Page 1

AccuTouch

®

Product Manual

Revision H

P/N 821615-000

Elo TouchSystems, Inc.

1-800-ELOTOUCH

www.elotouch.com

Page 2

Copyright © 1988, 1992, 1994, 1995, 2001, 2005 by Elo T ouchSystems, Inc.

All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system,

or translated into any language or computer language, in any form or by an y means, includ ing, b ut n ot

limited to, electronic, magnetic, optical, chemical, manual, or otherwise without prior written

permission of Elo TouchSystems.

The information in this document is subject to change without notice. Elo TouchSystems makes no

representations or warranties with respect to the contents hereof, and specifically disclaims any

implied warranties of merchantability or fitness for a particular purpose. Elo TouchSystems reserves

the right to revise this publication and to make changes from time to time in the content hereof

without obligation of Elo TouchSystems to notify any person of such revisions or changes.

Trademark Acknowledgements

AccuTouch, IntelliTouch, DuraTouch, and MonitorMouse are registered trademarks, and ELODE V,

TouchUp, TouchBack, SmartSet, and COACH are trademarks of Elo TouchSystems, Inc. All other

trademarks are the property of their respective holders.

3

Page 3

4

Page 4

List of Figures

AccuTouch Touchscreen . . . . . . . . . . .18

USB Controller Installation . . . . . . . . .24

External Serial Controller Installation .26

PC-Bus Controller Installation . . . . . . . 28

Typical AccuTouch Touchscreen

Installation (for use with external

controller) . . . . . . . . . . . . . . . . . . . . . . . 33

Bezel design 3 . . . . . . . . . . . . . . . . . . . . .4

Rear View of an AccuTouch Touchscreen

with Mounting Materials . . . . . . . . . . .42

Side View of an AccuTouch Touchscreen

Installation . . . . . . . . . . . . . . . . . . . . . .47

Touchscreen Cabling System for Internal

Serial Controller . . . . . . . . . . . . . . . . . .48

AccuTouch Touchscreen Simulation

Circuits . . . . . . . . . . . . . . . . . . . . . . . . .68

Tabletop Controller Power Supply Cable

Connector . . . . . . . . . . . . . . . . . . . . . . .73

Transient Protection Circuit . . . . . . . . .76

DB9 and DB25 Connector Pin

Positions . . . . . . . . . . . . . . . . . . . . . . . .79

SmartSet Controller Jumper Settings . .82

E271-2210 Serial Controller . . . . . . . .83

E271-2201 PC-Bus Controller . . . . . . .85

11

Page 5

12

Page 6

C

HAPTER

0

L

IMITED

(a) Elo TouchSystems, Inc., ("Seller") warrants to Buyer that the Products (i)

shall be free of defects in materials and workmanship for five (5) years from the

date of shipment for touchscreen components and controllers (except COACH

chip controller) and two (2) years from the date of shipment for TouchMonitors

(each a "Warranty Period"), (ii) shall conform to Seller's specifications for such

Products throughout the applicable Warranty Period, and (iii) shall be free of

liens and encumbrances when shipped to Buyer. If Seller agrees in writing to

provide and does provide system design, drawings, technical advice, or any

other services to Buyer in connection with Products, then Seller further warrants

to Buyer during the applicable Warranty Period that such services shall be

undertaken in accordance with Seller's reasonable technical judgment based on

Seller's understanding of pertinent technical data as of the date of performance

of such services. Seller's warranties will not apply to any Product with respect to

which there has been (i) improper installation or testing, (ii) failure to provide a

suitable operating environment, (iii) use of the Product for purposes other than

that for which it was designed, (iv) failure to monitor or operate in accordance

with applicable Seller specifications and good industry practice, (v)

unauthorized attachment or removal or alteration of any part, (vi) un usual

mechanical, physical or electrical stress, (vii) modifications or repairs done by

other than Seller, or (viii) any other abuse, misuse, neglect or accident. In no

circumstance shall Seller have any liability or obligation with respect to

expenses, liabilities or losses associated with the installation or removal of any

Product or the installation or removal of any components for inspection, testing

or redesign occasioned by any defect or by repair or replacement of a Product.

W

ARRANTY

(b) Seller makes no warranty regarding the model life of monitors. Seller's

suppliers may at any time and from time to time make changes in the monitors

delivered as Products or components.

(c) Buyer shall notify Seller in writing promptly (and in no case later than thirty

(30) days after discovery) of the failure of any Product to conform to the

warranty set forth above, shall describe in commercially reasonable detail in

such notice the symptoms associated with such failure, and shall provide to

Seller the opportunity to inspect such Products as installed, if possible. The

notice must be received by Seller during the Warranty Period for such Prod uct.

Unless otherwise directed in writing by Seller, within thirty (30) days after

submitting such notice, Buyer shall package the allegedly defective Product in

its original shipping carton(s) or a functional equivalent and shall ship it to

Seller at Buyer's expense and risk.

(d) Within a reasonable time after receipt of the allegedly defective Product and

verification by Seller that the Product fails to meet the warranty set forth above,

Seller shall correct such failure by, at Seller's option, either (i) modifying or

5

Page 7

repairing the Product or (ii) replacing the Product. Such modification, repair or

replacement and the return shipment of the Product with minimum insurance to

Buyer shall be at Seller's expense. Buyer shall bear the risk of loss or damage in

transit, and may insure the Product. Buyer shall reimburse Seller for

transportation costs incurred for Products returned but found by Seller not to be

defective. Modification or repair of Products may, at Seller's option, take place

either at Seller's facilities or at Buyer's premises. If Seller is unable to modify,

repair or replace a Product to conform to the warranty set forth above, then

Seller shall, at Seller's option, either refund to Buyer or credit to Buyer's account

the purchase price of the Product less depreciation calculated on a straight-line

basis over Seller's stated useful life of the Product (three years for touchscreen

components and controllers and one year for TouchMonitors). THESE

REMEDIES SHALL BE BUYER'S EXCLUSIVE REMEDIES FOR BREACH

OF WARRANTY.

(e) EXCEPT FOR THE EXPRESS WARRANTY SET FORTH ABOVE,

SELLER GRANTS NO OTHER WARRANTIES, EXPRESS OR IMPLIED,

BY STATUTE OR OTHERWISE, REGARDING THE PRODUCTS, THEIR

FITNESS FOR ANY PURPOSE, THEIR QUALITY, THEIR

MERCHANTABILITY, THEIR NONINFRINGEMENT, OR OTHERWISE.

NO EMPLOYEE OF SELLER OR ANY OTHER PARTY IS AUTHORIZED

TO MAKE ANY WARRANTY FOR THE GOODS OTHER THAN THE

WARRANTY SET FORTH HEREIN. SELLER'S LIABILITY UNDER THE

WARRANTY SHALL BE LIMITED TO A REFUND OF THE PURCHASE

PRICE OF THE PRODUCT. IN NO EVENT SHALL SELLER BE LIABLE

FOR THE COST OF PROCUREMENT OR INSTALLATION OF

SUBSTITUTE GOODS BY BUYER OR FOR ANY SPECIAL,

CONSEQUENTIAL, INDIRECT OR INCIDENTAL DAMAGES.

(f) Buyer assumes the risk and agrees to indemnify Seller against and hold

Seller harmless from all liability relating to (i) assessing the suitability for

Buyer's intended use of the Products and of any system design or drawing and

(ii) determining the compliance of Buyer's use of the Products with applicable

laws, regulations, codes and standards. Buyer retains and accepts full

responsibility for all warranty and other claims relating to, or arising from,

Buyer's Products which include or incorporate Products or components

manufactured or supplied by Seller. Buyer is solely responsible for any and all

representations and warranties regarding the Products made or authorized by

Buyer. Buyer will indemnify Seller and hold Seller harmless from any liability,

claims, loss, cost or expenses (including reasonable attorneys' fees) attributable

to Buyer's products or representations or warranties concerning same.

(g) This manual may contain reference to, or information about, Elo products

(equipment or programs), that are not now available. Such references or

information must not be construed to mean that Elo intends to provide such

products, programming, or services.

6

Page 8

FCC Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interference

that may cause undesired operation.

UL Notice

Elo PC-Bus controllers are for use only with IBM or compatible UL Listed

personal computers that have installation instructions detailing user installation

of card cage accessories.

7

Page 9

8

Page 10

Table of Contents

Chapter 1

Introducing Touchscreens . . . . . . . . . . . . 13

Driver Software . . . . . . . . . . . . . . . . . 14

Shipping Damage . . . . . . . . . . . . . . . . 14

Care and Cleaning . . . . . . . . . . . . . . . 15

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . 17

The AccuTouch Touchscreen . . . . . . . . . . 18

The AccuTouch Controllers . . . . . . . . . . . 20

Driver Software . . . . . . . . . . . . . . . . . 20

Chapter 3

Touchmonitor Benefits. . . . . . . . . . . . . . 21

Touchmonitor Configurations . . . . . . . . . . 22

Touchmonitor Connections . . . . . . . . . . . 22

Connecting the Power and Video . . . . . . 22

Touchmonitor with Internal Ser ial Controller . 23

Contents . . . . . . . . . . . . . . . . . 23

Installation . . . . . . . . . . . . . . . . 23

Touchmonitor with Internal USB Controller . 24

Contents . . . . . . . . . . . . . . . . . 24

Installation . . . . . . . . . . . . . . . . 24

2210MX External Serial Controller. . . . . . 25

Contents . . . . . . . . . . . . . . . . . 25

Installation . . . . . . . . . . . . . . . . 25

Configure the Controller. . . . . . . . . . . 25

Connect the Controller . . . . . . . . . . . 25

PC-Bus Controller . . . . . . . . . . . . . . 27

Contents . . . . . . . . . . . . . . . . . 27

Installation . . . . . . . . . . . . . . . . 27

Configure the Controller. . . . . . . . . . . 27

Install the Controller in Your PC and Connect

the Touchmonitor . . . . . . . . . . . . . 27

Touchscreen Application Tips . . . . . . . . . . 28

Where to Go from Here . . . . . . . . . . . . . 30

Chapter 4

Safety Information. . . . . . . . . . . . . . . . 32

Work Area . . . . . . . . . . . . . . . . . . 32

Protective Clothing. . . . . . . . . . . . . . 32

Getting Started . . . . . . . . . . . . . . . . . 33

Bezel Design . . . . . . . . . . . . . . . . . . 34

Testing Components . . . . . . . . . . . . . 34

Installation Steps. . . . . . . . . . . . . . . 35

Suggested Tools . . . . . . . . . . . . . . . 35

Disassembling the Display . . . . . . . . . . . 36

Removing the Back Case . . . . . . . . . . 36

Discharging the CRT. . . . . . . . . . . . . 37

Removing the Electronics Chassis . . . . . 38

Removing the CRT . . . . . . . . . . . . . 39

Installing the Touchscreen . . . . . . . . . . . 40

Spacing the CRT from the Bezel . . . . . . 44

Transient Protection. . . . . . . . . . . . . . . 46

Controller Interface Options. . . . . . . . . . . 47

Internal Controllers . . . . . . . . . . . . . 48

2210 Serial Controller and 3000U USB

Controller . . . . . . . . . . . . . . . . . 48

Installing the 2210 Serial Controller . . . 49

Installing the 3000U USB Controller . . . 51

External Controllers . . . . . . . . . . . . . 53

Installing the 2210MX Serial Controller. . 53

Installing the 2201 PC-Bus Controller . . 54

Routing the Touchscreen Cables . . . . . . . . 56

Reassembling the Monitor . . . . . . . . . . . 57

Sealing the Monitor . . . . . . . . . . . . . . . 58

Flat Panel Display Integration. . . . . . . . . . 59

Where to Go from Here. . . . . . . . . . . . . 59

Appendix A

The Troubleshooting Process . . . . . . . . . . 61

Display Problems . . . . . . . . . . . . . . . . 62

Software Troubleshooting. . . . . . . . . . . . 62

Video Alignment Problems. . . . . . . . . . 63

Hardware Troubleshooting . . . . . . . . . . . 63

Touchscreen Diagnosis . . . . . . . . . . . 65

Touchscreen Simulation . . . . . . . . . . . 67

Serial Controller . . . . . . . . . . . . . . . 69

Using the COMDUMP Utility . . . . . . . 69

E271-2210 Controller Protocol . . . . . . . 70

E281A-4002 Controller Protocol. . . . . . . 70

E271-140 Controller Protocol . . . . . . . . 70

E261-280 Controller Protocol . . . . . . . . 70

Using the TOUCHES Utility. . . . . . . . 71

RS-232 Connections . . . . . . . . . . . 71

Power Supply . . . . . . . . . . . . . . . 73

Bus Controller . . . . . . . . . . . . . . . . 74

Using the BUSSTAT Utility . . . . . . . . 74

Touchscreen Cables . . . . . . . . . . . . . 75

P/N 454173-000 Cable . . . . . . . . . . 75

Transient Protection Components . . . . . . 76

Diagnostic LEDs . . . . . . . . . . . . . . . 76

9

Page 11

2210 Serial Controller. . . . . . . . . . . 76

3000U USB Controller . . . . . . . . . . 77

2201 PC-Bus Controller. . . . . . . . . . 77

Diagnostic Codes . . . . . . . . . . . . . . 78

DB9 and DB25 Connector Pin Positions . . . 79

Appendix B

General Information . . . . . . . . . . . . . . . 81

Jumper Settings . . . . . . . . . . . . . . . 82

2210 Serial Controller . . . . . . . . . . . . . . 83

Jumper Settings . . . . . . . . . . . . . . . 84

2210 Emulation Modes . . . . . . . . . . 85

3000U USB Controller. . . . . . . . . . . . . . 85

2201PC-Bus Controller . . . . . . . . . . . . . 85

Jumper Settings . . . . . . . . . . . . . . . 86

2201Emulation Modes . . . . . . . . . . 87

Appendix C

Mechanical . . . . . . . . . . . . . . . . . . . 89

Cable and Connector. . . . . . . . . . . . . 89

Positional Accuracy . . . . . . . . . . . . . 90

TouchPoint Density . . . . . . . . . . . . . . 90

Touch Activation Force. . . . . . . . . . . . 90

Hardcoat Pencil Hardness . . . . . . . . . . 90

Abrasion Test. . . . . . . . . . . . . . . . . 90

Expected Life Performance . . . . . . . . . 90

MTBF Calculations. . . . . . . . . . . . . . 90

Sealing . . . . . . . . . . . . . . . . . . . . 91

Dust Seal . . . . . . . . . . . . . . . . . 91

Watertight Seal . . . . . . . . . . . . . . 91

Optical. . . . . . . . . . . . . . . . . . . . . . 92

Light Transmission . . . . . . . . . . . . . . 92

Environmental. . . . . . . . . . . . . . . . . . 93

Temperature/Humidity . . . . . . . . . . . . 93

Temperature. . . . . . . . . . . . . . . . 93

Operating . . . . . . . . . . . . . . . . . . 93

Storage . . . . . . . . . . . . . . . . . . . 93

Relative Humidity . . . . . . . . . . . . . . 93

Thermal Cycling. . . . . . . . . . . . . . . 93

Immersion . . . . . . . . . . . . . . . . . . 93

Water Spray. . . . . . . . . . . . . . . . . 93

Chemical Resistance . . . . . . . . . . . . 94

Food Service Chemicals . . . . . . . . . . 94

Altitude . . . . . . . . . . . . . . . . . . . 94

Storage . . . . . . . . . . . . . . . . . . . 94

Vibration. . . . . . . . . . . . . . . . . . . 94

Shock . . . . . . . . . . . . . . . . . . . . 94

Electrical. . . . . . . . . . . . . . . . . . . . . 94

Electrostatic Discharge Protection . . . . . . 94

Contact Bounce . . . . . . . . . . . . . . . 95

Open Circuit Resistance. . . . . . . . . . . 95

Closed Circuit Resistance . . . . . . . . . . 95

Breakdown Voltage . . . . . . . . . . . . . 95

Agency Approvals. . . . . . . . . . . . . . . . 95

UL Compliance . . . . . . . . . . . . . . . 95

Ball Impact Compliance . . . . . . . . . . . 95

Fire Retardation Compliance . . . . . . . . 95

CE Compliance . . . . . . . . . . . . . . . 96

FCC . . . . . . . . . . . . . . . . . . . . . 96

Index 105

10

Page 12

Introducing Touchscreens

Touchscreens are the ultimate operator/machine interface. In a touchscreen

system, you touch what you see. The computer responds. The human action and

the computer's reaction is simple, direct, and natural. Using touchscreens,

workers can control complicated processes. People who have never used a

computer before can interact easily with a touchscreen-based system.

Touchscreens bring the power of the computer within reach—in airports,

factories, shopping malls, schools, and hospitals.

C HAPTER

C

HAPTER

1

I

NTRODUCTION

Applications for touchscreens include:

• Public Information Systems

• Multimedia

• Retail and Point-of-Sale

• Process Control

• Instrumentation

•Gaming

• Ticket and Lottery

• Simulation and Training

• Education

The AccuTouch

patented resistive technology. The AccuTouch touchscreen has gained a

worldwide reputation for fast, responsive accuracy and reliability. It has an

unmatched combination of performance, size, and environmental adaptability.

®

Model:SCN-AT (E274) touchscreen product line is based on

1-13

Page 13

Because of its many unique features, the AccuTouch touchscreen is ideally

suited for retail and restaurant point-of-sale, medical, instrumentation, and

process control applications. In fact, the AccuTouch touchscreen is used in

more applications than any other touchscreen.

Driver Software

Elo driver software provides a consistent software interface among all Elo

touchscreens and controllers.

The driver software scales the absolute coordinates received from the

touchscreen controller into translated screen coordinates, using the calibration

points obtained with the video alignment program included with the driver

software. The driver also performs other operations as directed by the

application.

Elo provides driver programs for the DOS, Windows 3.1, Windows CE,

Windows 95/98, Windows NT, Windows 2000, Windows XP, OS/2, and

Macintosh operating systems. Additional drivers are also available. Additional

operating systems are supported through outside sources. Refer to the Elo web

site, www.elotouch.com, for details.

If you cannot use an available driver, Elo can supply all the touchscreen related

information you will need to write your own driver for any type of system,

including UNIX workstations, real-time systems, and embedded systems. For

the 2500S controller, the SmartSet™ Touchscreen Controller Family Technical

Reference Manual which is available on the Elo web site, provide information

on this process. Machine-independent source code is included on a companion

disk and web site, www.elotouch.com.

Shipping Damage

If you notice damage to the shipping carton, or concealed damage, be sure to

save all packing materials for later inspection by the carrier, who is responsible

for any shipping damage.

If failure occurs during the warranty period, see the Limited Warranty section at

the beginning of this manual for instructions.

1-14 Elo Entuitive Touchmonitor

Page 14

Care and Cleaning

Handle the touchscreen with reasonable care when not integrated into a monitor.

Do not pull or stress the cables.

Clean the touchscreen with Isopropyl 99% and lint free wipes. Always dampen

the wipes and then clean the touchscreen.

For operating and storage specifications, refer to Appendix C.

1-15 Elo Entuitive Touchmonitor

Page 15

1-16 Elo Entuitive Touchmonitor

Page 16

C

HAPTER

Elo purchases and resells a variety of monitors, called Touchmonitors, both

CRT and LCD, with touchscreens and all related components fully installed. If

you are installing components ra ther than a touchmonitor, proceed to Chapter 4,

install your touchscreen components, then return to this chapter.

Touchmonitor Benefits

Touchmonitor benefits include:

C HAPTER

3

T

OUCHMONITOR INSTALLATION

• Single source for touchscreen and display.

• Professionally engineered touchscreen installation.

• UL,cUL, FCC, TÜV, CE, and other agency approvals.

• Elo warranty.

• Plug-and-play convenience.

Controller boards, cables, and power supplies may also be ordered separately.

3-21

Page 17

Touchmonitor Configurations

This chapter assumes you have one of the following:

• A touchmonitor with an internal 2210 serial controller.

• A touchmonitor with an internal 3000U USB controller.

• A touchmonitor with one of the following external controllers:

• 2210MX serial controller.

• 2201 PC-Bus controller.

Touchmonitors with an internal serial controller typically have a DB9 female

RS-232 connector on the back of the touchmonitor. A serial cable connects

directly from the back of the touchmonitor to the serial port on the computer.

Touchmonitors with an internal USB controller will have a USB cable exiting

the back of the touchmonitor. The USB cable connects directly to a USB port on

the computer.

The 2210MX serial controller is typically mounted on the back of the display

and uses either a keyboard power tap or external power supply. The serial cable

attached to the controller enclosure connects to the serial port on your computer.

PC-Bus controllers plug directly into a slot in your computer and do no t require

a special enclosure or power supply. A cable connects directly from the back of

the touchmonitor to the PC-Bus controller.

Controller boards, cables, and power supplies may also be ordered separately.

Touchmonitor Connections

Connecting the Power and Video

If you do not have a touchscreen installed in your display, skip to Chapter 4,

which details the installation of touchscreen and controller components.

The video display function of the touchmonitor and the touchscreen installed on

the monitor are entirely separate systems. You should first connect and test your

touchmonitor as a video display only. Follow the instructions provided by the

monitor manufacturer.

3-22 Elo Entuitive Touchmonitor

Page 18

Next, refer to the appropriate page to continue your installation:

Controller Configuration Page

2210 Touchmonitor with Internal Serial Controller 23

3000U Touchmonitor with Internal USB Controller 24

2210 2210MX External Serial Controller 25

2201 PC-Bus Controller 27

Touchmonitor with Inter nal Serial Contr o ller

Contents

This configuration includes a touchmonitor with an internal 2210 serial

controller and a serial cable. Actual configuration may vary due to third-party

integrations.

Installation

The 2210 controller is internal to the monitor and is shipped preconfigured for

use with Elo software.

Complete these steps:

1 Plug the DB9 male end of the supplied serial cable into the DB9 female

connector typically labeled "Touch Interface" on the back of the

touchmonitor case.

2 Plug the DB9 female end of this cable into the computer's DB9 serial port. If

you have a 25-pin serial port, use a DB9 male to DB25 female adapter.

Proceed to “Where to Go from Here” on page 3-30.

3-23

Page 19

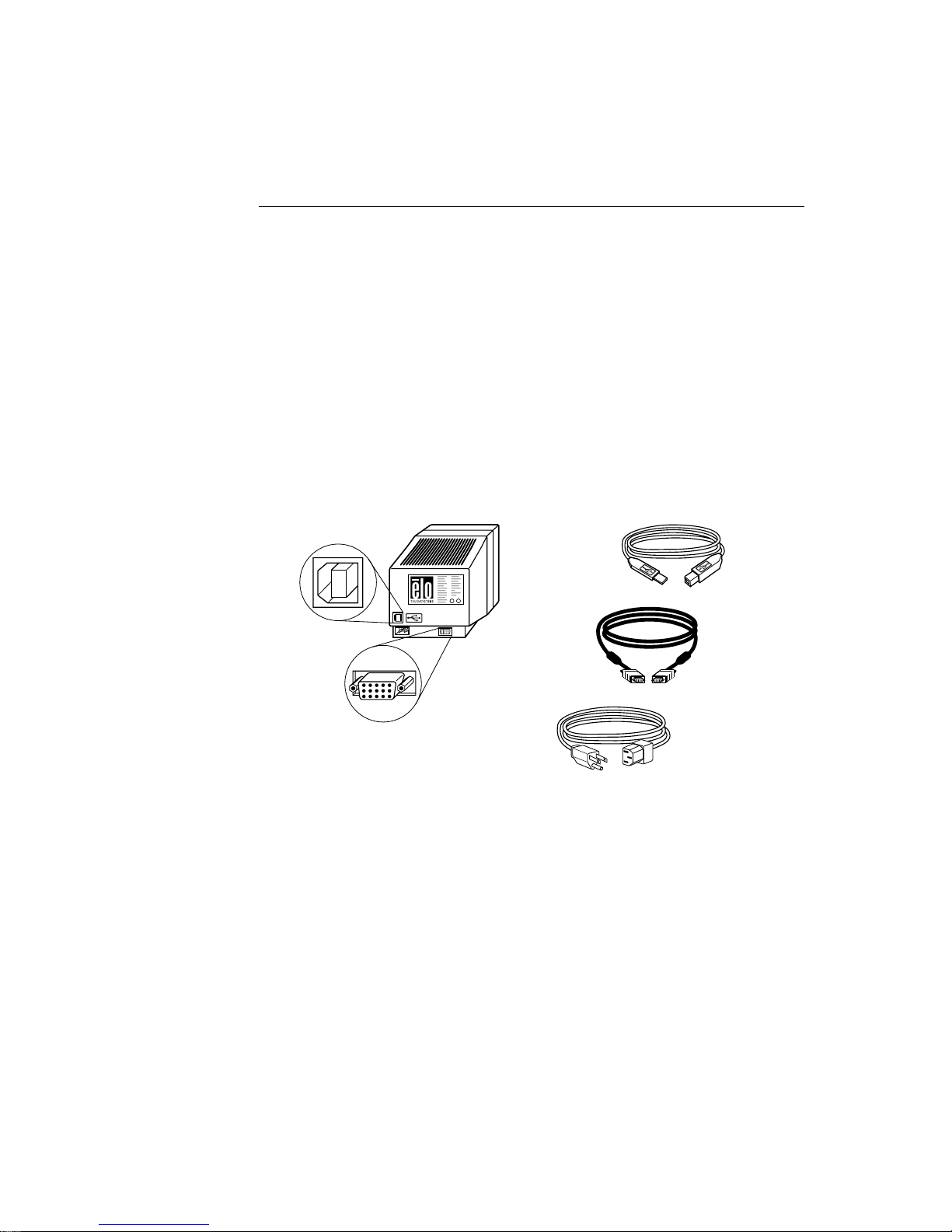

Touchmonitor with Internal USB Controller

Contents

This configuration includes a touchmonitor with an internal 3000U USB

controller.

Installation

Note:

You can leave your computer on when you conn ec t to a USB port.

The 3000U USB controller is internal to the monitor and is shipped

preconfigured for use with Elo software.

Complete this step:

1 Plug the USB cable exiting the touchmonitor into a USB port on the

computer.

Proceed to “Where to Go from Here” on page 3-30.

Touchscreen

monitor

USB

connector

Female 15-pin

video

connector

Video cable

Monitor

power cable

USB cable

Figure 3.1

3-24 Elo Entuitive Touchmonitor

USB Controller Installation

Page 20

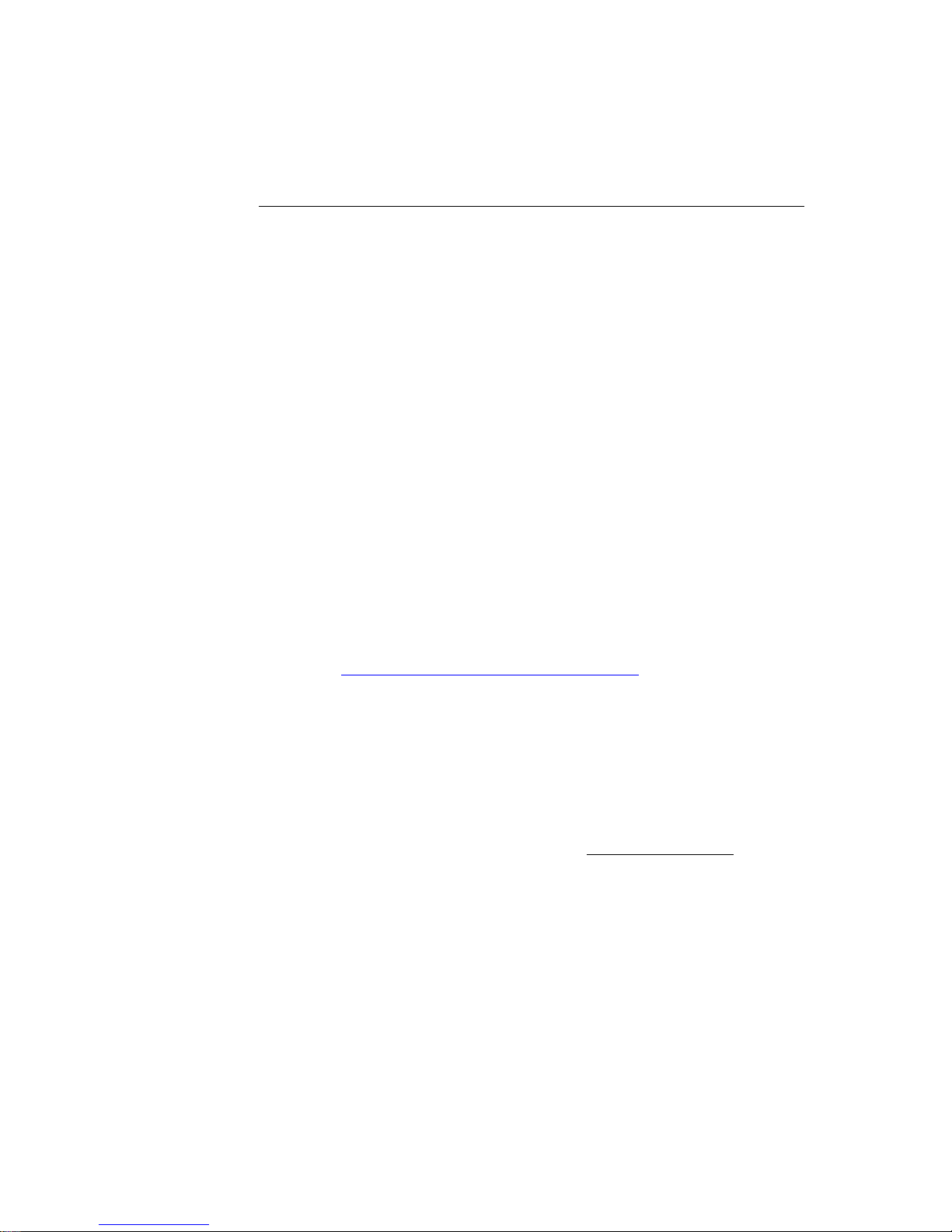

2210MX External Serial Controller

Contents

This configuration includes a 2210 serial controller in a small enclosure with a

keyboard power tap or external power supply and connecting cables.

Installation

Complete these steps:

1 Configure the controller

2 Connect the touchscreen controller and the supplied cables.

Configure the Contr oller

The controller is shipped preconfigured for use with Elo software. No changes

are necessary for most users. Specific settings and options available for your

controller are listed in Appendix B.

The 2210MX External Serial Controller is typically shipped co nfigured at 96 00

baud. If your software does not support the 2210 directly, you may o perate the

2210 in E271-140, E261-280, or E281A-4002 emulation modes. See B for

jumper settings.

Additional technical information about the 2210 controller can be found in the

SmartSet Touchscreen Controller Family Technical Reference Manual,

available at www.elotouch.com/support/dwnldmnls.asp

.

CAUTION

Connect the Controller

Before using a keyboard power tap, be sure sufficient power is available for the

touchscreen controller or damage may occur to the computer.

Before connecting a keyboard power tap to the controller, be sure that power to

the computer is OFF. Connecting a keyboard power tap to a powered computer

may seriously damage the computer or the controller.

Complete the following steps if you are using a keyboard power tap:

1 Two different keyboard power taps are available. Use Elo P/N 980773-00 0 if

you have a standard keyboard connector and Elo P/N 388923-000 if you have

a PS/2 keyboard connector.

2 Unplug the keyboard from the computer.

3 Plug the male connector on the Y end of the adapter cable into the keyboard

connector on the back of the computer.

3-25

Page 21

4 Plug the keyboard cable into the female connector on the Y end of the

adapter cable.

5 Plug the other end of the adapter cable into the connector on the serial cable.

6 Plug the DB9F end of the attached serial cable into a serial port.

7 Proceed to “Where to Go from Here” on page 3-30.

Complete the following steps if you are using a wall mount power supply

:

1 Two different wall mount power supplies are available. Use Elo P/N 580979-

000 if you are using this inside the United States and Elo P/N 319865-000 if

you are using this outside of the United States.

2 Plug the single male connector on one end of the power supply into the

connector on the serial cable.

3 Plug the other end of the power supply into a proper receptacle.

4 Plug the DB9F end of the attached serial cable into a serial port.

Proceed to “Where to Go from Here” on page 3-30.

Touchscreen

cable

Male 9-pin

touchscreen

connector

Female 15-pin

video

connector

Touchscreen

monitor

External serial

touchscreen

controller

Video

cable

Controller

power supply

Alternate keyboard

controller power cable

Monitor

power cable

Figure 3.2

3-26 Elo Entuitive Touchmonitor

External Serial Controller Installation

Page 22

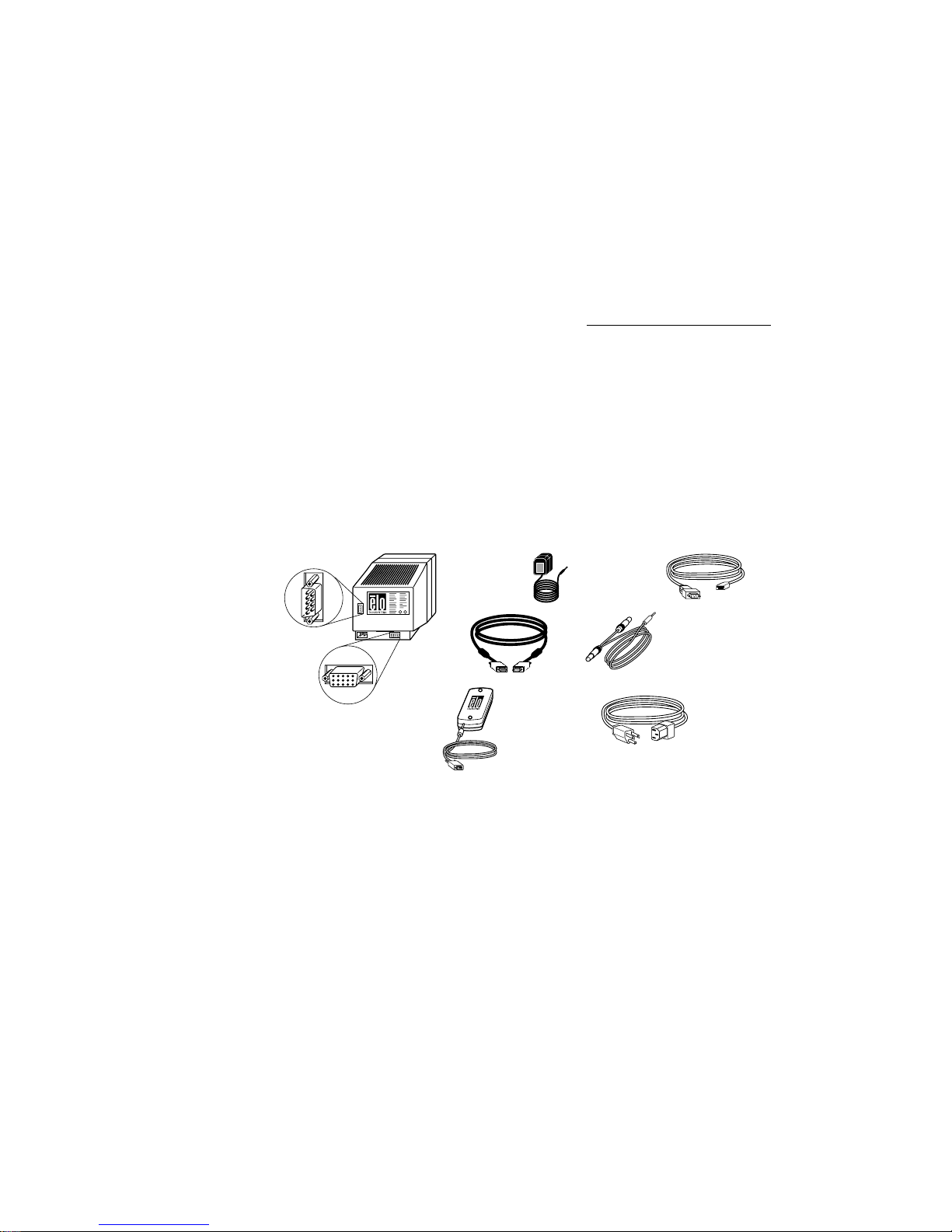

PC-Bus Controller

Contents

This configuration includes the 2201 PC-Bus controller and a touchscreen

cable.

Installation

Complete these steps:

1 Configure the controller.

2 Install the controller in your PC and connect the touchmonitor.

Configure the Contr oller

The controller is shipped preconfigured for use with Elo software. Except for

the Base I/O Port and Interrupt (IRQ) settings, no changes are necessary for

most users. Specific jumper settings and options available for your controller

are listed in Appendix B.

If your software does not support the 2201 directly, you may operate the

controller in E271-141 emulation mode. See B for jumper settings.

Additional technical information about the 2201 controller can be found in the

SmartSet Touchscreen Controller Family Technical Reference Manual,

available at www.elotouch.com/support/dwnldmnls.asp

.

Install the Controller in Your PC and Connect the Touchmonitor

Complete these steps:

1 Discharge any static charge on your body by touching the back o f the

computer cabinet.

2 Note the Base I/O Port for use with the driver software. Factory default

settings are 280 (hexadecimal) and no interrupt. (The driver software selects

the interrupt.)

3 Turn the computer off and unplug the AC power cord from the outlet.

4 Remove the computer's cover. Refer to the computer user's manual for

instructions.

5 Choose an available expansion slot.

6 Remove the screw holding the expansion slot's access bracket, then remove

the bracket.

3-27

Page 23

7 Insert the touchscreen controller into the expansion slot. The controller

should seat fully into the slot and the access bracket should mate with the

frame of the computer.

8 Replace the access bracket retaining screw, insuring that the controller

remains seated in the socket.

9 Replace the computer's cover.

10Plug the DB9 female end of the supplied touchscreen cable into the DB9

male connector labeled "Touchscreen Interface" on the back of the

touchmonitor case. Plug the DB9 male end of the touchscreen cable to the

DB9 female connector on the controller.

11Plug the AC power cord back into the outlet and reboot the computer.

12Proceed to “Where to Go from Here” on page 3-30.

Touchscreen

monitor

Male 9-pin

touchscreen

connector

Female 15-pin

video

connector

Figure 3.3

PC-Bus Controller Installation

Touchscreen Application Tips

Sometimes a simple change to your application may mean the difference

between success and failure.

1 Windows applications should be run full screen-don’t display a title bar or

menu bar in kiosk applications.

2 Bright background colors (no black!) in your application will hide

fingerprints and reduce glare. Dithering or other patterned backgrounds, such

as a crumbled paper look, will help the eye focus on the screen image instead

of reflections, even in areas with no icons or menu choices.

Video cable

Monitor

power cable

Touchscreen

cable

PC-Bus

touchscreen

controller

3 Use a simple point-and click interface with large buttons. Do not use

dragging, double-clicks, scroll bars, drop-down menus, multiple windows, or

3-28 Elo Entuitive Touchmonitor

Page 24

other elements that can confuse the user and interfere with usability and

efficiency.

4 Turn the cursor off—your user will focus on the entire screen instead of the

arrow. A cursor on the screen makes the user subconsciously think, “How do

I get the arrow to do what I want?” Remove the cursor, and the user’s

thinking and action will be direct instead of indirect, unlocking the true

power of touchscreens.

5 Always give your users feedback as soon as they touch the screen. A 3-D

button effect (similar to a Windows standard button) works well. Output a

“click” or other sound whenever they touch the screen. Also, be sure that the

display clears immediately and displays an hourglass while loading the next

screen. Immediate feedback is critical to reassure users that their touch is

registered.

6 Make your application run fast. Users will walk away from a sluggish

system, but you can keep their attention with a quick response to touches.

Speedy systems also reduce vandalism. (Graphics modes with excessive

colors or resolution only slow down your system, Using 256 colors is

typically more important than resolution above 640 x 480.)

7 Try to make the application intuitive; limit choices; and guide the user as

much as possible. Testing your application on focus groups will disclose the

areas that need improvement. If anyone pauses in confusion for even a

moment, think how to improve the application.

8 Digitized speech via a sound card can walk users through your application.

For example, “Touch the first letter of the company you are looking for.”

Click. “Now touch OK.” There is something almost magical about a user

interface with voice prompting and touch response. Your brain can

simultaneously process voice while absorbing image.

9 Animation and large fonts help attract users to kiosk applications. The kiosk

design (cabinet) should also be attractive.

10When designing a kiosk cabinet, consider the following. If using forced air

ventilation, put your fan at the top, near the monitor’s vents. Keep the intake

away from the floor and airborne dust from footsteps. Keep air from entering

around the CRT face, too. The kiosk design should accommodate variation in

monitor dimensions and bezels, as monitor models may come and go every

few months. Remember to point your speakers in the direction of the user’s

ears. Finally, choose a finish that does not show fingerprints—avoid polished

stainless steel, chrome, or glossy black paint.

3-29

Page 25

Where to Go from Here

The hardware installation is now complete.

Load the Elo driver specific to your operating system

If you will be writing your own driver program, see the SmartSet Touchscreen

Controller Family Technical Reference Manual available at

www.elotouch.com/support/dwnldmnls.asp

process. Machine-independent source code is included on a companion disk

along with a setup utility.

for step-by-step instructions on this

3-30 Elo Entuitive Touchmonitor

Page 26

C HAPTER

C

HAPTER

4

C

OMPONENT INSTALLATION

Elo purchases and resells a variety of monitors, called touchmonitors, with

touchscreens and all related components fully installed. If you already have a

touchmonitor, follow the installation instructions in Chapter 3.

If you do not have a touchmonitor, read this chapter for details on installing

touchscreen components that will convert your monitor into a touchmonitor.

Details are given on mounting the touchscreen, controller, and connecting

cables. While this chapter refers primarily to CRT-based monitor technologies,

much of this information can be applied to other monitor technologies. See “Flat

Panel Display Integration” on page 4-59.

These instructions assume you have purchased an Elo touchscreen installation

kit (P/N 458095-000), and a transient protection cable (PN 899389-000). Only a

minimum of equipment and materials is required beyond what is provided in the

kits.

In brief, adhesive materials are used to fasten the touchscreen to the CRT and

then the assembly is reinstalled in the original enclosure with minor

modifications. If this procedure is not suitable for mechanical, electrical, or

optical reasons, there are other techniques for touchscreen installation that may

achieve the desired results. These techniques often require specialized

equipment or materials, and a complete discussion is beyond the scope of this

manual. See “Installing the Touchscreen” on page 4-40.

4-31

Page 27

Safety Information

WARNING:

The touchscreen installation procedure outlined in this chapter may require exposure to high-voltage components and handling of the CRT. This procedure can be

dangerous and an accident is potentially lethal. Therefore, the procedure should

only be performed by a qualified person. Read this entire chapter before attempting a touchscreen installation. Follow the procedure carefully, w ork with the power

off and the unit unplugged, observe all warnings, and wear pr otective c lothing . Elo

is not liable for damage or injury that could result from your actions.

Consider purchasing a touchmonitor from Elo if you do not have previous

experience working with touchscreens and disassembling monitors. Elo also

offers touchscreen installation services for customers specified monitor.

Work Area

Before proceeding with the installation, prepare a padded work surface. A

plastic waste basket is recommended for supporting the CRT during part of the

installation.

Protective Clothing

Wear safety glasses, gloves, a rubber apron, and heavy protective clothing for

any portion of this procedure that involves handling or working near the CRT.

4-32 Elo Entuitive Touchmonitor

Page 28

Getting Started

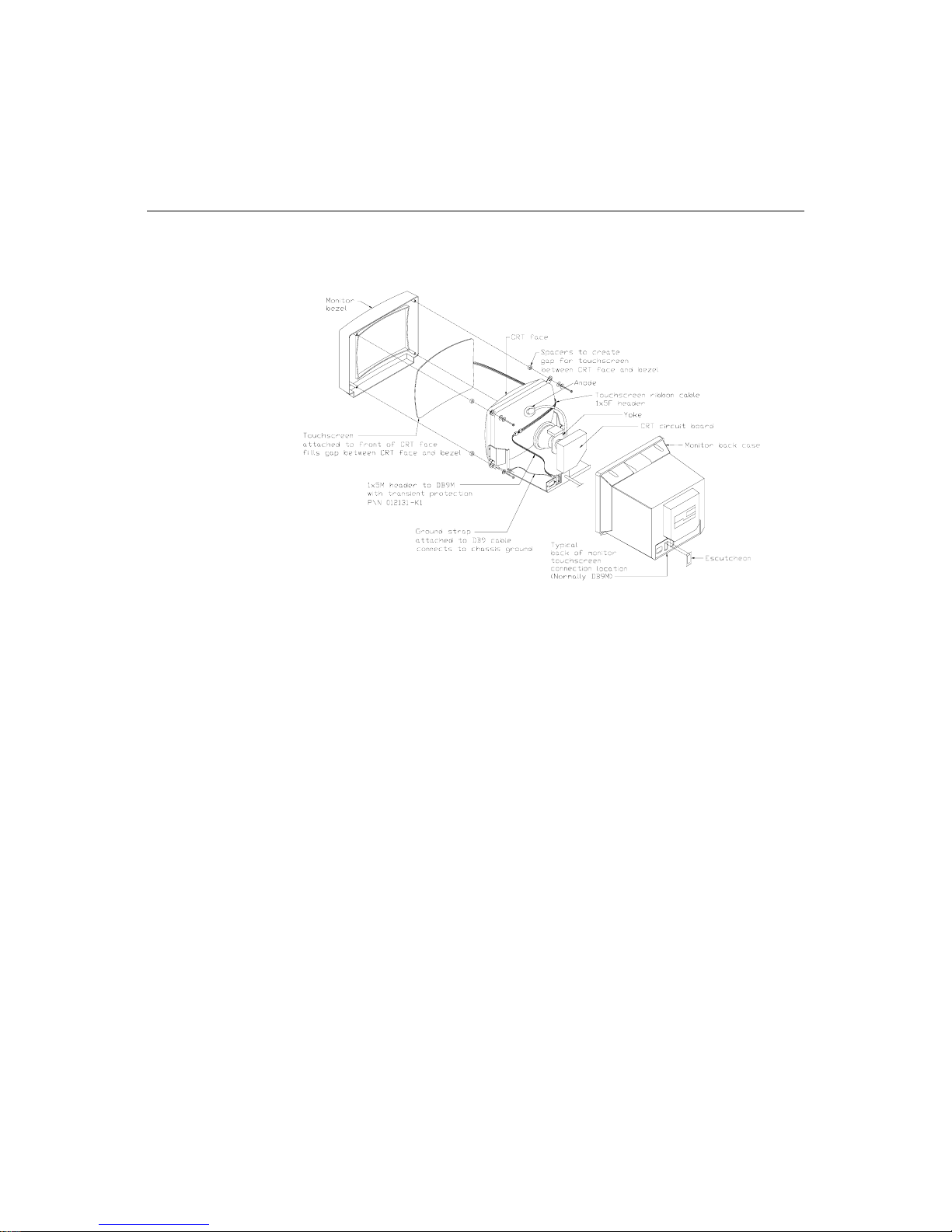

AccuTouch touchscreens can be installed on most types of monitors. Figure 4-1

shows a typical installation.

Figure 4.1

Typical AccuTouch Touchscreen Installation (for use with external

controller)

AccuTouch touchscreens are available for most monitors. Each monitor may

pose unique installation issues. Although your monitor may not be a standard

touchmonitor product from Elo, we may have had some experience with it.

Contact Elo Technical Support for more information.

This section assumes you have already determined compatibility between the

touchscreen and the monitor. A touchscreen installation kit is available from Elo

(P/N 458095-000), which includes the commonly used materials needed for

installation.

Most monitors require complete disassembly, including removal of the CRT, to

install a touchscreen. Disassembling the monitor can be a dangerous procedure

if done improperly. Before proceeding, review the rest of this chapter. Basic

assembly skills are required. Seek qualified help if you have any doubts about

your ability to complete the installation.

Any damage to the monitor or the touchscreen as a result of improper

installation is the installer’s responsibility.

4-33

Page 29

Without prior approval of the monitor manufacturer, you will probably void the

monitor's warranty by disassembling it. Also, it will be necessary to recertify the

monitor and touchscreen system for regulatory agencies (such as FCC,

UL/CSA, TÜV, CE, etc.) if those certifications were originally present and need

to be maintained for your intended application. (Elo offers touchmonitors with

full agency approvals.)

Handle the touchscreen with care. Avoid excessive handling and stress on the

touchscreen cable.

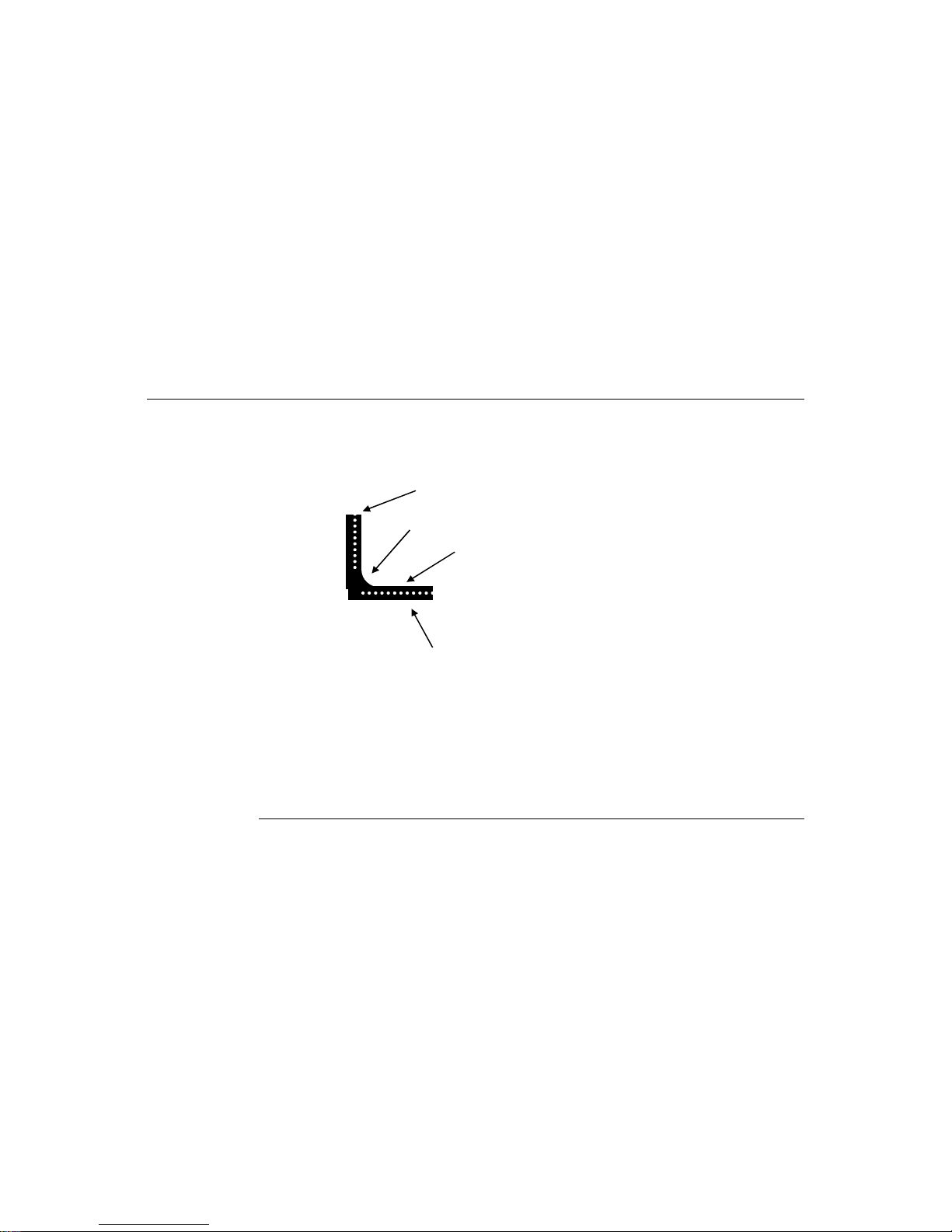

Bezel Design

The following graphic displays some bezel ideas in order to help you mount the

bezel to the touchscreen.

Bevel edge for nice appearance

Round corners for nice appearance and easy cleaning

Flat inner lip fo r se alin g tap e

Figure 4.2

Bezel design

T esting Components

The display must be in good working order before beginning the installation of

the touchscreen. With a new display, it is suggested that you test the display by

running it overnight. Do not leave a constant image at normal brightness on the

screen during this test, as it may burn an image into the screen.

Familiarize yourself with the operation of the touchscreen and controller before

you proceed with the installation. Use the COMDUMP, BUSSTAT, or

TOUCHES programs as described in Appendix A to test serial and PC-Bus

controllers while the touchscreen components are arranged on the work surface.

Currently, there is no separate diagnostic test for USB controllers.

4-34 Elo Entuitive Touchmonitor

On bezel and cabinet, choose paint finish and/or surface

texture so fingerprints do not show

Avoid tilt/swivel bases unless they are very stable - the

display should not move or shake when touched

Page 30

Installation Steps

The installation process consists of the following steps:

• Disassembling the monitor.

• Attaching the touchscreen to the CRT.

• Installing transient protection.

• Optionally installing an internal serial controller.

• Interfacing the touchscreen or serial data cables to the exterior of the monitor.

• Reassembling the monitor.

• Optionally sealing the monitor.

Specific compatibility may not be confirmed until well into the installation.

Suggested Tools

The following is a list of tools that may be needed to install the touchscreen.

Some of the tools are optional, but will be useful if needed.

• Long (at least 9 inches, 200 mm) flat blade screwdriver with insulated

handle.

• Clip lead or heavy-gauge wire.

• #2 Phillips screwdriver.

• Scissors.

• X-Acto knife (No. 11 blade) or hand milling tool.

• DB9 hole punch.

• Cable ties.

• Household glass cleaner.

• Paper towels.

• Small containers or plastic bags to hold loose parts.

The Elo Touchscreen Installation Kit (P/N 458095-000) is also recommended,

and includes commonly used materials needed for touchscreen installation. This

kit is useful for identifying preferred materials for your own procurement and

may also be cost-effective and convenient when purchased for a limited number

of installations. A copy of the monitor manufacturer’s service manual is also

useful, if available.

4-35

Page 31

Disassembling the Display

Disassemble the monitor on a large, well-lit work surface. Leave space to set

aside major monitor components. Group screws and other hardware in small

containers or in specific areas on the work surface as you remove them, in

relation to the part of the monitor where you are working. If you complete the

installation process in one session (which may require several hours for your

first efforts), it is unlikely that you will have trouble reassembling the monitor.

Most monitor manufacturers connect the major components with detachable

cables that have labeled and keyed connectors; these cables are of lengths that

will usually connect to only one place. Also, screws are identifiable by type and

size, and usually will not fit in the wrong place. The most difficult problem with

missing or wrong hardware or connections will be with single ground cables

that attach to obscure ground points on the metal chassis. When in doubt, make

notes of the connection points.

Removing the Back Case

Figure 4.1 on page 4-33, shows the typical construction of a 14-inch monitor.

Disassembly usually starts with removal of the back case. For assistance with

disassembly, consult your particular manufacturer's service manual. Carefully

lay the monitor on its face on the padded work surface and remove the screws

that attach the back case to the bezel or frame.

While removing the back case, note the clearance between the inside rear

surface of the case and a small circuit board plugged into a socket on the end of

the CRT. If there is not enough clearance to move the CRT and this circuit

board about 3/8-inch (9 mm) toward the rear of the case, you may be unable to

successfully install a touchscreen on the monitor and completely reinstall the

back case. Contact Elo Technical Support for possible alternatives.

After the back case is removed, the CRT is substantially exposed. Use extreme

care when working around the CRT.

WARNING:

4-36 Elo Entuitive Touchmonitor

Impact or force against the neck of the CRT, or the pins at the end where the small

circuit board is attached, could crack the tube, resulting in loss of vacuum or

implosion of the tube. Either result destroys the CRT. Implosion (collapse of the

glass inward, caused by the high vacuum inside the tube), followed by the

rebound of many glass pieces outward, is potentially lethal to any one in the immediate area. Handle the CRT carefully, keep tools away from the CRT, and wear protective clothing including eye protection. See Safety Information, page 32.

Page 32

Discharging the CRT

WARNING:

Dangerous voltages may be present on the CRT anode. The anode may retain a

very dangerous voltage even after the monitor has been off for days. Accidental

contact with the anode lead or anode button (the small hole in the CRT glass

where the anode lead is attached) prior to discharge may result in a potentially

lethal shock. Follow the procedure below carefully to avoid injury.

The anode lead of the monitor feeds high voltage from the flyback transformer

to the anode button on the CRT. The anode lead is usually red in color, and the

actual connection to the anode button is usually covered by a large rubber

suction cup-like boot. In most monitors, the button is located on the tapered

face, or bell of the CRT glass near the top of the monitor. See Figure 4.1 on

page 4-33.

It may be necessary to remove some sheet metal to gain access to the anode

lead—be very careful to do this without making contact to the anode lead itself.

Carefully discharge the CRT using the following procedure:

• Connect a clip lead or a heavy-gauge wire to chassis ground of the monitor

(or if the CRT is free-standing, the mounting ears or the spring-tensioned

ground strap).

• Connect the other end of the clip lead or wire to the stem of a flat blade

screwdriver that has an insulated handle.

• Hold the screwdriver by the insulated handle only. Insert the blade of the

screwdriver under the rubber boot and make contact with the anode lead at

the button. A distinct “snap” may or may not be heard as it discharges,

depending on the amount of charge present on the anode.

WARNING:

• Disconnect the anode lead from the button by unhooking the spring wire

clips. Note the location of the anode for proper CRT orientation during

reassembly.

The CRT will regain a charge over time, even after it has been discharged. To av oid

a dangerous electric shock, always discharge the CRT just before handling it, and

treat it with respect thereafter.

4-37

Page 33

Removing the Electronics Chassis

Continue disassembling the monitor until the face of the CRT is completely

exposed. The degree of disassembly required will vary from monitor to monitor.

Normally the next step will be to remove the electronics chassis from the

monitor. This requires removal of a small circuit board that is usually plugged

into the socket on the end of the CRT. The circuit board is often glued to the

CRT socket with a soft adhesive which must be cut away to remove the board.

Several cables must also be unplugged from the electronics. Typically these

cables are:

• Four wires from the yoke of the CRT, typically in a single four-pin

connector. The yoke is the copper wire and magnet assembly at the base of

the neck of the CRT. MPR II-compliant monitors may have additional cables

and connectors on the yoke.

• A two-wire cable from the degaussing coil. This coil may be attached to the

CRT, or be laying out of sight between the CRT and the bezel. Some

monitors may have two separate coils.

• A one- or two-wire ground cable connected between the CRT circuit board

and a ground strap. This strap is a long, annulated, braided wire which is

spring tensioned to maintain contact with the bell of the CRT.

• Various cables connected to the power switch, pilot light, front panel

controls, etc.

Other cables may have to be unplugged from the electronics cha ssis. The need

for this may not be apparent until the chassis is removed, as instructed below.

Another preliminary step in determining touchscreen-monitor compatibility

should be performed at this point. Before removing the electronics chassis, note

the clearance between the chassis components and the bell of the CRT. Since

the standard technique for mounting the touchscreen involves moving the CRT

back in the monitor chassis, there must be enough clearance between

components on the chassis and the CRT after allowing for about 1/4-inch (6

mm) movement of the CRT towards the rear of the chassis. Failure to allow for

this clearance requirement may result in mechanical damage later (especially in

shipping). It may also cause electrical damage from shorts between "live"

components on the chassis, such as heat sinks or uninsulated component leads,

and the bell of the CRT which is usually painted with a conductive coating that

is grounded to the chassis through the braided wire ground strap. Repositioning

or substituting low profile components may be an option. Contact Elo Technical

Support for assistance (1-800-557-1458 x6).

4-38 Elo Entuitive Touchmonitor

Page 34

After disconnecting any necessary cables, remove the screws that attach the

electronics chassis to the bezel. Note the bezel is essentially where all parts of

the mechanical assembly are attached, unless you have a rare unit that has an

internal frame. As you pull the chassis away from the bezel, make sure that

cables and circuit boards do not hit the neck of the CRT and that nothing

becomes caught on the adjustment rings or other components on the neck of the

CRT. Also watch for other cables that need to be disconnected. After removal,

set the electronics chassis aside.

Removing the CRT

Removal of the CRT is next. Prepare a soft surface to set the CRT on. Remove

the screws attaching the CRT to the bezel, and then remove the CRT. Do not lift

or carry the CRT by the neck or yoke assembly. Avoid contact with the anode

button, which may still have some residual charge on it, (you may wish to

discharge it again at this point). Set the CRT on the prepared surface.

Several other preliminary compatibility requirements should now be assessed:

• Position the CRT so the face is accessible, providing a soft cushion for the

neck and the yoke if they must rest on the work surface. Alternatively, set the

CRT face-up in an office-type plastic waste basket, making sure that the tube

is not resting on the neck (The small part of the CRT is the neck). Place the

touchscreen on the face of the tube, and check to see that the face of the CRT

and touchscreen are about the same size, and that the radius of curvature

(ROC) of each surface matches well. If both of these conditions are not met,

you may not have the proper touchscreen for the monitor. Most color

monitors have standard size CRT's with standard ROC's, and Elo has

touchscreens for most of them.

• N ext, determine if the touchscreen will fit in the bezel without modifications

to the bezel. Modifications, if necessary, should be done without

compromising the mechanical integrity of the monitor.

• Lay the touchscreen face-down in the bezel. Leave the degaussing coil in

place, if present. The degaussing coil is a hoop, often located between the

CRT and bezel, approximately 1/4-inch (6 mm) thick, with a two-wire

cable and connector. The coil was probably unplugged from the power

supply earlier.

• If the touchscreen will not fit flush against the lip of the bezel, do not force

it. An interference fit between the edge of an AccuTouch touchscreen and

some of the plastic ribs found in monitor bezels could result in fracture of

the glass after reassembly.

4-39

Page 35

• It may be necessary to cut the ribs and struts inside the bezel. Cutting these

ribs and struts does not usually cause difficulties, although the stiffness of

the bezel may be reduced slightly. Try not to cut into the posts for the CRT

attachment screws. Bezel and tube combinations that require this cut are

rare.

• Generally, a total clearance between the edge of the touchscreen and any

ribs or struts of at least 1/4-inch (6 mm) in both axes is necessary. This

prevents the interference fit problem discussed above and allows for

variation in touchscreen mounting position.

• The potential interference between the degaussing coil and the

touchscreen must also be evaluated. The coil will usually fit between the

touchscreen and the inside surface of the bezel, as there is typically a

natural cavity for it. If there is not enough space for the coil, you may have

to provide additional setback for the CRT. It may also be possible to

relocate the coil to the bell side of the CRT. Normally, this does not

significantly reduce the coil’s effectiveness. However, you must determine

this by inspecting the monitor for color problems after reassembly.

1 Check for adequate clearance of the cable from the bezel structure. If the

position of the cable causes difficulty, the touchscreen may be rotated 180°

only if the touchscreen is sealed and Elo drovers are used. The preferred

orientation of the AccuTouch touchscreen is with the cable exiting from the

left side, when viewed from the front of the monitor. Rotation will cause an

inversion of the output coordinates, which will be compensated for

automatically by Elo driver software, but perhaps not by other drivers. (Flat

touchscreens should have the plastic surface on the side facing the user.)

Installing the Touchscreen

CAUTION:

4-40 Elo Entuitive Touchmonitor

After the touchscreen is attached to the CRT, transient protection must be in place

before applying power to the monitor. Transient protection is discussed on

page 4-46.

When preparing the touchscreen for mounting to the CRT, major considerations

are:

• Reasonable mechanical alignment with the display.

• A complete dust seal between the touchscreen and the CRT.

• A mounting technique that evenly supports the touchscreen on at least two

opposite edges. Elo recommends double-sided tape between the touchscreen

and the CRT.

Page 36

• Creating enough space between the CRT and the bezel to accommodate the

touchscreen. Adequate spacing can normally be accomplished by:

1 trimming or milling the inside of the bezel

2 using spacers to move the CRT back in the chassis

3 using spacers to move the bezel away from the touchscreen.

A combination of moving the CRT back with spacers and trimming the bezel

is the usual solution.

• Depending on the touchscreen selected, avoidance of contact between the

display bezel and the active area of the touchscreen may be necessary. The

active area is that portion of the touchscreen inside the solid line. This "line"

can be easily seen on the touchscreen itself as the edge of a piece of

translucent material which is between the touchscreen glass and cover

sheet.A small force applied to the cover sheet in the active area will produce

contact between the glass and cover sheet registering a touch. A permanent

touch, such as one produced by a bezel, will defeat the normal operation of

the touchscreen. (It is permissible for the display bezel or a gasket to make

permanent contact with the inactive border region of the touchscreen, and

this often produces a more attractive solution.) Some AccuTouch

touchscreens are sized so the active area is larger than typical bezel openings,

so bezel contact often produces a touch.

Some of the popular touchscreen sizes are available with a wider inactive

border region. This will allow you to install the touchscreen with the display

bezel in contact with the touchscreen. The factors you should consider when

selecting this installation method are:

• Spacer Selection - Spacers between the bezel and CRT cannot be

eliminated using this method, and in fact should be chosen carefully. The

desired result is to have the bezel just touch the touchscreen, but put little

or no pressure on it.

• Sealing - Sealing touchscreens in the inactive border region will be easier.

Caulks and gaskets of almost any type may be used to make a seal between

the touchscreen and bezel in this region.

Double-sided tape and foam sealing tape are included in the Elo touchscreen

installation kit (P/N 458095-000). The following steps assume you will use

these materials to mount the touchscreen to the CRT.

4-41

Page 37

Figure 4.3

Rear View of an AccuTouch Touchscreen with Mounting Materials

Before mounting the touchscreen, clean the face of the monitor and the back of

the touchscreen with household glass cleaner. Be sure to remove all

fingerprints. The space between the touchscreen and the monitor face must be

clean and free of any foreign objects.

Mount the touchscreen as follows:

• Use two layers of the double-sided adhesive tape to achieve a total thickness

of 1/16-inch (2 mm). While specific touchscreen and CRT combinations may

allow the use of thinner materials, 1/16-inch (2 mm) is generally necessary to

allow for variations in ROC between the two glass surfaces. Review the fit

between the touchscreen and the CRT before applying the tape. If one pair of

opposite edges has a closer fit than the other, put the adhesive tape on the

edges of the touchscreen with the better fit. See figure 4-2 for typical

placement. If there is a good fit on all four edges, you may want to use

double-sided adhesive tape on all four edges. When doing this, move the

adhesive tape in slightly on one pair of edges and add foam sealing tape

outside these two edges. The thicker foam tape will keep the adhesive tape

away from the CRT until you are ready to adhere the touchscreen to the

monitor.

In general, the adhesive tape should be set back slightly from the edge of the

active area of the touchscreen. When the monitor is reassembled, the

mounting tape should not be visible. Do not remove the liner from the

exposed side of the adhesive tape yet.

4-42 Elo Entuitive Touchmonitor

Page 38

• Cut and place the foam sealing tape on the back of the touchscreen to form a

dust seal as shown in Figure 4.2 on page 4-34. This seal is particularly

important because the CRT is a good electrostatic precipitator and will attract

dust. The adhesive tape and foam sealing tape should form a complete seal

around the touchscreen. Do not leave any gaps. The sealing tape should not

be visible when the monitor is reassembled.

• Practice aligning the touchscreen on the CRT without removing the adhesive

tape liner. The installation can tolerate some horizontal and vertical shift.

However, rotational skew between the touchscreen and monitor axes cannot

be easily compensated for in the calibration, and will also interfere with

proper mounting of the tube in the bezel.

• When you have a good feel for the placement of the touchscreen, clean the

back side of the touchscreen and the face of the CRT again. Avoid all contact

between the cleaning solution and the mounting materials as the cleaner may

cause the mounting materials to eventually release from the glass. Remove

all lint with a brush or compressed air. Remove the liner from the adhesive

tape and align the touchscreen on the monitor. The thicker foam tape will

keep the adhesive tape away from the CRT until you are ready to adhere the

touchscreen to the monitor. Now press the touchscreen firmly against the

CRT.

• Inspect your results carefully for alignment, trapped dust or lint, and a good

seal between the touchscreen and CRT. If there is trapped lint, you may be

able to remove it without removing the touchscreen by capturing it with a

thin wire with a small spot of glue. Poke the wire through the foam gasket

and stick the lint to the wire. Pull the lint back into the gasket and embed it

there, or remove it completely and reseal the gasket.

• If you must remove the touchscreen from the CRT, cut the adhesive tape

away with a sharp thin blade, such as an X-Acto knife. The touchscreen glass

will probably break if you try to pull it off by a corner or an edge. Shave the

old adhesive tape from the touchscreen and CRT with the knife. Adhesive

residues can be removed with isopropyl alcohol, which will leave streaks and

fingerprint smears. Use glass cleaner for the final cleaning prior to

reapplication of new tape.

4-43

Page 39

Spacing the CRT from the Bezel

The last part of the touchscreen mounting procedure is to determine the

appropriate spacing of the CRT from the bezel, (with the touchscreen attached),

and to reinstall the CRT with the required spacers in place (refer to, Figure 4.1

on page 4-33.) Do not clamp the touchscreen between the bezel and the CRT

without proper spacers as breakage will almost certainly occur. The nominal

thickness of the touchscreen and the two layers of adhesive tape is 3/16-inch

(5 mm). If your installation has a 1/8-inch (3 mm) touchscreen-to-bezel gap,

5/16-inch spacers would be required. If the touchscreen is to be in contact with

the bezel, 3/16-inch (5 mm) nominal spacers would be required.

Because the original CRT face-to-bezel mount is often an interference fit, with

the bezel shape altered slightly to draw it up tightly against the CRT, you should

start with a 1/16-inch (2 mm) thicker spacer than the nominal d ime nsion ab ove.

Two thicknesses of spacers, plus additional washers to use as shims, are

available in the Touchscreen Installation Kit (458095-000).

During the spacer selection process, you may have to install the CRT with the

touchscreen attached in the bezel several times. To prevent the CRT from

dislodging the spacers, temporarily insert plastic tie wraps or toothpicks as

guides in the mounting post holes. After selecting the correct spacers, discard

the guides and fix the spacers more securely in place with the adhesive

"doughnuts" provided in the Touchscreen Installation Kit.

When spacers for the desired gap have been selected, install the CRT. Make

sure you have previously reinstalled the degaussing coil. Select a screw that is

long enough to compensate for the spacer thickness (provides at least three full

turns into the mounting post threads) but not so long as to penetrate the surface

of the bezel. Over-tightening the screws may strip or split the mounting posts.

After the screws have been tightened snugly, examine the clearance between the

bezel and touchscreen. Try to adjust for the clearances suggested unless the

available space is insufficient.

If you are trying for zero clearance between the touchscreen and the monitor

(using a wider inactive region touchscreen), the above process should still be

generally followed. Do not clamp the touchscreen between the bezel and the

CRT with no spacers as breakage will almost certainly occur.

Evaluate the bezel to touchscreen fit carefully. Before selecting spacers, check

the fit by placing the bezel over the touchscreen/CRT combination (using the

plastic waste bucket to hold the CRT), or gently setting the touchscreen/CRT

combination on top of the inverted bezel on the workbench. Look for reasonably

even fit. If the bezel in its relaxed state has a different curvature than the

touchscreen, this method may not work, and you may want to complete the

installation with a gap between the touchscreen and bezel as described earlier.

4-44 Elo Entuitive Touchmonitor

Page 40

Select spacers to allow the touchscreen to just touch the bezel. If the bezel is in

contact in some areas and not in others, be wary of warping the bezel to achieve

uniform contact by using thinner spacers. While mounting tape will provide

some compliance and the touchscreen may also flex slightly, shipping damage

may occur.

4-45

Page 41

Transient Protection

WARNING:

Lack of transient protecti on may produce a dangerous shock hazard. Touchscreen

damage resulting from transient discharge is not covered by the Elo warranty.

Procedures discussed in this section must be followed to maintain safety and

assure reliability of the touchscreen system.

When an AccuTouch touchscreen is installed on a monitormonitor, the

combination becomes a capacitor which stores an electric charge. The simplest

capacitors are parallel plates of conductive material separated by an insulating

material called the dielectric. In this case, the plates are the metallized coatings

of the touchscreen and the CRT face, and the dielectric consists of the various

air and glass layers between them. See Figure 4.3 on page 4-42 . The

capacitance increases with the size of the plates and closer spacing.

The potential on the inside face of the CRT can be more than 30,000 volts.

When the monitor is turned on or off, a large difference in charge builds up

between the two plates (mainly C1 in Figure 4.3 on page 4-42 ). To balance the

charge, some current must flow from the system ground to the touchscreen. If

this current does not flow, the potential on the touchscreen rises until sufficient

potential exists to cause an arc. This arc can damage the touchscreen or cause a

dangerous electrical shock. Transient protection provides a safe, controlled path

for this current by limiting the voltage buildup on the touchscreen.

Elo recommends connecting the cathodes of four transient suppression diodes to

the four glass substrate terminals of the touchscreen. Make the connection as

close to the touchscreen as possible. The anode end of all four diodes must be

attached to the CRT chassis ground through a short wire of the largest possible

diameter (16 gauge or heavier recommended). See Figure A.3 on page A-76, for

a circuit diagram.

In monitor installations where the touchscreen controller will be external to the

monitor, use the Elo transient protection cable (899389-000), included with the

touchscreen kit. You must attach the transient protection component(s) to the

touchscreen cable and connect the groun d wire to the monitor’s chassis ground

before turning the monitor on. The controller need not be connected to the

touchscreen.

In monitor installations where the touchscreen controller will be installed

internal to the monitor, the serial controller’s on-board transient protection may

be used. The touchscreen must be connected to the controller and controller

grounded through one of the plated-through mounting holes be fore turning the

monitor on.

Some form of transient protection must be connected at all times. If you cannot

use one of the recommended solutions, contact Elo Technical Support for

alternatives.

4-46 Elo Entuitive Touchmonitor

Page 42

Figure 4.4

Side View of an AccuTouch Touchscreen Installation

Controller Interface Options

Elo offers PC-Bus and serial (RS-232) controllers for AccuTouch touchscreens.

The serial controller may be purchased in a Tabletop enclosure (see Chapter 3)

or as components. This section includes a procedure for installing a CTR221000-AT-SER serial controller inside the monitor.

Regardless of the configuration of touchscreen and controller, you are

responsible for any recertification for agency approvals (FCC, UL/CSA, TÜV,

CE, etc.) that may be necessary for your application.

4-47

Page 43

Internal Contro ller s

An AccuTouch internal controller mounting kit is available from Elo. P/N

734849-000 is for use with 2210 controllers. P/N 310900-000 is for use with

3000U controllers. These kits are useful together with the touchscreen

installation kit (P/N 458095-000) for identifying preferred materials for your

own procurement. The controller mounting kit may also be cost-effective and

convenient when purchased for a limited number of installations.

Figure 4.5

Touchscreen Cabling System for Internal Serial Controller

2210 Serial Controller and 3000U USB Controller

The mounting holes of the 2210 serial controller and the 3 000U USB controller

are sized for 0.156-inch (4mm) snap-in standoffs. All AccuTouch touchscreens

have a cable termination that mates directly with the male header (P3) on the

controller. See Appendix B for specific mounting dimensions and connections.

Mounting an internal serial controller presents some challenges:

• Space for the controller and the cable headers, and for any additional

shielding that may be required to prevent noise and crosstalk between the

monitor and the controller. Noise can cause instability in the touch data or

other forms of intermittent operation.

4-48 Elo Entuitive Touchmonitor

Page 44

• Space for an internal +5 Vdc power supply if required. The 2210 controller

power requirements are: 65 mA @ +5Vdc ± 10% standby, 160 mA average

with touch, 240 mA peak. Elo offers a 100 to 240 Vac international power

supply (P/N 742067-000) for use with the AccuTouch serial controller. The

3000U USB controller does not require a power supply as it gets its power

from the USB bus. See the SmartSet Touchscreen Controller Family

Technical Reference Manual available at www.elotouch.com/support/

dwnldmnls.asp for specific power requirements and connections for the 2210

controller and www.elotouch.com/products/accutec/c3000u.asp

for specific

power requirements and connections for the 3000U controller.

• Cable routing that may contribute to noise and crosstalk.

• Electromagnetic Interference (EMI) suppression. Installing a touchscreen

and controller will affect the EMI characteristics of the monitor.

• Heat dissipation. The 3000U controller dissipates about 0.25 watt. The 2210

controller dissipates about 0.3 watt. A typical power supply, if required, may

dissipate several watts more. This places an additional load on the cooling

system of the display. The available locations to mount a controller and

power supply may also affect the cooling system of the display.

Both the serial and USB controller have transient protection on-board.

Mounting the controller internally is the only instance where this on-board

transient protection can be substituted for the transient protection solutions

discussed in the previous section. When using the on-board protection, you must

insure that the touchscreen is connected to the controller and the controller is

grounded when cycling power to the display. The 2210 has two plated-through

mounting holes, and its on-board transient protection is grounded through them.

The 3000U has four plated-through holes, and its on-board transient protection

is grounded through them. You must connect chassis ground to at least one of

these plated-through holes.

Installing the 2210 Serial Controller

Complete these steps to install the 2210 controller, using the internal controller

mounting kit (P/N 734849-000):

1 Be sure all controller jumper settings are made prior to installation. See

Appendix B.

2 Once proper component positioning has been determined, insert the desired

profile standoffs into at least three of the mounting holes, but do not peel off

the adhesive backing. Wait until some of the following steps are

accomplished:

4-49

Page 45

3 Enable the controller’s on-board transient protection. This may be

accomplished one of two ways:

• If the controller can be mounted to a metal chassis, it can be grounded

through one of the plated-through mounting hol es b y u sing one of the No.

6 sheet metal screws and spacers provided in the kit. Use either of the

holes marked "PTH" in Figure B.2 on page B-83 .

• If the controller cannot be mounted to a metal chassis, use a ground wire

with a lug attached to connect one of the controller's plated-through

mounting holes to chassis ground.

When using the controller’s on-board transient protection, you must ensure that

the touchscreen is connected to the controller and the controller is grounded

when cycling power to the monitor.

1 Connect the power cable harness to the 1x2 male connector at P4 on the

controller. Connect the power source to the harness and then to AC. The

2210 controller power requirements are +55 mA at +5 Vdc ±10% standby,

160 mA average with touch, 240 mA peak.

2 Connect the 2x5 female connector on the serial output cable to the 2x5 male

connector at P2 on the controller. Mount the DB9 female end of the cable as

described for the 899389-000 cable in the following section. The serial cable

connector shell must be grounded to satisfy safety agenc y app r ov als , as the

grounding protects the user in case a wiring fault develops in the monitor.

Attach the other ground wire supplied in the kit to one of the DB9's mounting

screws and the other end to chassis ground if the shell is not already

grounded.

Mechanically, there may be several options for mounting the bulkhead

connector on the monitor case:

• Mounting the cable to a chassis member that is exposed to the display

exterior. This requires a DB9 hole punch to mount the connector neatly, but

makes reassembly of the back of the case very easy, and is usually the best

functional and cosmetic solution.

• Mounting the cable to a concealed chassis member, with a hole in the exterior

of the case (usually plastic) to provide access to the connector. This

technique also requires a metal punch to mount the DB9 connector, but the

plastic case hole can often be routed, nibbled, or punched with simple tools,

and usually provides a neat appearance. This is also an excellent functional

solution as the back case is again very simple to reassemble.

4-50 Elo Entuitive Touchmonitor

Page 46

• Mounting the cable to the plastic case. Plastic cases are usually rather thick,

making it necessary to mount the flange of the connector on the outside of the

case. This is cosmetically less acceptable than an inside mount and there is

less support for the serial cable. Also the standard DB9 hole may not provide

adequate clearance for the connector. Avoid mounting to curved surfaces if

possible as hole punching is more difficult and mounting hardware will warp

the connector when tightened. If mounted on the inside, the mounting

hardware may interfere with proper mating with the P/N 899389-000 cable.

Also, the touchscreen cable must be connected to the P/N 899389-000 cable

as the back case is being reinstalled, and the ground cable from the transient

protection must also be connected. The shell of the DB9 connector is

internally connected to the ground wire.

An escutcheon,, or identifying metal plate labeled with the legend "Touch

Interface" (P/N 172001), is included in the touchscreen installation kit (P/N

458095-000). It provides an attractive and convenient finish to most of the

bulkhead mounts typically used on a display. A similar plate is also available

with vertical labeling (P/N 172003).

Installing the 3000U USB Controller

Complete these steps to install the 3000U USB controller, using the internal

controller mounting kit (P/N 310900-000):

1 Once proper component positioning has been determined, insert the desired

profile standoffs into at least three of the mounting holes, but do not peel off