Page 1

SB-8510.4

Measurement Engineers Since 1836

www.americanmeter.com

1800B2 & 1800B2-HC

Service Regulators

Maximum Inlet Pressure 125 PSIG

Dutch Council

for Accreditation

AMC Quality System

QMI is Accredited by:

ISO 9001 Certified

Certificate #006697

ANSI RAB

A

C

C

R

E

D

I

T

E

D

R

E

G

I

S

T

R

A

R

Page 2

against downstream overpressure. Models 1853B2 and

1893B2 also include an underpressure shut-off (UPSO)

that provides protection in the event of an upstream failure.

Valve body configuration permits the 1800B2 Series regulators to be supplied in four positions as specified on page

7. All Series 1800B2 regulators are available with either

right angle (90 degree) or straight flow (180-degree)

valve bodies. Vents can also be supplied in four

different positions.

All models are designed with an extra large, removable

weather and bug-proof stainless steel screened vent to

resist freeze-ups and to exclude foreign matter.The vent is

threaded 3/4 or 1 inch NPT and is also available with BSPTR threads making it suitable for indoor installations.

Options

Vent Elbow- The regulator vent opening should face downward (6 o'clock)to minimize the chance of blockage from

ice and snow. If not, a 3/4" NPT plastic, 90˚ vent elbow

(Part number 78041P025) and separate protective screen

(Part number 70400P017) may be screwed into the vent to

provide the necessary protection.

Elevation Compensation- E.C. orifices are also available,

which provide constant outlet pressure even when inlet

pressure fluctuates greatly. The elevation compensation

orifice is a device which reduces changes in regulator

outlet pressure due to change in inlet pressure.

The E.C.orifice is recommended for installations where the

inlet pressure may vary over a wide range.The E.C. orifice

is available in two sizes: 1/8" x 3/16" (Part number

73698G006) and 3/16" (Part number 73698G005). Its

capacity is the same as a standard orifice of the same size.

Consult your American Meter Sales Representative for

specific applications.

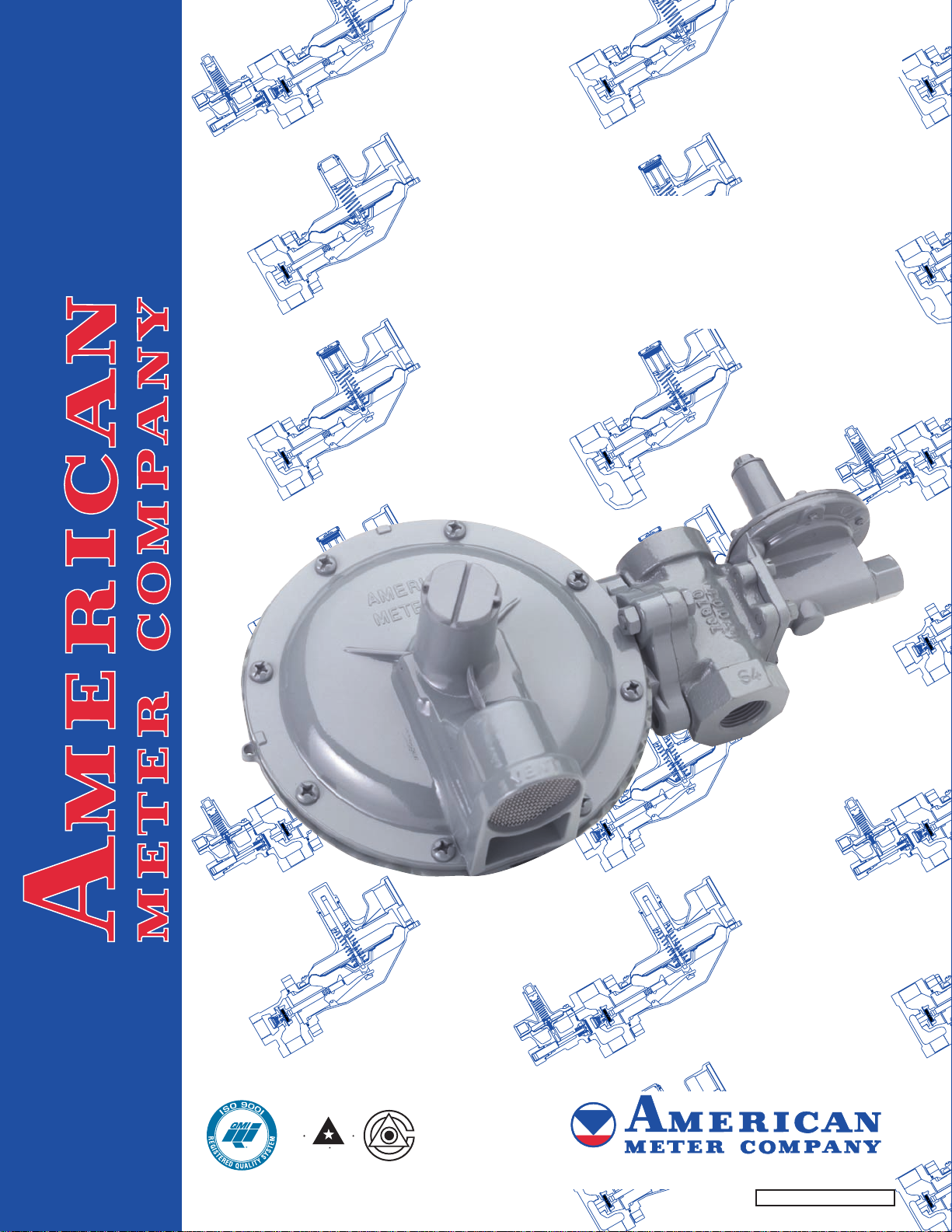

① AC-250 Meter ➁ 1813B2 Regulator

2

1800B2 Service Regulators

➁

➀

General Information

The American Meter Series 1800B2 pressure regulators are

designed for natural gas applications and features a compact, lightweight design for fast, easy installation.

Interchangeable orifices and springs provide a wide range

of outlet pressures and flow rates.Outlet pressures between

3.5" W.C. and 2 PSIG are available. Operating temperature

range is -20˚ F to 150˚ F (-30˚C to 65˚C). Maximum flow rate

is 2500 SCFH (70.8 m3/h).

The diaphragm case may be easily removed for routine

inspection without disturbing the line connections. All models conform to ANSI Code B109.4-1998, and CGA Servicetype Regulator Specification CAN/CGA-6.18-M95.

Exclusive, 7 - Step Corrosion

Protection

The protective finish on the Series 1800B2 regulators

resists corrosive effects of weather and harsh environments better than any other in the industry. Each precision

die cast aluminum regulator is treated-inside and out-with a

special conversion coating that's part of an exclusive, 7step finishing process.This coating greatly inhibits oxidation

of the metal's surface that can eventually compromise the

integrity of the metal. It also prevents finish paint from

cracking and blistering.

A single coat polyester primer and the high solid

polyurethane top coat provides a long-lasting protection to

all exterior regulator surfaces.The American Meter conversion coating process meets all environmental protection

regulations.

High Tensile Strength Valve Bodies

Each Series of 1800B2 regulator is equipped with a high

tensile strength cast iron valve body that rotates in 90degree increments and features extr a hea vy w all thic kness.

This provides maximum strength to withstand installation

stresses without damage and prevents thread galling

experienced with aluminum.

Series 1800B2 regulator valve bodies are treated with a 5step metal finishing process. The treated metal is painted

with a single coat polyester paint.

Available valve body sizes are: 3/4" x 3/4", 3/4" x 1",

3/4" x 1-1/4", 1" x 1", 1" x 1-1/4" and 1-1/4" x 1-1/4" NPT or

BSP-TR. Also available is a offset valve body in 3/4" x

3/4", 3/4" x 1" and 1" x 1" NPT or BSP-TR.

Application

Models 1813B2, 1833B2, 1843B2 and 1853B2 features a

full capacity internal relief valve with large passages to

assure the fast release of gas (See performance graphs on

page 6). For added protection, a relief valve stop is provided to assure operation under the most severe conditions.

The standard relief spring setting is 8.0" W.C. above the

normal 7" W.C. outlet pressure.

Models 1843B2, 1853B2, 1883B2 & 1893B2 are equipped

with overpressure shut-off (OPSO) that provides protection

Page 3

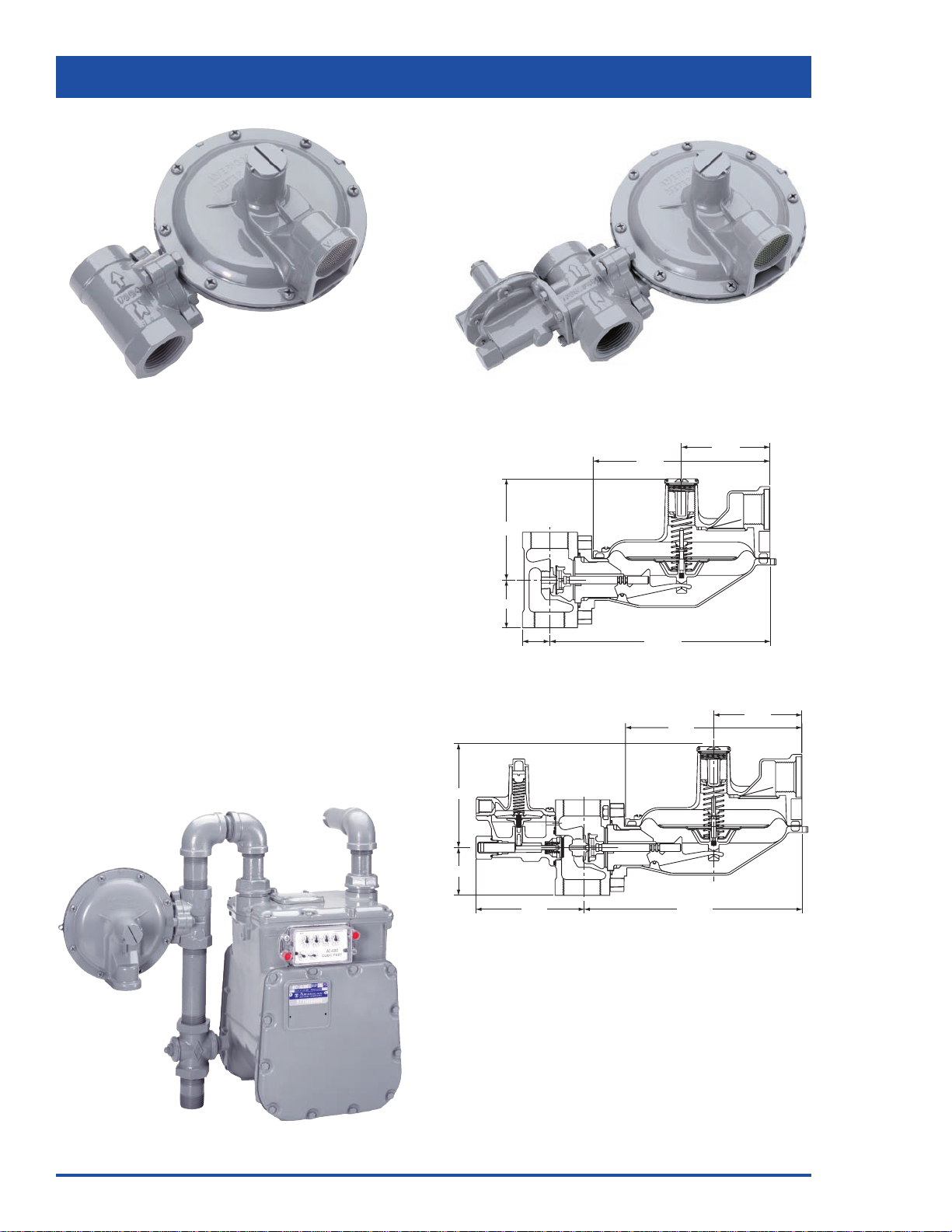

1813B2-HC-180˚ Dimensions

1843B2-HC Dimensions

3

1800B2-HC Service Regulators

General Information

Ideal for light commercial and industrial use, the 1-1/4"

1800B2-HC Series regulator is designed to increase output

capacity and lessen compounding during medium- to highinlet pressure operations. Compounding usually occurs

when a larger valve body introduces undesirable flow

characteristics, thereby creating an inefficient, boosting

effect in the outlet port of the body.

The 1800B2-HC regulator’s lightweight design features

high-capacity capabilities for 1-1/4" NPT connections and

flow capacities up to 4600 SCFH depending on inlet

pressure and orifice selection. It complements the 1800B2

Series family of regulators.

A lightweight regulator designed to increase capacity output and minimize the outlet boosting effect that is typical

from a larger valve body.

All models conform to ANSI Code B109.4-1998 and CGA

Service-type Regulator Specification CAN/CGA-6.18-M95.

① AC-630 Meter ➁ 1813B2-HC Regulator

1-3/16"

2"

1-15/16"

4-1/8"

7-1/4"

3-5/8"

3-5/8"

7-1/4"

4-1/8"

2"

4-1/2"

8-15/16"

1813B2-HC 1843B2-HC

➀

➁

Page 4

4

Inlet Outlet A B C D E F

3/4" 3/4" 4-1/2" 8-15/16" 7-1/4" 5-1/8" 2" 3-5/8"

3/4" 1" 4-1/2" 8-15/16" 7-1/4" 5-1/8" 2" 3-5/8"

1" 1" 4-1/2" 8-15/16" 7-1/4" 5-1/8" 2" 3-5/8"

1" 1-1/4" 4-1/2" 8-15/16" 7-1/4" 5-1/8" 2" 3-5/8"

1-1/4" 1-1/4" 4-1/2" 8-15/16" 7-1/4" 5-1/8" 2" 3-5/8"

AE

Inlet Outlet 90˚* 180˚* Offset B C D E Offset F

3/4" 3/4" 1-9/16" 1" 1” 8-7/8" 7-1/4" 5-1/8" 2" 2” 3-5/8"

3/4" 1" 1-9/16" 1" 1” 8-7/8" 7-1/4" 5-1/8" 2" 2” 3-5/8"

1" 1" 1-9/16" 1" 1" 8-7/8" 7-1/4" 5-1/8" 2" 2" 3-5/8"

1" 1-1/4" — 1-1/8" — 8-7/8" 7-1/4" 5-1/8" 2" — 3-5/8"

1-1/4" 1-1/4" — 1-1/8" — 8-7/8" 7-1/4" 5-1/8" 2" — 3-5/8"

3/4" 1-1/4" — 1-1/8" — 8-7/8" 7-1/4" 5-1/8" 2" — 3-5/8"

*1833B2 Only

1800B2 Service Regulators

Dimensions Model 1843B2 & 1883B2

Model 1803B2-180˚ Model 1813B2-180˚

Model 1813B2-Offset Model 1843B2

Model 1883B2 Not Shown

Model 1833B2-90˚ Model 1853B2

Model 1823B2 Not Shown Model 1893B2 Not Shown

Dimensions Model 1803B2 & 1813B2

Inlet Outlet A B C D E F

3/4" 3/4" 4-1/2" 8-15/16" 7-1/4" 4-1/8" 2" 3-5/8"

3/4" 1" 4-1/2" 8-15/16" 7-1/4" 4-1/8" 2" 3-5/8"

1" 1" 4-1/2" 8-15/16" 7-1/4" 4-1/8" 2" 3-5/8"

1" 1-1/4" 4-1/2" 8-15/16" 7-1/4" 4-1/8" 2" 3-5/8"

1-1/4" 1-1/4" 4-1/2" 8-15/16" 7-1/4" 4-1/8" 2" 3-5/8"

Dimensions Model 1853B2 & 1893B2

Dimensions Model 1823B2 & 1833B2

A

B

C

F

D

E

F

C

B

D

E

A

C

D

A

B

F

E

C

F

B

A

E

D

F

A

B

D

C

E

F

C

D

B

A

E

AE

Inlet Outlet 90˚*180˚* Offset B C D E Offset F

3/4" 3/4" 1-9/16" 1" 1” 8-7/8" 7-1/4" 4-1/8" 2" 2” 3-5/8"

3/4" 1" 1-9/16" 1" 1” 8-7/8" 7-1/4" 4-1/8" 2" 2” 3-5/8"

1" 1" 1-9/16" 1" 1" 8-7/8" 7-1/4" 4-1/8" 2" 2" 3-5/8"

1" 1-1/4" — 1-1/8" — 8-7/8" 7-1/4" 4-1/8" 2" — 3-5/8"

1-1/4" 1-1/4" — 1-1/8" — 8-7/8" 7-1/4" 4-1/8" 2" — 3-5/8"

3/4" 1-1/4" — 1-1/8" — 8-7/8" 7-1/4" 4-1/8" 2" — 3-5/8"

*1813B2 Only

Page 5

5

Overpressure Shut-off Regulators

Overpressure Shut-off (OPSO)

Regulators

Models 1843B2, 1843B2-HC, 1853B2, 1883B2, 1883B2-HC

and 1893B2 regulators are compact units designed to regulate line pressure and to provide protection against any

downstream overpressure.

Rugged, Compact OPSO - Operates independently. The

OPSO will shut-off the gas supply in the event of a serious

downstream pressure build-up.

Adjustable Overpressure Shut-off - Pressure is adjustable

via the overpressure shut-off adjustment screw to settings

from 14" to 35" W.C.and 1 to 3-1/2 PSIG depending on spring

selected.

Extra Safety - Models 1843B2, 1843B2-HC and 1853B2

provide added protection by incorporating a full capacity relief

valve.This inter nal valve is the same as in the 1813B2 and

1813B2-HC and operates in the same manner to combine

safety features.

How The OPSO Operates

When the outlet pressure exceeds the OPSO set point, the

pressure under the OPSO diaphragm (A) compresses the

pressure spring (B) forcing the diaphragm stem (E) upwards

and releasing plunger (D).This permits the shut-off spring (F)

to force the shut-off disc (G) against the back side of the

special double ended orifice.

Shut-off Assembly Adjustable Trip Point Range

72978G070 14" to 35" W.C.

72978G071 1 to 3-1/2 PSIG

Note: When selecting the shut-off spring range, a

differential of 14" W.C. above the normal operating pressure

and the shut-off pressure is recommended for normal line

pressure variations. The OPSO setting is preset at the

factory to the desired trip point.

To reset the OPSO simply unscrew cap (C), pull back the

plunger (D) until the diaphragm stem (E) repositions.

B

D

C

A

G

F

E

Overpressure Shut-off

Tripped Position

1800B2 & 1800B2-HC Service Regulators

For sizing downstream relief valves, use

the following formulas to determine the

regulator full open capacity:

For critical flow rates For sub-critical flows

Key:

Q = Maximum capacity of regulator

C = Or ifice constant, see table

P

1

= Inlet absolute pressure (PSIA)

P

2

= Outlet absolute pressure (PSIA)

h = Differential pressure (P1 - P2)

G = Specific gravity of gas

Full Open Regulator Relief Capacity

Q = 0.5 C x

P

1

G

Q=C

P

2

h

G

Orifice C

1/8" 25

1/8" x 3/16" 25

3/16" 57

1/4" 98

5/16" 149

3/8" 208

1/2" 353

9/16" 421

Page 6

6

Inlet Orifice Size

(PSIG) 1/8 x 3/16 3/16 1/4 5/16 3/8 1/2 9/16

1 150 175 250 300 350 350

2 150 225 275 375 400 475 475

3 200 300 375 425 500 550 600

5 250 400 500 600 700 800 1000

10 350 600 850 1000 1200 1300 1400

15 425 900 1100 1500 1500 1500 1600

20 500 1100 1400 1600 1800 1800 1900

30 650 1400 1800 2100 2100 2100

40 800 1800 2200 2400 2500

60 1100 2200 2500 2500

100 1700 2400 2500

125 2000

Inlet Orifice Size

(PSIG) 1/8 x 3/16 3/16 1/4 5/16 3/8 1/2 9/16

1 150 200 275 350 400 400

2 175 250 350 475 500 650 900

3 225 325 475 550 700 1000 1500

5 275 475 750 1000 1200 2000 2500

10 375 800 1500 2200 2500 2500 2500

15 450 1000 1800 2500 2500 2500 2500

20 500 1200 2100 2500 2500

30 650 1600 2500

40 800 1900

60 1100

100 1700

1800B2 Service Regulators

Inlet Orifice Size

(PSIG) 1/8 x 3/16 3/16 1/4 5/16 3/8 1/2 9/16

3 200 225 275 300 375 450

5 200 300 375 475 475 600 700

10 325 450 600 750 800 1100 1200

15 425 600 800 1000 1000 1400 1500

20 500 750 1000 1200 1300 1600 1800

30 600 950 1300 1600 1700 2300

40 750 1200 1600 1900 2100 2500

60 1100 1600 2100 2300 2500

100 1600 2200 2500

125 2000

Inlet Orifice Size

(PSIG) 1/8 x 3/16 3/16 1/4 5/16 3/8 1/2 9/16

1 150 200 250 300 350 350

2 175 250 350 375 400 475 475

3 200 325 400 425 500 550 600

5 275 425 550 600 700 1000 1000

10 350 650 900 1000 1400 1500 1800

15 425 900 1200 1500 1800 2100 2400

20 500 1100 1600 1800 2300 2500 2500

30 650 1400 2000 2500 2500 2500

40 800 1800 2500 2500 2500 2500

60 1100 2400 2500 2500 2500

100 1700 2500 2500

125 2000

1800B2 Regulator Capacity Performance

Capacity 1" Outlet 1800B2 Regulator

Set Point 7.0" W.C. @ 50 SCFH

SCFH 0.60 specific gravity gas @ 60˚ F & 14.7 PSIA. Pressure spring

70017P044. Outlet pressure variance not to exceed +2" -1" W.C. from

set point, horizontal position.

Capacity 3/4" Outlet 1800B2 Regulator

Set Point 7.0" W.C. @ 50 SCFH

SCFH 0.60 specific gravity gas @ 60˚ F & 14.7 PSIA. Pressure spring

70017P044. Outlet pressure variance not to exceed +2" -1" W.C. from

set point, horizontal position.

Capacity 1-1/4" Outlet 1800B2 Regulator

Set Point 7.0" W.C. @ 50 SCFH

SCFH 0.60 specific gravity gas @ 60˚ F & 14.7 PSIA. Pressure spring

70017P044. Outlet pressure variance not to exceed +2" -1" W.C. from

set point, horizontal position.

Capacity 3/4" Outlet 1800B2 Regulator

Set Point 2 PSIG @ 50 SCFH

SCFH 0.60 specific gravity gas @ 60˚ F & 14.7 PSIA. Pressure spring

70017P049. Outlet pressure variance not to exceed +/- 10% from set

point, horizontal position.

For optimum performance, maximum inlet

pressure should not exceed maximum capacity

rating for any given orifice size.

For optimum performance, maximum inlet

pressure should not exceed maximum capacity

rating for any given orifice size.

For optimum performance, maximum inlet

pressure should not exceed maximum capacity

rating for any given orifice size.

For optimum performance, maximum inlet

pressure should not exceed maximum capacity

rating for any given orifice size.

Inlet Orifice Size

(PSIG) 1/8 x 3/16 3/16 1/4 5/16 3/8 1/2 9/16

3 200 225 275 300 375 450

5 200 300 375 475 500 600 750

10 350 500 600 750 950 1200 1400

15 425 650 850 1100 1300 1800 2100

20 500 850 1100 1400 1700 2400 2500

30 650 1100 1600 2300 2500 2500

40 800 1500 2200 2500 2500 2500

60 1100 2400 2500 2500 2500

100 1700 2500 2500

125 2100

Inlet Orifice Size

(PSIG) 1/8 x 3/16 3/16 1/4 5/16 3/8 1/2 9/16

3 200 225 275 300 375 450

5 200 300 375 475 475 600 700

10 350 475 600 750 850 1200 1300

15 425 650 850 1000 1100 1500 1700

20 500 800 1100 1300 1400 2000 2300

30 650 1000 1500 1800 2000 2500

40 800 1300 1900 2400 2500 2500

60 1100 2100 2500 2500 2500

100 1600 2500 2500

125 2000

Capacity 1" Outlet 1800B2 Regulator

Set Point 2 PSIG @ 50 SCFH

SCFH 0.60 specific gravity gas @ 60˚ F & 14.7 PSIA. Pressure spring

70017P049. Outlet pressure variance not to exceed +/- 10% from set

point, horizontal position.

Capacity 1-1/4" Outlet 1800B2 Regulator

Set Point 2 PSIG @ 50 SCFH

SCFH 0.60 specific gravity gas @ 60˚ F & 14.7 PSIA. Pressure spring

70017P049. Outlet pressure variance not to exceed +/- 10% from set

point, horizontal position.

For optimum performance, maximum inlet

pressure should not exceed maximum capacity

rating for any given orifice size.

For optimum performance, maximum inlet

pressure should not exceed maximum capacity

rating for any given orifice size.

Page 7

7

Inlet Orifice Size

(PSIG) 1/8 x 3/16 3/16 1/4 5/16 3/8 1/2 9/16

1 150 225 225 200 325 300

2 150 200 275 300 350 375 450

3 200 250 350 350 425 600 600

5 250 350 425 500 600 750 850

10 350 500 650 800 800 1500 1700

15 425 600 900 950 1500 2200 2300

20 500 750 1000 2100 2200 2700 2900

30 650 1200 1700 3600 3000 3900

40 800 1650 2600 4300 4100

60 1100 2500 4500 4600 3900

100 1700 3900

125 1900

1800B2-HC Service Regulators

Capacity 1-1/4" Outlet 1800B2-HC Regulator

Set Point 7.0" W.C. @ 50 SCFH

SCFH 0.60 specific gravity gas @ 60˚ F & 14.7 PSIA. Pressure spring

70017P044. Outlet pressure variance not to exceed +2" -1" W.C. from

set point, horizontal position.

For optimum performance, maximum inlet

pressure should not exceed maximum capacity

rating for any given orifice size.

1800B2-HC Regulator Capacity Performance

1800B2 & 1800B2-HC Service Regulators

Pressure Springs Orifice Sizes

Outlet Pressure Color Code Part Number

3.5" to 6" W.C. Blue 70017P043

3.5" to 7.5" W.C. Tan 70017P089

5.5" to 8.5" W.C. Yellow 70017P044

6" to 15" W.C. Purple 70017P042

12" to 28" W.C. White 70017P060

24" to 48" W.C. Red 70017P082

42" W .C. to Red-Red 70017P049

2 PSIG

Orifice Size Inlet Pressure

(PSIG)

9/16" 20

1/2" 40

3/8" 100

5/16" 110

1/4" 125

3/16" 125

1/8" x 3/16" 125

1/8" 125

Orifice Size Part Number

Standard w/ OPSO

9/16" 72494P026 72751P019

1/2" 72494P025 72751P016

3/8" 72494P023 72751P014

5/16" 72494P022 72751P013

UPSO 71422G004 71422G004

1/4" 72494P021 72751P012

3/16" 72494P020 72751P011

1/8" x 3/16" 72494P030 72751P020

1/8" 72494P019 N/A

See page 5 for maximum inlet recommendations and capacity

performance for each orifice size.

Maximum Recommended Inlet Pressure

Page 8

8

1800B2 & 1800B2-HC Service Regulators

0 10 20 30 40 50 60 70 80 90 100 110 120 130

90

80

70

60

50

40

30

20

10

0

Outlet Pressure - Inches W.C.

Inlet Pressure - PSIG

Outlet Pressure Relative To Inlet Pressure

3/4" Screened Vent - No Vent Pipe

Set Pressure 7" W.C.

0 10 20 30 40 50 60 70 80 90 100 110 120 130

9

8

7

6

5

4

3

2

1

0

Outlet Pressure - PSIG

Inlet Pressure - PSIG

Outlet Pressure Relative To Inlet Pressure

3/4" Screened Vent - No Vent Pipe

Set Pressure 2 PSIG

0 10 20 30 40 50 60 70 80 90 100 110 120 130

90

80

70

60

50

40

30

20

10

0

Outlet Pressure - Inches W.C.

Inlet Pressure - PSIG

Outlet Pressure Relative To Inlet Pressure

1" Screened Vent - No Vent Pipe

Set Pressure 7" W.C.

0 10 20 30 40 50 60 70 80 90 100 110 120 130

9

8

7

6

5

4

3

2

1

0

Outlet Pressure - PSIG

Inlet Pressure - PSIG

Outlet Pressure Relative To Inlet Pressure

1" Screened Vent - No Vent Pipe

Set Pressure 2 PSIG

Regulator Relief Valve Performance

There are several methods of measuring the relief performance of a regulator.The worst case scenario will occur when the lever

is disconnected.The data presented in the tables below represent this condition.

5/16"

3/8"

9/16" 1/2"

1/4"

3/16"

1/8" x 3/16"

5/16"

3/8"

9/16"

1/4"

3/16"

1/8" x 3/16"

1/2"

5/16"

3/8"

9/16"

1/4"

3/16"

1/8" x 3/16"

1/2"

5/16"

3/8"

9/16"

1/4"

3/16"

1/8" x 3/16"

1/2"

Page 9

Model Description

Number

1803B2 Basic regulator, non-relieving with 3/4" or 1" NPT vent.

&1803B2-HC

1813B2 Basic regulator with full capacity internal relief with 3/4" or 1" NPT vent.

& 1813B2-HC

1823B2 Basic regulator, non-relieving with under-pressure shut-off and 3/4" or 1" NPT vent.

*

1833B2 Basic regulator with full capacity internal relief and underpressure shut-off and

* 3/4" or 1" NPT vent.

1843B2 Basic regulator with full capacity internal relief and overpressure shut-off and

& 1843B2-HC 3/4" or 1" NPT vent.

1853B2 Basic regulator with full capacity internal relief and overpressure, underpressure shut-off

* and 3/4" or 1" NPT vent.

1883B2 Basic regulator, non-relieving with over-pressure shut-off and 3/4" or 1" NPT vent.

& 1883B2-HC

1893B2 Basic regulator, non-relieving with over-pressure, underpressure shut-off and

* 3/4" or 1" NPT vent.

1853B2 w/ Jeavons Basic regulator with full capacity internal relief and overpressure, underpressure

& 1853B2-HC w/ Jeavons shut-off and 3/4" or 1" NPT vent.

**

1893B2 w/ Jeavons Basic regulator, non-relieving with overpressure, underpressure shut-off and

& 1893B2-HC w/ Jeavons 3/4" or 1" NPT vent.

**

9

1800B2 & 1800B2-HC Service Regulators

Regulator Assembly Positions

For 180˚ Models For Offset Models For 90˚ Models

Regulator Descriptions

* For UPSO operation, see Brochure TDB-8620.

** For Jeavons (USSA) operation, see Brochure SB-8556.

1

4

2

3

STANDARD

VENT POSITION

VALVE HEAD POSITION "D"

VENT

73985

VENT

3

2

1

4

STANDARD

VENT POSITION

VENT

3

2

4

STANDARD

VENT POSITION

1

3

2

4

1

VALVE HEAD POSITION "D"

STANDARD

VENT POSITION

VALVE HEAD POSITION "A"

VENT

1

4

2

3

VALVE HEAD POSITION "C"

STANDARD

VENT POSITION

VALVE HEAD POSITION "B"

VENT

VALVE HEAD POSITION "D"VALVE HEAD POSITION "C"

STANDARD

VENT POSITIONVENT POSITION

STANDARD

VALVE HEAD POSITION "B"VALVE HEAD POSITION "A"

VENT POSITION

STANDARD

VENT POSITION

STANDARD

3

2

1

4

3

4

1

2

3

4

1

2

1

4

3

2

VENTVENT

VENT

VENT

Page 10

10

1800B2 & 1800B2-HC Service Regulators

Ordering Information

1 Model number.

2 Size of inlet and outlet.

3 Inlet pressure, psi.

4 Outlet pressure, inches W.C. (or PSIG).

5 Flow, scfh.

6 Kind and specific gravity of gas.

7 Orifice size.

8 Regulator assembly position number.

9 Possible variation in inlet pressure

for E.C.Orifice models.

Maximum_______PSIG

Minimum________PSIG

Shipping Weight -

17.5 lbs/carton of four regulators

Regulator Pressure Rating

125 psig = Maximum recommended inlet pressure for normal service.

Maximum recommended pressure may vary with orifice size.

175 psig = Maximum inlet pressure for abnormal or emergency service, without

causing damage to regulator case.

2 psig = Maximum outlet pressure for normal service.

10 psig = Maximum outlet pressure which can be contained by pressure carrying

components (no flange leakage to atmosphere except for normal relief action).

If regulator is subjected to these conditions, it should be removed from service.

50 psig = Maximum outlet pressure for abnormal service without damage to

internal components. If regulator is subjected to these conditions, it should be

removed from service.

Construction

Lower Diaphragm Case - Precision die cast aluminum with a

exclusive 7-step advanced conversion coating, single coat

polyester primer and High Solid Polyurethane Top Coat.

Top Assembly - Precision die cast aluminum with a exclusive

7-step advanced conversion coating, single coat polyester

primer and High Solid Polyurethane Top Coat.

Valve Bod y - Cast grey iron, undercoated, single coat polyester

primer and High Solid Polyurethane Top Coat, (Rotates in 90

degree increments).

Pressure Spring - Steel, Zinc plated and yellow chromate.

Color coded for identification.

Diaphragm Plate - Steel, terne plated.

Seat Disc - Buna-N.

Orifice - Super high strength, corrosion-resistant, aluminum.

Lever - Steel, zinc plated and yellow chromate.

Vent Screen - Stainless steel.

Seal Plug - Ultraviolet stabilized, minlon.

Corrosion Protection

10

PB/2500/03-01 FB 10-94

Due to continuous development the information in this document is subject to change.

AMERICAN METER

300 Welsh Road, Building One Horsham, PA 19044-2234 USA Tel: (215) 830-1800 Fax: (215) 830-1890

CANADIAN METER

3037 Derry Road, West Milton, Ontario L9T 2X6 Canada Tel: (905) 878-2361 Fax: (905) 878-5758

Loading...

Loading...