Page 1

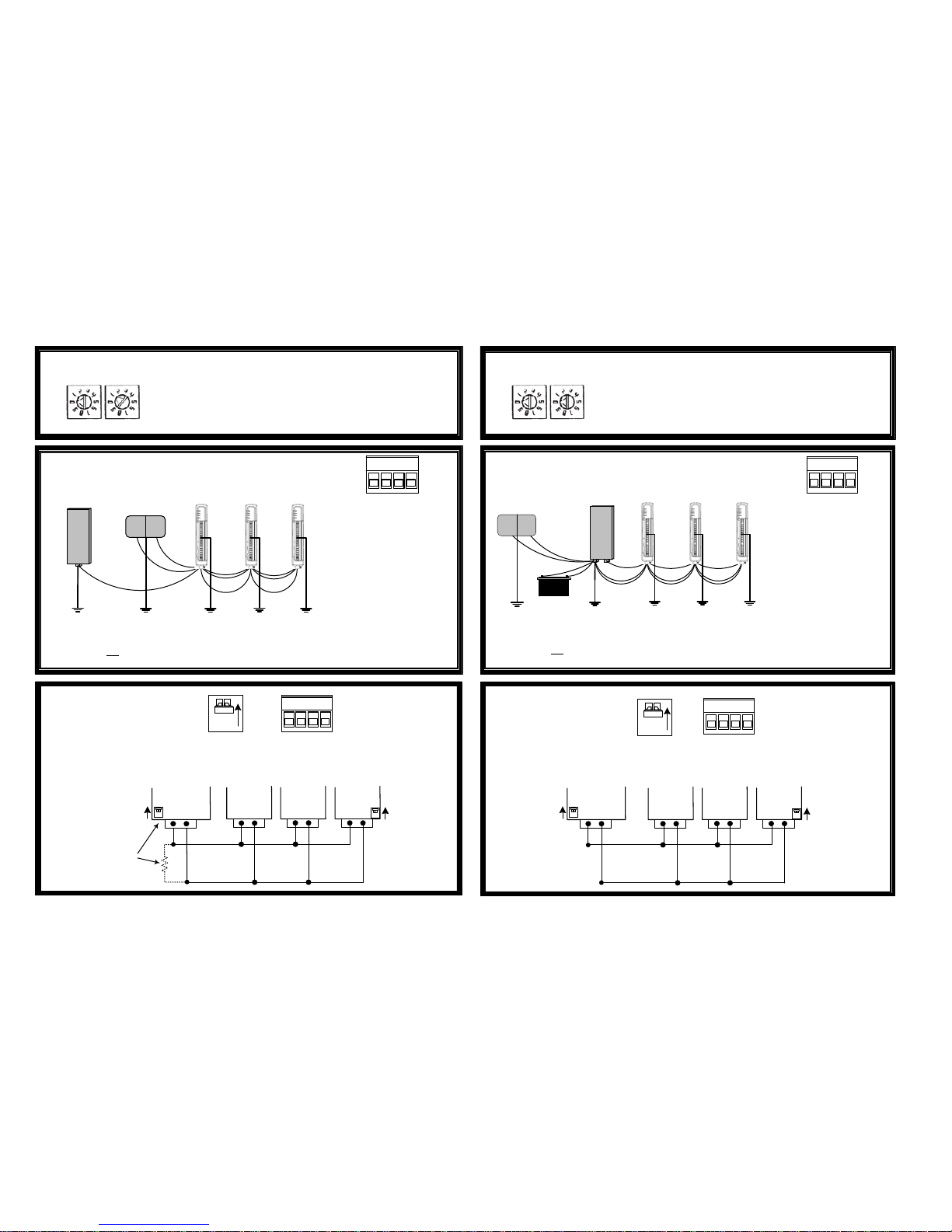

A, B: Connect RS485

(Modbus)

RS485

termination

switch

Up = terminated

Down = un-terminated

Power and

Modbus

connector

Modbus

Master

115S 115S 115S

A

AB ABAB

RS485

RS485

Termination

switch up

(terminated)

Set a unique Modbus slave address for each 115S

connected to the Modbus Master

Example shows address “01”

Consult user manual for Modbus addresses

ADDRESSING

x10

x1

115S

B A

-

+

POWER

Modbus

Master

Power

Supply

Power Connections:

EARTH wiring minimum 2mm² - 14 AWG

B A

-

+

ON

115S Quick Setup Guide - Connections

inst_115S_1.13.vsd © ELPRO Technologies.

Address switches must be 00 for E-Series protocol

Example shows address “00”

Setup using ELPRO E-Series configuration utility.

ADDRESSING

x10

x1

Connection to Modbus Master

Connection to E-Series Radio

Power

Power

Power

Modbus

Modbus Modbus

+

-

A, B: Connect RS485

(Elpro)

RS485

Termination

switch

Up = terminated

Down = un-terminated

Power and

RS485

connector

E-Series

Module

115S 115S 115S

AB

AB AB AB

RS485

RS485

Termination

switch up

(terminated)

B A

-

+

POWER

E-Series

Radio

Power

Supply

Power Connections:

115S-11: 300mA max

115S-12: 900mA max

115S-13: 900mA max

+

-

B A

-

+

RS485

Termination

switch up

(terminated)

ON

**Check rear label for

operating voltages

Power Power Power

RS485

RS485

RS485

Battery

_

+

Supply

Earth

115S 115S

B

RS485 Termination

switch up (terminated)

or

120Ω Fitted across

RS485

115S 115S 115S

Earth

EarthEarth

Earth

Earth

Earth

Earth Earth

Earth

‘+’ : Pos Supply

(10.8 to 30 VDC**)

‘-’ : Neg Supply

Ensure all earth connections are at the same potential.

EARTH wiring minimum 2mm² - 14 AWG

Ensure all earth connections are at the same potential.

THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS 1 DIVISION 2 GROUPS A,B,C AND D, OR NONHAZARDOUS LOCATIONS ONLY.

WARNING ‐ EXPLOSION HAZARD ‐ DO NOT DISCONNECT EQUIPMENT WHILE THE CIRCUIT IS LIVE OR UNLESS THE AREA IS KNOW TO BE FREE OF IGNITABLE CONCENTRATIONS.

WARNING ‐ EXPLOSION HAZARD ‐ SUBSTITUTION OF ANY COMPONENT MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2.

115S-11: 300mA max

115S-12: 900mA max

115S-13: 900mA max

**Check rear label for

operating voltages

‘+’ : Pos Supply

(10.8 to 30 VDC**)

‘-’ : Neg Supply

Page 2

inst_115S_1.13.vsd

© ELPRO Technologies

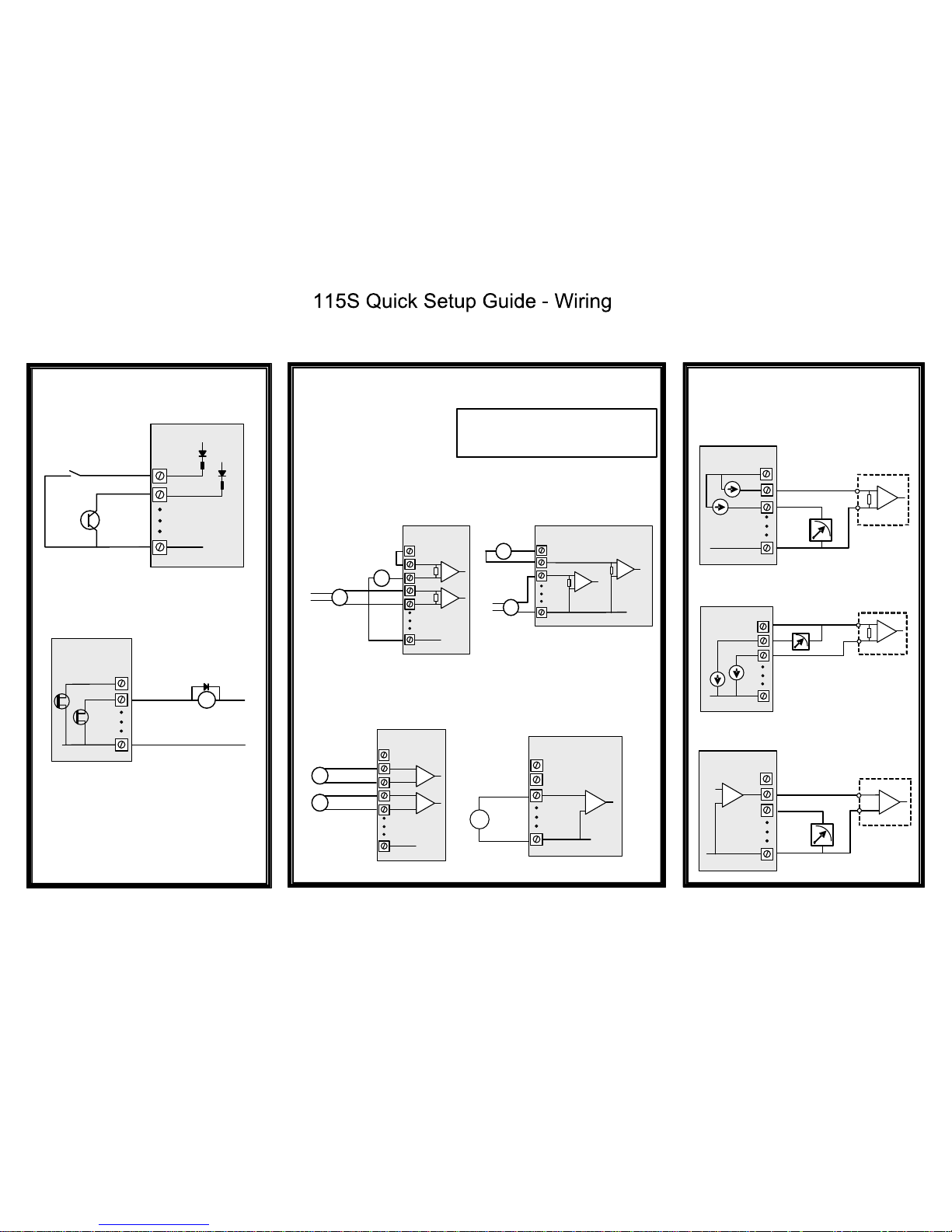

Voltage free

contact

Transistor

switch

device

V+

V+

DIO1

DIO2

115S Module

_

+

DC

Load

Max 30VDC

200mA

V-

DIO1

DIO2

GND

115S Module

115S-11

DIGITAL

INPUTS

V-

AIN3

AIN4

GND

ALS +24V

AIN1

AIN2

Power

Supply

V-

AIN1

AIN2

GND

ALS +24V

Loop powered

sensor

V-

AIN3

AIN4

GND

ALS +24V

Sensors with

voltage

signals

AIN1

AIN2

V-

AIN1

AIN2

GND

115S-12

ALS +24V

Sensor with

voltage signal

DIFFERENTIAL

CURRENT INPUTS

(Default configuration)

(Select using DIP switches AND

config software)

V-

AOT1

AOT2

GND

ALS +24V

PLC

AI

COM

+

-

CURRENT SOURCE OUTPUT

(Default configuration)

V-

AOT1

AOT2

GND

ALS +24V

PLC

AI+

AI-

+

-

CURRENT SINK OUTPUT

(Select using config software)

V-

AOT1

AOT2

GND

115S-13

ALS +24V

PLC VOLTAGE

INPUT

AI

COM

+

-

VOLTAGE OUTPUT

(Select using config software)

WARNING !

115S-12

115S-13

DIGITAL

OUTPUTS

DIFFERENTIAL

VOLTAGE INPUTS

SINGLE ENDED

VOLTAGE INPUTS

SINGLE ENDED

CURRENT INPUTS

(Select using DIP switches AND

config software)

115S-12

115S-12

Externally

powered sensor

(Select using DIP switches AND

config software)

Loop powered

sensor

115S-12

Externally

powered sensor

V-

GND

+

-

-

+

-

+

+

-

+

-

+

+

-

115S-13

Ensure correct DIP switch positions AND

software configuration has been completed for

each analogue input BEFORE connecting

external signals to the 115S-12 module.

THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS 1 DIVISION 2 GROUPS A,B,C AND D, OR NONHAZARDOUS LOCATIONS ONLY.

WARNING ‐ EXPLOSION HAZARD ‐ DO NOT DISCONNECT EQUIPMENT WHILE THE CIRCUIT IS LIVE OR UNLESS THE AREA IS KNOW TO BE FREE OF IGNITABLE CONCENTRATIONS.

WARNING ‐ EXPLOSION HAZARD ‐ SUBSTITUTION OF ANY COMPONENT MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2.

Loading...

Loading...