ELPROG PULSAR 2 User Manual

15.09.2008

PULSAR 2 v 2.15

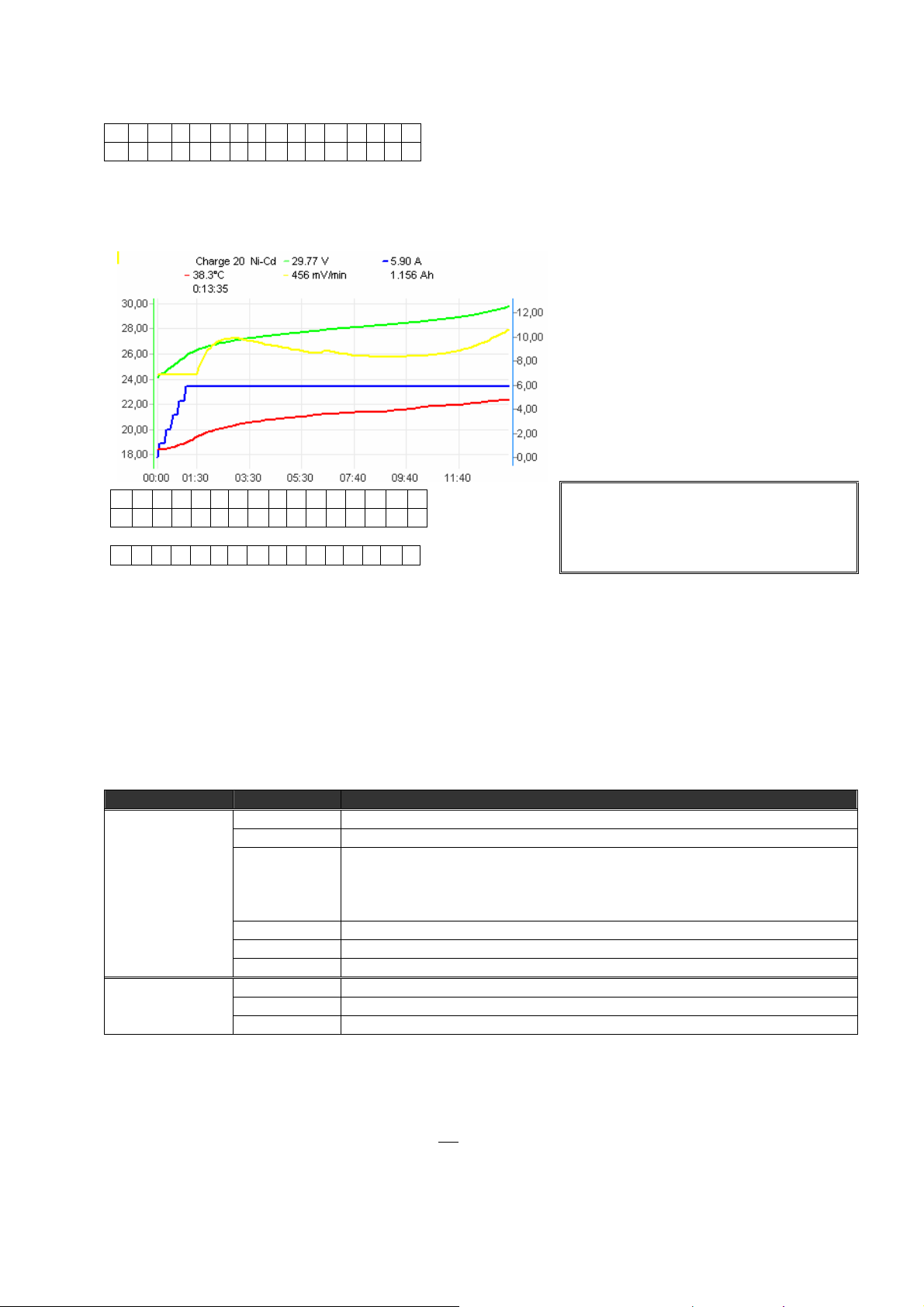

PULSAR 2 is a fast, microcontroller-based charger suitable for use with various types of batteries. Special design of

hardware and software makes it possible to charge batteries with high currents without risk of damage and in some

cases even improving their durability. During charging process all important parameters are displayed on LCD and

transmitted via serial port (RS232) to a desktop computer. Additional software allows visualization of changes in

voltage, current, voltage time derivative and temperature during whole charging process which allows user to

determine precisely status of batteries and decide whether they need conditioning or not. A data communication

between Pulsar 2 and Pulsar-EQUAL Equalizer (Balancer) is possible and increases the safety of working with Li-Xx

packs.

Technical specification

Battery types supported Ni-Cd, Ni-MH, Pb-bat, RAM, Li-Ion, Li-Pol, Li-Ta, Li-Ph (Li-Ion FePO4)

Supply voltage 10 – 16V DC (car battery min 30Ah (70Ah recommended) or power supply

14V/30A)

Low voltage alarm level (alarm) min 10 – 11,5V adjustable in Setup

max 16V

Charging voltage 0.5 - 60V from 1 up to 32 Ni-Cd cells

Charging current 200mA – 9,9A (250W)

Discharging current 200mA – 9,9A (250W) with energy return

200mA – 9,9A (35W) with heat dissipation

Temperature measurement

Voltage measurement 0,1 – 60V

Current measurement 0,1 – 11A

Time measurement up to 14 hours

Max voltage on supply battery Revers - On 15,3V

0 - 99°C with 0.1°C accuracy

Starting-up Pulsar Charger

PULSAR charger is designed to work with car battery, but it is possible to use it with DC power supply with output

voltage 12-14V and output current at least 5A (30A recommended).

Red cable +12V

Blue cable -12V, ground

There are three connectors on the left side of the device:

• temperature sensor connector

• fan connector (max. 1.2A) – for cooling battery pack

• serial port connector (RS232 – DB9) – to connect to PC (9 pin)

After turning the charger on you can enter Setup by pressing ‘M’ key and switch on/off sound signal and adjust

minimum input voltage level, which protects supply battery from discharging - if supply voltage fall below desired

level charging is stopped and alarm turns on (protection against excessive discharge of car battery).

Pressing Start (‘E’ key) takes you to the main menu.

- P U L S A R - V 2 . 1 5

S t a r t S e t u p

Mode Keys Action

Start E Main menu

Mem 1-8; Format,Test

Setup

(+,-); E – choose a parameter with ‘+’or ‘-’ keys and confirm selection with ‘E’ key.

Adjusted parameter is blinking on LCD panel.

Tmax on – Start analyzing temperature Ton and Toff.

Ton – if packet temperature exceeds set up Ton temperature, process will start only after cell temperature

Toff – exceeding set up Toff temperature, will stop the process and start alarm

Current adjust and limiter function

By shortly pressing E key process’s current can be changed. If it is the complex process (Dis/Ch.

discharging/charging) different currents can be set.

D i s c h . 8 , 0 A R A

- - , - A h N i - C d 8

In current adjust mode it is possible to set the maximal package capacity (0,1 – 12 Ah). When it is reached the process

will be terminated – limiter. After pressing M key, + , - keys are used to set the value an d E key to accept (--,-Ah –

function disabled).

Process Initialization

Right after connecting packet to charger, connection test will start. After that charger estimate number of cells in the

packet. When battery is charged or excessively discharged number of cells should be corrected (+,-). Confirmation

with E key will start appropriate action, depending on a set mode.

D i s c h . 9 , 0 V R A

- - , - A h 0 7 N i - C d

During correction of number of cells, we can set maximal capacity of packet (0.1 – 12.0 Ah) after reaching it process

will be terminate. After pressing M key we will be able to set capacity by pressing + or –and confirm that with E key

(--,-Ah , means that function is turned off).

M

fall to Ton temperature.

Global parameters:

1. Bip ON/OFF – sound signal (+,-); E

2. T max On/Off – termic protection (+,-); E

3. T on < from 30 to 45°C – start with T<Ton (+,-); E

4. T off < from 50 to 65°C – stop with T>Toff (+,-); E

5. Voff from 10V to 11,5V - min supply voltage (+,-); E

Process end

Process end is signalized by flashing of the displayed data, display's backlight blinking and periodic sound signal.

After 30 seconds a sound signal is replaced by “silent knocking”. Display shows the last values measured during the

process.

A new process on the same accu pack can be started after reconnecting of the accu pack!

Main menu

Main menu consist of 10 windows.

• M 1-8 processes memory, formatting/regeneration and battery test

(battery is disconnected)

Memory of the processes M1-8

Memory number – a digit in the right down corner on display.

There are 8 memories. Each can save:

Process parameters

Main parameter is charging/discharging current. at the complex processes (discharging/ch a rging,

charging/discharging) there is a possibility to set up different value of charging/discharging current.

Work mode

discharging – Disch., charging – Charge,

discharging /charging – Dis/Ch., charging/discharging – Ch/Dis.

Cell Type

Ni-Cd, Ni-MH, Pb-bat, RAM, Li-Ion, Li-Pol, Li-Ta, Li-Ph

Info window (battery is disconnected)

To open information window press the M key.

V b = 1 2 , 5 V T c = 2 3 , 7

M e m 2 , 1 3 1 A h

Vb=12,5V - supply voltage

Tc=23,7 - battery pack temperature (--,- - sensor not connected)

Mem - saved data from 8 previous processes

2,131Ah - energy measure from last process

To read data from 8 previous press the E key.

M 8 1 6 N i - C d

M e n u - 2 , 1 3 1 A h

M8 - save no. 8

16 - amount of cells

Ni-Cd - cell type

Menu - return to main menu (E)

-2,131Ah - energy, mark (-) means discharge

Info. Keys Function

+ or – change program Battery

disconnected

M info window

Saved data

M return to main menu Info window

E saved data from 8 previous processes

+ or – change save no.

E return to main menu

M return to info window

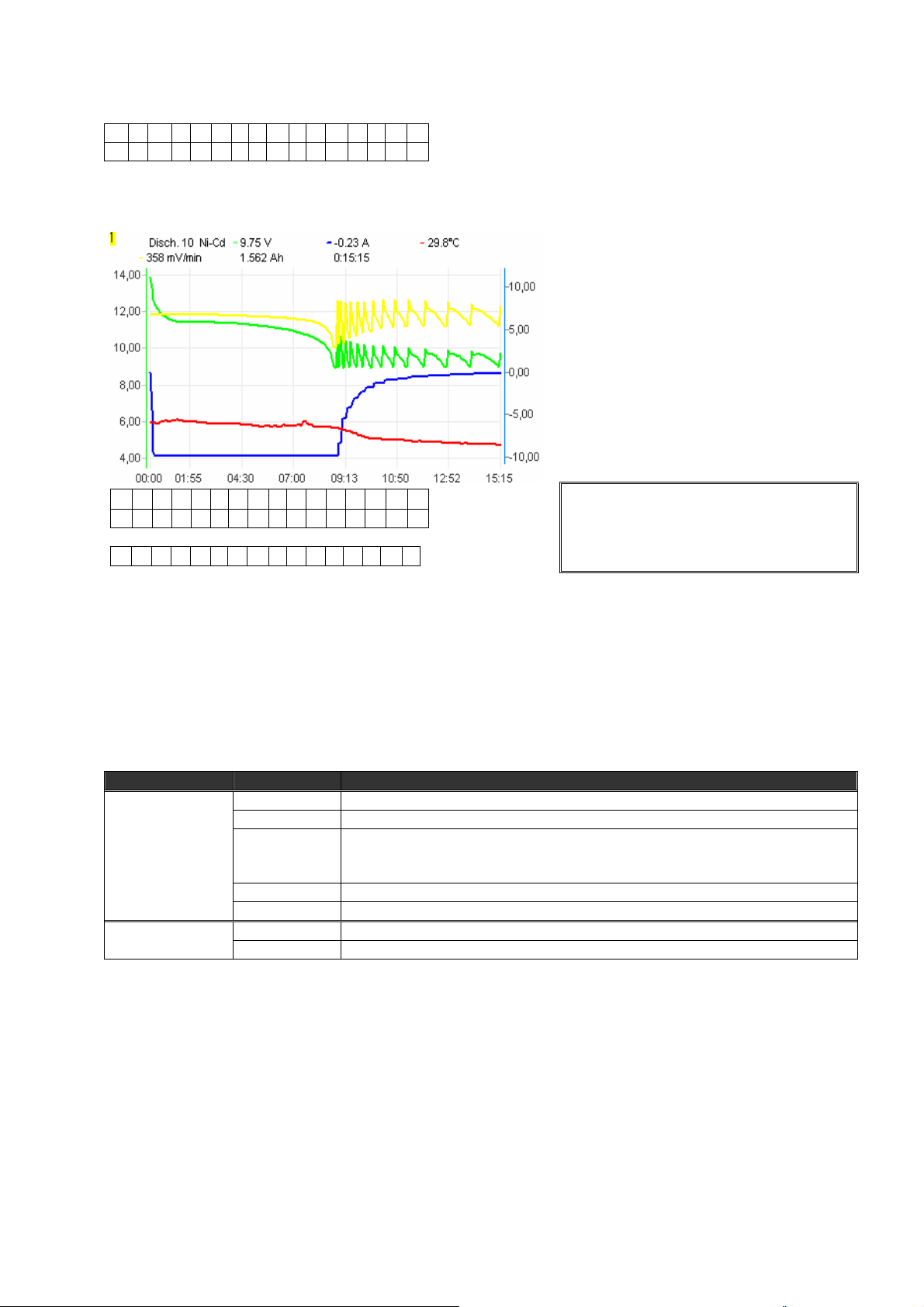

Discharging (0, 2 – 9, 9A, Revers, Auto)

D i s c h . 8 , 0 A R A

- - , - A h N i - C d 8

R - Reverse mode is on

A - Auto mode is on

Discharging lasts until battery voltage

reaches threshold voltage for given cell type.

In Auto mode current is decreased by ¼ each

time the threshold voltage is reached.

Discharging process ends when discharging

current is less than 200mA.

Reverse mode – energy from discharging

battery is transferred back to the supply

accumulator.

D 0 8 - 8 , 0 A 7 , 2 V ↓E

0 0 : 1 2 : 3 4 1 , 9 1 5 A h

every 5 seconds – second line

V b = 1 3 , 5 V 4 4 , 7 ° C

D 08 - discharging; 8 cells

-8,0A - actual, measured current

7,2V - actual, measured voltage

↓ - marker of decreasing voltage

E - marker of current limit (blinking)

00:12:34 - time elapsed from start of the process

1,915Ah - energy returned

Vb=13,5V - supply voltage

44,7°C - battery temperature

Disch. Keys Function

Battery

disconnected

Important Notices

• Maximal duration of this process – 14 hours.

• You must NOT use Reverse function if you are using external DC power supply unit.

• While working in reverse mode (reverse – on) discha rging current will be limited if voltage on supply battery

exceeds 15,3V (protection from overcharging)

+ or – change program

E current set up ( + , – ); E

E (1 s) remaining parameters set up

M (1 s) change work mode and cell type

M info window

E (1 s) stop discharging Battery connected

M LCD light

1. Revers On/Off – energy return ( + , – ); E

2. Auto On/Off – decreasing voltage ( + , – ); E

A bold ‘A’ after a value of current indicates

that charger has limited current due to

maximum power.

Charging Ni-Cd & Ni-MH (0,2 – 9,9A, Inflex, Reflex, Delta peak)

C h A r g e 8 , 0 A i r d

- - , - A h N i - C d 7

i - Inflex mode is ON

r - Reflex mode is ON

d - Delta – Δ low ( D – Δ high) function is ON

Charging ends when voltage drop (-Δv) or

inflex point is detected.

The Inflex mode allows finishing charging

process before unnecessary heating of

charged battery (inflex point marker –

vertical line on the current graph).

The Reflex mode makes it possible to

recharge batteries and avoid memory effect

(charging with short compensatory

discharging pulse)

C 0 8 8 , 0 A 1 2 , 9 V ↑ i

0 0 : 1 6 : 0 0 2 , 3 2 6 A h

every 5 seconds – second line

V b = 1 2 , 1 V 4 0 , 0 ° C

C 08 - charging; 8 cells

8,0A - actual, measured current

12,9V - actual, measured voltage

↑ - marker of increasing voltag e

i - marker of inflex point detection (blinking)

S - marker of slow start mode (blinking)

00:16:00 - time elapsed from start of the process

2,326Ah - energy taken

Vb=12,1V - supply voltage

40,0°C - battery temperature

Charge Keys Function

Battery

disconnected

Battery connected

Important Notices

• Maximal duration of this process – 14 hours.

• *) Forced start – charging diode protected battery (RC transmitter). Reflex function will be automatically

disabled! Charging currents > 1,2 A should

• Delta low – 7mV Ni-Cd, 3mV Ni-MH; Delta high - 10mV Ni-Cd, 5mV Ni-MH

• Delta high – rather for currents lower than 1C for Ni-Cd and 0,5C for Ni-MH

• Inflex – switched on for currents higher than 1C and from 4 cells

+ or – change program

E current set up ( + , – ); E

E (1 s) remaining parameters set up

M (1 s) change work mode and cell type

+ and – *forced start

M info window

E (1 s) stop charging

+ shorten slowly start (if pointer S blinks)

M LCD light

1. Inflex On/Off – stop at inflexion point ( + , – ); E

2. Reflex On/Off – equalizing impulse ( + , – ); E

3. Delta low / high – value -ΔV ( + , – ); E

not be used.

A bold ‘A’ after a value of current indicates

that charger has limited current due to

maximum power.

Loading...

Loading...