ELREHA EVP 3150-1, EVP 3150-2 Technical Manual

In controllers which contain older software

versions, some functions may not be available!

Brief Description / Applications

• Controller for all kind of Storages, such as Walk-In Coolers/Freezers,

Refrigerated Shelfs, Refrigerated Counters, Refrigerated Cases, etc.

• For standard cold storages or cold storages with pulse-width modulated

expansion valves or expansion valves with thermal drive

• For single or network operation

• 4 Temperature sensors, 4 Relays, 2 Digital Inputs, Analogue In-/Output

Standard Functions

• Controls temperature, defrost device, evaporator fans, roller blinds, etc.

• Up to 3 evaporators with a single device

• 2 expansion Valve control methods selectable

• Valve control is fully autoadaptive

• Foresight control and condenser pressure optimization in cooperation

with the VPR compressor compounds central unit

• Intelligent defrost control, able to learn, no additional sensors

• Defrost Start fully automatic, by 6 release times or manually

• Defrost cycle is pulsed, controlled by evap sensor (variable intervals)

• Automatic recognition of the leading evaporator

• Emergency Mode if sensor or defrost recognition fails.

Autoreset after repair

• Use of Latency Heat by intelligent fan control

This may be a brief version of the technical manual.

A complete version with the pages 7...16 you can

find on www.elreha.de or our free INFO-CD.

Programming

All parameters of the EVP are distributed on different pages.

While normal operation or if no key is pressed for about 3 minutes, the EVP

displays the following information:

1st priority: current failure (blinking)

2nd priority: operating states (e.g. 'oFF')

3rd priority: selected 'permanent parameter' display

Selecting and Changing of Parameters

key action

P (> 2 sec.) .......Page name will be displayed

...................Select desired page

P .....................Enter the page

...................Select parameter

P .....................Prepare programming. Enter access code if necessary

...................Change value.

If you hold the key, the values change faster and faster

P .....................Confirm programming

P (> 2 sec.) .......Page name will be displayed again

If an older version must be replaced

- please note the modified terminals!

Technical Manual 5311092-00/26E

Cold Storage Controller

from SoftVers. 1.61

Types:

EVP 3150-1

EVP 3150-2

ELE KTR ONI SCH E R EGE LUN GEN G MBH

Please note safety instructions !

Parameter Pages

P

(L)

> 2 sec.

Actual

Values

Page

P

(r)

Setpoint

Page

(d)

Defrost

Page

(P)

Mode

Page

(h)

Assignment

Page

L01

r01

d01

P01

h01

1st. Parameter on the:

P

P

P

P

Access Protection

Except the temperature setpoints, parameters can be changed only after

entering a correct access code. If you want to change such a parameter after

pushing the "P"-key, then the following display appears:

Now the controller expects the entry of a code number .

This code number is always 88. Enter it by the up/down keys

and confirm it by pressing "P" again.

If no key is pushed for about 3 minutes, the code number must be entered

again.

88

(00

Manual Defrost

Start manual defrost: - Select "

d50" (Defrost Page),

- Set it to "on" and confirm.

Stop manual defrost: - Select "d50" (Defrost Page),

- Set it to "oFF" and confirm.

CAUTION

DANGER

Notice

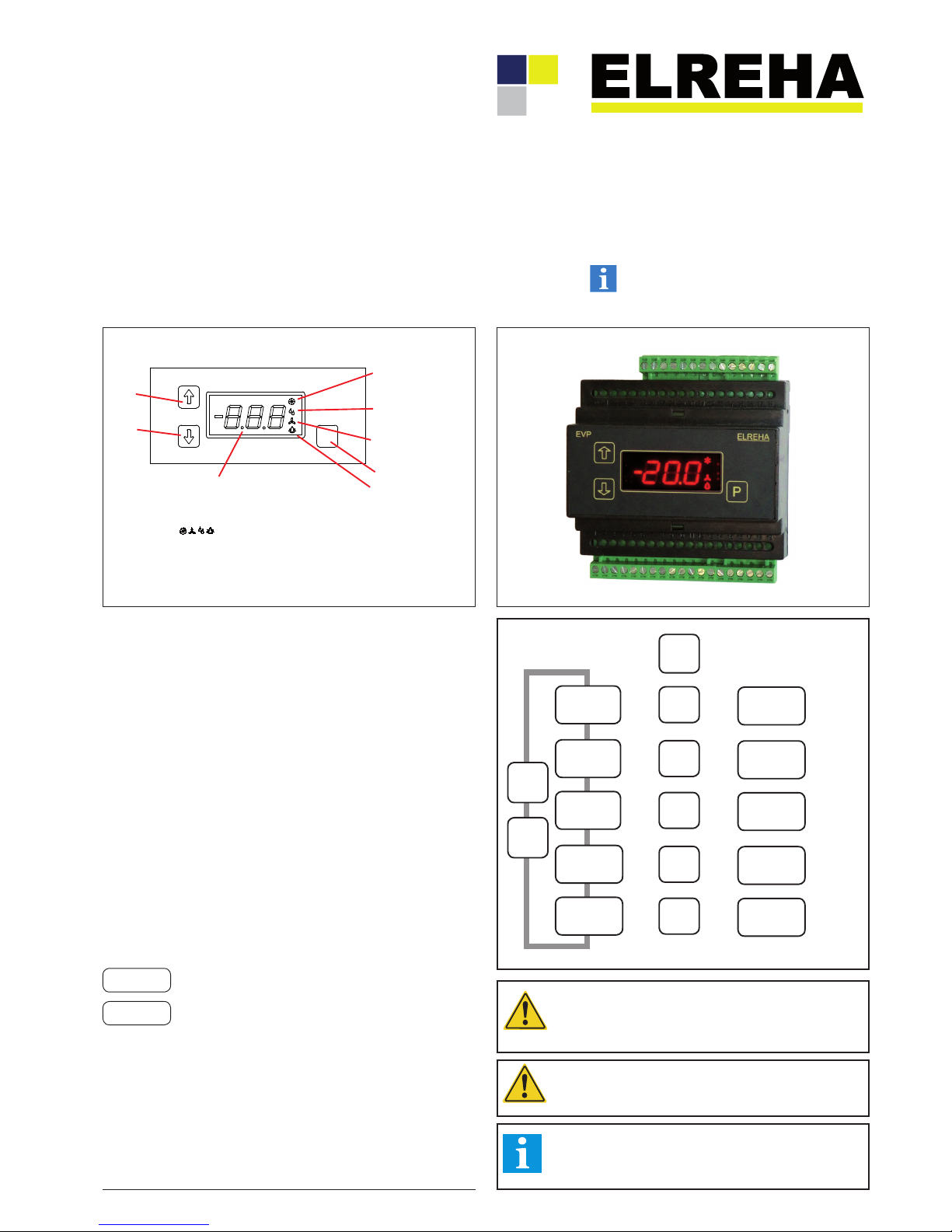

Operating / Operating Elements

increase

values

decrease

values

The currently displayed

setpoint is active

1 2 3

4

EVP

ELR EHA

P

3 keys allow programming the unit, all parameters will be displayed on

the red LED-7-segment display. 4 red symbols at the right side indicate

specific control functions (not the relay states, these are displayed on the

'Actual Page' !).

LED on = cooling

LED on = fan is running

Programming key

LED blinking = alarm

LEDs are blinking the same time =

control functions are disabled by digital input or via interface

LED on = defrost

The current states of the digital inputs can be read under L60, the state of the

relays and the data transmission can be read under L61 (Actual Values Page).

EV P

P

EL RE H A

The front view of the version with an older display you will find on page 6.

Technical Manual Cold Storage Controller EVP 3150-1 and EVP 3150-2Page 2

For the device EVP 3150-2 we state the following: When operated in accordance

with the technical manual, the criteria have been met that are outlined in the

EMC Directive 2014/30/EC and the Low Voltage Directive 2014/35/EC.

This declaration is valid for those products covered by the technical manual

which itself is part of the declaration.

Following standards were consulted for the conformity testing to meet the

requirements of EMC and Low Voltage Guidelines:

EN

55011:2016

EN 61010-1:2010

EN 61326-1:2013

CE marking of year: 2017

This statement is made from the manufacturer / importer by:

ELREHA, Elektronische Regelungen GmbH

D-68766 Hockenheim

by

Werner Roemer, Technical Director

(Name)

Hockenheim.............26.6.2017......................................................................

(City) (Date) (Signature)

EC Declaration of Conformity

Accessories

- Temperature sensor TF 501, quantity depends on application

- Pressure Transducer DG 0/10 2/10V with 2-10VDC output

- PC-Software "COOLVision"

Module "COOLVision-MES" for remote control and configuration

Modules "COOLVision-Analyse" and "COOLVision-SMM"

for data logging, visualization and alarm forwarding.

Technical Data

Supply Voltage EVP 3150-x ............................. 230V, 50-60Hz, max. 9VA

EVP 23150-x ................................

115V, 60 Hz, max. 9VA

max. 240VA with full load of the SSR-output

Ambient Temperature .......................................................................0...+50°C

Max. Ambient Humidity ...........................................85% r.F., not condensing

Analogue Inputs ...................................................

4x Temperature Sensors

TF 201 (PTC) or TF 501 (Pt 1000)

1x pressure transducer 0(2)-10V (scalable), Ri=69 kOhm

Measuring ranges ...................TF 501 (Pt1000) .................... -100°C...+100°C

of the probe inputs TF 201

(PTC, 2 kΩ at°C) ........... -50°C...+100°C

So1 .........................................

-40°C...+25°C

So2 .........................................

-50°C...+50°C

The temperature ranges of the probe heads

and cables must be obeserved !

Accuracy .....................................................±0.5K in range -35...25°C within

the ambient temperature range 10...30°C

Digital Inputs ......................................................2x mains voltage, 3mA max.

Relay Outputs ........................................ 3x SPDT isolated, 8A res/3A ind./250V

EEx-Valve Output ..............

1x Solid-State-Relay (SSR), max. 1A / 250VAC

or 230V DC / 500mA

Please note the information at the connection plan about a

necessary snubber circuit at the SSR output!

Transducer Supply .............................................22V DC ±10%, 40 mA max.

Analogue Output ...........................................0...10V or 4...20mA (selectable)

0...10VDC, max. current typ. 1mA

4...20 mA, max. shunt resistance 250 ohms

Display/Parameter Ranges ..........................................see parameter pages

Data Interface ......................................................................................RS 485

Data storage ......................................................................................unlimited

Real Time Clock ..........................................automatic summer/winter switch

10 days clock backup without mains voltage

Housing ................ plastic with foil keypad for rail mounting (DIN EN 50022),

screw terminals 2,5 mm

Danger

Notice

CONNECTION INFORMATION & SAFETY INSTRUCTIONS

The guarantee will lapse in case of damage caused by failure

to comply with these operating instructions! We shall not be

liable for any consequent loss! We do not accept liability for

personal injury or damage to property caused by inadequate

handling or non-observance of the safety instructions! The

guarantee will lapse in such cases.

This manual contains additional safety instructions in the

functional description. Please note them!

If you notice any damage, the product may not be connected

to mains voltage! Danger of Life!

A riskless operation is impossible if:

• The device has visible damages or doesn't work

• After a long-time storage under unfavourable conditions

• The device is strongly draggled or wet

• After inadequate shipping conditions

• Never use this product in equipment or systems that are

intended to be used under such circumstances that may

affect human life. For applications requiring extremely

high reliability, please contact the manufacturer first.

• The product may only be used for the applications

described on page 1.

• Electrical installation and putting into service must be

done from qualified personnel.

• During installation and wiring never work when the

electricity is not cut-off ! Danger of electric shock!

• To prevent electrical shock, the device may only be

operated in a closed control cabinet or control box.

• Never operate unit without housing.

Danger of electric shock!

• All ‘PE’ terminals must be connected to PE.

Danger of electric shock! Additionally, the internal noise

filter will not work, faulty indicated values may occur.

• Please note the safety instructions and standards of your

place of installation!

• Before installation: Check the limits of the controller and

the application (see tech. data). Check amongst others:

- Make sure that all wiring has been made in accordance

with the wiring diagram in this manual.

- Supply voltage (is printed on the type label).

- Environmental limits for temperature/humidity.

- Maximum admitted current rate for the relays. Compare

it with the peak start-up currents of the controlled loads

(motors, heaters,etc.).

Outside these limits malfunction or damages may occur.

• Sensor/probe cables must be shielded. Don’t install them

in parallel to high-current cables. Shielding must be

connected to PE at the end close to the controller.

If not, inductive interferences may occur.

• Please note for elongation: The wire gauge is not critical,

but should have 0,5mm² as a minimum.

• Mounting the controller close to power relays is

unfavourable. Strong electro-magnetic interference,

malfunction may occur!

• Take care that the wiring of interface lines meets the

necessary requirements.

• All used temperature sensors must be identical. Never

use different types at the same time. This will not work.

• TF-type sensors are not designed for being immersed in

fluids permanently. In such a case, always use dip-fittings.

With extreme temperature variations, the sensor may be

damaged.

Cleaning

The use of a dry, lint-free cloth and household agents is

sufficient to clean the product.

Never use acids or acidic fluids! Risk of damage!

Technical Manual Cold Storage Controller EVP 3150-1 and EVP 3150-2 Page 3

Error Messages / Error Memory / Error Codes

If a failure occurs, the controller will show parameter P43 with an error code with a flashing display automatically. Always the last 15 errot messages keep memorized with date and time of their appearance

and can be read-out via data interface.

---- .............. no error

sel ............ error in assignment page, e.g. function selected too often

Thi ............ alarm sensor, overtemperature

tlo ............ alarm sensor, undertemperature

tXb ............ sensor X broken

tXc ............ sensor X hot-wired

dbt ............ number of defrost cycles without termination by temperature exceeded,

maybe too many ice or heater malfunction.

rrt ............ cooling has achieved maximum runtime. This message is only active at point-in-time

set by

P42 (mode page).

rdo ............ door contact is open too long. This message is only active at point-in-time set

by

P42 (mode page).

dor ............ door X is open

opc ............ alarm at digital input X

cha ............ safety chain open

hrd ............ hardware failure

If a sensor is short or broken, a time delay of 5 seconds takes effect before an alarm will be activated.

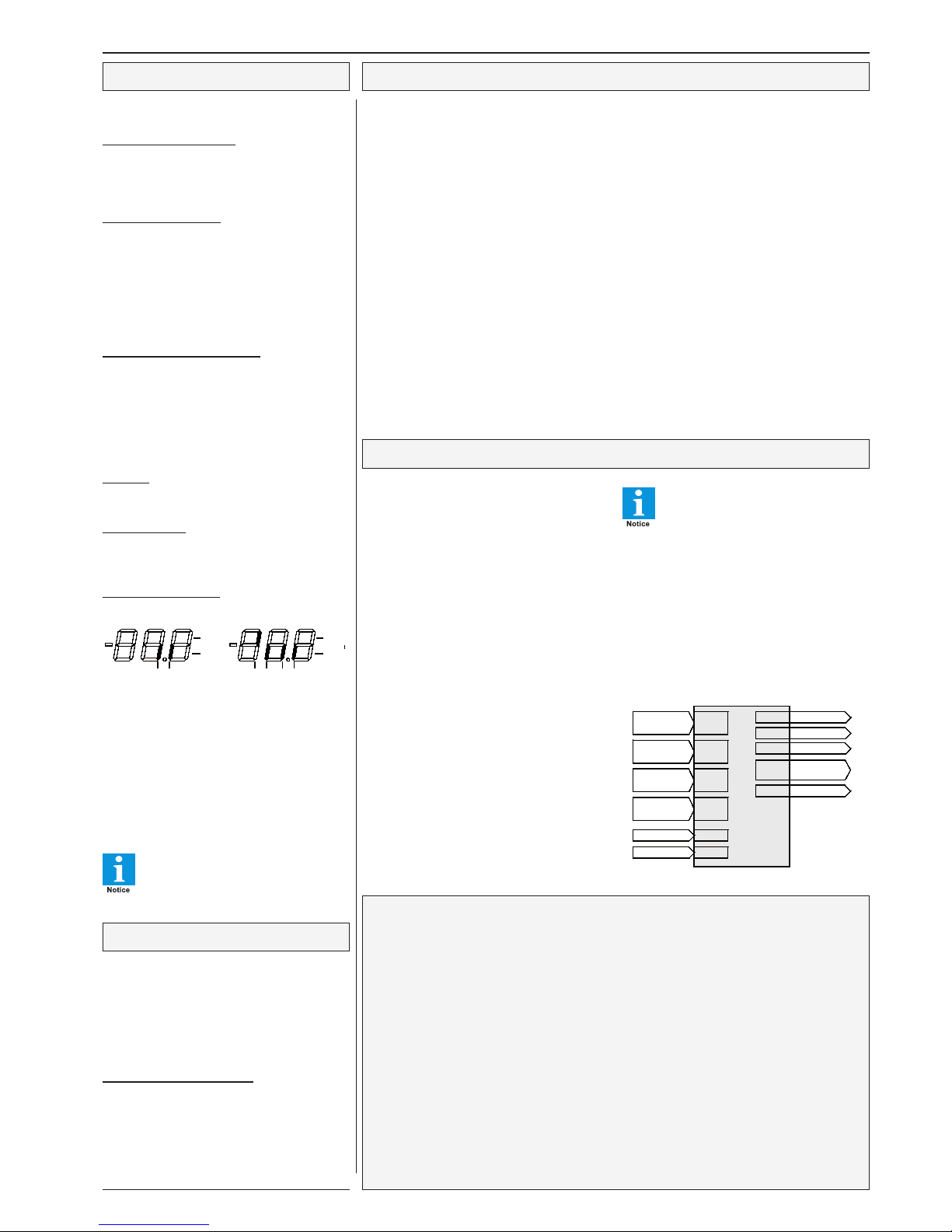

Configuration Concept

The inputs/outputs of the EVP-cold storage controller

have no fixed tasks. The EVP works with a "free

configurable" concept, this means that all available

inputs and outputs (relays, sensors, digital inputs,

analogue output) can be configured to work with any

integrated control function or control circuit.

Sensors

Each sensor can fulfill each function, even up to 3

functions at the same time. (Function (a) of sensor

X, Function (b) of sensor X, Function (c) of sensor

X, X = sensor#). e.g.:

1. Control sensor /alarm sensor at the same time

2. Defrost limitation sensor and control sensor at

the same time, e.g. to control a refrigerated

shelf by the temperature of its air outlet.

Virtual Sensors

Up to 4 sensors can be combined to a 'virtual' sensor

to realize averaging with selectable emphasis.

Digital inputs (Optocoupler inputs)

Each digital input can be assigned to one of the

possible functions.

Relay Outputs

Each relay can be used to control one of the possible

functions. The same function can even be assigned

to multiple relays.

Relay output #4 is a Solid State Relay

with a lower contact rating than the

standard relay outputs. Normally, this

output is used for driving Electronic Ex-

pansion Valves, but can be used for any

other task if it works within the specified current

range.

Parameter

Parameters of functions which are not assigned will not

appear in the parameter pages to improve survey.

Assignment

The function of each input and output can be preset

on the 'assignment page'. The assignment can be

done by keys or via interface.

Configuration Example for an EEx-Valve

Configuration of the controller

Hereby we use the example from above: A cold storage with an evaporator with Electronic Expansion

Valve.

Action Key Display Remarks

enter page lising ..........................."P" .......(A) ...............hold key for > 2 seconds

select assignment page................"" .... (h)

enter asssignment page ..............."P" .......h01 ..............h01 is the 1st parameter on the page and

determines the function of relay 1

displaying the function of relay 1 .."P" .......any

new assignment of relay 1 ..........."P" ....... C00 ............(Code expected) only if no key key is hit for

about 3 minutes

enter access code ........................"" .......C88

confirm .........................................."P" ....... any

select function ..............................."" .... ALA .............ALA = alarm relay

confirm .........................................."P" ....... h01 ..............parameter # will be displayed again

select new in-/output ....................."" .......h02 ..............determines the function of relay 2

displaying the function of relay 2 .."P" .......any

new assignment of relay 2 ..........."P" ....... any

select function ..............................."" .... dF1 .............dF 1= defrost relay (evaporator 1)

confirm .........................................."P" ....... h02 ..............parameter # will be displayed again

Repeat this steps until all inputs and outputs are assigned to the desired functions.

Display of actual values and states

All actual values are shown on the "Actual Values

Page" ((l)).

Status of the controller unit

If the 4 status LED's on the front are blinking

simultaneously and the display shows "oFF", the

control functions are disabled by digital input or

data interface.

Display of temperatures

"L01" -" L04" (Actual Values Page) show the actual

temperature value of the sensors 1-4 in a range

within -100... +100°C. "L05" shows a temperature

value which is calculated from the pressure value

of the transducer and the selected refrigerant table,

"L07" shows the 'virtual' temperature value.

With "P31"-"P34" and "P36" (Mode Page) this

displays can be calibrated.

Expansion Valve Status Display

This shows the current, average aperture size

from 0...100 % and additionally the actual state

of the valve.

cut = Restart of the evaporator after abnormal

operating conditions (cutoff)

pdo = Pumpdown of the refrigerant

(cooling relay ON for 30 sec.)

Setpoints

The active day or night setpoints are indicated by

the left decimal point switched on.

Time information

The Actual Values Page contains all runtime- /

remaining time information, so the times up to the

start of a function can be read.

Status of inputs/outputs

Digital-(OK)-Inputs State of the relays

Analogue Output: Parameter L50, value in %

Temperature Sensors

These types of temperature sensors can be used:

- TF 201, PTC sensor (2000 ohms@25°C)

- TF 501, PT1000 sensor (1000 ohms@0°C)

- customer specific sensor So1 (-40...+25°C)

- customer specific sensor So2 (-50...+50°C)

The type of sensor can be set by 'P35' (Mode

Page).

Please don't use the TF 201 sensor

if you work with Electronic

Expansion Valves.

'Permanent Parameter' - Function

After power-up of the controller, the display will

indicate the 'permanent parameter' after some

seconds (or in case of a failure it will display the

current failure). This can also be read if you don’t

touch a key for more than 3 minutes.

If you think that it is suggestive to show any sensor

value as permanent parameter, do the following:

Change permanent parameter

- Select the parameter you want to have as

'permanent parameter'

- Press "

" and " " simultaneously.

The display shows "

888" for a moment, after

that the selected parameter will be shown as

the 'permanent parameter'.

OK 21

23 0V

0V

Relay

On

OFF

1: con

2: ALA

3:........................

1: dF1

2: .......................

3:........................

1: out

2: .......................

3:........................

1: InL

2: .......................

3:........................

dEF

dnh

sensor 1

sensor 2

sensor 3

sensor 4

relay 1

relay 2

relay 3

SolidState

Relay 4

Analog

EVP

Assignment

In-/Outputs

ALA

dF1

FAn

EEP

dIS

DI 1

DI 2

Technical Manual Cold Storage Controller EVP 3150-1 and EVP 3150-2Page 4

Parameter Pages

Actual Values Page (L)

Setpoint Page (r)

Defrost Page (d)

Param. Note Range Factory Setting

r01 ..........................Setpoint Layer ..........................................................................................................................1, 2 ............................... 1

r02 ..........................Setpoint 1 (day) ........................................................................................................................-100/+100°C ................ -20°C

r03 ..........................Setpoint 2 (night) ......................................................................................................................-100/+100°C ................ -20°C

r04 ..........................Setpoint 1 (day), Setpoint Layer 2 ...........................................................................................-100/+100°C ................ -20°C

r05 ..........................Setpoint 2 (night), Setpoint Layer 2 .........................................................................................-100/+100°C ................ -20°C

r10 ..........................Hysteresis .................................................................................................................................0,1...20K ...................... 2 K

r22 ..........................Fan start delay ..........................................................................................................................0...30 (min.) ............... 5 min.

r23 ..........................Fan trailing delay ......................................................................................................................0...30 (min.) .............. 0 min.

r31 ..........................Runtime check cooling (in 10 minute steps) ................................... .......................................off, 00.0...23.5 ........... off

r32 ..........................Runtime check door (in 10 minute steps) ................................................................................off, 00.0...23.5 ........... off

r33 ..........................Minimum compressor idle time ................................................................................................0...30 min. ................... 0 min.

r34 ..........................Cooling delay after mains voltage loss ....................................................................................0...30 min. ................... 0 min.

r41 ..........................Alarm offset (relative to the setpoint) .......................................................................................0...100K ...................... 7 K

r42 .............. ............Alarm offset, Layer 2 (relative to the setpoint) .........................................................................0...100K ....................... 7 K

r43 ..........................Lower Alarm Limit (absolute value, threshold for low temperature limitation/alarm) .............-100/+100°C ................ - 50°C

!! Function cannot be switched off.

r44 ..........................Lower Alarm Limit, Layer 2 (absolute value) ...........................................................................-100/+100°C ................ - 50°C

r45 ..........................Temperature Alarm Delay ........................................................................................................0...120 min. ................. 45 min.

r46 ..........................Release time of safety chain ....................................................................................................0...60 sec. .................... 60 sec.

r51 ..........................PID proportional band ..............................................................................................................0.1...30.0 ...................... 4.0

r52 ..........................PID integration time ..................................................................................................................off, 1...600 sec. ......... 10 sec.

r53 ..........................PID attack time .........................................................................................................................off, 1...10 sec. ........... off

r54 ..........................PID delay ..................................................................................................................................off, 0.1...10.0 sec. ...... off

r56 ..........................Actuating Variable Delay of Analogue Output (for PID only) / output delay ...........................0...240 sec. .................. 0 sec.

r57 ..........................Actuating Variable Delay of Analogue Output (for PID only) / step size .................................1...100% ...................... 100%

r58 ..........................Cooling/Heating Relay Time Period ........................................................................................1...240 sec. .................. 1 sec.

r59 ..........................Cooling/Heating Relay ON-Time .............................................................................................1...240 sec. .................. 240 sec.

r61 ..........................Digital inputs alarm delay .........................................................................................................0 bis 120 min. ............. 5 min.

r62 ..........................Digital inputs door contact delay ..............................................................................................1 bis 240 min. ............. 5 min.

r63 ..........................Digital input analog value: Voltage/current at the analog outp. with active digital input ........0.0...100.0 %, ............. 0%

Param. Disp. Note Range Factory Setting

d01 .........................Fan during defrost ....................................................................................................................on, off ........................ off

d02 ..........................Defrost Mode ............................................................................................................................etn = external only, .... int

int = extern+intern

AdA = adaptive

d03 ..........................Fan operation before defrost ..................................................................................................0...15 minutes .............. 3 minutes

d04 ............X ..........Time up to defrost (in 10-minutes steps) .................................................................................168.0 h/min.... .............. 00.0

d05 ..........................Maximum time up to defrost (10-minutes steps) .....................................................................02.0...48.0 h/min .......... 24.0 h

d11 ..........................Defrost release time 1 (in 10-minutes steps) ..........................................................................00.0 - 23.5, off .......... 05.0

d12 ..........................Defrost release time 2 (in 10-minutes steps) ..........................................................................00.0 - 23.5, off .......... off

d13 ..........................Defrost release time 3 (in 10-minutes steps) ..........................................................................00.0 - 23.5, off .......... off

d14 ..........................Defrost release time 4 (in 10-minutes steps) ..........................................................................00.0 - 23.5, off .......... off

d15 ..........................Defrost release time 5 (in 10-minutes steps) ..........................................................................00.0 - 23.5, off .......... off

d16 ..........................Defrost release time 6 (in 10-minutes steps) ..........................................................................00.0 - 23.5, off .......... off

d31 ..........................Defrost limitation temperature .................................................................................................0.0°C...100°C .............. 14.0°C

d32 ..........................Max. defrost runtime (defrost safety time) ...............................................................................0...240 minutes ............ 45 min.

d33 ..........................Alarm time extension after defrost ...........................................................................................0...60 minutes .............. 30 min.

d34 ..........................Pulse-defrost threshold ............................................................................................................-5,0...+100°C ............... 100°C

d35 ..........................Cooling pause after defrost (drain time) ..................................................................................0...30 minutes .............. 0 min.

d36 ............X ..........Duration of last defrost .............................................................................................................minutes

d37 ..........................Number of defrost cycles limited by time, then alarm .............................................................off, 1-15...................... oFF

d38 ............X ..........Break before defrost .................................................................................................................0...15 minutes .............. 0 min

d50 ..........................Manual defrost initialization ......................................................................................................on, off

- Parameters marked by "Disp" are for information only and cannot be changed.

Param. Disp. Note Range Factory Setting

L01 ...........X ...........Actual temperature at sensor 1 .................................................................................................± 100°C ---

up to (can be corrected +/- 10K)

L04 ...........X ...........Actual temperature at sensor 4 ..................................................................................................± 100°C ---

L05 ...........X ...........Actual temp, calculated from pressure+refrigerant ....................................................................± 100°C ---

L07 ...........X ............Virtual temperature value, calculated from real values and selected emphasis .......................± 100°C ---

L09 ...........X ............Actual Overheat Temperature .....................................................................................................± 100°C ---

L21 ...........X ...........Runtime of cooling ......................................................................................................................24.0 h:(10min) max. 00:00

L22 ...........X ...........Runtime of open door .................................................................................................................24.0 h:(10min) max. 00:00

L31 ...........X ...........Remaining time of open door .....................................................................................................240 minutes max.

L32 ...........X ...........Remaining time of temperature alarm delay ..............................................................................120 minuten max.

L33 ...........X ...........Remaining defrost time ...............................................................................................................minutes

L34 ...........X ...........Remaining defrost idle time ........................................................................................................minutes

L35 ...........X ...........Remaining fan start delay time ...................................................................................................minutes

L36 ...........X ...........Remaining compressor idle time ................................................................................................minutes

L41 ...........X ...........Solenoid valve .............................................................................................................................0, 1, off

L42 ...........X ...........State of the Electronic Expansion Valve, actual aperture size in % or state .............................cut = cutoff

pdo = pumpdown

L43 ...........X ...........Day/Night Operation....................................................................................................................on, off

L44 ...........X ...........Operation state of the controller unit ..........................................................................................on, off

L50 ...........X ...........Actual Value of the analogue output in X% of the selected range ............................................0-100%

L60 ...........X ...........State of digital inputs OK1 (DI1) and OK2 (DI2) ........................................................................

L61 ...........X ...........States of relays 1-4, information about data transmission .........................................................

OK 21

230 V

0V

Relay

ON

OFF

If this point is ON while displaying a

parameter number (marked with X),

the parameter is active at present

blinking =

data transm.

Technical Manual Cold Storage Controller EVP 3150-1 and EVP 3150-2 Page 5

Mode Page (P)

Assignment Page (h)

Param. Disp. Note Range Factory Setting

P01 .........................Assigned to compressor compound #

(0 = not assigned)

.................0, 1, 2, 3 ............................................................. 1

P02 ..........................Fan operation mode .........................................................................int = Interval, per = Permanent .................... int

Add = Special mode pos. room temp.

+ latency heat utilisation

P03 ..........................Cooling mode (!note correct relay wiring)........................................ nor = normal, ın = inverted .............................. nor

P04 ..........................Emergency mode if sensor fails in % of the max. power .................0...100% .............................................................. 50%

P11 ..........................Frame heater, period time ................................................................10...60 minutes .........................1 ........................ 15 min.

P12 ..........................Frame heater, pulse width (day operation) ......................................0...100% .............................................................. 100%

P13 ..........................Frame heater, pulse width (night operation) ....................................0...100% .............................................................. 100%

P14 ..............X .........Current Pulse Width of the frame heater .........................................(eventually shifted by a VPR-host)

P21 ..........................Night operation ON at (in 10 min-steps) ..........................................00.0...23.5, oFf .................................................. oFf

P22 ..........................Night operation OFF at (in 10 min-steps) ........................................00.0...23.5, oFf .................................................. oFf

P31 ..........................Calibration sensor 1 .........................................................................+/-10.0, adjustable ............................................. 0.0

P32 ..........................Calibration sensor 2 .........................................................................+/-10.0, adjustable ............................................ 0.0

P33 ..........................Calibration sensor 3 .........................................................................+/-10.0, adjustable .............................................. 0.0

P34 ..........................Calibration sensor 4 .........................................................................+/-10.0, adjustable .............................................. 0.0

P35 ..........................Sensor type (with EExV's only use 501 types !) .............................201 = TF201 501 = TF501 (Pt1000) ............... 501

P36 ..........................Calibr. temp. value calculated by pressure/refrigerant ....................+/-10.0, adjustable .............................................. 0.0 K

P41 ..........................Undertemperature Alarm .................................................................on, off ............................................................... on

P42 ..........................Runtime message at (time) ..............................................................0...23 o'clock, off .............................................. 6 o'clock

P43 ..............X .........Current failure

P51 ..........................Analogue output delivers 0V if control sensor temp. = ...................-/+ 100°C ............................................................. -100°C

P52 ..........................Analogue output delivers 10V if control sensor temp. = .................-/+ 100°C ............................................................. +100°C

P53 ..........................Lower limit of pressure transmitter ..................................................-1,0...+90,0 bar .................................................... -1,0 bar

P54 ..........................Upper limit of pressure transmitter ..................................................-1,0...+90,0 bar .................................................... +9,0 bar

P55 ..........................Used refrigerant ................................................................................1= NH3, 2= R134a, 3= R22, 4= R23, 5= R404a, 0

0= switched OFF, control by temperature sensor 6= R507, 7= R404a, 8= R402b, 9= R407C

refrigerant selected = pressure/temperature method is active (wet steam), 10 = R407C (due p.), 11= R123

12 = R290, 13 = CO2, 14 = R502, 15= R 723

16= R410A , 17= R407F (due p.), 18= R449A

P56 ..........................Lower voltage limit of pressure transmitter input.............................0,0...10,0 V .......................................................... 0 V

Voltage below this limit = Error message "sensor broken"

P57 ..........................Upper voltage limit of pressure transmitter input.............................0,0...10,0 V .......................................................... 10,0 V

Voltage above this limit = Error message "sensor short circuit"

P60 ..........................Superheat (depends on evaporator) minimum value .....................0,0...50,0 K .......................................................... 8,0 K

P61 ..........................MOP (Limitation of evaporation temperature, ................................-100,0...+100,0°C ................................................ +100,0°C

depends on compressor resp. plant)

P62 ..........................P-Part of the Expansion Valve Control ............................................0,1...20,0 K .......................................................... 8,0 K

P63 ..........................I-Part of the Expansion Valve Control..............................................1...999 sec. .......................................................... 240 sec

P65 ..........................Superheat, maximum value .............................................................2,0...100,0K ......................................................... 8,0K

P66 ..........................Limitation of EEx-valve signal ..........................................................0...100% .............................................................. 100%

P67 ..........................Actuating Variable Delay (EEx-valve) / step size ............................1...100% .............................................................. 100%

P68 ..........................Actuating Variable Delay (EEx-valve) / output delay ......................0...240 sec. .......................................................... 0

P79 ..............X .........Software version

P81 ..........................Standard of summer/winter switch ..................................................oFF, on = EU since '96 ...................................... on

P82, P83 .................Year, Month

P84, P85 ..................Day, Hour

P86, P87 ..................Minute, Second

P90 ..........................Address of the controller unit in a network ......................................0 - 78 .................................................................... 78

P91 ..........................Data transmission speed (Baudrate) ...............................................Aut(o), 12(00)...576(00) ...................................... 96(00)

Param. Disp Note Range Factory Setting

h01 ...........................Function of relay 1 ...............................................---, on= continuous on, ref= cooling, dF1= defrost 1... dF3= def.3 ...... ref

fan

= fan, alA = alarm, fra = frame heater, Rol = roller blind,

Lit = light, kea = heater, eeP = EExValve, Uni = Relay OFF

with "controller OFF", continuous ON while normal opration

h02 ...........................Function of relay 2 ...............................................dto. ...............................................................................................................dF1

h03 ...........................Function of relay 3 ...............................................dto. ...............................................................................................................fan

h04 ...........................Function of relay 4 (Solid State Relay) ...............dto. ...............................................................................................................eeP

h11 ...........................Function (a) of sensor 1 ...................................... --- = off, con = control sens., dF1 = defrost limit. sens 1, ..................con

dF2

= defrost limit. sensor 2, dF3 = defrost limit. sensor 3,

alA

= alarm sensor, dis = display only sensor,

inL

= inlet sensor, ovt = outlet sensor

h12 ...........................Function (b) of sensor 1 ..................................... dto. ...............................................................................................................alA

h13 ...........................Function (c) of sensor 1 ......................................dto. ............................................................................................................... ---

h17 ...........................Sensor 1, emphasis for virtual sensor ................ 0...100% ......................................................................................................0%

h21 ...........................Function (a) of sensor 2 ...................................... dto. ...............................................................................................................dF1

h22 ...........................Function (b) of sensor 2 ..................................... dto. ...............................................................................................................---

h23 ...........................Function (c) of sensor 2 ......................................dto. ............................................................................................................... ---

h27 ...........................Sensor 2, emphasis for virtual sensor ................ 0...100% ......................................................................................................0%

h31 ...........................Function (a) of sensor 3 ...................................... dto. ...............................................................................................................InL

h32 ...........................Function (b) of sensor 3 ...................................... dto. ...............................................................................................................---

h33 ...........................Function (c) of sensor 3 ......................................dto. ............................................................................................................... ---

h37 ...........................Sensor 3, emphasis for virtual sensor ................ 0...100% ......................................................................................................0%

h41 ...........................Function (a) of sensor 4 ...................................... dto. ...............................................................................................................ovt

h42 ...........................Function (b) of sensor 4 ...................................... dto. ...............................................................................................................---

h43 ...........................Function (c) of sensor 4 ......................................dto. ............................................................................................................... ---

h47 ...........................Sensor 4, emphasis for virtual sensor ................ 0...100% ......................................................................................................0%

h71 ...........................Function (a) of the virtual sensor ........................dto. (the same like the real sensors)

h72 ...........................Function (b) of the virtual sensor ..........................."

h73 ..........................Function (c) of the virtual sensor ..........................."

h51 ........................... Analogue output delivers ....................................010 = voltage 0-10V, 420 = current 4-20mA ..........................................010

h52 ...........................Analogue output works as/delivers ....................0 = 0% (0V resp. 4 mA), I00 = 100% (10V resp. 20 mA) .....................0

dis = actual value image, P= PID-T1 control,

Pr= PID-T1 control, inverted, EEP= for EEx-Valve

h61 ...........................Function of digital input (OK/DI) 1 ......................---= switched off, def= external defrost, ..............................................---

dnL

= night operat., act. low, dnK= night operat., act. high

ofl

= unit oFF, act. low, ofK= unit oFF, act. high

cKA

= Safety chain, set= Setpoint layer, dor= Door contact,

alA

= external alarm, anA= Analogue output to fixed value

rll

= Cooling lock, act. low, rlk= Cooling lock, act. high

rFl

= Cooling release, act. low, rFK= Cool. rel., act. high

h62 ...........................Function of digital input (OK/DI) 2 ......................dto. ...............................................................................................................---

Parameters marked by "Disp" are for

information only and cannot be changed.

Loading...

Loading...