Page 1

1800C and 1800C-HC Series Service Regulators

Technical Bulletin

Page 2

1800C and 1800C-HC Series Service Regulators 02 Elster American Meter

The 1800C Series pressure regulators are designed to control natural gas,

air, nitrogen, carbon dioxide, propane vapor, and other non-corrosive gases

in residential, light commercial, and small industrial applications.

General Information

Outlet pressures between 3.5" W.C.

and 2 PSIG are available. Operating

temperature range is -20°F to 150°F

(-30°C to 65°C). Maximum flow rate

is 2500 SCFH (70.8 m3/h).

All models conform to ANSI Code

B109.4-1998, and CGA Service-Type Regulator Specification CAN/CGA-6.18-M95.

Features

• Varietyofinterchangeableorifices

and spring ranges

• 90Degree(RightAngle),180Degree

(Straight-Flow),orOffsetValveBody

(See photo below)

• Widerangeofvalvebody

connection sizes

Options

VentElbow

The regulator vent opening should face

downward (6 o'clock) to minimize the

chance of blockage from ice and snow.

If not possible, a 3/4" NPT plastic, 90°

vent elbow (part number 78041P025) and

separate protective screen (part number

70400P017) may be screwed into the vent

to provide the necessary protection.

ElevationCompensation

TheE.C.orificeisrecommendedfor

installations where the inlet pressure

mayvaryoverawiderange.TheE.C.

orifice is available in two sizes: 1/8" x

3/16" and 3/16". The capacities of these

orifices are the same as the standard

orifice of the same size.

Applications

Model Number Description

1813C Basic regulator with full-capacity internal relief with

1813C-HC Basic regulator with full-capacity internal relief with

1843C Basic regulator with full-capacity internal relief and

1843C-HC Basic regulator with full-capacity internal relief and

1853C w/ USSA Basic regulator with full-capacity internal relief and

1853C-HC w/ USSA Basic regulator with full-capacity internal relief and

splashes while providing a large external

vent opening to keep regulators working

properly.

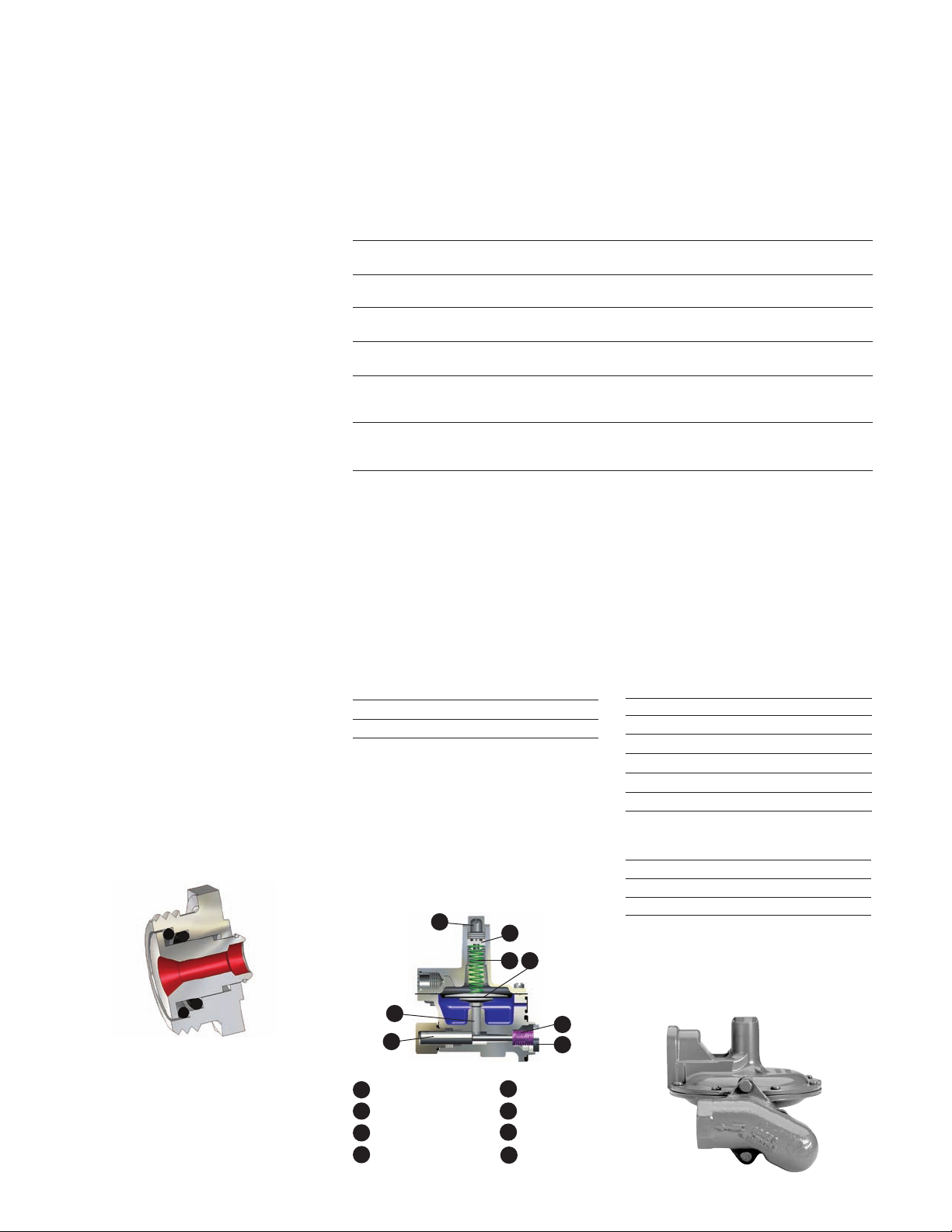

SafetyShutoffDevices

Overpressure Shutoff (OPSO) — Operates

independently. The OPSO will shut off

the gas supply in the event of a serious

downstream pressure build-up. These are

available in two pressure ranges on the

Models 1843C and 1843C-HC.

Spring Range Part Number

14" W.C. to 35" W.C. 71403P005

1 PSIG to 3 1/2 PSIG 71403P004

When the outlet pressure exceeds the

OPSO set point, the pressure under the

OPSO diaphragm (A) compresses the

pressure spring (B) forcing the diaphragm

stem(E)upwardsandreleasingplunger

(D).Thispermitstheshut-offspring(F)

to force the shut-off disc (G) against the

back side of the special double-ended

orifice.

C

H

B A

3/4" or 1" NPT vent.

3/4" or 1" NPT vent.

overpressure shut-off and 3/4" or 1" NPT vent.

overpressure shut-off and 3/4" or 1" NPT vent.

overpressure, underpressure shut-off and 3/4" or 1"

NPT vent.

overpressure, underpressure shut-off and 3/4" or 1"

NPT vent.

Universal Safety Shutoff Assembly

(USSA) — USSA protects the downstream

piping from both over- and under-pressure

conditions by shutting off the gas flow

at the inlet side of the regulator orifice.

Both Over- and under-pressure shut-off

set points are adjustable depending on

spring ranges selected.

USSA Shutoff Spring Ranges

Over Pressure Spring Ranges

Spring Range Part Number

7.5 - 24“ W.C. 70017P123

20 - 32” W.C. 70017P124

24 - 44” W.C. 70017P125

40 - 84” W.C. 70017P126

3 - 5 PSIG 70017P127

4 - 7 PSIG 70017P128

Under Pressure Spring Ranges

Spring Range Part Number

3 - 6“ W.C. 70017P133

6 - 24” W.C. 70017P134

24 - 60” W.C. 70017P135

Pressure Taps

1/8" NPT taps are available on most

valve heads.

FullCapacityReliefValve

Full capacity internal relief valve standard

on all models. (See Performance Graphs

on page 9)

Splashguards

UVstabilized,weather-resistant,resin

device that protects the vent screen from

E

D

A OPSODiaphragmPlate B Pressure Spring

C Cap D Plunger

E DiaphragmStem F Shut-off Spring

G Shut-offDisc H Adjusting Screw

F

G

OffsetValveBody

Page 3

1800C and 1800C-HC Series Service Regulators 03 Elster American Meter

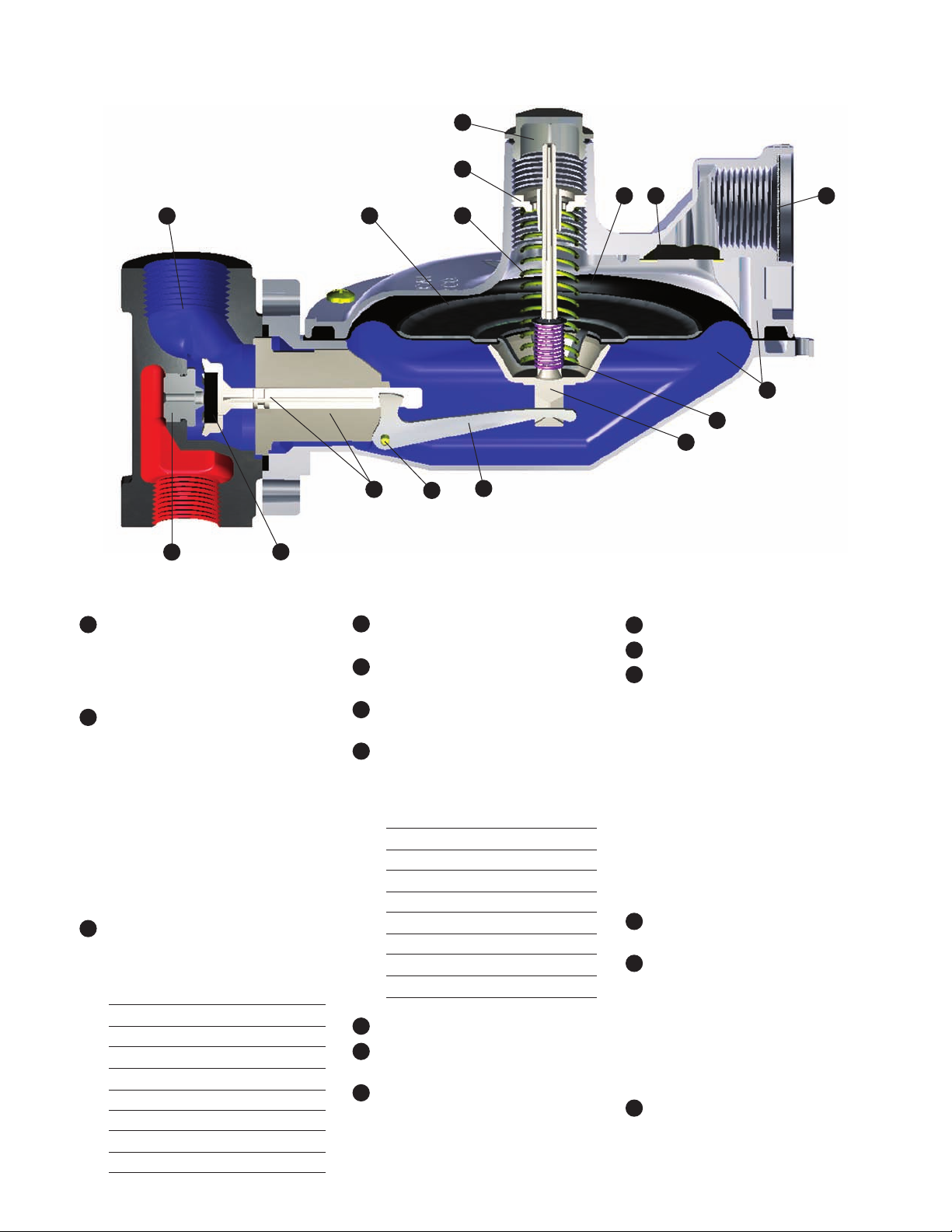

2

4

9

11

5 13

14

3

1

15

12

7

6

Material Specifications

1 Diaphragm Case - Precision die-cast

aluminum with an exclusive seven step advanced conversion coating,

single-coat polyester primer and

high solids polyurethane top coat.

2 Valve Body - Cast grey iron,

undercoated, single coat polyester

primer and high solids polyurethane

top coat. NPT threads meet ANSI/

ASME B1.20.1. BSP-TR threads meet

BS EN 10226.

Available sizes: 3/4” x 3/4”, 3/4” x 1”,

3/4” x 1-1/4”, 1” x 1”, 1” x 1-1/4” and

1-1/4” x 1-1/4” NPT or BSP-TR

Offset valve body: 3/4” x 3/4”,

3/4” x 1” and 1” x 1” NPT or BSP-TR

3 Pressure Spring - Steel, zinc plated

and yellow chromate. Color coded

for identification.

Outlet

Pressure

3.5" to 6" W.C. Blue 70017P043

3.5" to 7.5" W.C. Tan 70017P089

5.5" to 8.5" W.C. Yellow 70017P044

6" to 12" W.C. Brown 70017P137

6" to 15" W.C. Purple 70017P042

12" to 28" W.C. White 70017P060

24" to 48" W.C. Red 70017P082

42" W.C. to 2 PSIG Red - Red 70017P049

Color

Code

Part

Number

10

4 Diaphragm Plate - Steel,

16

8

Electrogalvanized.

5 Diaphragm - Buna N; Nylon

fabric reinforced.

6 Seat Disc - Buna N; 60, 70 (std.)

or 80 durometer rating.

7 Orifice Valve - High strength,

corrosion resistant aluminum.

Orifice

Size

9/16" 72494P026 72751P019

1/2" 72494P025 72751P016

3/8" 72494P023 72751P014

5/16" 72494P022 72751P013

1/4" 72494P021 72751P012

3/16" 72494P020 72751P011

1/8" x 3/16" 72494P030 72751P020

1/8" 72494P019 N/A

8 Lever - Stamped aluminum.

9 Seal Plug - Polyester thermoplastic

Standard

Part

Number

Part Number

with OPSO

UV stabilized.

10 Plunger Valve/Plunger Guide -

Minlon.

11 Pressure Adjustment Screw - Minlon.

12 Relief Valve Stem - Minlon.

13 Vent Screen - Stainless Steel -

All models are designed with a

removable weather and bug-proof

stainless steel screen to resist freeze ups and to exclude foreign matter.

The vent is threaded ¾” or 1”

NPT (BSP-TR threads available).

Inside installation requires a vent

line of sufficient diameter to carry

gas vented by the regulator to a

safe outside location away from

any opening(s) in the structure.

Comply with applicable Federal,

State and local codes.

14 Vent Valve - Stainless Steel with

Electrogalvanized steel retainer.

15 Relief Valve Spring - Steel, zinc

plated and yellow chromate.

Color coded for identification.

Non-adjustable, standard set point

of 8" w.c. above outlet set pressure

of 7" w.c. Standard set point of

1.3 PSIG above outlet set pressure

of 2 PSIG.

16 Lever Pin - Carbon steel, zinc plated

and yellow chromate.

Page 4

1800C and 1800C-HC Series Service Regulators 04 Elster American Meter

1800C Series Regulator Capacity Performance

3/4" Outlet

Set Point 7.0" W.C. (17.4 mbar)

at 50 SCFH

SCFH (m3/h) 0.60 specific gravity gas at

60°F and 14.7 PSIA (20°C and 1.01 bar).

Pressure spring 70017P044. Outlet

pressure variance not to exceed +2" -1" W.C.

from set point, horizontal position.

1800C Series Regulator Capacity SCFH (m3/h)

Inlet

PSIG

1/8" x 3/16"

(bar)

1

(0.07)

2

(0.14)

3

(0.21)

5

(0.34)

10

(0.70)

15

(1.00)

20

(1.40)

30

(2.10)

40

(2.80)

60

(4.10)

100

(6.90)

125

(8.60)

For optimum performance, maximum inlet pressure should not exceed maximum capacity rating for any given

orifice size.

Orifice

—

—

—

275

(7.8)

375

(10.6)

450

(12.7)

500

(14.2)

700

(19.8)

800

(22.7)

1100

(31.2)

1700

(48.1)

2100

(59.5)

3/16"

Orifice

175

(5.0)

300

(8.5)

375

(10.6)

500

(14.2)

750

(21.2)

950

(26.9)

1100

(31.2)

1400

(39.6)

1700

(48.1)

2300

(65.1)

2500

(70.8)

— — — — — —

1/4"

Orifice

250

(7.1)

425

(12.0)

500

(14.2)

700

(19.8)

1100

(31.2)

1400

(39.6)

1700

(48.1)

2000

(56.6)

2400

(68.0)

2500

(70.8)

2500

(70.8)

5/16"

Orifice

325

(9.2)

475

(13.5)

600

(17.0)

800

(22.7)

1200

(34.0)

1500

(42.5)

1700

(48.1)

2200

(62.3)

2500

(70.8)

2500

(70.8)

— — — —

3/8"

Orifice

350

(9.9)

550

(15.6)

700

(19.8)

950

(26.9)

1400

(39.6)

1600

(45.3)

1900

(53.8)

2400

(68.0)

2500

(70.8)

— — —

1/2"

Orifice

400

(11.3)

650

(18.4)

800

(22.7)

1000

(28.3)

1500

(42.5)

1900

(53.8)

2200

(62.3)

2500

(70.8)

— —

9/16"

Orifice

400

(11.3)

650

(18.4)

800

(22.7)

1200

(34.0)

1700

(48.1)

2000

(56.6)

2300

(65.1)

—

1" Outlet

Set Point 7.0" W.C. (17.4 mbar)

at 50 SCFH

SCFH (m3/h) 0.60 specific gravity gas at

60°F and 14.7 PSIA (20°C and 1.01 bar).

Pressure spring 70017P044. Outlet

pressure variance not to exceed +2" -1" W.C.

from set point, horizontal position.

1800C Series Regulator Capacity SCFH (m3/h)

Inlet

PSIG

1/8" x 3/16"

(bar)

1

(0.07)

2

(0.14)

3

(0.21)

5

(0.34)

10

(0.70)

15

(1.00)

20

(1.40)

30

(2.10)

40

(2.80)

60

(4.10)

100

(6.90)

125

(8.60)

For optimum performance, maximum inlet pressure should not exceed maximum capacity rating for any given

orifice size.

Orifice

—

—

—

250

(7.1)

350

(9.9)

425

(12.0)

500

(14.2)

600

(17.0)

750

(21.2)

1000

(28.3)

1600

(45.3)

2000

(56.6)

3/16"

Orifice

175

(5.0)

250

(7.1)

300

(8.5)

450

(12.7)

700

(19.8)

900

(25.5)

1100

(31.2)

1400

(39.6)

1700

(48.1)

2400

(68.0)

2500

(70.8)

— — — — — —

1/4"

Orifice

250

(7.1)

350

(9.9)

450

(12.7)

650

(18.4)

1000

(28.3)

1400

(39.6)

1700

(48.1)

2300

(65.1)

2500

(70.8)

2500

(70.8)

— — — — —

5/16"

Orifice

300

(8.5)

450

(12.7)

550

(15.6)

750

(21.2)

1400

(39.6)

1900

(53.8)

2300

(65.1)

2500

(70.8)

2500

(70.8)

— — — —

3/8"

Orifice

375

(10.6)

500

(14.2)

700

(19.8)

950

(26.9)

1600

(45.3)

2100

(59.5)

2500

(70.8)

2500

(70.8)

— — —

1/2"

Orifice

475

(13.5)

600

(17.0)

850

(24.1)

1200

(34.0)

1900

(53.8)

2500

(70.8)

2500

(70.8)

— —

9/16"

Orifice

500

(14.2)

650

(18.4)

950

(26.9)

1300

(36.8)

2000

(56.6)

2500

(70.8)

—

Page 5

1800C and 1800C-HC Series Service Regulators 05 Elster American Meter

1800C Series Regulator Capacity Performance

1-1/4" Outlet

Set Point 7.0" W.C. (17.4 mbar)

at 50 SCFH

SCFH (m3/h) 0.60 specific gravity gas at

60°F and 14.7 PSIA (20°C and 1.01 bar).

Pressure spring 70017P044. Outlet

pressure variance not to exceed +2" -1" W.C.

from set point, horizontal position.

1800C Series Regulator Capacity SCFH (m3/h)

Inlet

PSIG

1/8" x 3/16"

(bar)

1

(0.07)

2

(0.14)

3

(0.21)

5

(0.34)

10

(0.70)

15

(1.00)

20

(1.40)

30

(2.10)

40

(2.80)

60

(4.10)

100

(6.90)

For optimum performance, maximum inlet pressure should not exceed maximum capacity rating for any given

orifice size.

Orifice

— 200

— 325

— 425

275

(7.8)

375

(10.6)

450

(12.7)

550

(15.6)

700

(19.8)

800

(22.7)

1100

(31.2)

1400

(39.6)

3/16"

Orifice

(5.7)

(9.2)

(12.0)

550

(15.6)

850

(24.1)

1000

(28.3)

1200

(34.0)

1600

(45.3)

— — — — — —

— — — — — —

— — — — — —

1/4"

Orifice

325

(9.2)

500

(14.2)

650

(18.4)

1000

(28.3)

1500

(42.5)

1800

(51.0)

2100

(59.5)

— — — — —

5/16"

Orifice

350

(9.9)

600

(17.0)

950

(26.9)

1600

(45.3)

2400

(68.0)

2500

(70.8)

— — — —

3/8"

Orifice

375

(10.6)

700

(19.8)

1200

(34.0)

2100

(59.5)

2500

(70.8)

— — —

1/2"

Orifice

475

(13.5)

950

(26.9)

1700

(48.1)

2500

(70.8)

2500

(70.8)

9/16"

Orifice

500

(14.2)

1400

(39.6)

1900

(53.8)

2500

(70.8)

2500

(70.8)

3/4" Outlet

Set Point 2 PSIG (0.14 bar)

at 50 SCFH

SCFH (m3/h) 0.60 specific gravity gas at

60°F and 14.7 PSIA (20°C and 1.01 bar).

Pressure spring 70017P049. Outlet

pressure variance not to exceed +/- 10%

from set point, horizontal position.

1800C Series Regulator Capacity SCFH (m3/h)

Inlet

PSIG

1/8" x 3/16"

(bar)

3

(0.21)

5

(0.34)

10

(0.70)

15

(1.00)

20

(1.40)

30

(2.10)

40

(2.80)

60

(4.10)

100

(6.90)

125

(8.60)

For optimum performance, maximum inlet pressure should not exceed maximum capacity rating for any given

orifice size.

Orifice

150

(4.2)

250

(7.1)

375

(10.6)

450

(12.7)

550

(15.6)

700

(19.8)

850

(24.1)

1100

(31.2)

1700

(48.1)

2100

(59.5)

3/16"

Orifice

175

(5.0)

325

(9.2)

550

(15.6)

750

(21.2)

900

(25.5)

1200

(34.0)

1500

(42.5)

2100

(59.5)

2500

(70.8)

— — — — — —

1/4"

Orifice

300

(8.5)

450

(12.7)

700

(19.8)

900

(25.5)

1200

(34.0)

1500

(42.5)

2000

(56.6)

2500

(70.8)

— — — — —

5/16"

Orifice

325

(9.2)

525

(14.9)

825

(23.4)

1100

(31.2)

1300

(36.8)

1800

(51.0)

2200

(62.3)

— — — —

3/8"

Orifice

375

(10.6)

575

(16.3)

1000

(28.3)

1300

(36.8)

1600

(45.3)

2100

(59.5)

— — —

1/2"

Orifice

400

(11.3)

700

(19.8)

1200

(34.0)

1500

(42.5)

1900

(53.8)

— —

9/16"

Orifice

500

(14.2)

750

(21.2)

1300

(36.8)

1800

(51.0)

—

Page 6

1800C and 1800C-HC Series Service Regulators 06 Elster American Meter

1800C Series Regulator Capacity Performance

1" Outlet

Set Point 2 PSIG (0.14 bar)

at 50 SCFH

SCFH (m3/h) 0.60 specific gravity gas at

60°F and 14.7 PSIA (20°C and 1.01 bar).

Pressure spring 70017P049. Outlet

pressure variance not to exceed +/- 10%

from set point, horizontal position.

1800C Series Regulator Capacity SCFH (m3/h)

Inlet

PSIG

1/8" x 3/16"

(bar)

3

(0.21)

5

(0.34)

10

(0.70)

15

(1.00)

20

(1.40)

30

(2.10)

40

(2.80)

60

(4.10)

100

(6.90)

125

(8.60)

For optimum performance, maximum inlet pressure should not exceed maximum capacity rating for any given

orifice size.

Orifice

150

(4.2)

225

(6.4)

350

(9.9)

425

(12.0)

500

(14.2)

650

(18.4)

800

(22.7)

1100

(31.2)

1700

(48.1)

2100

(59.5)

3/16"

Orifice

225

(6.4)

350

(9.9)

600

(17.0)

800

(22.7)

1000

(28.3)

1300

(36.8)

1700

(48.1)

2500

(70.8)

2500

(70.8)

— — — — — —

1/4"

Orifice

250

(7.1)

450

(12.7)

750

(21.2)

1000

(28.3)

1200

(34.0)

1700

(48.1)

2200

(62.3)

2500

(70.8)

— — — — —

5/16"

Orifice

350

(9.9)

500

(14.2)

850

(24.1)

1100

(31.2)

1400

(39.6)

2000

(56.6)

2500

(70.8)

— — — —

3/8"

Orifice

425

(12.0)

650

(18.4)

1000

(28.3)

1400

(39.6)

1800

(51.0)

2500

(70.8)

— — —

1/2"

Orifice

550

(15.6)

750

(21.2)

1300

(36.8)

1700

(48.1)

2100

(59.5)

— —

9/16"

Orifice

550

(15.6)

900

(25.5)

1500

(42.5)

2000

(56.6)

—

1-1/4" Outlet

Set Point 2 PSIG (0.14 bar)

at 50 SCFH

SCFH (m3/h) 0.60 specific gravity gas at

60°F and 14.7 PSIA (20°C and 1.01 bar).

Pressure spring 70017P049. Outlet

pressure variance not to exceed +/- 10%

from set point, horizontal position.

1800C Series Regulator Capacity SCFH (m3/h)

Inlet

PSIG

1/8" x 3/16"

(bar)

3

(0.21)

5

(0.34)

10

(0.70)

15

(1.00)

20

(1.40)

30

(2.10)

40

(2.80)

60

(4.10)

100

(6.90)

125

(8.60)

For optimum performance, maximum inlet pressure should not exceed maximum capacity rating for any given

orifice size.

Orifice

150

(4.2)

225

(6.4)

350

(9.9)

425

(12.0)

500

(14.2)

650

(18.4)

800

(22.7)

1100

(31.2)

1700

(48.1)

2100

(59.5)

3/16"

Orifice

225

(6.4)

350

(9.9)

600

(17.0)

850

(24.1)

1000

(28.3)

1500

(42.5)

1900

(53.8)

2500

(70.8)

2500

(70.8)

— — — — — —

1/4"

Orifice

350

(9.9)

500

(14.2)

850

(24.1)

1200

(34.0)

1700

(48.1)

2500

(70.8)

2500

(70.8)

2500

(70.8)

— — — — —

5/16"

Orifice

375

(10.6)

600

(17.0)

1100

(31.2)

1600

(45.3)

2200

(62.3)

2500

(70.8)

2500

(70.8)

— — — —

3/8"

Orifice

425

(12.0)

700

(19.8)

1200

(34.0)

1900

(53.8)

2500

(70.8)

2500

(70.8)

— — —

1/2"

Orifice

550

(15.6)

900

(25.5)

1700

(48.1)

2500

(70.8)

2500

(70.8)

— —

9/16"

Orifice

550

(15.6)

1100

(31.2)

2200

(62.3)

2500

(70.8)

—

Page 7

1800C and 1800C-HC Series Service Regulators 07 Elster American Meter

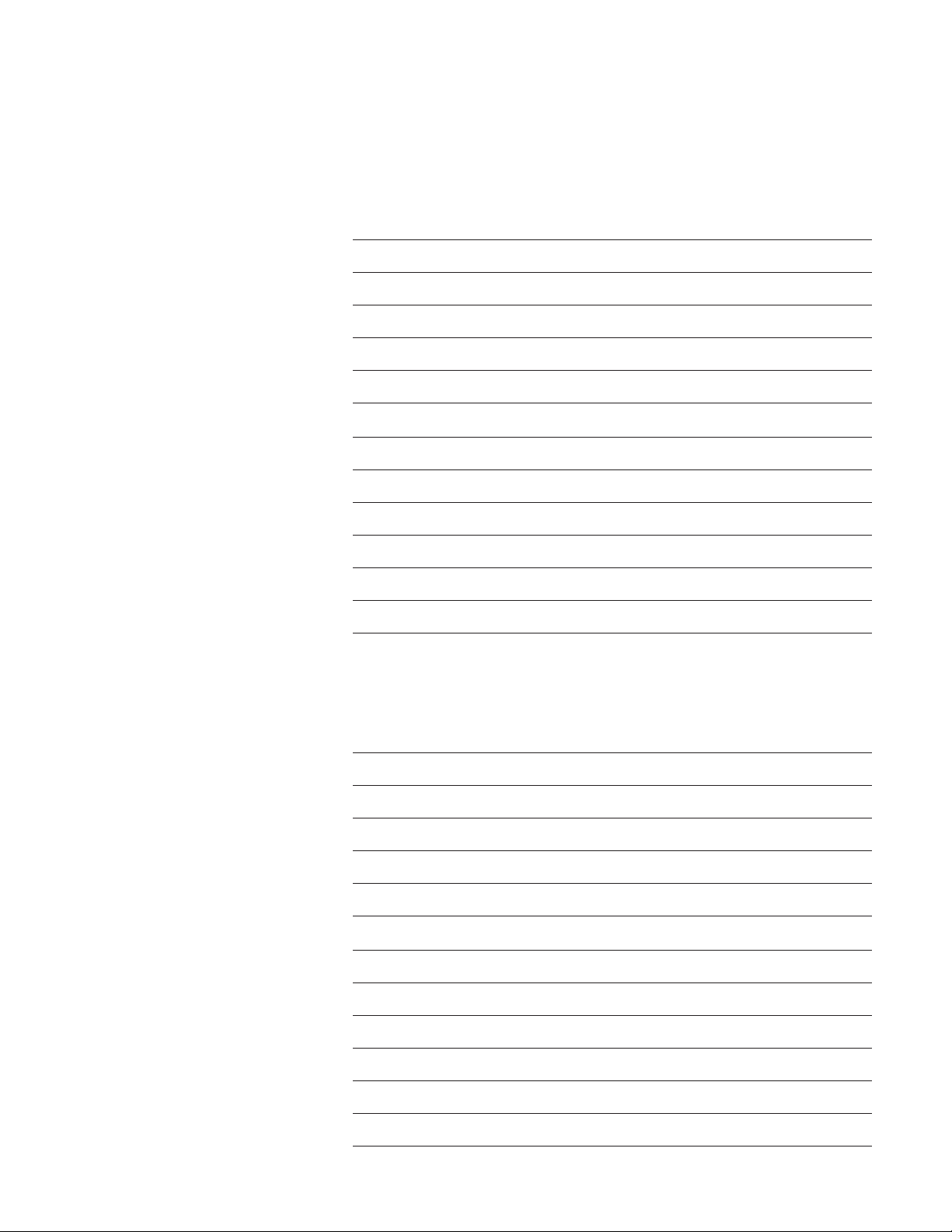

1800C-HC Series Regulators

Ideal for light commercial and industrial use, the 1-1/4"

1800C-HC Series regulator is designed to increase output

capacity during medium to high inlet pressure operations.

General Information

The 1800C-HC Series regulator’s

lightweight design features high-capacity

capabilities for 1-1/4" NPT connections

and flow capacities up to 4900 SCFH

depending on inlet pressure and orifice

selection. It complements the 1800C

Series family of regulators.

AC-630 Meter with 1813C-HC Regulator

1800C-HC Series Regulator

Capacity Performance

1-1/4" Outlet

Set Point 7.0" W.C. (17.4 mbar)

at 50 SCFH

SCFH (m3/h) 0.60 specific gravity gas at

60°F and 14.7 PSIA (20°C and 1.01 bar).

Pressure spring 70017P044. Outlet

pressure variance not to exceed +2" -1" W.C.

from set point, horizontal position.

1800C Series Regulator Capacity SCFH (m3/h)

Inlet PSIG

(bar)

(0.07)

(0.14)

(0.21)

(0.34)

(0.70)

(1.00)

(1.40)

(2.10)

(2.80)

(4.10)

(6.90)

(8.60)

For optimum performance, maximum inlet pressure should not exceed maximum capacity rating for any given

orifice size.

10

15

20

30

40

60

100

125

1/8" x 3/16"

Orifice

1

2

3

5

—

—

—

275

(7.8)

350

(9.9)

425

(12.0)

475

(13.5)

600

(17.0)

750

(21.2)

1100

(31.2)

1600

(45.3)

2000

(56.6)

3/16"

Orifice

175

(5.0)

275

(7.8)

350

(9.9)

450

(12.7)

600

(17.0)

950

(26.9)

1100

(31.2)

1500

(42.5)

1800

(51.0)

2500

(70.8)

3800

(107.6)

— — — — — —

1/4"

Orifice

200

(5.7)

350

(9.9)

450

(12.7)

700

(19.8)

1100

(31.2)

1300

(36.8)

1900

(53.8)

2500

(70.8)

3200

(90.6)

4400

(124.6)

— — — — —

5/16"

Orifice

250

(7.1)

450

(12.7)

600

(17.0)

850

(24.1)

1500

(42.5)

2300

(65.1)

2900

(82.1)

4000

(113.3)

4900

(138.8)

4900

(138.8)

3/8"

Orifice

350

(9.9)

525

(14.9)

750

(21.2)

1000

(28.3)

1600

(45.3)

2600

(73.6)

3400

(96.3)

4600

(130.3)

4900

(138.8)

— — —

1/2"

Orifice

475

(13.5)

675

(19.1)

800

(22.7)

1500

(42.5)

2500

(70.8)

3300

(93.5)

4200

(118.9)

4900

(138.8)

— —

9/16"

Orifice

525

(14.9)

800

(22.7)

1100

(31.2)

1600

(45.3)

2700

(76.5)

3300

(93.5)

3900

(110.4)

—

Page 8

1800C and 1800C-HC Series Service Regulators 08 Elster American Meter

1800C and 1800C-HC Series Service

Regulators - Other Technical Data

Full-Open Regulator

Relief Capacity

For sizing downstream relief valves,

use the following formulas to determine

the regulator full-open capacity:

Critical flow rates Sub-critical flows

P

Q = 0.5 C x Q = C x

Critical flow occurs when the absolute

outlet pressure is less than about 1/2

of the absolute inlet pressure.

Q Maximum capacity of regulator

C Orifice constant (see table below)

P1 Inlet absolute pressure (PSIA)

P2 Outlet absolute pressure (PSIA)

h Differentialpressure

G Specific gravity of gas

1

√G

√P2h

√G

Orifice Constants

Orifice C

1/8" 25

1/8" x 3/16" 25

3/16" 57

1/4" 98

5/16" 149

3/8" 208

1/2" 353

9/16" 421

Maximum Recommended

Maximum Recommended

Inlet Pressure

Inlet Pressure

Orifice Size Inlet Pressure (PSIG)

9/16" 20

1/2" 50

3/8" 70

5/16" 125

1/4" 125

3/16" 125

1/8" x 3/16" 125

1/8" 125

This is the maximum inlet the regulator should operate

at to insure complete lockup at no-flow conditions.

Other Gas Capacities

To determine the capacity of these regulators for gases other than natural gas, multiply

the values within the capacity tables by a Specific Gravity Conversion Factor (Fg). The

table below lists this factor for some of the more common gases.

Gas Type Specific Gravity Conversion Factor (Fg)

Air 1.00 0.77

Butane 2.01 0.55

CarbonDioxide 1.52 0.63

Nitrogen 0.97 0.79

Propane 1.53 0.63

To calculate the Conversion Factor for other gases:

(Fg) =

Example:Ifusingpropaneandonlyhavingtablesbasedonnaturalgas,

the Specific Gravity Conversion Factor is :

(Fg) =

(Fg) =

(Fg) = 0.626

Specific gravity of gas on which the capacity table is based

√

Specific gravity of natural gas (0.6)

Specific gravity of propane (1.53)

√

0.60

1.53

√

Specific gravity of gas being used

Regulator Pressure Rating

125 PSIG (8.6 bar) = Maximum recommended inlet pressure for normal service.

Maximum recommended pressure may vary with orifice size.

175 PSIG (12 bar) = Maximum inlet pressure for abnormal or emergency service,

without causing damage to regulator case.

2 PSIG (138 mbar) = Maximum outlet pressure for normal service.

10 PSIG (689 mbar) = Maximum outlet pressure which can be contained by pressure

carrying components (no flange leakage to atmosphere except for normal relief action).

If regulator is subjected to these conditions, it should be removed from service.

50 PSIG (3.5 bar) = Maximum outlet pressure for abnormal service without damage to

internal components. If regulator is subjected to these conditions, it should be removed

from service.

Page 9

1800C and 1800C-HC Series Service Regulators 09 Elster American Meter

90

(224)

80

(199)

70

(174)

60

(149)

50

(124)

40

(100)

30

(75)

20

(50)

10

(25)

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130

(.7) (1.4) (2.1) (2.8) (3.4) (4.1) (4.8) (5.5) (6.2) (6.9) (7.6) (8.3) (9.0)

9/16” 3/8” 1/4” 1/8“ x 3/16”

1/2” 5/16” 3/16”

Outlet Pressure - Inches W.C. (mbar)

Inlet Pressure - PSIG (bar)

9

(.62)

8

(.55)

7

(.48)

6

(.41)

5

(.34)

4

(.26)

3

(.21)

2

(.14)

1

(.07)

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130

(.7) (1.4) (2.1) (2.8) (3.4) (4.1) (4.8) (5.5) (6.2) (6.9) (7.6) (8.3) (9.0)

9/16” 3/8” 1/4” 1/8“ x 3/16”

1/2” 5/16” 3/16”

Outlet Pressure - PSIG (bar)

Inlet Pressure - PSIG (bar)

9

(.62)

8

(.55)

7

(.48)

6

(.41)

5

(.34)

4

(.26)

3

(.21)

2

(.14)

1

(.07)

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130

(.7) (1.4) (2.1) (2.8) (3.4) (4.1) (4.8) (5.5) (6.2) (6.9) (7.6) (8.3) (9.0)

9/16” 3/8” 1/4” 1/8“ x 3/16”

1/2” 5/16” 3/16”

Outlet Pressure - PSIG (bar)

Inlet Pressure - PSIG (bar)

90

(224)

80

(199)

70

(174)

60

(149)

50

(124)

40

(100)

30

(75)

20

(50)

10

(25)

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130

(.7) (1.4) (2.1) (2.8) (3.4) (4.1) (4.8) (5.5) (6.2) (6.9) (7.6) (8.3) (9.0)

9/16” 3/8” 1/4” 1/8“ x 3/16”

1/2” 5/16” 3/16”

Outlet Pressure - Inches W.C. (mbar)

Inlet Pressure - PSIG (bar)

1800C and 1800C-HC Series Service Regulators

RegulatorReliefValvePerformance

There are several methods of measuring the relief performance of a regulator.

The worst case scenario will occur when the lever is disconnected. The data

presented in the tables below represent this condition.

Outlet Pressure Relative to Inlet Pressure

3/4"ScreenedVent–NoVentPipeSetPressure7"W.C.

1"ScreenedVent–NoVentPipeSetPressure7"W.C.

3/4"ScreenedVent–NoVentPipeSetPressure2PSIG

2 PSIG

1 PSIG

2 PSIG

1 PSIG

1"ScreenedVent–NoVentPipeSetPressure2PSIG

Page 10

1800C and 1800C-HC Series Service Regulators 10 Elster American Meter

C

F

D

E

A

B

C

F

D

E

A

B

C

F

D

E

A

B

C

F

D

E

A

B

1800C and 1800C-HC Series

Service Regulator Dimensions

C

F

D

E

A

B

Model 1813C - 90°

Inlet Outlet A B C D E F

3/4" 3/4" 1-9/16"

39.7mm

3/4" 1" 1-9/16"

39.7mm

1" 1" 1-9/16"

39.7mm

8-7/8"

225.4mm

8-7/8"

225.4mm

8-7/8"

225.4mm

7-1/4"

184.2mm

7-1/4"

184.2mm

7-1/4"

184.2mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

3-5/8"

92.1mm

3-5/8"

92.1mm

3-5/8"

92.1mm

Model 1813C and 1813C-HC - 180°

C

F

D

E

A

B

Inlet Outlet A B C D E F

3/4" 3/4" 1"

25.4mm

3/4" 1" 1"

25.4mm

1" 1" 1"

25.4mm

1" 1-1/4" 1-1/8"

28.6mm

1-1/4" 1-1/4" 1-1/8"

28.6mm

3/4" 1-1/4" 1-1/8"

28.6mm

8-7/8"

225.4mm

8-7/8"

225.4mm

8-7/8"

225.4mm

8-7/8"

225.4mm

8-7/8"

225.4mm

8-7/8"

225.4mm

7-1/4"

184.2mm

7-1/4"

184.2mm

7-1/4"

184.2mm

7-1/4"

184.2mm

7-1/4"

184.2mm

7-1/4"

184.2mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

92.1mm

92.1mm

92.1mm

92.1mm

92.1mm

92.1mm

3-5/8"

3-5/8"

3-5/8"

3-5/8"

3-5/8"

3-5/8"

C

F

D

E

A

B

Model 1813C - Offset

Inlet Outlet A B C D E F

3/4" 3/4" 1"

25.4mm

3/4" 1" 1"

25.4mm

1" 1" 1"

25.4mm

8-7/8"

225.4mm

8-7/8"

225.4mm

8-7/8"

225.4mm

7-1/4"

184.2mm

7-1/4"

184.2mm

7-1/4"

184.2mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

3-5/8"

92.1mm

3-5/8"

92.1mm

3-5/8"

92.1mm

Model 1843C and 1843C-HC

C

D

E

A

F

B

Inlet Outlet A B C D E F

3/4" 3/4" 4-1/2"

114.3mm

3/4" 1" 4-1/2"

114.3mm

1" 1" 4-1/2"

114.3mm

1" 1-1/4" 4-1/2"

114.3mm

1-1/4" 1-1/4" 4-1/2"

114.3mm

8-15/16"

227.0mm

8-15/16"

227.0mm

8-15/16"

227.0mm

8-15/16"

227.0mm

8-15/16"

227.0mm

7-1/4"

184.2mm

7-1/4"

184.2mm

7-1/4"

184.2mm

7-1/4"

184.2mm

7-1/4"

184.2mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

4-1/8"

104.8mm2"50.8mm

92.1mm

92.1mm

92.1mm

92.1mm

92.1mm

3-5/8"

3-5/8"

3-5/8"

3-5/8"

3-5/8"

Page 11

1800C and 1800C-HC Series Service Regulators 11 Elster American Meter

Standard

Vent Position

Standard

Vent Position

2

4

31

2

4

31

Standard

Vent Position

Valve Head Position "D"

Standard

Vent Position

Valve Head Position "C"

Valve Head Position "B"

Valve Head Position "A"

4

2

1

3

2

4

31

Standard

Vent Position

Valve Head Position "D"

1

3

2

4

Standard

Vent Position

4

2

1

3

Valve Head Position "B"

Standard

Vent Position

2

4

3

1

Valve Head Position "A"

Standard

Vent Position

Valve Head Position "C"

2

4

3

1

Standard

Vent Position

VENT

Valve Head Position "D"

2

4

3

1

Regulator Assembly Positions

180° Models

AC-250 Meter with 1813C Regulator

90° Models

Offset Models

ExampleofRegulator

Assembly Position

In the photo above the 1813C Regulator

shown has an 180 degree valve head in

Position "C" (Flow upward) with the vent in

position 2 (Looking down). This would be

assembly position C2.

Ordering Information

1 Model number

2 Size of inlet and outlet

3 Inlet pressure, PSIG (bar)

4 Outlet pressure, inches w.c.

(mbar) or PSIG (bar)

5 Flow, scfh (m3/h)

6 Kind and specific gravity of gas

7 Orifice size

8 Regulator assembly position

number

9 Possible variation in inlet pressure

forE.C.Orificemodels

Maximum ___ PSIG (bar)

Minimum ___ PSIG (bar)

Shipping Weight

17.5 lbs/carton of four regulators

Page 12

AboutElsterGroup

A world leader in advanced metering

infrastructure, integrated metering, and

utilization solutions to the gas, electricity

andwaterindustries,Elster’ssystems

and solutions reflect over 170 years of

knowledge and experience in measuring

precious resources and energy.

Elsterprovidessolutionsandadvanced

technologies to help utilities more easily,

efficiently and reliably obtain and use

advanced metering intelligence to

improve customer service, enhance

operational efficiency, and increase

revenues.Elster'sAMIsolutionsenable

utilities to cost-effectively generate, deliver,

manage, and conserve the life-essential

resources of gas, electricity, and water.

Elsterhasover7,500staffand

operations in 38 countries in North

andSouthAmerica,Europe,andAsia.

ElsterAmericanMeter

2221 Industrial Road

NebraskaCity,NE68410

USA

T +1 402 873 8200

F +1 402 873 7616

www.elster-americanmeter.com

ElsterCanadianMeter

T +1 519 650 1900

F +1 519 650 1917

www.elster-canadianmeter.com

©2008ElsterAmericanMeter.Allrightsreserved

Information contained herein is subject to change

without notice. Product specifications may change.

ContactyourElsterAmericanMeterrepresentative

for the most current product information. Printed in

the United States.

EAM-TB8515.11-EN-P-June2008

SupersedesEAM-TB8515.10-EN-P

Loading...

Loading...