ELPRO 215U-2, ANTSG2400-E, ANTWH2400-SMA, ANTMD2400-EL, ANTY2400-18EL User Manual

...

User Manual MN032EN

Effective October 2017

New information

215U-2 802.11

wireless I/O and gateway

Version 2.11

User Manual MN032EN

Effective October 2017

215U-2 802.11

wireless I/O and gateway

Documentation note

Eaton acquired Cooper Industries in November, 2012. “Cooper

Bussmann” may appear in some screen images within this guide.

ATTENTION

INCORRECT TERMINATION OF SUPPLY WIRES MAY CAUSE INTERNAL

DAMAGE AND WILL VOID THE WARRANTY. TO ENSURE THAT YOUR

215U-2 WIRELESS I/O AND GATEWAY ENJOYS A LONG LIFE, CHECK THIS

USER MANUAL TO VERIFY THAT ALL CONNECTIONS ARETERMINATED

CORRECTLY BEFORE TURNING ON POWER FOR THEFIRST TIME.

CAUTION

TO COMPLY WITH FCC RF EXPOSURE REQUIREMENTS IN SECTION 1.1310

OF THE FCC RULES, ANTENNAS USED WITH THIS DEVICE MUST BE

INSTALLED TO PROVIDE A SEPARATION DISTANCE OF AT LEAST 20 CM

FROM ALL PERSONS TO SATISFY RF EXPOSURE COMPLIANCE.

DO NOT OPERATE THE TRANSMITTER WHEN ANYONE IS WITHIN 20 CM OF

THE ANTENNA. ENSURE THAT THE ANTENNA IS CORRECTLY INSTALLED IN

ORDER TO SATISFY THIS SAFETY REQUIREMENT.

Avoid

•

Operate the transmitter unless all RF connectors are secure

andany open connectors are properly terminated

•

Operate the equipment near electrical blasting caps or in an

explosive atmosphere

ote:N All equipment must be properly grounded for safe operations.

All equipment should be serviced only by a qualifiedtechnician.

Manufacturer Model number Coax kit Net

ELPRO ANTMD2400-EL Includes 5 m RG58 3 dBi gain

ELPRO ANTWH2400-SMA Direct mount Unity gain

ELPRO ANTSG2400-EL CC3-SMA 5 dBi gain

ELPRO ANTY2400-18EL CC10-SMA 12 dBi gain

ELPRO ANTZ2400-EL CC3-SMA 8 dBi gain

Safety notices

Exposure to RF energy is an important safety consideration. The

FCC has adopted a safety standard for human exposure to radio

frequency electromagnetic energy emitted by FCC regulated

equipment as a result of its actions in Docket 93-62 and OET

Bulletin65 Edition 97-01.

Hazardous location notices

This equipment complies with the following standards:

•

IEC 60079-0:2012/A11:2013

•

IEC 60079-15:2010

This equipment complies with 2014/35/EU—ATEX Directive

ExnA IIC T4 Gc –40 °C ≤ Ta ≤ +70 °C.

Special conditions

This equipment is designed to be installed in anenclosure

that meets IP54.

WARNING: EXPLOSION HAZARD

DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN SWITCHED

OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

FCC notice

Part 15.19—This device complies with part 15 of the FCC rules.

Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause

undesired operation.

Part 15.21—The grantee is not responsible for any changes or

modifications not expressly approved by the party responsible for

compliance. Such modifications could void the user’s authority to

operate the equipment.

Part 15.105(b)—This equipment has been tested and found to

comply with the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

•

Reorient or relocate the receiving antenna

•

Increase the separation between the equipment and receiver

•

Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected

•

Consult the dealer or an experienced radio/TV technician for help

ote:N This device should only be connected to PCs that are covered by either

a FCC DoC or are FCC certified.

This equipment is suitable for use in Class 1, Division2,

Groups A, B, C and D; Tamb –40° C to +70° C or

non-hazardous locations only.

This equipment shall be installed in accordance with

the requirements specified in Article 820 of the National

Electrical Code (NEC), ANSI/NFPA 70-2011. Section 820.40

of the NEC provides guidelines for proper grounding, and

in particular specifies that the antenna ground (shield) shall

be connected to the grounding system of the building, as

close to the point of cable entry as practical.

This equipment shall be installed in a restricted access

location, such as a dedicated equipment room or service

closet.

The earth/ground terminal of this equipment shall be

connected to earth ground in the equipment installation.

The external power supply installed with this equipment

shall be a listed, Class 2 power supply, with a rated output

between 15 Vdc and 30 Vdc, and minimum 3500 mA.

ii

EATON www.eaton.com

215U-2 802.11

wireless I/O and gateway

User Manual MN032EN

Effective October 2017

GNU free documentation license

Copyright © 2009 Eaton

Eaton is using a part of Free Software code under the GNU General

Public License in operating the 215U-2 product. This General Public

License applies to most of the Free Software Foundation’s code and

to any other program whose authors commit by using it. The Free

Software is copyrighted by Free Software Foundation, Inc., and the

program is licensed “as is” without warranty of any kind. Users are

free to contact Eaton at the following email address: www.eaton.

com/wireless for instructions on how to obtain the source code used

for the 215U-2.

A copy of the license is included in GNU Free Document License at

the end of the manual.

Important notice

ELPRO products are designed to be used in industrial environments

by experienced industrial engineering personnel with adequate

knowledge of safety design considerations.

ELPRO products use communications channels that are subject to

noise and interference. The products are designed to operate in the

presence of noise and interference, but in an extreme case noise

and interference can cause product operation delays or operation

failure. Like all industrial electronic products, ELPRO products can

fail in a variety of modes due to misuse, age, or malfunction. We

recommend that users and designers design systems using design

techniques intended to prevent personal injury or damage during

product operation, and provide failure tolerant systems to prevent

personal injury or damage in the event of product failure. Designers

must warn users of the equipment or systems if adequate

protection against failure has not been included in the system

design. Designers must include this Important Notice in operating

procedures and system manuals.

These products should not be used in non-industrial applications, or

life-support systems, without first consulting Eaton.

To avoid accidents during maintenance or adjustment of remotely

controlled equipment, all equipment should be first disconnected

from the 215U-2 module during these adjustments. Equipment

should carry clear markings to indicate remote or automatic

operation. For example: “This equipment is remotely controlled

and may start without warning. Isolate at the switchboard before

attempting adjustments.”

Release notice

This is the September 2017 release of the 215U-2 Wireless I/O and

Gateway User Manual version 2.11, which applies to firmware

version 2.11.

Follow instructions

Read this entire manual and all other publications pertaining to the

work to be performed before installing, operating, or servicing this

equipment. Practice all plant and safety instructions and precautions.

Failure to follow the instructions can cause personal injury and/or

property damage.

Proper use

Any unauthorized modifications to or use of this equipment outside

its specified mechanical, electrical, or other operating limits may

cause personal injury and/or property damage, including damage to

the equipment. Any such unauthorized modifications: (1) constitute

“misuse” and/or “negligence” within the meaning of the product

warranty, thereby excluding warranty coverage for any resulting

damage; and (2) invalidate product certifications or listings.

Product disposal

When your product reaches the end of its useful life, it is important

to take care in the disposal of the product to minimize the impact on

the environment.

General instructions

The product housing is made of polycarbonate plastic

(Code 7) andmay be recycled through regular recycling

operators in your area.

The product circuit board should be disposed according to your

country’s regulations for disposing electronics equipment.

Europe

In Europe, you can return the product to the place of

purchase to have the product disposed in accordance with

EU WEEE legislation.

Deployment of Eaton products in customer environment

There is increasing concern regarding cybersecurity across

industries, where companies are steadily integrating field devices

into enterprise-wide information systems. This is why Eaton

has incorporated secure development life cycle in their product

development to ensure that cybersecurity is addressed at all levels

ofdevelopment and commissioning of our products.

There is no protection method that is completely secure.

Industrial Control Systems continue to be the target for attacks.

The complexities of these attacks make it very difficult to have a

complete secure system. A defense mechanism that is effective

today may not be effective tomorrow as the ways and means

of cyber-attacks constantly change. Therefore it’s critical that our

customers remain aware of changes in cybersecurity and continue

to work to prevent any potential vulnerability of their products and

systems in their environment.

At Eaton we are focusing on analyzing emerging threats and

ensuring that we are developing secure products and helping

our customers deploy and maintain our solutions in a secure

environment. We continue to evaluate cybersecurity updates that

webecome aware of and provide the necessary communication

onour website as soon as possible.

Eaton strongly recommends our customers to apply the deployment

practices that are outlined on our Cybersecurity whitepaper

"Electrical Distribution Cybersecurity considerations".

EATON www.eaton.com

iii

User Manual MN032EN

Effective October 2017

Table of contents

215U-2 802.11

wireless I/O and gateway

Introduction ...........................................1

Overview ...........................................1

Module structure .....................................2

Getting started .........................................2

Installation ............................................3

General .............................................3

Power supply ........................................3

Powering from the SUP+ and SUP– terminals ..............3

Connecting a back-up battery to the BAT+

and GNDterminals ....................................3

Powering expansion I/O modules ........................3

Powering the module directly from

the BAT+ and GNDterminals ...........................4

Internal I/O .........................................4

Grounding ...........................................4

Antennas ...........................................4

Connections .........................................6

Side access configuration panel .........................7

Front panel connections ................................8

Digital or pulsed inputs ................................8

Digital outputs (pulsed outputs) ..........................8

Analog inputs ........................................9

Analog outputs ......................................11

System design ........................................11

Design for failures ...................................11

Testing and commissioning ............................11

Connecting to the device ...............................12

Connecting to the module for the first time ...............12

Connecting to the device’s USB port .....................12

Connecting to the Device’s Ethernet port .................12

Quick start configuration ................................13

Identification ........................................13

Wireless Interface ...................................13

Network settings ....................................14

Additional network settings items .......................14

I/O Back to Back configuration ..........................14

Connecting to Other 802.11 devices .......................15

Connecting a 215U-2 to existing 802.11 network ...........15

Connecting your device to an existing 215U-2 network ......15

Accessing Ethernet devices connected to 215U-2 ..........15

Device configuration ...................................16

Modbus TCP Configuration ............................16

Dashboard .........................................17

I/O Mapping configuration .............................18

Default Back-To-Back gather scatter mapping ..............20

Serial functionality – Connecting ........................21

to RS-232 and RS-485 device

Adding expansion I/O modules .........................22

Configuration of the on-board I/O .......................22

Failsafe configuration .................................23

Advanced network configuration ..........................25

Network ...........................................25

Radio .............................................25

Repeaters ..........................................26

IP Routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Network Filtering ....................................26

DHCP Server .......................................27

VLAN Configuration ..................................28

Module information web page ..........................29

System tools .......................................29

Patch file firmware upgrade ............................30

Setting the date and time .............................30

Feature license keys ..................................32

Using demonstration mode ............................32

Enabling a feature license key ..........................32

Changing your password ..............................33

Recovery after lost admin password .....................34

Diagnostics ..........................................35

IO diagnostics ......................................35

Watchdog error log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Module information registers ...........................35

Expansion I/O error registers ...........................36

Diagnostic registers—device statistics ...................36

Monitoring communications ...........................37

Data logging .........................................38

Configuring data logging ..............................38

Viewing current data .................................39

Retrieving logged data ................................39

Retrieving stored log file data ..........................40

Specifications ........................................41

Troubleshooting .......................................42

Restoring the factory default connection settings . . . . . . . . . . . 42

Configuring PC networking settings .....................42

for Ethernet and Wireless

Configuring PC networking settings for USB ...............42

LED function .........................................43

Front panel LEDs ....................................43

LED boot sequence ..................................43

Input and output LEDs ................................44

Ethernet LEDs ......................................44

Register memory map .................................45

Physical I/O registers .................................48

115S serial expansion modules I/O registers ...............50

Modbus error codes ...................................51

Full firmware upgrade ..................................52

GNU free document license .............................55

Glossary .............................................58

iv

EATON www.eaton.com

215U-2 802.11

wireless I/O and gateway

Introduction

User Manual MN032EN

Effective October 2017

Overview

The ELPRO 215U-2 Ethernet Networking I/O and Gateway is a

multiple I/O node that extends communications to sensors and

actuators in local, remote, or difficult to reach locations. Designed to

work with wired and wireless devices, the ELPRO 215U-2 is capable

of providing IP-based I/O across sprawling industrial environments

typical of industrial applications.

The ELPRO 215U-2 communicates using standard 802.11 (WiFi)

communications and will interoperate with existing 802.11 products

and networks operating on the 2.4GHz band.

The 215U-2 can serve as an end node or network gateway andis

scalable to thousands of nodes. Gather-scatter and block mapping

technology offers the efficient use of network resources, allowing

point-to-point transfer of process signal within complex monitoring

and control systems. Integrated Modbus

®

server capability allows

further I/O expansion through the use of ELPRO 115S expansion

modules.

The module can monitor the following types of signals:

•

Digital (on/off) signals, such as a contact closure or switch

•

Analog (continuously variable) signals, such as tank level, motor

speed, or temperature

•

Pulsed signal, frequency signals, such as metering, accumulated

total, or rainfall

•

Internal signals, such as supply voltage, supply failure, or battery

status

The modules monitor the input signals and transmit the values by

radio or Ethernet cabling to another module (or modules) that have

been configured to receive this information.

Input signals that are connected to the module are transmitted and

appear as output signals on other modules. A transmission occurs

whenever a change of state (COS) occurs on an input signal. A

COS of a digital or an internal digital input is a change from “off”

to “on,” or a change from “on” to “off.” For an analog input, internal

analog input, or pulse input rate, a COS is a configurable value

referred to as sensitivity. The default sensitivity is 1000 counts (3%),

but you can change this value using the device’s sensitivity block

configuration web page.

In addition to COS messages, update messages are automatically

transmitted on a configurable time basis. These updates ensure

system integrity. Pulse inputs counts are accumulated and the

totalcount is transmitted regularly according to the configured

update time.

The 215U-2 modules transmit the input/output data using radio

or Ethernet. The data frame includes the address of the sending

module and the receiving module, so that each transmitted message

is acted upon only by the correct receiving unit. Each message

includes error checking to ensure that no corruption of the data

frame has occurred due to noise or interference. The module with

the correct receiving address will acknowledge the message with a

return transmission (acknowledgment). If the original module does

not receive a correct acknowledgment, it will retry multiple times

before setting the communications status of that message to “fail.”

For critical messages, this status can be reflected on an output on

the module for alert purposes. The module will continue to try to

establish communications and retry each time an update or COS

occurs.

The 215U-2 comes from the factory with ELPRO WIB and Modbus

TCP/RTU protocols as standard. WIB protocol provides powerful

enhanced features, including IP addressing, and it allows thousands

of modules to exist in a system. Modbus TCP protocol provides a

standards-based interface to a multitude of commercially available

controls systems, including PLCs, DCS, andSCADA.

A system can be a complex network or a simple pair of modules.

Aneasy-to-use configuration procedure allows you to specify any

output destination for each input. Each 215U-2 device can have up

to 19 expansion I/O modules (ELPRO 115S) connected by RS-485

twisted pair cable. Any input signal at any module may be configured

to appear at any output on any module in the entire system.

The units can be configured by accessing the internal Web pages

using a Web browser. See section “Connecting to the device” on

page 12 for more information.

EATON www.eaton.com

1

User Manual MN032EN

Effective October 2017

215U-2 802.11

wireless I/O and gateway

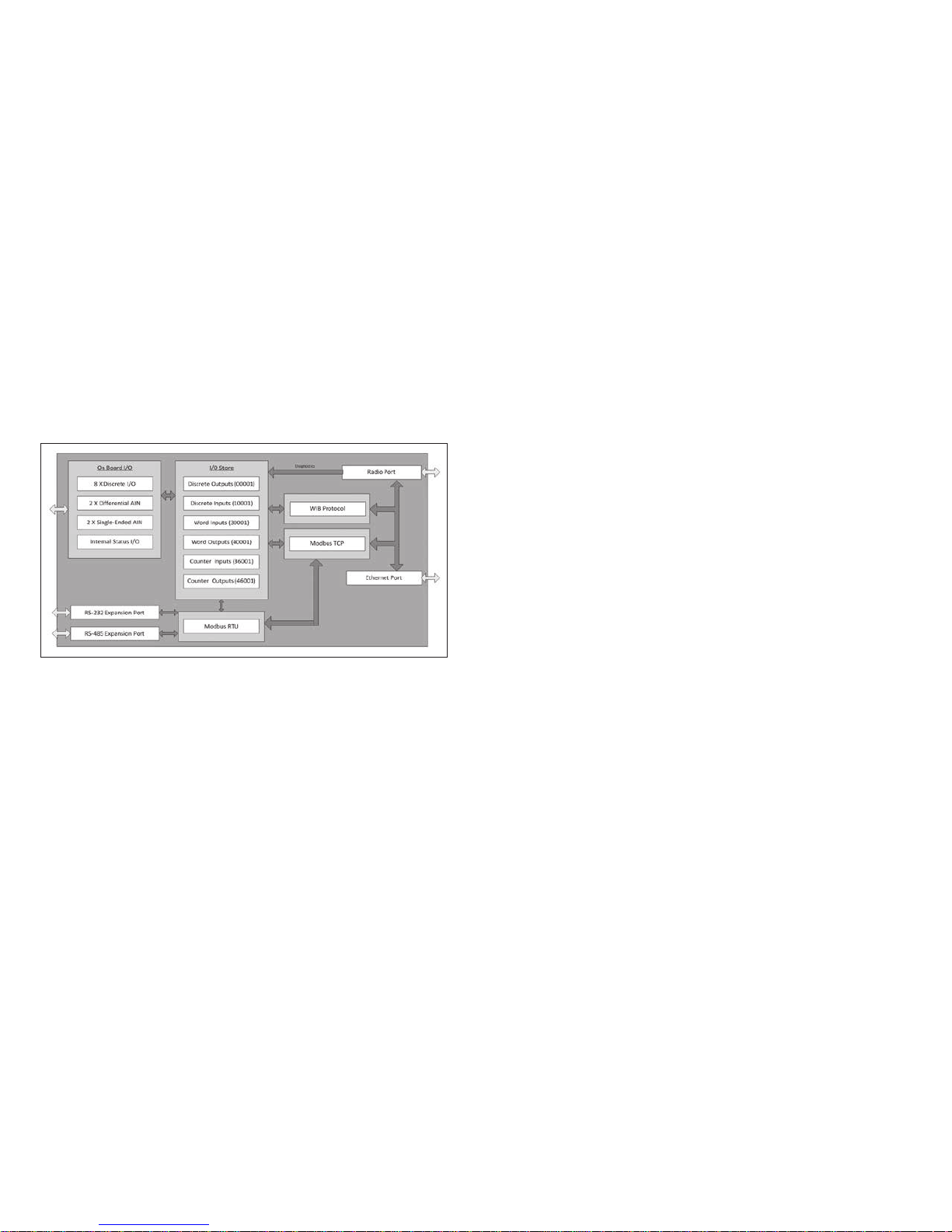

Module structure

The 215U-2 module is made up of different interface areas with a

central input and output storage area (I/O store). The I/O store is

an area of memory made available for the status of the physical

on-board I/O and internal I/O registers. It also provides services for

other processes within the module.

The I/O store is split into eight different block types:

•

Two blocks made available for bit data (discrete)

•

Two blocks made available for word data (analog)

•

Two blocks made available for 32-bit words data (32-bit analogs)

•

Two blocks made available for floating point data (floats)

Each of these block types in turn support input and output locations

that can interface with the physical I/O on the local machine and

also be used for data storage when used as a gateway to external

devices. These block type locations are illustrated in Figure 1 and

are described in “Register memory map” on page 45. There are

other registers within the database that can be used for system

management.

Figure 1. Module structure

The radio and Ethernet interfaces (see Figure 1) allow the 215U-2

to communicate with other modules within the system using a

proprietary protocol called WIB. I/O Messages from other 215U-2

modules are received on the communication ports and then passed

to the I/O store which will in turn update the register locations

accordingly. The WIB protocol is designed to provide reliable

communications suitable for an Ethernet channel or for an open

license-free radio channel. It is an extremely efficient protocol

for radio communications because the messages are sent using

exception reporting (only transmitting when there is a change of

an input signal) rather than transmitting all of the time. Update

messages can also be configured at a predetermined time for

integrity checks.

Each message can be comprised of multiple I/O values, referred

to as a “block of I/O.” The messages use error checking and return

acknowledgment for greater reliability. Up to four attempts are made

when transmitting the message over each hop of the radio path,

and if no acknowledgment is received a Comms indication can be

flagged.

The on-board I/O includes eight discrete I/O, two single-ended

analog inputs, two differential analog inputs, and two current

sourcing analog outputs. Each discrete I/O can function as either

a discrete input (voltage-free contact input) or discrete output

(transistor output). Each I/O point is linked to separate I/O registers

within the I/O data store.

The following internal I/O can be accessed from the I/O store. The

inputs can be used to interpret the status of a single module or an

entire system:

•

Battery voltage—The battery terminal voltage, displayed as an

analog value.

•

Loop supply—The +24 Vdc analog loop supply (ALS) used to

power analog current loops, displayed as an analog value.

•

Expansion module volts—The supply voltage of the connected

expansion modules, displayed as an analog value.

•

RSSI—The radio signal level received from the upstream device,

reported as a dB level.

•

Comms Fail—A selectable register can indicate a

Communications Fail error for a particular message transmission.

The expansion port, allows 115S expansion I/O modules to be added

to the module. Expansion I/O is dynamically added to the internal I/O

of the 215U-2 module by adding an offset to the address.

Getting started

Most applications for the 215U-2 module require little configuration.

The 215U-2 has many sophisticated features, but if you do not

require these features you can use this section to configure the

units quickly.

To get started quickly:

1. Read “Installation” on page 3, which describes the power

supply, antenna/coax connections, and I/O connections.

2. Power on the 215U-2 module and set up a USB connection to

your PC. For detailed steps, see “Connecting to the device” on

page 12.

2

EATON www.eaton.com

215U-2 802.11

wireless I/O and gateway

Installation

User Manual MN032EN

Effective October 2017

General

The 215U-2 Series modules are housed in a plastic enclosure with

DIN rail mounting, providing options for up to 14 I/O points, and

separate power and communications connectors. The enclosure

measures 7.2”x6.0”x1.3” (183mm x 156mm x 33mm), including

the connectors. The antenna protrudes from the top.

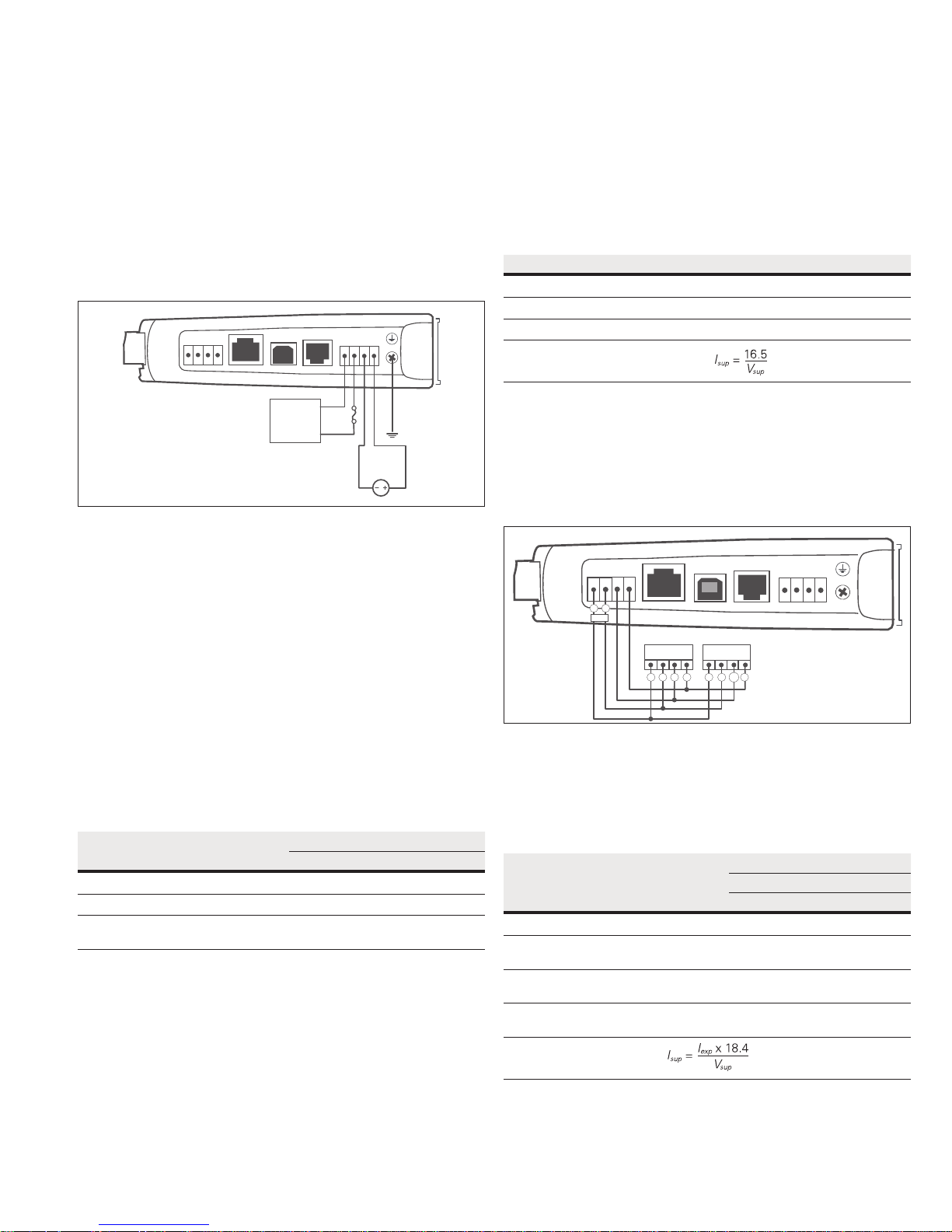

Power supply

SUP

BAT SUP

GND

+

B A

+

-

ETHERNET

USB RS232 SUPPLY

–

Optional

10.8–15 Vdc

Lead Acid

Battery

3A Fuse

+

+

-

15-30 Vdc

Supply

Figure 2. Supply connections

Powering from the SUP+ and SUP– terminals

The 215U-2 will operate from a 15–30 Vdc supply (nominal 24 Vdc)

connected to the SUP+ and SUP– terminals. The power supply must

be able to supply enough current to operate the device, to power all

of the I/O circuits, and to power the device’s radio transmitter when

it is sending data. A 24 Vdc 2.5 A power supply such as ELPRO

PSG60E or PS-DINAC-24DC-OK is suitable for all configurations,

including configurations requiring battery charging and expansion I/O.

If you need to use a supply with a lower power rating; or if you

need to power additional equipment in your installation; use these

guidelines to determine your required power supply current. Add

the relevant elements from Table 1 to determine your power supply

current requirement. Remember you also need to add current for

any other equipment being powered from the same power supply,

including relays, loop isolators, indicators, etc.

Table 1. Power supply current requirements

Supply voltage

17 Vd c 24 Vd c 30 Vdc

Base operating current 200 mA 150 m A 120 mA

Discrete I/O (per active input or output) 11 mA 7 mA 5 mA

Analog inputs and outputs

55 mA 38 mA 30 mA

(per 20 mA loop)

Connecting a back-up battery to the BAT+ and

GNDterminals

The 215U-2 provides an internal battery charger for Sealed Lead

Acid (SLA) batteries. You can connect a 13.8 V SLA battery to the

BAT+ and GND terminals to provide a backup power source if the

main supply fails. While the main supply is present, the battery will

charge at up to 0.5 A rate until the battery voltage reaches 14.3 V.

The battery charger will then maintain a float charge on the battery

at this voltage. To fully charge the SLA battery, the main supply must

be at least 17 Vdc.

When you connect a backup battery, you need to provide sufficient

power to support the additional charge current required when the

battery is discharged (when it is recovering from an extended power

interruption). Table 2 shows the additional current from your power

supply to support battery charging.

Table 2. Additional current to support battery charging

Supply voltage (V

) Current required (I

sup

)

sup

17 Vdc 1000 mA

24 Vdc 700 mA

30 Vdc 550 mA

Formula

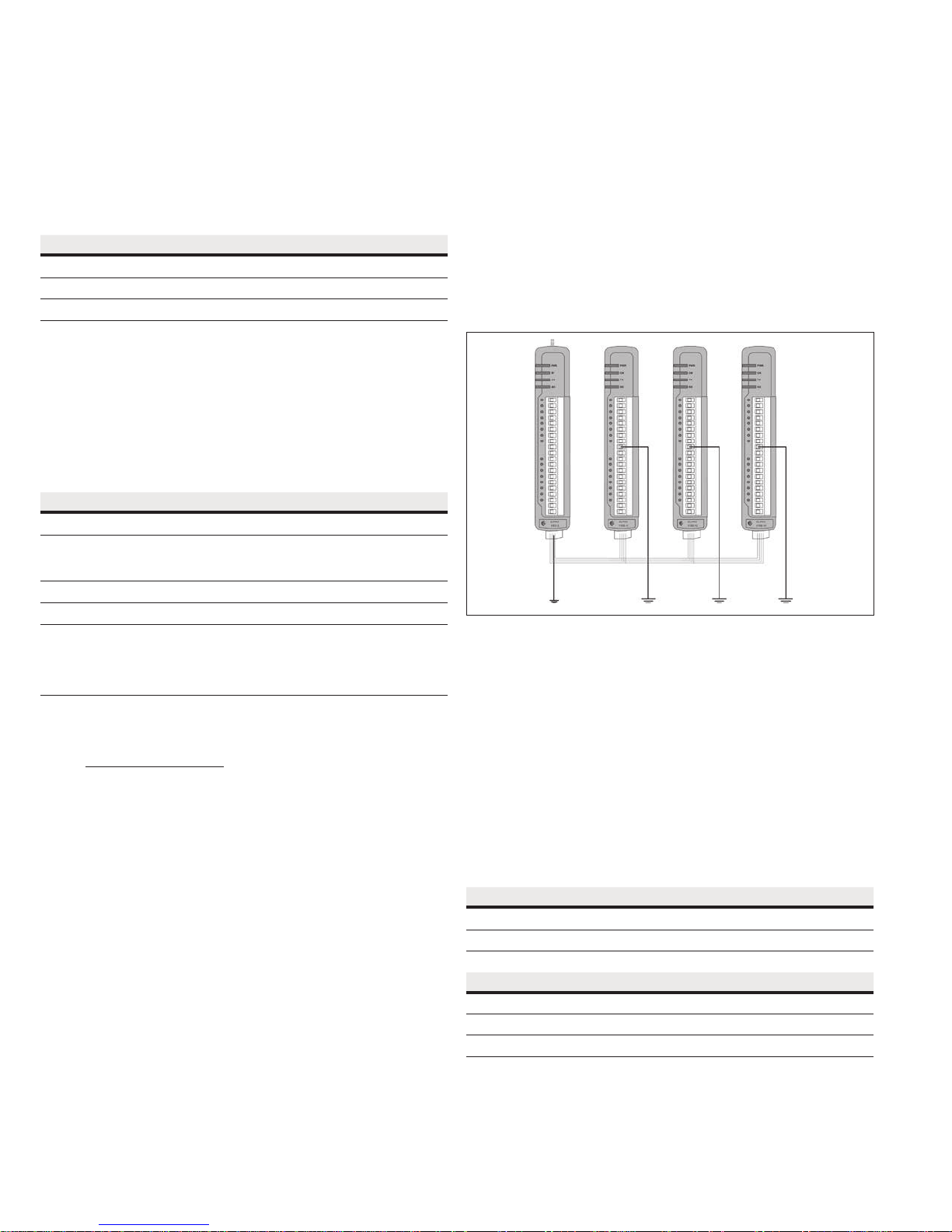

Powering expansion I/O modules

The 215U-2 allows connection of 115S Series modules to the RS-485

port to provide expanded I/O capacity. You can use the “+” and

“–“ connections on the 215U-2 to provide up to 500 mA supply for

expansion I/O modules. If you have a back-up SLA battery connected

to the 215U-2, then this connection will also be powered from the

back-up supply, so that the expansion I/O modules receive the

backup power as well as the main module.

SUP

BAT SUP

GND

+

B A

B A

RS-485

+

-

ETHERNET

B A B A

USB RS232 SUPPLY

115S-xx 115S-xx

+

-

+

-

+

-

Figure 3. Expansion I/O power and RS-485

When the module is being powered from the main supply (SUP+

and SUP– terminals), you need to provide sufficient power to

support the additional current required by the expansion I/O

modules. Table 3 shows the additional current from yourpower

supply to support expansion I/O connection.

Table 3. Additional supply current to support expansion I/O

Expansion

I/O

current

(I

)

exp

Current required (I

Supply voltage

17 Vd c 24 Vdc 30 Vdc

)

sup

Base operating current 115S 120 mA 130 mA 90 mA 75 mA

Discrete inputs

13 mA 14 mA 10 mA 8 mA

(per active input)

Discrete outputs

25 mA 27 mA 20 mA 16 mA

(per active output)

Analog inputs and outputs

50 mA 55 mA 38 mA 30 mA

(per 20 mA loop)

Formula

Powering the module directly from the BAT+ and

GNDterminals

In some situations it may be desirable to power the module

directly from a 13.8 Vdc supply. This may be because this voltage

supply is already available at an installation or because the power

EATON www.eaton.com

3

User Manual MN032EN

Effective October 2017

215U-2 802.11

wireless I/O and gateway

requirements for 115S modules are more than can be supplied by

the “+” and “–“ expansion I/O connections.

Use Table 4 to determine the device’s current requirements at

13.8 Vdc. Remember you also need to add current for any other

equipment being powered from the same power supply, including

relays, indicators, and any additional 115S modules.

Table 4. Current requirements

Supply current at 13.8 Vdc

Base operating current 230 mA

Discrete I/O (per active input or output) 10 mA

Analog inputs and outputs (per 20 mA loop) 50 mA

Internal I/O

The internal supply voltage register locations shown in the

following table can be monitored using the Diagnostics Web page

within the module’s Web-based configuration utility (see “Product

Reconfiguration” on page 36 for details). The values can also be

mapped to a register or an analog output on another module within

the network.

Table 5. Internal supply voltage registers

Register Description

30005 Local supply voltage (0–40 V scaling).

30006 Local 24 V loop voltage (0–40 V scaling). Internally generated

+24V supply used for analog loop supply. Maximum current

available is 100 mA.

30007 Local battery voltage (0– 40 V scaling).

30008 115S supply voltage (0–40 V scaling).

38005–38008 Floating point registers that display the actual supply voltage,

battery voltage, +24 V supply, and 115S supply. Note that these

are actual voltage values, whereas registers 30005 –30008

display a number between 8192 and 49152 that represents the

voltage scale 0–40 V.

To calculate the supply voltages from the register value use the

following calculation:

Volts = (Register Value) – 8192

1024

High and low voltage alarm indication may be configured for each of

these supply voltages. See "Analog inputs" on page 9 for details

on how to configure these alarms.

Grounding

To provide maximum surge and lightning protection each module

should be effectively earthed/grounded via a GND terminal on the

module. This is to ensure that the surge protection circuits inside the

module are effective. The module should be connected to the same

common ground point as the enclosure ground and the antenna

mast ground.

The 215U-2 has a dedicated earth/ground connection screw on the

bottom end plate next to the supply terminals. All earth/ground

wiring should be minimum 0.8in

2

(2 mm2), 14 AWG. If using the

215U-2 with serial expansion I/O modules, all expansion modules

must have a separate earth/ground connection from the front

terminal back to the common earth or ground point. See Figure 4.

Figure 4. Grounding

Antennas

Antennas can be either connected directly to the module’s

RFconnector or connected via 50-ohm coaxial cable (such as

RG58Cellfoil or RG213) terminated with a male SMA coaxial

connector. The higher the antenna is mounted, the greater the

transmission range, but as the length of coaxial cable increases

sodo cable losses.

The net gain of an antenna and cable configuration is the gain of the

antenna (in dBi) less the loss in the coaxial cable (in dB). Maximum

net gain for the 215U-2 will depend on the licensing regulation for

the country of operation and the operating frequency.

Typical antennas gains and losses are:

4

EATON www.eaton.com

Table 6. Typical antennas gains and losses

Antenna Gain (dBi)

Dipole 2 dBi

Collinear 5 or 8 dBi

Directional (Yagi) 6–15 dBi

Cable type Loss at 2.4GHz

RG58 cellfoil cable kits (3 m,10 m, 20 m) -1.8dB, -6dB, -12dB

RG213 per 10 m (33 ft) -4dB

LDF4 -50 per 10 m (33 ft) -2.2dB

The net gain of the antenna and cable configuration is determined

by adding the antenna gain and the cable loss. For example, an 8 dBi

antenna with 10 meters of Cellfoil (–6 dB) has a net gain of 2 dB

(8 dB – 6 dB).

215U-2 802.11

wireless I/O and gateway

User Manual MN032EN

Effective October 2017

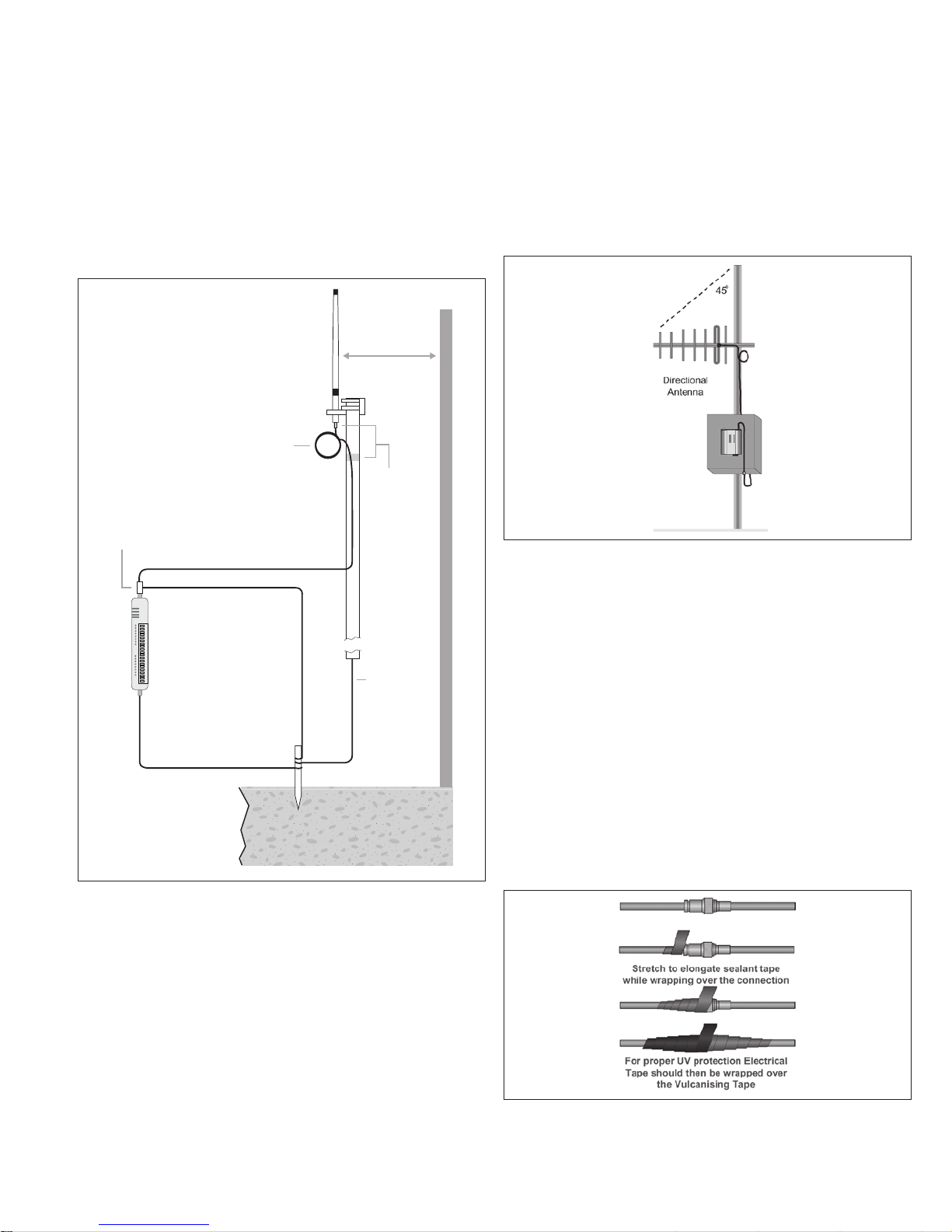

Dipole and Collinear antennas

Dipole and collinear antennas transmit the same amount of radio

power in all directions, and are easy to install and use because they

do not need to be aligned to the destination. The dipole antenna

does not require any additional coaxial cable. However, a cable must

be added if using any of the other collinear or directional antennas.

In order to obtain the maximum range, collinear and dipole antennas

should be mounted vertically, preferably at least one wavelength

away (see Figure 8 for distances) from a wall or mast and at least

3ft (1 m) from the radio module.

Stress

Relief

Loop

Antenna

*

1 Wavelength

(minimum)

Weatherproof

Connections

(recommended:

3M™ 23 selfbonding tape)

Wavelength:

2.4GHz: 5inch (12.5cm)

Surge Arrestor

(recommended)

Coaxial Cable

Directional radomes should be installed with the central beam

horizontal, and must be pointed exactly in the direction of

transmission to benefit from the gain of the antenna.

Parabolic antennas should be mounted according to the

manufacturer’s instructions, with the parabolic grid at the back and

the radiating element pointing in the direction of the transmission.

Ensure that the antenna mounting bracket is well connected

to ground.

Figure 6. Directional antenna

GND

215U-2

GND

at least 11 AWG (4 mm2)

Provide good ground

connection to mast,

module, and surge

arrestor.

If ground conditions

are poor, use more

than one stake.

Earth Stake

Mast

Earth Conductor

at least 5 AWG

(16 mm2)

For maximum

*

range, install

above local

obstructions.

Figure 5. Antennas installation—Collinear/Dipole

Directional antennas

A directional antenna provides high gain in the forward direction,

but lower gain in other directions. This type of antenna may be used

to compensate for coaxial cable loss for installations with marginal

radio path. Directional antennas can be any of the following:

•

Yagi antenna with a main beam and orthogonal elements

•

Directional radome, which is cylindrical in shape

•

Parabolic antenna

Yagi antennas should be installed with the main beam horizontal,

pointing in the forward direction. If the Yagi antenna is transmitting

to a vertically mounted omni-directional antenna, the Yagi elements

should be vertical. If the Yagi is transmitting to another Yagi, the

elements at each end of the wireless link need to be in the same

plane (horizontal or vertical).

Installation tips

Connections between the antenna and the coaxial cable should

be carefully taped to prevent ingress of moisture. Moisture

ingress in the coaxial cable is a common cause for problems with

radio systems because it greatly increases the radio losses. We

recommend that the connection be taped—first with a layer of PVC

tape, next with vulcanizing tape (such as 3M™ 23 tape), and finally

with another layer of PVC UV-stabilized insulating tape. The first layer

of tape allows the joint to be easily inspected when troubleshooting

because the vulcanizing seal can be easily removed (see Figure 10).

Where antennas are mounted on elevated masts, the masts should

be effectively grounded to avoid lightning surges. For high lightning

risk areas, approved ELPRO surge suppression devices, should be

fitted between the module and the antenna. The surge supression

must have a “turn on” voltage of between 10 and 20V. If the antenna

is not already shielded from lightning strike by an adjacent grounded

structure, a lightning rod may be installed above the antenna to

provide shielding.

Figure 7. Vulcanizing tape

EATON www.eaton.com

5

User Manual MN032EN

Effective October 2017

Connections

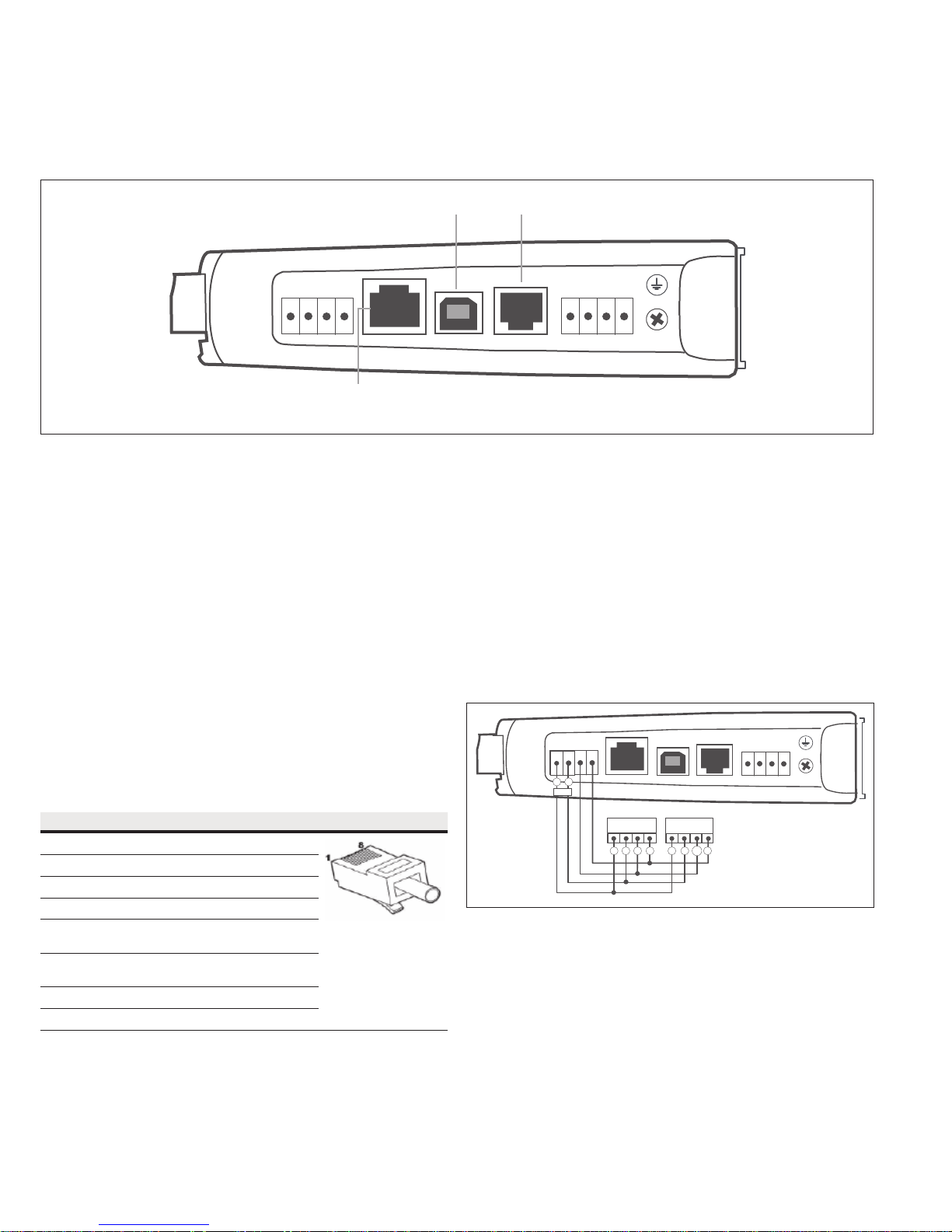

Bottom panel connections

Figure 8. Bottom panel connections

USB Port RS-232 Port

B A

+

-

ETHERNET USB RS232 SUPPLY

RJ-45 Ethernet Port

(connects to hub or switch)

GND

BAT SUP

+

215U-2 802.11

wireless I/O and gateway

SUP

+

-

Ethernet port

The 215U-2 modules provides a standard RJ-45 Ethernet port

compliant to IEEE 802.3 10/100Base-T. This port provides full

access to the module, including configuration, diagnostics, log file

download, and firmware upload of both the local and remote units.

Additionally, the Ethernet port can provide network connectivity for

locally connected third-party devices with Ethernet functionality.

USB device port for configuration

The 215U-2 module also provides a USB device (USB-B) connector.

This connector provides configuration of the device and remote

configuration access to other devices in the radio network.

RS-232 port

The 215U-2 module provides an RS-232 serial port that supports

operation at data rates up to 230,400 baud. This port supports

Modbus protocol. The RS-232 port is accessed using an RJ-45

connector wired as a DCE according to the EIA-562 Electrical

Standard.

Table 7. RJ-45 connector

RJ-45 Signal Required Signal name Connector

1 RI — Ring Indicator

2 DCD — Data Carrier Detect

3 DTR Y Data Terminal Ready

4 GND Y Signal Common

5 RXD Y Receive Data

(frommodule)

6 TXD Y Transmit Data

(tomodule)

7 CTS — Clear to Send

8 RTS — Request to Send

RS-485 port with Modbus support

The 215U-2 module provides an RS-485 serial port that supports

operations at data rates up to 230,400 baud. The default baud rate is

9600 baud, no parity, 8 data bits and 1 stop bit, which matches the

115S serial expansion module default settings. This port supports the

Modbus protocol.

The RS-485 port terminal is hosted on the four-way expansion

connector on the bottom edge of the module. An on-board RS-485

termination resistor provides line termination for long runs. As a

general rule, termination resistors should be enabled at each end

of the RS-485 cable. When using 115S expansion I/O modules,

remember to enable the RS-485 termination resistor switch that is

located on the end module.

SUP

BAT SUP

GND

+

B A

B A

RS-485

+

-

ETHERNET

B A B A

USB RS232 SUPPLY

115S-xx 115S-xx

+

-

+

-

+

-

Figure 9. RS-485 connections

6

EATON www.eaton.com

215U-2 802.11

wireless I/O and gateway

Side access configuration panel

A small access panel on the side of the module hides a factory boot

switch, USB host port, and a small bank of DIPswitches that are

used for analog input voltage and current selection, external boot,

and default configuration settings. Use a screw-driver to free the

latch to open the access panel.

PWR

RF

LED Indicator Lights

232

485

User Manual MN032EN

Effective October 2017

Side

Access

Panel

I/O Connectors

Figure 10. Access panel

Factory boot switch

The factory boot switch is used for factory setup and diagnostics.

This switch should only be used if advised by ELPRO technical

support.

USB host port

This port is a USB host (master port) that can interface with

USB storage devices for upgrading the module firmware and for

uploading logged data files. For details, see“To perform a full

firmware upgrade using USB flash drive” on page 53. Also see

“Data logging” on page 38.

DIP switches

The DIP switches are used to select a number of functions within

the module, as shown in the following table.

•

DIP switches 1 to 2—Used for measuring current or voltage

onanalog input 3. Set DIP switches to “on” to measure current

(0–20 mA) and “off” for voltage (0–5 Vdc).

•

DIP switches 3 to 4—Used for measuring current or voltage

onanalog input 4. Set DIP switches to “on” to measure current

(0–20 mA) and “off” for voltage (0–5 Vdc).

•

DIP switch 5—Not used.

•

DIP switch 6—When set to “on” (enabled) and the module is

restarted, the module boots up with a known factory default

configuration, including a default IP address for the Ethernet

connection. See “Connecting to the module” on page 13.

ote:N When DIP switch 6 is “on,” radio and I/O functionality isdisabled.

Factory Boot

Switch

USB Host

Conguration

Switches

Table 8. Switch functions

Switch Function Current Voltage

DIP 1 and 2 Analog

input 3

DIP 3 and 4 Analog

input 4

Switch Function Disabled Enabled

DIP 5 Not used

DIP 6 Setup mode

EATON www.eaton.com

7

User Manual MN032EN

Effective October 2017

215U-2 802.11

wireless I/O and gateway

Front panel connections

The front panel on the 215U-2 module provides connections for the

following:

•

Eight digital input/output (DIO 1–8)

•

Two 12-bit, 0.1% accuracy differential analog inputs

•

Two single-ended 12-bit, 0.1% accuracy analog inputs

•

Two 13-bit, 0.1% accuracy current sourcing analog outputs

•

Connection terminals for common and +24 V analog loop supply

(ALS); maximum ALS current limit is 100 mA

Figure 11. Front panel connections

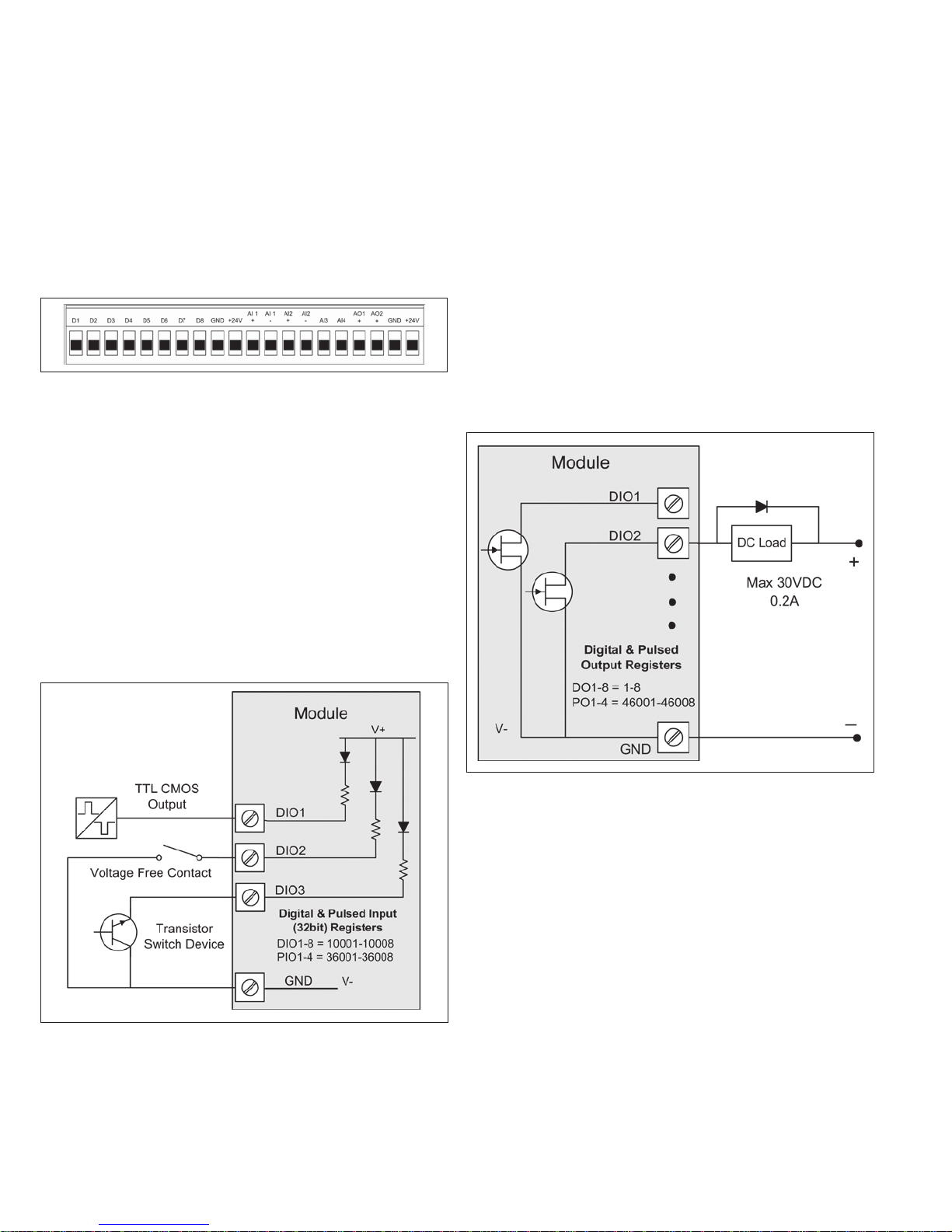

Digital or pulsed inputs

Each digital I/O channel on the 215U-2 module can act as either

an input or an output. The input/output direction is automatically

determined by the connections and configuration of the I/O. If you

have an I/O channel wired as an input but operate the channel as an

output, no electrical damage will occur but the I/O system will not

operate correctly. If you are operating the channel as an output and

you read the corresponding input value, it will indicate the status of

the output.

Marked D1–8, the digital inputs share the same terminals as the

digital outputs on the 215U-2 module. A digital input is activated by

connecting the input terminal to GND or common, either by voltagefree contact, TTL level, or transistor switch. Each digital input has

an orange indication LED that will turn on when the input has been

connected to a GND.

Digital inputs 1–4 can be used as pulsed inputs. The maximum pulse

frequency is 50 kHz for input 1 and 2, and 1kHz for input 3 and 4.

Digital/pulsed inputs are suitable for TTL signal level, NPN-transistor

switch devices, or voltage-free contacts (a relay or switch with

debounce capacitor).

Frequencies greater than 1 kHz need to use a TTL logic drive or an

external pull-up resistor (1 KΩ to V+). Pulsed inputs are converted

to two different values internally. The first value is the pulse count,

which is an indication of how many times the input has changed

state over a configured time period. The second value is a pulse

rate, which is an analog input derived from the pulse frequency.

Forexample, 0 Hz = 4 mA and 1 kHz = 20 mA.

All pulsed input counts are stored in non-volatile memory, so thatthe

values are saved in the event of a power failure or a modulereset.

Digital outputs (pulsed outputs)

Digital outputs are open-collector transistors, and are able to switch

loads up to 30 Vdc, 200 mA. The eight digital outputs sharethe

same terminals as the digital input. These terminals aremarked D1–8.

Figure 12. Digital/pulsed input wiring

8

EATON www.eaton.com

Figure 13. Digital pulsed output wiring

When active, the digital outputs provide a transistor switch to

EARTH (Common). To connect a digital output, see Figure 13. A

bypass diode (IN4004) is recommended to protect against switching

surges for inductive loads such as relay coils. The digital channels

D1–4 on the 215U-2 module can be used as pulse outputs with a

maximum output frequency of 10 kHz.

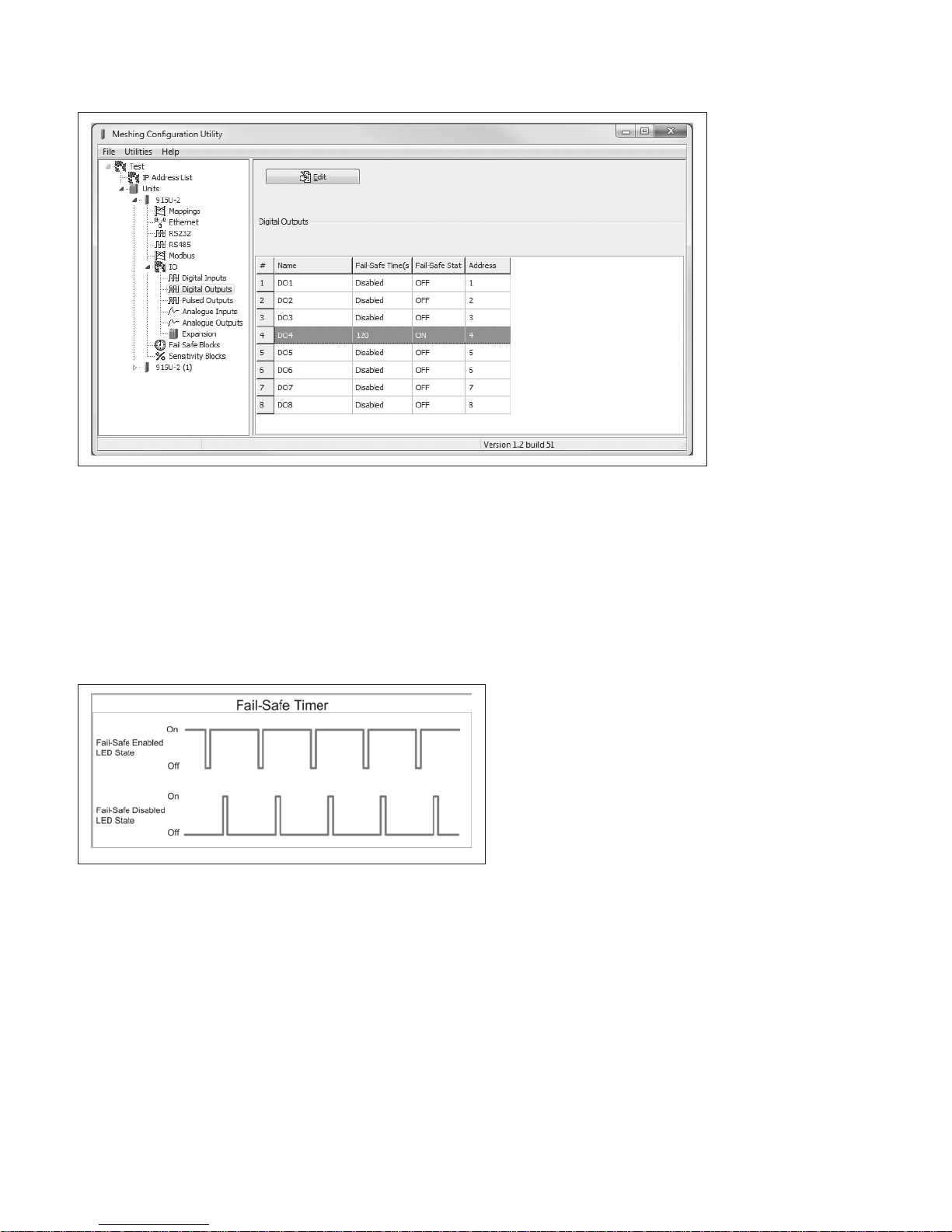

Digital output fail-safe status

In addition to indicating the digital output status (on or off), the LEDs

can also indicate a communications failure by flashing the output

LED. This feature can be used by configuring a fail-safe time and

status via the I/O Digital Output screen in the MConfig utility.

215U-2 802.11

wireless I/O and gateway

Figure 14. Digital output fail-safe times

User Manual MN032EN

Effective October 2017

The fail-safe time is the time the output counts down before

activating a fail-safe state. Normally this would be configured for a

little more than twice the update time of the mapping that is sending

data to it. This is because the fail-safe timer is restarted whenever

it receives an update. If you send two successive updates and fail

to receive both of these messages, the timer counts down to zero

and activates the fail-safe state. If the fail-safe state is enabled (on),

the LED flashes briefly off and the digital output turns on. If the failsafe state is disabled (off), the LED flashes briefly on and the digital

output turns off.

Figure 15. Fail-safe state

Analog inputs

The 215U-2 module provides two floating differential analog inputs

and two grounded single-ended analog inputs. Analog inputs 1 and

2 will automatically measure current (0–20 mA) or voltage (0–25V),

depending on what is connected to the input. Analog inputs 3 and 4

must be configured to measure current (0–20 mA) or voltage (0–5V)

via the DIP switches on the configuration panel (see “Side access

configuration panel” on page 7).

An internal 24 V analog loop supply (ALS) provides power for any

current loops with a maximum current limit of 100mA. The LEDs

have an analog diagnostic function and will indicate the status of the

input. The LED comes ON when any analog signal is detected, and

will go OFF when the analog signal drops to zero.

ote:N By default, there is a one-second delay on the input because of the

filter. Filter times can be changed using the Analog Input screen within the

MConfig utility. For more information, see "Analog inputs" on page 9.

The LEDs next to AI1+, AI2+ indicate the current on these inputs.

The LEDs next to AI1– and AI2– indicate the voltage on the

analog inputs.

EATON www.eaton.com

9

User Manual MN032EN

Effective October 2017

215U-2 802.11

wireless I/O and gateway

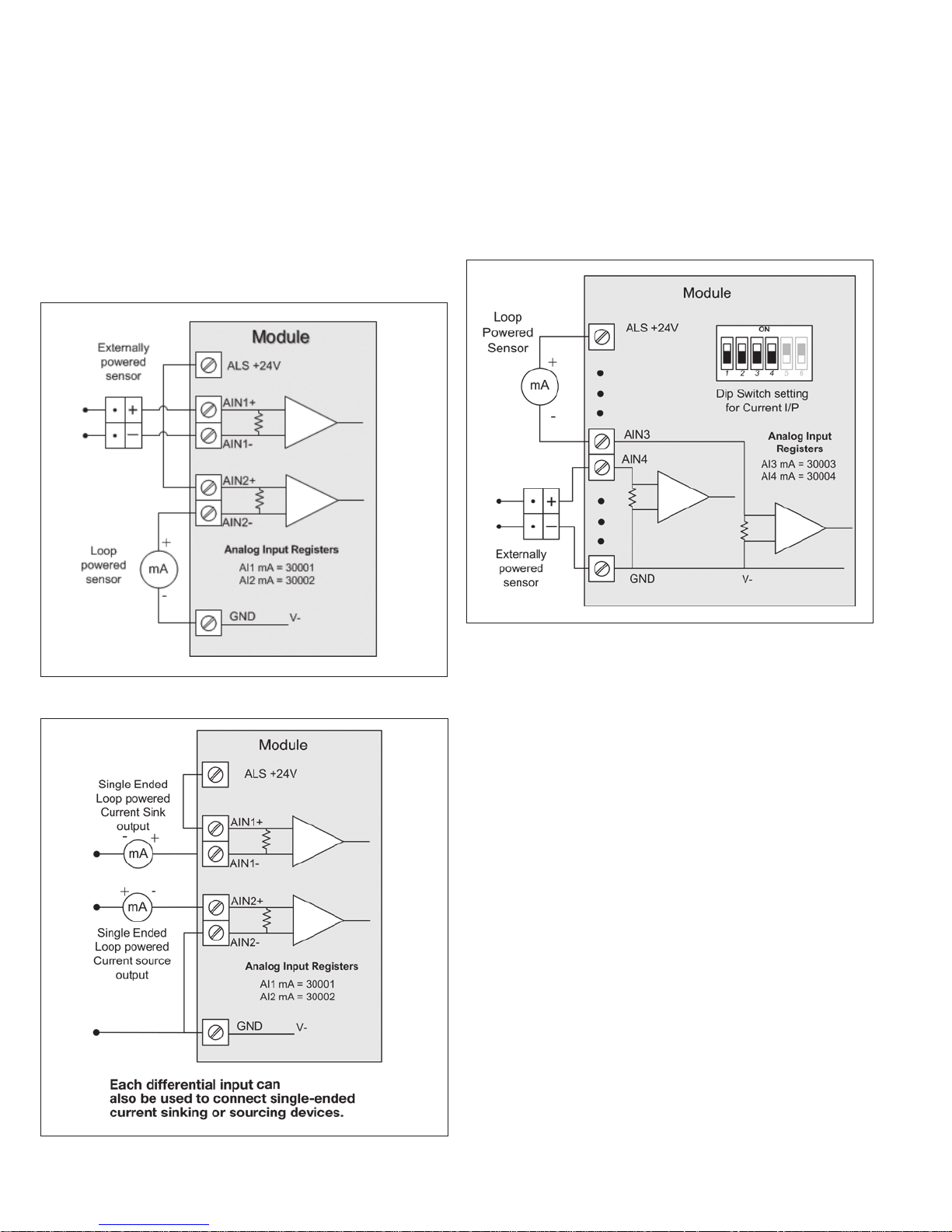

Differential current inputs

Only analog input 1 and 2 can be wired as differential Inputs.

Differential mode current inputs should be used when measuring a

current loop, which cannot be connected to ground. This allows the

input to be connected anywhere in the current loop. Common mode

voltage can be up to 27 Vdc.

Figure 16 indicates how to connect loop-powered or externally

powered devices to the 215U-2 differential analog inputs. It should

also be noted that the differential inputs can also be used to connect

single-ended current sinking or current sourcing devices. Figure 18

shows how to connect to these types of devices.

Single-ended current input mode is useful if the sensor loop is

grounded to the 215U-2 module. Devices can be powered from the

24V analog loop supply (ALS) generated internally from the module.

The DIP switches (located in the side access panel) are used to

determine if the inputs will be current or voltage. DIP switches 1

and 2 are used for analog 3, and DIP switches 3 and 4 are used for

analog 4. For current, set both DIP switches to the “on” position.

Forvoltage, set both to “off.”

Figure 16. Differential current inputs (AI1 and AI2)

Figure 18. Al3 and Al4 Single-ended current inputs

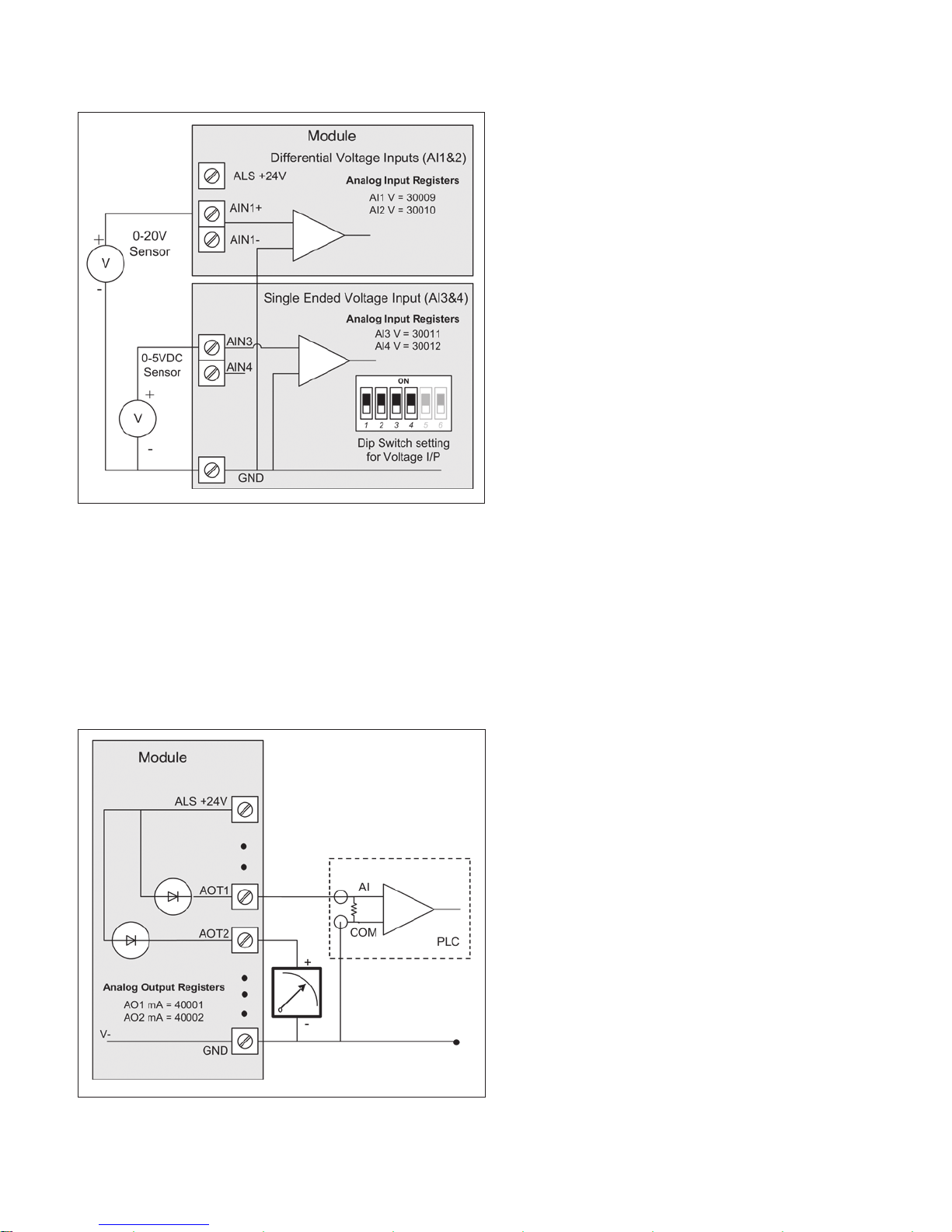

Voltage inputs

All analog inputs can be set up to read voltage. If using analog input

1 and 2, connect the voltage source across the positive terminal of

the input and ground. If using analog input 3 and 4, connect across

the input terminal and GND.

ote:N Default scaling gives 0–20 V for 0–20 mA output on analog 1 and 2.

Default scaling for analog 3and4 gives 0–5 V for 0–20mA output. For voltage

input on analog 3 and 4, set both DIP switches to the OFF position.

Figure 17. Al1 and Al2 single-ended current inputs

10

EATON www.eaton.com

215U-2 802.11

wireless I/O and gateway

Figure 19. Single-ended voltage inputs

Analog outputs

The 215U-2 module provides two 0–24 mA DC analog outputs for

connecting to analog inputs on equipment (such as PLCs, DCS, and

loggers) or connecting to instrument indicators for displaying remote

analog measurements. The 215U-2 analog outputs are a sourcing

output and should be connected from the analog output terminal

through the device or indicator to ground (GND). See Figure 20 for

connections. The LEDs provide level indication depending on current.

The LEDs appear dimmed for 4 mA and bright for 20 mA.

User Manual MN032EN

Effective October 2017

System design

Design for failures

All well-designed systems consider system failure. I/O systems

operating on a wire link will fail eventually. Failures can be shortterm, such as interference on the radio channel or power supply

failure, or long-term, such as equipment failure.

The modules provide the following features for system failure:

•

Outputs can reset if they do not receive a message within a

configured time. If an output should receive an update or change

message every 10 minutes and it has not received a message

within this time, some form of failure is likely. If the output

is controlling machinery, it is good design to switch off the

equipment until communications are re-established.

•

The modules provide a fail-safe feature for outputs. This is a

configurable time value for each output. If a message has not

been received for this output within the configured time, the

output will assume a configured value. We suggest that this reset

time be a little more than twice the update time of the input. It

is possible to miss one update message because of short-term

interference. However, if two successive update messages are

missed, long term failure is likely and the output should be reset.

For example, if the input update time is three minutes, set the

output reset time to seven minutes.

•

A module can provide an output that activates on communication

failure to another module. This can be used to provide an external

alarm indicating that there is a system fault.

Testing and commissioning

We recommend that the system is fully bench tested before

installation. It is much easier to find configuration problems on

the bench when the modules are next to each other as opposed

to being miles apart. When the system is configured and you are

confident that it works, back up the configurations of all modules.

Figure 20. Analog outputs

EATON www.eaton.com

11

User Manual MN032EN

Effective October 2017

Connecting to the device

To configure the 215U-2 you connect to it using a web browser on

your PC or mobile device.

Connecting to the module for the first time

On first connection, you can only connect to the device through

its USB port. Once you have connected to the device for the first

time, you can enable access through the Ethernet port and remotely

through the 802.11 Wireless port.

ote:N Before enabling the Ethernet Port or Wireless port for Configuration

access, read the section “Device Security”.

Connecting to the device’s USB port

The USB port is located on the bottom side of the module. (Refer

Figure 11 “Bottom Panel Connections”). To connect, you need an

USB cable (USB-A to USB-B) for connecting from your computer to

the module’s USB-B port.

If this is the first time you have used your computer to connect

to an ELPRO device through the USB port, then you will need to

download the USB driver file from the product’s internet website.

This is available from the same location that you downloaded this

user manual.

You will also need to know the username/password configured for

the device. If the module is new out-of-the-box you can use the

default settings. Otherwise, you may need to restore these settings.

If you have lost the password, you can set the username and

password back to the default values. For instructions, see “Restoring

the factory default connection settings” on page 42.

1. Install the USB Device driver to your PC. You do this by running

the installer ".exe" file and following the prompts.

2. Power on the device, and wait for the device to finish booting

and for the “PWR” LED to go solid green (about 1 minute).

3. Plug in the USB cable and wait for your computer to recognize

the new USB device.

4. Once the device is connected, you will have an additional

Network Adapter in your device manager list

“Elpro 215U-2 USB Ethernet/ RNDIS Interface”

5. Open your web browser (recommended Internet Explorer

version 10 or later) and type “http://192.168.111.1” into the

browser bar. The device’s USB address is always the same.

The module responds with a username and password box.

6. Type the username and password. The default username is

“user” and the default password is “user”.

215U-2 802.11

wireless I/O and gateway

The module’s default settings are as follows:

IP Address 192.168.0.1XX

(shown on the printed label on the side of

the module)

Subnet Mask 255.255.255.0

User Name user

Password user

ote:N You cannot access the device through Ethernet until remote access

has been enabled. The first time you access the device, you need to use the

USB method described above. Then you can enable remote access on the

quick start configuration page.

Once you have the device’s IP address and password:

1. Connect an Ethernet cable between the module’s Ethernet port

and the PC.

2. Configure your PC networking settings to be on the same

network as the device. For instructions on how to do this, see

“Configuring PC networking settings for Ethernet and Wireless”

on page 42.

3. Open your web browser (recommended Internet Explorer

version 10 or later) and type “http://” followed by the IP address

of the module and press Enter.

The module responds with a username and password box.

If the module does not respond, check that you have configured

your PC according to the section “Configuring PC networking

settings for Ethernet and Wireless” on page 42.

4. Type the username and password. The default username is

“user” and the default password is “user”.

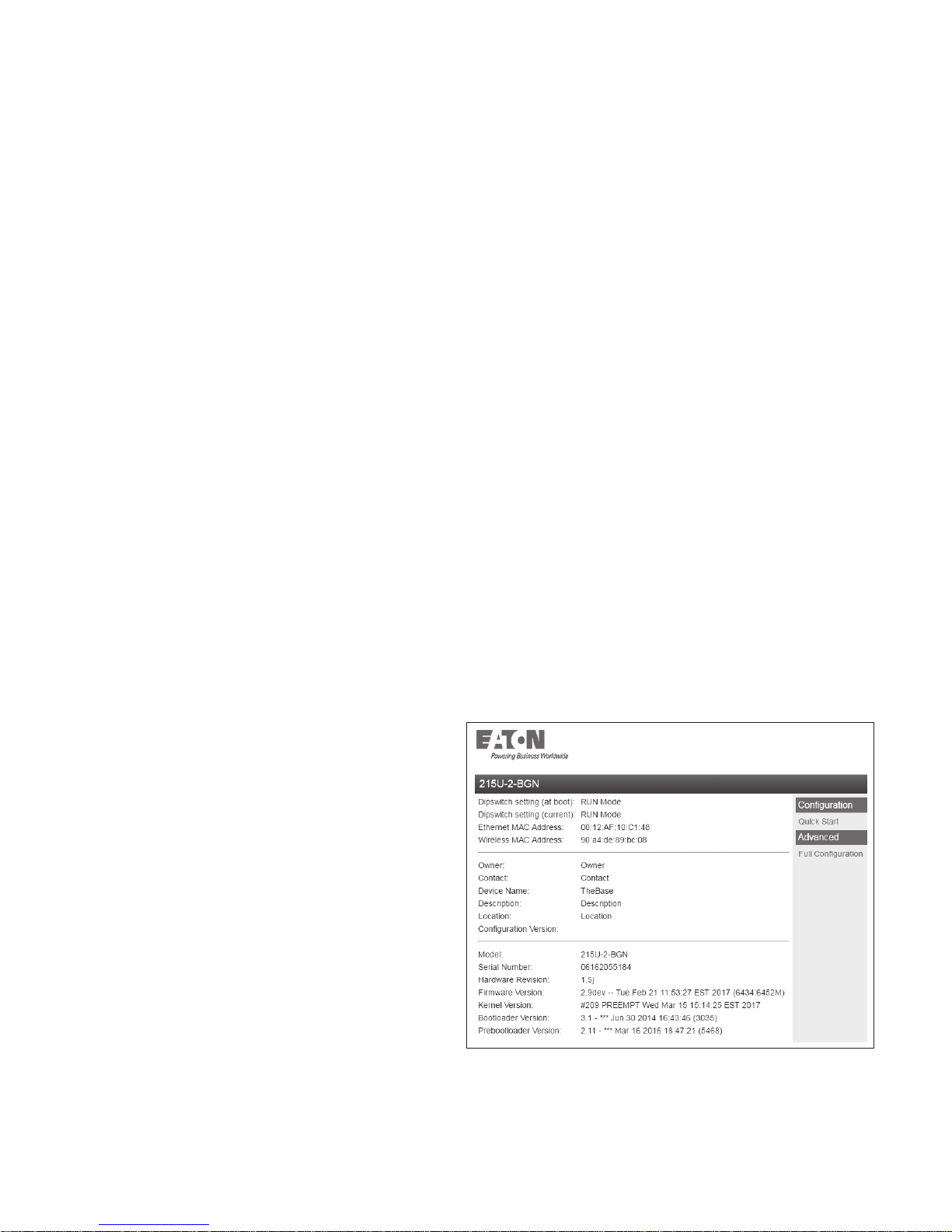

This connects you to the home page of the Web-based configuration

utility (see Figure 21). This utility allows you to manage wireless

connection links between all modules in the system through a

standard browser, such as Microsoft

®

Internet Explorer®.

This connects you to the home page of the Web-based configuration

utility (see Figure 21). This utility allows you to manage wireless

connection links between all modules in the system through a

standard browser, such as Microsoft

®

Internet Explorer®.

Connecting to the Device’s Ethernet port

The Ethernet port is located on the bottom side of the module.

(Refer Figure 8 “Bottom Panel Connections”). To connect, you need

an Ethernet cable for connecting to the module’s Ethernet port.

You also need to know the device’s IP Address and the username/

password configured for the device.

12

EATON www.eaton.com

Figure 21. Device home page

215U-2 802.11

wireless I/O and gateway

User Manual MN032EN

Effective October 2017

Device Security

The 215U-2 supports industrial protocols such as Modbus and WIB

that do not provide encryption or authentication. These protocols are

convenient to use as they are widely known and supported by an

extensive range of equipment.

The downside of using these protocols is that they are also

vulnerable to a variety of cyber-attacks, so you must consider the

security of the networks that they operate over.

As a precaution, these protocols are disabled in the default

configuration. Before enabling any of these protocols, you should

ensure that the following precautions are in place.

•

Change the device’s access password from the default (“user”).

•

Make sure that any network connected to the device’s Ethernet

port is secured from outside access. If an internet connection is

present, ensure it is effectively firewalled.

•

Secure the radio network using WPA-PSK encryption.

•

Ensure that the radio network encryption passphrase is long (at

least 20 characters) and complex. Quality of security assurance

offered depends on the complexity of this passphrase. Short

and simple passphrases can easily be compromised by skilled

attackers.

•

Ensure that knowledge of the radio network encryption

passphrase is kept to a limited number of workers and ensure the

access password and radio passphrase are changed whenever

any of these workers' security status changes.

•

Ensure physical security of the devices connected to the network.

•

In the event that a device is lost or stolen, ensure that the

encryption key used to secure communications on the radio

network is changed.

Peer-to-Peer I/O mapping, Serial port configuration, Data Logging,

Advanced networking configuration, diagnostics, and User

management. These pages are described later in this manual.

•

If your system is based on Modbus TCP protocol, you need to

enable Modbus TCP Server by selecting Full Configuration >>

Modbus TCP and checking "Enable Modbus TCP Server". Once

you have the device configured, you will be able to access it using

a Modbus TCP client (Master) at the IP address you configure.

ote:N Before navigating away from this page, you need to click the “Save

Changes” or “Save Changes and Reset” button at the bottom of the page.

Otherwise your changes will be lost.

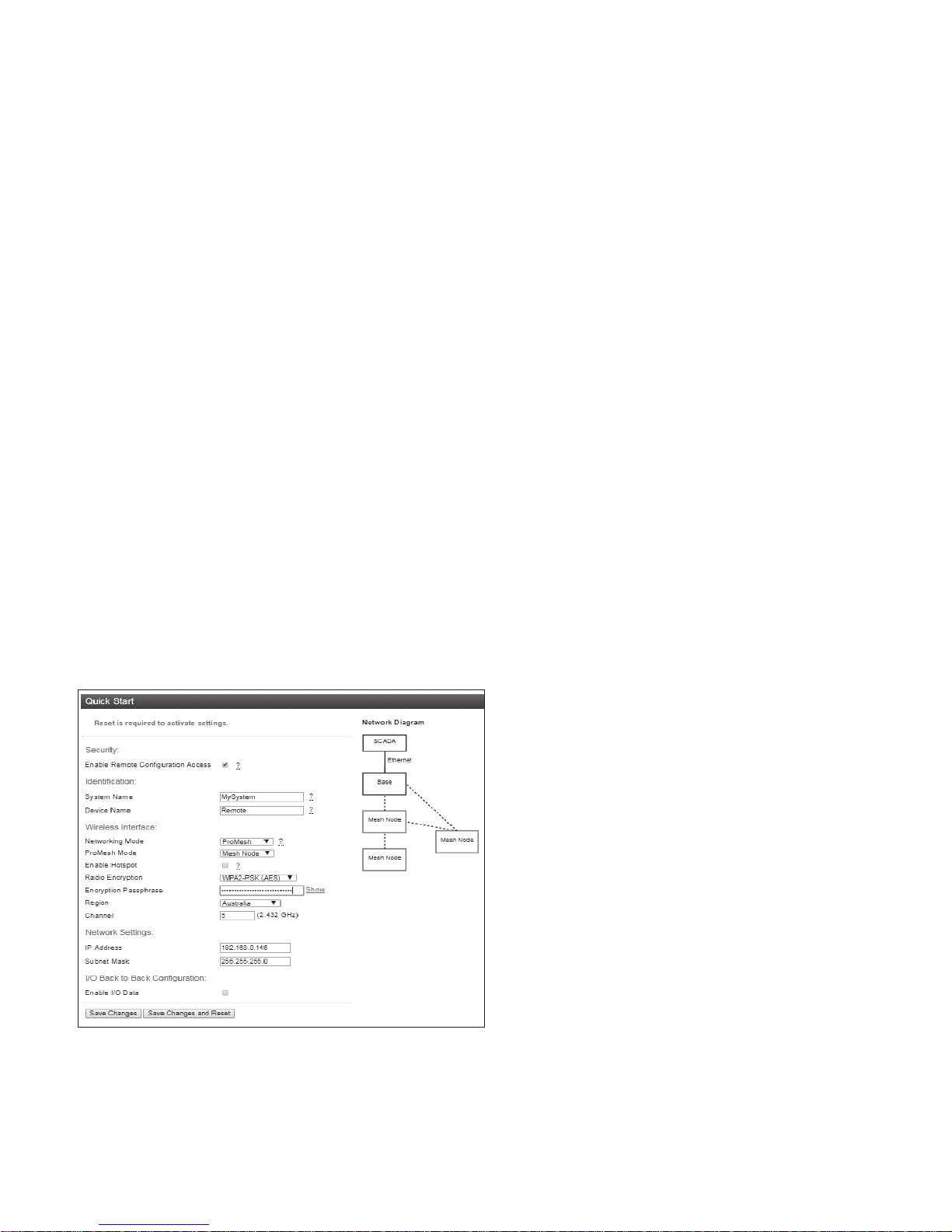

Security

Enable Remote Configuration Access: Select this to enable access

to the device configuration and the dashboard web pages through

Ethernet or Wireless interfaces. If this is not selected, you can only

access the device web pages through the USB connection.

Identification

System Name: All devices in a system are configured with a

common system name. This is used in ProMesh mode as a common

network ID for all devices to connect.

Device Name: Each device in the system should be configured

with a unique device name. This name is used to identify devices in

diagnostic display (Connectivity) and is used in Fixed Link mode as

the device ID for other devices to connect to.

Quick start conguration

Access the quick start configuration by clicking on the “Quick Start”

text on the right side menu under “Configuration”.

Figure 22. Quick start

•

For the majority of installations, you will only need to access

this Quick Start page. This configuration will get your devices

connected and communicating. You can then connect remotely if

you need to configure other functionality.

•

Click “Full Configuration” to access advanced configuration pages.

These pages provide access to additional functionality including

EATON www.eaton.com

13

User Manual MN032EN

Effective October 2017

215U-2 802.11

wireless I/O and gateway

Wireless Interface

Networking Mode: You can choose one of three networking modes

depending on your system requirements:

•

Manual Mode implements traditional 802.11 networking

configuration. You configure units as Access Point or Client. Client

units connect to an Access Point with matching SSID (System

Address).

•

ProMesh Mode implements automatic repeater configuration,

where devices (Mesh Node) automatically choose and maintain

the best path back to a central station (Base). All devices in the

network use a common SSID (System Name).

•

Fixed Links Mode implements a fixed repeater configuration

where field devices (Remote) are configured to connect directly or

via intermediate sites (Repeater) to a central station (Base).

802.11 Mode: This option is available when the Networking mode

is set to Manual. A traditional 802.11 network has a single Access

Point and one or more Clients.

•

System Address (ESSID): This is the “Extended Service Set

Identification” used in 802.11 mode. For a client to connect, the

client needs to have this set to the same value configured on the

Access Point.

ProMesh Mode: This option is available when the Networking Mode

is set to ProMesh. A ProMesh network consists of a single central

station (Base), and one or more remote sites (Mesh Nodes) which

can each operate as a repeater for other stations.

The Mesh Nodes select the best path to the Base depending on

the number of hops to the base, and based on signal strength of

the hops in the path. Once connected, the Mesh Nodes monitor

the path quality and will swap to use a better path if one comes

available.

All devices in a ProMesh network share the same SSID (the

configured “System Name”).

•

Enable Hotspot: This option is only available for Mesh Nodes

in a ProMesh network. Because the ProMesh is designed to

be flexible, the Mesh Nodes devices may not always advertise

for a connection. If you want to be able to connect from a non

ProMesh device to one of the Mesh Nodes, then select this

option on that Mesh Node to ensure it remains available for

connection.

Device Mode: This option is available when the Networking mode

is set to “Fixed Links”. A Fixed Link network consists of a central

station (Base) accessing a fixed arrangement of repeater stations

(Repeater) and remote stations (Remote). All devices ultimately

connect to the central station (Base). Repeaters and remotes can

either connect directly to the base, or connect using additional

repeater stations to extend the radio range.

•

Upstream Device Name: When the Device Mode is “Repeater”

or “Remote”, you need to select the Upstream device. When

the connection is direct to the base, this is the Device Name

of the base station. When the connection is via repeaters, this

is the name of the repeater station that is used to reach the

base station.

Radio Encryption: Select the desired Encryption mode. Normally

this should be WPA2-PSK (AES), which is the strongest encryption

available. Only select other modes if you need to do this to connect

to a third party or legacy system that does not support WPA2

protocol.

ote:N Selecting Encryption “None” or “WEP” makes your network vulnerable

to attack. This product makes use of standard 802.11 physical signaling, so

without encryption there is no protection from attackers with off-the-shelf

hardware. Selecting WEP provides very limited protection from attack. WEP

protocol has known weaknesses that make it relatively simple to penetrate.

Encryption Passphrase: This is the secret key for your network

encryption. All devices in the network need the same passphrase to

communicate.

ote:N For best security, this passphrase must be long (at least 20 characters)

and should not include text that could be guessed such as names, dates, etc.

ote:N Always keep this passphrase private, and ensure that the system

configuration is updated with a new passphrase if this key becomes

compromised.

Region: The module is configured from the factory to allow

operation globally. To take advantage of additional radio channels

and higher allowed power in some countries, you can select a

different region. The power is automatically set to the maximum

for the selected region. Refer to the table below for the maximum

radiated power in different regions. You can adjust the power on the

Radio page (“Full Configuration >> Radio” on right side menu) to

accommodate higher gain antennas if needed. Note that every time

you change the Region selection, the power setting reverts to the

maximum for that region.

Table 9.

Region Allowed channels Power setting Maximum EIRP

North America 1-11 23 dBm (200mW) +36 dBm

Europe 1-13 20 dBm (100mW) +20 dBm

Australia 1-13 23 dBm(200mW) +36 dBm

Channel: You can select a radio channel to avoid interference from

other 802.11 networks in your area, or to allocate radio spectrum

between several of your own networks. For 802.11 communication,

channels 1,6, and 11 are non-overlapping.

Network settings

IP Address: This selects the IP address for the device. You can leave

this at the default value, which is printed on the module side label.

If you chose to do this, take care that you don’t have two modules

with the same IP address assigned (The default IP address is

assigned from the factory based on the last two digits of the device

serial number).

Subnet Mask: The subnet mask identifies how the IP address is

divided between the local device address and the global network

address. The default subnet mask of 255.255.255.0 allocates 24

bits to the network address, and 8 bits for the host device. This

allows up to 254 devices (hosts) on a single network. If you need to

support more devices, or if you need to operate within an existing

addressing scheme, you should discuss this setting with an IP

network expert.

14

EATON www.eaton.com

215U-2 802.11

wireless I/O and gateway

User Manual MN032EN

Effective October 2017

Additional network settings items

These additional items will display on the Quickstart page

if the Network Mode has been modified in the Advanced

Networking configuration. Normally they will not be visible

on the Quickstart page.

Network Mode: This allows you to choose between bridged and

routed networking. Bridged networking is the simplest to configure

and will be the correct choice in almost all networks.

•

Bridge: The 215U-2 acts as a network bridge between the radio

and Ethernet ports. Ethernet packets are transparently passed

between the radio and Ethernet ports using rules learned from

traffic that has already passed.

•

Router: The 215U-2 acts as an IP Router between the radio and

Ethernet ports. Only IP packets are passed between the radio

and Ethernet, which are on separate sub-networks. You configure

the rules for which packets are transferred on the routing

configuration page.

Wireless IP Address/Netmask: When the network mode is set to

Router, the Ethernet and Wireless interfaces on the device each

have separate IP addresses. This sets the IP address for the

wireless interface.

I/O Back to Back configuration

This provides a simple method to configure I/O mappings between

two sites in a system. When the networking mode is ProMesh, you

can select this check box to configure the device to automatically

send the I/O data to another device connected to the same network.

You can also connect 115S-12 and 115S-13 modules to provide

additional I/O points.

When you select this option, input data from a remote site is sent to

the system Base. Input data at the base is sent to the remote site

that first sends the data to the Base. You should only set this option

at the base and at one remote site in the system. For more detail

on how this feature operates, refer to section "Default Back-To-Back

gather scatter mapping" on page 20.

Save Changes: Clicking this button saves changes to non-volatile

storage. Changes don’t take effect until the device has been

restarted. If you plan to make changes to multiple pages, use this

button before navigating to another page.

Save Change and Reset: Clicking this button immediately applies

the changes on you have made by saving the new configuration to

non-volatile storage, then forcing the device to reset immediately.

Once the device has booted, the new changes will be in effect.

Connecting to Other 802.11 devices

The 215U-2 uses standard 802.11 networking protocols and it is

possible to use it in conjunction with other 802.11 devices, either

joining an existing network, or allowing other devices to join the

215U-2 network.

mode and passphrase to match the settings in the existing network.

You also need to find the correct network name (SSID) to connect

to. This depends on the type of network you have configured as

shown below:

•

Manual: To connect to an “Access Point” unit in “Manual” mode,

connect to the network which matches the unit’s configured

“System Address (ESSID)” parameter.

ote:N You cannot connect to a “Station (Client)” unit.

•

Fixed Links: To connect to a “Base” unit or a “Repeater” unit in

“Fixed Links” mode, connect to the network that matches the

unit’s configured “Device Name”. Each Base and Repeater should

have a unique device name in the network.

ote:N You cannot connect to a “Field Station” unit.

•

ProMesh: Connecting to device configured for “ProMesh” mode

takes some care. In a ProMesh network all the devices share the

same SSID. This is the configured “System Name”, so your device

may see multiple networks with the same name.

You will always be able to connect to the “Base” unit by selecting

the correct network. For “Mesh Node” units, you must check

the “Enable Hotspot” check box on the unit’s configuration page

to ensure that it remains available for connection. Normally you

can connect to the unit with the best signal strength, and use

the 215U-2 ProMesh network to automatically reach the unit you

need to access.

Your device might also need to be configured with the correct IP

Address. You can do this through manually configuring your device,

or using automatic IP address assignment (DHCP). If you need

your device to be assigned an IP Address through DHCP, you can

configure the DHCP server on the central unit in the 215U-2 network

(This is the Base unit or the Access Point unit). You can access the

DHCP Configuration by selecting “Full Configuration >> DHCP

Server” on the right side menu. Refer to section “DHCP Server” on

page 27 for information on configuring the DHCP server.

Accessing Ethernet devices connected to 215U-2

You can connect devices such as PLCs or HMIs to the Ethernet port

on the remote 215U-2 devices. With the default configuration, you

will be able to access these devices directly from a PC or HMI at the

central site.

The 215U-2 default configuration bridges the wireless and Ethernet

connections. This means that all of the devices, including devices

connected to the remote Ethernet ports, are connected to a single

bridged network.

The 215U-2 can also be configured to route between the Wireless

and Ethernet ports. If you configure your 215U-2 network as a

routed network, then you will need to set up routing rules in your

devices to allow the data packets to reach the correct destination.

Connecting a 215U-2 to existing 802.11 network

To connect to an existing 802.11 Access Point, you need to set

encryption mode and passphrase to match the existing network.

•

For a Manual Mode Client – Set the “System Address (ESSID)”

field to match the SSID of the Access Point

•

For a ProMesh Mesh Node, set the “System Name” field to

match the SSID of the Access Point.

•

For a Fixed Mesh Repeater and Fixed Mesh Remote, set the

“Upstream Device” field to match the SSID of the Access Point.

Connecting your device to an existing 215U-2 network

To connect an 802.11 capable device as a client to an existing

network of 215U-2 devices, you need to set the device’s encryption

EATON www.eaton.com

15

Loading...

Loading...