Page 1

Page 2

Elo Entuitive Touchmonitor

User Guide

17" LCD Desktop Touchmonitor

with Magnetic Swipe Reader

1725L Series

Revision A

P/N 008583

Elo TouchSystems, Inc.

1-800-ELOTOUCH

www.elotouch.com

Page 3

Copyright © 2004 Elo TouchSystems, Inc. All Rights Reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system,

or translated into any language or computer language, in any form or by any means, including, but not

limited to, electronic, magnetic, optical, chemical, manual, or otherwise without prior written

permission of Elo TouchSystems.

Disclaimer

The information in this document is subject to change without notice. Elo TouchSystems makes no

representations or warranties with respect to the contents hereof, and specifically disclaims any

implied warranties of merchantability or fitness for a particular purpose. Elo TouchSystems reserves

the right to revise this publication and to make changes from time to time in the content hereof

without obligation of Elo TouchSystems to notify any person of such revisions or changes.

Trademark Acknowledgments

IntelliTouch, SecureTouch, AccuTouch, Entuitive, and MonitorMouse are trademarks of Elo

TouchSystems, Inc.

Other product names mentioned herein may be trademarks or registered trademarks of their

respective companies. Elo TouchSystems claims no interest in trademarks other than its own.

iii

Page 4

Table of Contents

Chapter 1

Introduction 1

Precautions . . . . . . . . . . . . . . . . . . . . 1

About the Product . . . . . . . . . . . . . . . . . 1

Chapter 2

Installation and Setup 3

Unpacking Your Touchmonitor. . . . . . . . . . . 3

Product Overview . . . . . . . . . . . . . . . . . 4

Main Unit . . . . . . . . . . . . . . . . . . . . 4

Rear View . . . . . . . . . . . . . . . . . . . 4

Side View. . . . . . . . . . . . . . . . . . . . 5

Base Bottom View . . . . . . . . . . . . . . . 5

Touch Interface Connection . . . . . . . . . . . . 6

Serial or USB Connection . . . . . . . . . . . 6

Removing the Back Cover . . . . . . . . . 7

Routing the Cables . . . . . . . . . . . . . 8

Connecting the Video Cable or DVI-D Video

Cable . . . . . . . . . . . . . . . . . . . . 9

Connecting the Serial or USB Touchscreen

Cable . . . . . . . . . . . . . . . . . . . 10

Connecting the Speaker Cable . . . . . . 11

Connecting the Power Cable . . . . . . . 12

Replacing the Back Cover . . . . . . . . 12

Optimizing the LCD Display . . . . . . . . . . . 13

VESA Mount on Your Touchmonitor . . . . . . . 13

Accessing the VESA Mounting Interface. . . 14

Mounting the Base . . . . . . . . . . . . . . . 14

Installing the Driver Software . . . . . . . . . . 15

Installing the Serial Touch Driver for Windows

XP, Windows 2000, Me, 95/98 and NT 4.0 . 16

Installing the Serial Touch Driver for MS-DOS

and Windows 3.1 . . . . . . . . . . . . . 17

Installing the USB Touch Driver . . . . . . . 18

Installing the USB Touch Driver for Windows

XP, Windows 2000, Me and 98 . . . . . . 18

Chapter 4

Troubleshooting 23

Solutions to Common Problems . . . . . . . . 23

Appendix A

Native Resolution 25

Appendix B

Touchmonitor Safety 27

Care and Handling of Your Touchmonitor. . . . 28

Appendix C

Technical Specifications 29

Compatible Video Modes . . . . . . . . . . . . 29

Touchmonitor Specifications . . . . . . . . . . 30

17" LCD Touchmonitor (ET17-XXWF-1)

Specifications . . . . . . . . . . . . . . . 30

IntelliTouch Touchmonitor Specifications . . 31

AccuTouch Touchmonitor Specifications. . . 32

17" LCD Touchmonitor Dimensions. . . . . . . 33

Regulatory Information 35

Warranty 39

Index 41

MSR Serial Reference Manual 43

MSR USB Reference Manual 76

Programming Reference Manual 131

Chapter 3

Operation 19

About Touchmonitor Adjustments . . . . . . . . 19

Using the On-Screen Display (OSD) Menus . . 19

Side Bezel Buttons . . . . . . . . . . . . . . . 20

OSD Menu Function. . . . . . . . . . . . . . . 21

iv

Page 5

Congratulations on your purchase of an Elo TouchSystems Entuitive

touchmonitor. Your new touchmonitor combines the reliable performance of

Elo’s touch technology with the latest advances in LCD display design. This

combination of features creates a natural flow of information between a user

and your touchmonitor.

Precautions

C HAPTER

1

C

HAPTER

1

I

NTRODUCTION

Follow all warnings, precautions and maintenance as recommended in this

user’s manual to maximize the life of your unit. See Appendix B for more

information on touchmonitor safety.

About the Product

Your LCD Desktop Touchmonitor is a 17" XGA TFT color display with the

following features:

• Direct analog RGB input

• 17" diagonal screen size

• 16.7 million displayable colors

• 1280 x 1024 resolution

• SXGA/XGA/ SVGA/ VGA/VESA/ Mac compatible

• 30kHz~80 horizontal scan

• 56~75Hz refresh rate

1-1

Page 6

• Auto adjustment capability

• High quality full screen re-scaling

• Multilingual OSD menus in six languages: English, French, German,

Spanish, Italian and Japanese

• Serial or USB touch interface (USB requires Windows 98, 2000, Me and

XP.)

• Built in speakers with volume, treble, bass And balance control thorough

OSD

• Patented touch technology of Elo TouchSystems

• VESA DDC 1/2B data communication

• VESA DPMS power saving

• Stand with minimum 95° angle of tilt.

• Cable management device

• VESA flat panel monitor physical mounting interface (Both 75 & 100mm)

• OSD and Power button lockouts

• Wall mountable with existing stand

• VESA 100 mm M5 threaded holes on bottom of stand for securing to desk or

other surface, i.e. table top

• Cable strain reliefs for all cables

For full Product Specifications refer to Appendix C.

1-2 Elo Entuitive Touchmonitor User Guide

Page 7

C

HAPTER

2

I

NSTALLATION AND

This chapter discusses how to install your LCD touchmonitor and how to install

Elo TouchSystems driver software.

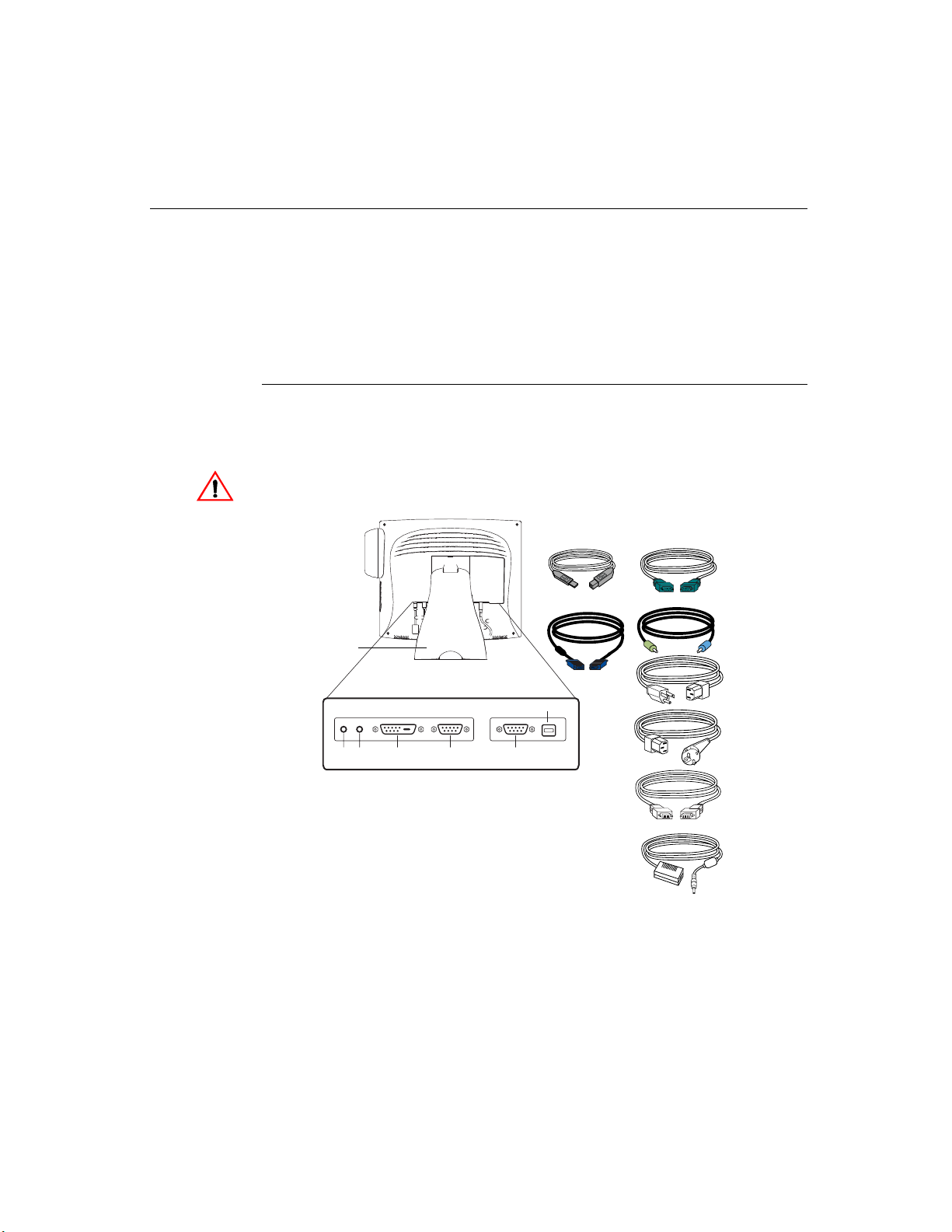

Unpacking Your Touchmonitor

Check that the following 9 items are present and in good condition:

C HAPTER

2

S

ETUP

LCD Display

Quick Install Guide

CD

Software

User Guide-on CD,

Quick Install Guide

and software CD

OR

Video cable

European monitor power cable

Speaker Cable

Adapter

Serial cableUSB touchscreen cable

DVI-D video

cable

Monitor power cable

(US/Canada)

2-3

Page 8

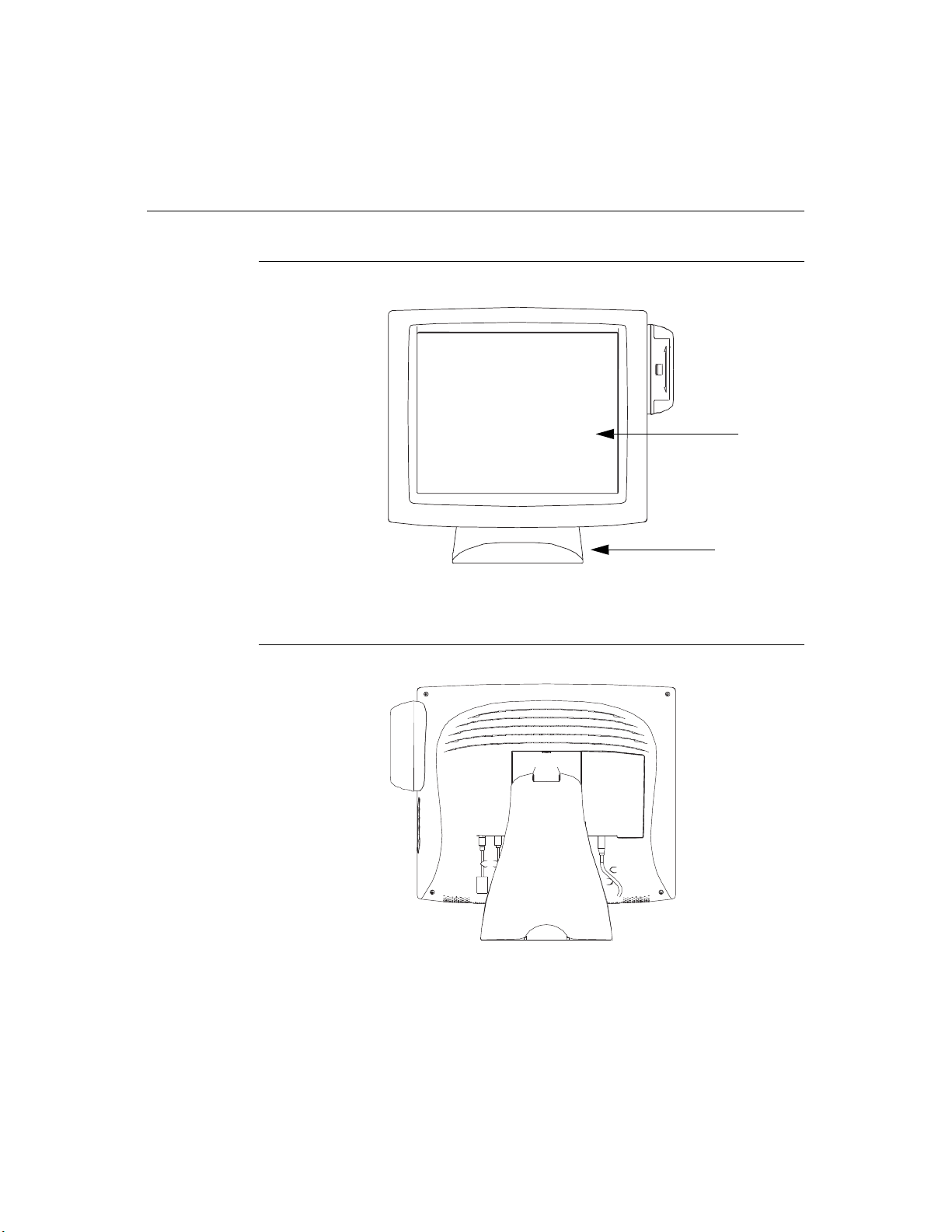

Product Overview

Main Unit

Rear View

LCD Display

Stand

2-4 Elo Entuitive Touchmonitor User Guide

Page 9

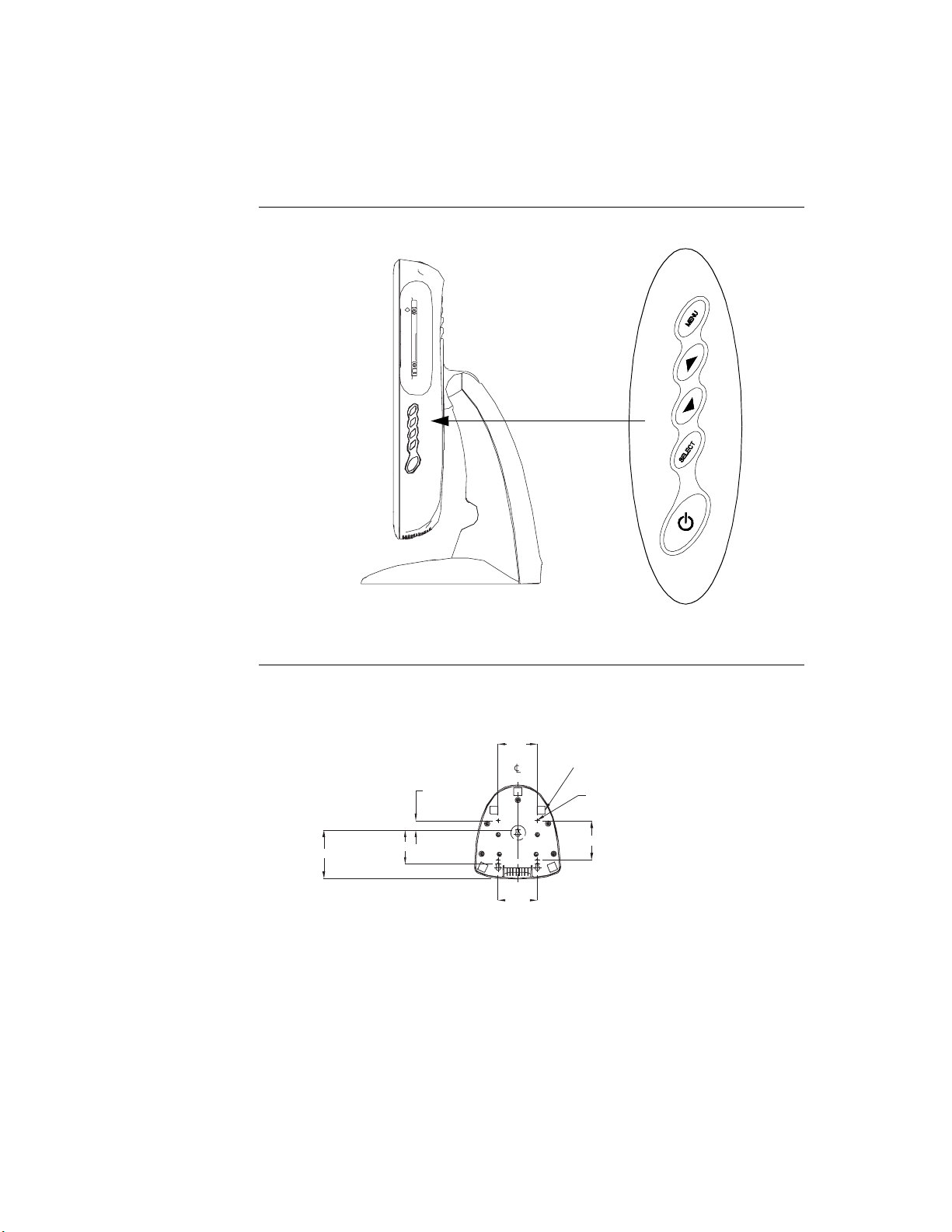

Side View

User Controls

Base Bottom View

123.2

86.6

23.6

100

5X Stability Pad

M5 Mounting Holes (4X)

100

100

Base Bottom

Scale 1:4

2-5

Page 10

Touch Interface Connection

N

OTE

:

Your interface cables may have been pre-connected to your monitor at the factory.

Your touchmonitor comes with one of the following touchscreen connector

cables: Serial (RS-232) cable or USB cable. (For Windows 98, 2000, Me and

XP systems only.)

To set up this display, please refer to the following figures and procedures:

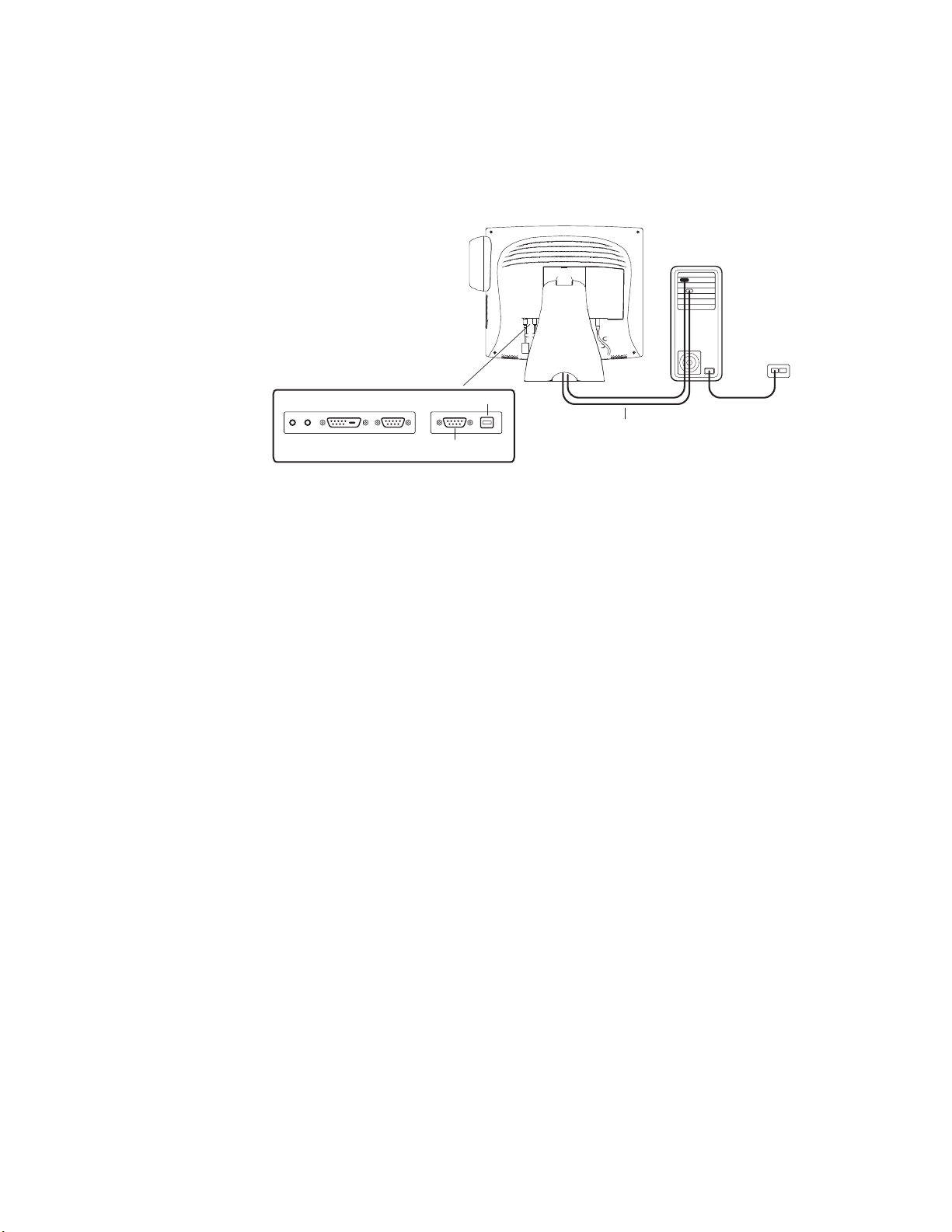

Serial or USB Connection

The following illustrations guide you step by step in connecting your

touchmonitor using a serial cable connection.

CAUTION

Before connecting the cables to your touchmonitor and PC, be sure that the computer

and the touchmonitor are turned off.

Removable back cover

USB cable

OR

Serial touchscreen

cable

Speaker cable

Connections on underside

Power Speaker

port

Female DVI-D

video connector

Female 15-pin

video connector

2-6 Elo Entuitive Touchmonitor User Guide

USB connector

Female 9-pin serial

Touchscreen connector

Video cable

Monitor

power cable

(US/Canada)

European monitor

pow

er cable

DVI-D cable

Adapter

Page 11

Removing the Back Cover

Bottom cut-out

• The cables are routed through the back of the stand.

• To remove the back cover, place one hand at the top of the stand and your

other hand on the bottom cut-out.

• Pull forward from the bottom cut-out and twist the cover until it snaps off.

The cable ports are located on the underside of your touchmonitor.

2-7

Page 12

Routing the Cables

• The cables are routed through the cable management channel in the stand.

2-8 Elo Entuitive Touchmonitor User Guide

Page 13

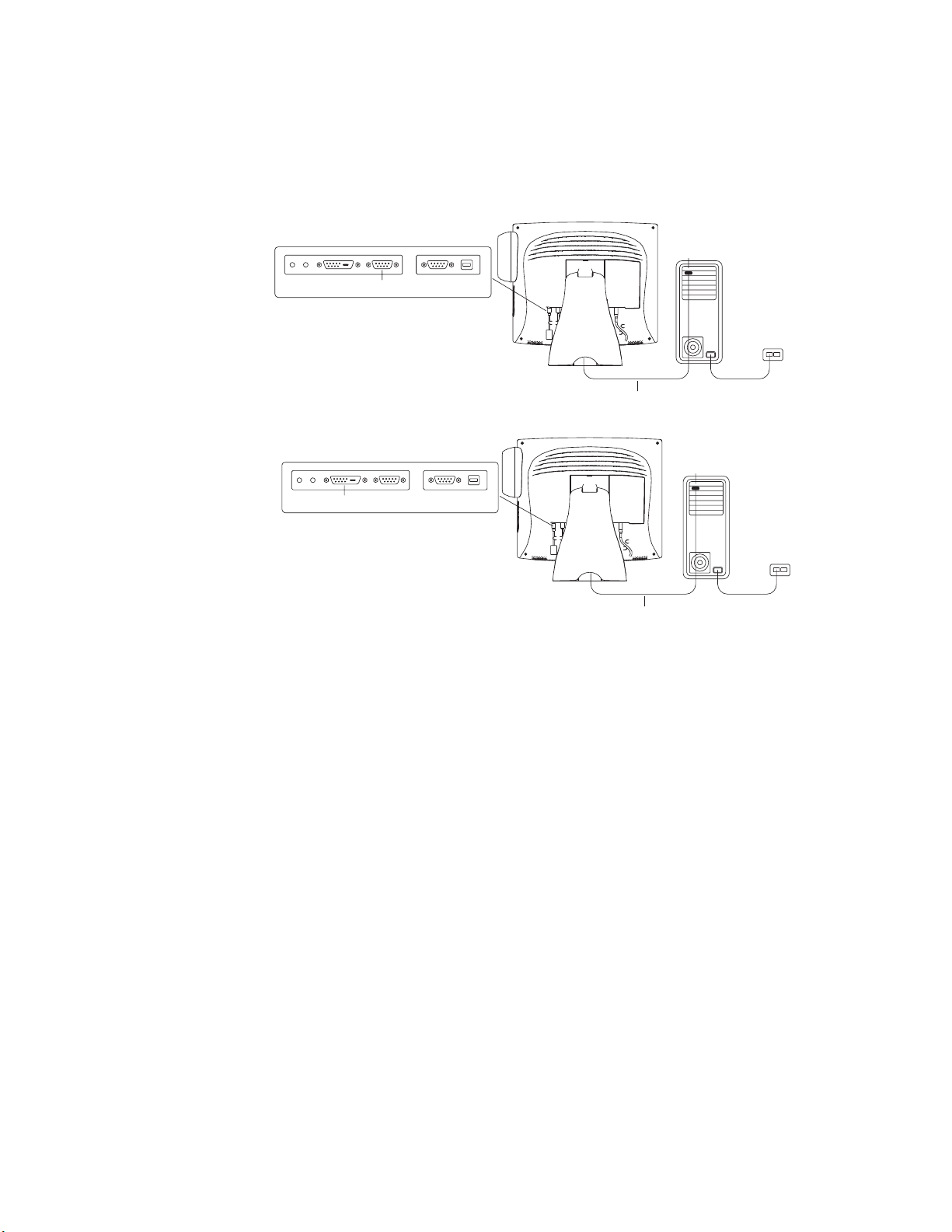

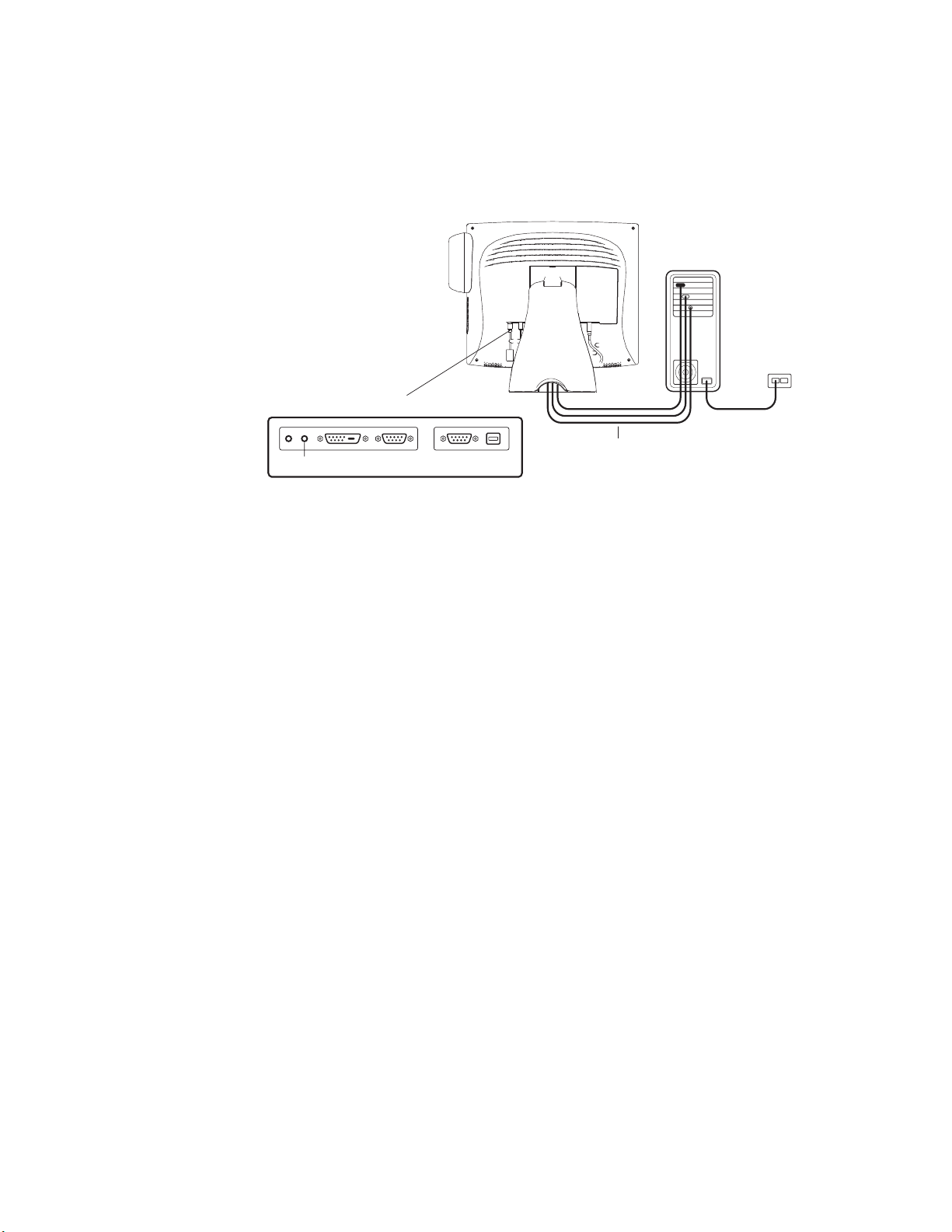

Connecting the Video Cable or DVI-D Video Cable

Connections on underside

Female 15 pin Video connector

Connections on underside

Female DVI-D Video connector

OR

Video cable

Video cable

Video cable

Video port

• Tilt the screen up and out (away from the stand) to access the connection

ports.

• Connect the 15-pin video cable (the ferrite bead end) or the 24-pin DVI-D

cable to the video port on your PC.

• Connect the other end of the video cable to the video connector on your

touchmonitor by routing the cable through the hole in the stand.

• Secure the cable to your touchmonitor and PC by turning the screws on the

connector clockwise.

• Place the cable in the cable management clip.

2-9

Page 14

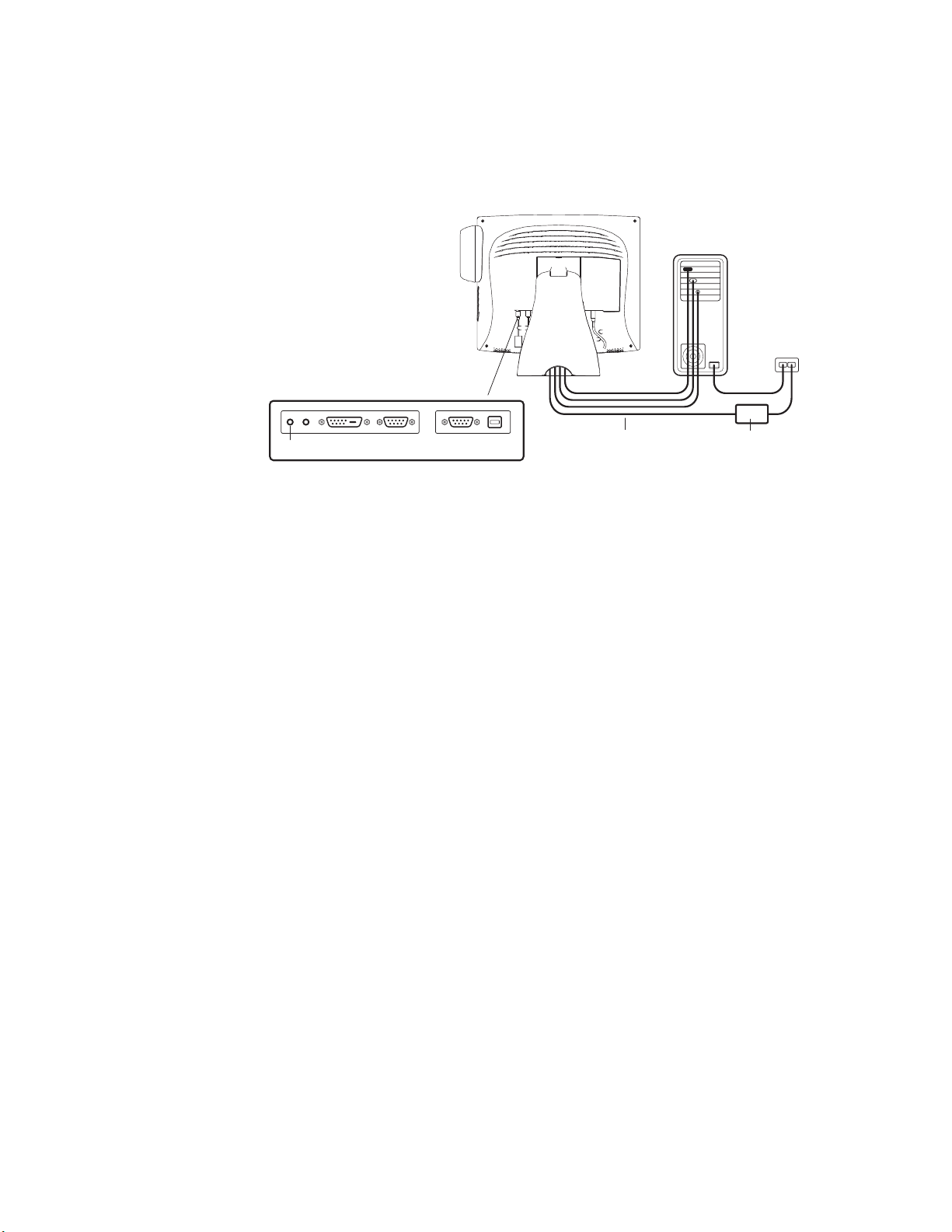

Connecting the Serial or USB Touchscreen Cable

Connections on underside

USB Touchscreen connector

Serial Touchscreen cable

Female 9-pin serial

Touchscreen connector

• Connect the female end of the serial (RS-232) cable to the serial port on the

back of your PC, or connect the USB touchscreen cable to the USB

touchscreen connector on the back of your touchmonitor.

• Connect the male end of the cable to the serial touchscreen connector on your

touchmonitor, or connect the other end of the USB touchscreen cable to your

PC.

• Secure the cable to your touchmonitor and PC by turning the screws on the

connector.

• Route the cable through the cable management clip.

2-10 Elo Entuitive Touchmonitor User Guide

Page 15

N

Connecting the Speaker Cable

CONNECTIONS ON UNDERSIDE

SPEAKER CABLE

Speaker port

OTE

:

If you do not wish to connect the speaker cable, go to step 5.

• To use the built in speakers, you need to connect the speaker cable. Connect

the light blue end of the speaker cable to thelight blue speaker port of the

touchmonitor (audio in).

• Connect the lime (light green) end of the speaker cable to the lime speaker

port on your PC (audio out).

2-11

Page 16

Connecting the Power Cable

Connections on Underside

N

Powe r

Power Ca ble

Depending on where you live, you will use either the European or US/Canadian

power cable.

• Connect the female end of the power cable to theBrick power supply.

• Connect the Brick power cable into the power port on the touchmonitor.

• Route the cable through the cable management clip.

OTE

:

To protect your equipment against risk of damage from electrical surges in the power

line, plug the touchmonitor’s power cord into a surge protector, and then connect the

surge protector to a grounded AC electrical outlet.

Replacing the Back Cover

When all the cables have been connected:

• Replace the back stand cover.

• Power on your PC then your touchmonitor. After a brief pause the picture

should appear.

• Tilt the screen up and back to access the connection ports.

• Connect the 15-pin video cable (the ferrite bead end) to the video port on

your PC.

Brick Power Supply

• Connect the other end of the video cable to the video connector on your

touchmonitor by routing the cable through the hole in the stand.

• Secure the cable to your touchmonitor and PC by turning the screws on the

connector clockwise.

• Place the cable in the cable management clip.

• Connect the other end of the USB touchscreen cable to your PC.

2-12 Elo Entuitive Touchmonitor User Guide

Page 17

Optimizing the LCD Display

To ensure the LCD display works well with your computer, configure the

display mode of your graphic card to make it less than or equal to 1024 x 768

resolution, and make sure the timing of the display mode is compatible with the

LCD display. Refer to Appendix A for more information about resolution.

Compatible video modes for your touchmonitor are listed in Appendix C.

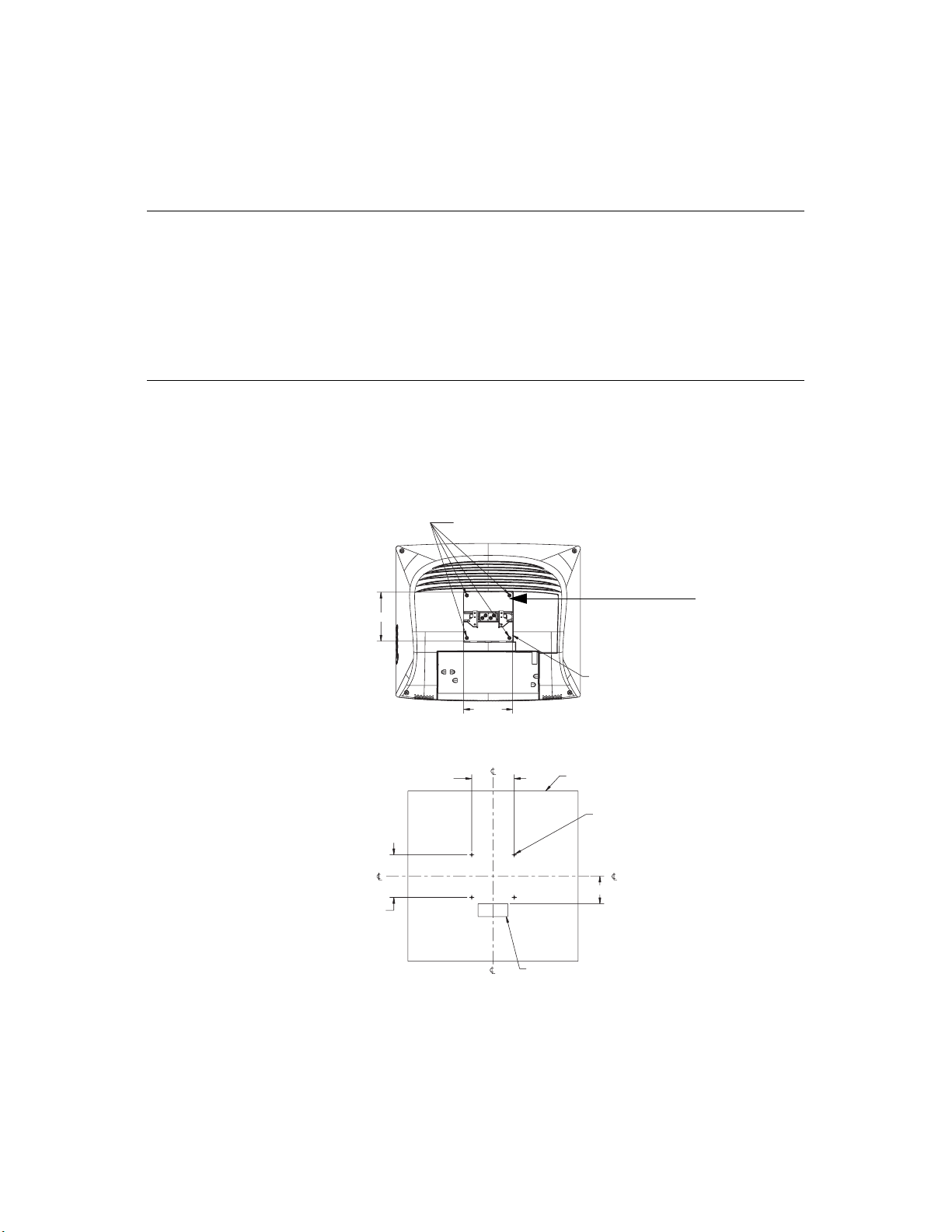

VESA Mount on Your Touchmonitor

Your touchmonitor conforms to the VESA Flat Panel Monitor Physical

Mounting Interface (FPMPMI™) Standard which defines a physical mounting

interface for flat panel monitors, and corresponding standards for flat panel

monitor mounting devices, such as wall and table arms. The VESA mounting

interface is located on the back of your touchmonitor and is shipped

pre-connected to the base.

Remove these four screws

(retain for reassembly)

115

VESA mounting

interface

N

VESA mounting surface is located

12mm below the surface of the

plastic.

115

Wall mount/Surface mount template

100

100

OTE

:

The above drawing displays the VESA mounting interface after the removal of the

Customer wall

(4X) M5

clearance hole

65

70 X 30 cable access hole

mounting cover and base.

2-13

Page 18

N

Accessing the VESA Mounting Interface

If you want to convert your desktop monitor to a wall mount or kiosk monitor,

follow the steps below to access the VESA mounting interface.

OTE

:

You will need a screwdriver for the following steps.

1 Remove the back cover of the stand by pulling forward on the bottom

cut-out.

2 Carefully lay the monitor face down. At the top of the mounting screw cover

there are two slots. With a screwdriver, pry open the mounting screw cover.

The cover fit is tight so remove it carefully.

3 When you remove the mounting screw cover, you will see four screws.

Remove the screws to mount your monitor. Refer to the drawing on page 18.

The following companies provide VESA mounting devices compatible with

your touchmonitor:

Ergotron

800-888-8458

651-681-7600

www.ergotron.com

GCX

800-228-2555

707-773-1100

www.gcx.com

Mounting the Base

You can also mount your touchmonitor by using the keyholes in the base of the

stand. These keyholes provide easy slide on mounting. You can also bolt your

touchmonitor to a tabletop or other flat surface. Please refer to Appendix C for

location and dimension of the mounting holes.

Innovative Office Products

800-524-2744

610-253-9554

www.innov-office-prod.com

MRI

800-688-2414

www.mediarecovery.com

2-14 Elo Entuitive Touchmonitor User Guide

Page 19

Installing the Driver Software

Elo TouchSystems provides driver software that allows your touchmonitor to

work with your computer. Drivers are located on the enclosed CD-ROM for the

following operating systems:

• Windows XP

• Windows 2000

• Windows Me

• Windows 98

• Windows 95

• Windows NT 4.0

Additional drivers and driver information for other operating systems are

available on the Elo TouchSystems web site at www.elotouch.com.

Your Elo touchmonitor is plug-and-play compliant. Information on the video

capabilities of your touchmonitor is sent to your video display adapter when

Windows starts. If Windows detects your touchmonitor, follow the instructions

on the screen to install a generic plug-and-play monitor.

Refer to the appropriate following section for driver installation instructions.

2-15

Page 20

N

Installing the Serial Touch Driver for Windows XP,

Windows 20001, Me, 95/98 and NT 4.0

OTE

:

For Windows 2000 and NT 4.0 you must have administrator access rights to install the

driver.

1 Insert the Elo CD-ROM in your computer’s CD-ROM drive.

If the AutoStart feature for your CD-ROM drive is active, the system

automatically detects the CD and starts the setup program.

2 Follow the directions on the screen to complete the driver setup for your

version of Windows.

If the AutoStart feature is not active:

1 Click Start > Run.

2 Click the Browse button to locate the EloCd.exe program on the CD-ROM.

3 Click Open, then OK to run EloCd.exe.

4 Follow the directions on the screen to complete the driver setup for your

version of Windows.

1.To install Windows 2000 and Windows XP, you must use the "update driver"

method; you will not find a setup.exe file within the download.

2-16 Elo Entuitive Touchmonitor User Guide

Page 21

Installing the Serial Touch Driver for MS-DOS and

Windows 3.1

You must have a DOS mouse driver (MOUSE.COM) installed for your mouse

if you wish to continue using your mouse along with your touchmonitor in

DOS.

To install Windows 3.x and MS-DOS from Windows 95/98, follow the

directions below:

1 Insert the Elo CD-ROM in your computer’s CD-ROM drive.

2 From DOS, type d:\EloDos_W31 to change to the correct directory on the

CD-ROM (your CD-ROM drive may be mapped to a different drive letter).

3 Type install and press Enter to start the installation.

4 Align the touchscreen.

You must have already completed Steps 1 and 2 before proceeding. Refer to

Chapter 2 of the Elo DOS and Windows Driver Guide as necessary for

additional installation information.

To run the INSTALL program:

1 Type INSTALL at the DOS prompt in the directory containing the driver

install files.

2 INSTALL asks you to select the software to install. Then choose

d:\EloDos_W31 from the displayed list.

3 INSTALL also asks you for the paths to use during installation, or you may

use its defaults. INSTALL creates directories as necessary, and warns you if

they exist.

If you are updating your software, you may wish to specify the paths containing

the earlier versions, and overwrite the obsolete files. All executable programs

are upward compatible. For a list of differences from each previous version of

the drivers, be sure to select "Differences from Previous Versions" during the

installation process.

INSTALL updates your AUTOEXEC.BAT file with the drivers you select.

INSTALL makes a copy of your original AUTOEXEC.BAT file, called

AUTOEXEC.OLD. If you already have Elo driver commands in your

AUTOEXEC.BAT file, they will be commented out.

When INSTALL is finished, it leaves a file called GO.BAT in the subdirectory

you specified. GO loads the touchscreen driver, runs the calibration program

ELOCALIB, and gives you some final instructions.

If you are using Windows 3.1, you will also calibrate the touchscreen within

Windows 3.1 with the Touchscreen Control Panel.

2-17

Page 22

Installing the USB Touch Driver

N

Installing the USB Touch Driver for Windows XP,

2

Windows 2000

1 Insert the Elo CD-ROM in your computer’s CD-ROM drive.

If Windows 98, Windows Me or Windows 2000 starts the Add New

Hardware Wizard:

2 Choose Next. Select “Search for the best driver for your device

(Recommended)” and choose Next.

3 When a list of search locations is displayed, place a checkmark on “Specify a

location” and use Browse to select the \EloUSB directory on the Elo

CD-ROM.

4 Choose Next. Once the Elo TouchSystems USB touchscreen driver has been

detected, choose Next again.

5 You will see several files being copied. Insert your Windows 98 CD if

prompted. Choose Finish.

If Windows 98, Windows Me or Windows 2000 does not start the Add New

Hardware Wizard:

OTE

:

For Windows 2000 you must have administrator access rights to install the driver.

1 Insert the Elo CD-ROM in your computer’s CD-ROM drive.

If the AutoStart feature for your CD-ROM drive is active, the system

automatically detects the CD and starts the setup program.

, Me and 98

2 Follow the directions on the screen to complete the driver setup for your

version of Windows.

If the AutoStart feature is not active:

1 Click Start > Run.

2 Click the Browse button to locate the EloCd.exe program on the CD-ROM.

3 Click Open, then OK to run EloCd.exe.

4 Follow the directions on the screen to complete the driver setup for your

version of Windows.

2.To install Windows 2000 and Windows XP, you must use the "update driver"

method; you will not find a setup.exe file within the download.

2-18 Elo Entuitive Touchmonitor User Guide

Page 23

About Touchmonitor Adjustments

Your touchmonitor will unlikely require adjustment. Variations in video output

and application may require adjustments to your touchmonitor to optimize the

quality of the display.

For best performance, your touchmonitor should be operating in native

resolution, that is 1280 x 1024 at 60-75 Hz. Use the Display control panel in

Windows to choose 1280 x 1024 resolution.

C HAPTER

3

C

HAPTER

3

O

PERATION

Operating in other resolutions will degrade video performance. For further

information, please refer to Appendix A.

All adjustments you make to the controls are automatically memorized. This

feature saves you from having to reset your choices every time you unplug or

power your touchmonitor off and on. If there is a power failure your

touchmonitor settings will not default to the factory specifications.

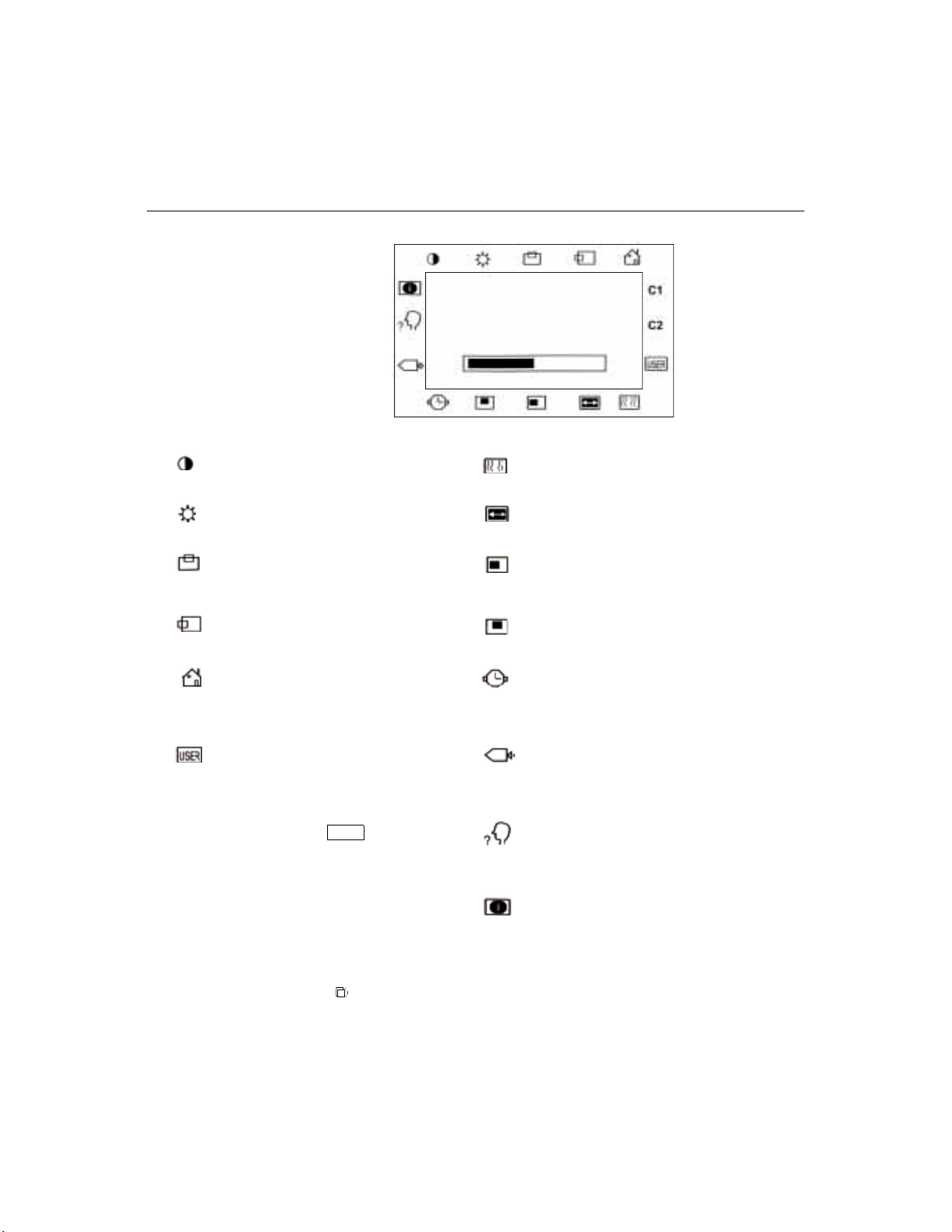

Using the On-Screen Display (OSD) Menus

All adjustments are made by using the on-screen display (OSD) menus. All

menu items can be selected by using the buttons on the side bezel.

N

OTE

:

OSD menu default is enabled.

3-19

Page 24

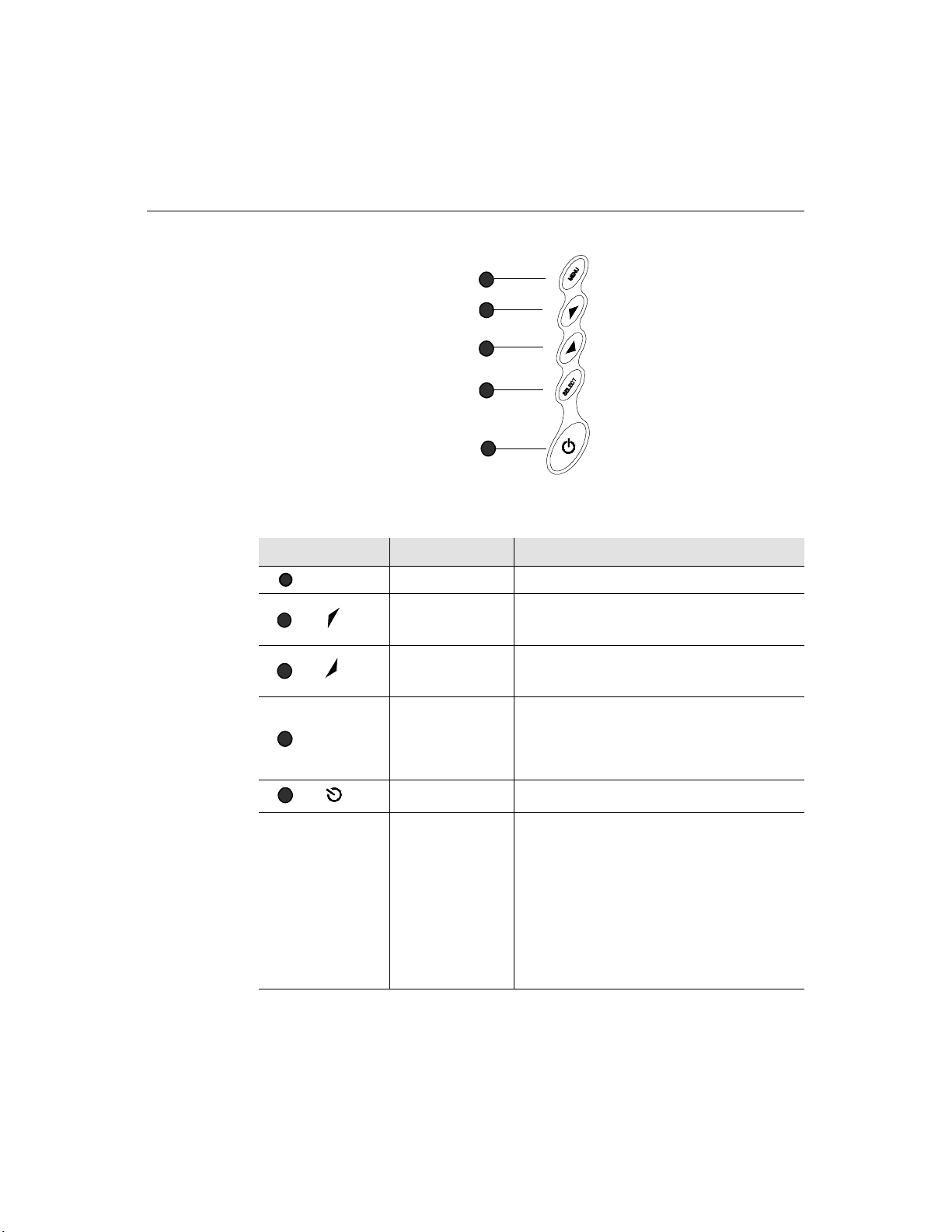

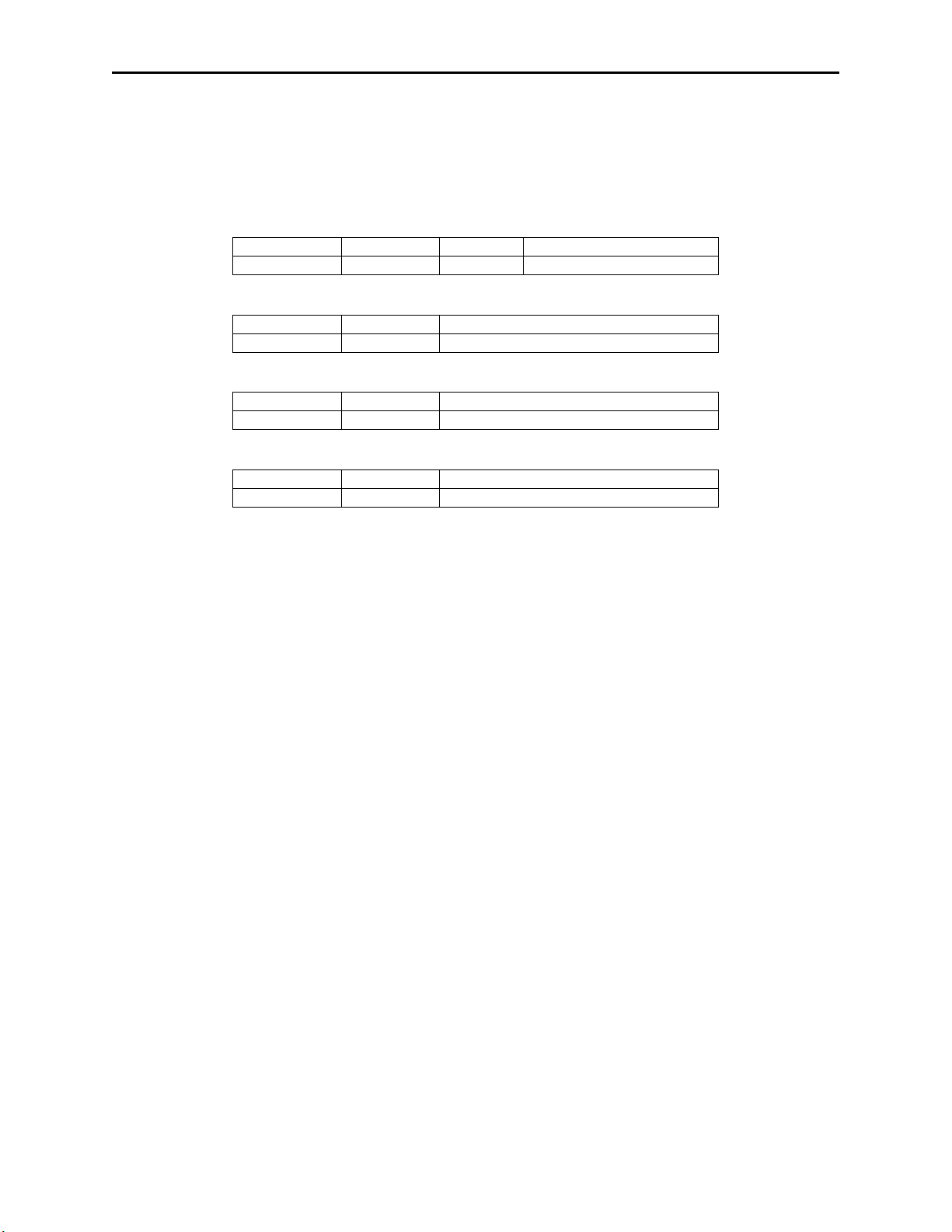

Side Bezel Buttons

MENU

1

2

3

SELECT

4

1

2

3

4

5

Control Function

Menu Display on exit the OSD menus.

Contrast/

Up/Toggle

Volume/Down

Toggle

Enter Select item

1. Shortcut to Contrast adjustment

2. Increase value of adjustment items

3. With menu on toggles OSD options

1. Shortcut to Volume adjustment

2. Decrease value of the adjustment items

3. With menu on toggles OSD options

1. Shortcut to Auto Adjust

2. Select- To select the adjustment items from the

OSD menus.

3. Auto- To activate the “Auto Adjustment”

function to obtain an optimum image.

5

3-20 Elo Entuitive Touchmonitor User Guide

Power Switch Switches the power on/off to your touchmonitor.

Enable/Disable 1. Press the Up and Down buttons at the same

time to enable/disable the MUTE functions. OSD

menu default is enabled

2. Press the Menu and Up buttons at the same

time and hold for two seconds to enable/disable

the OSD functions. OSD menu default is

enabled.

3. Press the Menu and Down buttons at the same

time and hold for two seconds to enable/disable

the power lock function. OSD menu default is

enabled.

Page 25

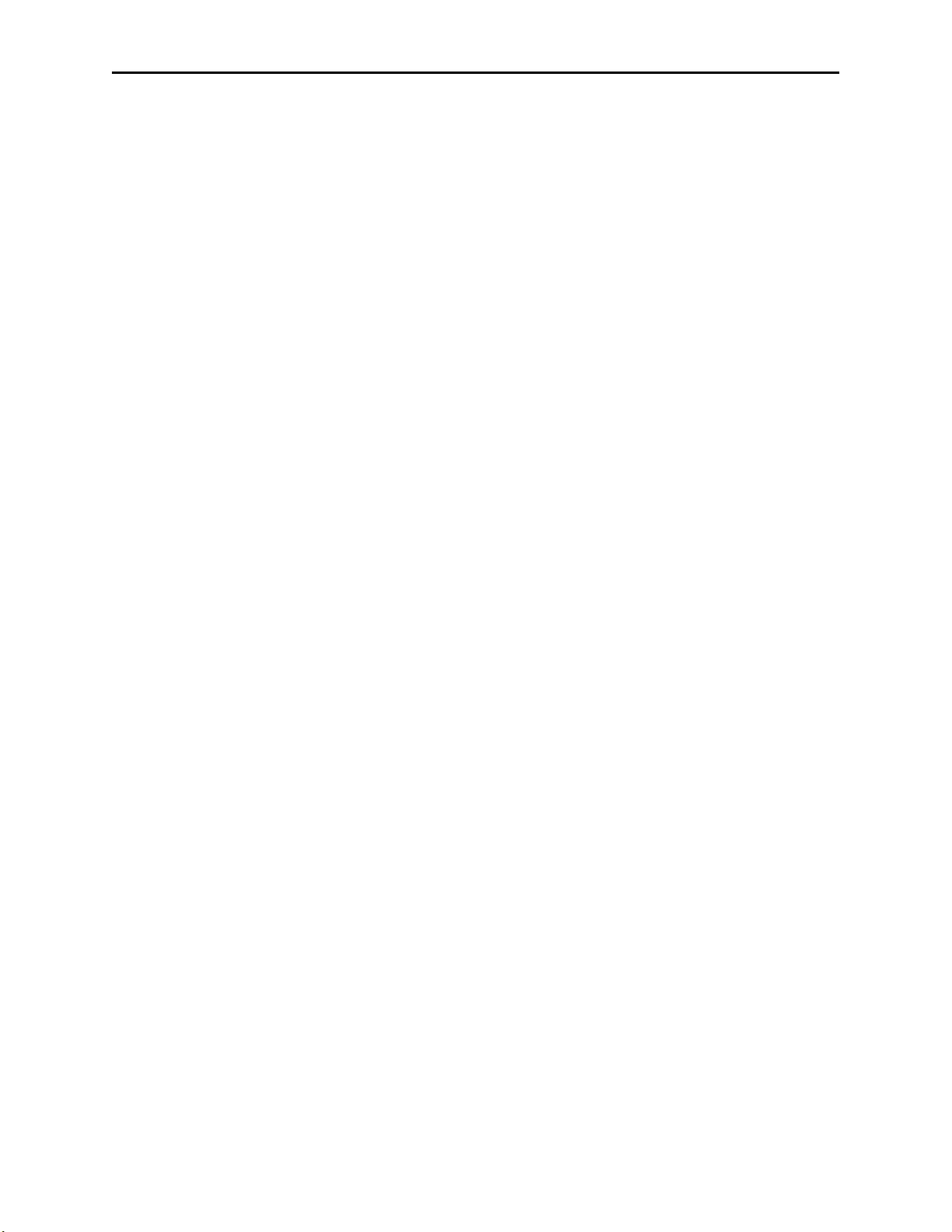

OSD Menu Function

CONTRAST

50

Contrast

Controls the picture contrast

Brightness

Controls the picture brightness

V-Position

Controls the vertical position

H-Position

Controls the horizontal position

Recall Defaults

Recalls factory settings of the image

parameters

C1/C2/USER (Color)

Using these icons, you can select one of

the preset color temperatures (9300°K or

6500°K). Confirm your choice by

pressing the SELECT button. If you

want to change the color temperatures

individually, select USER and confirm by

pressing the OSD button SELECT. Now

you can use the OSD dial to toggle

between the settings R, G and B (red,

green and blue foreground). To change a

setting, first press the SELECT button,

then choose the desired value with the

OSD dial. To confirm the setting, press

the SELECT button again.

If you don’t need to adjust any further

settings, choose the

icon to return to the OSD main menu.

Phase

Controls the vertical fine adjustment

Clock

Controls the horizontal fine adjustment

OSD H-Position

Adjusts the horizontal position of the OSD

menu

OSD V-Position

Adjust the vertical position of the OSD menu

OSD Time

Determines how long (in seconds) the OSD

menu waits before closing automatically after

no action has been performed.

Auto Adjust

Automatically selects the optional settings for

image parameters (brightness, contrast, image

position, phase, etc.)

OSD Language

Selection of the OSD menu language: English,

French, German, Spanish, Japanese.

Image Information

Displays the current graphics mode.

3-21

Page 26

3-22 Elo Entuitive Touchmonitor User Guide

Page 27

If you are experiencing trouble with your touchmonitor, refer to the following

table. If the problem persists, please contact your local dealer or our service

center.

Solutions to Common Problems

Problem Suggestion(s)

C HAPTER

4

C

HAPTER

4

T

ROUBLESHOOTING

No image appears on screen. Check that all the I/O and power connectors are properly

“Out of Range” display Check to see if the resolution of your computer is higher

connected as described in Chapter 2.

Make sure the pins of the connectors are not crooked or

broken.

Test power supply by trying different cables, a different

wall outlet or plug another appliance into the outlet.

Make certain the video cable is properly connected and that

it is not damaged. Check for bent pins on the cable

connectors.

Ensure that your computer and video card are properly

configured. (Consult video card documentation.)

than that of the LCD display.

Reconfigure the resolution of your computer to make it less

than or equal to

information on resolution.

1280 x 1024. See Appendix A for more

4-23

Page 28

Image has vertical flickering line bars. Use “PHASE” to make an adjustment.

Check and reconfigure the display mode of the vertical

refresh rate of your graphic card to make it compatible with

the LCD display.

Image is unstable and flickering Use “CLOCK” to make an adjustment.

Image is scrolling Make sure the VGA signal cable (or adapter) is well

connected.

Check and reconfigure the display mode of the vertical

refresh rate of your graphic card to make it compatible with

the LCD display.

Touch doesn’t work Make sure cable is securely attached at both ends.

4-24 Elo Entuitive Touchmonitor User Guide

Page 29

A PPENDIX

A

C

HAPTER

4

N

ATIVE

The native resolution of a monitor is the resolution level at which the LCD

panel is designed to perform best. For the Elo LCD touchmonitor, the native

resolution is 1280 x 1024 for the SXGA-17 inch size. In almost all cases, screen

images look best when viewed at their native resolution. You can lower the

resolution setting of a monitor but not increase it.

Input Video 17" LCD

640x480 (VGA) Transforms input format to 1280x1024

800x600 (SVGA) Transforms input format to 1280x1024

1024x768 (XGA) Transforms input format to 1280x1024

1280x1024 (SXGA) Displays in Native Resolution

R

ESOLUTION

The native resolution of an LCD is the actual number of pixels horizontally in

the LCD by the number of pixels vertically in the LCD. LCD resolution is

usually represented by the following symbols:

VGA

SVGA

XGA

SXGA

UXGA

640x480

800x600

1024x768

1280x1024

1600x1200

A-25

Page 30

As an example, a SVGA resolution LCD panel has 800 pixels horizontally by

600 pixels vertically. Input video is also represented by the same terms. XGA

input video has a format of 1024 pixels horizontally by 768 pixels vertically.

When the input pixels contained in the video input format match the native

resolution of the panel, there is a one to one correspondence of mapping of input

video pixels to LCD pixels. As an example, the pixel in column 45 and row 26

of the input video is in column 45 and row 26 of the LCD. For the case when

the input video is at a lower resolution than the native resolution of the LCD, the

direct correspondence between the video pixels and the LCD pixels is lost. The

LCD controller can compute the correspondence between video pixels and LCD

pixels using algorithms contained on its controller. The accuracy of the

algorithms determines the fidelity of conversion of video pixels to LCD pixels.

Poor fidelity conversion can result in artifacts in the LCD displayed image such

as varying width characters.

A-26 Elo Entuitive Touchmonitor User Guide

Page 31

A PPENDIX

B

C

HAPTER

4

T

OUCHMONITOR

This manual contains information that is important for the proper setup and

maintenance of your touchmonitor. Before setting up and powering on your new

touchmonitor, read through this manual, especially Chapter 2 (Installation), and

Chapter 3 (Operation).

1 To reduce the risk of electric shock, follow all safety notices and never open

the touchmonitor case.

2 Turn off the product before cleaning

S

AFETY

3 Your new touchmonitor is equipped with a 3-wire, grounding power cord.

The power cord plug will only fit into a grounded outlet. Do not attempt to fit

the plug into an outlet that has not been configured for this purpose. Do not

use a damaged power cord. Use only the power cord that comes with your

Elo TouchSystems Touchmonitor. Use of an unauthorized power cord may

invalidate your warranty.

4 The slots located on the sides and top of the touchmonitor case are for

ventilation. Do not block or insert anything inside the ventilation slots.

5 It is important that your touchmonitor remains dry. Do not pour liquid into or

onto your touchmonitor. If your touchmonitor becomes wet do not attempt to

repair it yourself.

B-27

Page 32

Care and Handling of Your Touchmonitor

The following tips will help keep your Elo Entuitive touchmonitor functioning

at the optimal level.

• To avoid risk of electric shock, do not disassemble the brick supply or

display unit cabinet. The unit is not user serviceable. Remember to unplug

the display unit from the power outlet before cleaning.

• Do not use alcohol (methyl, ethyl or isopropyl) or any strong dissolvent. Do

not use thinner or benzene, abrasive cleaners or compressed air.

• To clean the display unit cabinet, use a cloth lightly dampened with a mild

detergent.

• Avoid getting liquids inside your touchmonitor. If liquid does get inside,

have a qualified service technician check it before you power it on again.

• Do not wipe the screen with a cloth or sponge that could scratch the surface.

• To clean the touchscreen, use window or glass cleaner. Put the cleaner on the

rag and wipe the touchscreen. Never apply the cleaner directly on the

touchscreen

B-28 Elo Entuitive Touchmonitor User Guide

Page 33

A PPENDIX

C

C

HAPTER

0

T

ECHNICAL

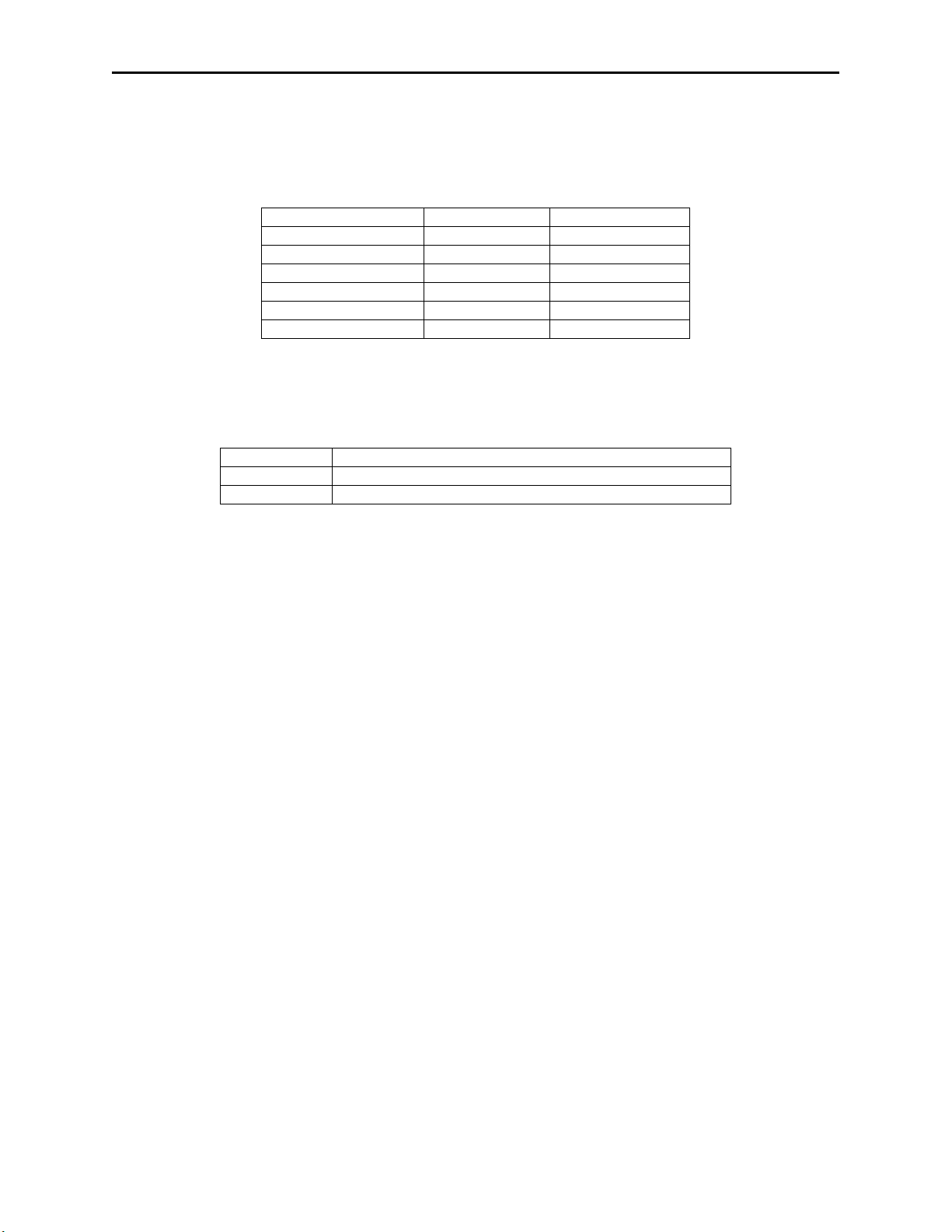

Compatible Video Modes

Your Elo Entuitive touchmonitor is compatible with the following standard

video modes:

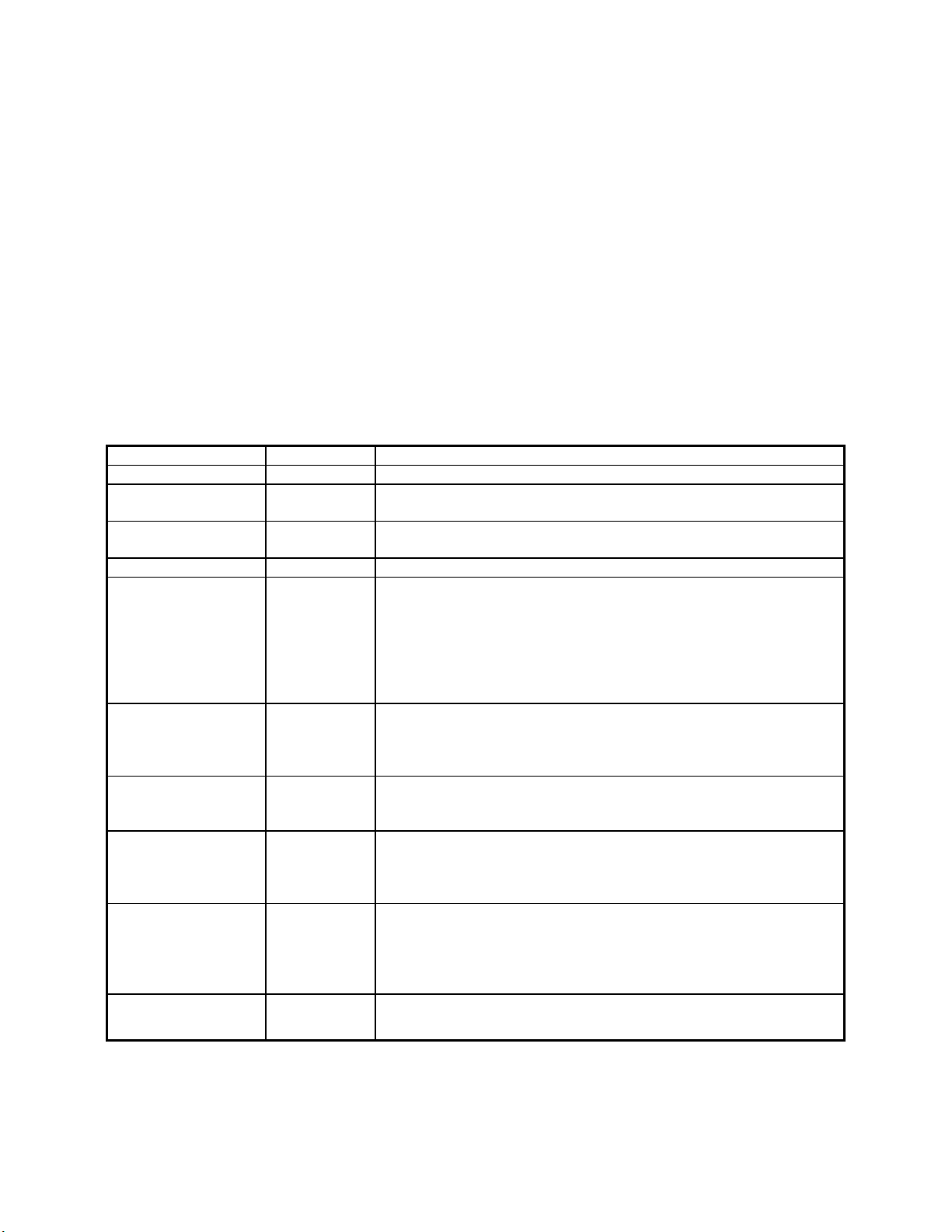

Mode Resolution H. Frequency (kHz) V. Frequency (Hz)

IBM & VESA VGA 720 x 400 31.47 70.09

IBM & VESA VGA 640 x 480 31.47 59.94

IBM & VESA VGA 640 x 480 37.86 72.81

IBM & VESA VGA 640 x 480 37.50 75.00

VESA SVGA 800 x 600 35.16 56.25

VESA SVGA 800 x 600 37.88 60.32

VESA SVGA 800 x 600 48.08 72.19

VESA SVGA 800 x 600 46.88 75.00

VESA XGA 1024 x 768 48.36 60.00

VESA XGA 1024 x 768 56.48 70.07

VESA XGA 1024 x 768 60.02 75.03

VESA SXGA 1280 x 1024 64 60

VESA SXGA 1280 x 1024 80 75

VESA SXGA 1152 x 864 67.5 75

Apple Macintosh 16” 832 x 624 49.73 74.55

NEC FC-98 series 640 x 400 24.83 56.42

NEC FC-98 series 640 x 400 31.47 70.01

NEC FC-98 series 640 x 480 31.47 59.94

S

PECIFICATIONS

C-29

Page 34

Touchmonitor Specifications

17" LCD Touchmonitor (ET17-XXWF-1) Specifications

Display Type

Size

Pixel Format

Touchscreen

Colors

Display Brightness

Back-light Lamp Life

Viewing Angle

(typical) (CR=10)

Viewing Angle

(typical) (CR=5)

Contrast Ratio

Display Response

Time

Environmental

Humidity

Mechanical

Active matrix, thin film transistor

(TFT), liquid crystal display

17-inch diagonal Horizontal: 13.3” (338mm) useful screen

area

Vertical: 10.6” (270mm) useful screen

area

1280 x 1024

0.125-inch IntelliTouch and

AccuTouch, anti-glare

IntelliTouch or AccuTouch

16.7 million with dithering, 6 bits

per color data

250 cd/m² typical AccuTouch: 205 cd/m² typical

IntelliTouch: 230 cd/m² typical

typical 40,000 hours to half

brightness

Horizontal

Vertical

Horizontal

Vertical

450:1 typical

16 msec (typical)

Operating Temp

Storage Temp

Operating Temp

Storage Temp

Weight 21.6 lbs. (9.82 kg.) maximum approx.

Size See drawings in this Appendix.

±70° or 140° total

±70° or 140° total

±80° or 160° total

±80° or 160° total

0°C to 40°C

-20°C to +60°C

20%-80%

5%-95% noncondensing

weight for IntelliTouch and AccuTouch

Electrical

Speakers

Agencies

C-30 Elo Entuitive Touchmonitor User Guide

Input Video

Input Power

Power Dissipation

8 ohms, 1 watt per speaker

Safety & EMC UL, cUL, FCC-B, IC, CE, TÜV-GS,

Analog (no proprietary video card

needed); Digital Video Input (DVI-D)

100-240 VAC, 50/60 Hz.

45 W max.

VCCI, and C-Tick

Page 35

IntelliTouch Touchmonitor Specifications

Mechanical

Positional Accuracy

Touchpoint Density

Touch Activation Force

Surface Durability

Expected Life Performance

Sealing

Optical

Light Transmission (per ASTM

D1003)

Visual Resolution

Gloss (per ASTM D2457 using a

60-degree gloss meter)

Environmental

Chemical Resistance

Electrostatic Protection

(per EN 61 000-4-2, 1995)

Standard deviation of error is less than 0.080 in. (2.03 mm). Equates to

less than ±1%.

More than 100,000 touchpoints/in2 (15,500 touchpoints/cm2).

Typically less than 3 ounces (85 grams).

Surface durability is that of glass, Mohs’ hardness rating of 7.

No known wear-out mechanism, as there are no layers, coatings, or

moving parts. IntelliTouch technology has been operationally tested to

more than 50 million touches in one location without failure, using a

stylus similar to a finger.

Unit is sealed to protect against splashed liquids, dirt, and dust.

90%

All measurements made using USAF 1951 Resolution Chart, under 30X

magnification, with test unit located approximately 1.5 in (38 mm) from

surface of resolution chart.

Clear surface: Excellent, with no noticeable degradation.

Antiglare surface: 6:1 minimum.

Antiglare surface: Curved: 60 ± 20 gloss units or 75 ± 15 gloss units.

The active area of the touchscreen is resistant to all chemicals that do

not affect glass, such as:

Acetone

Toluene

Methyl ethyl ketone

Isopropyl alcohol

Methyl alcohol

Ethyl acetate

Ammonia-based glass cleaners

Gasoline

Kerosene

Vinegar

Meets Level 4 (15 kV air/8 kV contact discharges).

C-31

Page 36

AccuTouch Touchmonitor Specifications

Mechanical

Construction

Positional Accuracy

Touchpoint Density

Touch Activation Force

Surface Durability

Expected Life

Performance

Optical

Light Transmission

(per ASTM D1003)

Visual Resolution

Haze (per ASTM D1003)

Gloss (per ASTM D2457)

Top: Polyester with outside hard-surface coating with clear or antiglare

finish.

Inside: Transparent conductive coating.

Bottom: Glass substrate with uniform resistive coating. Top and bottom

layers separated by Elo-patented separator dots.

Standard deviation of error is less than 0.080 in. (2.03 mm). This equates to

less than ±1%.

More than 100,000 touchpoints/in² (15,500 touchpoints/cm²).

Typically less than 4 ounces (113 grams).

Meets Taber Abrasion Test (ASTM D1044), CS-10F wheel, 500 g. Meets

pencil hardness 3H.

AccuTouch technology has been operationally tested to greater than 35

million touches in one location without failure, using a stylus similar to a

finger.

Typically 75% at 550-nm wavelength (visible light spectrum).

All measurements made using USAF 1951 Resolution Chart, under 30 X

magnification, with test unit located approximately 1.5 in. (38 mm) from

surface of resolution chart.

Antiglare surface: 6:1 minimum.

Antiglare surface: Less than 15%.

Antiglare surface: 90 ± 20 gloss units tested on a hard-coated front surface.

C-32 Elo Entuitive Touchmonitor User Guide

Page 37

17" LCD Touchmonitor Dimensions

478

434

338

429

370

43

270.3

219

C-33

Page 38

67.7

See Detail A

123.2

See Detail A

86.6

23.6

100

100

Base Bottom

Scale 1:4

239

5X Stability Pad

M5 Mounting Holes (4X)

100

279

10.8

Detail A

Detail A

Scale 1:1

6.5

R3.25

R6.25

C-34 Elo Entuitive Touchmonitor User Guide

Page 39

C

HAPTER

0

R

EGULATORY INFORMATION

I. Electrical Safety Information:

A) Compliance is required with respect to the voltage, frequency, and current

requirements indicated on the manufacturer’s label. Connection to a different

power source than those specified herein will likely result in improper operation,

damage to the equipment or pose a fire hazard if the limitations are not followed.

B) There are no operator serviceable parts inside this equipment. There are hazardous voltages generated by this equipment which constitute a safety hazard. Service

should be provided only by a qualified service technician.

C) This equipment is provided with a detachable power cord which has an integral

safety ground wire intended for connection to a grounded safety outlet.

1) Do not substitute the cord with other than the provided approved type.

Under no circumstances use an adapter plug to connect to a 2-wire outlet as

this will defeat the continuity of the grounding wire.

2) The equipment requires the use of the ground wire as a part of the safety

certification, modification or misuse can provide a shock hazard that can

result in serious injury or death.

3) Contact a qualified electrician or the manufacturer if there are questions

about the installation prior to connecting the equipment to mains power.

II. Emissions and Immunity Information

A) Notice to Users in the United States: This equipment has been tested and found

to comply with the limits for a Class B digital device, pursuant to Part 15 of FCC

Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy, and if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

B) Notice to Users in Canada: This equipment complies with the Class B limits for

radio noise emissions from digital apparatus as established by the Radio Interference Regulations of Industrie Canada.

C) Notice to Users in the European Union: Use only the provided power cords and

interconnecting cabling provided with the equipment. Substitution of provided

cords and cabling may compromise electrical safety or CE Mark Certification for

emissions or immunity as required by the following standards:

35

Page 40

This Information Technology Equipment (ITE) is required to have a CE Mark

on the manufacturer’s label which means that the equipment has been tested

to the following Directives and Standards:

This equipment has been tested to the requirements for the CE Mark as

required by EMC Directive 89/336/EEC indicated in European Standard EN

55 022 Class B and the Low Voltage Directive 73/23/EEC as indicated in

European Standard EN 60 950.

D) General Information to all Users: This equipment generates, uses and can radiate radio frequency energy. If not installed and used according to this manual the

equipment may cause interference with radio and television communications.

There is, however, no guarantee that interference will not occur in any particular

installation due to site-specific factors.

1) In order to meet emission and immunity requirements, the user must

observe the following:

a) Use only the provided I/O cables to connect this digital device with

any computer.

b) To ensure compliance, use only the provided manufacturer’s approved

line cord.

c) The user is cautioned that changes or modifications to the equipment

not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

2) If this equipment appears to cause interference with radio or television

reception, or any other device:

a) Verify as an emission source by turning the equipment off and on.

b) If you determine that this equipment is causing the interference, try to

correct the interference by using one or more of the following measures:

i) Move the digital device away from the affected receiver.

ii) Reposition (turn) the digital device with respect to the affected

receiver.

iii) Reorient the affected receiver’s antenna.

iv) Plug the digital device into a different AC outlet so the digital

device and the receiver are on different branch circuits.

v) Disconnect and remove any I/O cables that the digital device

does not use. (Unterminated I/O cables are a potential source of

high RF emission levels.)

vi) Plug the digital device into only a grounded outlet receptacle.

Do not use AC adapter plugs. (Removing or cutting the line cord

ground may increase RF emission levels and may also present a

lethal shock hazard to the user.)

If you need additional help, consult your dealer, manufacturer, or an experienced radio or television technician.

36 Elo Entuitive Touchmonitor User Guide

Page 41

N10051

37

Page 42

38 Elo Entuitive Touchmonitor User Guide

Page 43

C

HAPTER

0

W

ARRANTY

Except as otherwise stated herein or in an order acknowledgment delivered to

Buyer, Seller warrants to Buyer that the Product shall be free of defects in

materials and workmanship. The warranty for the touchmonitors and

components of the product is 1 year.

Seller makes no warranty regarding the model life of components. Seller’s

suppliers may at any time and from time to time make changes in the

components delivered as Products or components.

Buyer shall notify Seller in writing promptly (and in no case later than thirty

(30) days after discovery) of the failure of any Product to conform to the

warranty set forth above; shall describe in commercially reasonable detail in

such notice the symptoms associated with such failure; and shall provide to

Seller the opportunity to inspect such Products as installed, if possible. The

notice must be received by Seller during the Warranty Period for such product,

unless otherwise directed in writing by the Seller. Within thirty (30) days after

submitting such notice, Buyer shall package the allegedly defective Product in

its original shipping carton(s) or a functional equivalent and shall ship to Seller

at Buyer’s expense and risk.

Within a reasonable time after receipt of the allegedly defective Product and

verification by Seller that the Product fails to meet the warranty set forth above,

Seller shall correct such failure by, at Seller’s options, either (i) modifying or

repairing the Product or (ii) replacing the Product. Such modification, repair, or

replacement and the return shipment of the Product with minimum insurance to

Buyer shall be at Seller’s expense. Buyer shall bear the risk of loss or damage in

transit, and may insure the Product. Buyer shall reimburse Seller for

transportation cost incurred for Product returned but not found by Seller to be

defective. Modification or repair, of Products may, at Seller’s option, take place

either at Seller’s facilities or at Buyer’s premises. If Seller is unable to modify,

repair, or replace a Product to conform to the warranty set forth above, then

Seller shall, at Seller’s option, either refund to Buyer or credit to Buyer’s

account the purchase price of the Product less depreciation calculated on a

straight-line basis over Seller’s stated Warranty Period.

39

Page 44

THESE REMEDIES SHALL BE THE BUYER’S EXCLUSIVE REMEDIES

FOR BREACH OF WARRANTY. EXCEPT FOR THE EXPRESS

WARRANTY SET FORTH ABOVE, SELLER GRANTS NO OTHER

WARRANTIES, EXPRESS OR IMPLIED BY STATUTE OR OTHERWISE,

REGARDING THE PRODUCTS, THEIR FITNESS FOR ANY PURPOSE,

THEIR QUALITY, THEIR MERCHANTABILITY, THEIR

NONINFRINGEMENT, OR OTHERWISE. NO EMPLOYEE OF SELLER

OR ANY OTHER PARTY IS AUTHORIZED TO MAKE ANY WARRANTY

FOR THE GOODS OTHER THAN THE WARRANTY SET FORTH

HEREIN. SELLER’S LIABILITY UNDER THE WARRANTY SHALL BE

LIMITED TO A REFUND OF THE PURCHASE PRICE OF THE PRODUCT.

IN NO EVENT SHALL SELLER BE LIABLE FOR THE COST OF

PROCUREMENT OR INSTALLATION OF SUBSTITUTE GOODS BY

BUYER OR FOR ANY SPECIAL, CONSEQUENTIAL, INDIRECT, OR

INCIDENTAL DAMAGES.

Buyer assumes the risk and agrees to indemnify Seller against and hold Seller

harmless from all liability relating to (i) assessing the suitability for Buyer’s

intended use of the Products and of any system design or drawing and (ii)

determining the compliance of Buyer’s use of the Products with applicable

laws, regulations, codes, and standards. Buyer retains and accepts full

responsibility for all warranty and other claims relating to or arising from

Buyer’s products, which include or incorporate Products or components

manufactured or supplied by Seller. Buyer is solely responsible for any and all

representations and warranties regarding the Products made or authorized by

Buyer. Buyer will indemnify Seller and hold Seller harmless from any liability,

claims, loss, cost, or expenses (including reasonable attorney’s fees) attributable

to Buyer’s products or representations or warranties concerning same.

40 Elo Entuitive Touchmonitor User Guide

Page 45

Index

Numerics

17" LCD Touchmonitor (ET17-XXWF-1) Specifications, 30

17" LCD Touchmonitor Dimensions, 33

A

About the Product, 1

About Touchmonitor Adjustments, 19

Accessing the VESA Mounting Interface, 14

AccuTouch Touchmonitor Specifications, 32

Agencies, 30

Auto Adjust, 21

B

Back-light Lamp Life, 30

Base Bottom View, 5

Brightness, 21

C

C1/C2/USER (Color), 21

Care and Handling of Your Touchmonitor, 28

Chemical Resistance, IntelliTouch, 31

Cleaning Your Touchmonitor, 28

Clock, 21

Colors, 30

Compatible Video Modes, 29

Connecting the Power Cable, 12

Connecting the Serial or USB Touchscreen Cable, 10

Connecting the Speaker Cable, 11

Connecting the Video Cable or DVI-D Video Cable, 9

Construction, AccuTouch, 32

Contrast, 20, 21

Contrast Ratio, 30

D

Display Brightness, 30

Display Response Time, 30

Display Type, 30

E

Electrical, 30

Electrical Safety Information, 35

Electrostatic Protection, IntelliTouch, 31

Emissions and Immunity Information, 35

Enable/Disable, 20

Environmental, 30, 31

Ergotron, 14

Expected Life Performance, AccuTouch, 32

Expected Life Performance, IntelliTouch, 31

G

GCX, 14

Gloss, AccuTouch, 32

Gloss, IntelliTouch, 31

H

Haze, AccuTouch, 32

H-Position, 21

Humidity, 30

I

Image Information, 21

Image problem, 23

Image, scrolling, 24

Image, unstable, 24

Image, vertical flickering, 24

Innovative Office Products, 14

Installation and Setup, 3

Installing the Driver Software, 15

Installing the Serial Touch Driver for MS-DOS and

Windows 3.1, 17

Installing the Serial Touch Driver for Windows XP,

Windows 2000, Me, 95/98 and NT 4.0, 16

Installing the USB Touch Driver, 18

Installing the USB Touch Driver for Windows XP, Windows

2000, Me and 98, 18

IntelliTouch Touchmonitor Specifications, 31

Introduction, 1

L

Light Transmission, AccuTouch, 32

Light Transmission, IntelliTouch, 31

M

Main Unit, 4

Mechanical, 30

Mechanical, AccuTouch, 32

Mechanical, IntelliTouch, 31

Menu, 20

Minus Counter-clockwise, 20

Mounting the Base, 14

MRI, 14

Index-41

Page 46

N

Native Resolution, 25

O

Operation, 19

Optical, AccuTouch, 32

Optical, IntelliTouch, 31

Optimizing the LCD Display, 13

OSD H-Position, 21

OSD Language, 21

OSD Menu Function, 21

OSD Time, 21

OSD V-Position, 21

Out of Range display, 23

P

Phase, 21

Pixel Format, 30

Plus/Clockwise, 20

Positional Accuracy, AccuTouch, 32

Positional Accuracy, IntelliTouch, 31

Power Switch, 20

Precautions, 1

Product Overview, 4

R

Rear View, 4

Recall Defaults, 21

Regulatory Information, 35

Removing the Back Cover, 7

Replacing the Back Cover, 12

Routing the Cables, 8

Surface Durability, AccuTouch, 32

Surface Durability, IntelliTouch, 31

SVGA, 25

SXGA, 25

T

Technical Specifications, 29

Touch Activation Force, AccuTouch, 32

Touch Activation Force, IntelliTouch, 31

Touch Interface Connection, 6

Touch not working, 24

Touchmonitor Safety, 27

Touchmonitor Specifications, 30

Touchpoint Density, AccuTouch, 32

Touchpoint Density, IntelliTouch, 31

Touchscreen, 30

Troubleshooting, 23

U

Unpacking Your Touchmonitor, 3

Using the On-Screen Display (OSD) Menus, 19

UXGA, 25

V

VESA Mount on Your Touchmonitor, 13

VGA, 25

Viewing Angle (typical) (CR=10), 30

Viewing Angle (typical) (CR=5), 30

Visual Resolution, AccuTouch, 32

Visual Resolution, IntelliTouch, 31

Volume, 20

V-Position, 21

S

Sealing, IntelliTouch, 31

Serial or USB Connection, 6

Side Bezel Buttons, 20

Side View, 5

Solutions to Common Problems, 23

Speakers, 30

W

Warranty, 39

X

XGA, 25

Index-42

Page 47

PORT POWERED

SWIPE READER

TECHNICAL REFERENCE MANUAL

Manual Part Number 99875094 Rev 10

JULY 2001

20725 South Annalee Avenue

Carson, CA 90746

Phone: (310) 631-8602

FAX: (310) 631-3956

Technical Support: (888) 624-8350

www.magtek.com

Page 48

Copyright 1997-2001

MAG-TEK, Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may

be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written permission of Mag-Tek, Inc.

Mag-Tek is a registered trademark of Mag-Tek, Inc.

Procomm is a registered trademark of Datastorm Technologies, Inc.

REVISIONS

Rev Number Date Notes

1 11 Dec 97 Initial Release

2 18 Dec 97 Sec 1 Changed spec Dimensions; Sec 1, 3 Changed illustrations

for clarity.

3 11 May 98 Sections 1, 2, and 3 revised to reflect latest firmware revisions.

Sec 4 deleted.

4 15 Jun 98 Two part numbers added.

5 1 Mar 99 Sec 1, Added 3 part numbers, changed specs, Changed

Dimensions Figure 1-3, removed Figure 1-4, Mounting

Dimensions, added Mag-Tek Windows Drivers; Added note to

Table 1-1.

Section 2, added mounting instructions and Figure 2-1, Mounting

Dimensions. Section 3, added 3 track symbols to Table 3-1 and

3 sign-on configurations to 3-2.

6 14 Jun 99 Title change, Removed MT-211 and RS-232; Sec 1, Table 1-1,

added Pin List for Cable 21040077, added RS-232

Communication; Sec 2, added Demo Program from Net; Sec 3,

Clarified Fig 3-1, Described firmware P/Ns and revisions.

7 1 Dec 99 Section 1: Added P/N 21040084, Updated table for 9- and 25-pin

connectors; Section 3: Added P/N 21040084 to Sign-on table.

8 21 Sep 00 Editorial changes throughout. Sec 1: Configuration list expanded

and moved to Sec 3; Specification weight changed from 5.9 oz to

5.8oz, Converted symbols to Metric System [SI]. Sec 3: Added 5

new part numbers with firmware, tracks, and configurations.

9 09 Mar 01 Front Matter: Corrected Agency Approvals to include

Class B for FCC and Class B for CE. Changed RMA Warranty

address to 20801 S. Annalee. Section 3: Removed “Track 3 – 7

bit” line from Table 3-1. Added 094 and 096 configurations in

Table 3-2.

10 25 Jul 01 Front Matter: Agency Approvals: Corrected Class B for CE and

Corrected UL and CUL . Copyright 2001 added.

ii

Page 49

Limited Warranty

Mag-Tek, Inc. (hereinafter “Mag-Tek”) warrants this Mag-Tek product IN ITS ENTIRETY, to

be in good working order for a period of one year from the date of purchase from Mag-Tek.

Should this product fail to be in good working order at any time during this warranty period,

Mag-Tek will, at its option, repair or replace this product at no additional charge except as set

forth below. Repair parts and replacement products will be furnished on an exchange basis and

will be either reconditioned or new. All replaced parts and products become the property of

Mag-Tek. This limited warranty does not include service to repair damage to the product

resulting from accident, disaster, misuse, abuse, or non-Mag-Tek modification of the product.

Limited Warranty service may be obtained by delivering the product during the warranty period

to Mag-Tek (20801 S. Annalee Ave., Carson, CA 90746). If this product is delivered by mail,

you agree to insure the product or assume the risk of loss or damage in transit, to prepay shipping

charges to the warranty service location and to use the original shipping container or equivalent.

ALL EXPRESS AND IMPLIED WARRANTIES FOR THIS PRODUCT, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED IN DURATION TO A PERIOD OF ONE YEAR FROM THE

DATE OF PURCHASE, AND NO WARRANTIES, WHETHER EXPRESS OR IMPLIED,

WILL APPLY AFTER THIS PERIOD, EXCEPT AS PROVIDED IN THE PRECEDING

SENTENCE. EACH PURCHASER UNDERSTANDS THAT THE MAG-TEK PRODUCT IS

OFFERED AS IS.

IF THIS PRODUCT IS NOT IN GOOD WORKING ORDER AS WARRANTED ABOVE,

YOUR SOLE REMEDY SHALL BE REPAIR OR REPLACEMENT AS PROVIDED ABOVE.

IN NO EVENT WILL MAG-TEK BE LIABLE TO YOU FOR ANY DAMAGES,

INCLUDING ANY LOST PROFITS, LOST SAVINGS OR OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF OR INABILITY TO USE

SUCH PRODUCT, EVEN IF MAG-TEK HAS BEEN ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES, OR FOR ANY CLAIM BY ANY OTHER PARTY.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

iii

Page 50

FCC WARNING STATEMENT

This equipment has been tested and found to comply with the limits for Class B digital device, pursuant to

Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residential environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation.

FCC COMPLIANCE STATEMENT

This device complies with Part 15 of the FCC Rules. Operation of this device is subject to the following

two conditions: (1) This device may not cause harmful interference; and (2) this device must accept any

interference received, including interference that may cause undesired operation.

CANADIAN DOC STATEMENT

This digital apparatus does not exceed the Class B limits for radio noise for digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables

aux appareils numériques de las classe B prescrites dans le Réglement sur le brouillage radioélectrique

édicté par les ministère des Communications du Canada.

CE STANDARDS

Testing for compliance to CE and FCC requirements was performed by an independent laboratory. The

unit under test was found compliant to Class B.

UL/CSA

This product is recognized per Underwriter Laboratories and Canadian Underwriter Laboratories 1950.

iv

Page 51

TABLE OF CONTENTS

SECTION 1. FEATURES AND SPECIFICATIONS --------------------------------------------------------------------- 1

MAG-TEK DEVICE DRIVERS FOR WINDOWS ---------------------------------------------------------------------- 1

FEATURES--------------------------------------------------------------------------------------------------------------------- 1

CONFIGURATION------------------------------------------------------------------------------------------------------------ 2

SPECIFICATIONS ------------------------------------------------------------------------------------------------------------ 3

SECTION 2. INSTALLATION ------------------------------------------------------------------------------------------------ 5

REQUIREMENTS------------------------------------------------------------------------------------------------------------- 5

MOUNTING--------------------------------------------------------------------------------------------------------------------- 5

INSTALLATION AND TEST ------------------------------------------------------------------------------------------------ 6

SECTION 3. OPERATION ----------------------------------------------------------------------------------------------------- 9

LED INDICATOR-------------------------------------------------------------------------------------------------------------- 9

CARD READ ------------------------------------------------------------------------------------------------------------------- 9

READER TO HOST MESSAGE FORMAT ----------------------------------------------------------------------------- 9

TIMING FOR ID SIGN ON -------------------------------------------------------------------------------------------------10

FIGURES

Figure 1-1. Port-Powered Swipe Reader-----------------------------------------------------------------------------------vi

Figure 1-2. Reader Cable and Optional Adapter ------------------------------------------------------------------------- 2

Figure 1-3. Dimensions---------------------------------------------------------------------------------------------------------4

Figure 2-1. Mounting Hole Dimensions For Surface -------------------------------------------------------------------- 6

Figure 3-1. Timing For ID Sign-on and Transmission Bursts. --------------------------------------------------------10

TABLES

Table 1-1. OEM and 9-Pin Connectors and 25-Pin Adapter ---------------------------------------------------------- 2

Table 1-2. Specifications------------------------------------------------------------------------------------------------------- 3

Table 3-1. SS and ES Track Symbols -------------------------------------------------------------------------------------- 9

Table 3-2. Sign-on ID for Configurations----------------------------------------------------------------------------------11

v

Page 52

vi

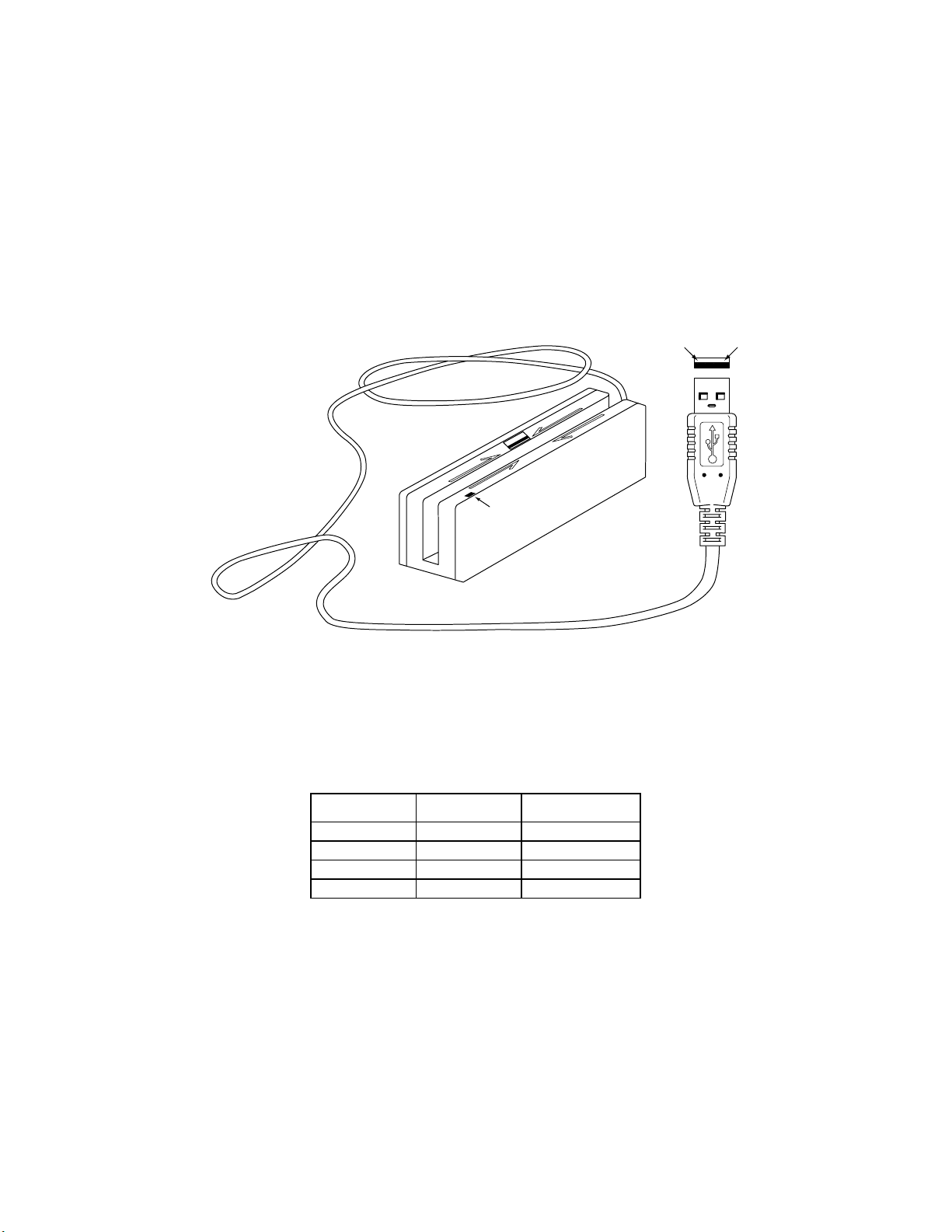

Figure 1-1. Port-Powered Swipe Reader

Page 53

SECTION 1. FEATURES AND SPECIFICATIONS

The Port Powered Swipe Reader is a compact magnetic stripe card reader which conforms to

ISO/ANSI standards. The Reader is compatible with the PC series of personal computers or any

device with a serial RS-232 interface. A card is read by sliding it, stripe down and facing the

LED side, through the slot either forward or backward.

A green LED (Light Emitting Diode) indicator on the Reader panel provides the operator with

continuous status of the Reader operations.

When power is applied, the Reader transmits a sign-on ID message. About 150 milliseconds

after DTR is applied, the Reader sends the part number of the firmware in the following form:

21088819A01 <CR>. The first 8 characters indicate the firmware number; the letter is the

revision, which is followed by a revision sublevel of 01 to 99. The <CR> indicates carriage

return (0x0D). The sign-on messages for part numbers are listed in Section 3. Timing is also

shown in Section 3.

Since the input voltage is supplied by a relatively low source of power, the Reader depends on its

input capacitor to maintain proper charge during all operations. In order to reduce the drain on

this internal power source during data transmission, the output data is transmitted in 5 to 6

millisecond bursts with a 10-millisecond gap between bursts to allow the capacitor to recharge.

The PC software should be able to tolerate this 10-millisecond space between characters. The

Timing is shown is Section 3, Figure 3-1. Configurations, including part numbers, firmware,

tracks, and unit configuration, are listed in Section 3, Table 3-2.

MAG-TEK DEVICE DRIVERS FOR WINDOWS

The Mag-Tek Device Drivers for Windows, Part Number 30037385, may be used with the Port

Powered Swipe Reader. When this program is used, refer to Mag-Tek Device Driver for

Windows, Programming Reference Manual, Part Number 99875125.

FEATURES

Major features of the Swipe Reader are as follows:

• Powered through the RS-232 serial port – no external power supply required

• Hardware Compatible with PC or any computer or terminal with an RS-232 interface

• Software Compatible with Procomm, or any RS-232 communications program

• Bidirectional card reading

• Reads encoded data that meets ANSI/ISO/CDL/AAMVA standards

• Green LED for status

1

Page 54

Port Powered Swipe Reader

CONFIGURATION

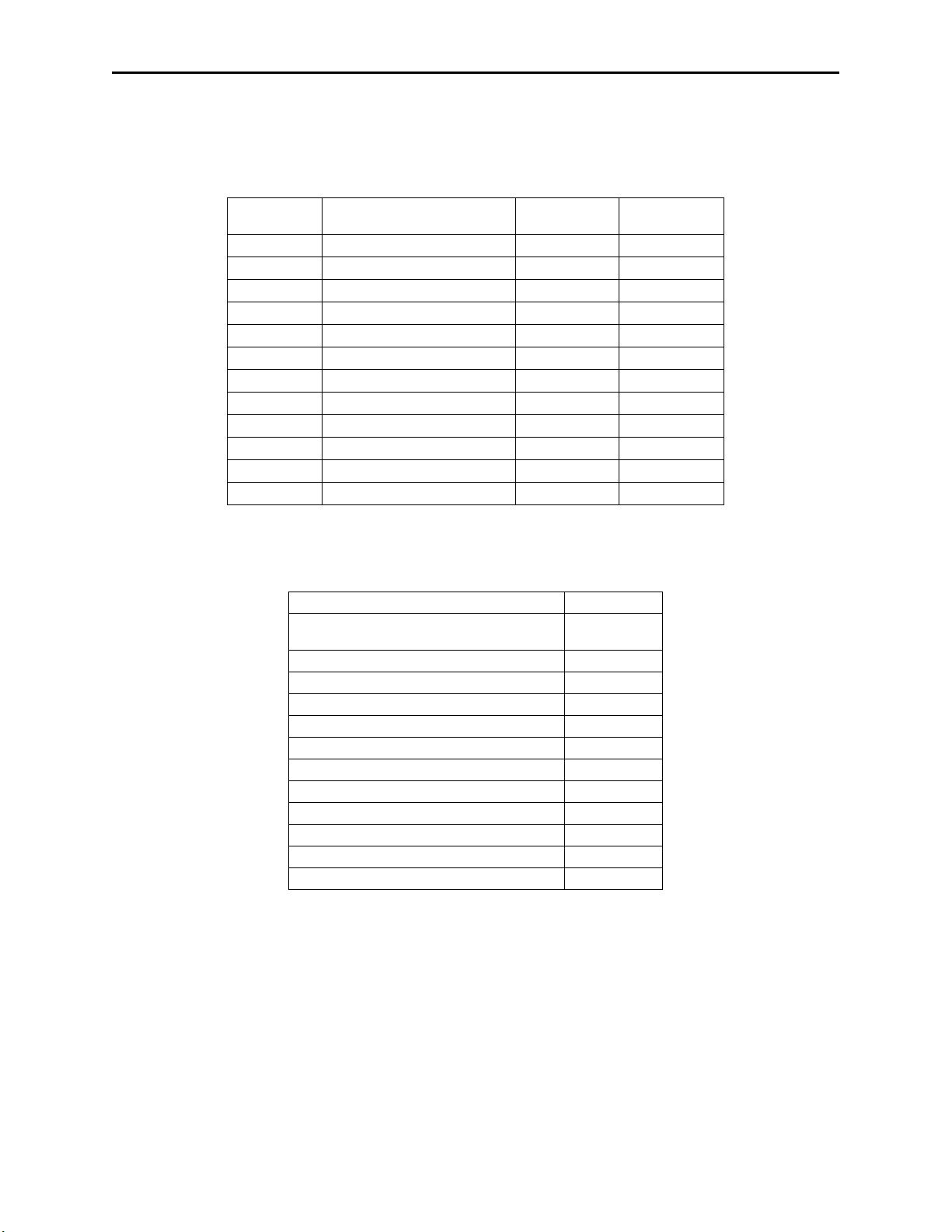

The Reader, LED Indicator, pin numbers for the 9-pin connector, and the Adapter are shown in

Figure 1-2.

Figure 1-2. Reader Cable and Optional Adapter

Pin numbers and signal descriptions for the 9-pin (DE9) cable and 25-pin (DB25) adapter shown

in the illustration are listed in Table 1-1. Also listed is the pin list OEM version, P/N 21040077.

Table 1-1. OEM and 9-Pin Connectors and 25-Pin Adapter

Connector for OEM

Version 21040077

J2 on the PCB

- 1 NC*

1 3 2 RXD (to PC)

2 2 3 TXD** (from PC)

3 20 4 DTR (from PC)

4 7 5 GND

- 6-9 NC*

* No Connection

** Pin must be connected to TXD (or DTR if TXD not available).

25-pin

Adapter

DE9-pin

Connector

Signal

2

Page 55

Section 1. Features and Specifications

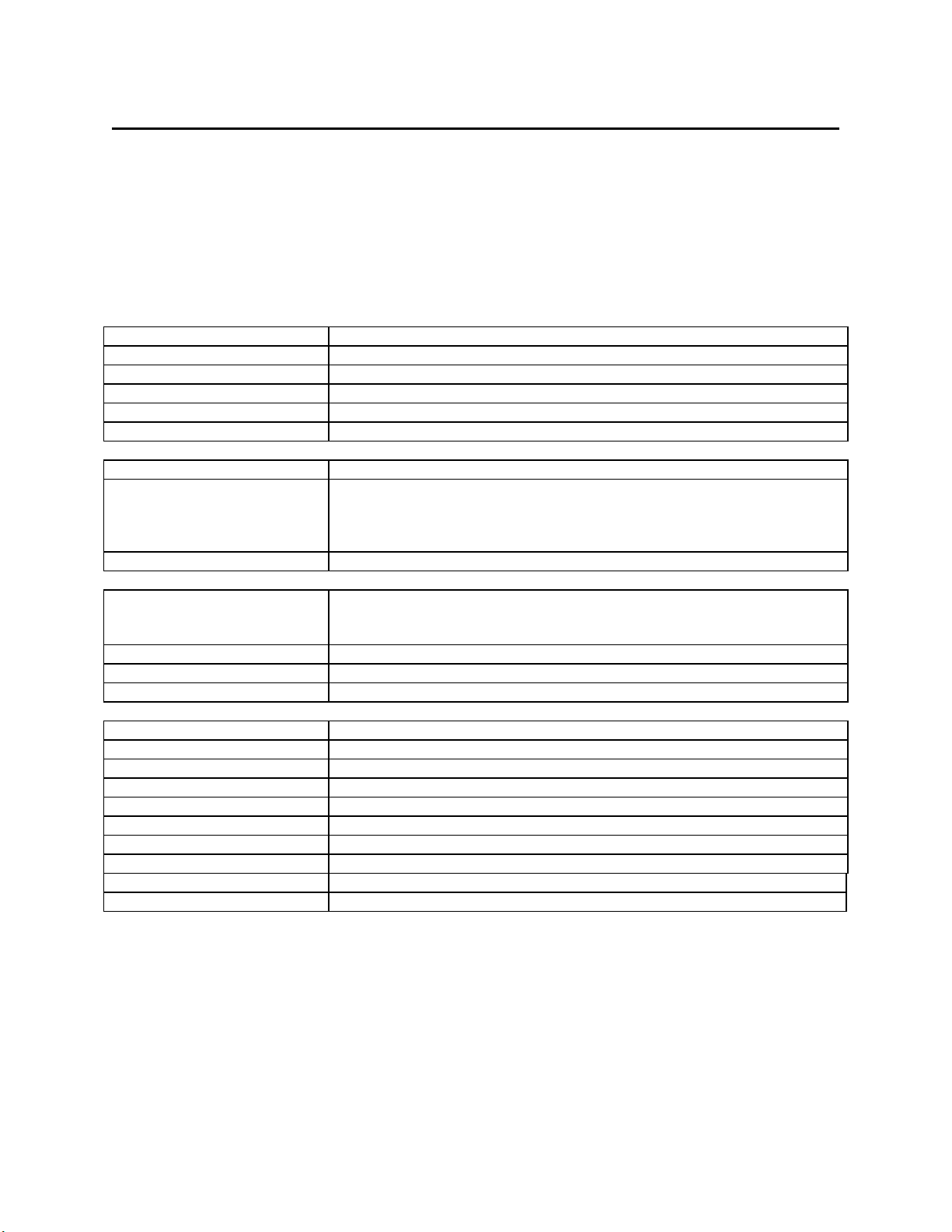

SPECIFICATIONS

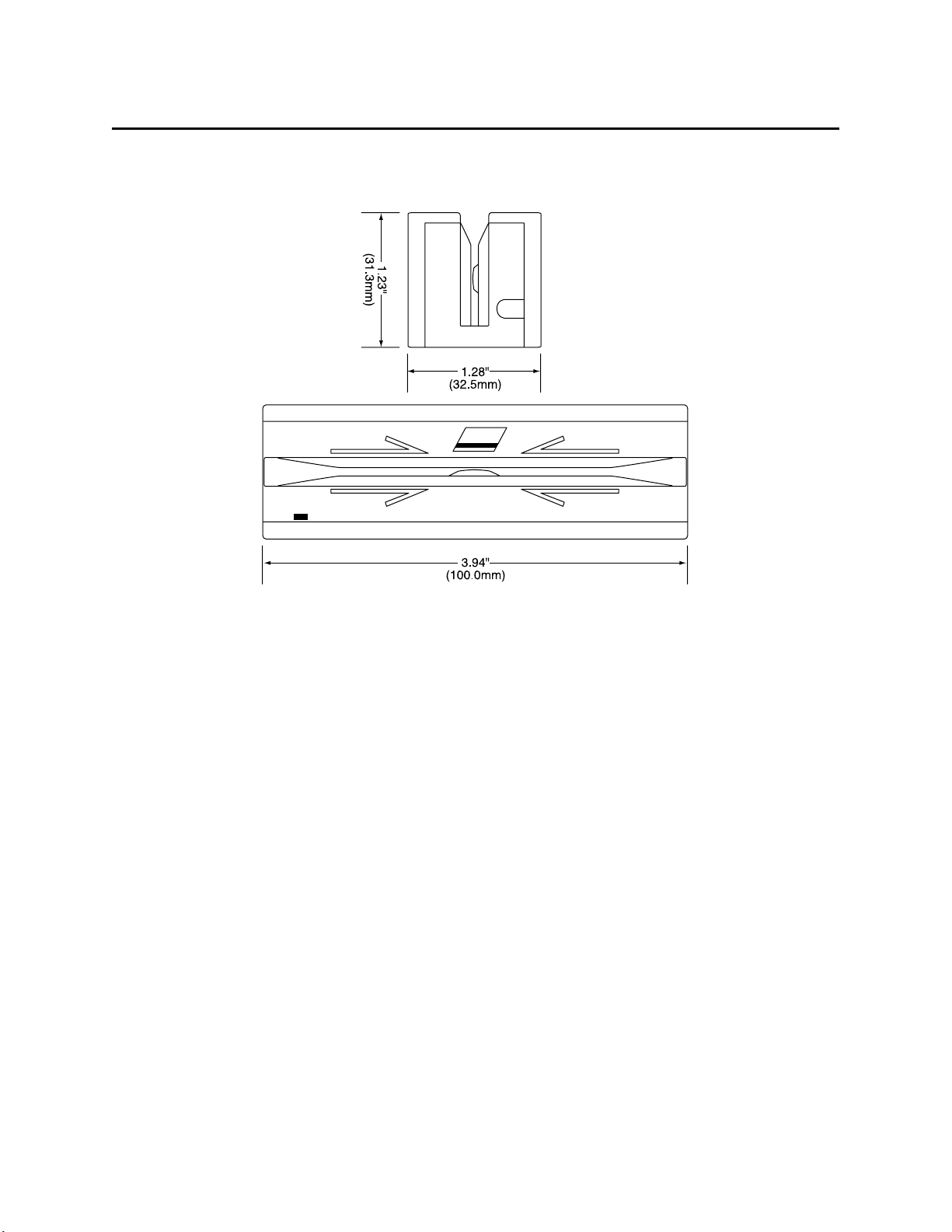

Table 1-2 lists the specifications for the Port Powered Swipe Reader. Figure 1-3 shows the

dimensions for the standard product. Other sizes are available by special order.

Table 1-2. Specifications

OPERATING

Reference Standards ISO/ANSI/ CDL/ AAMVA*

Power Input From RS-232 interface

Recording Method Two-frequency coherent phase (F2F)

Message Format ASCII

Card Speed 3 to 50 IPS

MTBF Electronics: 125,000 hours. Head: 1,000,000 passes

ELECTRICAL

DTR Voltage 5 to 15 VDC

Current

Quiescent

Transmitting

Peak at Power On

RS-232 Communication 9600 bps, no parity, 8 data bits, 1 stop bit

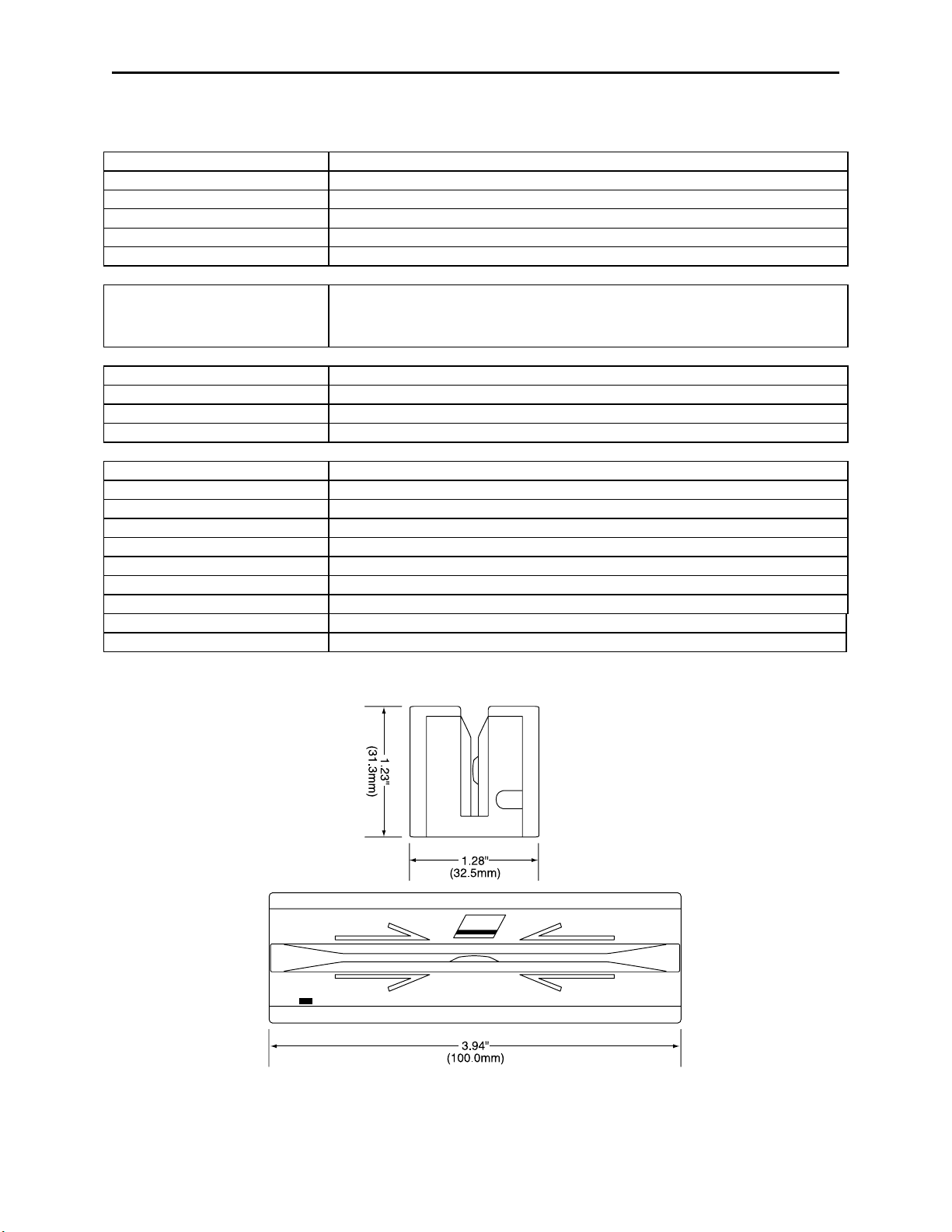

Dimensions Length: 3.94” (100.0 mm),

Weight Reader 5.8 oz. (165 gr.)

Cable length 5 Ft. (1.5 m)

Connector 9 pin D female (May require a 25-pin adapter)

Temperature

Operating 32oF to 131oF (0oC to 55oC)

Storage -22oF to 158oF (-30oC to 70oC)

Humidity

Operating 10% to 90% noncondensing

Storage Up to 100% noncondensing

Altitude

Operating 0-10,000 ft. (0-3048 m.)

Storage 0-50,000 ft. (0-15240 m.)

1 to 2 mA typical (continuous)

8 to 9 mA typical (5 ms duration)

12 mA

MECHANICAL (STANDARD PRODUCT)

Width: 1.28” (32.5 mm)

Height: 1.23” (31.3 mm)

ENVIRONMENTAL

* ISO (International Standards Organization), ANSI (American National Standards Institute), CDL

(California Drivers License), and AAMVA (American Association of Motor Vehicle Administrators).

3

Page 56

Port Powered Swipe Reader

Figure 1-3. Dimensions

4

Page 57

SECTION 2. INSTALLATION

The hardware installation consists of plugging the cable into the PC and optional adapter, if

required, Com Port setup, and testing the Reader.

REQUIREMENTS

• Port Powered Swipe Reader

• Optional 9- to 25-pin Adapter, P/N 78200018

• PC with Com Port

• Procomm, Hyper Terminal, Mag-Tek Windows Drivers, or other RS-232 communications

program

MOUNTING

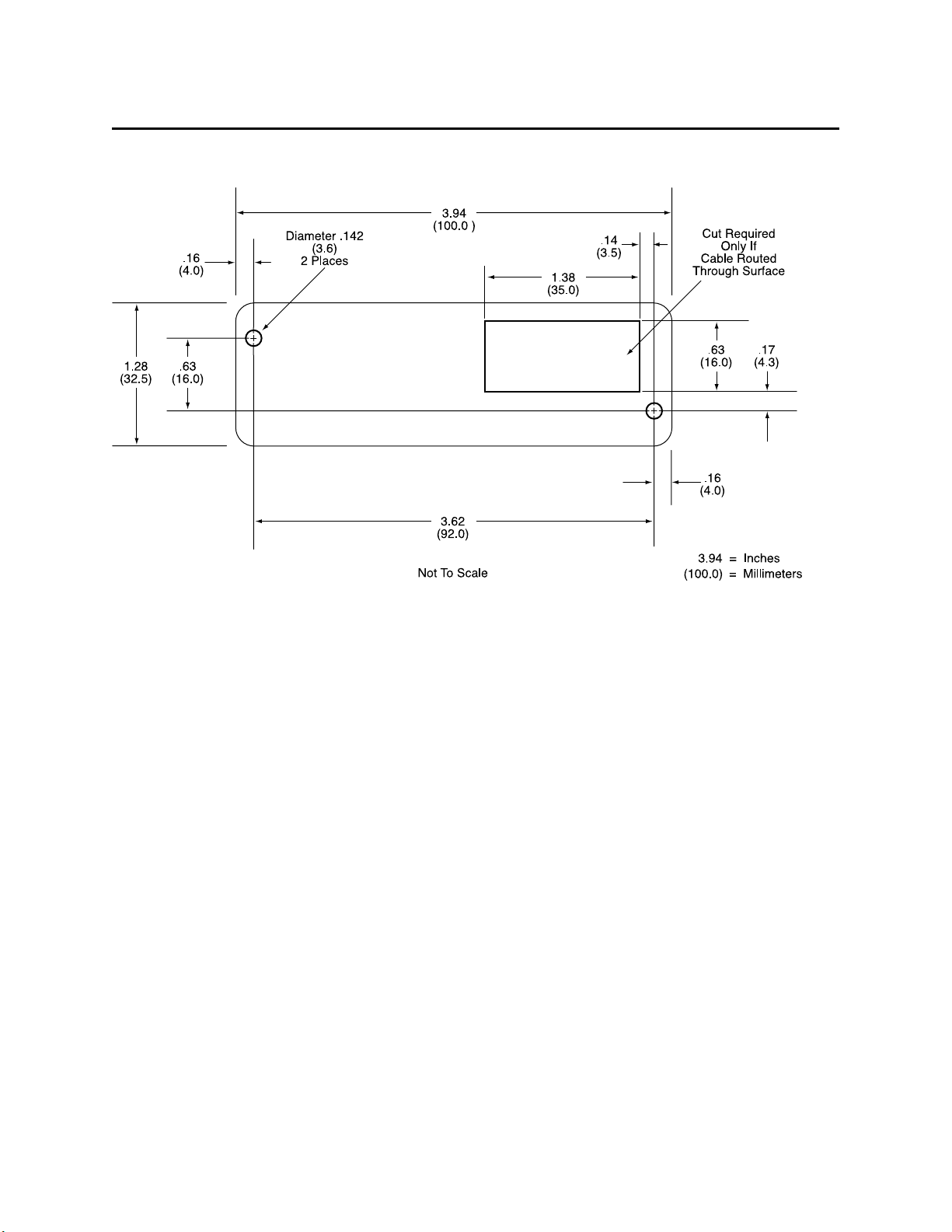

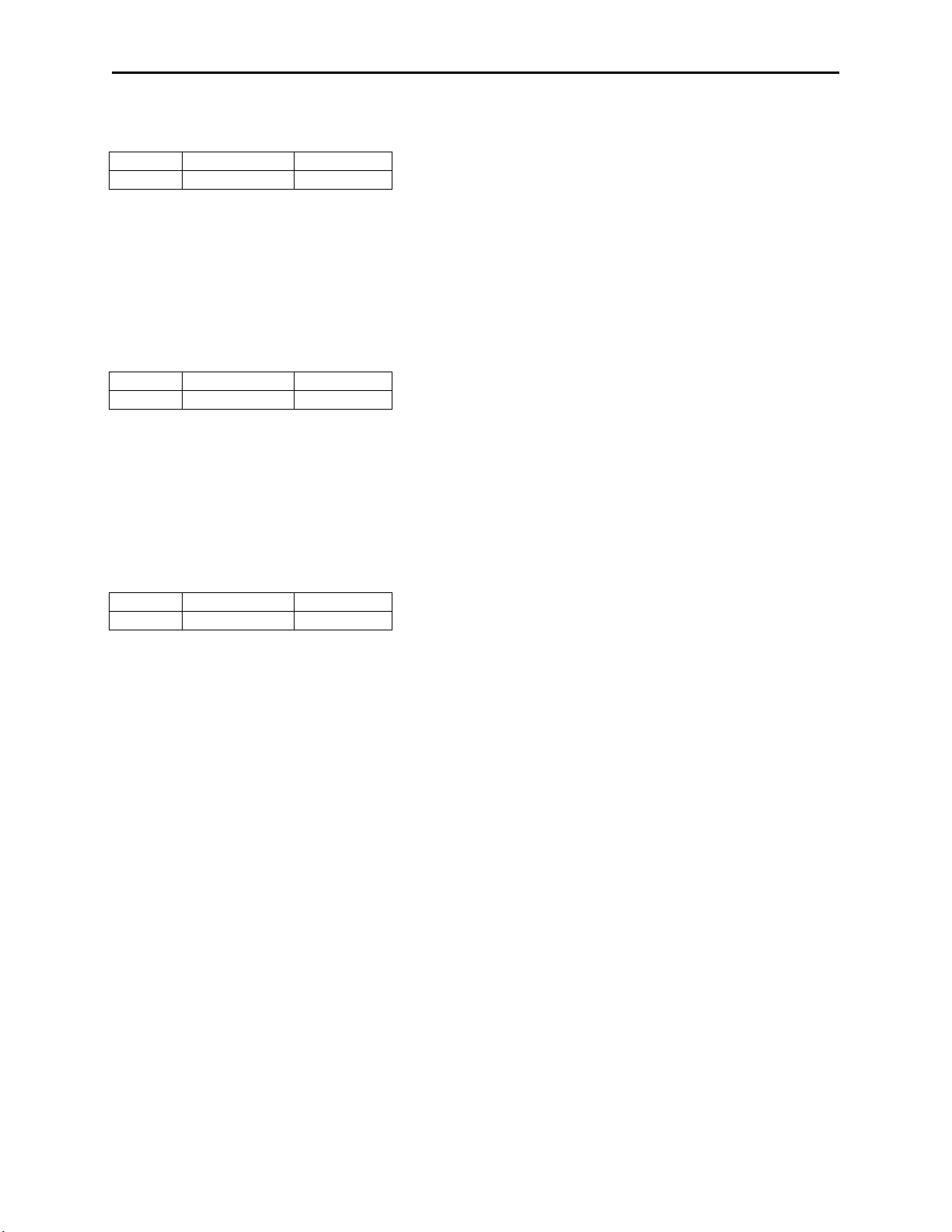

1. The Reader can be mounted on a surface in three ways:

• By two screws through the surface attached to the bottom of the unit and running the

cable on the top of the surface;

• By two screws through the surface attached to the bottom of the unit and by drilling a

hole in the surface for the cable and running the cable through the hole;

• By attaching the unit to the surface with fastening tape and running the cable on the top

of the surface.

Note

The two mounting inserts are 3 mm diameter; 0.5 mm pitch; 6.4

mm deep. The length of the screws used depends on the mounting

surface thickness and the thickness of washers (if used).

The mounting dimensions are shown in Figure 2-1. Determine the method of mounting

required.

2. Ensure the Reader is positioned on a flat, accessible surface with at least 4 inches

clearance on either end for room to swipe a card. Orient the Reader so the side with the

LED is facing the direction of intended use.

If fastening tape is to be used, clean the area that the Reader will be mounted on with

isopropyl alcohol. Remove the adhesive protective cover on the fastening tape, and

position the Reader and push down firmly.

5

Page 58

Port Powered Swipe Reader

Figure 2-1. Mounting Hole Dimensions For Surface

3. Mount the Reader.

INSTALLATION AND TEST

To install the Swipe Reader, perform the following steps:

1. Connect the Swipe Reader cable connector into a 9-pin serial Com Port on the PC. If a

25-pin Adapter is required, plug the 9-pin connector on the Reader into the Adapter, and

the adapter into the PC.

2. Open a communications program such as the Mag-Tek Encoder/Reader Demonstration

Program, which may be obtained from the Internet at www.magtek.com. Navigate to the

Demo Programs and select Reader & Encoder Demos (Win 95/98/NT).

3. On the program, select the Com Port the Reader is connected to.

4. If the Com Port selected is correct, the green LED on the Reader will light; if the wrong

Com Port is selected, the LED will not light.

5. Select the baud rate of 9600.

Page 59

Section 2. Installation

6. Select 8 data bits, no parity, 1 stop bit.

7. With the LED on, swipe a card. The data on the screen will show Track 1 beginning with

“%” and ending with “?”. Track 2 begins with “;” and ends with “?”. Track 3 begins

with “+” (normal) or "!" (CDL) and ends with “?”. The following is an example:

%B123^Smith/Joann^9812101000?;112222333333444444444?<0x0D>

If a track cannot be read, an E will appear in place of the track data; for example, if

Track 2 is bad and Tracks 1 and 3 are good, the display will be similar to the following:

%11111111111111111111?;E?+3333333333333333333?<0x0D>

If Tracks 1 and 3 are bad and Track 2 is good, the display will be similar to the following:

%E?;22222222222222222222?+E?<0x0D>

8. If the data on the screen is not numeric or alphanumeric similar to the above, check the

communications rate. If the alphanumeric characters are similar to the above, the unit is

ready for operation.

7

Page 60

Port Powered Swipe Reader

8

Page 61

SECTION 3. OPERATION

Included in this section are Indicator, Card Read, Reader to Host Message Format, and a timing

diagram of sign-on ID.

LED INDICATOR

A green LED indicator on the panel gives the operator the status of the Reader. If the cabling is

correct and the correct Com Port is selected, the indicator will be on. If the indictor does not

come on, check the cabling and the Com Port. The LED is turned off during a card swipe and

while the unit is transmitting.

CARD READ

A card may be swiped through the Reader slot when the green LED is lit. The magnetic stripe

must face toward the front (the side with the LED) and may be swiped in either direction.

READER TO HOST MESSAGE FORMAT

Track data is sent in the following order: SS, Card Data, ES.

The format in which data is transmitted (in track order) after a card is read successfully is as

follows:

SS CARD DATA ES CR

Carriage Return

End Sentinel

Card Data or "E" (for Error)

Start Sentinel Character

Table 3-1 lists Start Sentinel and End Sentinel symbols.

Table 3-1. SS and ES Track Symbols

Start Sentinel End Sentinel Description

% ? Track 1

; ? Track 2

+ ? Track 3 - ISO

# ? Track 3 - AAMVA

! ? Track 3 - CDL

9

Page 62

Port Powered Swipe Reader

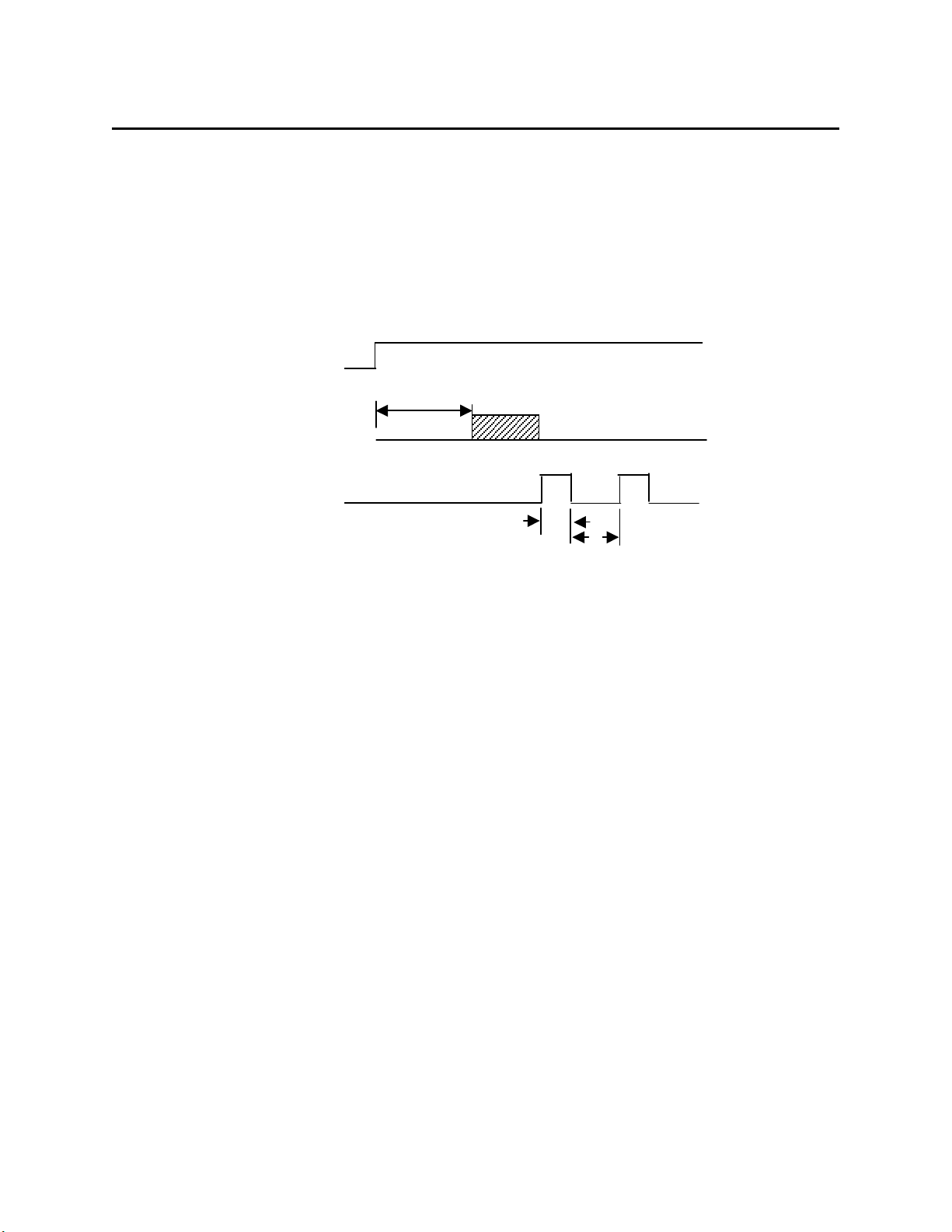

TIMING FOR ID SIGN ON

Timing for the ID Sign-on and transmission bursts (5 ms with 10 ms between bursts) are shown

in Figure 3-1.

DTR

150 ms

Sign-on ID

Transmission

Burst

5 ms

10 ms

Figure 3-1. Timing For ID Sign-on and Transmission Bursts.

The firmware controls the operation of Sign-on ID and Transmission bursts in the following

format:

210888xxLnn <CR>

Where:

the first 8 digits are the firmware part number (xx represents the Swipe Reader series),

L is the alpha revision,

nn is the number sub-revision.

<CR> is 0x0D.

10

Page 63

Section 3. Operation

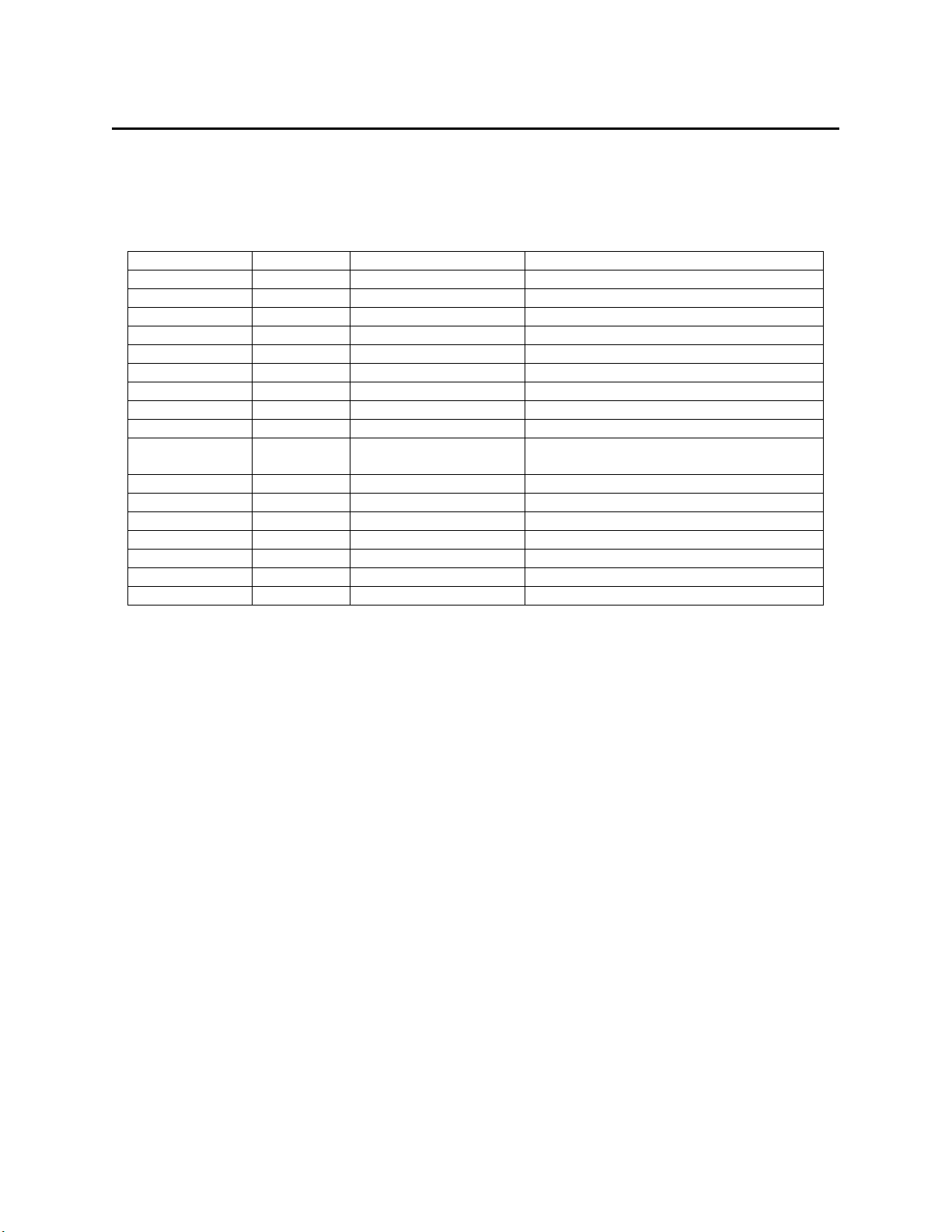

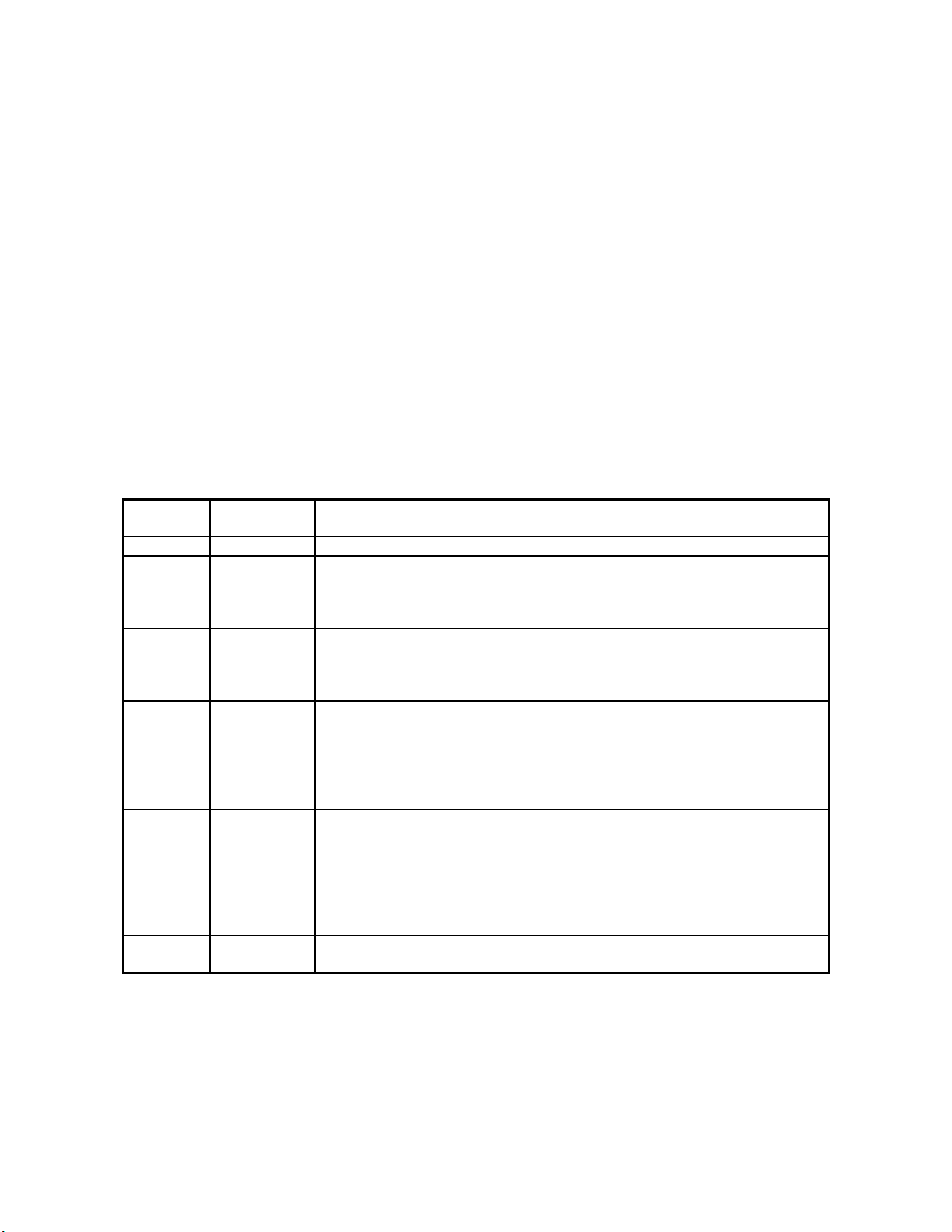

Table 3-2 lists the available part number, firmware, and configuration.

Table 3-2. Sign-on ID for Configurations

Part Number Firmware Track Configuration Configuration*

21040071 21088811 1,2 Pearl White

21040073 21088812 2,3 Pearl White

21040074 21088817 1,2,3 Pearl White

21040075 21088814 2 Pearl White

21040077 21088817 1,2,3 Black, No Cover, No Cable

21040079 21088811 1,2 Black

21040080 21088814 2 Black

21040081 21088811 1,2 Black (150 mm)

21040082 21088817 1,2,3 Black

21040084 21088811 1,2 Pearl White

(with STX and ETX)

21040086 21088817 1,2,3 Pearl White, No Cover, 12" Cable, 6-pin

21040088 21088824 1,2,3 Pearl White, 4800/7O, 10' cable

21040089 21088811 1,2 Pearl White, 10' cable

21040091 21088811 1,2 Black, No Cover, 5.9" Cable, 4-pin

21040092 21088817 1,2,3 Pearl White, 5 m cable

21040094 21068811 1,2 Pearl White, No Cover

21040096 21088811 1,2 Black, 4” Cable, 4-pin

*All cables are 6' DE9 unless otherwise specified.

11

Page 64

USB (UNIVERSAL SERIAL BUS)

SWIPE READER

TECHNICAL REFERENCE MANUAL

Manual Part Number 99875191 Rev 4

AUGUST 2001

20725 South Annalee Avenue

Carson, CA 90746

Phone: (310) 631-8602

FAX: (310) 631-3956

Technical Support: (888) 624-8350

www.magtek.com

Page 65

Copyright 2001

MAG-TEK, Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may

be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written permission of Mag-Tek, Inc.

Mag-Tek is a registered trademark of Mag-Tek, Inc.

USB (Universal Serial Bus) Specification is Copyright¤ 1998 by Compaq Computer

Corporation, Intel Corporation, Microsoft Corporation, NEC Corporation.

REVISIONS

Rev Number Date Notes

1 15 Jun 01 Initial Release

2 22 Jun 01 Section 4. On Tracks 1, 2, and 3 Decode

Status delete “more than eight bits of data”

and add “data on it that is not noise.” From

Card Encode Type, Value 3, delete “This

device does not detect blank cards so this

value will never occur.”

3 25 Jul 01 Front Matter: Agency Approvals: Corrected

Class B for CE.

4 17 Aug 01 Section 4, Report Descriptor: Changed

Logical Maximum from 25 ff to 26 ff 00.

ii

Page 66

Limited Warranty

Mag-Tek, Inc. (hereinafter “Mag-Tek”) warrants this Mag-Tek product IN ITS ENTIRETY, to

be in good working order for a period of one year from the date of purchase from Mag-Tek.

Should this product fail to be in good working order at any time during this warranty period,

Mag-Tek will, at its option, repair or replace this product at no additional charge except as set

forth below. Repair parts and replacement products will be furnished on an exchange basis and

will be either reconditioned or new. All replaced parts and products become the property of

Mag-Tek. This limited warranty does not include service to repair damage to the product

resulting from accident, disaster, misuse, abuse, or non-Mag-Tek modification of the product.

Limited Warranty service may be obtained by delivering the product during the warranty period

to Mag-Tek (20801 S. Annalee Ave., Carson, CA 90746). If this product is delivered by mail,

you agree to insure the product or assume the risk of loss or damage in transit, to prepay shipping

charges to the warranty service location and to use the original shipping container or equivalent.

ALL EXPRESS AND IMPLIED WARRANTIES FOR THIS PRODUCT, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR