Page 1

F

NL

I

SK

050886/00 · Edition 0.

D GB F NL I SK

xx.xx Fx/ivd x.xxx

Operating instructions

➔ www.docuthek.com

Diaphragm gas meters

BK-G.6 to BK-G5

Translation from the German

© 2012 Elster GmbH

Contents

Contents

Diaphragm gas meters

BK-G.6 to BK-G5 .....................

Contents ..............................

Safety.................................

Checking the usage .....................

Diaphragm gas meters BK-G1.6 to G25 ......2

BK with integrated “Smart Valve”............2

Type code .............................2

Part designations ........................2

Type label/Index plate.....................2

ATEX identification .......................3

Installation ............................

Temperature test point ..................4

Connecting the pressure measuring line ...4

Tightness test ..........................4

Commissioning.........................5

BK-G..M with mechanical index.............5

BK-G..A with Absolute ENCODER indexAE1/Z6 . 5

BK-G..A with Absolute ENCODER AE2 and

communications module ACM..............5

BK-G..E with electronic index ..............5

Diaphragm gas meters BK with integrated valve 5

Maintenance/Removal...................6

Technical data .........................6

Declaration of conformity ................7

ATEX legend ...........................8

Contact ...............................8

Safety

Safety

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Following the

installation, pass the instructions on to the opera-

tor. This unit must be installed and commissioned

in accordance with the regulations in force. These

instructions can also be found at www.docuthek.com.

Explanation of symbols

• , , , ... = Action

▷ = Instruction

Liability

We will not be held liable for damages resulting

from non-observance of the instructions and non-

compliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Transport

Diaphragm gas meters are always to be transported

in the upright position. On receipt of the product,

check that the delivery is complete (see Part desig-

nations). Report any transport damage immediately.

Storage

Diaphragm gas meters are always to be stored in the

upright position and in a dry place. Ambient tempera-

ture: see Technical data.

GB

GB-1

Page 2

F

NL

I

SK

Checking the usage

m

3

,

-

BK-G..M..

12345678

DE-07-MI002-PTB001

class 1,5

NG-47001BM0443 DIN EN 1359:2007

Q

max

Q

min

002545632734 1 imp =^ 0,01 m

3

M12 0102

Diaphragm gas meters BK-G.6 to G5

Residential or commercial diaphragm gas meters

BK for recording gas consumption values for natural

gas, town gas, propane and butane, as gases of the

first to third families pursuant to DIN EN 437:2003

(DVGW Code of Practice G260). If used for internal

measurements which are not subject to statutory

testing, the gas meter is also suitable for hydrogen,

nitrogen, air and inert gases.

BK with integrated “Smart Valve”

Not suitable for highly contaminated gases, e.g.

town gas.

GB

Potentially explosive atmosphere

Diaphragm gas meters that are labelled with and

(see sticker near the index) are suitable for opera-

tion in potentially explosive atmospheres, see page7

(Declaration of conformity).

This function is only guaranteed when used under the

specified operating conditions– see page6 (Technical

data). Any other use is considered as non-compliant.

Type code

Code Description

BK-G Diaphragm gas meter

.6

.5

4

6

0

6

5

M

C

A

E

B

T

Te

Chekker mechanical index

Absolute ENCODER index

Indication of volume at base conditions

Temperature conversion:

Flow rate

0.016 – 2.5 m

0.025 – 4 m3/h

0.04 – 6 m3/h

0.06 – 10 m3/h

0.1 – 16 m3/h

0.16 – 25 m3/h

0.25 – 40 m3/h

Mechanical index

Electronic index

mechanical

electronic

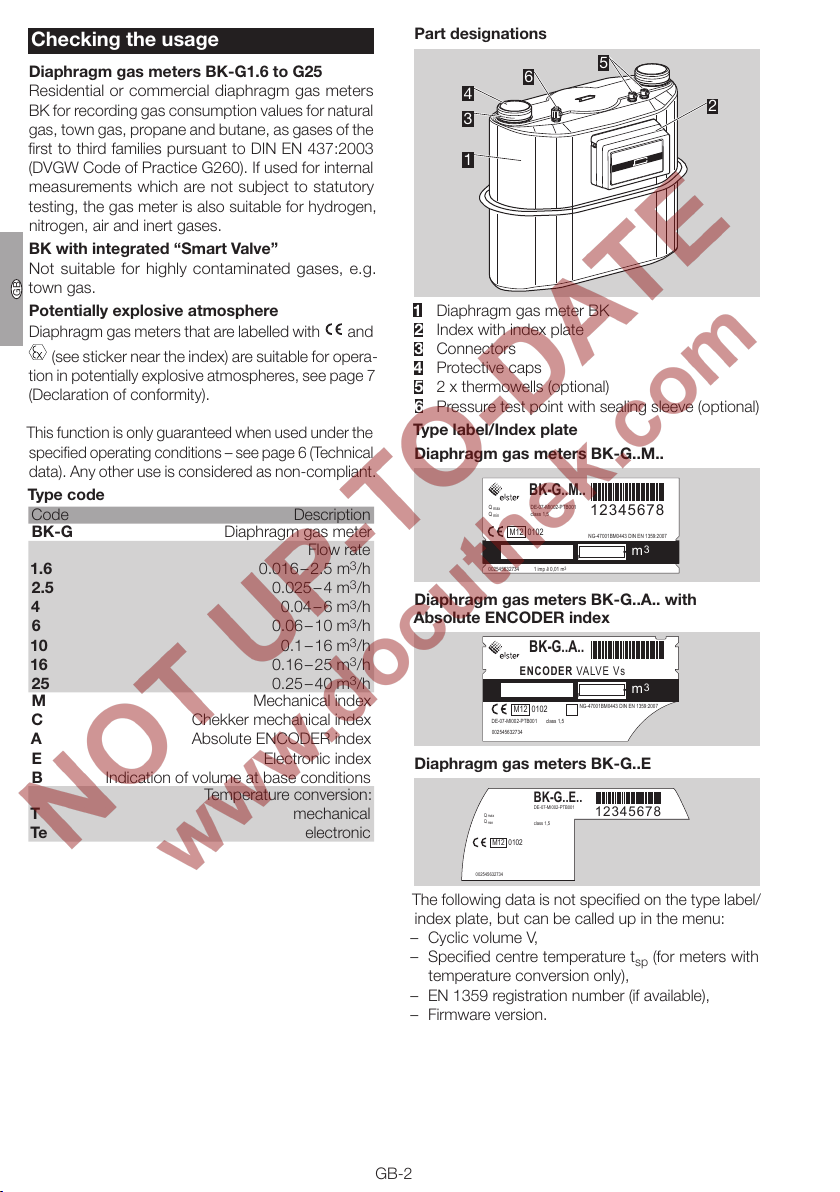

Part designations

6

4

3

5

2

1

Diaphragm gas meter BK

Index with index plate

Connectors

4 Protective caps

5 2 x thermowells (optional)

6 Pressure test point with sealing sleeve (optional)

Type label/Index plate

Diaphragm gas meters BK-G..M..

BK-G..M..

DE-07-MI002-PTB001

Q

max

Q

min

M12 0102

3

/h

002545632734 1 imp =^ 0,01 m

class 1,5

12345678

NG-47001BM0443 DIN EN 1359:2007

,

3

3

m

-

Diaphragm gas meters BK-G..A.. with

Absolute ENCODER index

BK-G..A..

ENCODER VALVE Vs

M12 0102

DE-07-MI002-PTB001

class 1,5

002545632734

,

NG-47001BM0443 DIN EN 1359:2007

3

m

-

Diaphragm gas meters BK-G..E

BK-G..E..

Q

max

Q

min

M12 0102

002545632734

DE-07-MI002-PTB001

class 1,5

12345678

The following data is not specified on the type label/

index plate, but can be called up in the menu:

– Cyclic volume V,

– Specified centre temperature tsp (for meters with

temperature conversion only),

– EN 1359 registration number (if available),

– Firmware version.

GB-2

Page 3

F

NL

I

SK

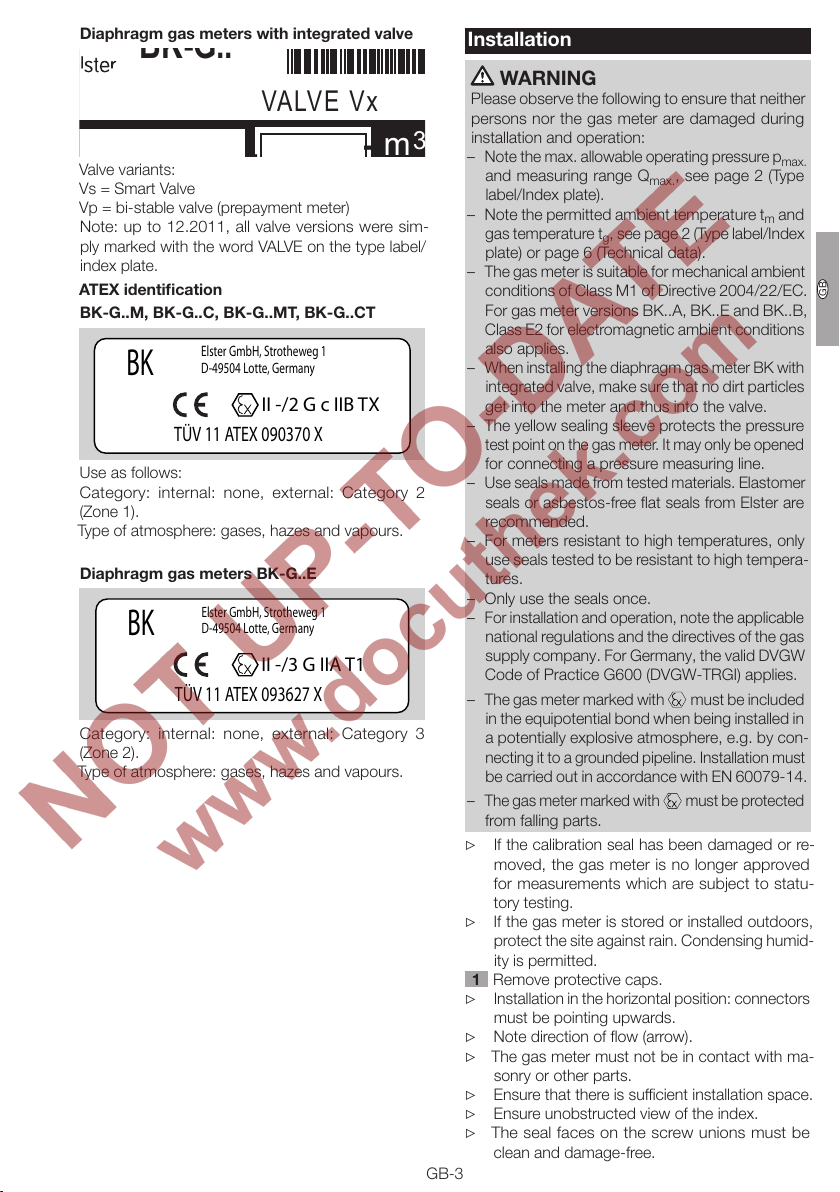

Diaphragm gas meters with integrated valve

BK-G..

m

3

VALVE Vx

Valve variants:

Vs = Smart Valve

Vp = bi-stable valve (prepayment meter)

Note: up to 12.2011, all valve versions were sim-

ply marked with the word VALVE on the type label/

index plate.

ATEX identification

BK-G..M, BK-G..C, BK-G..MT, BK-G..CT

Elster GmbH, Strotheweg 1

BK

D-49504 Lotte, Germany

II -/2 G c IIB TX

TÜV 11 ATEX 090370 X

Use as follows:

Category: internal: none, external: Category 2

(Zone1).

Type of atmosphere: gases, hazes and vapours.

Diaphragm gas meters BK-G..E

Elster GmbH, Strotheweg 1

BK

D-49504 Lotte, Germany

II -/3 G IIA T1

TÜV 11 ATEX 093627 X

Category: internal: none, external: Category 3

(Zone2).

Type of atmosphere: gases, hazes and vapours.

Installation

WARNING

Please observe the following to ensure that neither

persons nor the gas meter are damaged during

installation and operation:

– Note the max. allowable operating pressurep

and measuring rangeQ

label/Index plate).

– Note the permitted ambient temperaturetm and

gas temperaturetg, see page2 (Type label/Index

plate) or page 6 (Technical data).

– The gas meter is suitable for mechanical ambient

conditions of Class M1 of Directive 2004/22/EC.

For gas meter versions BK..A, BK..E and BK..B,

ClassE2 for electromagnetic ambient conditions

also applies.

– When installing the diaphragm gas meterBK with

integrated valve, make sure that no dirt particles

get into the meter and thus into the valve.

– The yellow sealing sleeve protects the pressure

test point on the gas meter. It may only be opened

for connecting a pressure measuring line.

– Use seals made from tested materials. Elastomer

seals or asbestos-free flat seals from Elster are

recommended.

– For meters resistant to high temperatures, only

use seals tested to be resistant to high tempera-

tures.

– Only use the seals once.

– For installation and operation, note the applicable

national regulations and the directives of the gas

supply company. For Germany, the valid DVGW

Code of Practice G600 (DVGW-TRGI) applies.

– The gas meter marked with

in the equipotential bond when being installed in

a potentially explosive atmosphere, e.g. by con-

necting it to a grounded pipeline. Installation must

be carried out in accordance with EN60079-14.

– The gas meter marked with must be protected

from falling parts.

▷ If the calibration seal has been damaged or re-

moved, the gas meter is no longer approved

for measurements which are subject to statu-

tory testing.

▷ If the gas meter is stored or installed outdoors,

protect the site against rain. Condensing humid-

ity is permitted.

Remove protective caps.

▷

Installation in the horizontal position: connectors

must be pointing upwards.

▷ Note direction of flow (arrow).

▷ The gas meter must not be in contact with ma-

sonry or other parts.

▷ Ensure that there is sufficient installation space.

▷ Ensure unobstructed view of the index.

▷

The seal faces on the screw unions must be

clean and damage-free.

GB-3

, see page2 (Type

max.

must be included

max.

GB

Page 4

F

NL

I

SK

▷ For the compression of seals and the resulting

1 2

1

2

3

4

5

1

6

7

2

3

4

5

tightening torques for the screw unions, the seal

manufacturers’ specifications must be observed.

Tightening torques for the recommended flat

seals in conjunction with screw connectors

pursuant to DIN 3376-1 and 3376-2, see

www.docuthek.com → Elster-Instromet → Prod-

ucts → Gas measuring devices → Diaphragm

meters → Ergänzung für Betriebsanleitung BK,

Verschraubungen und Anzugsmomente für

BK-G1,6 bis BK-G25 (Supplement for BK op-

erating instructions, Screw unions and tightening

torques for BK-G1.6 to BK-G25) (D).

Install the gas meter free of mechanical stress.

GB

▷

If a pulse sensor IN-Z6x is used for pulse tap-

ping on the gas meter marked with – see

Data sheet for pulse sensorIN-Z6x (D, GB)

www.docuthek.com→ Elster-Instromet→ Prod-

ucts→ Gas measuring devices→ Diaphragm

meters→ Pulse sensorIN-Z61 and the stand-

ardEN 60079-14 (Explosive atmospheres).

Temperature test point

▷

Temperature sensors can be inserted into the

thermowells for measuring the gas temperature

in the meter housing.

1

4

▷

Use corrosion-resistant, seamless precision

2

3

5

steel tube pursuant to DINEN10305-4 (exter-

nal diameter 6mm, material E235= 1.0308). For

other materials, use a suitable adapter and note

the Parker/EO recommendations.

▷ Install pipes free of mechanical stress.

6

7

8 Screw on the union nut by hand as far as it will

go.

▷

At the same time, press the end of the pipe firmly

against the stop.

9 Mark the position of the union nut and tighten

with about 1½ turns.

Secure each of the temperature sensors using

the capstan screw provided.

Connecting the pressure measuring line

WARNING

In order to ensure that the gas meter is tight:

– The pressure test nipple must not be twisted,

bent, or otherwise manipulated.

– When installing, always secure the pressure test

nipple using a suitable spanner.

▷

Functional safety and reliability are ensured only if

the material combination of the screw connector

and the pressure line are intermatched.

▷

Only use the olive and the attached union nut

supplied. The olive is secured to the sealing

sleeve.

▷

When re-ordering, use original Parker EO pro-

gressive ring fittings PSR/DPR.

▷ When re-installing, the union nut will be turned

to the original position and then further tightened

through approx. 30°.

Once the installation and tightness test are com-

plete, see page4 (Tightness test), protect the

pressure test point against external access with

the sealing sleeve and the seal.

Tightness test

▷

Check the pipework for leaks prior to installation

of the gas meter, in case the pipework is tested

with a greater test pressure than the max. al-

lowable operating pressure p

meter. Otherwise, the installed gas meter may

be damaged.

▷ If a valve is integrated in the diaphragm gas me-

terBK, see page2 (Type label/Index plate), this

must be opened for the tightness test.

▷ Ensure the customer’s consumers are closed.

GB-4

max.

for the gas

Page 5

F

NL

I

SK

Apply the test pressure slowly to the gas meter.

2

2

BK-G..E with electronic index

For further commissioning of diaphragm gas

meter BK-G..E with electronic index – see Elec-

tronic index operating instructions (D, GB) →

www.docuthek.com→ Elster-Instromet→ Prod-

ucts→ Gas measuring devices→ Diaphragm me-

ters→ Smart Metering.

▷ If a pressure measuring line has been retrofitted

to the diaphragm gas meter, check this connec-

tion for tightness.

3

Diaphragm gas meters BK with integrated valve

In the event that the diaphragm gas meterBK is fitted

with an integrated valve, see page3 (Diaphragm gas

meters with integrated valve), the gas supply can be

connected or disconnected remotely.

Unless otherwise agreed, the valve is open on delivery

GB

as standard.

4 After the tightness test, slowly vent the gas meter.

5 If a pressure measuring line has been retrofitted

to the diaphragm gas meter, protect the pressure

test point against external access with a sealing

sleeve and a seal.

WARNING

– The network provider is responsible for the safe

remote shut-down and restart of the diaphragm

gas meter.

– The integrated valve does not assume the func-

tions of a safety shut-off valve.

... with valve variantVp

Commissioning

Once the tightness test has been successfully com-

pleted, the gas meter is ready for operation.

▷ Slowly open the manual valve.

BK-G..M with mechanical index

For pulse tapping, the pulse sensorIN-Z6x can be

connected – see Data sheet for pulse sensorIN-Z6x

(D, GB)→ www.docuthek.com→ Elster-Instromet→

Products→ Gas measuring devices→ Diaphragm

meters→ Pulse sensorIN-Z61.

BK-G..A with Absolute ENCODER

indexAE/Z6

Interface description for gas meters with

ENCODER index– see Specification (D, GB)→

www.docuthek.com→ Elster-Instromet→ Prod-

ucts → Gas measuring devices → Diaphragm

meters→ Smart Metering→ SpecificationM-BUS

orSCR+.

BK-G..A with Absolute ENCODER AE and

communications module ACM

If the diaphragm gas meter BK-G..A is fitted with

communications module ACM – for further commis-

sioning see Communications module ACM M-BUS

WIRE, ACM SCR+ WIRE... or Communications mod-

ule ACM WAVE SYSTEM RF operating instructions (D,

GB, NL) → www.docuthek.com→ Elster-Instromet→

Products→ Gas measuring devices→ Diaphragm

meters→ Smart Metering.

▷

Should the diaphragm gas meter BK be ordered

with a valve Vp, but without control electronics to

be complemented by a third party, the technical

data of the control interface is to be requested

from Elster GmbH and observed.

The manufacturer of the control electronics is

▷

responsible for creating the conditions required

for safe operation of the valve. Instructions on

commissioning and operation are to be taken

from the operating instructions for the control

electronics.

... with valve variantVs (Smart Valve)

WARNING

– Depending on national regulations, a limited and

technically safe gas flow rate in the customer’s

open consumer piping is allowed, see page6

(Technical data).

– Assessment of the non-critical gas flow rate with

regard to amount and duration, which occurs

when the valve is released, is to be defined by

the network provider.

– The minimum operating pressure on the inlet

must not be undershot, see page6 (Technical

data). Otherwise, when the valve is released and

if the customer’s consumer piping is open at the

same time, the valve may be completely opened.

“Smart Valve” valve function

▷

The “Smart Valve” is switched remotely by

the data management system. The valve first

switches to the “Released” position. From the

“Released” position, the valve automatically

switches to the “Open” position, if the down-

stream installation is tight.

GB-5

Page 6

F

NL

I

SK

Released

▷

The “Smart Valve” opens an internal bypass and

releases a minimum gas flow into the customer’s

closed consumer piping. Pressure equalization

takes place between the inlet and outlet side

of the valve.

Open

▷ Following pressure equalization, the valve auto-

matically opens by spring force and fully releases

the gas supply. If consumers of the customer are

open, pressure equalization cannot occur and

the valve remains in the “Released” position and

continues to release only the minimum gas flow

rate of the bypass.

GB

Closed

▷

The valve and the bypass are closed in the event

of remote shut-down.

▷ All valve positions are kept de-energized.

Maintenance/Removal

Gas meters BK-G1.6 to 25 from Elster are mainte-

nance-free.

▷ When used for custody transfer measurements,

recalibration must be carried out in accordance

with national directives.

▷

If the screw unions are loosened for maintenance

work or retesting, replace the seals.

▷ After the gas meter has been removed, immedi-

ately close the connectors with protective caps,

in order to prevent an ingress of dirt particles.

WARNING

A certain amount of gas may remain in the gas

meter. Taking into consideration the risk of explo-

sion, it is important to adopt safety measures, e.g.:

– Following removal of the gas meter, purge it thor-

oughly with inert gas.

– For transporting the gas meter with gas residue,

use a vehicle with an open or a ventilated loading

area.

– The indexes must not be opened in an explosion-

hazard area even for maintenance and repair.

Opening of the service cover on the electronic

index, e.g. to change the battery, is permitted–

see operating instructions for “Electronic index

for diaphragm gas meters BK..E”.

Technical data

Diaphragm gas meters BK

Gas type: natural gas, town gas, propane and butane,

as gases of the first to third families pursuant to

DINEN437:2003 (DVGW Code of PracticeG260).

Max. allowable operating pressurep

label/index plate.

Max. allowable measuring rangeQ

type label/index plate.

Transitional flow rate Qt = 0.1 x Q

Max. allowable ambient temperature rangetm, see

type label/index plate.

Max. allowable storage temperature range:

-25 to +60°C.

Gas temperature tg, where the measuring error still

lies within the error limits set out in the Directive, see

type label/index plate. If no gas temperature tg is

specified on the index plate, tg = tm applies.

Cyclic volume V, see type label/index plate.

Base temperature tb (for meters with temperature

conversion only), see type label/index plate.

Specified centre temperature tsp (for meters with tem-

perature conversion only), see type label/index plate.

For BK..E.., the cyclic volume V and the specified

centre temperaturetsp are not stated on the index

plate, but can be called up in the display using the

menu.

Diaphragm gas meters BK with pressure test

point

Pressure test point: 24° olive fitting to ENISO8434-1,

L6x M12x1.5-St.

Diaphragm gas meters BK with explosion

protection

Max. allowable ambient temperature rangetm/gas

temperature rangetg: -25 to +55°C; for constraints,

see type label/index plate.

Diaphragm gas meters BK with integrated

“Smart Valve”Vs

Not suitable for highly contaminated gases, e.g.

town gas.

Opening time from closed to open/released state:

≤ 4 s,

closing time: ≤ 0.5 s.

Min. operating pressure: 17.5mbar.

Allowed leakage flow in the customer’s piping:

valve released: max. 13 l/h at 35 mbar,

valve closed: max. 5 l/h.

max.

min./Qmax.

.

max.

, see type

, see

GB-6

Page 7

F

NL

I

SK

Declaration of conformity

Scan of the following Declarations of conformity – see

www.docuthek.com

Diaphragm gas meters BK-G..M, BK-G..C,

BK-G..MT, BK-G..CT

We, the manufacturer, hereby declare that the prod-

ucts labelled accordingly comply with the require-

ments of the listed Directives and Standards:

– MID

EC Directive: 2004/22/EC – MID

Standard: DIN EN1359:2007

(EN1359:1998+A1:2006)

EC type-examinations:

DE-07-MI002-PTB001, DE-07-MI002-PTB002.

The production is subject to the surveillance

procedure pursuant to 2004/22/EC, Annex D,

Physikalisch-Technische Bundesanstalt (German

National Metrological Institute), Notified Body 0102.

Markings:

M...

DE-07-MI002-PTB002

After the “M”, the year of construction is given.

– ATEX (only valid if marked on the meter)

EC Directive: 94/9/EC – ATEX

Standards:

EN 13463-1:2009

EN 13463-5:2011

Tests and inspections:

TÜV NORD CERT GmbH, Declaration of con-

formity–No. TÜV11ATEX090370X.

The production is subject to the conformity

assessment procedure pursuant to 94/9/EC,

AnnexVIII.

Markings:

II -/2 G c IIB TX.

Elster GmbH

Diaphragm gas meters BK-G..A, BK-G..AT

We, the manufacturer, hereby declare that the prod-

ucts labelled accordingly comply with the require-

ments of the listed Directives and Standards:

– MID

EC Directive: 2004/22/EC – MID

Standard: DIN EN1359:2007

(EN1359:1998+A1:2006)

EC type-examinations:

DE-07-MI002-PTB001, DE-07-MI002-PTB002.

The production is subject to the surveillance

procedure pursuant to 2004/22/EC, Annex D,

Physikalisch-Technische Bundesanstalt (German

National Metrological Institute), Notified Body 0102.

Markings:

DE-07-MI002-PTB002

0102, DE-07-MI002-PTB001 or

M...

0102, DE-07-MI002-PTB001 or

After the “M”, the year of construction is given.

– EMC

EC Directive: 2004/108/EC – EMC

Standards:

OIML D11:2004, Sec.12

EN55022:2006+A1:2007

Tests and inspections:

EMC Test NRW GmbH:

Test Report No. P09-Z-00005-001

Elster GmbH

Diaphragm gas meters BK-G..E

We, the manufacturer, hereby declare that the prod-

ucts labelled accordingly comply with the require-

ments of the listed Directives and Standards:

– MID

EC Directive: 2004/22/EC – MID

Standard: DIN EN1359:2007

(EN1359:1998+A1:2006)

EC type-examinations: DE-11-MI002-PTB001

The production is subject to the surveillance

procedure pursuant to 2004/22/EC, Annex D,

Physikalisch-Technische Bundesanstalt (German

National Metrological Institute), Notified Body 0102.

Markings:

M...

0102, DE-11-MI002-PTB001

After the “M”, the year of construction is given.

– EMC

EC Directive: 2004/108/EC – EMC

Standards:

OIML D11:2004, Sec.12

EN55022:2006+A1:2007

Tests and inspections:

EMC Test NRW GmbH:

Test Report No. P10-Z-00086-002

– ATEX (only valid if marked on the meter)

EC Directive: 94/9/EC – ATEX

Standards:

EN 1127-1:2007

Tests and inspections:

TÜV NORD CERT GmbH, Declaration of con-

formity– No. TÜV11 ATEX093627X.

The production is subject to the conformity

assessment procedure pursuant to 94/9/EC,

AnnexVIII.

Markings:

II -/3 G IIA T1.

Elster GmbH

GB-7

GB

Page 8

F

NL

I

SK

ATEX legend

= Marking of explosion protection

II = Equipment group ll for general industries

(with the exception of mines)

-/2 = Category:

internal: none

external: Category 2 (Zone 1)

-/3 = Category:

internal: none

external: Category 3 (Zone 2)

G = Type of atmosphere: gases, hazes and

vapours

c = “Constructional safety” explosion protec-

GB

tion type

IIB, IIA = Explosion group for gases

TX = No intrinsic heating

T1 = Temperature class: maximum allowable

surface temperature 450°C

Contact

Contact

Germany

Elster GmbH

Strotheweg 1

49504 Lotte

T +49 541 1214-0

F +49 541 1214-370

info@elster-instromet.com

www.elster-instromet.com

United Kingdom

Elster Metering Limited

Paton Drive

Tollgate Business Park

Beaconside

Stafford, ST16 3EF

T +44 1785 275200

F +44 1785 275305

jeavons.info@gb.elster.com

www.elstermetering.co.uk

Ireland

Active Energy Control Ltd.

Unit 4, Clare Marts

Quin Road

Ennis, Co. Clare

T +353 65 6840600

F +353 65 6840610

info@aec.ie

www.aec.ie

in the interests of progress.

We reserve the right to make technical modifications

GB-8

Loading...

Loading...