Elster 6 Series, Q.Sonic Plus Operation And Maintenance Manual

73023467_B_EN

i 2018-06-07

Doc: 10000050188

Page 2 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

Tel.:

+49 6134 6050

Fax:

+49 6134 605 566

E-Mail:

info@elster-instromet.com

Elster GmbH

Steinern Strasse 19-21

D - 55252 Mainz-Kastel, Germany

Page 3 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

Contents

1 General Information 6

1.1 About these Instructions 6

1.2 Limitation of Liability 7

2 Text Labelling 8

2.1 Presentation of Safety and Risk Instructions 8

2.1.1 Paragraph Formats 9

2.1.2 Character Formats 10

2.1.3 Abbreviations 11

3 Ultrasonic Flow Meter Series 6 12

3.1 General 12

3.2 Applicable Standards 13

3.3 Configuration 13

3.4 Calibration 14

4 Theory of Operation 15

4.1 Flow Velocity Measurement 15

4.2 Correction after Calibration 16

4.3 Volume Flow at Line Conditions 17

5 System Description 18

5.1 Flow Cell 18

5.2 Signal Processing Unit 19

5.3 Transducers 20

5.4 Flow Cell Pressure Sensor (Optional) 21

5.5 Flow Cell Temperature Sensor 21

5.6 Labels and Nameplates 22

5.6.1 ATEX Certified 23

5.6.2 IECEx Certified 23

Contents

Page 4 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

5.6.3 FM Certified 24

5.6.4 CSA Certified 25

5.7 Sealing 26

5.7.1 Main Plate 26

5.7.2 SPU 26

6 Installation and Commissioning 29

6.1 Introduction 29

6.2 Flow Cell Installation Requirements 29

6.2.1 Installing a Meter in the Pipeline 29

6.2.2 Testing Installation 30

6.3 Wiring Instructions 31

6.4 SPU Configuration 31

6.5 Cold Commissioning 31

6.6 Hot Commissioning 32

7 Operation 33

7.1 LED at Display 33

7.2 Front Panel and Touch Display 35

7.3 Basic Display 36

7.4 Home Screen 37

7.5 Diagnostics 42

7.6 Info 48

8 Maintenance 50

8.1 Collecting Data 50

8.2 Inspection of Measured Data 50

8.2.1 Sample Rate 50

8.2.2 Performance 51

8.2.3 Velocity of Sound 51

8.2.4 Gas Velocity (Zero Flow Measurement) 51

Contents

UFM Series 6

Q.Sonic-plus

Operation and Maintenance

Page 5 of 68

8.2.5 Presentation of AGC-Levels and AGC-Limits 52

8.2.6 Swirl Angle 52

8.3 Exchanging Components 53

8.3.1 Pressure Sensors Exchange 53

8.3.2 Temperature Sensors Exchange 54

8.3.3 Transducer Exchange 54

8.3.4 SPU Exchange 55

9 Verifying Software Versions 57

9.1 Verifying the Components with their Checksums 57

9.2 Verifying the Software Status of the Parameter Build Up 58

9.3 Display Test 59

9.4 Checking Errors and Warnings 59

9.5 PC Software Package 60

10 User Rights / Login 61

11 Shipping and Storage 62

12 MID Requirements 63

12.1 General 63

12.2 EC Declaration of Conformity 63

12.3 Sealing 64

12.4 Calibration 64

12.5 Installation Requirements 64

13 Index 65

Appendix I – References 67

General Information

1

Page 6 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

Important!

It is required to read and understand all other documentation of

your meter.

Please see Appendix I – References on page 67 for a

complete list of resources. Additionally, you may look online

at http://www.docuthek.com/.

1 General Information

1.1 About these Instructions

This manual is a complete guide to the operation and maintenance of an

Ultrasonic Flow Meter (UFM) Series 6 Q.Sonic

plus

meter. This manual

together with the UFM Series 6 Safety Instructions and UFM Series 6 Wiring

Instructions provide essential information for safe use in compliance with

and insofar applicable:

European Directives (e.g. ATEX, PED, EMC, MID).

International IECEx standards.

North American FM Approvals standards.

Canadian CSA standards.

This manual explains how to verify which certifications your flow meter

complies with, based on the labelling from the ultrasonic flow meter. The

manual also contains important instructions to prevent accidents and serious

damage before start-up, during operation, and to maintain trouble-free

operation in the safest possible way throughout the entire lifespan of the

device. Before using the product read this manual carefully, familiarise

yourself with the operation of the product, and strictly follow the instructions.

If you have any questions, or need further details on specific matters

concerning this product, please do not hesitate to contact one of our staff

members by email at info@elster-instromet.com (or see more contact

information on page 2).

1

General Information

UFM Series 6

Q.Sonic-plus

Operation and Maintenance

Page 7 of 68

Read through this Operation and Maintenance manual carefully

before beginning any work.

The manufacturer assumes no liability for loss and malfunctions

that result from non-compliance with these instructions.

1.2 Limitation of Liability

This manual is based on the latest information available. It is provided

subject to alterations. We reserve the right to change the construction and/or

configuration of our products at any time without obligation to update

previously shipped equipment.

The warranty provisions stipulated in the manufacturer's Terms of Delivery

are applicable to the product. The manufacturer shall have no obligation in

the event that:

Repair or replacement of equipment or parts is required through

normal wear and tear, or by necessity in whole or part by

catastrophe, or the fault or negligence of the purchaser;

The equipment, or parts, have been maintained or repaired by

someone other than an authorized representative of the

manufacturer, or have been modified in any manner without prior

express written permission of the manufacturer;

Non-original parts are used;

Equipment is used improperly, incorrectly, carelessly or not in line

with its nature and/or purpose;

Use of this product with unauthorized equipment or peripherals,

including, but not necessarily limited to, cables, testing equipment,

computers, voltage, etc.

The manufacturer is not responsible for the incidental or consequential

damages resulting from the breach of any express or implied warranties,

including damage to property, and to the extent permitted by law, damage

for personal injury.

Text Labelling

2

Page 8 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

DANGER WORD!

Type of danger / consequences in case of non-compliance

Avoiding danger

Safety instruction (optional)

Safety instruction text

We reserve the right to make technical changes within the scope of improving performance characteristics and continuous development of the

device.

Current warranty conditions in the General Terms and Conditions are

available on our website:

http://www.elster-instromet.com/en/general-terms-of-business

2 Text Labelling

This manual employs consistent visual cues and standard text formats to

help you easily locate and interpret information. This information will help

you quickly identify relevant content.

2.1 Presentation of Safety and Risk Instructions

Hazard Warnings

Hazard warnings indicate hazardous situations which may result in material

damage and bodily harm or even death if disregarded. Hazard warnings are

described below:

Safety Instructions

Safety instructions include notes and information which if disregarded may

lead to functions not working correctly or not working at all. Safety

instructions are described below:

2

Text Labelling

UFM Series 6

Q.Sonic-plus

Operation and Maintenance

Page 9 of 68

Heading (optional)

Hint text

Multi-row examples are marked by two continuous blue lines and the

keyword “Example”.

Tips and Recommendations

Tips include notes and information that make it easier for the user. Tips are

described below:

2.1.1 Paragraph Formats

► This triangle prompts you for an action.

This character will show you the immediate result of your action.

Example

Text Labelling

2

Page 10 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

Example

Use

See Chapter 5 System

Description (p.18)

References to additional information are

marked with an arrow. If the arrow refers to

information within the document, these

references are formatted as hyperlinks in blue

font. You can go directly to the corresponding

section by clicking on the blue text.

www.docuthek.com

Links (Hyperlink). Click to open in a browser.

Seen on the meter screen itself; this shows a

hyperlink within the meter software. You must

highlight the hyperlink before it will open the

next screen.

The hyperlink (shown above) has been

highlighted. Press the button on the

touch screen (or PC) to open the new

window. Ex: Open the Info section.

2.1.2 Character Formats

Table 1: Character formats

2

Text Labelling

UFM Series 6

Q.Sonic-plus

Operation and Maintenance

Page 11 of 68

AFB

Application Function Block

ATEX

Atmosphères Explosibles; European Directive

94/9/EC on equipment and protective systems

intended for use in potentially explosive

atmospheres

New Directive (valid 20.04.2016): 2014/34/EU

CSA

Canadian Standards Association

DC

Direct Current

EC

European Community

EMC

ElectroMagnetic Compatibility; European EMC

Directive 2004/108/EC

New directive (valid 20.04.2016): 2014/30/EU

HART

Highway Addressable Remote Transducer

IECEx

International Electrotechnical Commission System

for Certification to Standards Relating to

Equipment for use in Explosive Atmospheres

FM

Factory Mutual Approvals

NMi

Nederlands Meetinstituut

PED

Pressure Equipment Directive; European Directive

97/23/EC concerning pressure equipment

New Directive (valid 19.07.2016): 2014/68/EU

PC

Personal Computer

PCB

Printed Circuit Board

SPU

Signal Processing Unit

UFM

Ultrasonic Flow Meter

2.1.3 Abbreviations

The following abbreviations may appear in this document:

Ultrasonic Flow Meter Series 6

3

Page 12 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

WARNING!

Improper use of an UFM Series 6 may not only result in

unreliable performance, but may lead to hazardous

situations.

Please refer to the type plates, located on the meter for the

correct operating conditions. Never use the meter outside these

limitations!

3 Ultrasonic Flow Meter Series 6

3.1 General

The UFM Series 6 Q.Sonic

plus

is a sophisticated, multi-path ultrasonic gas

flow meter manufactured by Elster. It has been specifically designed for

custody transfer measuring applications that demand a high degree of

accuracy and reliability. It can be extended with an extra functionality

whereby the flow meter has the possibility to convert the measured line

volume to standardised volume, mass or energy.

The Ultrasonic Flowmeter Series 6 contains 2 type plates:

• Main plate: Provides information on mechanical design conditions as well

as flow related information such as meter factor and range

• SPU type plate: Provides information on applicable hazardous area

approval.

Ensure the meter never operates outside the limits stated on the type plates.

Any discrepancy between the type plates should be reported to Elster or

your local agent immediately. Please refer to Chapter 5.6 Labels and

Nameplates (p.22) for more information.

3

Ultrasonic Flow Meter Series 6

UFM Series 6

Q.Sonic-plus

Operation and Maintenance

Page 13 of 68

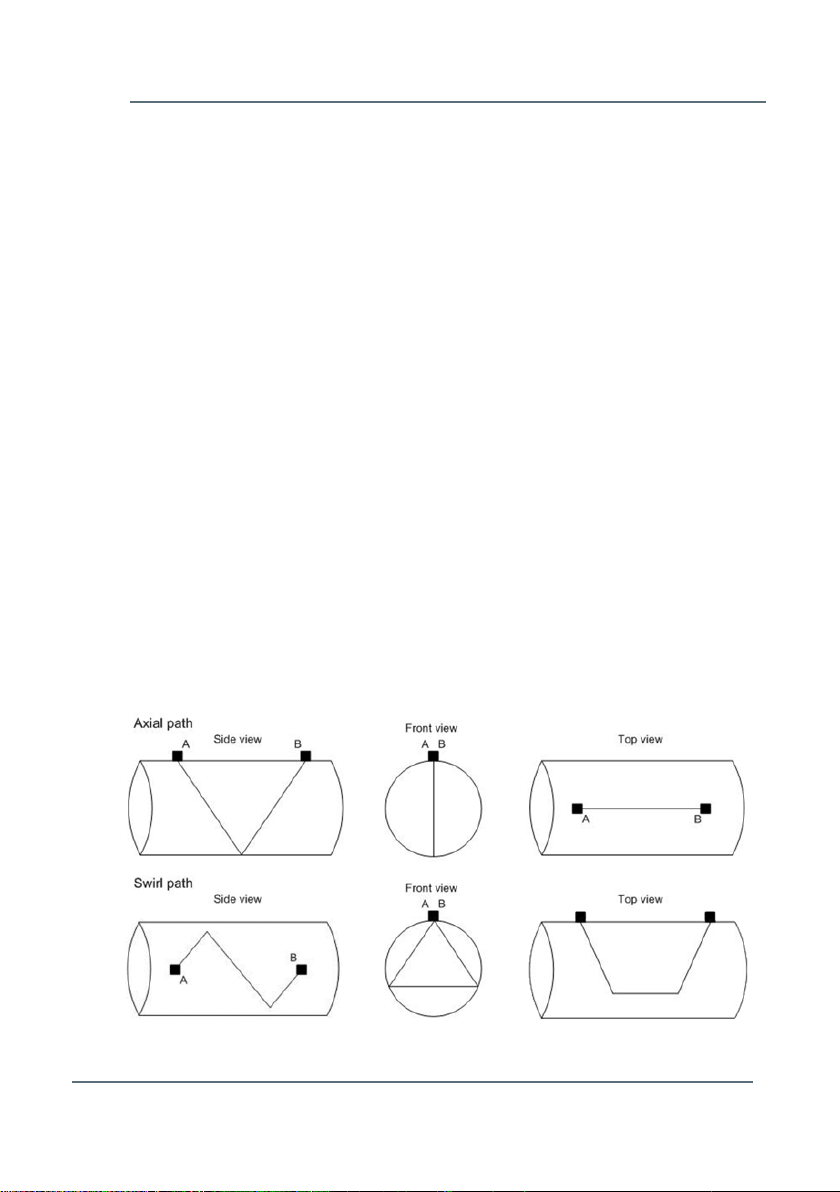

Figure 3-1: Path Types

3.2 Applicable Standards

The Ultrasonic Flow Meter Series 6 is manufactured to be in accordance

with European Directives: ATEX, PED, EMC and optionally MID.

If the meter is ordered for use at a location where European Directives are

NOT mandatory, the meter can alternatively be manufactured in compliance

with IECEx, FM Approval or CSA certificate for use in hazardous areas.

Applicable standards for the optional integrated flow computer functionality

are: AGA8-92 DC, SGERG-88, AGA-NX19 and ISO 6976.

3.3 Configuration

Several pairs of transducers are mounted in pairs on the flow cell of the

UFM. Each pair of transducers represents one individual measuring path.

There are two measuring path types on the Q.Sonic

and Swirl (double bounce). These are shown in Figure 3-1.

The Q.Sonic

plus

path layout consists of 2 axial paths and 4 swirl paths. This

combination results in a completely symmetrical path layout, ensuring the

most optimal accuracy. Figure 3-2 below shows the path layout of the

Q.Sonic

plus

.

plus

: Axial (single bounce)

Ultrasonic Flow Meter Series 6

3

Page 14 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

Q.Sonic

plus

Path Configuration

Top view:

Front view:

Trd. Path Nr:

Path Type:

1A / 1B

Swirl path (B1-CW*)

2A / 2B

Swirl path (B1-CCW**)

3A / 3B

Axial path (A1)

4A / 4B

Axial path (A2)

5A / 5B

Swirl path (B2-CW*)

6A / 6B

Swirl path (B2-CCW**)

Figure 3-2: Path Layout Q.Sonic

plus

* CW: Path travels clockwise through the pipe

** CCW: Path travels counter-clockwise through the pipe

3.4 Calibration

When using the UFM Series 6 Q.Sonic

most countries demand (by law) a calibration from a certified calibration

institute supervised by an inspector of weights and measures. Examples of

facilities generally used for calibrations are Euroloop in Rotterdam (NL),

TransCanada Calibrations in Canada and PIGSAR GH45 or Open Grid

European Dorsten (D).

plus

in custody transfer applications,

4

Theory of Operation

UFM Series 6

Q.Sonic-plus

Operation and Maintenance

Page 15 of 68

v

B

A

L

D

If the Q.Sonic

plus

meter has to be in accordance with MID, extra restrictions

should be taken into account. Please see Chapter 12.4 Calibration (p.64).

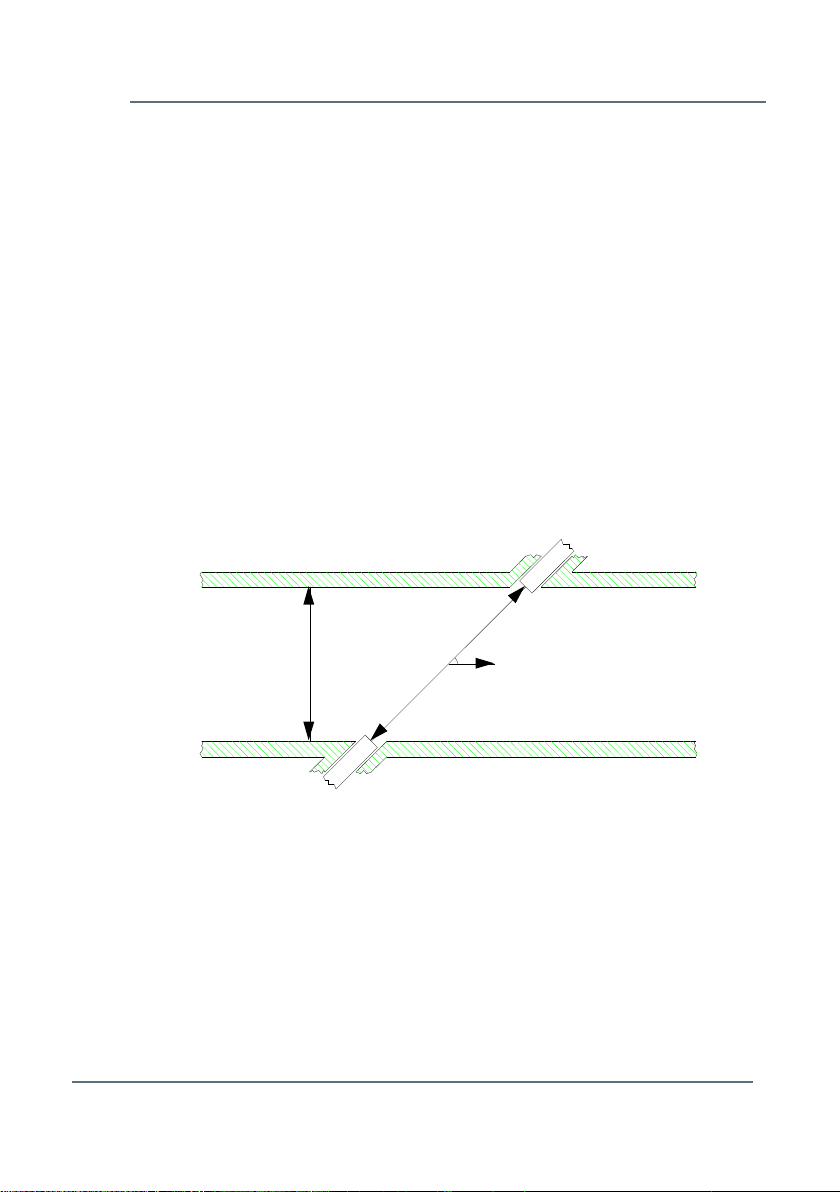

4 Theory of Operation

An ultrasonic flow meter is an inferential measurement device that consists

of ultrasonic transducers that are typically located along a pipe's wall. The

transducers are inserted into the piping using a gas tight mechanism.

Ultrasonic pulses are alternately transmitted by one transducer and received

by the other one.

Figure 4-1 shows a simple geometry of two transducers, ‘A’ and ‘B’, at a

sharp angle “” with respect to the axis of a straight cylindrical pipe with

diameter “D”. Please note: the Q.Sonic

paths, where the acoustic pulses reflect one or more times off the pipe wall.

plus

flow meter employs reflection

4.1 Flow Velocity Measurement

The acoustic pulses are crossing the pipe like a ferryman crossing a river.

Without flow, they propagate with the same speed in both directions. If the

gas in the pipe has a flow velocity different from zero, pulses travelling

downstream with the flow will move faster, while those travelling upstream

against the flow will move slower. Thus, the downstream travel times “tab“ will

Figure 4-1: Ultrasonic Measuring Line

Theory of Operation

4

Page 16 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

nnn

n

raw

tbatab

L

VoG

n

11

cos2

be shorter, while the upstream ones “tba“ will be longer as compared when

the gas is not moving. The equation below illustrates the computation:

where:

t

the downstream travel time of path n.

abn

t

the upstream travel time of path n.

ban

Ln the straight line length of the acoustic path between

the two transducers.

VoGraw is the average uncorrected (raw) gas velocity.

n the angle between the gas flow and ultrasonic signal.

The raw gas velocity is corrected by a Reynolds flow profile correction. This

correction is depending on the path type. Also the contribution of the gas

velocity of each path to the combined gas velocity is depending on the path

type.

4.2 Correction after Calibration

After flow calibration the meter can be adjusted either through an adjust

factor or through linearization. How the meter is adjusted can be visualized

at the display. Please see Chapter 7.1 LED at Display (p.33).

4

Theory of Operation

UFM Series 6

Q.Sonic-plus

Operation and Maintenance

Page 17 of 68

h

m

D

V

tAVQ

line

lineline

3

2

3600

4

4.3 Volume Flow at Line Conditions

The volume flow at line conditions Q

gas velocity V

multiplied by the internal cross section A of the flow cell:

line

where:

Q

the volume flow at line conditions

Line

V

the adjusted profile-corrected gas velocity

line

D the internal diameter of the meter

A the internal cross-section of the flow cell

t time coefficient to go from seconds to hours.

is the (adjusted) profile-corrected

Line

System Description

5

Page 18 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

Figure 5-1: Example of an Elster Ultrasonic Gas Flow Meter

SPU label

(rear side)

SPU

Temperature

Sensor

(rear side)

Main Type

Plate

Ultrasonic

Transducer

Flow Cell

Pressure

Connection

Pressure

Sensor

(optional)

5 System Description

5.1 Flow Cell

The flow cell is the part of the UFM Series 6 that is mounted in the piping

system. All components making the UFM Series 6 (SPU, transducers, type

plates, temperature sensor, and optional pressure sensor) are mounted on

the flow cell. Please see Figure 5-1 below.

5

System Description

UFM Series 6

Q.Sonic-plus

Operation and Maintenance

Page 19 of 68

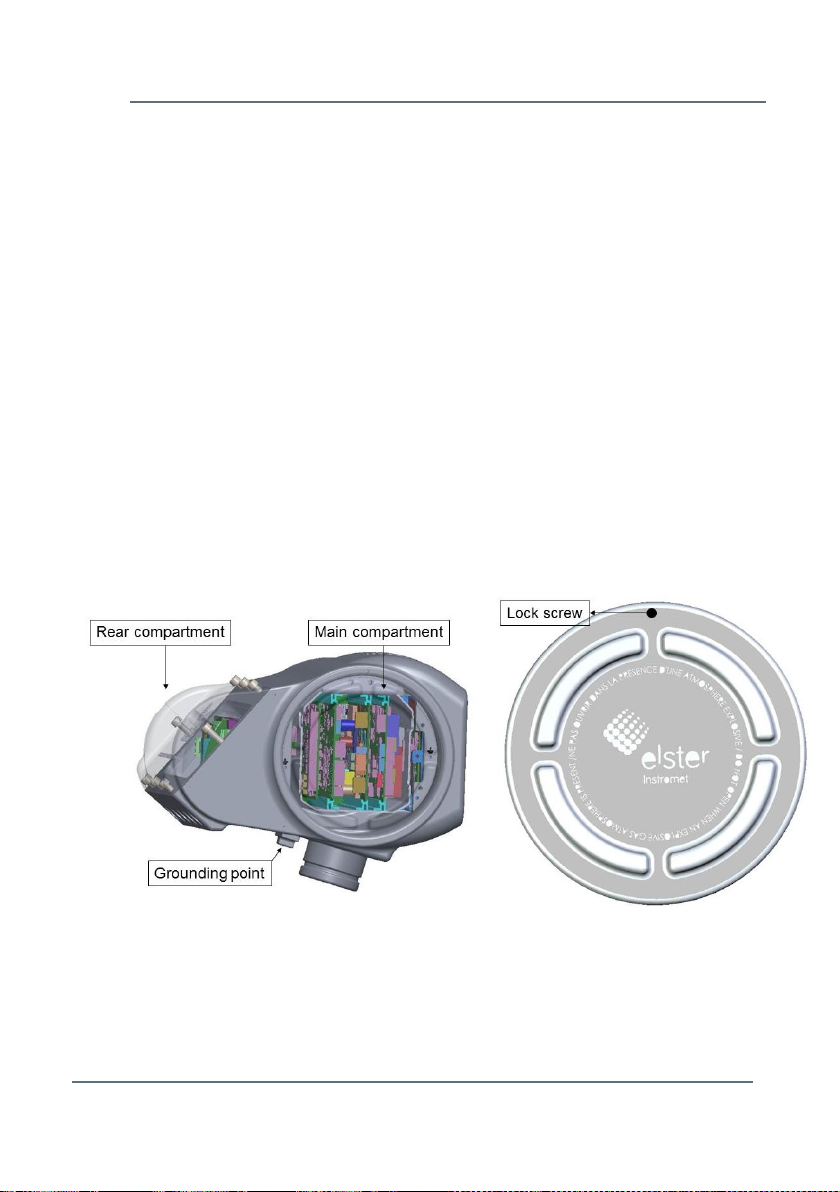

Figure 5-2: SPU Compartments and SPU Cover

5.2 Signal Processing Unit

The SPU is mounted in an explosion proof housing. The box consists of two

separate compartments; a main and a rear compartment (see Figure 5-2).

The main compartment can be opened from the side of the SPU and

contains the main circuit boards. The main compartment also comprises

intrinsically safe connections for the ultrasonic transducers and temperature

and optional pressure sensors. All data processing from excitation of the

transducers to calculating the flow rate is handled by the electronics in this

compartment.

To prevent the box from opening by vibration, the covers on the side need to

be firmly tightened and secured with the lock screw in the cover, as seen in

Figure 5-2. When closing the back compartment, ensure all screws are used.

A grounding point can be seen at the bottom of the SPU. As the meter is

already internally grounded, it is not necessary to use this grounding for

normal operation.

The rear compartment comprises of a field terminal board used for

connecting the Ultrasonic Flow Meter Series 6 to the end user’s applications.

For detailed information about this see Chapter 6.3 Wiring Instructions

(p.31).

System Description

5

Page 20 of 68

Operation and Maintenance

UFM Series 6

Q.Sonic-plus

Figure 5-3: NG Transducer

Figure 5-4: NG Transducer

with Mounting Bracket

5.3 Transducers

The ultrasonic signals required for the flow measurement are generated and

received by ultrasonic transducers.

Piezoelectric transducers employ crystals or ceramics that are set into

vibration when an alternating voltage is applied to the piezoelectric element.

The vibrating element generates sound waves in the gas. Since the

piezoelectric effect is reversible, the element will become electrically

polarised and produce voltages related to the mechanical strain, when the

crystal is distorted by the action of incident sound waves. Because the

acoustic impedance of the gas is much smaller compared to the acoustic

impedance of the piezoelectric element, and to maximise the acoustic

efficiency, a matching layer is employed between the gas and the

piezoelectric element.

The transducers used in the Ultrasonic Flow Meter Series 6 are type ‘NG’,

see Figure 5-3. Figure 5-4 visualises the NG transducer with the mounting

bracket.

5

System Description

UFM Series 6

Q.Sonic-plus

Operation and Maintenance

Page 21 of 68

CAUTION!

The pressure sensor is not used for volume conversion.

5.4 Flow Cell Pressure Sensor (Optional)

As an optional feature the UFM can be equipped with a pressure sensor.

This pressure sensor is used for:

Reynolds flow profile correction

Compensation of the flow cell expansion due to gas pressure.

5.5 Flow Cell Temperature Sensor

The UFM is equipped with a temperature sensor. The temperature sensor is

used for:

The Reynolds flow profile correction

Compensation of the flow cell expansion due to flow cell

temperature

Loading...

Loading...