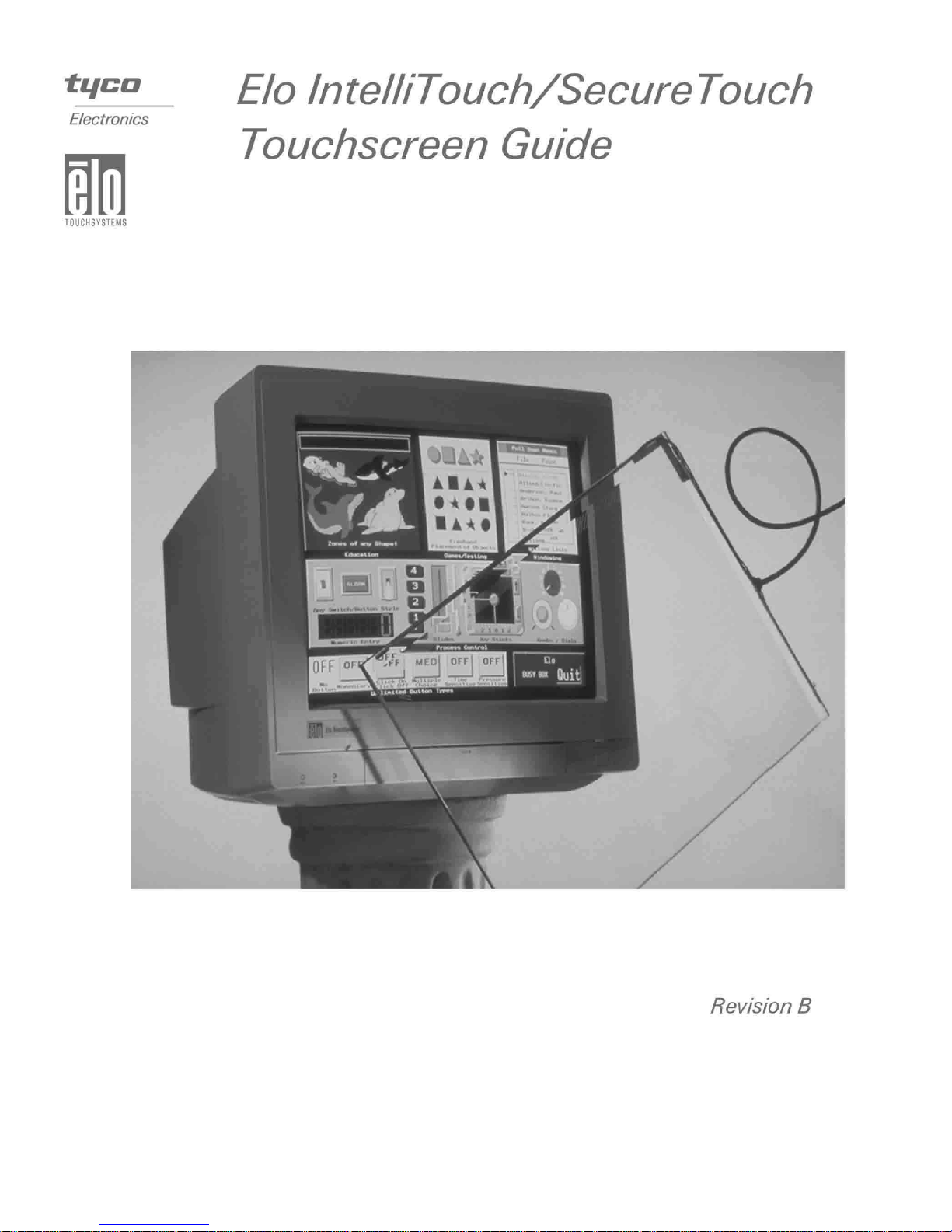

Elo TouchSystems IntelliTouch SecureTouch, IntelliTouch Series, SecureTouch Series User Manual

Page 1

Page 2

Elo IntelliTouch®/SecureTouch

Touchscreen Guide

Revision B

P/N 0082 12M

Elo TouchSystems, Inc.

1-800-ELOTOUCH

www.elotouch.com

Page 3

Copyright © 1989, 1992, 1995, 1996, 2001 Elo TouchSystems Inc.

All Rights Reserved.

No part of this p ublic ation ma y be repr oduce d, tra nsmitte d, transc ribe d, stor ed in a ret rieval system,

or translated into any langu age or computer language, in any form or by any means, including, but not

limited to, electronic, magnetic, optical, chemical, manual, or otherwise without prior written permission of Elo TouchSystems.

Disclaimer

The informat ion in this docum ent is subje ct to change with out notice . Elo TouchSystems make s no

representations or warranties with respect to the contents hereof, and specifically disclaims any

implied warranti es of mer chanta bilit y or fitness for a parti cular purp ose. El o TouchSystems rese rves

the right to rev ise th is pu blic a tio n and to mak e ch ang e s fr om t im e to t im e in the c o nten t h er eof w i thout obli gation of Elo TouchSystems to not ify any person of such revi s ions or changes.

Trademark Acknowledgments

iTouch, IntelliTouch, SecureTouch, AccuTouch, Entuitive, MonitorMouse, ELODEV, and SmartSet

are trademarks of Elo TouchSystems, Inc.

Other product names mentioned herein may be trademarks or registered trademarks of their respective companies. Elo TouchSystems claims no interest in trademarks other than its own.

i

Page 4

ii

Page 5

C

HAPTER

0

I

NTELLITOUCH

Except as otherwise stated herein or in an order acknowledgment delivered to

Buyer, Seller warrants to Buyer that the Product shall be free of defects in

materials and workmanship. The warranty for IntelliTouc h touchs creens is 10

years and for IntelliTouch controllers 5 years.

Seller makes no warranty regarding the model life of components. Seller’s

suppliers may at any time and from time to time make changes in the

components deliver ed as Products or components.

Buyer shall notify Seller in writing promptly (and in no case later than thirty

(30) days after discov ery) of the failure of any Product to conform to the

warranty set forth above; shall describe in commercially reasonable detail in

such notice the symptoms assoc iated with such failure; and shall provide to

Seller the opportun ity to inspect such Products as installed, if possible. The

notice must be received by Seller during the Warranty Period for such product,

unless otherwise directed in writing by the Seller. Within thirty (30) days after

submitting such noti ce, Bu yer shall package the allegedly defective Product in

its original ship ping carton(s) or a functional equivalent and shall ship to Seller

at Buyer’s expense and risk.

Within a reasonable time after receipt of the allegedly defective Product and

verification by Seller that the Product f ails to meet the warranty set for th above,

Seller shall corr ect such failure by, at Seller’s options, either (i) modifying or

repairing t he Product or (ii) rep lacing the Product. Such modification, repair, or

replacement and the return shipment of the Product with minimum insurance to

Buyer shall be at Se ller’s expense. Buye r shall be ar the r isk of loss or damage in

transit, and may insure the Product. Buyer shall reimburse Seller for

transportat ion cost incurred for Product returned but not found by Seller to be

defective. Modifi cati on or repair, of Products may, at Seller’ s option , take place

either at Seller ’s facilities or at Buyer’s premises. I f Seller is unable to modify,

repair, or replace a Product to conform to the warranty set forth above, then

Seller shall, at Seller’s option, either refund to Buyer or credit to Buyer’s

account the purchase price of the Product less depreciation calculated on a

straight-line basis over Seller’s stated Warranty Period.

10-Y

EAR

W

ARRANTY

iii

Page 6

THESE REMEDIES SHALL BE THE BUYER’S EXCLUSIVE REMEDIES

FOR BRE ACH OF WARR ANTY. EXCE PT FOR THE EXPRESS

WARRANTY SET FORTH ABOVE, SELLER GRANTS NO OTHER

WARRANTIES, EXPRESS OR IMPLIED BY STATUTE OR OTHERWISE,

REGARDING THE PRODUCTS, THEIR FITNESS FOR ANY PURPOSE,

THEIR QUALITY, THEIR MERCHANTABILITY, THEIR

NONINFRINGEMENT, OR OTHERWISE. NO EMPLOYEE OF SELLER

OR ANY OTHER PARTY IS AUTHORIZED TO MAKE ANY WARRANTY

FOR THE GOODS OTHER THAN THE WARRANTY SET FORTH

HEREIN. SELLER’S LIABILITY UNDER THE WARRANTY SHALL BE

LIMITED TO A REFUND OF THE PURCHASE PRICE OF THE PR ODUCT.

IN NO EVENT SHALL SELLER BE LIABLE FOR THE COST OF

PROCUREMENT OR INSTALLATION OF SUBSTITUTE GOODS BY

BUYER OR FOR ANY SPECIAL, CONSEQUENTIAL, INDIRECT, OR

INCIDENTAL DAMAGES.

Buyer assumes the risk and agrees to indemnify Seller against and hold Seller

harmless from all liability relating to (i) assessing the suitability for Buyer’s

intended use of the Product s and of any system design or drawing and (ii)

determining the complia nce of Buyer’s use of the Products with applicable

laws, regulations, codes, and standards. Buyer retains and accepts full

responsibil ity for all warranty and other claims relating to or arising from

Buyer’s products, which include or incorporate Products or componen ts

manufactured or supplied by Seller. Buyer is solely responsible for any and all

representations and warranties regarding the Products made or authorized by

Buyer. Buyer will indemnify Seller and hold Seller harmless from any liability,

claims, los s, cos t, or expe nses (inc lu ding rea sonable a tto rney’s fees) a ttribu table

to Buyer’s products or representations or warranties concerning same.

iv

Page 7

Table of Contents

IntelliTouch 10-Year Warranty. . . . . . . . . iii

Chapter 1

IntelliTouch Technology . . . . . . . . . . . . 1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

The IntelliTouch Touchscreen . . . . . . . . . . . . . . 1-2

The IntelliTouch Controller. . . . . . . . . . . . . . . . . 1-3

Driver Software . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . .1-4

Chapter 2

Component Installation. . . . . . . . . . . . . 2-5

Safety Information. . . . . . . . . . . . . . . . . . . . . . . 2-5

Work Area. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Protective Clothing . . . . . . . . . . . . . . . . . . . . 2-6

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Design Consider ations for CRTs and LCDs . . . 2-6

Bezel Design . . . . . . . . . . . . . . . . . . . . . . . .2-7

CRT Integration. . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Safety Information . . . . . . . . . . . . . . . . . . . . 2-8

Definition of Terms:. . . . . . . . . . . . . . . . . . . . 2-9

Suggested Tools. . . . . . . . . . . . . . . . . . . . . . 2-9

Summary of Installation Steps . . . . . . . . . . 2-10

Incoming Inspection . . . . . . . . . . . . . . . . . . 2-11

Unpacking the Touchscreen . . . . . . . . .2-11

Testing the Monitor . . . . . . . . . . . . . . . . 2-11

Disassembling the Monitor. . . . . . . . . . . . .2-11

Remove the Back Case. . . . . . . . . . . . . 2-12

Discharge the CRT . . . . . . . . . . . . . . . . 2-12

Remove the Ele ctronic Chassis. . . . . . .2-13

Remove the CRT. . . . . . . . . . . . . . . . . . 2-15

Verify Touchscreen Fit . . . . . . . . . . . . . . 2-16

Attaching the Touchscreen. . . . . . . . . . . . . 2-18

Spacing the CRT from the Bezel . . . . . . . . 2-20

Installing the Controller. . . . . . . . . . . . . . . . 2-21

Internal Serial Controller (2500S) . . . . . 2-22

External Serial Controller. . . . . . . . . . . . 2-25

Internal USB Controller (2500U) . . . . . .2-27

Routing the Touchscreen Cables . . . . . . . . 2-29

Reassembling th e Mo n ito r . . . . . . . . . . . . .2-29

Sealing the Monitor . . . . . . . . . . . . . . . . . . . . .2-30

Sealing Material Selection . . . . . . . . . . . . . 2-31

System Evaluation . . . . . . . . . . . . . . . . . . . 2-31

LCD Integration . . . . . . . . . . . . . . . . . . . . . . . .2-32

Safet y Informatio n. . . . . . . . . . . . . . . . . . . 2-32

Summary of Installati on Steps. . . . . . . . . . 2-33

Unpacking the Touchscreen . . . . . . . . . . . 2-33

Testing the Monitor . . . . . . . . . . . . . . . . 2-33

Disassembling the LC D Monitor . . . . . . . . 2-34

Definition of Terms . . . . . . . . . . . . . . . . 2-34

Tools and Equipment . . . . . . . . . . . . . . 2-35

Required Parts for Serial Connection . . 2-35

Required Parts for USB Connection. . . 2-35

Optional Parts for Serial Connection. . . 2-36

Optional Parts for USB Connection . . . 2-36

Notes on Disassembling the Monitor. . . . . 2-36

Removing the Rear Case . . . . . . . . . . . . . 2-37

Removing the LCD . . . . . . . . . . . . . . . . . . 2-37

Determining Touchscreen Fit. . . . . . . . . . . 2-38

Mounting the Touchscreen. . . . . . . . . . . . . 2-39

Sealing. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Spacing the LCD from the Bezel. . . . . . . . 2-41

Installing the Controller . . . . . . . . . . . . . . . 2-42

Internal Serial Controller (2500S). . . . . 2-42

Internal USB Controller (2500U). . . . . . 2-43

Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

Parasitic Tap of 5Vdc . . . . . . . . . . . . . . 2-44

Parasitic Tap of 7-30Vdc (DC to DC

converter) . . . . . . . . . . . . . . . . . . . . . . . 2-45

Modifying the Case for Serial Output. . . . . 2-46

Modifying the Case for USB Output. . . . . . 2-46

Re-assembling the Display . . . . . . . . . . . . 2-47

Appendix A

Troubleshooting Guide. . . . .A-49

The Troubleshooting Proc ess. . . . . . . . . . . . . A-49

Display Problems . . . . . . . . . . . . . . . . . . . . . . A-50

Software Troubleshooting . . . . . . . . . . . . . . . . A-50

Video Alignmen t Problems . . . . . . . . . . . . A-51

Hardware Troubleshooting . . . . . . . . . . . . . . . A-51

Serial Controller. . . . . . . . . . . . . . . . . . . . . A-52

Using the COMDUMP Utility. . . . . . . . . A-52

2500S Controller Protocol . . . . . . . . . . . . A-53

A-4002 Controller Protocol . . . . . . . . . . . A-53

RS-232 Connection s. . . . . . . . . . . . . . . A-54

Po wer Connections. . . . . . . . . . . . . . . . A-55

Touchscreen and Touchscreen Cables. . . . . . A-56

IC1 Cable . . . . . . . . . . . . . . . . . . . . . . . A-57

EC2 Cable. . . . . . . . . . . . . . . . . . . . . . . A-57

v

Page 8

Diagnostic LED's . . . . . . . . . . . . . . . . . . . .A-58

IntelliTouch Serial Controllers . . . . . . . .A-58

Diagnostic Codes . . . . . . . . . . . . . . . . . . . .A-59

IntelliTouch Serial Controller (2500S) . .A- 59

DB9 and DB25 Connector Pin Positions . .A-60

Appendix B

Specifications . . . . . . . . . . . .B-61

IntelliTouch Touchscreens. . . . . . . . . . . . . . . .B-62

IntelliTouch 2500U USB Controller . . . . . . . . .B-64

LED Diagnostic Characteristics. . . . . . .B-68

Agency Approvals. . . . . . . . . . . . . . . . . . . .B-68

2500U USB Controller Drawings . . . . . . . .B-69

IntelliTouch 2500S Serial Controller . . . . . . . .B-71

Jumper Settings. . . . . . . . . . . . . . . . . . .B-75

LED Diagnostic Characteristics. . . . . . .B-75

Agency Approvals. . . . . . . . . . . . . . . . . . . .B-76

Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . .B-77

Appendix C

Elo Part Numb ers . . . . . . . . . . .79

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . .83

Inde x. . . . . . . . . . . . . . . . . . . . . .89

vi

Page 9

List of Figures

IntelliTouch Touchscreen . . . . . . . . . . . .1-2

IntelliTouch controller . . . . . . . . . . . . . . 1-3

Bezel design . . . . . . . . . . . . . . . . . . 2-7

Bezel edge . . . . . . . . . . . . . . . . . . 2-8

Typ ical IntelliTouch Touchscreen Installation . 2-10

Proper placement of adhesive tape to the

touchscreen. . . . . . . . . . . . . . . . 2-19

Touchscreen Cabling System for Internal Serial

Controller . . . . . . . . . . . . . . . . 2-22

Internal USB Controller (2500U) . . . . . . . 2-27

Proper and Improper Sealing . . . . . . . . . 2-30

Proper and Improper Bezel Mounting . . . . 2-31

Attaching double-sided adhesive tape to the

touchscreen . . . . . . . . . . . . . . . 2-40

2500S Internal Serial Controller . . . . . . . 2-42

2500U USB controller . . . . . . . . . . . . . 2-43

DC to DC converter . . . . . . . . . . . . . . 2-45

Horizontal escutcheon plate . . . . . . . . . 2-47

Pin positions for the serial port connector . . A-54

Transducer and Wedge Assembly . . . . . . A-56

Pinouts for the IC1 Cable . . . . . . . . . . . A-57

DB9 and DB25 Connector Pin Positions . . . A-60

P2, USB board-mounted header and cable-

mounted plug. . . . . . . . . . . . . . . B-66

Pin diagram for touchscreen connector, P3, as

viewed from connector mating surfaces. B-66

Power connector board-mounted header and cable

mounted-plug. . . . . . . . . . . . . . . B-66

2500U USB Controller, top vie w . . . . . . . B-69

2500U USB Controller, thru-hole locations . . B-69

2500U USB Controller, bottom-view . . . . . B-70

2500U USB Controller, side vie w . . . . . . . B-70

Pin diagram for serial connector, P2, as viewed

from connector mati ng surfaces. . . . . B-72

Pin diagram for touchscreen connector, P3, as

viewed from connector mating surfaces. B-74

Pin diagram for power connecto r, P4, as viewed

from connector mati ng surfaces . . . . . B-74

2500S Serial Controller, top vie w . . . . . . . B-77

2500S Serial Controller, bottom view . . . . . B-77

2500S Serial Controller . . . . . . . . . . . . B-78

2500S Serial Controller, side vie w . . . . . . B-78

vii

Page 10

viii

Page 11

List of Tables

Serial port controller signals . . . . . . . . . A-54

Pinouts for IC1 Cable and header . . . . . . A-57

The IntelliTouch Serial Controller (2500S) bit

position relating to each byte. . . . . . . A-59

USB connector pin numbers and signal

names . . . . . . . . . . . . . . . . . . B-66

IntelliTouch touchscreen conn ector pin numbers

and signal descriptions . . . . . . . . . B-67

Power connector, P4 pins and signal

descriptions . . . . . . . . . . . . . . . B-67

Serial Connector, P2, signal names and

functions . . . . . . . . . . . . . . . . B-73

Serial signal electrical characteristics . . . . B-73

Touchscreen connector, P3, pins and signal

names . . . . . . . . . . . . . . . . . . B-74

Power connector, P4, pins and signal names . B-75

Jumper Loc ati ons and function if insta ll ed . . B-75

ix

Page 12

x

Page 13

Intr oductio n

The IntelliTouch system has three main components: a clear solid glass screen

formed to match the shape of a display, a sophisticated electr onic controller , and

a software driver. The IntelliTouch touchscreen is based on patented surface

wave technology. Surface waves are mechanical waves that propagate in the

surface of material s such a s glas s. The t ouchscree n may be a flat gl as s panel or a

segment of a sphe re or cy lind ri cal g la ss. Thi s pan el is ins tal le d over t he face of

the display. Because there are no layers or coatings on the glass as with other

technologies, the IntelliTouch touchscreen is extremely durable and allows a

clear, sharp image.

C

HAPTER

1

I

NTELLITOUCH

C HAPTER

1

T

ECHNOLOGY

IntelliTouch touc hscreen features include :

• Excellent image clarity with high light transmission

• Extremely fast and sensitive, with the highest resolution of any touchscreen

• Excellent durability, resistant to deep scratches and abrasion

• Activated by a finger, gloved-hand or soft stylus

• Inherently stable, drift-free operation

• Dirt and splash sealing capa bility

• Z-axis response

• Standard sizes for flat, spherical, and cylindrical displays

• Choice of surface treatment (clear, anti-glare or priv acy filter)

• Custom size s avai lab l e for OEM quantities

• 10- year touchscree n w a r rant y

1-1

Page 14

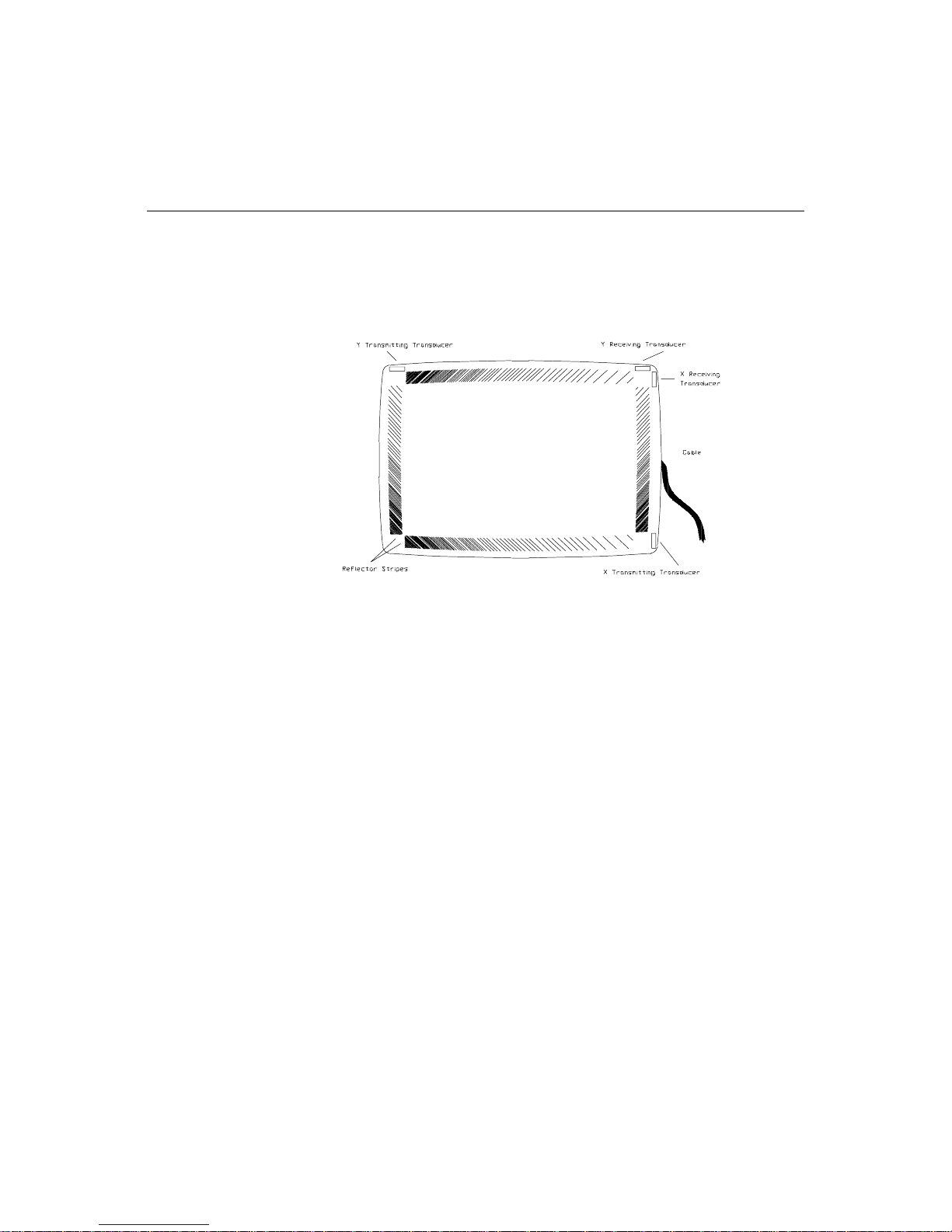

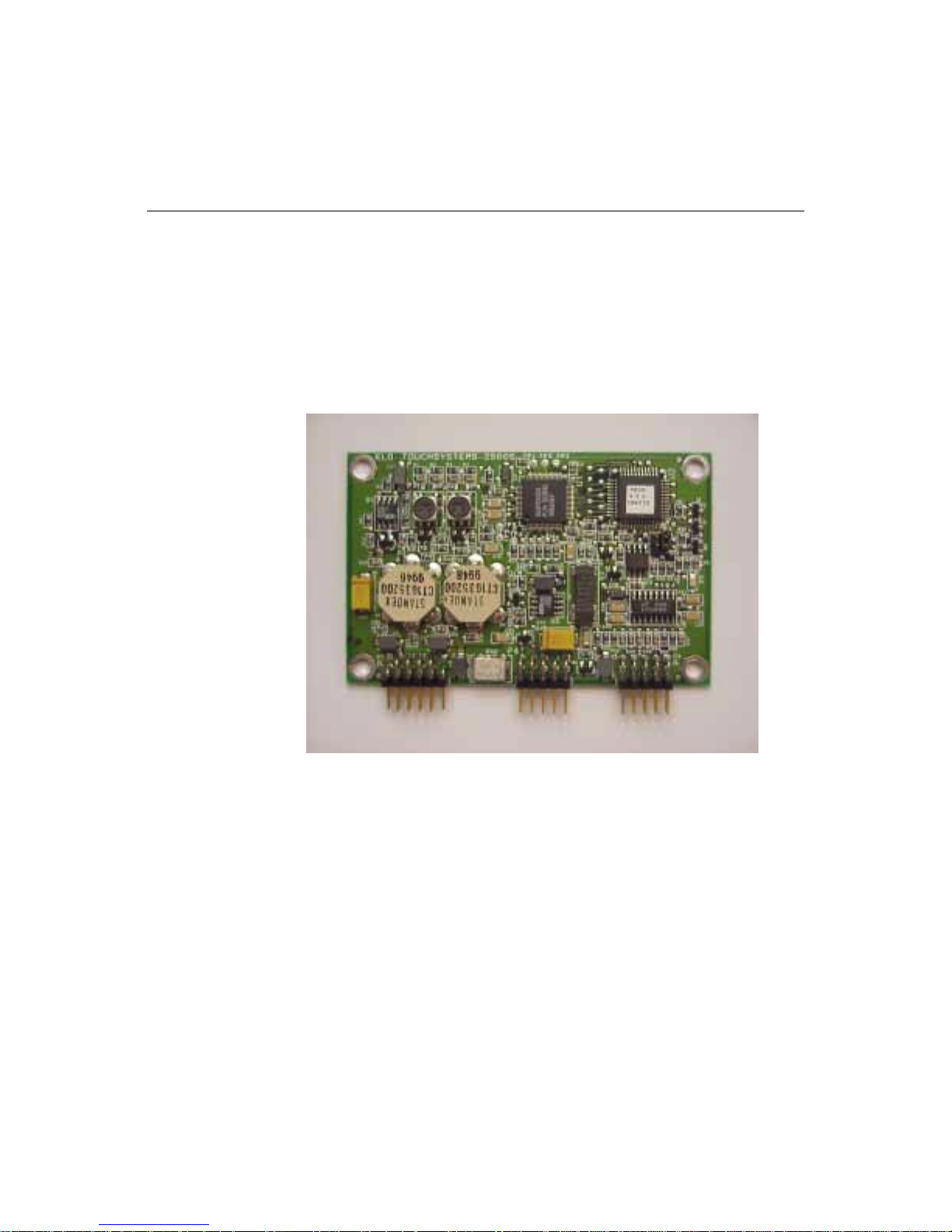

The IntelliTouch Touch screen

The IntelliTouc h surface wave technology touchscreen consists of a glass panel

molded to the shape of a display's face. Each axis of the touchscreen panel has a

transmitting a nd receiving piezoel ectr ic transducer, and sets of reflector stripes.

See Figure 2.3 on page 10 for details on the construct ion of an IntelliTouch

touchscreen.

Figure 1.1

Surface wave energy is generated by the transmitting transducers mounted in

the corners of the touchscr een. A set of reflector stripes refle cts these waves

across the activ e area of the glas s and to the receiv i ng tran s du cer whi ch

reconverts the surf ace waves into an electrical signal.

When a finger or other energy-absorbing object touches the touchscre en a

portion of the wave is absorbed. The res ulting change in the received signal is

analyzed by the controller and a digitized X and Y coordinate is determined. A

Z-axis level is determined by measuring the amount of signal attenuation at the

touch location. The X, Y, and Z coordinates are determined and the controller

transmits them to the computer.

IntelliTouch Touchscreen

1-2 IntelliTouch/SecureTouch Guide

Page 15

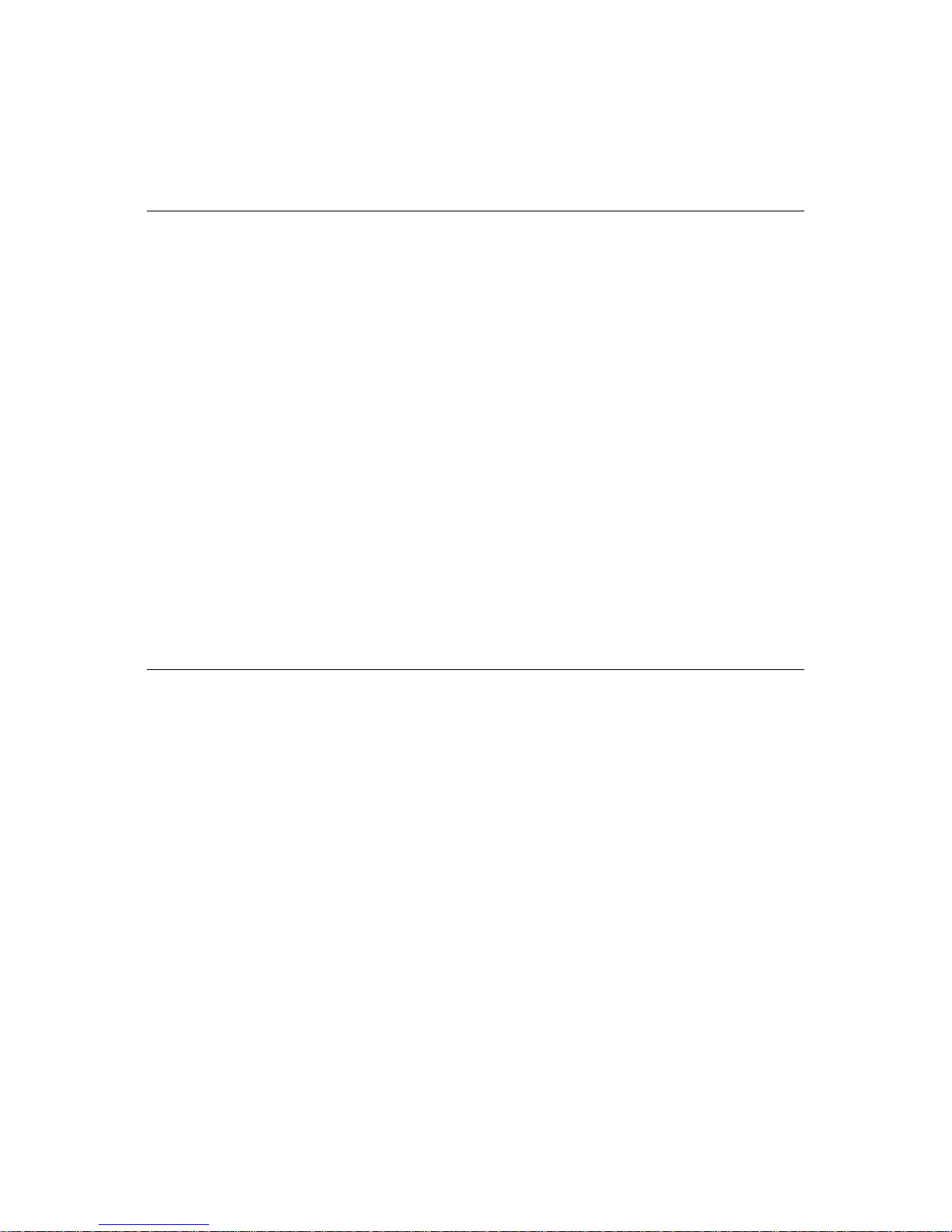

The IntelliTouch C ontro ller

The IntelliTouch controller provides the drive signal for the touchscreen,

converts the recei ved analog signals into digital touch coordinates, and sends

these coordinates to the computer.

The controller detec ts touc hes by comparing received signals to a reference

waveform acquired when the touchscreen is in an untouched condition. The

IntelliTouch controller detects dirt, dust particles, scratches and other

contaminants on the scre en and “learns around” them. It incorporates those

signals into the reference waveform to ignore the contaminants. If the

contamination is removed, the controller relearns the refere nce signal.

Figure 1.2

Because of the stabili ty of the Int elliTouch system, video realignment is not

necessary unless the position of the video image changes.

Resolution of the Intel liTouch system is defined by the controller and is

typically 4096 x 4096, with the controller transmitting at a rate of 48

coordinates per second during a touch.

The controller performs advanced internal diagnostics as well as touchscreen

diagnostics. The diagnostic results are obtain able through software as well as a

diagnostic LED. USB and serial controllers are available.

IntelliTouch controller

1-3

Page 16

Driver Software

Elo driver software pro vides a consistent software interface among all Elo

touchscreens and contr ollers.

The driver software scales the absolute coordinates received from the

touchscreen controller into translated screen coordina tes, using the calibration

points obtained with the video alignment program included with the driver

software. The driver also performs other operations as directed by the

application.

Elo provides driver pro grams for the DOS, Windows 3.1, Windows CE,

Windows 95/98, Windows NT, Windows 2000, OS/2, and Macintosh operating

systems. Additional drivers a re also available. Additional operating systems are

supported through outside sources. Refer to the Elo web site,

www.elotouch.com, for details.

If you cannot use an avai la ble driver, Elo can supply all the touchscreen related

information you will need to write your own driver for any type of system,

including UNIX workstations, real-time systems, and embedded systems. For

the 2500S contr oller, the SmartSe t™ Touchscreen Controlle r Family Technical

Reference Manual which is available on the Elo website, provide information

on this process. Machine-independent source code is included on a companion

disk and Web site, www.elotouch.com.

Agency Approvals

Elo IntelliTouch touc hscreens and controllers are “CNR/USR” UL Recogni zed

Components for USA and C anada, Category NWGQ2, I nformation Technol ogy

Equipment Including Business Equipment.

Elo IntelliTouch touc hscreens and controllers are TUV Bauart certified as

components.

Elo IntelliTouch touchscreens and controllers have been tested for compliance

with FCC Part 15 Class B limits.

1. Depending on the application, it may be necessary to pay special attention to system grounding and

shieldin g, an d it may be ne cessary to apply ferrit e suppressor beads.

1-4 IntelliTouch/SecureTouch Guide

1

Page 17

This chapter outl ines the procedures for installing touchscreen componen ts that

will convert your monitor into a touchmonitor. Details are given on mounting

the touchscreen, controller, and connecting cabl es.

Safe ty Inform ation

C HAPTER

2

C

HAPTER

2

C

OMPONENT INSTALLATION

W ARN ING

The touchscreen installation procedure outlined in this chapter may require exposure to

high-voltage components and handl ing of the CRT. This procedure can be dangerous

and an accident is potentially lethal . Therefore, the procedure should only be perfo rmed

by a qualif ied person. Read this entire chapter before attempting a touchscreen

installation.

Follow the procedure caref ully, work with the pow er off and the unit unplugged, observe

all warnings, and wear protective clothing. Elo is not liable for damage or injury resu lt ing

from the users act ions.

Consider purchasi ng a touch monitor from Elo if you do not have previous

experience working with touc hscreens and disassembling displays. Elo also

offers touchscreen installation services in quantity for a variety of displays or

can recommend third-party intergators in your area.

Work Area

Before proceeding with the installation, prepare a padded work surface. A

plastic waste baske t is recommended for supporting the CRT during part of the

installation.

2-5

Page 18

Protective Clothing

Wear safety glasses, gloves, a rubber apron, and heavy protective clothing for

any portion of this proced ure that involves handling or working near the CRT.

Getting Started

There are two types of display technologies, CRT displays and LCD displays.

IntelliTouch tou chscre ens are availabl e for most displ ays, howe ver ea ch display

may pose unique installat ion issues. If, afte r reading these instructio ns, you need

further assist ance please contact E lo Ap plicat i on Engi n eerin g for mo re

information.

These instructions assume you have purchased an Elo Touchscreen Kit and

Touchscreen Installation Kit. Only a minimum of equipment and materials is

required beyond what is provide d in the kits. Before proceeding with the

component inte gration design conside rations, please revie w the section on page

6, De sign Considerations for CRTs and LCDs, in order to optimize your

touchmonitor performance.

Design Co nsiderat ions for CR Ts and LCD s

Before designing an LCD or a CRT touchmonitor you should consider the

followin g criter ia (all detai led late r in t he chapter.):

• Ensure the touchscree n active area and overall glass dimensions are

compatible with the displa y viewing area. For CRT displays, additionally

check to make sure the radius of curva ture (ROC) of the display matches the

radius of curvature of the touchscreen.

• Ensure that adequate powe r is avai lable for the controller.

• Ensure the bezel does not contact the transducers located on the edge of the

touchscreen.

• Ensure the bezel lands in the sealing area of the touchscreen. See Figure 2.1

on page 7.

• Ensure there is a suitable location to mount the IntelliTouch controller.

• A seal should be use d between the display bezel and the touchscre en. Ensure

that the display and its mounting can withstand the force from the

compressed seal. See page 30.

• Ensure the CRT tube can be moved back so there is space for the

touchscreen.

2-6 IntelliTouch/SecureTouch Guide

Page 19

• To prevent touchscreen breakage, there should be a compliant gasket

between the back of the tou c hsc reen an d the fro nt of the display to allow for

variation in the sur face s when asse mbling. A gap is also r equire d betwe en the

touchscreen a nd the face of an LCD display to prevent damage to the displ ay.

• Unlike CRT's, plasma, EL, and backlit LCD displays may be a significant

source of heat. The situation may be more significant if the unit is sealed.

Any installation must avoid heat rise that exceeds the touchscreen

specification.

Bezel Design

The following graphic displays som e bezel ideas in or der to help you mount the

bezel to the touch scree n .

Hard

Lip

Bezel

Figure 2.1

Transducer

Wedge

With thin bezel,

add a 2-3mm

hard lip to

protect

transducer

wedge.

Bezel design

With thick

bezel, mill

out hole for

transducer

wedge.

Before

Compression

Even on a beveled touchscreen,

the transducer sticks up 1mm

above the glass. Add a spacer

to ensure clearan ce . Seal

thickness will not suffice.

After

Compression

Another idea:

Add a hard lip

behind the seal

to control

compression.

2-7

Page 20

Bevel edge for nice appearance

Round corners for nice appearance and easy cleaning

On bezel and cabinet, choose paint finish and/or

surface texture so fingerprints do not show

Figure 2.2

It may be necessary to cut r ibs and struts inside the bez el. Cutting these ribs and

struts does not usually caus e difficulties, although the stif fness of the bezel may

be reduced slightly . Try not to c ut into the posts for the CRT attachment sc rews.

Bezel and tube combinations tha t require this cut are rare.

Generally, a total cleara nce between the edge of the touchscre en and any ribs or

struts of at least 0.25-inch (6 mm) in both axes is necessary. This prevents the

interferen ce fit problem and allows for variation in touchscreen mounting

position.

CR T Integr ation

Safety Infor mati on

Before proceeding with the installation, prepare a padded work surface. A

plastic waste baske t is recommended for supporting the CRT during part of the

installat ion. Wear safety glasses, gloves, a rubber apron, and heavy protective

clothing for any portion of this procedure that involves handling or working

near the CRT.

Note:

This document describes the basic tasks common to the majority of CRT monitor

integrations. These in structions assume an audience of trained integration personn el.

Bezel ed g e

2-8 IntelliTouch/SecureTouch Guide

Page 21

Definiti on o f Terms:

MONITOR: The term "monitor" refers only to t he monitor, tele vision, or other

display that is to be integra ted.

BEZEL: The term “bezel” refers to a specific part of the molded plastic cabinet

of the monitor. The bezel is the part that covers the front of the CRT and

separates it from the rear case.

CASE: The term "case" refers to a specific part of the molded plastic cabinet of

the monitor. Th e cas e is the part tha t sep ara te s from the fron t bezel . Th e cas e

normally covers the top, sides, back and bottom of the monitor assembly.

LCD: Liquid Crystal Display. Also referred to as the Panel.

CONTROLLER: The electronic device that converts touch data into USB

information. For purposes of this document the controller referred to is the

2500U, which is the Elo internal IntelliTouch USB controller 2500U. Part

number 714259-000.

Suggested Tools

Along with a copy of the monitor manufactur er’s manual, the following list of

tools may be needed to install the touchscreen. Some of the tools are optional,

but useful.

• Long (at least 9 inches, 230 mm) flat blade screwdriver with insula ted handle

• Clip lead or heavy-gauge wire

• #2 Phillips screwdriver

• Scissors

• X-Acto knife (No. 11 blade) or hand milling tool

• DB9 hole punch (not needed for 2500U)

•Cable ties

• Household glass cleane r

• Paper towels

• Small containers or plastic bags to hold loose parts

The Elo Touchscreen Insta lla tion Kit is also recommended, and includes

commonly used materials neede d for touc hscreen installation. This kit is useful

for identifyi ng preferred materials for your own procurement and may also be

cost-effective and convenient when purchased for a limited number of

installations. (See “Elo Part Numbers” on page 79.)

2-9

Page 22

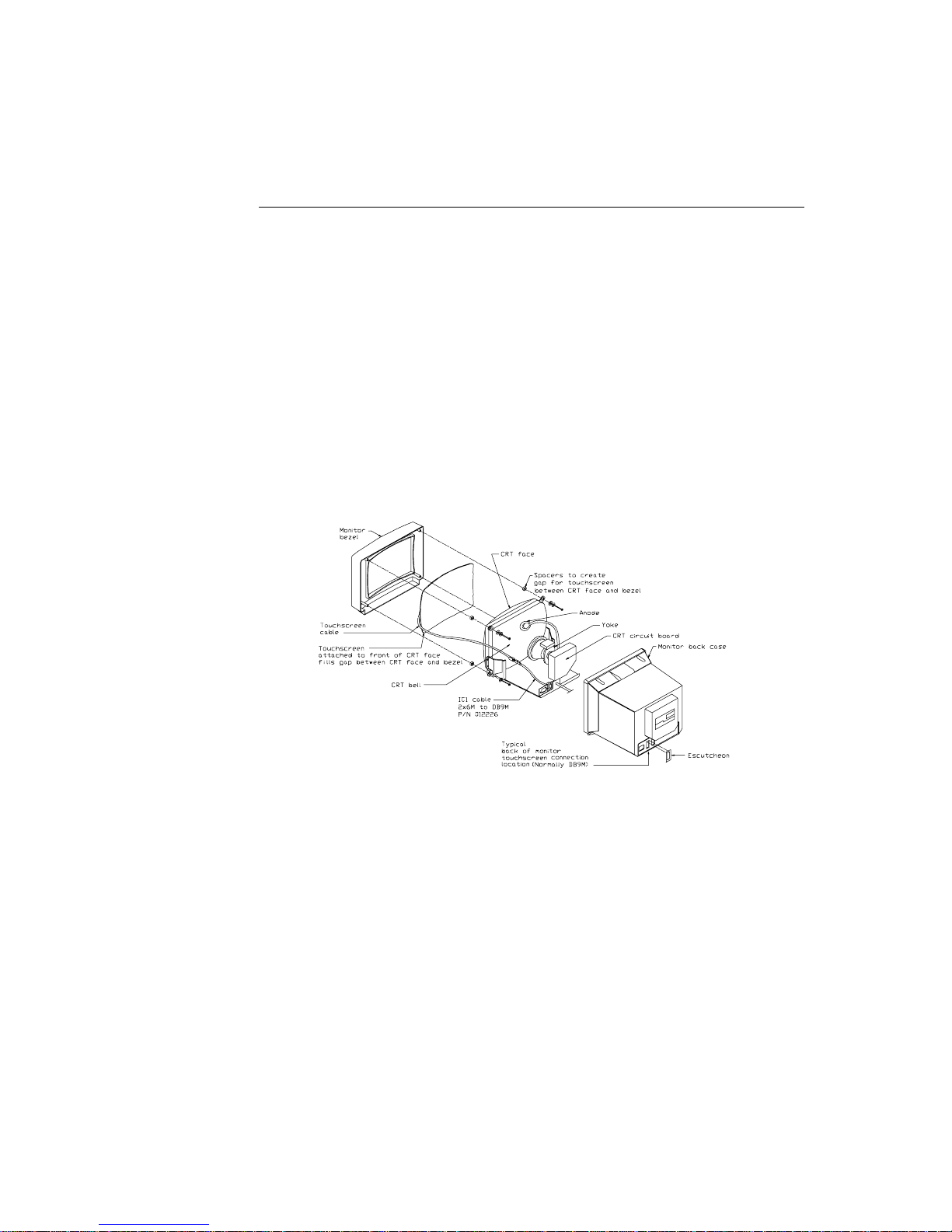

Summ ar y of In st all ati on Ste p s

The CRT installation process consists of the following steps:

1 Incoming inspection

2 Disassembling the monitor

3 Attaching the touchscreen to the CRT

4 Installing the controller

5 Routing the touchscreen cables

6 Reassembling the monitor

7 Sealing the monitor

Specific compati bility may not be confirmed until well into the installation.

IntelliTouch touc hscreens can be installed on most types of CRT displays.

Figure 2.3 shows a typical installation.

1

Figure 2.3

Most displays require complete disassembly, including remova l of the CRT, to

install a touchscr een. Dis ass embling the displa y ca n be a da nger ous proce dure if

done improperly. Any damage to the displa y or the touchscreen as a result of

improper installation is the installer’s responsibility. Without prior approval of

the display manufacturer, you will probably void the display’s warranty by

disassembling it. Also, it will be necessary to recertify the display and

touchscreen syst em for regul ato ry agen cies suc h as FC C, CE and U L /CSA if

those certific ations were originally present and need to be maintained for your

intended application.

1. To complete the first integration may take several hours.

2-10 IntelliTouch/SecureTouch Guide

Typical Int elliTouch Touchscr een Installation

Page 23

Incoming Inspection

Unpacking the Touchscreen

Handle the touchscreen with care. Note the transducers in the corners are

especially fragile. Note the location of the transducers and wiring. If any of

these are accidentally broken during handling or installa tion, or if a wire is

pulled loose, the touchscreen will not operate. Avoid excessive handling and

stress on the touchs creen cable . Wear gloves to avo id getting finge rpr ints on the

touchscreen . The touc hscreens are pre-cl ean e d by Elo .

Testing the Monitor

The CRT display must be in good working order before beginning the

installation of the touchscreen. Inspect the monitor for cosmetic flaws or

damage. With a new display, it is suggested that you t est the display by running

it overnight. Check for acce ptable color, linearity, br ightness, contrast,

distortion, and other QC tests.

Disassembling the Monitor

Disassemble the monito r on a large, well -lit work surface. Leave space to set

aside major display compon ents. Group screws and other hardware in small

containers or in specif ic areas on the work surface as you remove them, in

relation to the part of the display where you are working.

Most display manufactur ers connect the major components with detachable

cables that have label ed and keyed con nectors; these cables are of lengths that

will usually connect to only one place. Also, screws are identifiable by type and

size, and usually will not f it in the wrong pla ce. The most dif ficult pr obl em with

missing or wrong hardware or connec tions will be with ground cables that

attach to obscure ground points on the metal chassis. When in doubt, make

notes of the connection points.

2-11

Page 24

W ARN ING

Remove the Back Case

Figure 2.3 on page 10 shows the typical construction of a 15-inch display.

Disassembly usually starts with removal of the back case. For assistance with

disassembly, consult your particular manufacturer's service manual. Carefully

lay the monitor on its face on the padded work surface and remove the screws

that attach the back case t o the be zel or frame.

While remov ing the bac k case, n ote the cle ara nce be t ween the insid e rea r

surface of the c ase a nd a small circuit board plugge d into a socket on the end of

the CRT. If there is not enough clearance to move the CRT and this circuit

board about.25 inch (6 mm) toward the rear of the case, you may be unable to

successfully install a touchscreen on the display and completely reinstall the

back case. Contact Elo Application Engineering, (1-800-557-1458 x6) for

possible alter natives.

After the back case is removed, the CRT is substantially exposed. Use extreme

care when working around the CRT.

Impact or forc e against the neck of the CRT, or the pins at the end where the small cir cuit

board is attached, could crack the tube, resulting in loss of vacuum or implosion of the

tube. Either result destroys the CRT. Implosion (collapse of the glass inward, caused by

the high va cuum in side th e tube), foll owed b y th e rebound of many gl ass pi eces ou tward ,

is potential ly l ethal to anyone in the i mmedi ate area . Handl e the CR T ca reful ly, keep tools

away from the CRT, and wear protective clothing including eye protection and gloves.

Discharge the CRT

W ARN ING

Dangerous voltages may be pr esent on the CRT anode. The anode m ay retain a very

dangerous v ol tage e v en af ter t he disp la y has been o ff f or da ys . Whil e most CRT m onit ors

now incorporat e bleeder circuits t o discharge the CRT, one must not assume that the

CRT is properly dischar ged. Accidental contact with the anode lead or anode button (the

small hole in the CRT glass where the anode lead i s att ached) prior to discharge may

result in a potentially lethal shock. Follow the procedure below carefully.

The anode le ad of the di splay fe eds hi gh vol tage from the f lyback t ransfor mer to

the anode button on the CRT. The anode lead is usually red in color, and the

actual connecti on to the anode button is usually covered by a large rubber

suction cup-li ke boot. In most displ ays, th e button i s locate d on the ta pered face,

or bell, of the CRT glass near the top of the display. See Figure 2.3 on page 10.

2-12 IntelliTouch/SecureTouch Guide

Page 25

W ARN ING

It may be necessary to remove some sheet metal to gain access to the anode

lead—be very careful to do this without making contact to the anode lead itself.

Carefully discharge the CRT using the following procedure:

1 Connect a clip lead or a heavy-gauge wire to the mounting ears or the spring-

tensioned ground str ap.

2 Connect the other end of the clip lead or wire to the stem of a flat blade

screwdriver that ha s an insulated handle.

3 Hold the screwdriver by the insulated handle only. Insert the blade of the

screwdriver under the rubber boot and make contact with the anode lead at

the button. A distinct “snap” may or may not be heard as it discharges,

depending on the amount of charge pres ent on the anode.

4 Disconnect the anode lead from the button by unhooking the spring wire

clips. Note the location of the anode for proper CRT orientation during

reassembly.

The CRT will re gain a charge over ti m e, even after it has been discharged. To avoid a

dangerous elect ric shock, always discharge the CR T just before handling it , and treat it

with respect thereafter.

Remove the Electronic Chassis

Continue disassembling the display until the face of the CRT is completely

exposed. The degree of disassembly required will vary from display to display.

Normally the next step will be to remove the electronics chassis from the

display. This requires removal of a small circuit board that is usually plugged

into the socket on the end of the CRT. The circuit board is often glued to the

CRT socket with a soft adhesive which must be cut away to remove the board.

Several cables must als o be unplugged from the electronics. Typically the se

cables are:

• Four wires from the yoke of the CRT, typically in a single four-pin

connector. The yoke is the copper wire and magnet assembly at the base of

the neck of the CRT. MPR II-compliant monit ors may have addit ional cables

and connectors on the yoke.

• A two-wire cable from the degaussing coil. This coil may be attached to the

CRT, or be laying out of sight between the CRT and the bezel. Some

monitors may have two separate coi ls.

• A one- or two-wire ground cable connected between the CRT circuit board

and a ground strap. This strap is a long, uninsulated, braided wire which is

spring-tensioned to maintain contact with the bell of the CRT.

• Various cables connected to the power switch, pilot light, front panel

controls, etc.

2-13

Page 26

• Various cables connected to the power switch, pilot light, front panel

controls, etc.

Other cables may have to be unplugged from the electronic chassis. The need

for this may not be apparent until the chassis is removed, as instructed below.

Another prelimina ry step in determining touchscreen/display compatibility

should be pe rformed at this point. Before r emoving the electronics chassis, note

the clearance betwe en the chassis components and the bell of the CRT. Since

the standard technique for mounting the touchscreen involves moving the CRT

back in the display chassi s, the re must be enough clearance between

components on the chassis and the CRT after allowing for about 0.25-inch

(6 mm) movement of the CRT towards the rear of the chassis. Fail ure to allow

for this clearanc e requi rement may result in mechanical damage later

(especially in shipping). It may also cause electrical damage from shorts

between “live” components on the chassis, such as heat sinks or uninsulated

component leads, and the bell of the CRT which is usually painted with a

conductive coating tha t is grounded to the chassis through the braided wire

ground strap. Repositioning or substituting low profile components may be an

option. Contact Elo Technical Support, (1-800-557-1458 x6), for assistance.

After disconnect ing any necessary cables remove the screws that atta ch the

electronics ch assis to the bezel. Note the bezel is essentially where all parts of

the mechanical assembl y are atta ched, unless you have a rare unit that has an

internal frame . A s you pu ll the chas s is awa y from the b eze l, mak e sure tha t

cables and circuit boa rds do not hit the neck of the CRT and that nothing

becomes caught on the adjustment r ings or other components on the neck of the

CRT. Also watch for other cables that need to be disconnected. After removal,

set the electron ics ch assis aside .

2-14 IntelliTouch/SecureTouch Guide

Page 27

Remove the CRT

Removal of the CRT is next. Prepare a soft surface to set the CRT on. Remove

the screws attachi ng the CRT to the bez el, and the n remove the CRT. Do not lift

or carry the CRT by the neck or yoke assembly. Avoid contact with the anode

button, which may still have some residual charge on it, (you may wish to

discharge it again at this point). Set the CRT on the prepared surface.

Several other preliminary compatibility requirements should now be assessed:

• Position the CRT so the face is accessible, providing a soft cushion for the

neck and the yoke if they must rest on the work surfa ce. Alte rnative ly, set th e

CRT face-up in an office-type plastic was te basket, making su re that the tube

is not resting on the neck (The small thin part of the CRT is the neck). Place

the touchscree n on the face of the tube, an d ch eck to s ee tha t the face o f the

CRT and touchs creen are about the s ame size, and tha t the radi us of cur vatur e

(ROC) of each surface matches well. I f both of these conditions are not met,

you may not have the prope r touchscreen f or the displa y. Most color displays

have standard size CRT's with standard ROC's, and Elo has touchscreens for

most of them.

• Next, determine if the touchscreen will fit in the bezel without modificati ons

to the bezel. Modifications, if necessary, should be done without

compromising the mechanical integrity of the display.

• Lay the touchscreen face-down in the bezel, being careful not to damage the

transducers. Leave the degaussing coil in place, if present. The degaussing

coil is a hoop, often located between the CRT and bezel, approximately

0.25-inch (6 mm) thick, with a two-wire cable and connector. The coil was

probably unplugged from the power supply earlier.

If the touchscree n will not fit flush again st the lip of the bezel, do not force it .

An interference fit be tween the edge of an IntelliTouch touc hscreen and some

of the plastic ribs f ound in displa y bezels c an pinch and break the small wires

which carry the signals al ong the edges of the touchscreen or even result in

fracture of the glass after reassembly.

It may be necessary to cut these ribs and struts inside the bezel. Cutting these

ribs and struts does not usually cause difficult ies although the st iffness of the

bezel may be reduced slightly. Try not to cut into the posts for the CRT

attachment screws. Bezel and tube combinations that require this cut are rare.

Generally, a total cleara nce between the e dge of the touchscr een and any ribs

or struts of at least 0.25-inch (6 mm) in both axe s is necessary. This prevents

the interferenc e fit problem discussed above and allows for variat ion in

touchscreen mounting position.

2-15

Page 28

The potential inte rference between the degaussing coil and the touchsc reen

must also be evalua ted. The coil will usually fit between t he touchscreen and

the inside surface of the bezel, as there is typically a natural cavity for it. If

there is not enough space for the coil, you may have to provide additional

setback for the CRT. It may also be possible to reloc ate the coil to the bell

side of the CRT. Normally, this does not significantly reduce the coil’s

effectiveness. However, you must determine this by inspecting the display

for color proble ms aft er reas s embl y .

• Check for adequate clearance of the transducers and the cable from the bezel

structure. If the position of the cable causes difficulty, the touchscreen may

be rotated 180° (only if the touchscreen is sealed and using Elo drivers).The

preferred or ientation of the IntelliTouch touchscreen is with the cable exiting

from the right side, when viewed from the fr ont of the display. Rotation will

cause an inversion of the outp ut coordinates, which will be compensated for

automatically by Elo dri ver software, but perhaps not by other driver s. ( Flat

touchscreens should ha ve the reflector stripes on the side facing the user.)

V erify Touchscreen Fit

1 Check to ensure touchscreen dimensions match CRT display. Pla ce the

touchscreen on the face of the tube to see that the face of the CRT and

touchscreen are about the same size , a nd that the radius of curvature (ROC)

of each surface matches well. I f both of these conditions are not met, you

may not have the proper touchscreen for the display. Most color displays

have standard size CRT's with standard ROC's, and Elo has touchscreens for

most of them.

2 Determine if the touchscreen will fit in the bezel wit hout modific ations to th e

bezel. The bezel should not touch the transducers and should land in the

sealing area, not on the reflector strips.

2

Modifications, if necessary, should

be done without compromising the mechanical integrity of the display. Also

see Bezel Design section for r ecommen dations.

Note:

2. Clearance around the transducers should be 1-2 mm clearance above transducers (to prevent

dampening vibrat ion, electrical short or breakage), and 3-5 mm around transdu cers. Allow for

manufacturing variances of touch screen and integration. If the position of the cable causes difficulty,

the touchscreen may be rotated 180°. The preferred orientation of the IntelliTouch touchscreen is with

the cable exiting from the ri ght side, when view ed from the front of the display. Rotation will caus e an

inversion of the output coordinat es, which will be compensated for autom atically by Elo driver

software, but perhaps not by other drivers. (Flat touchscreens shoul d have the reflector stripes on the

side facing the use r.)

2-16 IntelliTouch/SecureTouch Guide

If the touchscreen will not fit flush agai nst the lip of the bezel, do not force it. An

interference fit between the edge of an IntelliTouch touchscreen and some of the plastic

ribs found in displ ay bezels can pi nch and break the small wires which carry the signals

along the edges of t he touchscreen or even result in fracture of the glass after

reassembly.

Page 29

3 It may be necessary to cut ribs and struts inside the bezel. Cutting these ribs

and struts does not usuall y cause difficulties, althoug h the stiffness of the

bezel may be reduced slightly. Try not to cut into the posts for the CRT

attachment screws. Bezel and tube combinations that require this cut are rare.

Generally, a total cleara nce between the e dge of the touchscr een and any ribs

or struts of at least 0.25-inch (6 mm) in both axe s is necessary. This prevents

the interference fit problem discussed above, and allows for variation in

touchscreen mounting position.

4 The potential interference between the degaussing coil and the touchscreen

must also be evalua ted. The coil will usually fit between t he touchscreen and

the inside surface of the bezel, as there is typically a natural cavity for it. If

there is not enough space for the coil, you may have to provide additional

setback for the CRT. It may also be possible to reloc ate the coil to the bell

side of the CRT. Normally, this does not significantly reduce the coil’s

effectiveness. However, you must determine this by inspecting the display

for color proble ms aft er reas s embl y .

5 Check for adequate clearance of the transducers and the cable from the bezel

structure. If the position of the cable causes difficulty, the touchscreen may

be rotated 180° (only if the touchscreen is sealed and using Elo drivers).

6 The preferred orientation of the IntelliTouch touchscreen is with the cable

exiting from the right side, when viewed from the front of the monitor.

Rotation will cause an inver sion of the output coordinates, which will be

compensated for automatically by Elo driver software, but perhaps not by

other drivers. (Flat touchscreens should have the reflector strips on the side

facing the user.)

2-17

Page 30

Attaching the T ouchscreen

Once you have verified all dimensions and checked that the bezel has plenty of

clearance around the transducers and lands inside the sealing area, you are ready

to install the touchsc reen.

1 Check room for cable routing:

• Route away from noise sourc es (flyback transfor mer, power supply, yoke ,

high voltage lead, etc.)

• Cable can be on either side.

• Avoid pinch points.

• Make up excess cable with tie wraps.

2 Ensure the display and touchscreen and are clean before inst allation.

• Use black background to ensure fingerprints and smudges are not visible.

• Compressed air is best to remove dust.

3 Use double-sided high tack adhesive tape

touchscreen to the display.

• 3 mm thi ck fo r cu rved

• 2 mm thick for flats > 15"

• 1 mm thi ck fo r fla ts <= 1 5"

3

on all four sides to attach the

• Acts as dust seal as well as an adhesive. (Make a flat “T” in corners for

dust seal.)

• Or substitute foam tape on two sides

• Or use metal frame on flats, but still use foam tape for dust seal.

3.Refer to “Elo Part Numbers” on pag e C-79 to ensure you are using the prop er

adhesive

2-18 IntelliTouch/SecureTouch Guide

Page 31

Use two layers of the double-si ded adhesive tape to achieve a total thickness

of 1/16-inch ( 2 mm). Whil e specific touchsc reen and C RT combinations may

allow the use of thi nner materia ls, 1/16- inch (2 mm) is general ly necessar y to

allow for variat ions in ROC between the two gla ss surfaces. Review the fit

between the touchscreen and the CRT before appl ying the tape. If one pair of

opposite edges has a closer fit than the other, put the adhesive tape on the

edges of the touchscreen with the better fit. See Figure 2.4 on page 19 for

typical placem en t. Y ou wan t the seal in g tap e on the rear o f the touc hscreen

so it can’t be seen in t he viewable ar ea once r eassemble d. If the re is a good fit

on all four edges, you may want to use double- sided a dhesive tape on al l four

edges. When doing this, move the adhesive tape in slightly on one pair of

edges and add foam sealing tape outside these two edges. The thicker foam

tape will keep the adhesive tape away from the CRT until you are ready to

adhere the touchscr een to the display.

Figure 2.4

Proper placement of adhesive tape to the touchscreen.

In general, the adhesive tape should be set back slightly from the edge of the

active area of the touchscreen. The adhesive tape should be attached to the

glass. When the display is reassembled, the mounting tape should not be

visible. Do not remove the liner from the exposed side of the adhesive tape

yet.

Cut and place the foam sealing tape on the back of the touchscreen to form a

dust seal as shown in Figure on page 31. This seal is particularly important

because the CRT is a good electrostatic preci pitator and will attract dust. The

adhesive tape and foam sealing tape should form a complete seal around the

touchscreen. Do not leave any gaps. The sealing tape should not be visible

when the display is reassembl ed.

Practice aligning the touchscreen on the CRT without removing the adhesive

tape liner. The installation can tolerate some horizontal and vertical shift.

However, rotational skew between the touchscreen and display axes canno t

be easily compensate d for in the video alig nment, and will also interfe re with

proper mounting of the tube in the bezel.

2-19

Page 32

When you have a good feel for the placement of the touchscreen, clean the

back side of the touchscr een and the face of the CRT again. Avoid all cont act

between the cleaning solution and the mounting materials as the cleaner may

cause the mounting materials to eventually release from the glass. Remove

all lint with a brush or compressed a ir. Remove the liner from the adhesive

tape and align the touchscr een on the display. The thicker foam tape will

keep the adhesive tape away from the CRT until you are ready to adher e the

touchscreen to the display. Now press the touchscreen firmly against the

CRT.

If you must remove the touchscreen from the CRT, cut the adhesive tape

away with a sharp thin blade, such as an X-Acto knife. The touchscreen glass

will probably break if you try to pull it off by a corner or an edge. Shave the

old adhesive tape from the touchscreen and CRT with the knife. Adhesive

residues c an be r emoved wi th d enatured a lcohol , which wil l l eave st reaks and

fingerprint smears. Use glass cleaner for the final cleaning pr ior to

reapplication of new tape.

4 Place touchscreen on CRT straight and centered.

5 Peel off 3 cm of tape backer in two opposite corners. Fold to make tabs.

6 Pull back on tab to remove tape backer from under touchscreen while

pres s in g on tou chsc re en.

7 Ensure there is nothing, such as tape, touching the reflector strips or

transducers.

Spac in g th e CRT fr om the B ezel

The last part of the touchscreen mounting procedure is to determine the

appropriate spacing of the CRT from the bezel, (with the touchs creen attached),

and to reinstall the CRT with the requi red spacers in place (refer to Figure 2.8

on page 31). Do not clamp the touchscreen between the bezel and the CRT

without proper spacers as breakage will almost certainly occur. The nominal

thickness of the touchsc reen and the two layers of adhesive tape is 3/16-inch

(5 mm). If the touchscreen is to be in contact with the bezel, 3/16-inch (5 mm)

nominal spacers would be requir ed.

Because the original CRT face-t o-bezel mount is often an interference fit, with

the bezel shape alter ed slight ly to draw it up ti ghtly a gains t the CRT, you shoul d

start with a 1/16-inch (2 mm) thicker spacer than the nominal dimension above.

Two thicknesses of spacers, plus additional washers to use as shims, are

available in the Touchscreen Installation Kit. (See “Elo Part Numbers” on

page C-79 for Touchscreen Ins tal lation Kit).

2-20 IntelliTouch/SecureTouch Guide

Page 33

During the spacer selection process, you may have to install the CRT with the

touchscreen attached in the bezel several times. To prevent the CRT from

dislodging the space rs, temporarily insert plastic tie wraps or toothpicks as

guides in the mounting post holes. After selecting the correct spacers, discard

the guides and fix the spacers more securely in place with the adhesive

"doughnuts" provide d in the Touchscreen Installati on Kit.

When spacers for the desired gap have been selected, install the CRT. Make

sure you have previously reinstalled the degaussing coil. Select a screw that is

long enough to compensate for the spacer thickness (provides at least three full

turns into the mounting post thr eads) but not so long as to penetrate the surface

of the bezel. Over-tightening the screws may strip or split the mounting posts.

Installing the Controller

Elo offers IntelliTouch USB or serial (RS-232) controllers which are typically

installed int ernal to the display.

Before installing an IntelliTouch controller, you need to ensure the following

design condition s:

• Ensure there is space for the controller and the cable headers.

• Note that cable routing may contribute to noise and crosstalk. Make sure

the controller is pla ced away from voltage sources.

• Ensure there is space for an inte rn al DC-to-DC converter or AC power

supply if either is requ ired.

Note:

• Verify power source and check specs for adequate power. The 2500

controllers use +5V@60 mA ±5% regulated.

• Ensure sufficie nt electromagnetic Interference (EMI) suppression. Instal ling

a touchscreen and controller will affect the EMI characteristics of the display.

Ensure sufficient heat d issipation. The IntelliTouch serial controller dissipates som e heat

(less than 1 wat t). A typical power supply, if requir ed, may dissipa te sever al watts more.

This places an addi ti onal load on the cooling system of the display. The available

locations to mount a controller and po wer supply may als o aff ect the cooling system of

the displa y. Only applicable if you are not using AC-to-DC power supply.

• Ensure controller can be mounted securely to metal bracket and grounded.

• Ground at least one mounting hole, but for best EMI characteristics,

ground all four mounting holes.

2-21

Page 34

Internal Serial Controller (2500S)

The mounting holes of the IntelliTouch serial controllers are sized for 0.156inch (4mm) snap-in standoff s. All IntelliTouch touchscree ns have a cable

termination that mates directly with the male header (P3) on the controller. See

Appendix B for specific mounting dim ensions and connections.

Figure 2.5

Touchscree n Cabl ing S ystem for Internal Serial Controller

Follow these steps to inst all an IntelliTouch serial controller:

1 Evaluate the monitor for proper posit ioning of the cont rol ler. Make sure th ere

is sufficient space for cable headers .

2 Evaluate the back case of the monitor to determine the best position for the

DB9 female connector. A hole for this connector may be furnished in a

variety of ways: a) mounting the connector to a chassis member that is

exposed to the display exte rior, b) mounting the connector to a chassis

member with a hole in the exterior of the case to provide access to the

connector, and c) mounting the connector to the case.

3 Mount and ground the controller card following one of the two methods:

• Mount the controller to the metal chassis using metal screws and spacers.

It can be grounded through one of the mounting holes by using one of the

No. 6 sheet metal screws and spacers provide d in the kit (See “Elo Part

Numbers” on page C-79 for installa tion kit part number). On the 2500S,

all mounting holes are plated.

2-22 IntelliTouch/SecureTouch Guide

Page 35

• If the controller cannot be mounted to a metal chassis, use a ground wire

with a lug attached to connect one of the contro ller's plated-through

mounting holes to chassis ground.

4 Connect the power cable harness (See “Elo Part Numbers” on page 79 for

part number) to the 2x5 male connec tor (See “Elo Part Numbers” on page 79

for part number) at P4 on the controlle r. Connect the other end to a power

source. If a suitable +5 Vdc power source cannot be found inside the displa y,

use an AC-to-DC power supply. The 2500S controller power requirements

are +5 Vdc nominal. Refer to Appendix B for current requirements.

P4 Pins Signal Function

1 +Pwr Supply voltage positive

2 PwrCom Supply voltage negative (tied to pin 4)

3 N/C Not connected

4 PwrCom Supply voltage negative (tied to pin 2)

5 LED Remote External LED driver

6Key

7N/C

8 Chassis Frame ground connectio n

9 -Reset Open collec tor input: = normal operatio n; short to

PwrCom = hardware reset.

10 N/C

If you have grounded the controller to the metal chassis as recommended in

Step 3 on page 22, the chassis ground connection through the power

connector, P4 pin 8, does not need to be c onnected. Likewise, do not connect

the Reset and LED Remote lines unless you have provided the appropriate

circuits.

The microprocessor pin that drives the status LED is connected to pin 5 of

the P4 power supply connector. This signal from the microprocessor may

also be used to drive an external indicator such as another LED.

To operate an external LED, connect the LED cathode to ground and the

anode to pi n 5 of the P4 conne ctor. Nominal current through the LED will be

6 mA, so a low-operating current LED should be used. An external resistor is

not required.

2-23

Page 36

5 Connect the 2x5 female connector, on the serial output cabl e (See “Elo Part

Numbers” on page 79), to the 2x5 male connector at P2 on the controller.

Mount the DB9 female end of the cable in the position determined in step 2.

The serial cable connector shell must be grounded to satisfy safety agency

approvals, as the grounding protects the user in case a wiring fault develops

in the display. If the DB9 connector she ll is not already grounded, attach the

ground wire supplied in the kit to one of the DB9s mounting screws and the

other end to chassis ground.

6 Adhere the metal plate labeled with the legend, “Touchscr een Interface”, to

the outside of the bulkhead-mounted DB9 connector. A similar plate (See

“Elo Part Numbers” on page 79) is also available with vertical labeling.

7 Label the monitor to indicate what IntelliTouch serial controller is installe d

inside the display and include its jumper settings, if any.

2-24 IntelliTouch/SecureTouch Guide

Page 37

CAUT ION

External Serial Controller

An external serial cont roller is the best choice for many integrator s for several

reasons:

• No additional cables are requir ed to install the controller . The 30-inc h

touchscreen c able is routed thr ough the rear of the display case to a 2x6 male

connector lo cated on the r ear of the control le r. Once the contr oller is inst alle d

on the rear of the display, little or none of the touchscreen cable is visible .

• The base of the controller may be permanently attached to the rear of the

display, but is easily removed from the display if necessary.

• The serial cable is permanently connected to the controller and features an

armored, moisture-resistant sleeve where the cable enters the controller

enclosure.

• An external serial cont r oller offers the added flexibil ity of using a keyboard

tap or wall-mount power supply (See “Elo Part Numbers” on page 79) if

using an internal power sourc e is inconvenient or impractical. This featur e

places fewer constra ints on the design and location of kiosks and other

applications.

Follow these steps to inst all the IntelliTouch external serial controller:

1 Determine supply power source to the controller. The controller requires +5

Vdc regulated pow er (± 0.25 Vdc) with 100 mA typical. Average power

dissipation is 0.7 W.

Before making any attempt to power the controller from any monitor power source, you

should confi rm the inst allation with your monitor supplier. F ailure to observe this caution

may destroy the monitor or seriously impair monitor performance.

• Provided you first confir m the installation with your monitor supplier, you

may attach a dire ct pow er ca ble t o a +5 Vdc sou rc e ins i de the d ispl ay or tap

unregulated monitor power in the +9 Vdc to +30 Vdc range using the Elo

DC-to-DC converter (See “Elo Part Numbers” on page 79). Typical

converter power consumption is approximately 1 W. Remember that each

integration situation is unique; you must carefully evaluate available power

rails and consi der how drawing additional powe r fr om the display will affect

monitor performance .

If you have a suitable +5 Vdc power source, atta ch the direct power cable

harness (See “Elo Part Numbers” on page 79) to the source, red to + 5 Vdc

and black to common. You must attach the green ground cable to a suitable

chassis ground for noise immunity and safety considerations. Also ensure

that the cable is long enough to reac h the back of the monitor and the

controller.

2-25

Page 38

CAUT ION

CAUT ION

Observe polarity when connecting the power leads to the power sup ply. Reversing

polarity ma y dam age the controller.

Possible power supply sourc es included:

• A direct power cable to a +5 Vdc source inside the dis play or tap unregul ated

monitor power in the +9 Vdc to +30 Vdc range using the Elo DC-to-DC

converter (See “Elo Part Numbers” on page 79). Attach the direct power

cable (See “Elo Part Numbers” on page 79) to the source, red to + 5 Vdc and

black to common. You must attach the green ground cable to a suitable

chassis ground for noise immunity and safety considerations. Observe

polarity when connect ing the power leads to the power supply. Reversing

polarity will damage the controller.

• Typical converter power consumption is approxim ately 1 W. Remember

that each integration situation is unique; you must carefully evaluate

available power rails and consi der how dr awing additi onal powe r from the

display will affect monitor performance.

• Install a powe r supply which requires a 100-240 Vac input. Connect a power

cable harness to P4 on the controller, a 2x5 header with pins on 0.100-inch

(2.54 mm) centers. Use a ribbon cabl e with an IDC connect or or crimp-towire pin receptacles. An acceptable plug can be selected from Molex series

70450, Amp AMPMODU Mod. IV product line, or Berg mini-latch housing

with Mini-PV pins. Connect a power supply to the harness and then to AC.

• If none of the above options are practical, you must use either an optional

keyboard power ta p or wall-mount power supply to furnish +5 Vdc power

to the contr o ller.

Before using a keyboard power tap, be sure sufficient power is available for the

touchscreen controller or damage ma y occur to the computer.

Before connecting a keyboard power tap to the contr oller, be sure that po wer to the CPU

is OFF. Connecting a keyboard power tap to a powered CPU may seriously damage the

CPU or the controller and will blow the keyboard fuse.

1 Decide where to mount the controller on the rear of the display case. After

choosing a location, use masking tape to hold the template in the desired spot

and drill a 1-inch diameter hole for cabling exiting the display and drill two

holes for screws that will be mounted in the display case.

2 Rou te the tou c hsc reen cab le (an d power cable if using an int ernal ly locat ed

power source) through the 1-inch diamet er hole in the displa y case. Inse rt the

touchscreen cable into the keyed receptacle in the rear of the controlle r box.

You will hear a “click” when the cable connector is properly connected to the

controller. Pull any excess cabling back into the display case and attac h the

controller to the display case.

3 Wrap excess cabling with tie wraps as required, and pr oceed to “Routing the

Touchscreen Cables ” on page 2-29.

2-26 IntelliTouch/SecureTouch Guide

Page 39

Internal USB Controller (2500U )

The mounting holes for the 2500U USB controll er are sized for 0.156-inch

(4 mm) snap-in standoffs. All current IntelliTouch touchscreens have a cable

that mates directly with the male header (P3) on the controller. The controller

must be powered from inside the monitor .

CAUT ION

Figure 2.6

Before making any attempt to power the controller from any monitor power source, you

should confi rm the inst allation with your monitor supplier. F ailure to observe this caution

may destroy the monitor or seriously impair monitor performance.

Internal USB Controller (2500U)

Follow these steps to inst all the IntelliTouch 2500U USB controller:

1 Evaluate the monitor for proper posit ioning of the cont rol ler. Make sure th ere

is sufficient space for cable headers .

2 Evaluate the back case of the monitor to determine the best position for the

USB connector. There are two possible configurations for insta lling the USB

controller.

• Configuration 1: mount the controller card so the USB connector is flush

with the back of the mo ni tor .

• Configuration 2: mount the controller inside the controller inside the

monitor and use the Elo USB cable pack (See “Elo Part Numbers” on

page 79) to mount a USB connector.

2-27

Page 40

3 Mount and ground the controller card. The grounding scheme for the

controller shou ld typically be determined consistent with EMI suppression

requirements. This may be accomplished one of two ways:

• The controller should be mounted to the metal chassis using metal scr ews

and spacers. It can be grounded through one of the mounting holes by

using one of the No.6 sheet metal screws and space rs provided in the kit.

• If the controller cannot be mounted to a metal chassis, use a ground wire

with a lug attached to connect one of the contro ller's plated-through

mounting holes to chassis ground.

4 Connect the power cable harness to the 2x5 male connector at P4 on the

controller. Connect the other end to a power source. If a suitable +5 Vdc

power source cannot be found inside the display, use a dedicated power

supply. The 2500 U contr oller powe r r equirement s are +5 Vdc nomi nal. Re fer

to Appendix C for current requirements.

5 If you have grounded the controller to the metal chassis as prefer red, the

chassis ground connec tion through the power connector, P4 pin 8, does not

need to be connected.

6 Plug the X007X cable between the card and the bulk head mounting USB

connector.

7 Adhere the metal plate labeled with the legend, “Touchscr een Interface” to

the outside of the bulkhead-mounted USB connector. A similar plate (see

pg. 79 for part number) is also available with vertical labeling.

8 Label the monitor to indicate that an IntelliTouch 2500U USB controller is

installed insi de the display.

2-28 IntelliTouch/SecureTouch Guide

Page 41

Routing the Touchscreen Cables

The intern al cables that car ry the analog touchs creen signa ls are subject to

interferen ce from variou s source s within t he display . The routing of the se c ables

should avoid the following a reas, listed in order of importance:

• flyback transformer-CRT (anode lead)

• anode lead-CRT

• inverter secti on of the power supply-Flat Panels only (most displa y power

supplies are switching power supplies, and the main DC to AC inversion

section produces most of the noise)

• yoke-CRT

• RGB video drive section of the displa y

• video input cable

• horizontal and vertical oscillator/drive sections-CRT (large caps)

Once acceptable cabl e positioning is determined, tie the cabl e down to avoid

movement during shipment. In addition to careful cable routing, other EMI

suppression techniques may be necessary to satisfy agency approval

requirements. Use ferrite beads or other radio frequency (RF) suppression

elements, additional shielding, and different gr ounding techniques as needed.

Also, attach all excess cable/service loops as close to the chassis as practical to

reduce noise emissions.

Reassembling the Monitor

With the touchscreen mounte d, a nd the cable routing and exterior interface

determined, the display must be reassembled. Reassembly is genera lly in

reverse order of disa ssembly. Beware of potential clearanc e problems between

the bell of t he CRT an d the e lectro nics chas sis, a s sho rts in this area can pr oduce

catastrophi c failure s of the displa y. Also, if the insi de surfa ce of the back case is

paint e d with a conductive c o a t ing, watch for s horts betwe e n th e CRT c i r c u i t

board and the rear of the back case, as these can also produce disastrous results .

When the electronics chassis is reinstalled, the CRT circuit board is usually

carried along with it . It is often adv isable to have a second person assist you, to

insure that this circ uit board and various other cables do not interfere with the

yoke or neck of the CRT. Safety glasses, gloves, heavy protective clothing, and

caution are strongly adv ised for all participants.

2-29

Page 42

Reconnect all cables that were removed during the disassembly procedure.

Watch for single ground connections from the CRT mount to the chassis,

between individua l chassis members, etc., which may have lugs and screws to

connect them, or sometimes individual push-on solderless connectors. Failure

to reconnect these impor tant cables may result in improper performanc e of the

display after reasse mbly and may render the unit unsafe.

Re-glue the CRT circuit board to the connector with an electronic-grade

(non-corrosive) silicone adhesive (such as GE RTV-162). Discharge the CRT

again (see Discharging the CRT, page 12), and t hen reconnect the anode lead to

the anode button, making sure the spring hooks catch inside the hole.

If practical, test the monitor and touc hsc reen at the earliest time possible before

reassembling the display, as the reassembly of the back case can be tedious. If

mistakes have been made, correc tions are easier to make if the covers are still

off.

Next, label the monitor with information about the touchscreen installed, along

with the model and settings of any internal serial controller.

For example :

Contains -2500S Serial Controller

Settings: 9600/8/1/N SmartSet/Binary/Stream Mode

Finally, remove any agency certifications (UL/cUL, FCC, TÜV, CE, etc.) for

which you have not resubmitted.

Sealing the Mo nitor

A variety of methods may be used to seal an IntelliTouch system from dust or

splashed liquids as required by the application or an industry standard:

1 Use only closed cell polyolefin (Volara) foam available from Elo.

2 Adhere the seal to the lip of the bezel. When the bezel is compressed against

the touchscreen, the Volara material will act as a seal. Make sure the bezel

and sealing tape (Volara) do not touch the reflector strips. See Figure 2. 8 on

page 31 for proper sealing loc at ion.

Proper Sealing

Figure 2.7

2-30 IntelliTouch/SecureTouch Guide

Proper and Improper Sealing

Improper Sealing

Page 43

Proper Bezel Mounting

Improper Bezel Mounting

Figure 2.8

1

Compress the seal evenly around the bezel. If the display is to be used in a

Proper and Improper Bezel Mounting

kiosk with for ced air ventil ation, the air should be filtered a nd fans should be

positioned at the intake, creating positive pressure inside the cabinet.

Sealin g Material Se le c tio n

Elo recommends a crosslinked polyolefin closed-cell foam called Volara,

manufactured by Voltek. This material is available through Elo or can be

purchased from Voltek dire ctly (use 2A, 2E, 4A or 4E weight, black flame

retardant ma teri al ).

System E valua t ion

As the IntelliTouch sys tem gain is dynamic, and responds to a changing

environment quickly, the application of a seal to the system typically produces

no user perceivable effects. The touch should be just as sensitive after

integration a nd sealing as before. However, the designer should be aware of the

impact of the seal on system perform ance. Elo provides several software tools

downloadable from the website that can aid in this assessment. Use these tools

to establish basel ine performance prior to the application of the seal, as well as

after. If you need more assista nce, please contact Elo Applicatio n Engineering

(1-800-557-1458 x6).

2-31

Page 44

LCD Integration

This section outli nes the procedures for installing touchscreen components that

will convert your monitor into a touchmonitor. Details are given on mounting

the touchscreen, controller, and connecting cabl es.

Safety Infor mati on

W ARN ING

The touchscreen installation procedure outlined in this chapter may require exposure to

high-voltage components and handling of the LCD. This procedure can be dangerous

and an accident is potentially lethal . Therefore, the procedure should only be perfo rmed

by a qualif ied person. Read this entire chapter before attempting a touchscreen

installation.

Follow the procedure caref ully, work with the pow er off and the unit unplugged, observe

all warnings, and wear protective clothing. Elo is not liable for damage or injury resu lt ing

from the users act ions.

Consider purchasing a touchmonitor from Elo if you do not have previous