Page 1

Eclipse PrimeFire 100 Burners

Oxygen-Oil

Operating Instructions Edition 9.12

Page 2

Copyright

Copyright 2012 by Eclipse, inc. All rights reserved

worldwide. This publication is protected by federal

regulation and shall not be copied, distributed,

transmitted, transcribed or translated into any human or

computer language, in any form or by any means, to any

third parties, without the express written consent of

Eclipse, inc.

Disclaimer Notice

In accordance with the manufacturer’s policy of continual

product improvement, the product presented in this

brochure is subject to change without notice or obligation.

The material in this manual is believed adequate for the

intended use of the product. If the product is used for

purposes other than those specified herein, confirmation

of validity and suitability must be obtained. Eclipse

warrants that the product itself does not infringe upon any

United States patents. No further warranty is expressed or

implied.

Liability & Warranty

We have made every effort to make this manual as

accurate and complete as possible. Should you find errors

or omissions, please bring them to our attention so that we

may correct them. In this way we hope to improve our

product documentation for the benefit of our customers.

Please send your corrections and comments to our

Technical Documentation Specialist.

It must be understood that Eclipse’s liability for its product,

whether due to breach of warranty, negligence, strict

liability, or otherwise is limited to the furnishing of

replacement parts and Eclipse will not be liable for any

other injury, loss, damage or expenses, whether direct or

consequential, including but not limited to loss of use,

income, or damage to material arising in connection with

the sale, installation, use of, inability to use, or the repair

or replacement of Eclipse’s products.

Any operation expressly prohibited in this manual, any

adjustment, or assembly procedures not recommended or

authorized in these instructions shall void the warranty.

Document Conventions

There are several special symbols in this document. You

must know their meaning and importance.

The explanation of these symbols follows below. Please

read it thoroughly.

How To Get Help

If you need help, contact your local Eclipse

representative. You can also contact Eclipse at:

1665 Elmwood Rd.

Rockford, Illinois 61103 U.S.A.

Phone: 815-877-3031

Fax: 815-877-3336

http://www.eclipsenet.com

Please have the information on the product label available

when contacting the factory so we may better serve you.

www.eclipsenet.com

Product Name

Item #

S/N

DD MMM YYYY

WARNING

CAUTION

NOTICE

NOTE

This is the safety alert symbol. It is used to alert you to potential personal

injurt hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Is used to address practices not related to personal injury.

Indicates an important part of text. Read thoroughly.

2

Page 3

Table of Contents

1 Introduction............................................................................................................................ 4

Product Description .............................................................................................................. 4

Audience............................................................................................................................... 4

Purpose ................................................................................................................................ 4

PrimeFire 100 Documents.................................................................................................... 4

Related Documents .............................................................................................................. 4

2 Safety ...................................................................................................................................... 5

Safety Warnings ................................................................................................................... 5

Capabilities ........................................................................................................................... 6

Operator Training ................................................................................................................. 6

Replacement Parts ...............................................................................................................6

3 Installation.............................................................................................................................. 7

Installing the Mounting Bracket ............................................................................................ 7

Adjusting the Burner Tip ....................................................................................................... 7

Notes on Burner Cooling ...................................................................................................... 7

Installing the Burner.............................................................................................................. 8

Firing the Burner with Heavy Oil........................................................................................... 8

Adjusting the Flame Shape .................................................................................................. 9

Shutting Down and Removing the Burner ............................................................................ 9

Inspecting the Burner ...........................................................................................................9

Maintaining the Burner ......................................................................................................... 9

Cleaning the Burner Parts .................................................................................................... 10

Appendix.................................................................................................................................... i

Conversion Factors ..............................................................................................................i

3PrimeFire 100, Oil, Operating Instructions, Edition 9.12

Page 4

Introduction

1

Product Description

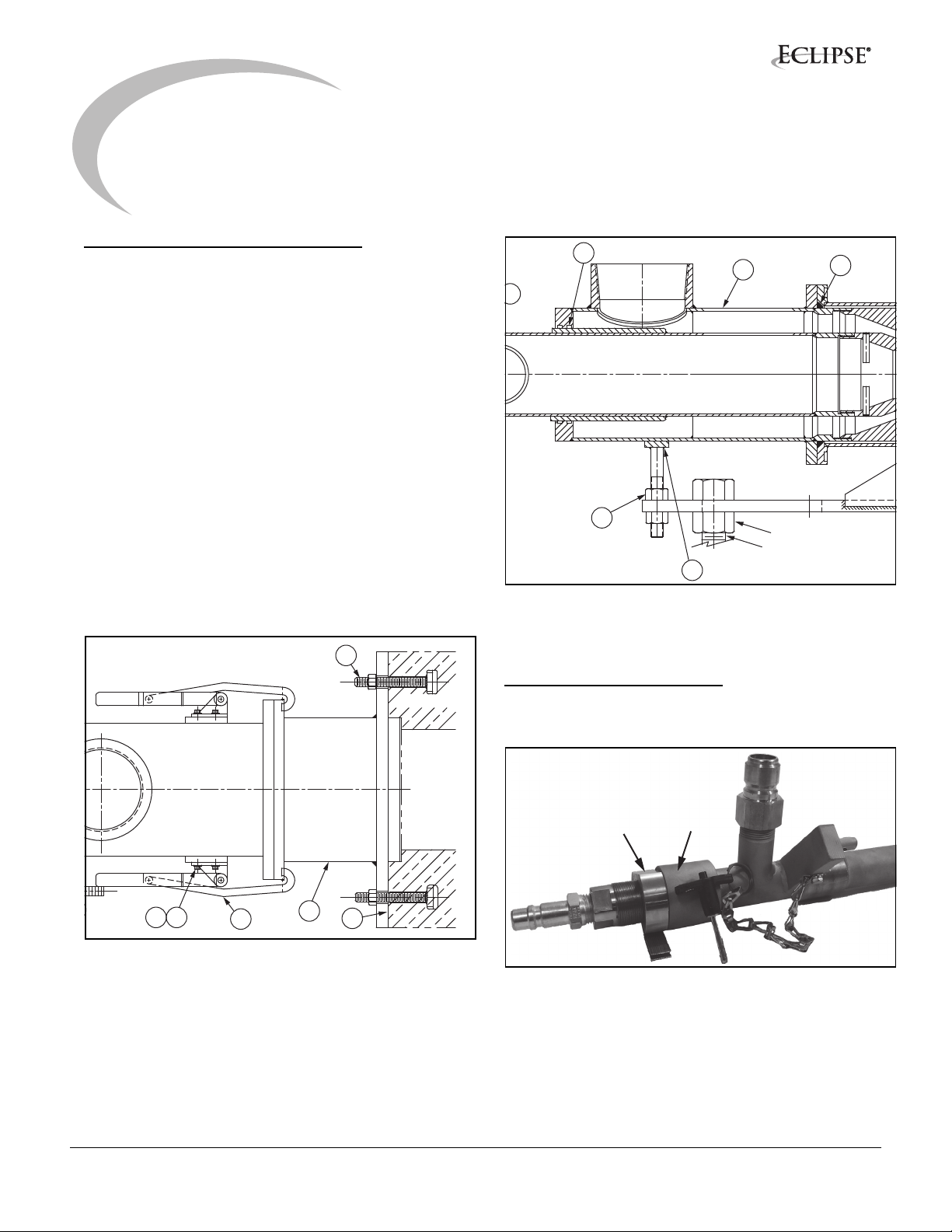

The PrimeFire 100 provides flexibility, extended fuel firing

capability, increased melter efficiency, improved refractory

life, and reduced melting cost. The Primefire 100 oxygenfuel burner produces a conventional shape flame and the

adjustable control on the burner allows variation in flame

coverage to suit melter size and temperature profile.

To fire oil on a dual fuel setup, the plug at the rear of the

gas inlet (Figure 1.1) is removed and the oil/atomizing

assembly (Figure 1.3) is installed.

For oil firing only, the gas inlet assembly is not needed,

and the oil/atomizing assembly is installed in its place.

Figure 1.1. PrimeFire 100 Dual Fuel Assembly

oxygen tip

Audience

This manual has been written for personnel already

familiar with all aspects of a glass industry burner and its

add-on components, also referred to as the burner

package.

These aspects are:

• Design/Selection

• Installation

• Use

• Maintenance

The audience is expected to be qualified and have

experience with this type of equipment and its working

environment.

Purpose

The purpose of this manual is to provide necessary

operating instructions regarding the PrimeFire 100 burner

to help ensure a safe, effective and trouble-free

combustion system is ultimately achieved.

PrimeFire 100 Documents

PrimeFire 100 Gas Burner Information Guide No.

1120-1

• Provides operating instructions for the gas burning

option of the PrimeFire 100

PrimeFire 100 Oil Burner Information Guide No.

1120-2

Figure 1.2. PrimeFire 100 Oil Burner Assembly

Figure 1.3 PrimeFire 100 Oil/Atomizing Assembly

• This document

Related Documents

• EFE 825 (Combustion Engineering Guide)

• Eclipse Bulletins and Information Guides: 818, 820,

826, 832, 852, 854, 856

4PrimeFire 100, Oil, Operating Instructions, Edition 9.12

Page 5

Safety

2

Important notices which help provide safe burner

operation will be found in this section. To avoid personal

injury and damage to the property or facility, the following

warnings must be observed. All involved personnel should

read this entire manual carefully before attempting to start

or operate this system. If any part of the information in this

manual is not understood, contact Eclipse before

continuing.

Safety Warnings

DANGER

■ The burners, described herein, are designed to mix

fuel with air and burn the resulting mixture. All fuel

burning devices are capable of producing fires and

explosions if improperly applied, installed,

adjusted, controlled or maintained.

■ Do not bypass any safety feature; fire or explosion

could result.

■ Never try to light a burner if it shows signs of

damage or malfunction

WARNING

■ Pressurized gas lines can damage equipment and

injure personnel.

The oxygen pipelines can contain pressures up to 200

PSIG. Exercise care when working on or around these

pressurized lines. Ensure the pressures have been

vented before breaking any connection. Tag out a line

before performing any work on it. Wear a face shield when

working on pressurized lines.

■ High concentrations of oxygen rapidly accelerate

combustion of most materials and could damage

equipment and injure personnel.

Oxygen concentrations in excess of 25% significantly

increase the fire hazard exposure to personnel and

equipment. Those materials which burn in air will burn

more violently and sometimes explosively in oxygen.

Reducing the hazard requires meeting stringent oxygen

guidelines for specifying equipment, materials of

construction, and system cleanliness. Only those

personnel familiar with the hazards of oxygen and safe

practices for oxygen systems should be permitted to

operate and maintain the system.

■ The burner and duct sections are likely to have

HOT surfaces. Always wear the appropriate

protective equipment when approaching the

burner

■ Exposure to liquid oxygen or cold oxygen gas can

cause severe burn-like injuries.

The temperature of the liquid oxygen in the storage vessel

is -279°F (-173°C). Contact with liquid or cold gaseous

oxygen will freeze living tissue within seconds. Typically,

the hazard exists only within the boundaries of the storage

area, specifically between the storage vessel and the

vaporizers. The oxygen pipeline downstream of the

storage area contains oxygen gas at ambient

temperatures. Interlocks at the storage area prevent liquid

or cold gas from entering the oxygen pipeline.

When working near cryogenic liquids or cold gas

pipelines, wear loose-fitting gloves, e.g. leather, and

safety glasses or goggles.

NOTICE

■ Open all valves slowly.

Since many materials will burn in the presence of oxygen,

the temperature rise caused by adiabatic compression of

the oxygen gas could result in igniting pipeline materials.

Rapid filling of an oxygen line from one pressure level to

another will result in a temperature increase of the gas

within the line due to adiabatic compression. Lines should

thus be pressurized slowly to minimize this temperature

rise. To avoid adiabatic compression, slowly open all

valves until pressures have equalized across the valve;

then open the valve fully. Ignition of flammable materials

in the pipeline, if present, could occur if the line were

fabricated of ferrous material.

5

Page 6

■ Use only equipment specifically designed for

oxygen service.

The equipment installed in the flow control and oxygen

distribution system has been carefully selected to meet

strict oxygen compatibility and velocity requirements.

Inappropriate materials of construction increase the

danger of ignition of pipelines and controls. Sizing is just

as important to ensure all velocity restrictions for oxygen

are met. Do not substitute components or equipment

without written approval from Eclipse, Inc.

■ Maintain oxygen cleanliness at all times.

All equipment and piping in contact with oxygen must be

cleaned to conform to specifications outlined in CGA

Pamphlet G-4.1. Failure to clean components and piping

increases the danger of ignition and fire. Note that even

the cleaning solvent must be removed completely before

the equipment can be placed into service. Maintain

cleanliness during assembly, installation, and repair.

■ No open flames, smoking, or sparks are permitted

near oxygen equipment.

Since many materials will burn in oxygen, the best method

in preventing fires is to eliminate sources of ignition.

Where oxygen control equipment is being used or where

concentrations of oxygen are greater than 25%, avoid

open flames, sparks, or sources of heat. Never weld on a

pressurized oxygen line. Make sure signs are posted

warning personnel that oxygen is in use.

Capabilities

Only qualified personnel, with sufficient mechanical

aptitude and experience with combustion equipment,

should adjust, maintain or troubleshoot any mechanical or

electrical part of this system.

Operator Training

The best safety precaution is an alert and trained

operator. Train new operators thoroughly and have them

demonstrate an adequate understanding of the

equipment and its operation. A regular retraining schedule

should be administered to ensure operators maintain a

high degree of proficiency.

Replacement Parts

Order replacement parts from Eclipse only. All Eclipse

approved valves or switches should carry UL, FM, CSA,

CGA and/or CE approval where applicable

■ Do not substitute oxygen for compressed air.

Substituting oxygen for compressed air is dangerous.

Chances are the instrument air equipment is neither

compatible with oxygen, nor cleaned for oxygen service.

Oxygen used to clean off equipment or clothing could

come in contact with a source of ignition (spark, flames, or

other) and ignite. In some cases, the elevated oxygen

levels could linger even after the source has been shut off.

■ This manual provides information regarding the

use of these burners for their specific design

purpose. Do not deviate from any instructions or

application limits described herein without written

approval from Eclipse

6

Page 7

Installation

3

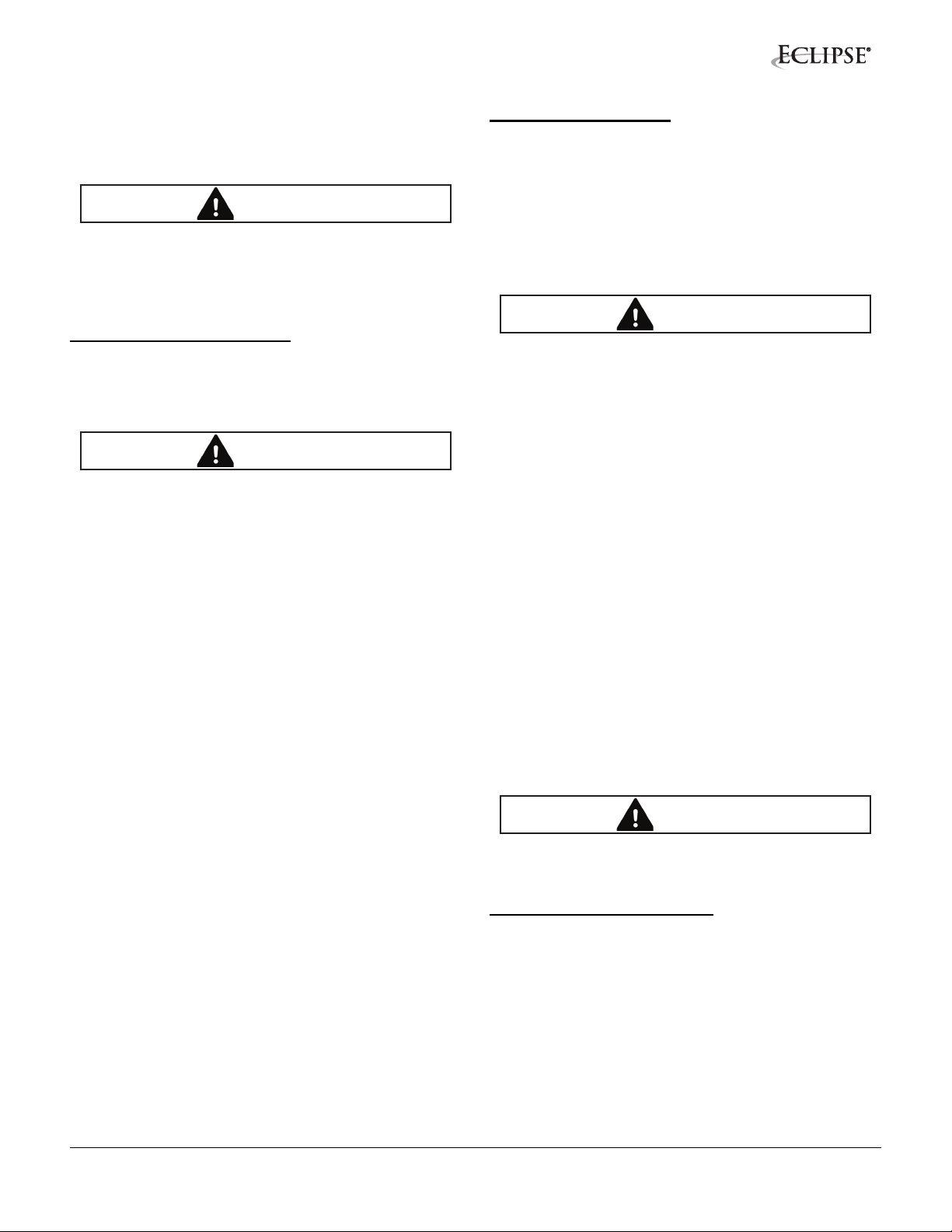

Installing the Mounting Bracket

Use this procedure to install the mounting hardware in

preparation for installing the burner.

NOTE: If possible, do this work before (or in the very early

stages of) furnace heat-up.

1. Install the burner mounting bracket (21) with gasket on the precombustor using four T-bolts, washers, and nuts (23). See Figure 3.1.

The T-bolts are only intended to secure the mounting

plate to the precombustor. The mounting plate must

be supported by the bolt assembly before installing

the burner.

2. Support the burner mounting bracket with a jack screw (A) and nuts (B). Make sure the horizontal plate is level. See Figure 3.2.

3. Briefly install the burner and flexible hoses into the precombustor to make sure the supply piping will permit easy burner installation.

23

Precombustor

17

5

6

26

A

B

25

Figure 3.2 PrimeFire 100 interior

NOTE: Whenever the burner is not in use, plug the burner

block with a high temperature fiber wool rolled blanket.

16

Adjusting the Burner Tip

The atomizing orifice in the burner oil tip is adjustable. Use

this procedure to adjust the burner tip.

3029

Figure 3.1 PrimeFire 100 exterior

20

21

22

locking

collar

1. Unscrew the locking collar. See Figure 3.3 above.

2. Rotate the oil boss to open or close the area of the atomizing orifice.

For startup, open the atomizing area by retracting the

oil tip (by rotating the oil boss) 1.5 mm (0.06 inch)

back.

o-rings

(inside)

Figure 3.3

7PrimeFire 100, Oil, Operating Instructions, Edition 9.12

Page 8

To set the initial oil tip position, set the oil tip flush with

the atomizing tip, then rotate the oil tube two full turns

back from flush. Two turns = 1.5 mm = 0.06 inch.

Installing the Burner

After the mounting hardware is installed and cooling

requirements are in place, use this procedure to install the

burner.

WARNING

■ Never operate this burner with the atomizing

oxygen orifice completely closed; this will cause it

to inject oil into the furnace without atomization,

which will cause a severe safety-related incident.

Notes on Burner Cooling

Use the following guidelines to make sure that the cooling

requirements for the burner are in place before installing

the burner.

WARNING

■ Combustion and atomizing oxygen cool the burner

and block, as well as supporting combustion. The

burner oxygen nozzles and fuel oil atomizing

assembly are made of a heat-resistant steel alloy,

but they can still be damaged if they are exposed

to furnace radiation without cooling oxygen flows

in the form of combustion and atomizing oxygen.

For oxy/oil firing, the fuel oil atomizing assembly is

extended well into the pre-combustor. It is roughly 63.5

mm (2.5 inches) back from the hot face of the precombustor. At this location, the atomizing assembly must

have atomizing oxygen flow for cooling purposes at all

times. Otherwise, it could suffer extensive heat damage or

meltdown.

The flow should be 10—23 Nm3/h (320 to 800 SCFH).

The combustion oxygen flow of about 27 Nm3/h (1,000

SCFH) must also be maintained, to keep the precombustor cool and free from furnace gases which could

deposit particulates/volatile matter on the precombustor

inner wall. In case of an emergency or power failure, pull

the entire burner body out to the pre-combustor opening

and plug the pre-combustor with a refractory plug or hightemperature fiber wool blanket.

Before installing the burner, have the combustion oxygen,

atomizing oxygen, and the fuel oil supply lines ready and

pressurized, so that within a few minutes of the burner

being placed in the block, a combustion oxygen flow of

about 27 Nm3/h (1000 SCFH) and atomizing oxygen of 10

Nm3/h (320 SCFH) can be started to provide cooling. The

only action required to start the oxygen flow at this point

should be to open the ball shutoff valve closest to the

burner.

NOTE: Before installing the burner, make sure that all

steps to achieve minimum oxygen flow through the burner

can be completed within less than five minutes after

burner installation.

WARNING

■ If the burner is not level, premature failure of the

precombustor is possible

1. Clamp the burner to the mounting section using the

clamping mechanism on the burner. Do not overtighten the clamps. Use only enough pressure to

ensure a firm seal of the burner to the preprecombustor. Insert the safety pins through the

clamping mechanism to lock it in place.

2. Connect the combustion oxygen, atomizing oxygen,

and the fuel oil hoses to the burner.

3. If the oil purge system is supplied, set the purge/oil

switch to Purge.

4. Open the combustion oxygen shutoff valve closest to

the burner to begin flowing oxygen at a rate of about

27 Nm3/Hr (1000 SCFH) through the burner to

provide cooling.

5. Open the atomizing oxygen shutoff valve closest to

the burner to begin flowing oxygen at a rate of about

10 Nm3/Hr (320 SCFH) through the burner to provide

cooling.

WARNING

■ Make sure the furnace is at a minimal temperature

for auto-ignition, 800°C (1472°F).

Firing the Burner with Oil

After installing the burner, use this procedure to fire the

burner using fuel oil.

NOTE: When firing oil, the oil tube tip must be retracted

into the atomizing nozzle 0.03" at a minimum. Issues may

occur if the oil tube is mounted in the incorrect position.

NOTE: If heavy (#6) oil is used, the oil temperature should

be adjusted to maintain an oil viscosity of about 20

centistokes (between 90—110 SSU) at the burner. Higher

oil viscosities are desirable, short of the oil flashing or the

small amount of water found in heavy oil turning to steam.

8PrimeFire 100, Oil, Operating Instructions, Edition 9.12

Page 9

Either of these occurences may cause unstable (pulsing)

burner performance.

1. Adjust the combustion oxygen flow to the lowest firing range of the burner (approximately 2000 SCFH per MMBtu of fuel input).

2. Adjust the atomizing oxygen pressure to 10 PSI for light oil, 20 PSI for heavy oil.

3. Open the fuel oil shutoff valve and adjust the flow rate to the minimum firing range of the burner.

NOTE: Observe the initial firing to ensure the flame is

centered in the precombustor and atomization is

sufficient.

4. After initial firing, combustion oxygen, atomizing

oxygen and fuel flows may be adjusted as desired.

When satisfactory atomizing oxygen flow is achieved,

the combustion oxygen can be adjusted to obtain the

total oxygen flow requirements for a given input

(approximately 2000 SCFH per MMBtu of fuel input).

NOTE: The exact ratio will vary depending on the calorific

value of the fuel and the actual percentage of oxygen into

the oxygen delivered.

Combustion oxygen velocity is typically set at the

maximum velocity position. After firing has been

established, combustion oxygen velocity can be adjusted

if necessary.

WARNING

■ Do not fire burner above or below capacity ranges.

This may cause the burner block to overheat.

Adjusting the Flame Shape

After initial firing, use this procedure to adjust the flame

shape.

1. Before attempting any flame shape adjustment with the burner adjustment screw, loosen the locking bolt. See Figure 3.2 above.

2. The burner nozzle can be adjusted to 51 mm (2 inches) in relation to the front end flange. To move the nozzle forward, turn the adjustment screw (item 60) clockwise. Each increment on the position rod represents 3 mm (1/8 inch) of nozzle travel.

NOTE: Typically, the nozzle is set to the Full In (maximum

velocity) position to operate the burner when firing oil. If

the position is set too far back, combustion may start

quickly and cause overheating of the block.

3. Tighten the locking bolt after the desired flame shape adjustment has been made.

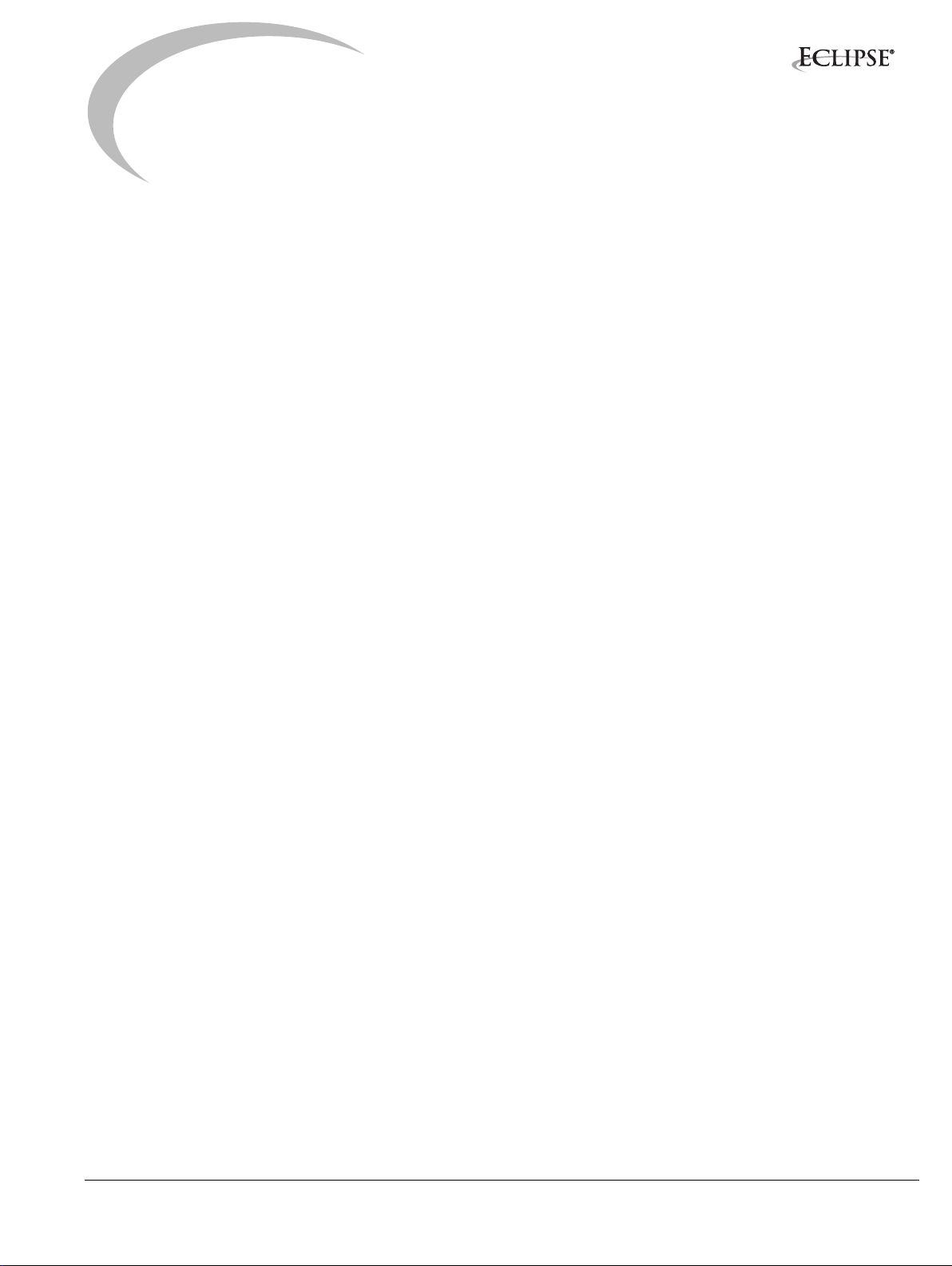

Shutting Down and Removing the Burner

If a burner needs to be shut down temporarily, or for an

extended period, use the following procedure.

If a burner is to be taken offline temporarily and not

removed from the burner block, combustion and

atomizing must be supplied to the burner for cooling

purposes. If both the combustion and atomizing oxygen to

the burner are interrupted for more than 10 minutes, the

burner must be removed from the precombustor.

If a burner is to be taken offline for an extended time, use

the following procedure.

oil

boss

o-rings

(inside)

burner

adjustment screw

Figure 3.4

o-rings

(inside)

roll pin

locking

bolt

1. If the purge system is provided, purge the oil from the burner.

2. After the purge is complete, reduce atomizing oxygen, combustion oxygen, and fuel oil flow control valves to minimum.

3. Shut off the combustion oxygen, atomizing oxygen, and fuel oil shutoff valves closest to the burner.

4. Release the burner clamps from the mounting bracket. Remove the burner from the precombustor and mounting bracket.

5. Disconnect the combustion oxygen, atomizing oxygen, and fuel oil lines from the burner inlet.

6. Place a high-temperature fiber wool rolled blanket in the cavity of the precombustor to prevent hot furnace gases from escaping through the block.

9PrimeFire 100, Oil, Operating Instructions, Edition 9.12

Page 10

7. If the burner is not being used for an extended time, plug or cover the block opening with mullite or a bonded AZS block instead of fiber wool.

4. To view and inspect the intermediate tip, remove the roll pin from the burner adjustment screw and pull the tube out of the burner body. See Figure 3.2

8. If the burner is to be left out of service, close all service valves on the metering and control skid.

WARNING

■ Ensure that all lock-out and tag-out procedures are

in place according to your plant procedures.

NOTE: Whenever removing a burner from service, always

keep the oxygen-compatible components cleaned and

sealed. Hoses should be capped when not used. Burners

should be cleaned and stored in a sealed plastic bag.

Inspecting the Burner

Each shift should inspect the Primefire burners just as you

would inspect firing conditions in your present furnace.

Use these guidelines to inspect the burners, blocks, and

operation.

Recommended checks:

• Flame shape and appearance

• Burner block appearance

• Proper cooling effect on burner and block

• Combustion oxygen flow

• Atomizing oxygen flow and pressure

• Fuel oil flow and pressure

Obvious changes from the standard should be

investigated. If needed, fuel should be shut off with

combustion and atomizing oxygen set to a minimum while

the situation is investigated.

Maintaining the Burner

Under normal operating conditions, the Primefire oxy-oil

burner should need little attention. If you need to remove

and inspect a burner, use this procedure.

1. Follow the steps above under Burner Shutdown and Removal.

2. The oxygen tip can be viewed and inspected. See Figure 1.2 on page 4.

3. To remove the atomizing assembly:

NOTE: The o-rings are used for sealing between the oil

and atomizing oxygen tubes, the intermediate and

atomizing oxygen tubes, and the intermediate and

combustion oxygen tubes. See Figure 1.1, 3.1 and 3.2.

Use only Eclipse supplied halocarbon grease on the orings to ensure oxygen compatibility. Also make sure the

surfaces that mate with the o-rings are kept clean and are

not scratched. A damaged surface can cause a leak.

Cleaning the Burner Parts

After the burner is disassembled, use the following

procedure to clean the parts.

1. Using compressed air and cleaning solvent, clean the oil tube tip.

Handle all tips carefully to prevent damage.

2. Wipe the oil tube clean.

3. Clean the atomizing oxygen tube with appropriate oxygen cleaning solvents. Wipe the tube clean when done.

4. Clean all oxygen-compatible components and wipe clean when done; reassemble the burner by reversing the disassembly instructions under Burner Maintenance.

When reassembling the burner:

• Examine all o-rings and apply fresh halocarbon

grease.

• Use the centering lugs for the oil tube, atomizing

oxygen tube, and intermediate tube to ensure the

respective tube is in the proper centered location for

efficient mixing.

NOTE: Be careful not to damage the sealing surface on

the atomizing tube assembly. A damaged surface can

cause a leak.

• Verify the oil tip is in the correct position, and is

locked in position.

Always store the burner in a sealed plastic bag. This will

ensure that the burner is oxygen-compatible and ready to

fire.

a.Remove the ball lock pin.

b.Gently pull the atomizing assembly out of the

burner body.

3. The oil tip can be removed by loosening the oil boss at the rear of the tube, then pulling the oil tube out.

10PrimeFire 100, Oil, Operating Instructions, Edition 9.12

Page 11

11PrimeFire 100, Oil, Operating Instructions, Edition 9.12

Page 12

Appendix

Conversion Factors

Metric to English

From To Multiply By

actual cubic meter/h (am³/h) actual cubic foot/h (acfh) 35.31

normal cubic meter/h (Nm³/h) standard cubic foot /h (scfh) 38.04

degrees Celsius (°C) degrees Fahrenheit (°F) (°C x 9/5) + 32

kilogram (kg) pound (lb) 2.205

kilowatt (kW) Btu/h 3415

meter (m) foot (ft) 3.281

millibar (mbar) inches water column ("w.c.) 0.402

millibar (mbar) pounds/sq in (psi)

millimeter (mm) inch (in) 3.94 x 10

MJ/Nm³ Btu/ft³ (standard) 26.86

Metric to Metric

14.5 x 10

-3

-2

English to Metric

actual cubic foot/h (acfh) actual cubic meter/h (am³/h) 2.832 x 10

standard cubic foot /h (scfh) normal cubic meter/h (Nm³/h) 2.629 x 10

degrees Fahrenheit (°F) degrees Celsius (°C) (°F - 32) x 5/9

inches water column ("w.c.) millibar (mbar) 2.489

From To Multiply By

kiloPascals (kPa) millibar (mbar) 10

meter (m) millimeter (mm) 1000

millibar (mbar) kiloPascals (kPa) 0.1

millimeter (mm) meter (m) 0.001

From To Multiply By

pound (lb) kilogram (kg) 0.454

Btu/h kilowatt (kW) 0.293 x 10

foot (ft) meter (m) 0.3048

pounds/sq in (psi) millibar (mbar) 68.95

inch (in) millimeter (mm) 25.4

Btu/ft³ (standard) MJ/Nm³ 37.2 x 10-3

-2

-2

-3

i

Page 13

Notes

ii

Page 14

© Eclipse, Inc. All Rights Reserved

Loading...

Loading...