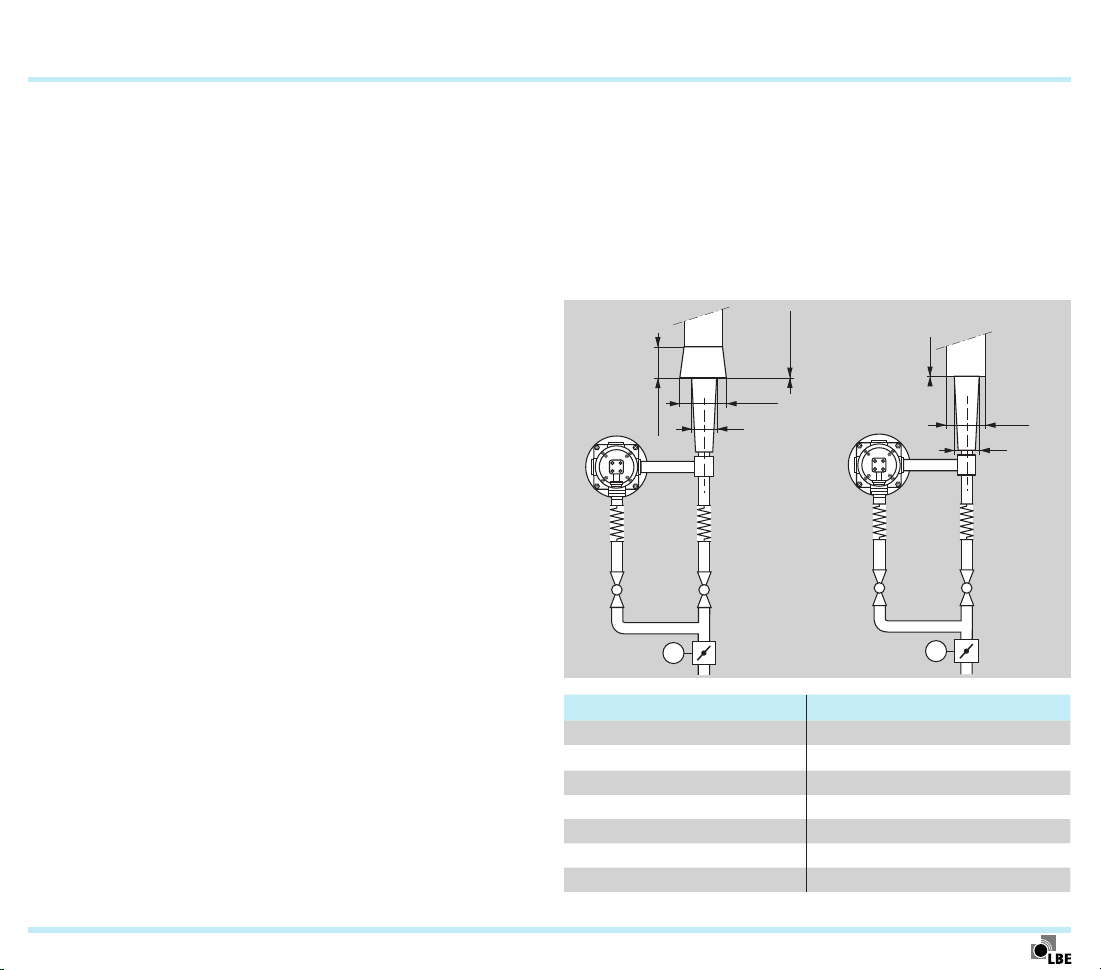

7.2 Dimensions

7.2.1 ECOMAX..C

P1

W1

E

B1

≥ 8 mm

41

W

G

G

S1

∅Y

S1

∅X

D1 (ECOMAX 0–3 = 30 mm)

C1

0.7 – 1.5 × ∅X

(ECOMAX 0 = M12)

∅ 18 mm

(ECOMAX 0 ∅ 14 mm)

I1

A1

F1

∅P

G1

ECOMAX · Edition 02.11

C

J1

D

∅A

∅B

H1

∅Q

∅U

∅J

T

K

M

Page 42

Technical data > Dimensions > ECOMAX..C

1)

2)

3)

4)

Type [mm]

∅ A ∅ B

C D E G

ECOMAX 0C 142 86 60 182 60 545–695

ECOMAX 1C 180 123 60 212 60 545–695

ECOMAX 2C 200 142 60 212 60 545–695

ECOMAX 3C 236 178 83 262 83 545–695

1)

∅ J

2)

R ½" 269 625 43 DN 32 297

2)

R ½" 269 625 43 DN 50 331

2)

R ½" 283 625 73 DN 50 331

2)

R ½" 292 820 79 DN 65 353

ECOMAX 4C 300 240 95 298 95 545 R ¾" 353 820 98 DN 100 399

ECOMAX 5C 336 273 95 298 95 695 R 1" 345 920 98 DN 100 399

K M

∅ P ∅ Q

42

T

Type [mm] Weight

∅ U

ECOMAX 0C R ¾"

W

∅ X ∅ Y

100 140 – 160

A1

∅ B1

C1 D1

30 – 90 182 210

∅ F1

G1

H1 ∅ I1

S1 kg

3)

ECOMAX 1C R 1" 142 182 280 200 30 330 90 236 290 20

ECOMAX 2C R 1½" 162 202 280 220 30 330 90 236 290 25

ECOMAX 3C R 2" 202 242 325 260 30 385 90 280 330 33

ECOMAX 4C R 2½" – – 420 – – 480 110 372 445 48

1000 – 2600

C1 =

n × 250 + 50

S1 =

ECOMAX 5C R 2½" – – 420 – – 480 110 372 445 57

Lengths > 695 mm in 100 mm increments (795, 895, 995 mm etc.); additional lengths on request.

545, 595, 645 or 695 mm

In increments of 100 mm. Other lengths on request.

For length G = 545 mm.

ECOMAX · Edition 02.11

4)

12

0 ± max. 20

Page 43

Technical data > Dimensions

t

7.2.2 ECOMAX..M

G

S1

∅Y

∅X

W

C1

43

M16

(ECOMAX 0 = M12)

(ECOMAX 6 = M20)

I1

G1

0,5 – 1,5 × ∅X

S1

∅B

D1

∅Q

ECOMAX 0 ∅ 14 mm

ECOMAX 6 ∅ 23 mm

ECOMAX 1 – 5 ∅ 18 mm

A1

F1

∅P

T

K

M

P1

G

E

∅A

H1

C

J1

D

∅U

∅J

ECOMAX · Edition 02.11

Page 44

1)

2)

3)

Technical data > Dimensions > ECOMAX..M

Type [mm]

∅ A ∅ B

C D E G

ECOMAX 1M 133 123 60 212 60 545–695

ECOMAX 2M 156 142 60 212 60 545–695

ECOMAX 3M 193 178 83 262 83 545–695

ECOMAX 4M 254 240 95 299 95 545–695

ECOMAX 5M 287 273 95 299 95 545–695

1)

∅ J

2)

R 1/2" 269 625 43 DN 50

2)

R 1/2" 283 625 73 DN 50

2)

R 1/2" 292 820 79 DN 65

2)

R 3/4" 353 820 98 DN 100

2)

R 1" 345 920 98 DN 100

ECOMAX 6M 390 370 150 400 150 695 R 1½" 530 1177 137 DN 150

Type [mm] Weight

T

∅ U

ECOMAX 1M 331 R 1" 280

A1 C1 D1

30 330 90 236 290

∅ F1

G1

ECOMAX 2M 331 R 1½" 280 30 330 90 236 290 48

ECOMAX 3M 353 R 2" 325 30 385 90 280 330 58

ECOMAX 4M 399 R 2½" 420 50 480 110 372 445 93

ECOMAX 5M 399 R 2½" 420 50 480 110 372 445 105

C1 =

n × 250 + 50

ECOMAX 6M 598 R 3" 690 50 740 150 550 650 228

Lengths > 695 mm in 100 mm increments (795, 895, 995 mm etc.); additional lengths on request.

545, 595, 645 or 695 mm

For length G = 545 mm.

K M

H1 ∅ I1

∅ P ∅ Q

S1 kg

S1 =

0 ± max. 20

3)

35

44

ECOMAX · Edition 02.11

Page 45

Technical data > Dimensions

t

7.2.3 ECOMAX..FTR

G

P1

W1

45

W

S1

C1

∅Y

∅X

0.5 – 1.5 × ∅X

D1

M16

(ECOMAX 0 = M12)

∅ 18 mm

(ECOMAX 0 ∅ 14 mm)

I1

A1

F1

E

G1

C

J1

D

ECOMAX · Edition 02.11

∅A

G

S1

∅B

∅Q

∅P

T

K

M

H1

∅U

∅J

Page 46

Technical data > Dimensions > ECOMAX..FTR

1)

2)

3)

Type [mm]

∅ A ∅ B

D E G

ECOMAX 1FTR 133 109 212 60 545–695

ECOMAX 2FTR 156 128 212 60 545–695

ECOMAX 3FTR 193 164 262 83 545–695

ECOMAX 4FTR 254 216 299 95 545–695

ECOMAX 5FTR 287 244 299 95 545–695

1)

2)

2)

2)

2)

2)

∅ J

K M

∅ P ∅ Q

R 1/2" 269 625 43 DN 50

R 1/2" 283 625 73 DN 50

R 1/2" 292 820 79 DN 65

R 3/4" 353 820 98 DN 100

R 1" 345 920 98 DN 100

46

Type [mm] Weight

T

∅ U

ECOMAX 1FTR 331 R 1" 280

A1 C1 D1

30 330 90 236 290

∅ F1

G1

H1 ∅ I1

S1 kg

27

ECOMAX 2FTR 331 R 1½" 280 30 330 90 236 290 28

ECOMAX 3FTR 353 R 2" 325 30 385 90 280 330 44

ECOMAX 4FTR 399 R 2½" 420 50 480 110 372 445 70

ECOMAX 5FTR 399 R 2½" 420 50 480 110 372 445 74

Lengths > 695 mm in 100 mm increments (795, 895, 995 mm, etc.); additional lengths on request.

545, 595, 645 or 695 mm

For length G = 545 mm.

C1 =

n × 250 + 50

S1 =

0 ± max. 20

3)

ECOMAX · Edition 02.11

Page 47

∅

L

∅

L

H1

1)

2)

Technical data > Dimensions

7.2.4 ECOMAX standard piping

ECOMAX 0

ECOMAX 1

ECOMAX 2

47

P

K

ECOMAX 3

ECOMAX 4

ECOMAX 5

ECOMAX 6

P

K

∅Q

T

∅Q

T

H1

N M

H

M

∅Z

∅J

Type [mm]

ECOMAX 0 670

ECOMAX 1 620

ECOMAX 2 620

ECOMAX 3 820

ECOMAX 4 660

ECOMAX 5 700

ECOMAX 6 990

± 20 mm.

± 10 mm.

H

1)

1)

1)

1)

1)

1)

1)

∅ J

R 1/2" 615

R 1/2" 591

R 1/2" 730

R 1/2" 775

R 3/4" 880

R 1" 765

R 1½" – – 598 DN 150 530 1375

R

∅ U

1)

R ¾" 230 DN 32 269 640

1)

R 1" 331 DN 50 269 690

1)

R 1½" 331 DN 50 283 765

1)

R 2" 353 DN 65 292 700

1)

R 2½" 399 DN 100 353 820

1)

R 2½" 399 DN 100 345 820

T

∅ Q

N M

∅Z

K L

ECOMAX 0

…

ECOMAX 4

R

∅U

∅ Z

2)

R 1½" 625 415

2)

R 2" 625 430

2)

R 2½" 625 466

2)

R 2½" 820 495

2)

R 3" 820 545

2)

R 3" 920 545

2)

R 4" 1177 1120

R

M N

2)

2)

2)

2)

2)

2)

2)

ECOMAX 5

∅U

∅ P

43

43

73

79

98

98

137

ECOMAX · Edition 02.11

Page 48

8 Maintenance

Twice per year, but if the media are highly contaminated, this

interval should be reduced.

48

ECOMAX · Edition 02.11

Page 49

49

9 Accessories

9.1 Flue gas guide tube FGT kit

When using the ECOMAX® burners for direct heating, a flue

gas guide tube FGT is required.

The FGT kit is available in lengths in various increments, which

are suited to different burner lengths.

For ECOMAX 1C, 2C und 3C, there is a standard version for

furnace temperatures up to 1200°C and a high temperature

version for furnace temperatures from 1200°C to 1300°C.

Scope of delivery: flue gas guide tube FGT with burner seal,

mounting gasket, as well as 4 threaded bolts, washers and

nuts for attaching it to the burner.

Order No. on request.

9.2 Flue gas eductor

For direct heating

The eductor generates a vacuum with a centrally positioned

nozzle and thus draws the flue gases out of the furnace

chamber through the burner’s heat exchanger.

On burners with metallic single-ended radiant tubes

The eductor ensures negative pressure in the radiant tube.

This prevents the inert gas atmosphere in the furnace being

contaminated by flue gases from the burner in the event of

leakage from the single-ended radiant tube.

For more information, see product brochure on the flue gas

eductor for self recuperative burners ECOMAX

Order No. on request.

®

.

ECOMAX · Edition 02.11

Page 50

Accessories

50

9.3 Ceramic radiant tube SER-C

For heat treatment processes in which combustion gases

must be kept separate from the product. The patented flange

connection is gas-tight.

Material: SiSiC, max. application temperature: 1300°C.

G

≥ 8 mm

B1

P1

W1

S1

∅Y

W

C1

∅X

0.7 – 1.5 × ∅X

D1 (ECOMAX 0–3 = 30 mm)

Further information can be found in the Technical Information

bulletin Ceramic radiant tube SER-C.

Order No. on request.

9.4 SICAFLEX® segmented flame tube

For guiding hot flue gases in single-ended radiant tubes.

Further information can be found in the Technical Information

bulletin SICAFLEX

Order No. on request.

®

segmented flame tube.

Type

∅ X ∅ B1 ∅ Y

Dimensions

[mm]

W*

SER-C 100/088 100 160 140 1000 – 2600

SER-C 142/128 142 200 182 1500 – 2600

SER-C 162/148 162 220 202 1500 – 2600

SER-C 202/188 202 260 242 1500 – 2600

* In 100 mm increments. Other lengths on request.

ECOMAX · Edition 02.11

Page 51

Accessories

9.5 P2/P3 set Eco

Nozzle to limit the volume of purging air in order to achieve

safe ignition and monitoring of the ECOMAX® burner and to

avoid condensation and overheating.

Nozzle* Order number

P2 set Eco 2.5 /E 22801111

P2 set Eco 4.0 /E 22801108

P3 set Eco 2.5 /B 22801107

P3 set Eco 4.0 /B 22801106

* Suitable for burners, see page 23 (Purging air and cooling air).

51

ECOMAX · Edition 02.11

Page 52

52

Kromschröder AG

Michael Rehkamp

m.rehkamp@kromschroeder.com

Osnabrüc

k

Feedback

Feedback

Finally, we are offering you the opportunity to assess this “Technical Information (TI)” and to give us your opinion, so that we

can improve our documents further and suit them to your needs.

Clarity

Found information quickly

Searched for a long time

Didn’t find information

What is missing?

No answer

Use

To get to know the product

To choose a product

Planning

To look for information

Remarks

Contact

Contact

Elster GmbH

Geschäftssegment LBE

Postfach 22 03 27 · 42373 Wuppertal

In der Fleute 153 · 42389 Wuppertal

Germany

T +49 202 60908-0

F +49 202 60908-20

info@lbe-online.de

www.lbe-online.de

www.kromschroeder.com

ECOMAX · Edition 02.11

Comprehension

Coherent

Too complicated

No answer

Navigation

I can find my way around

I got “lost”

No answer

The current addresses of our international

agents are available on the Internet:

www.lbe-online.de/3184.0.html?&L=1

Scope

Too little

Sufficient

Too wide

No answer

My scope of functions

Technical department

Sales

No answer

(Adobe Reader 7 or higher required)

www.adobe.com

We reserve the right to make technical

modifications in the interests of progress.

Copyright © 2007 – 2011 Elster Group

All rights reserved.

03250971

Loading...

Loading...