Page 1

EN

Salva KNX TH, Salva KNX basic

Smoke alarm

Installation and Operation

Page 2

1 Contents

1. Description ........................................................................................... 5

1.0.1. Deliverables ................................................................................................... 6

1.1. Technical specifications ........................................................................................... 6

1.1.1. Accuracy of temperature/humidity measurement ..................................... 7

2. Installation and commissioning ........................................................... 7

2.1. Installation notes ...................................................................................................... 7

2.2. Installation location .................................................................................................. 8

2.2.1. Equipping the building with smoke alarms ................................................ 8

2.2.2. Positioning and distances ............................................................................ 8

2.3. Device design ......................................................................................................... 10

2.3.1. Exterior view ............................................................................................... 10

2.3.2. Skirting ......................................................................................................... 11

2.3.3. Interior view of the housing ....................................................................... 11

2.4. Installing the device ............................................................................................... 12

2.4.1. Instructions for assembly and initial start-up ........................................... 12

2.4.2. Assembly preparation and skirting assembly .......................................... 12

2.4.3. Connection .................................................................................................. 13

2.4.4. Completing the installation ........................................................................ 14

3. Addressing the equipment ................................................................. 14

4. Maintenance ....................................................................................... 14

4.1. Function test ........................................................................................................... 15

4.2. Replace the battery ................................................................................................ 15

4.2.1. Types of batteries ....................................................................................... 16

4.2.2. Serial number .............................................................................................. 17

5. Device alarm functions ...................................................................... 17

5.1. Alarm mute (acknowledgement) .......................................................................... 17

5.2. Alarm memory ....................................................................................................... 17

5.3. Operating and alarm signals ................................................................................. 17

6. Transfer protocol ............................................................................... 19

6.1. List of all communication objects ......................................................................... 19

7. Setting the parameters for all models ............................................... 32

7.1. Behaviour on power failure/ restoration of power .............................................. 32

7.2. General settings ..................................................................................................... 32

7.3. Smoke alarm ........................................................................................................... 32

7.4. Variable comparator .............................................................................................. 37

7.4.1. Control variable comparator 1/2/3/4 .......................................................... 37

7.5. Computer ................................................................................................................ 38

7.5.1. Computer 1-8 ............................................................................................... 38

7.6. Logic ........................................................................................................................ 42

7.6.1. AND logic 1-8 and OR logic outputs 1-8 ................................................... 42

7.6.2. AND logic connection inputs ..................................................................... 44

7.6.3. Connection inputs of the OR logic ............................................................. 46

8. Temperature and humidity parameters .............................................. 48

Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany

Smoke alarm Salva KNX • ETS programme version 1.0

Status: 09.09.2016. Errors excepted. Subject to technical changes.

Page 3

2 Contents

8.1. Temperature Measurement ................................................................................... 48

8.2. Temperature threshold values .............................................................................. 48

8.2.1. Threshold value 1, 2, 3, 4 ........................................................................... 49

8.3. Temperature PI control .......................................................................................... 51

8.3.1. Heating control level 1/2 ............................................................................. 56

8.3.2. Cooling control level 1/2 ............................................................................. 59

8.4. Summer Compensation ......................................................................................... 61

8.5. Humidity Measurement ......................................................................................... 62

8.6. Humidity threshold values .................................................................................... 63

8.6.1. Threshold value 1, 2, 3, 4 ........................................................................... 63

8.7. Humidity PI control ................................................................................................ 65

8.8. Dewpoint measurement ........................................................................................ 68

8.8.1. Cooling medium temp. monitoring ........................................................... 68

8.9. Absolute humidity .................................................................................................. 70

8.10.Comfort field .......................................................................................................... 71

Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany

Smoke alarm Salva KNX • ETS programme version 1.0

Status: 09.09.2016. Errors excepted. Subject to technical changes.

Page 4

3 Clarification of signs

Installation, inspection, commissioning and troubleshooting of the device

must only be carried out by a competent electrician.

This manual is amended periodically and will be brought into line with new software

releases. The change status (software version and date) can be found in the contents footer.

If you have a device with a later software version, please check

www.elsner-elektronik.de in the menu area "Service" to find out whether a more up-todate version of the manual is available.

Clarification of signs used in this manual

Safety advice.

Safety advice for working on electrical connections, components,

etc.

DANGER!

WARNING!

CAUTION!

ATTENTION!

ETS In the ETS tables, the parameter default settings are marked by

... indicates an immediately hazardous situation which will lead to

death or severe injuries if it is not avoided.

... indicates a potentially hazardous situation which may lead to

death or severe injuries if it is not avoided.

... indicates a potentially hazardous situation which may lead to

trivial or minor injuries if it is not avoided.

... indicates a situation which may lead to damage to property if it is

not avoided.

underlining.

Page 5

4 Clarification of signs

Page 6

5 Description

This document describes the functions for ALL device models.

Please check the information at the beginning of the chapter and in the

text which describes the functions available for the respective individual

models.

1. Description

Salva KNX TH and Salva KNX basic are smoke detector sensors for the KNX build-

ing bus system. Their compact housing accommodates the sensors, evaluation circuits

and bus-coupling electronics.

The smoke alarm features an automatic evaluation sensor system for early and accurate fire alarms. Alarms are output as a local acoustic signal and a bus telegram. Salva

KNX basic signals smoke alarm, Salva KNX-TH signals smoke and/or heat alarm.

AND logic gates and OR logic gates allow for a link between data and statuses. Multifunctional modules change input data as required by means of calculations, querying

a condition, or converting the data point type.

The Salva KNX TH model additionally features integrated sensors for temperature

and air humidity. The measured values can be used for the control of limit-dependent

switching outputs. The devices have PI controls for heating/cooling (depending on

temperature) and for ventilation (depending on humidity).

Functions:

• Smoke alarm sensors with optical detection based on the scattered light

principle, certified according to EN 14604:2005/AC:2008 and 1172-CPR-150013.

Local acoustic alarm signal output (warning sound at least 85 dB) and transfer

to KNX bus. Local alarm acknowledgement

• Signalling of smoke alarm

• Smoke chamber pollution measurement and pollution display according to UL

directive

• Power supply via battery (9 V). Lack of battery capacity is signalled optically

and acoustically for 30 days and transmitted to the bus

• High operative safety due to elaborate automatic self-testing of the entire

electronics and separate energy measurement

• Faults signalled locally and via the bus

• High deceptive alarm immunity due to powerful measuring chamber and

consideration of temperature fluctuations (though no temperature smoke

alarm)

• 8 AND and 8 OR logic gates each with 4 inputs. All switching events as well

as 16 logic inputs (in the form of communications objects) can be used as

inputs for the logic gates. The output from each gate can be configured

optionally as 1-bit or 2 x 8-bit

• 8 multi-function modules (computers) for changing the input data by

calculations, by querying a condition or by converting the data point type

• 4 actuating variable comparators to output minimum, maximum or

average values. 5 inputs each for values received via communication objects

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 7

6 Description

Additional functions for Salva KNX TH:

• Signalling of heat alarms

• Temperature sensor and air humidity sensor with mixed value calculation,

dewpoint calculation, comfort field query (DIN 1946)

• Threshold values for measured and calculated values, adjustable via

parameters or communication objects

• PI control for heating/cooling (depending on temperature)

• PI controller for ventilation (depending on air humidity)

Configuration is made using the KNX software ETS. The product file can be downloaded from the Elsner Elektronik website on www.elsner-elektronik.de in the “Service” menu.

1.0.1. Deliverables

• Sensor (housing with skirting)

•9 V battery

• 2 screws and dowels for assembly (always use fastening material that is

suitable for the material underneath)

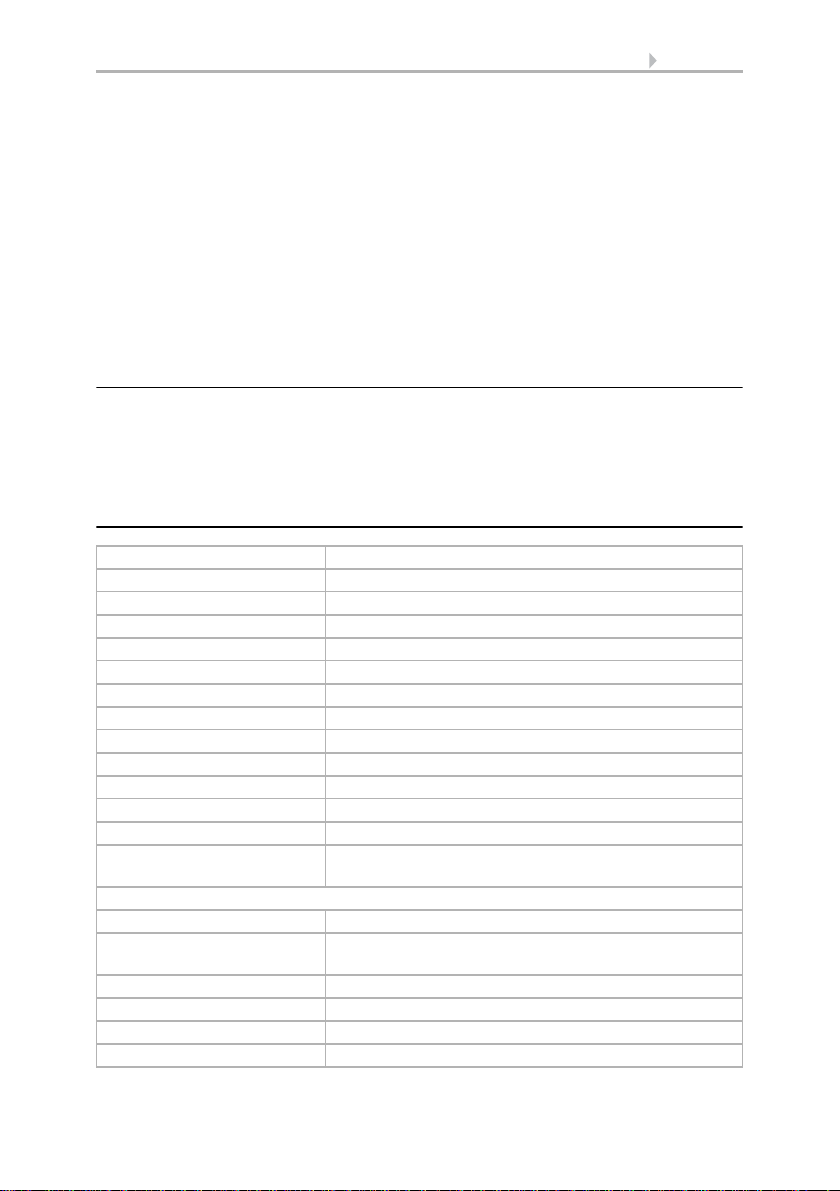

1.1. Technical specifications

Housing ABS, glass

Colour White / Translucent

Assembly Surface mount

Protection category IP 30

Dimensions Ø approx. 113 mm, height approx. 58 mm

Weight approx. 280 g

Ambient temperature Operation -10…+50°C, storage -10°C … +60°C

Surrounding air humidity max. 90% RH, avoid condensation

Operating voltage 9 V (battery)

Auxiliary supply KNX bus voltage

Data output KNX +/- bus connector terminal

BCU type Integrated microcontroller

PEI type 0

Communication objects Salva KNX TH: 311

Smoke alarm:

Detection principle Tyndall effect (optical)

Alarm display optically (LED red) and acoustically

Complies with EN 14604:2005

Max. monitoring area 60 m² to 6 m height

Air velocity max. 20 m/s

Response sensitivity 0.15 dB/m typical

Salva KNX basic: 192

(signal tone >85 dB(A) / 3 m)

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 8

7 Installation and commissioning

Shelf life for the alarm max. 2 years

Temperature sensor (Salva KNX TH):

Measurement range 0…+50°C

Resolution 0.1°C

Accuracy* ±1°C at -10...+85°C

Humidity sensor (Salva KNX TH):

Measurement range 0% RH … 90% RH

Resolution 0.1% RH

Accuracy ± 7,5% RH at 0% …10% RH

* Please note the information on Accuracy of temperature/humidity measurement, page 7

±1,5°C at -25...+150°C

± 4,5% RH at 10% … 90% RH

1.1.1. Accuracy of temperature/humidity measurement

Only for Salva KNX TH model.

Measured value deviations for temperature and humidity due to sources of interference (see chapter Installation location) must be corrected in the ETS in order to ensure

the specified accuracy of the sensor (offset).

During temperature measurement, the self-heating of the device is taken into consideration by the electronics. The software compensates the self-heating by reducing

the measured temperature. During the 2 hour warm-up phase, the displayed interior

temperature measured value increasingly approaches the actual room temperature.

2. Installation and commissioning

2.1. Installation notes

Installation, testing, operational start-up and troubleshooting should

only be performed by an electrician.

CAUTION!

Live voltage!

There are unprotected live components inside the device.

• National legal regulations are to be followed.

• Ensure that all lines to be assembled are free of voltage and take

precautions against accidental switching on.

• Do not use the device if it is damaged.

• Take the device or system out of service and secure it against

unintentional use, if it can be assumed, that risk-free operation is no

longer guaranteed.

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 9

8 Installation and commissioning

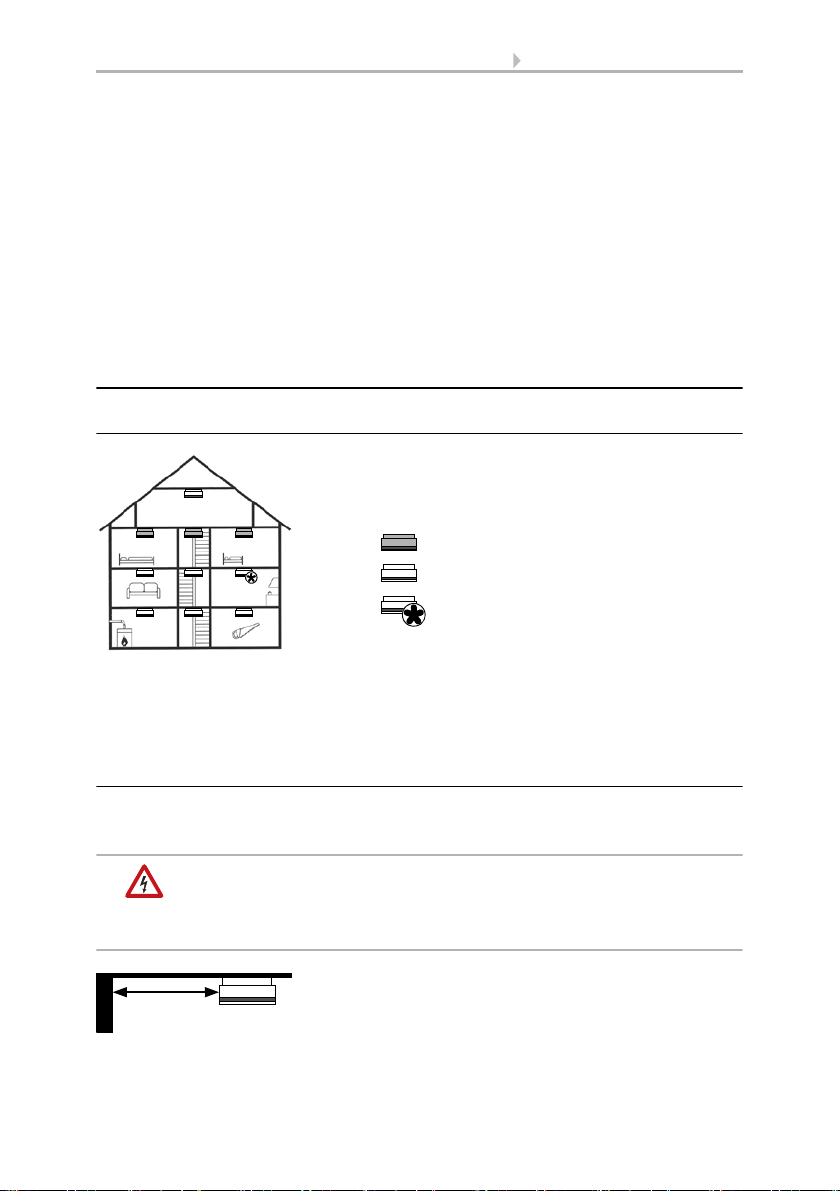

Fig. 1

Minimum equipment

Ideal equipment

Equipment with limitations

Maintain a minimum distance of 50 cm to:

• walls

•lamps

• live wires

≥ 50 cm

The device is only to be used for its intended purpose. Any improper modification or

failure to follow the operating instructions voids any and all warranty and guarantee

claims.

After unpacking the device, check it immediately for possible mechanical damage. If it

has been damaged in transport, inform the supplier immediately.

The device may only be used as a fixed-site installation; that means only when assembled and after conclusion of all installation and operational start-up tasks and only in

the surroundings designated for it.

Elsner Elektronik is not liable for any changes in norms and standards which may occur

after publication of these operating instructions.

2.2. Installation location

2.2.1. Equipping the building with smoke alarms

The minimum protection is the installation of smoke alarms in the bedrooms and halls

and/or corridors to ensure that you are woken up during the night in case of a smoke

alarm. If the building has several floors, at least one smoke alarm should be installed

in the hall on every floor. Please refer to DIN 14676 for further installation guidelines.

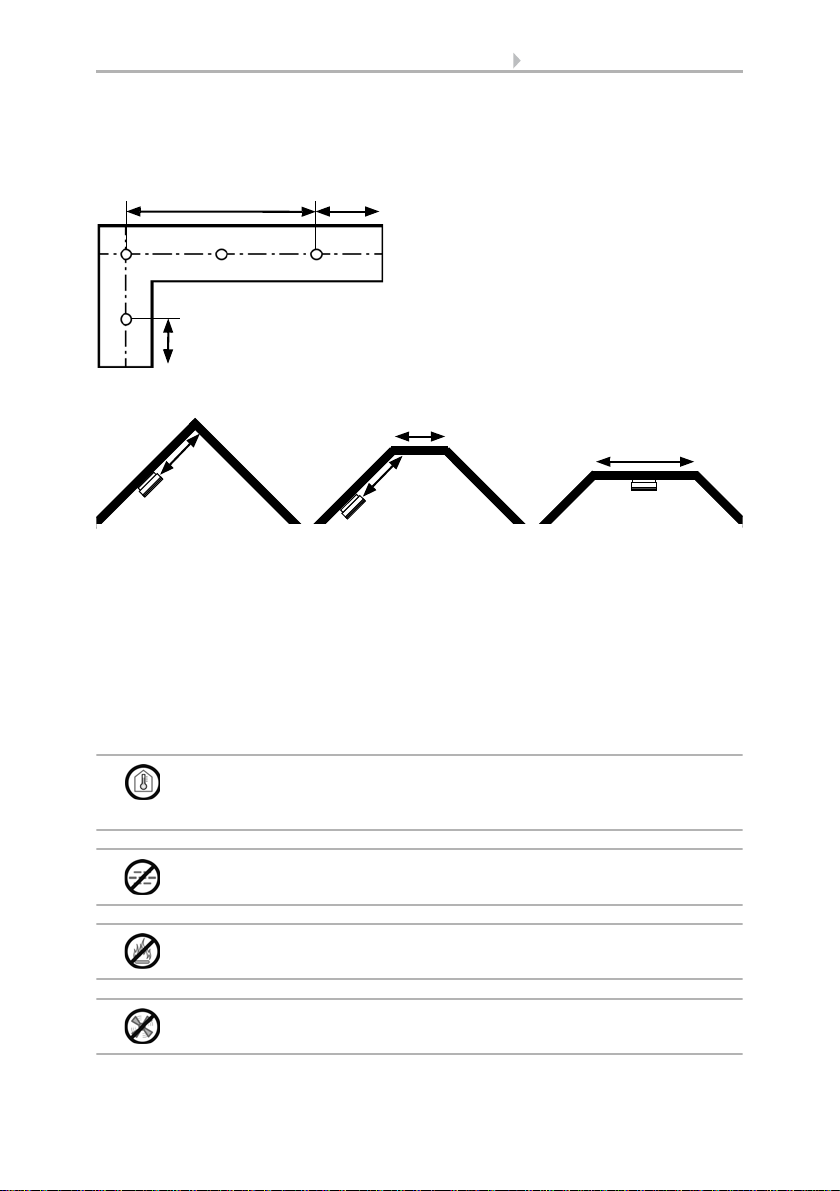

2.2.2. Positioning and distances

Install the smoke alarm on the room ceiling. If the smoke alarm is installed in the middle of the room, it has its best detection characteristics.

WARNING!

Mains voltage for in-wall concealed cables!

• If the device is attached by means of screws, first ensure

that there is no power line installed under the assembly point!

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 10

9 Installation and commissioning

Attach the first alarm at a maximum distance

of 7.50 m to the end of the room in long structures. Distribute at least 3 alarms on 15 m of

corridor. Attach alarms in the middle of corners and crossroads in the corridor.

Halls and corridors:

≤ 15 m ≤ 7,5 m

≤ 7,5 m

x

0,50 m < x < 1 m

x

< 1 m

0,50 m < x < 1 m

≥ 1 m

A + B: For pointed and flat gables with a ceiling area of less than 1 m width: Attach

alarms at a minimum distance of 0.50 m and a maximum distance of 1 m to the top.

C: For flat gables with a ceiling area of more than 1 m width: Attach to the middle of

the ceiling like in other rooms.

ABC

Gables:

Small rooms: If the minimum distance to the wall cannot be maintained, install the

alarm on the wall. Keep a distance of at least 0.50 m and maximum 1 m to the ceiling.

Rooms with a gallery: Attach an additional alarm underneath the gallery if said gallery is longer and wider than 2 m and has more than 16 m².

Segmented ceilings: If there are separate areas in the ceiling with a depth of more

than 0.20 m and an area of more than 32 m² (e.g. due to beams separating the areas),

install an alarm in each area (on the ceiling or on the beams).

The device is only approved for interior spaces. Do not install in rooms

with temperatures of less than -10°C or more than +50°C! Avoid

condensation.

Do not install in rooms in which a high degree of water vapour is

produced under normal circumstances (e.g. kitchen, bathroom, toilet)!

Do not install near places of fire or open fireplaces!

Do not install near ventilation shafts (e.g. of air conditioning or

circulating air systems)!

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 11

10 Installation and commissioning

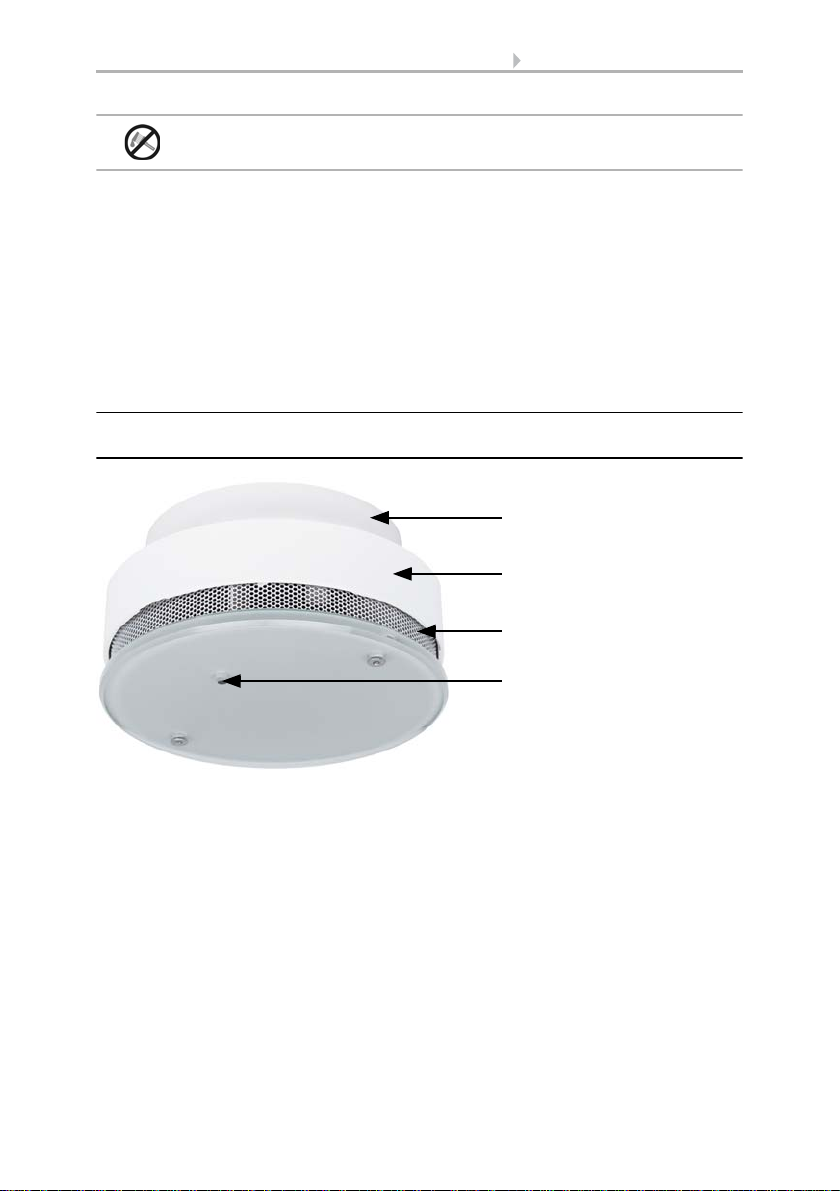

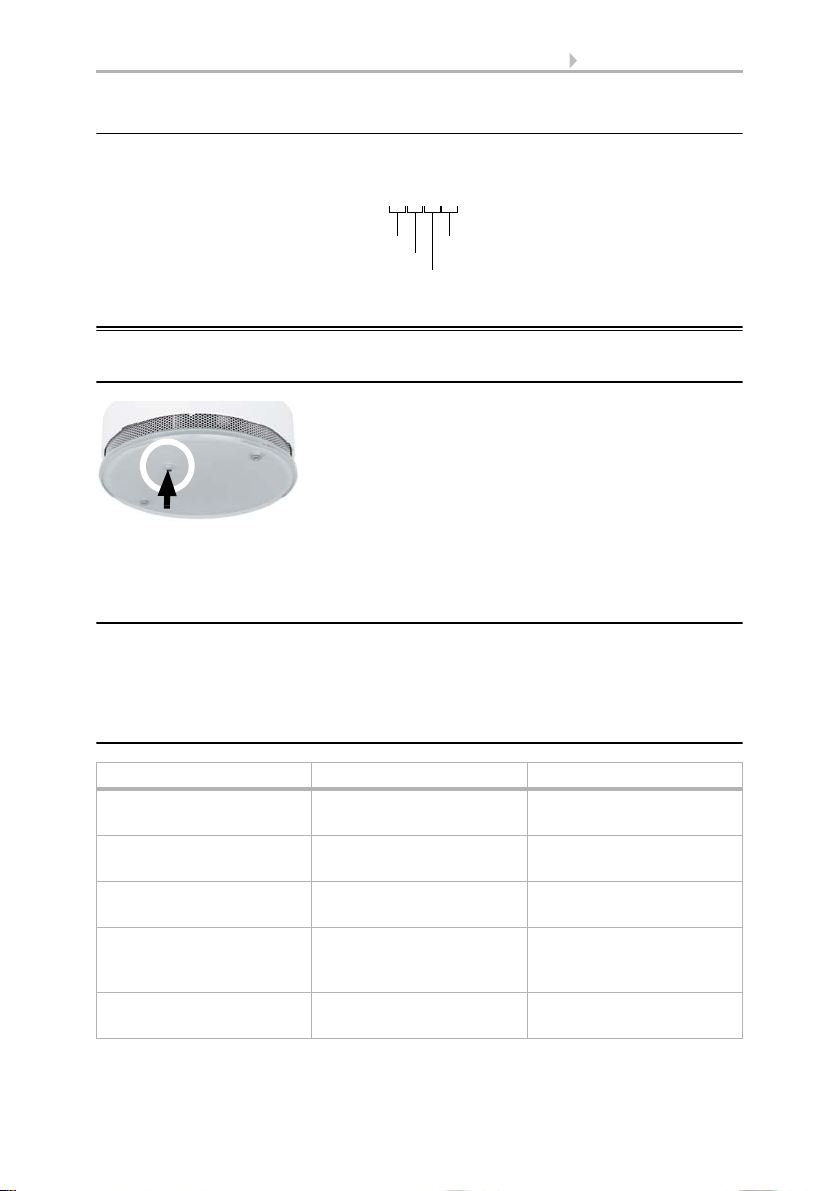

2

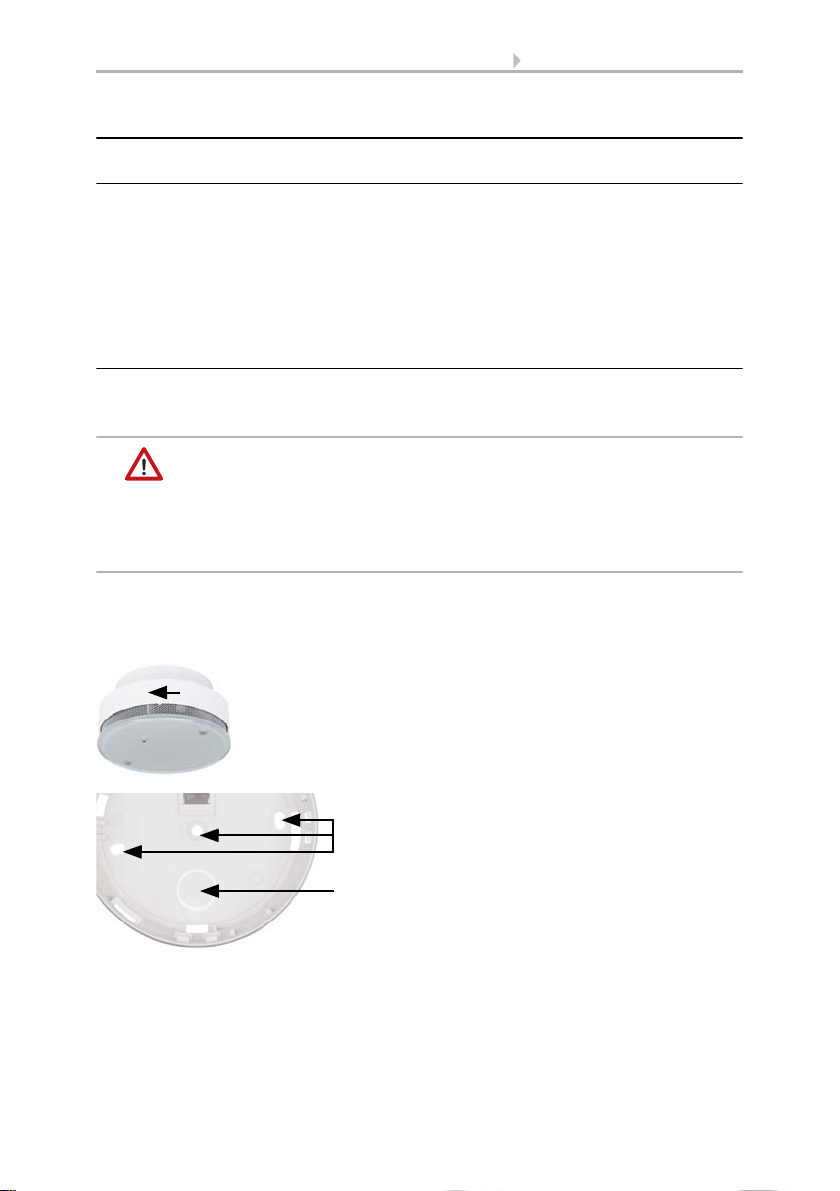

Fig. 2

1Skirting

2 Housing with electronics and battery

3 Openings for air circulation

4 Light transmission bar: Red LED for Operating and alarm signals, page 17 and

Push-button for Function test, page 15

3

4

1

Do not paint the smoke alarms!

Avoid the following sources of interference in order to limit distortion of measuring results for temperature, humidity and pressure:

• Direct sunlight

• Draughts from windows and doors

• Warming or cooling of the building structure on which the sensor is mounted,

e.g. due to sunlight, heating or cold water pipes

• Connection lines, which lead from warmer or colder areas to the sensor

Temperature variations from such sources of interference must be corrected in the ETS

in order to ensure the specified accuracy of the sensor (temperature offset).

2.3. Device design

2.3.1. Exterior view

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 12

11 Installation and commissioning

2

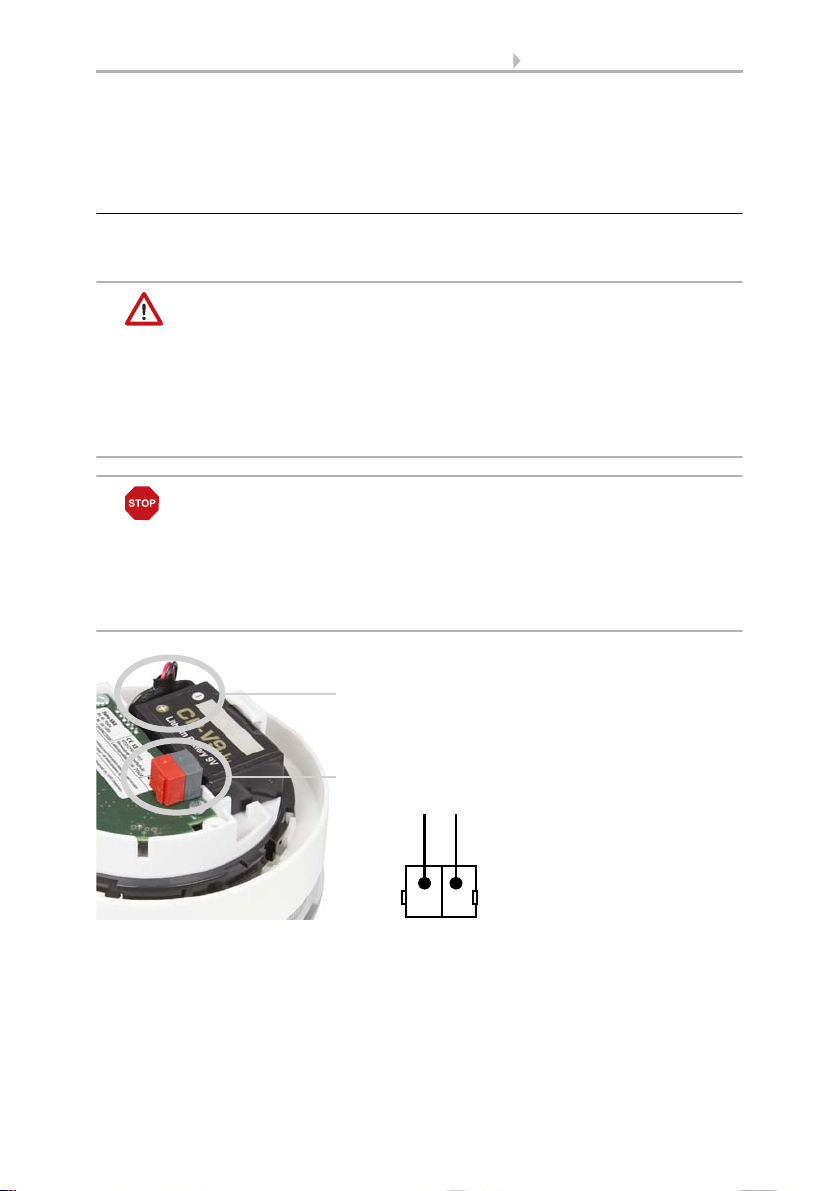

Fig. 3

1 Battery assembly lock (the housing cannot be closed without a battery)

2 Fastening opening with 1 screw

3 Openings for fastenings with 2 screws (distance 67 mm)

4 Opening for bus cable

3

4

1

2

Fig. 4

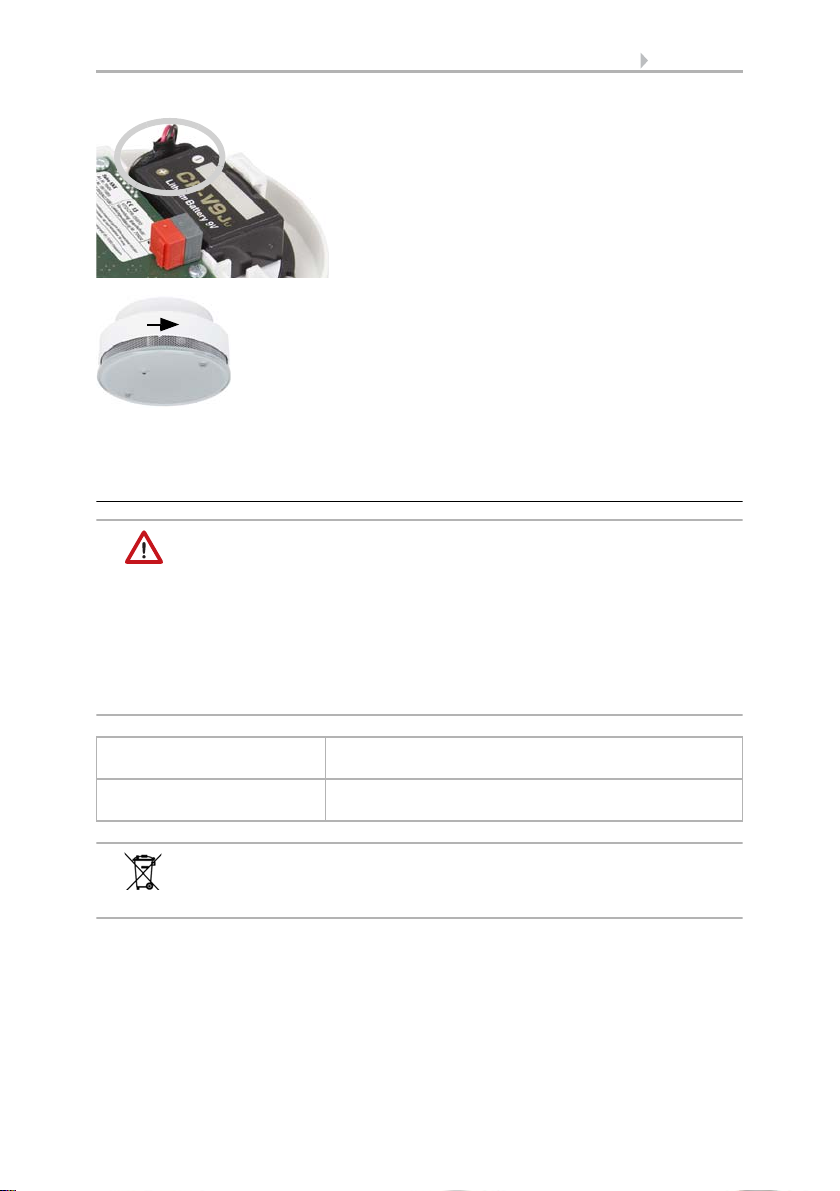

1Battery

2 KNX terminal

3 LED programming

4 Programming key (recessed) for bus addressing,

see Addressing the equipment, page 14

3

4

1

2.3.2. Skirting

2.3.3. Interior view of the housing

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 13

12 Installation and commissioning

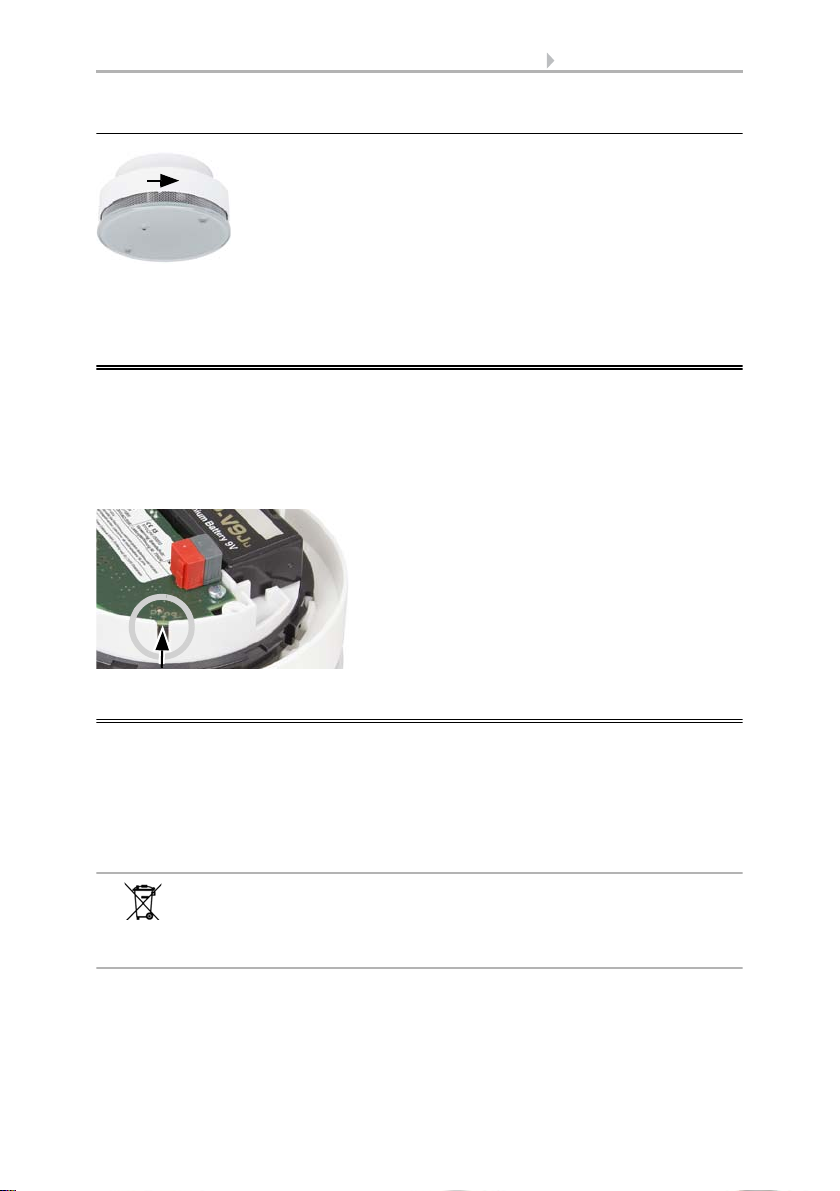

Fig. 5

The housing is removed from the skirting by

turning it anti-clockwise.

Fig. 6

Remove the cover on the opening for the supply line (1) from the skirting and thread the cable through it.

Screw the smoke alarm skirting onto the ceiling (2, openings for screws).

2

1

2.4. Installing the device

2.4.1. Instructions for assembly and initial start-up

Never expose the device to water (e.g. rain) or dust (e.g. drilling dust). This can damage

the electronics and the sensor system. A relative air humidity of 93% may not be exceeded. Avoid condensation.

After the bus voltage has been applied, the device will enter an initialisation phase lasting a few seconds. During this phase no information can be received or sent via the

bus.

2.4.2. Assembly preparation and skirting assembly

Determine the installation point on the room ceiling. Please observe the instructions in

chapter Installation location, page 8 for this.

BEWARE!

Injury hazard in case of improper fastening!

The device may fall and injure people if it is not fastened properly.

• Observe, the carrying capacity of the wall/ceiling material when

selecting the place of installation.

• Use fixing materials that are suitable for the material underneath.

If you are using the screws and dowels provided, use a 6mm drill to drill holes with a

distance of 67 mm (if you are using two screws for installation). Use the skirting of the

smoke alarm as a stencil. Insert the dowels into the drilling holes.

As an alternative, the skirting of the alarm may be attached to the ceiling with doublesided adhesive pad (VdS approved). Carefully check the ceiling surface carefully for

lasting carrying and adhesive capacity before using adhesive pads. If necessary, do a

test glueing application. Optimum adhesive power can only be obtained on a clean surface.

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 14

13 Installation and commissioning

Fig. 7

1. Connect the battery (check for correct polarity!) and insert it into the battery compartment.

2. Connect the device to the KNX bus via the

pluggable terminal (+|-).

1

2

-

+

-

+

KNX

Remove the protective foil form one side of the adhesive pad and attach the pad in the

middle of the alarm skirting. Then remove the protective foil on the other side and attach the skirting by firmly pressing it to the ceiling.

2.4.3. Connection

The supply line of the smoke alarm occurs via a 9 V battery. In addition, the KNX module receives the bus voltage via the KNX terminal.

WARNING!

Danger of explosion in case of improper handling of the battery!

Property damage by battery leakage.

• Do not recharge batteries.

• Do not short-circuit batteries.

• Do not force batteries open or damage them

• Do not bring batteries in contact with fire, water or high

temperatures.

ATTENTION!

Do not use rechargeable batteries or mains units for voltage

supply!

• In case of mains voltage, the device would be out of order

if the mains is out and could not signal any fire.

• The lower rechargeable battery voltage would trigger

a low battery capacity alarm.

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 15

14 Addressing the equipment

Fig. 8

Place the housing onto the skirting and fasten

it by turning it clockwise.

Fig. 9

Use a thin object to reach the button, e.g. a

wire.

2.4.4. Completing the installation

Check if the LED is flashing and conduct a function test.

> Function test, page 15

3. Addressing the equipment

The equipment is delivered with the bus address 15.15.250. You can program a different address in the ETS by overwriting the address 15.15.250 or by teaching the device

via the programming button.

The programming button is on the inside of the housing. The housing is removed from

the skirting by turning it anti-clockwise, and fixed in place by turning clockwise.

4. Maintenance

In some German federal states, the owner of houses and flats are responsible for the

installation and functioning of smoke alarms according to LBO (State construction

laws) (see www.rauchmelder-lebensretter.de). Maintenance has to be conducted at

least annually and, according to DIN 14676 includes a visual inspection, a function test

and, if required, a battery change. A function test also has to be conducted after any

longer absence, at ,after 1 year at the latest.

The used battery and the device must be disposed of correctly so that

valuable resources may be recycled. Neither the battery nor the device

may be disposed of together with domestic or company

waste.

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 16

15 Maintenance

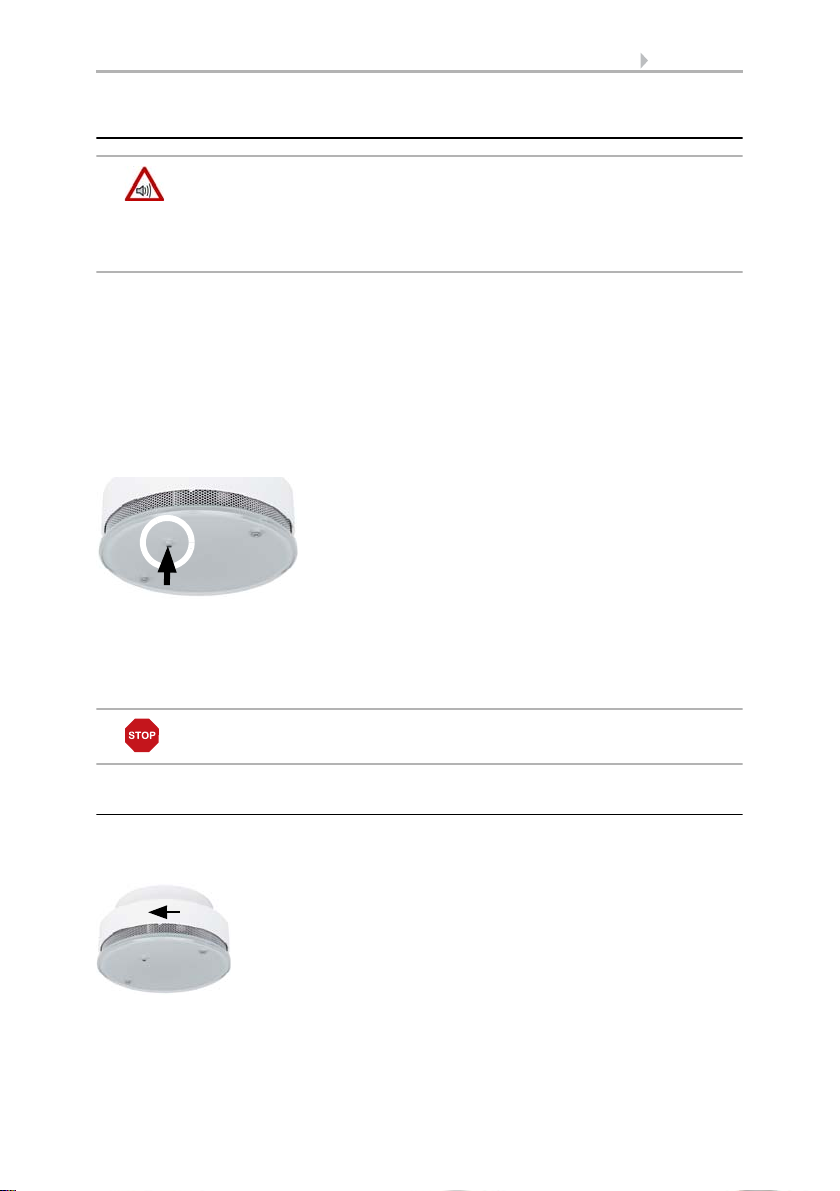

Fig. 10

Press the light transmission bar for at least 1

second.

Fig. 11

Separate the smoke alarm from the skirting

by turning it anti-clockwise.

4.1. Function test

BEWARE!

Danger of hearing damage!

During the function test (pressing on the light transmission bar),

a loud, shrill tone is sounded (at least 85 dB).

• Keep a minimum distance of 50 cm between smoke alarm and ear.

1. Conducting a visual inspection:

Check:

• Is the device found at the expected position?

• Are the smoke entry openings clean? - Remove dust if necessary. The device

must not be painted over.

• Is the device free from mechanical damage? - Replace the device if it is

damaged.

2. Conducting a function test:

If the function test is successful, a signal tone sounds. The smoke alarm works properly. If there is no signal tone, the device is not functioning. In this case, replace the battery and conduct the function test again. If there is still no signal tone, the device is defect and must be replaced.

Smoke alarms must be replaced with new devices after a maximum

period of 10 years according to DIN 14604.

4.2. Replace the battery

The device is supplied with 9 V voltage from a battery. Lack of battery capacity is signalled optically and acoustically for 30 days and transmitted to the bus.

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 17

16 Maintenance

Fig. 12

Connect the new battery to the smoke alarm

(check for correct polarity!) and insert it into

the battery compartment.

Fig. 13

Place the housing with the new battery onto

the skirting and fasten it by turning it clockwise.

Check if the LED is flashing and conduct a function test.

> Function test, page 15

4.2.1. Types of batteries

WARNING!

Danger of explosion in case of improper handling of the battery!

• Only replace with a lithium battery type DFK CP-V9Ju.

• Do not use rechargeable batteries or mains units for voltage supply

to ensure a sufficiently high voltage and supply even in case

of a mains outage.

• Do not recharge batteries and do not short-circuit them.

• Do not force batteries open or damage them and do not

bring them into contact with fire, water or high temperatures.

Approved battery type FDK CP-V9Ju

Average service life approx. 10 years (typical),

Only use lithium batteries

under normal conditions as per EN 14604

The used battery and the device must be disposed of properly so that

valuable resources may be recycled. Neither the battery nor the device

may be disposed of together with domestic or company waste.

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 18

17 Device alarm functions

Ser.no. 15111801

Year of production

-month

-day

Device number

Fig. 14

The alarm can be muted by pressing the

flashing light transmission bar.

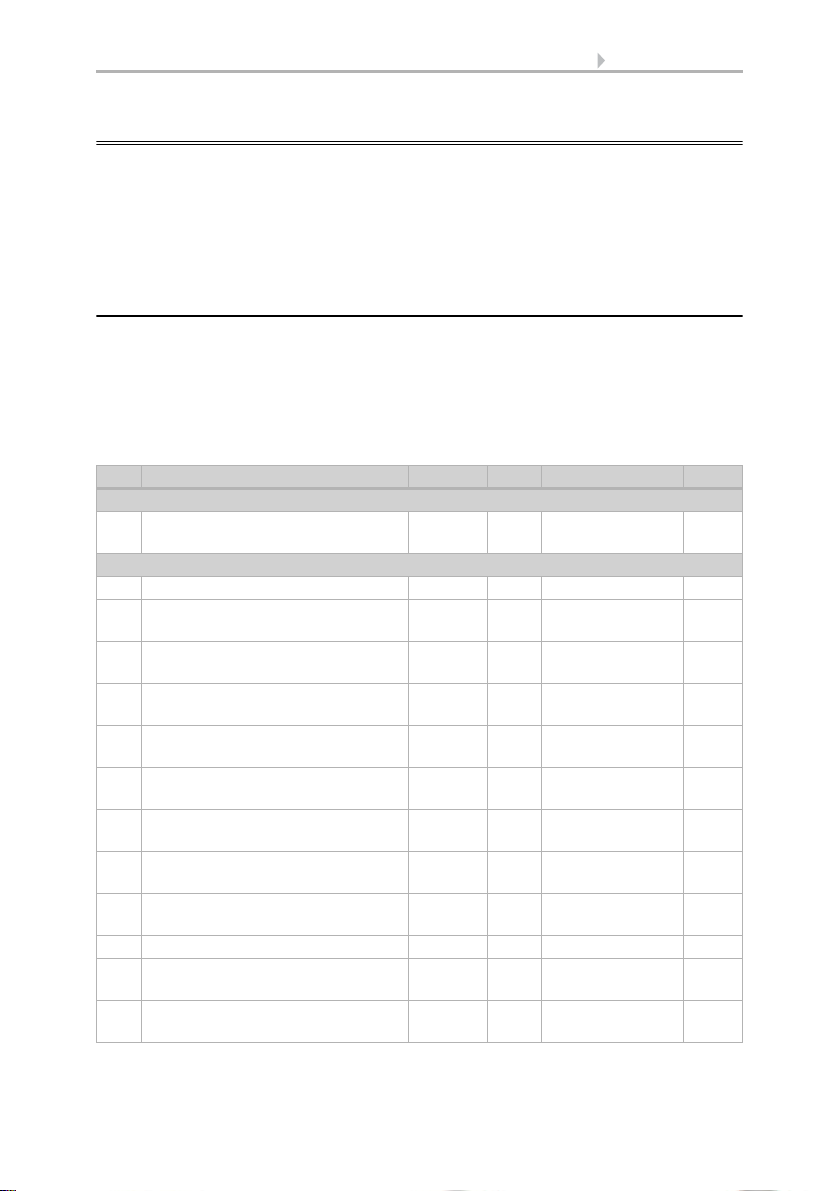

4.2.2. Serial number

The serial number on the type plate inside the device contains the production data and

device number:

5. Device alarm functions

5.1. Alarm mute (acknowledgement)

In this case, only the LED continues to flash every 10 seconds. After about 10 minutes,

the devices switches back to normal operating mode.

5.2. Alarm memory

An alarm is saved in the device for 24 hours. During this time, the LED briefly flashes

3 times every 43 seconds. The alarm memory can be reset by pressing the light transmission bar (red LED) once.

5.3. Operating and alarm signals

Function / meaning Signal tone Red LED

Normal operating mode

(automatic self-test)

Alarm status Loud interval tone in

Fault / dirt Short signal tone 3 times

Battery exchange display 1x Short signal tone

Alarm mute (acknowledgement)

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

No sound Flashes every 40 seconds

0.5 second rhythm

every 40 seconds

every 40 seconds

No sound Flashes every 10 seconds

Flashing twice per second

LED off

Flashes every 40 seconds

together with the signal

tone

Page 19

18 Device alarm functions

Function / meaning Signal tone Red LED

Alarm memory active

(i.e. there was an alarm

No sound Flashes 3 times every 43

seconds

state during the previous

24 hours)

Function test Loud interval tone Flashing twice per second

while the light transmis-

sion bar

is pressed

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 20

19 Transfer protocol

6. Transfer protocol

Units:

Temperatures in degrees Celsius

Air humidity in %

Absolute air humidity in g/kg and/or g/m

Variables in %

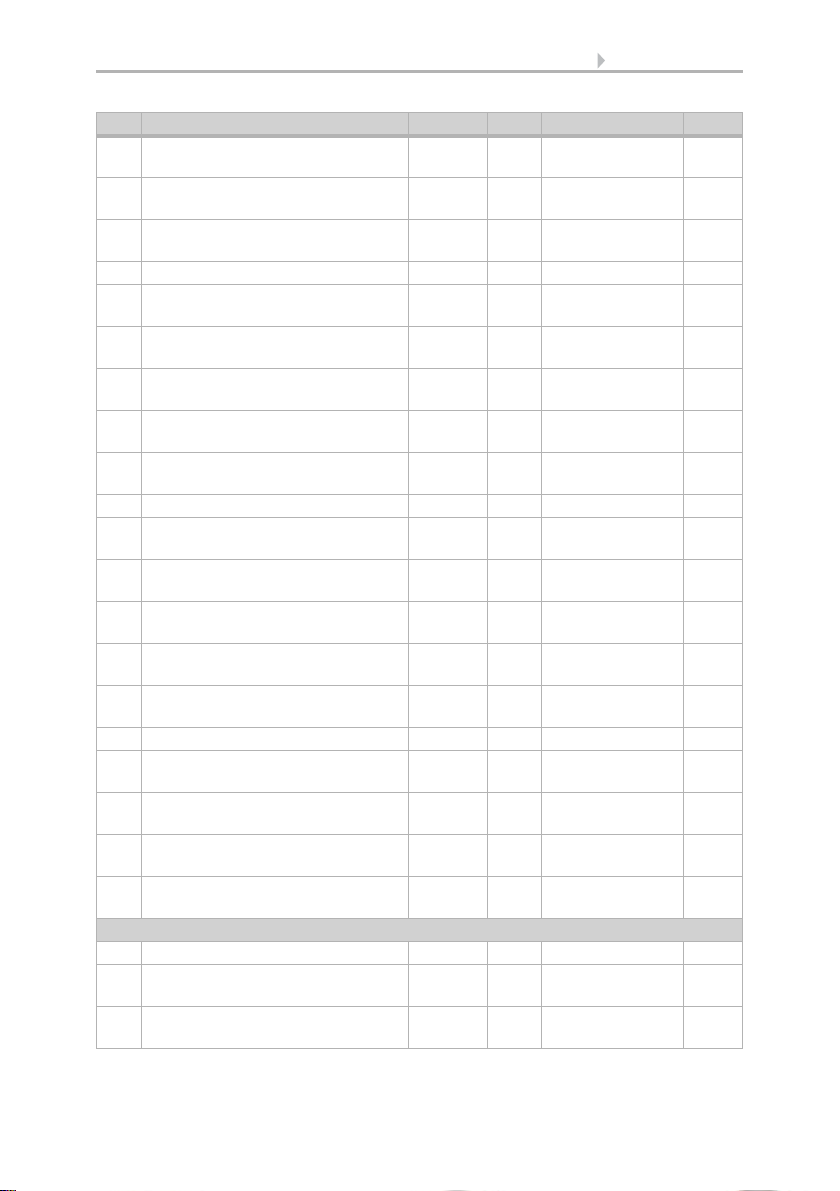

6.1. List of all communication objects

Abbreviation flags:

C Communication

R Read

WWrite

T Transfer

UUpdate

No. Text Function Flags DPT type Size

For all models:

1 Software version Output R-CT [217.1] DPT_Ver-

For Salva KNX TH only:

41 Temperature sensor: Malfunction Output R-CT [1.1] DPT_Switch 1 bit

42 Temperature sensor: External

measurement

43 Temperature sensor: Measured

value

44 Temperature sensor: Total

measurement

45 Temperature sensor: Min./Max.

measurement query

46 Temperature sensor: Minimum

measurement

47 Temperature sensor: Maximum

measurement

48 Temperature sensor: Min./Max.

measurement reset

51 Temp. threshold value 1: Absolute

value

52 Temp. threshold value 1: (1:+ | 0:-) Input -WC- [1.1] DPT_Switch 1 bit

53 Temp. threshold value 1: Switching

delay from 0 to 1

54 Temp. threshold value 1: Switching

delay from 1 to 0

3

sion

Input -WCT [9.1] DPT_Val-

Output R-CT [9.1] DPT_Val-

Output R-CT [9.1] DPT_Val-

Input -WC- [1.017] DPT_Trig-

Output R-CT [9.1] DPT_Val-

Output R-CT [9.1] DPT_Val-

Input -WC- [1.017] DPT_Trig-

Input/

Output

Input -WC- [7.5] DPT_TimePe-

Input -WC- [7.5] DPT_TimePe-

ue_Temp

ue_Temp

ue_Temp

ger

ue_Temp

ue_Temp

ger

RWCT [9.1] DPT_Val-

ue_Temp

riodSec

riodSec

2 bytes

2 bytes

2 bytes

2 bytes

1 bit

2 bytes

2 bytes

1 bit

2 bytes

2 bytes

2 bytes

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 21

20 Transfer protocol

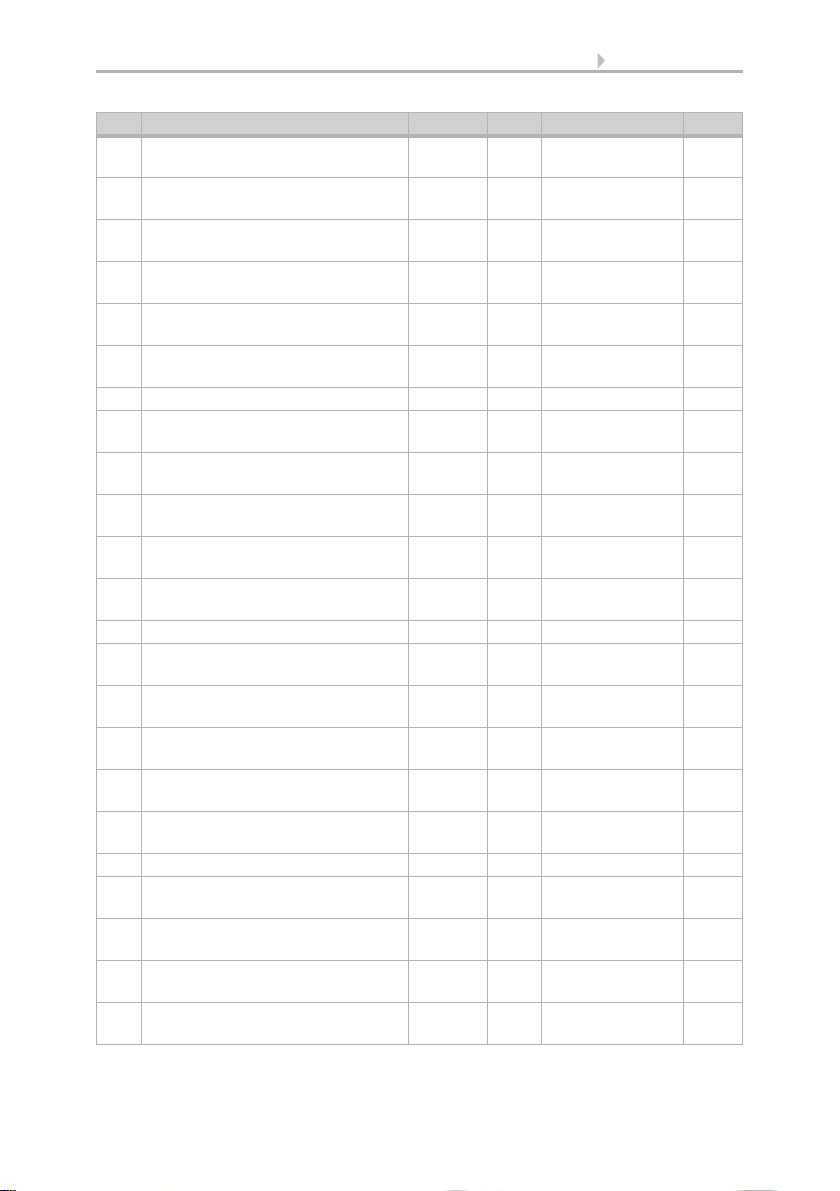

No. Text Function Flags DPT type Size

55 Temp. threshold value 1: Switching

Output R-CT [1.1] DPT_Switch 1 bit

output

56 Temp. threshold value 1: Switching

Input -WC- [1.1] DPT_Switch 1 bit

output block

58 Temp. threshold value 2: Absolute

value

Input/

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 bytes

59 Temp. threshold value 2: (1:+ | 0:-) Input -WC- [1.1] DPT_Switch 1 bit

60 Temp. threshold value 2: Switching

delay from 0 to 1

61 Temp. threshold value 2: Switching

delay from 1 to 0

62 Temp. threshold value 2: Switching

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Output R-CT [1.1] DPT_Switch 1 bit

output

63 Temp. threshold value 2: Switching

Input -WC- [1.1] DPT_Switch 1 bit

output block

65 Temp. threshold value 3: Absolute

value

Input/

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 bytes

66 Temp. threshold value 3: (1:+ | 0:-) Input -WC- [1.1] DPT_Switch 1 bit

67 Temp. threshold value 3: Switching

delay from 0 to 1

68 Temp. threshold value 3: Switching

delay from 1 to 0

69 Temp. threshold value 3: Switching

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Output R-CT [1.1] DPT_Switch 1 bit

output

70 Temp. threshold value 3: Switching

Input -WC- [1.1] DPT_Switch 1 bit

output block

72 Temp. threshold value 4: Absolute

value

Input/

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 bytes

73 Temp. threshold value 4: (1:+ | 0:-) Input -WC- [1.1] DPT_Switch 1 bit

74 Temp. threshold value 4: Switching

delay from 0 to 1

75 Temp. threshold value 4: Switching

delay from 1 to 0

76 Temp. threshold value 4: Switching

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Output R-CT [1.1] DPT_Switch 1 bit

output

77 Temp. threshold value 4: Switching

Input -WC- [1.1] DPT_Switch 1 bit

output block

For Salva KNX TH only:

311 Humidity sensor: Malfunction Output R-CT [1.1] DPT_Switch 1 bit

314 Humidity sensor: External

measurement

315 Humidity sensor: Measured value Output R-CT [9.7] DPT_Val-

Input -WCT [9.7] DPT_Val-

ue_Humidity

2 bytes

2 bytes

ue_Humidity

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 22

21 Transfer protocol

No. Text Function Flags DPT type Size

316 Humidity sensor: Total

measurement

317 Humidity sensor: Min./Max.

measurement query

318 Humidity sensor: Minimum

measurement

319 Humidity sensor: Maximum

measurement

320 Humidity sensor: Min./Max.

measurement reset

331 Humidity threshold value 1:

Absolute value

Output R-CT [9.7] DPT_Val-

ue_Humidity

Input -WC- [1.017] DPT_Trig-

ger

Output R-CT [9.7] DPT_Val-

ue_Humidity

Output R-CT [9.7] DPT_Val-

ue_Humidity

Input -WC- [1.017] DPT_Trig-

ger

Input/

Output

RWCT [9.7] DPT_Val-

ue_Humidity

2 bytes

1 bit

2 bytes

2 bytes

1 bit

2 bytes

332 Humidity threshold value 1: (1:+|0:-) Input -WC- [1.1] DPT_Switch 1 bit

333 Humidity threshold value 1: Delay

from 0 to 1

334 Humidity threshold value 1: Delay

from 1 to 0

335 Humidity threshold value 1:

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Output R-CT [1.1] DPT_Switch 1 bit

Switching output

336 Humidity threshold value 1:

Input -WC- [1.1] DPT_Switch 1 bit

Switching output block

337 Humidity threshold value 2:

Absolute value

Input/

Output

RWCT [9.7] DPT_Val-

ue_Humidity

2 bytes

338 Humidity threshold value 2: (1:+|0:-) Input -WC- [1.1] DPT_Switch 1 bit

339 Humidity threshold value 2:

Delay from 0 to 1

340 Humidity threshold value 2:

Delay from 1 to 0

341 Humidity threshold value 2:

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Output R-CT [1.1] DPT_Switch 1 bit

Switching output

342 Humidity threshold value 2:

Input -WC- [1.1] DPT_Switch 1 bit

Switching output block

343 Humidity threshold value 3:

Absolute value

Input/

Output

RWCT [9.7] DPT_Val-

ue_Humidity

2 bytes

344 Humidity threshold value 3: (1:+|0:-) Input -WC- [1.1] DPT_Switch 1 bit

345 Humidity threshold value 3:

Delay from 0 to 1

346 Humidity threshold value 3:

Delay from 1 to 0

347 Humidity threshold value 3:

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Output R-CT [1.1] DPT_Switch 1 bit

Switching output

348 Humidity threshold value 3:

Input -WC- [1.1] DPT_Switch 1 bit

Switching output block

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 23

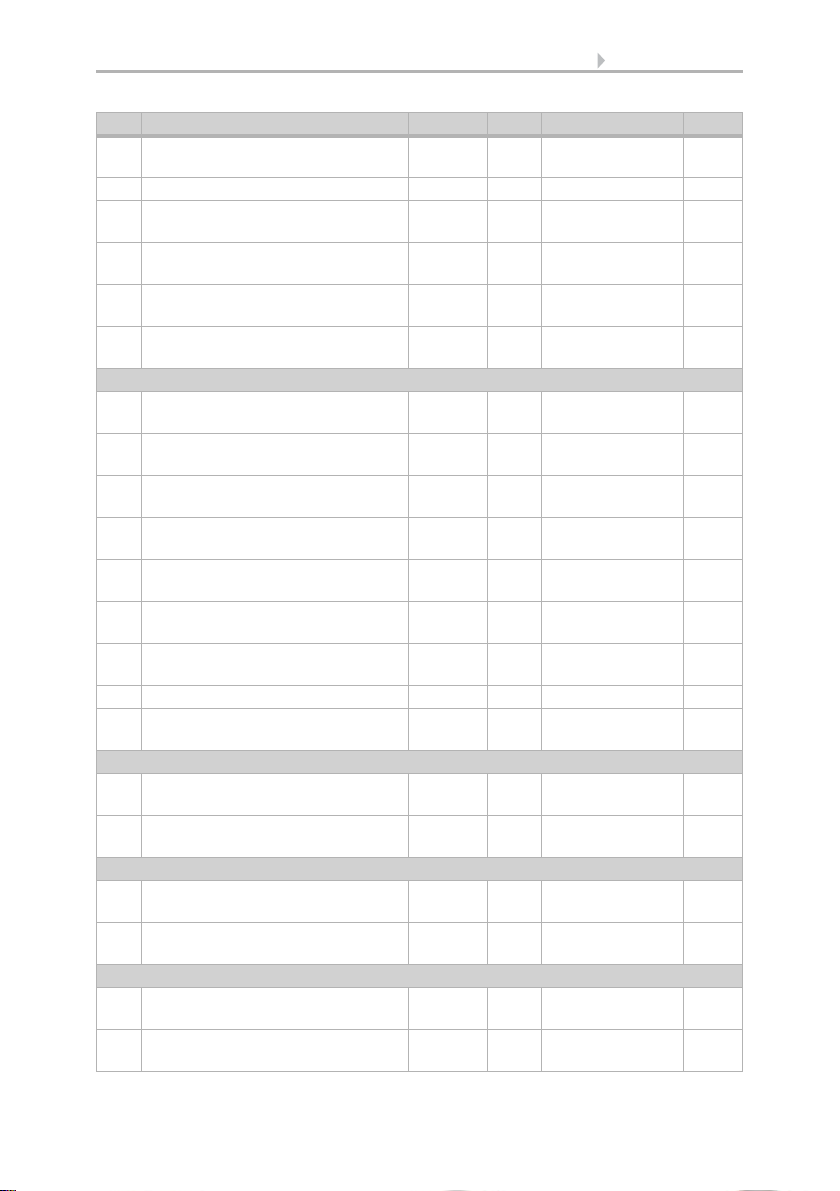

22 Transfer protocol

No. Text Function Flags DPT type Size

349 Humidity threshold value 4:

Absolute value

Input/

Output

RWCT [9.7] DPT_Val-

ue_Humidity

2 bytes

350 Humidity threshold value 4: (1:+|0:-) Input -WC- [1.1] DPT_Switch 1 bit

351 Humidity threshold value 4:

Delay from 0 to 1

352 Humidity threshold value 4:

Delay from 1 to 0

353 Humidity threshold value 4:

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Input -WC- [7.5] DPT_TimePe-

2 bytes

riodSec

Output R-CT [1.1] DPT_Switch 1 bit

Switching output

354 Humidity threshold value 4:

Input -WC- [1.1] DPT_Switch 1 bit

Switching output block

For Salva KNX TH only:

381 Dewpoint: Measured value Output R-CT [9.1] DPT_Val-

2 bytes

ue_Temp

382 Coolant temp.: Threshold value Output R-CT [9.1] DPT_Val-

2 bytes

ue_Temp

383 Coolant temp.: Actual value Input RWCT [9.1] DPT_Val-

2 bytes

ue_Temp

384 Coolant temp.: Offset change

Input -WC- [1.1] DPT_Switch 1 bit

(1:+ | 0:-)

385 Coolant temp.: Current offset Output R-CT [9.1] DPT_Val-

2 bytes

ue_Temp

386 Coolant temp.: Switching delay from

0 to 1

387 Coolant temp.: Switching delay from

1 to 0

Input -WC- [7.5] DPT_TimePe-

riodSec

Input -WC- [7.5] DPT_TimePe-

riodSec

2 bytes

2 bytes

388 Coolant temp.: Switching output Output R-CT [1.1] DPT_Switch 1 bit

389 Coolant temp.: Switching output

Input -WC- [1.1] DPT_Switch 1 bit

block

For Salva KNX TH only:

391 Absolute humidity [g/kg] Output R-CT [14.5] DPT_Val-

4 bytes

ue_Amplitude

392 Absolute humidity [g/m²] Output R-CT [14.17] DPT_Val-

4 bytes

ue_Density

For Salva KNX TH only:

394 Ambient climate status:

Output R-CT [1.1] DPT_Switch 1 bit

1 = comfortable | 0 = uncomfortable

395 Ambient climate status: Text Output R-CT [16.0]

DPT_String_ASCII

14

bytes

For Salva KNX TH only:

482 Temp. controller: HVAC mode

(priority 2)

483 Temp. controller: Mode frost/heat

Input RWCT [20.102] DPT_H-

1 byte

VACMode

Input RWCT [1.1] DPT_Switch 1 bit

protection activation

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 24

23 Transfer protocol

No. Text Function Flags DPT type Size

484 Temp. controller: Block

Input -WC- [1.1] DPT_Switch 1 bit

(1 = Blocking)

485 Temp. controller: Current setpoint Output R-CT [9.1] DPT_Val-

2 bytes

ue_Temp

486 Temp. controller: Switching

Input -WC- [1.1] DPT_Switch 1 bit

(0: Heating | 1: Cooling)

487 Temp. controller: Setpoint comfort

heating

488 Temp. controller: Setpoint comfort

Input/

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 bytes

Input -WC- [1.1] DPT_Switch 1 bit

heating (1:+ | 0: -)

489 Temp. controller: Setpoint comfort

cooling

490 Temp. controller: Setpoint comfort

Input/

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 bytes

Input -WC- [1.1] DPT_Switch 1 bit

cooling (1:+ | 0: -)

491 Temp. controller: Basic 16-bit

setpoint shift

492 Temp. controller: Setpoint standby

heating

493 Temp. controller: Setpoint standby

Input/

Output

Input/

Output

RWCT [9.1] DPT_Val-

ue_Temp

RWCT [9.1] DPT_Val-

ue_Temp

2 bytes

2 bytes

Input -WC- [1.1] DPT_Switch 1 bit

heating (1:+ | 0: -)

494 Temp. controller: Setpoint standby

cooling

495 Temp. controller: Setpoint standby

Input/

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 bytes

Input -WC- [1.1] DPT_Switch 1 bit

cooling (1:+ | 0: -)

496 Temp. controller: Setpoint eco

heating

497 Temp. controller: Setpoint, eco

Input/

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 bytes

Input -WC- [1.1] DPT_Switch 1 bit

heating (1:+ | 0: -)

498 Temp. controller: Setpoint eco

cooling

499 Temp. controller: Setpoint, eco

Input/

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 bytes

Input -WC- [1.1] DPT_Switch 1 bit

cooling (1:+ | 0: -)

500 Temp. controller: Control variable,

Output R-CT [5.1] DPT_Scaling 1 byte

heating (level 1)

501 Temp. controller: Control variable,

Output R-CT [5.1] DPT_Scaling 1 byte

heating (level 2)

502 Temp. controller: Control variable,

Output R-CT [5.1] DPT_Scaling 1 byte

cooling (level 1)

503 Temp. controller: Control variable,

Output R-CT [5.1] DPT_Scaling 1 byte

cooling (level 2)

482 Temp. controller: HVAC mode

(priority 2)

504 Temperature controller: Variable for

Input RWCT [20.102] DPT_H-

1 byte

VACMode

Output R-CT [5.1] DPT_Scaling 1 byte

4/6-way valve

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 25

24 Transfer protocol

No. Text Function Flags DPT type Size

505 Temp. controller: Status heating

Output R-CT [1.1] DPT_Switch 1 bit

level 1 (1:ON | 0:OFF)

506 Temp. controller: Status heating

Output R-CT [1.1] DPT_Switch 1 bit

level 2 (1:ON | 0:OFF)

507 Temp. controller: Status cooling

Output R-CT [1.1] DPT_Switch 1 bit

level 1 (1:ON | 0:OFF)

508 Temp. controller: Status cooling

Output R-CT [1.1] DPT_Switch 1 bit

level 2 (1:ON | 0:OFF)

509 Temp. controller: Comfort extension

status

510 Temp. controller: Comfort extension

time

Input/

RWCT [1.1] DPT_Switch 1 bit

Output

Input RWCT [7.5] DPT_TimePe-

riodSec

2 bytes

For Salva KNX TH only:

515 Summer Compensation: Outside

temperature

516 Summer Compensation: Setpoint

value

517 Summer Compensation: Block

Input -WCT [9.1] DPT_Val-

2 bytes

ue_Temp

Output R-CT [9.1] DPT_Val-

2 bytes

ue_Temp

Input -WC- [1.1] DPT_Switch 1 bit

(1 = Blocking)

For Salva KNX TH only:

521 Humidity controller: Block (1: block) Input -WC- [1.2] DPT_Bool 1 bit

522 Humidity controller: Setpoint value Input/

Output

523 Humidity controller: Setpoint

Input -WC- [1.2] DPT_Bool 1 bit

RWCT [9,007] DPT_Val-

ue_Humidity

2 bytes

value (1:+ | 0:-)

524 Humidity controller: Control variable

Output R-CT [5.1] DPT_Scaling 1 byte

dehumidification

525 Humidity controller: Control variable

Output R-CT [5.1] DPT_Scaling 1 byte

dehumidification level 2

526 Humidity controller: Control variable

Output R-CT [5.1] DPT_Scaling 1 byte

humidification

527 Humidity controller:

Output R-CT [1.1] DPT_Switch 1 bit

Dehumidification status (1:ON |

0:OFF)

528 Humidity controller:

Output R-CT [1.1] DPT_Switch 1 bit

Dehumidification 2 status (1:ON |

0:OFF)

529 Humidity controller: Humidification

Output R-CT [1.1] DPT_Switch 1 bit

status (1:ON | 0:OFF)

For all models:

1111 Control variable comparator 1:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 1

1112 Control variable comparator 1:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 2

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 26

25 Transfer protocol

No. Text Function Flags DPT type Size

1113 Control variable comparator 1:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 3

1114 Control variable comparator 1:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 4

1115 Control variable comparator 1:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 5

1116 Control variable comparator 1:

Output R-CT [5.1] DPT_Scaling 1 byte

Output

1117 Control variable comparator 1:

Output -WC- [1.2] DPT_Bool 1 bit

Block: block)

1118 Control variable comparator 2:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 1

1119 Control variable comparator 2:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 2

1120 Control variable comparator 2:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 3

1121 Control variable comparator 2:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 4

1122 Control variable comparator 2:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 5

1123 Control variable comparator 2:

Output R-CT [5.1] DPT_Scaling 1 byte

Output

1124 Control variable comparator 2:

Output -WC- [1.2] DPT_Bool 1 bit

Block (1: block)

1125 Control variable comparator 3:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 1

1126 Control variable comparator 3:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 2

1127 Control variable comparator 3:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 3

1128 Control variable comparator 3:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 4

1129 Control variable comparator 3:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 5

1130 Control variable comparator 3:

Output R-CT [5.1] DPT_Scaling 1 byte

Output

1131 Control variable comparator 3:

Output -WC- [1.2] DPT_Bool 1 bit

Block (1: block)

1132 Control variable comparator 4:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 1

1133 Control variable comparator 4:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 2

1134 Control variable comparator 4:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 3

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 27

26 Transfer protocol

No. Text Function Flags DPT type Size

1135 Control variable comparator 4:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 4

1136 Control variable comparator 4:

Input -WC- [5.1] DPT_Scaling 1 byte

Input 5

1137 Control variable comparator 4:

Output R-CT [5.1] DPT_Scaling 1 byte

Output

1138 Control variable comparator 4:

Output -WC- [1.2] DPT_Bool 1 bit

Block (1: block)

For all models:

1141 Computer 1: Input I1 Input RWCT Dep. on setting 4 bytes

1142 Computer 1: Input I2 Input RWCT Dep. on setting 4 bytes

1143 Computer 1: Input I3 Input RWCT Dep. on setting 4 bytes

1144 Computer 1: Output O1 Output R-CT Dep. on setting 4 bytes

1145 Computer 1: Output O2 Output R-CT Dep. on setting 4 bytes

1146 Computer 1: Condition text Output R-CT [16.0]

DPT_String_ASCII

14

bytes

1147 Computer 1: Monitoring status Output R-CT [1.1] DPT_Switch 1 bit

1148 Computer 1: Block (1: block) Input -WC- [1.1] DPT_Switch 1 bit

1149 Computer 2: Input I1 Input RWCT Dep. on setting 4 bytes

1150 Computer 2: Input I2 Input RWCT Dep. on setting 4 bytes

1151 Computer 2: Input I3 Input RWCT Dep. on setting 4 bytes

1152 Computer 2: Output O1 Output R-CT Dep. on setting 4 bytes

1153 Computer 2: Output O2 Output R-CT Dep. on setting 4 bytes

1154 Computer 2: Condition text Output R-CT [16.0]

DPT_String_ASCII

14

bytes

1155 Computer 2: Monitoring status Output R-CT [1.1] DPT_Switch 1 bit

1156 Computer 2: Block (1: block) Input -WC- [1.1] DPT_Switch 1 bit

1157 Computer 3: Input I1 Input RWCT Dep. on setting 4 bytes

1158 Computer 3: Input I2 Input RWCT Dep. on setting 4 bytes

1159 Computer 3: Input I3 Input RWCT Dep. on setting 4 bytes

1160 Computer 3: Output O1 Output R-CT Dep. on setting 4 bytes

1161 Computer 3: Output O2 Output R-CT Dep. on setting 4 bytes

1162 Computer 3: Condition text Output R-CT [16.0]

DPT_String_ASCII

14

bytes

1163 Computer 3: Monitoring status Output R-CT [1.1] DPT_Switch 1 bit

1164 Computer 3: Block (1: block) Input -WC- [1.1] DPT_Switch 1 bit

1165 Computer 4: Input I1 Input RWCT Dep. on setting 4 bytes

1166 Computer 4: Input I2 Input RWCT Dep. on setting 4 bytes

1167 Computer 4: Input I3 Input RWCT Dep. on setting 4 bytes

1168 Computer 4: Output O1 Output R-CT Dep. on setting 4 bytes

1169 Computer 4: Output O2 Output R-CT Dep. on setting 4 bytes

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 28

27 Transfer protocol

No. Text Function Flags DPT type Size

1170 Computer 4: Condition text Output R-CT [16.0]

DPT_String_ASCII

14

bytes

1171 Computer 4: Monitoring status Output R-CT [1.1] DPT_Switch 1 bit

1172 Computer 4: Block (1: block) Input -WC- [1.1] DPT_Switch 1 bit

1173 Computer 5: Input I1 Input RWCT Dep. on setting 4 bytes

1174 Computer 5: Input I2 Input RWCT Dep. on setting 4 bytes

1175 Computer 5: Input I3 Input RWCT Dep. on setting 4 bytes

1176 Computer 5: Output O1 Output R-CT Dep. on setting 4 bytes

1177 Computer 5: Output O2 Output R-CT Dep. on setting 4 bytes

1178 Computer 5: Condition text Output R-CT [16.0]

DPT_String_ASCII

14

bytes

1179 Computer 5: Monitoring status Output R-CT [1.1] DPT_Switch 1 bit

1180 Computer 5: Block (1: block) Input -WC- [1.1] DPT_Switch 1 bit

1181 Computer 6: Input I1 Input RWCT Dep. on setting 4 bytes

1182 Computer 6: Input I2 Input RWCT Dep. on setting 4 bytes

1183 Computer 6: Input I3 Input RWCT Dep. on setting 4 bytes

1184 Computer 6: Output O1 Output R-CT Dep. on setting 4 bytes

1185 Computer 6: Output O2 Output R-CT Dep. on setting 4 bytes

1186 Computer 6: Condition text Output R-CT [16.0]

DPT_String_ASCII

14

bytes

1187 Computer 6: Monitoring status Output R-CT [1.1] DPT_Switch 1 bit

1188 Computer 6: Block (1: block) Input -WC- [1.1] DPT_Switch 1 bit

1189 Computer 7: Input I1 Input RWCT Dep. on setting 4 bytes

1190 Computer 7: Input I2 Input RWCT Dep. on setting 4 bytes

1191 Computer 7: Input I3 Input RWCT Dep. on setting 4 bytes

1192 Computer 7: Output O1 Output R-CT Dep. on setting 4 bytes

1193 Computer 7: Output O2 Output R-CT Dep. on setting 4 bytes

1194 Computer 7: Condition text Output R-CT [16.0]

DPT_String_ASCII

14

bytes

1195 Computer 7: Monitoring status Output R-CT [1.1] DPT_Switch 1 bit

1196 Computer 7: Block (1: block) Input -WC- [1.1] DPT_Switch 1 bit

1197 Computer 8: Input I1 Input RWCT Dep. on setting 4 bytes

1198 Computer 8: Input I2 Input RWCT Dep. on setting 4 bytes

1199 Computer 8: Input I3 Input RWCT Dep. on setting 4 bytes

1200 Computer 8: Output O1 Output R-CT Dep. on setting 4 bytes

1201 Computer 8: Output O2 Output R-CT Dep. on setting 4 bytes

1202 Computer 8: Condition text Output R-CT [16.0]

DPT_String_ASCII

14

bytes

1203 Computer 8: Monitoring status Output R-CT [1.1] DPT_Switch 1 bit

1204 Computer 8: Block (1: block) Input -WC- [1.1] DPT_Switch 1 bit

For all models:

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 29

28 Transfer protocol

No. Text Function Flags DPT type Size

1391 Logic input 1 Input -WC- [1.2] DPT_Bool 1 bit

1392 Logic input 2 Input -WC- [1.2] DPT_Bool 1 bit

1393 Logic input 3 Input -WC- [1.2] DPT_Bool 1 bit

1394 Logic input 4 Input -WC- [1.2] DPT_Bool 1 bit

1395 Logic input 5 Input -WC- [1.2] DPT_Bool 1 bit

1396 Logic input 6 Input -WC- [1.2] DPT_Bool 1 bit

1397 Logic input 7 Input -WC- [1.2] DPT_Bool 1 bit

1398 Logic input 8 Input -WC- [1.2] DPT_Bool 1 bit

1399 Logic input 9 Input -WC- [1.2] DPT_Bool 1 bit

1400 Logic input 10 Input -WC- [1.2] DPT_Bool 1 bit

1401 Logic input 11 Input -WC- [1.2] DPT_Bool 1 bit

1402 Logic input 12 Input -WC- [1.2] DPT_Bool 1 bit

1403 Logic input 13 Input -WC- [1.2] DPT_Bool 1 bit

1404 Logic input 14 Input -WC- [1.2] DPT_Bool 1 bit

1405 Logic input 15 Input -WC- [1.2] DPT_Bool 1 bit

1406 Logic input 16 Input -WC- [1.2] DPT_Bool 1 bit

1411 AND logic 1: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1412 AND logic 1: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1413 AND logic 1: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1414 AND logic 1: Block Input -WC- [1.1] DPT_Switch 1 bit

1415 AND logic 2: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1416 AND logic 2: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1417 AND logic 2: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1418 AND logic 2: Block Input -WC- [1.1] DPT_Switch 1 bit

1419 AND logic 3: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1420 AND logic 3: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1421 AND logic 3: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1422 AND logic 3: Block Input -WC- [1.1] DPT_Switch 1 bit

1423 AND logic 4: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1424 AND logic 4: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1425 AND logic 4: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1426 AND logic 4: Block Input -WC- [1.1] DPT_Switch 1 bit

1427 AND logic 5: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 30

29 Transfer protocol

No. Text Function Flags DPT type Size

1428 AND logic 5: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1429 AND logic 5: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1430 AND logic 5: Block Input -WC- [1.1] DPT_Switch 1 bit

1431 AND logic 6: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1432 AND logic 6: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1433 AND logic 6: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1434 AND logic 6: Block Input -WC- [1.1] DPT_Switch 1 bit

1435 AND logic 7: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1436 AND logic 7: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1437 AND logic 7: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1438 AND logic 7: Block Input -WC- [1.1] DPT_Switch 1 bit

1439 AND logic 8: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1440 AND logic 8: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1441 AND logic 8: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1442 AND logic 8: Block Input -WC- [1.1] DPT_Switch 1 bit

1443 OR logic 1: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1444 OR logic 1: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1445 OR logic 1: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1446 OR logic 1: Block Input -WC- [1.1] DPT_Switch 1 bit

1447 OR logic 2: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1448 OR logic 2: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1449 OR logic 2: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1450 OR logic 2: Block Input -WC- [1.1] DPT_Switch 1 bit

1451 OR logic 3: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1452 OR logic 3: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1453 OR logic 3: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1454 OR logic 3: Block Input -WC- [1.1] DPT_Switch 1 bit

1455 OR logic 4: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 31

30 Transfer protocol

No. Text Function Flags DPT type Size

1456 OR logic 4: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1457 OR logic 4: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1458 OR logic 4: Block Input -WC- [1.1] DPT_Switch 1 bit

1459 OR logic 5: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1460 OR logic 5: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1461 OR logic 5: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1462 OR logic 5: Block Input -WC- [1.1] DPT_Switch 1 bit

1463 OR logic 6: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1464 OR logic 6: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1465 OR logic 6: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1466 OR logic 6: Block Input -WC- [1.1] DPT_Switch 1 bit

1467 OR logic 7: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1468 OR logic 7: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1469 OR logic 7: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1470 OR logic 7: Block Input -WC- [1.1] DPT_Switch 1 bit

1471 OR logic 8: 1-bit switching output Output R-CT [1.2] DPT_Bool 1 bit

1472 OR logic 8: 8-bit output A Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1473 OR logic 8: 8-bit output B Output R-CT [5.10] DPT_-

1 byte

Value_1_Ucount

1474 OR logic 8: Block Input -WC- [1.1] DPT_Switch 1 bit

For all models:

1491 Smoke alarm: alarm (1: active) Output R-CT [1.1] DPT_Switch 1-bit

1492 Smoke alarm: acknowledgeable

Output R-CT [1.1] DPT_Switch 1-bit

alarm (1: active)

1493 Smoke alarm: acknowledgeable

Input -WC- [1.1] DPT_Switch 1-bit

alarm off (1:Quit)

1495 Smoke alarm: button acknowledge-

Output R-CT [1.1] DPT_Switch 1-bit

ment (1: active)

1497 Smoke alarm: External alarm

Input -WC- [1.1] DPT_Switch 1-bit

(1: active)

1500 Smoke alarm malfunction (1: active) Output R-CT [1.1] DPT_Switch 1-bit

1502 Smoke alarm: Battery warning

Output R-CT [1.1] DPT_Switch 1-bit

(1: flat)

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 32

31 Transfer protocol

No. Text Function Flags DPT type Size

1503 Smoke alarm: Smoke chamber

Output R-CT [1.1] DPT_Switch 1-bit

warning (1: defective)

For Salva KNX TH only:

1504 Smoke alarm: Heat warning

Output R-CT [1.1] DPT_Switch 1-bit

(1: active)

For all models:

1508 Smoke alarm: Diagnosis memory

date/time

1509 Smoke alarm: Diagnosis memory

Input -WCT [19.1] DPT_Date-

8 bytes

Time

Input -WCT [11.1] DPT_Date 3 bytes

date

1510 Smoke alarm: Diagnosis memory

time of day

1511 Smoke alarm: Diagnosis memory

Input -WCT [10.1] DPT_-

3 bytes

TimeOfDay

Input -WC- [1.1] DPT_Switch 1-bit

scroll

1512 Smoke alarm: Diagnosis memory

Input -WC- [1.1] DPT_Switch 1-bit

(1: delete)

1513 Smoke alarm: Diagnosis memory

text: Name

1514 Smoke alarm: Diagnosis memory

text: Number

1515 Smoke alarm: Diagnosis memory

text: Type

1516 Smoke alarm: Diagnosis memory

text: Date

1517 Smoke alarm: Diagnosis memory

text: Time

Output R-CT [16.0]

DPT_String_ASCII

Output R-CT [16.0]

DPT_String_ASCII

Output R-CT [16.0]

DPT_String_ASCII

Output R-CT [16.0]

DPT_String_ASCII

Output R-CT [16.0]

DPT_String_ASCII

14

bytes

14

bytes

14

bytes

14

bytes

14

bytes

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 33

32 Setting the parameters for all models

7. Setting the parameters for all models

7.1. Behaviour on power failure/ restoration of power

Behaviour following a failure of the bus power supply:

The device sends nothing.

Behaviour on bus restoration of power and following programming or reset:

The device sends all outputs according to their send behaviour set in the parameters

with the delays established in the "General settings" parameter block.

7.2. General settings

Set basic characteristics for the data transfer. A different transmission delay prevents

an overload of the bus shortly after the reset.

Send delay after power-up and programming for:

Measured values 5 s • ... • 2 h

Threshold values and switching outputs

(Salva KNX TH only)

Controller objects

(Salva KNX TH only)

Comparator and computer objects 5 s • ... • 2 h

Logic objects 5 s • ... • 2 h

Maximum telegram rate • 1 telegrams per second

5 s • ... • 2 h

5 s • ... • 2 h

• ...

• 10 telegrams per second

• ...

• 20 telegrams per second

7.3. Smoke alarm

Activate the smoke alarm functions and assign a name to the device.

Use smoke alarm No • Yes

Smoke alarm name [Free text max. 14 characters.]

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 34

33 Setting the parameters for all models

Alarm

Set the value the smoke alarm object is to have in the event of an alarm, and the circumstances in which it is to be sent.

Object evaluation 1 = active • 0 = active

Send pattern • on change

Cycle

(if sent periodically)

• on change to active

• on change to inactive

• on change and periodically

• on change to active and periodically

• on change to inactive and periodical

5 s • 10 s • 30 s • ... 2 h

Acknowledgeable alarm

The acknowledgeable alarm is active when the smoke alarm is activated. This special

alarm message can, however, be acknowledged and thus "reset" via the bus, e.g. with

a button or a control display. Set the function to "yes" to send an acknowledgeable

alarm with the smoke alarm to the bus.

Use acknowledgeable alarm No • Yes

Then determine the value for the output object "smoke alarm: acknowledgeable alarm"

in the event of an alarm and when it is to be sent. The object is activated when there is

a smoke alarm.

Object evaluation 1 = active • 0 = active

Send pattern • on change

Cycle

(if sent periodically)

The alarm can only be switched off with the input object "smoke alarm: acknowledgeable alarm off". Set the value the acknowledgement is to have.

Evaluation of the acknowledgement object 1 = acknowledgement • 0 = acknowledge-

• on change to active

• on change to inactive

• on change and periodically

• on change to active and periodically

• on change to inactive and periodical

5 s • 10 s • 30 s • ... 2 h

ment

Button acknowledgement

Acknowledge the smoke alarm using the button on the device to turn the acoustic

alarm signal off (see also Alarm-Stummschaltung (Quittierung), Seite 18).

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 35

34 Setting the parameters for all models

If the button acknowledgement is to be sent to the bus, set the function to "yes". Acknowledgement is automatically switched off again 10 minutes after the end of the

smoke detection.

Use button acknowledgement No • Yes

Then determine the value for the output object "smoke alarm: button acknowledgement" in case of active acknowledgement and when it is to be sent.

Object evaluation 1 = active • 0 = active

Send pattern • on change

Cycle

(if sent periodically)

• on change to active

• on change to inactive

• on change and periodically

• on change to active and periodically

• on change to inactive and periodical

5 s • 10 s • 30 s • ... 2 h

External alarm

If an alarm message from another device to this device is also to trigger an alarm, then

set the function to "yes". Then determine the value for the alarm input object "smoke

alarm: external alarm" at which the external alarm should be active.

Use external alarm No • Yes

Object evaluation 1 = active • 0 = active

Sensor malfunction

If a sensor malfunction is to be sent to the bus, set the function to "yes".

Use malfunction object No • Yes

Then determine the value for the output object "smoke alarm: malfunction" in the event

of a malfunction and when it is to be sent.

Object evaluation 1 = active • 0 = active

Send pattern • on change

Cycle

(if sent periodically)

• on change to active

• on change to inactive

• on change and periodically

• on change to active and periodically

• on change to inactive and periodical

5 s • 10 s • 30 s • ... 2 h

Battery warning

If a warning is to be issued when the battery is nearly flat, set the function to "yes".

A battery that is nearly flat is also always indicated locally on the device.

Use battery warning No • Yes

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 36

35 Setting the parameters for all models

Then determine the value for the output object "smoke alarm: battery warning" should

the battery be nearly flat and when it is to be sent.

Object evaluation 1 = flat • 0 = flat

Send pattern • on change

Cycle

(if sent periodically)

• on change to active

• on change to inactive

• on change and periodically

• on change to active and periodically

• on change to inactive and periodical

5 s • 10 s • 30 s • ... 2 h

Smoke chamber fault warning

If a warning is to be issued when the smoke chamber is faulty, set the function to "yes".

Dirt in the smoke chamber is also indicated as a fault.

Use smoke chamber fault warning No • Yes

Then determine the value for the output object "smoke alarm: smoke chamber fault" in

the event that it is faulty and when it is to be sent.

Object evaluation 1 = faulty • 0 = faulty

Send pattern • on change

Cycle

(if sent periodically)

• on change to active

• on change to inactive

• on change and periodically

• on change to active and periodically

• on change to inactive and periodical

5 s • 10 s • 30 s • ... 2 h

Heat warning

This function is only available for Salva KNX TH.

If a drastic temperature rise is to be sent to the bus, set the function to "yes". The system can then detect the heat from fire, which does not always coincide with smoke

emission.

Use heat warning No • Yes

Set the threshold value and hysteresis for the heat warning. Warning stops when value

falls below the "threshold value minus hysteresis"

Heat warning threshold value (in 0.1°C) -300...800; 570

Heat warning hysteresis (in 0.1°C) 0...1100; 50

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 37

36 Setting the parameters for all models

Then determine the value for the output object "smoke alarm: heat warning" in the

event of active heat warning and when it is to be sent.

Object evaluation 1 = faulty • 0 = faulty

Send pattern • on change

Cycle

(if sent periodically)

• on change to active

• on change to inactive

• on change and periodically

• on change to active and periodically

• on change to inactive and periodical

5 s • 10 s • 30 s • ... 2 h

Diagnostics memory

If the messages and warnings set above are to appear in the diagnostics memory, set

this function to "yes". Only the functions marked with "yes" are saved to the memory.

The latest error always has the number 1.

Use diagnosis memory No • Yes

Messages are indicated with the date and time. For this, the time data must first be received via the bus. Set whether the time and date are to be received as separate objects

or as one common object.

If time and date are received via two objects , then a maximum of 10 seconds only may

elapse between receiving the date and receiving the time. Furthermore, a change of

date may not occur between receiving both objects. The objects must be received by

the device on the same day.

Date and time will be set by • two separate objects

The diagnosis memory may be deleted with the input object 1512 "smoke alarm: diagnosis memory (1/0:delete)". Set the object value at which the memory is to be cleared.

Clear diagnosis memory • at value 1

For a diagnosis message, the output text is:

1513 "smoke alarm.: Diagnosis memory text: name": Equipment name.

1514 "smoke alarm.: diagnosis memory text: number": The latest message always has

the number 1.

1515 "smoke alarm: diagnosis memory text: type": Define a separate text for each type

of message

1516 "smoke alarm.: diagnosis memory text: date:".

1517 "smoke alarm.: diagnosis memory text: time:".

Set the texts for the individual messages that are output with it:

• one common object

• at value 0

• at value 0 or 1

Internal alarm active [Free text max. 14 characters.]

Internal alarm inactive [Free text max. 14 characters.]

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 38

37 Setting the parameters for all models

Acknowledgeable alarm active [Free text max. 14 characters.]

Acknowledgeable alarm inactive [Free text max. 14 characters.]

External alarm active [Free text max. 14 characters.]

External alarm inactive [Free text max. 14 characters.]

Sensor malfunction active [Free text max. 14 characters.]

Sensor malfunction inactive [Free text max. 14 characters.]

Battery warning active [Free text max. 14 characters.]

Battery warning inactive [Free text max. 14 characters.]

Smoke chamber fault warning active [Free text max. 14 characters.]

Smoke chamber fault warning inactive [Free text max. 14 characters.]

Heat warning active [Free text max. 14 characters.]

Heat warning inactive [Free text max. 14 characters.]

Determine the cases in which diagnosis messages are to be sent.

Send pattern • on receipt of scroll object

• on receipt of scroll object and

new message

7.4. Variable comparator

The integrated variable comparators can output maximum, minimum and average

values.

Use comparator 1/2/3/4 No • Yes

7.4.1. Control variable comparator 1/2/3/4

Determine what the control variable comparator should output, and activate the input

objects to be used. Transmission patterns and blocks can also be set.

Output delivers • Maximum value

Use input 1 / 2 / 3 / 4 / 5 No • Yes

Output sends • on change of output

Send cycle

(if sent periodically)

At and above change of

(if sent on change)

Analysis of the blocking object • at value 1: block | at value 0: release

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

• Minimum value

• Average value

• on change of output and periodically

• when receiving an input object

• when receiving an input object and

periodically

5 s • 10 s • 30 s • ... • 5 min • … • 2 h

1% • 2% • 5% • 10% • 20% • 25% • 50%

• at value 0: block | at value 1: release

Page 39

38 Setting the parameters for all models

Blocking object value

before 1st communication

Behaviour of the switching output

On block • do not send message

Sent value in % 0 ... 100

output sends on release

(with 2 seconds release delay)

0 • 1

• Send value

• the current value

• the current value after receipt of an object

7.5. Computer

Activate the multi-functional computer, with which the input data can be changed by

calculation, querying a condition or converting the data point type. The menus for the

further setting of the computer are then displayed.

Computer 1/2/3/4/5/6/7/8 No • Yes

7.5.1. Computer 1-8

Set, in which cases input values received are to be kept per object. Please note that the

setting "After power restoration and programming" should not be used for the initial

start-up, as the factory settings are always used until the first call (setting via objects is

ignored).

Maintain the

input values received via communication

objects

• never

• after power supply restoration

• after power supply restoration and

programming

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 40

39 Setting the parameters for all models

Select the function set the input mode and starting values for input 1 and input 2.

Function (I = Input) • Prerequisite: E1 = E2

• Prerequisite: E1 > E2

• Prerequisite: E1 >= E2

• Prerequisite: E1 < E2

• Prerequisite: E1 <= E2

• Prerequisite: E1 - E2 >= E3

• Prerequisite: E2 - E1 >= E3

• Prerequisite: E1 - E2 amount >= E3

• Calculation: E1 + E2

• Calculation: E1 - E2

• Calculation: E2 - E1

• Calculation: E1 - E2 Amount

• Calculation: Output 1 = E1 × X + Y |

Output 2 = E2 × X + Y |

• Transformation: General

Tolerance for comparison

0 ... 4,294,967,295

(in the case of prerequisite E1 = E2)

Input type [Selection options depending on the func-

tion]

• 1 bit

• 1 byte (0...255)

• 1 byte (0%...100%)

• 1 byte (0°...360°)

• 2 byte counter without math. symbol

• 2 byte counter with math. symbol

• 2 byte floating point

• 4 byte counter without math. symbol

• 4 byte counter with math. symbol

• 4 byte floating point

Starting value E1 / E2 / E3 [Input range depending on the type of

input]

Prerequisites

When querying the prerequisites set the output type and output values at different statuses:

Output type • 1 bit

• 1 byte (0...255)

• 1 byte (0%...100%)

• 1 byte (0°...360°)

• 2 byte counter without math. symbol

• 2 byte counter with math. symbol

• 2 byte floating point

• 4 byte counter without math. symbol

• 4 byte counter with math. symbol

• 4 byte floating point

Output value (if applicable output value A1 / A2)

Smoke alarm Salva KNX • Version: 09.09.2016 • Technical Changes and Errors excepted.

Page 41

40 Setting the parameters for all models