Page 1

ModularFlatPanel

Mountingand

Environments

Guide

CARROLLTOUCH

TOUCHPRODUCTS

ancompanyAMP

Page 2

Modular Flat

Modular Flat

Panel Mounting

Panel Mounting

and Environments

and Environments

Guide

Guide

CARROLL TOUCH

TOUCH PRODUCTS

an AMP company

November 1996

Page 3

Copyright

Copyright ©1996 Carroll Touch. All rights reserved.

Disclaimer

Carroll Touch has a policy of continually improving products as new

technology becomes available. Carroll Touch reserves the right to make

changes and improvements to the specifications of this equipment at any

time without notice.

Carroll Touch has made every attempt to ensure that the information in

this document is accurate and complete. Carroll Touch assumes no

liability for any damages that result from the use of this manual or the

equipment it documents. Carroll Touch reserves the right to make

changes to this document at any time without notice.

Trademarks

All brand and product names are trademarks or registered trademarks of

their respective holders.

Page 4

CARROLL TOUCH Table of Contents

Table of Contents

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Technological Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Environmental Factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Shock and Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Moisture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Ambient Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Particulates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Application Environments. . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2. Mounting Techniques . . . . . . . . . . . . . . . . . . . . . . 2-1

Simplest Mounting Method. . . . . . . . . . . . . . . . . . . . . . . . 2-2

Typical NEMA4 Mounting Method . . . . . . . . . . . . . . . . . 2-3

Anti-Shock/Vibration Mounting Method . . . . . . . . . . . . . 2-5

Industrial or Medical Mounting Method . . . . . . . . . . . . . . 2-6

3. Bezel/Filter Assembly . . . . . . . . . . . . . . . . . . . . . . . 3-1

Component Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Polycarbonate Chemical Resistance . . . . . . . . . . . . . . . . . 3-2

4. Sealing and Coating . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Sealing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Coating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .GL-1

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IN-1

i

Page 5

Table of Contents CARROLL TOUCH

List of Figures

Figure 1-1. Scanning Infrared Technology . . . . . . . . . . . . . . . . . . 1-2

Figure 1-2. Modular Flat Panel Touch System Components . . . . 1-3

Figure 1-3. Mounting to Prevent Moisture Accumulation . . . . . . 1-5

Figure 2-1. Simplest Mounting Method (Front View) . . . . . . . . . 2-2

Figure 2-2. Simplest Mounting Method (Side View) . . . . . . . . . . 2-3

Figure 2-3. Typical NEMA4 Mounting Method (Front View) . . 2-4

Figure 2-4. Typical NEMA4 Mounting Method (Side View) . . . 2-5

Figure 2-5. Anti-Shock/Vibration Mounting Method . . . . . . . . . 2-6

Figure 2-6. Industrial or Medical Mounting Method . . . . . . . . . . 2-7

Figure 4-1. Modular Flat Panel Touch System Sealing . . . . . . . . 4-2

List of Tables

Table 1-1. Environmental Light Strengths . . . . . . . . . . . . . . . . . . 1-5

Table 1-2. Application/Operating Environments . . . . . . . . . . . . . 1-6

Table 3-1. Effects of Chemical Classes on Polycarbonates . . . . . 3-3

ii

Page 6

WelcomeWelcome

A

s computers become a part of daily life, a technology that makes

them easier to use has become a necessity. Carroll Touch provides

the solution through the power of touch.

Because pointing or touching is a natural means of indicating choice,

touch systems are ideal for selection-based applications where

easy-to-follow menus guide a user through a series of steps or choices.

Touch is well accepted by the casual user because its simple, natural

interface hides the complexity of computer systems.

Purpose

The modular flat panel touch system is especially well-suited to rugged

environments, such as industrial settings where exposure to chemicals

is likely, medical settings where the system must be scrubbed after

every use, and public settings (such as kiosks) that subject the system

to repeated, possibly abusive use.

Thank you for your interest in Carroll Touch products!

This guide explains the operation of a scanning infrared (IR) touch

system and reviews the types of mounting, sealing and coating

techniques to adapt an IR touch system to various environmental and

chemical factors.

Modular Flat Panel Mounting and Environments Guide iii

Page 7

Welcome CARROLL TOUCH

Audience

This guide is intended for analysts who need to determine how to use

and/or adapt an infrared scanning touch system to the needs of their

particular application.

Organization

Chapter 1, “Introduction,” contains a brief technological overview of

the ways in which scanning infrared touch systems function. The

chapter goes on to list environmental factors affecting touch, such as

temperature, ambient light, chemicals, particulate contaminants,

moisture, shock and vibration.

Chapter 2, “Flat Panel Mounting Techniques,” illustrates four separate

mounting schemes, each of which is designed to increase the

functionality of the touch system in reaction to a different environment.

The mounting methods include simple, typical NEMA/4,

anti-shock/vibration, and industrial/medical.

Conventions

Chapter 3, “Bezel/Filter Assembly,” shows the modular flat panel bezel

and filter and its standard manufacturing material, along with its

chemical properties.

Chapter 4, “Sealing and Coating,” discusses the concept of sealing,

along with an explanation of how to seal the modular flat panel touch

system. The concept of coating and reasons for it are explained, along

with Carroll Touch conformal coating.

The Glossary defines terms that are unique or whose usage is unique to

touch.

For clarity, this guide uses certain conventions to visually distinguish

different types of information. The conventions are:

• Bold is used to emphasize a word or phrase, including definitions

of important concepts.

• Information of particular importance or actions that may have

undesirable results if performed improperly are included under the

headings

Note and Caution.

iv Modular Flat Panel Mounting and Environments Guide

Page 8

1

T

Introduction

Introduction

his chapter contains a brief technological overview of scanning

infrared touch systems and describes the environmental factors

that affect touch, such as temperature, shock and vibration, chemicals,

moisture, ambient light, and particulates. A brief analysis of the

environmental factors present in various locations is also included.

The topics covered include:

• Technological Overview.

• Environmental Factors.

• Application Environments.

Modular Flat Panel Mounting and Environments Guide 1-1

Page 9

Chapter 1 - Introduction CARROLL TOUCH

Technological Overview

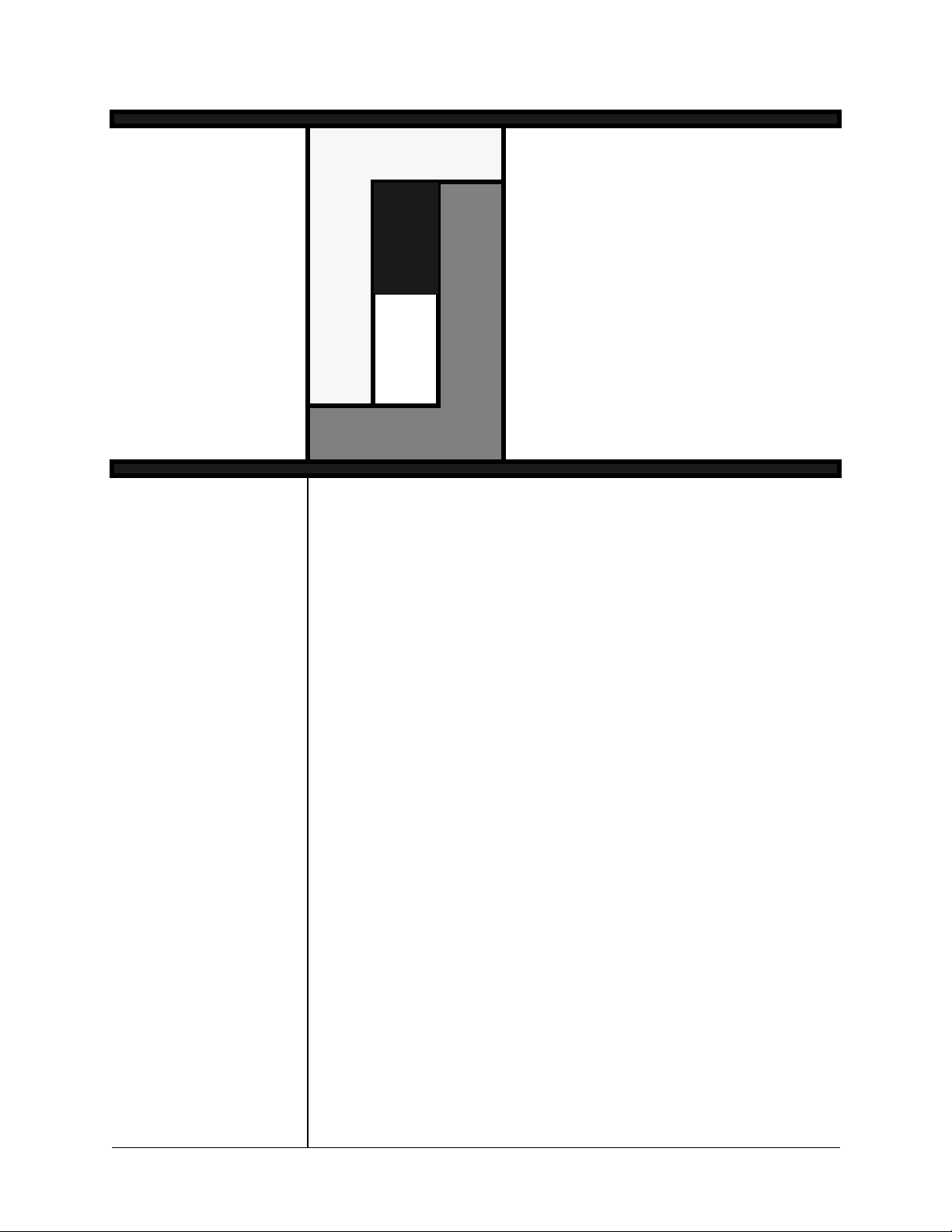

The operation of all scanning infrared (IR) touch systems is based on

the creation of a grid of IR light beams above the viewing surface of a

CRT monitor or flat panel display and the recognition of the location at

which individual beams within the grid are interrupted. To create such

a grid, IR light emitting diodes (LEDs) are paired with phototransistors,

each set constituting an opto-pair or physical beam, to create a

horizontal (x-axis) and a vertical (y-axis) array of beams. The two

arrays of beams and their circuitry make up an opto-matrix frame, as

shown in Figure 1-1.

Touch Activation Inside and Outside Edges of

Infrared-Transparent Bezel

Grid of Infrared Light Opto-Matrix Frame

Inside Bezel

Edge of Active

Display Area

Figure 1-1. Scanning Infrared Technology

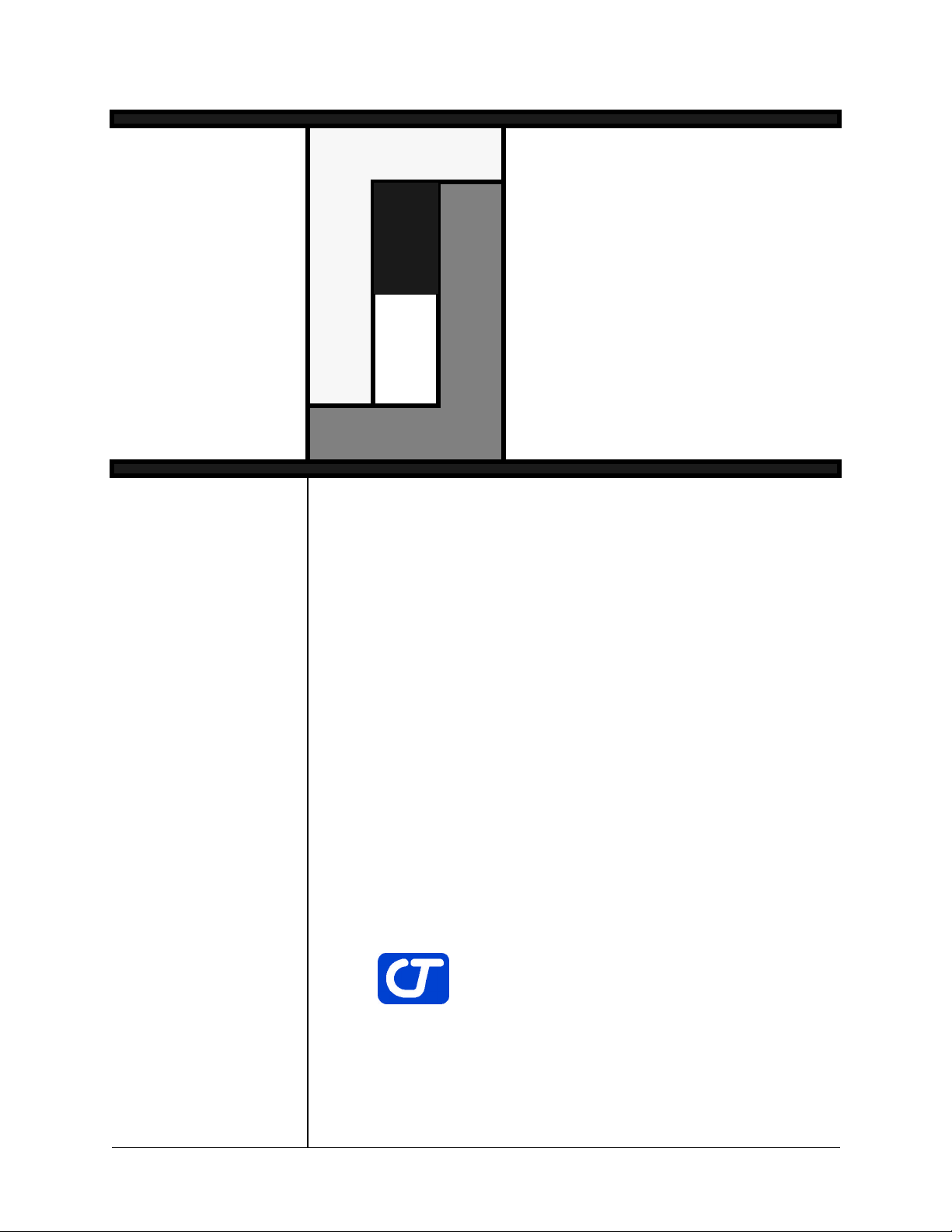

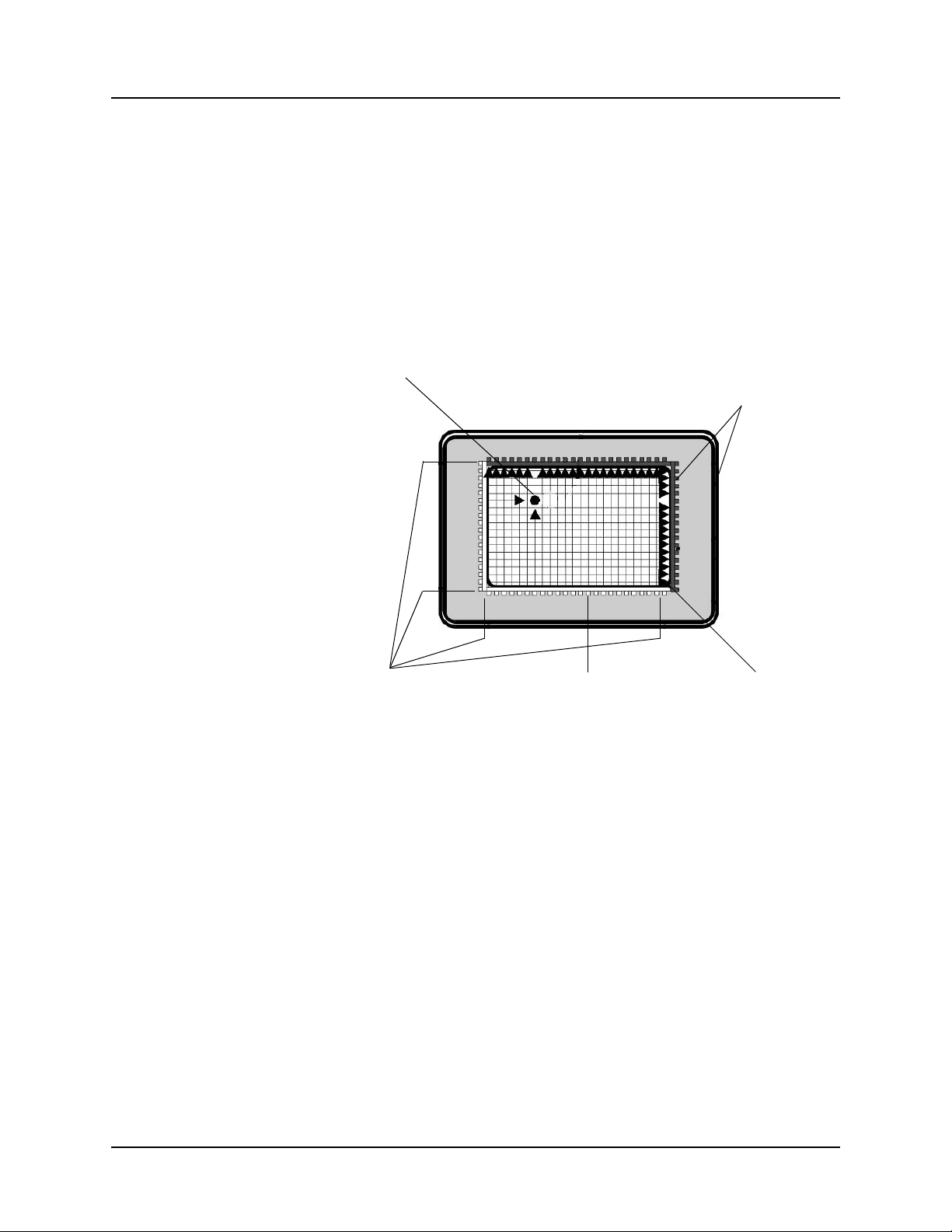

As shown in Figure 1-2, a Carroll Touch modular touch frame designed

to function with a flat panel is composed of an opto-matrix frame, an

IR-transparent protective bezel, and a transparent filter. To complete

the touch system, the modular touch frame is linked to a modular touch

controller via the modular digital interface (MDI), which is a standard

8-pin telephone-type plug attached to the touch frame by an 8-pin cable.

1-2 Modular Flat Panel Mounting and Environments Guide

Page 10

CARROLL TOUCH Chapter 1 - Introduction

Flat Panel DisplayFilterOpto-Matrix Frame

Bezel 8-Pin Telephone-

Type Cable

Figure 1-2. Modular Flat Panel Touch System Components

Environmental Factors

Traditionally, the successful implementation of a scanning IR touch

system has required that certain factors in the operational environment

be addressed. Historically, the environmental factors that could

influence the operation of a touch system were temperature, shock and

vibration, chemicals, moisture, ambient light, and particulate

contaminants (dust, dirt, etc.). Today’s Carroll Touch modular touch

systems with their improved hardware, software and firmware,

compensate for these environmental conditions, along with such factors

as misalignment or degradation of the opto-electronic devices, reducing

their ability to affect touch system operations.

Temperature

Carroll Touch’s use of solid state electronics and its ASIC-based

modular circuitry enables the touch system to withstand and adapt to

temperature extremes as well or better than the host display and system.

The standard Carroll Touch modular flat panel system is designed to

function in the temperature range from 0° C to 50° C (32° F to 122° F)

and can be stored in the range from -20° C to 75° C (-4° F to 167° F).

Customer systems have been designed to function at temperatures from

-55° C to 125° C (-67° F to 257° F). For heat dissipation, Carroll Touch

modular touch systems are designed to operate at altitudes up to 10,000

feet (3,048 meters) and at 0% to 95% non-condensing humidity, over

the full temperature range.

Modular Flat Panel Mounting and Environments Guide 1-3

Page 11

Chapter 1 - Introduction CARROLL TOUCH

Shock and Vibration

Carroll Touch modular flat panel touch systems can more than

withstand shock and vibration conditions that will disable a typical flat

panel display. The lightweight solid state circuit card assemblies,

because of their low mass, are relatively immune to shock and

vibration, as are the other components of the system.

In the unlikely event that a beam is lost to severe local shock, fault

tolerance begins and the touch system continues to function by virtue

of its failed beam algorithms while reporting the beam loss.

Chemicals

The modular touch system relies on the basic properties of the materials

from which it is manufactured for environmental protection. The

polycarbonate resins from which the touch system components are

manufactured and their resistance to harsh chemicals and

environmental extremes are discussed in Chapter 3.

If chemical factors make your operating environment unsuitable for

some components of the touch system, other materials and coatings for

touch systems and their components are available. These materials and

coatings, along with tips on sealing the touch system, are discussed in

Chapter 4.

Moisture

Carroll Touch modular flat panel touch system are designed to function

at up to 95% non-condensing humidity. In addition, modular flat panel

systems can be sealed, making the touch system impervious to

precipitated moisture, such as rain, dousing, or sprinkling, as long as it

is mounted in a vertical position. As shown in Figure 1-3, an improperly

mounted system can permit water to pool in the face of the modular

system, absorbing a portion of the IR beam strength. The

programmable gain features built into the ASIC and firmware will

compensate for losses of beam strength in the range of 50-90% with no

system failure.

1-4 Modular Flat Panel Mounting and Environments Guide

Page 12

CARROLL TOUCH Chapter 1 - Introduction

Figure 1-3. Mounting to Prevent Moisture Accumulation

Ambient Light

Since IR touch systems operate using the IR portion of light, ambient

light, the light in the touch environment, has long been a source of

concern. Ambient light has varying levels of IR radiation, depending on

whether the source of visible light is IR rich, as is sunlight, or IR poor,

as is fluorescent light commonly used in offices. A high ambient light

level in the well lit office would have little effect on the functionality of

a scanning IR touch system.

Carroll Touch has developed advanced design techniques that allow the

modular flat panel touch system to adjust to high levels of ambient

light. These methods involve hardware design and the use of patented

signal processing circuitry and algorithms, which can handle very high

ambient light levels. Carroll Touch modular flat panel touch systems

can tolerate well over 7,500 footcandles, and operate in full sunlight

with only minor modification. Typical ambient light measurements are

given in Table 1-1.

Table 1-1. Environmental Light Strengths

Ambient Light Footcandles Ambient Light Footcandles

Direct sunlight 10,000 Twilight 1

Indirect sunlight 4,000 Well lit office 80

Overcast day 100 Well lit factory 70

Dark overcast day 10

Modular Flat Panel Mounting and Environments Guide 1-5

Page 13

Chapter 1 - Introduction CARROLL TOUCH

Particulates

Particulate contaminants such as dust, powder, smoke, and other

particles found in the atmosphere of offices, manufacturing facilities,

industrial and outdoor sites, have been considered the most common

environmental hazard to IR touch systems. The two traditional places

for such buildup were on the outer surface of the protective bezel, and

on the IR LEDs and phototransistors themselves. The buildup of

particulates around the LEDs and receivers is easily prevented by basic

sealing. Today’s modular systems are so easily sealed that such buildup

is preventable at little cost. Guidelines for sealing a modular flat panel

touch system can be found in Chapter 4 of this guide.

While particulate buildup on the protective bezel can lower signal

strength in the opto-matrix grid, the integrity of the touch system is

safeguarded by programmable gain and servo-loop circuitry. This

circuitry and the attendant firmware dynamically compensates for

degradation of the opto-electronic devices and for the effects of such

environmental factors as ambient light variation and the accumulation

of particulate contaminants.

Despite this built-in protection against weakened signal strength caused

by buildup of particulates, the outer surface of the protective bezel

should be dusted and/or cleaned with a mild soapy solution as needed.

Application Environments

Table 1-2 identifies four types of application environments, gives

examples of each, and lists the environmental factors common to each.

Table 1-2. Application Environments

Application

Environment

Indoor Offices, lobbies, schools, retail Particulate contaminants

Outdoor Outdoor information kiosks,

Industrial Manufacturing facilities, laboratories,

Typical Locations Environmental Factors

Particulate contaminants, moisture,

automated teller machines (ATMs)

normal shop floor environments

chemicals, ambient light,

temperature, shock

Particulate contaminants, moisture,

chemicals

Harsh Ruggedized industrial equipment,

aircraft, vehicles, severe shop floor

environments

1-6 Modular Flat Panel Mounting and Environments Guide

Particulate contaminants, moisture,

chemicals, ambient light,

temperature, shock and vibration

Page 14

2

T

Mounting

Mounting Techniques

Techniques

his chapter describes and illustrates four separate mounting

schemes, each of which is designed to increase the functionality of

the touch system in a different environment. The mounting methods

include:

• Simplest Mounting Method.

• Typical NEMA 4 Mounting Method.

• Anti-Shock/Vibration Mounting Method.

• Industrial or Medical Mounting Method.

Modular Flat Panel Mounting and Environments Guide 2-1

Page 15

Chapter 2 - Mounting Techniques CARROLL TOUCH

Simplest Mounting Method

The simplest mounting technique provides effective sealing by merely

using industrial strength double-sided tape to adhere both the touch

system and the host display to the inside of a kiosk or enclosure

opening. Front and side views are shown in Figures 2-1 and 2-2.

Back Housing

Flat Panel Display

Filter

Gasket

Bezel

Double-Sided Tape

8-Pin TelephoneType Cable

Figure 2-1. Simplest Mounting Method (Front View)

2-2 Modular Flat Panel Mounting and Environments Guide

Page 16

CARROLL TOUCH Chapter 2 - Mounting Techniques

Bezel

Flat Panel Display

Back

Housing

Viewing

Area

Filter

Gasket

Front Panel

Contact Point of

Double-Sided Tape

Figure 2-2. Simplest Mounting Method (Side View)

Modular Flat Panel Mounting and Environments Guide 2-3

Page 17

Chapter 2 - Mounting Techniques CARROLL TOUCH

Typical NEMA 4 Mounting Method

Figures 2-3 and 2-4 show the front and side views of a typical NEMA

4 sealable mounting. For more information on gasketing materials, see

Chapter 4 of this guide.

Back Housing

Flat Panel Display

Filter

Gasket

Bezel

Front Panel Gasket

8-Pin TelephoneType Cable

Figure 2-3. Typical NEMA 4 Mounting Method (Front View)

2-4 Modular Flat Panel Mounting and Environments Guide

Page 18

CARROLL TOUCH Chapter 2 - Mounting Techniques

Bezel

Flat Panel Display

Back Housing

Viewing

Area

Filter

Front Panel

Gasket

Front Panel Gasket

Figure 2-4. Typical NEMA 4 Mounting Method (Side View)

Modular Flat Panel Mounting and Environments Guide 2-5

Page 19

Chapter 2 - Mounting Techniques CARROLL TOUCH

Anti-Shock/Vibration Mounting Method

The shock and vibration resistance of a Carroll Touch modular touch

system can be further enhanced by mounting techniques such as the one

shown in Figure 2-5. This mounting is used in commercial aircraft and

must withstand the vibration of the aircraft engines and the shock of air

turbulence and landings, which can often be measured in impacts of

multiple Gs of force.

Shock Absorbers

Back Housing

Flat Panel Display

Filter

Gasket

Touch Frame

Panel Gasket

Front Housing

Figure 2-5. Anti-Shock/Vibration Mounting Method

2-6 Modular Flat Panel Mounting and Environments Guide

Page 20

CARROLL TOUCH Chapter 2 - Mounting Techniques

Industrial or Medical Mounting Method

The sealing of a touch system is nowhere more important than in the

surgical operating room (O.R.), where the entire system must be

scrubbed between uses. The capacity to seal a system can be enhanced

by the mounting techniques shown in Figure 2-6. The use of a Carroll

Touch modular touch system and compact flat panel display in cramped

conditions such as those found in the surgical O.R. is further supported

by the touch frame’s capacity for being located up to six feet from its

host computer, connected only by a standard 8-pin telephone-type jack

and cable.

Back Housing

Flat Panel Display

Filter

Gasket

Touch Frame

Panel Gasket

Front Housing

Figure 2-6. Industrial or Medical Mounting Method

Modular Flat Panel Mounting and Environments Guide 2-7

Page 21

Chapter 2 - Mounting Techniques CARROLL TOUCH

2-8 Modular Flat Panel Mounting and Environments Guide

Page 22

3

T

Bezel/Filter

Bezel/Filter Assembly

Assembly

his chapter describes the component materials and chemical

properties of the bezel/filter assembly. Topics discussed include:

• Component Materials.

• Polycarbonate Chemical Resistance.

Modular Flat Panel Mounting and Environments Guide 3-1

Page 23

Chapter 3 - Bezel/Filter Assembly CARROLL TOUCH

Component Materials

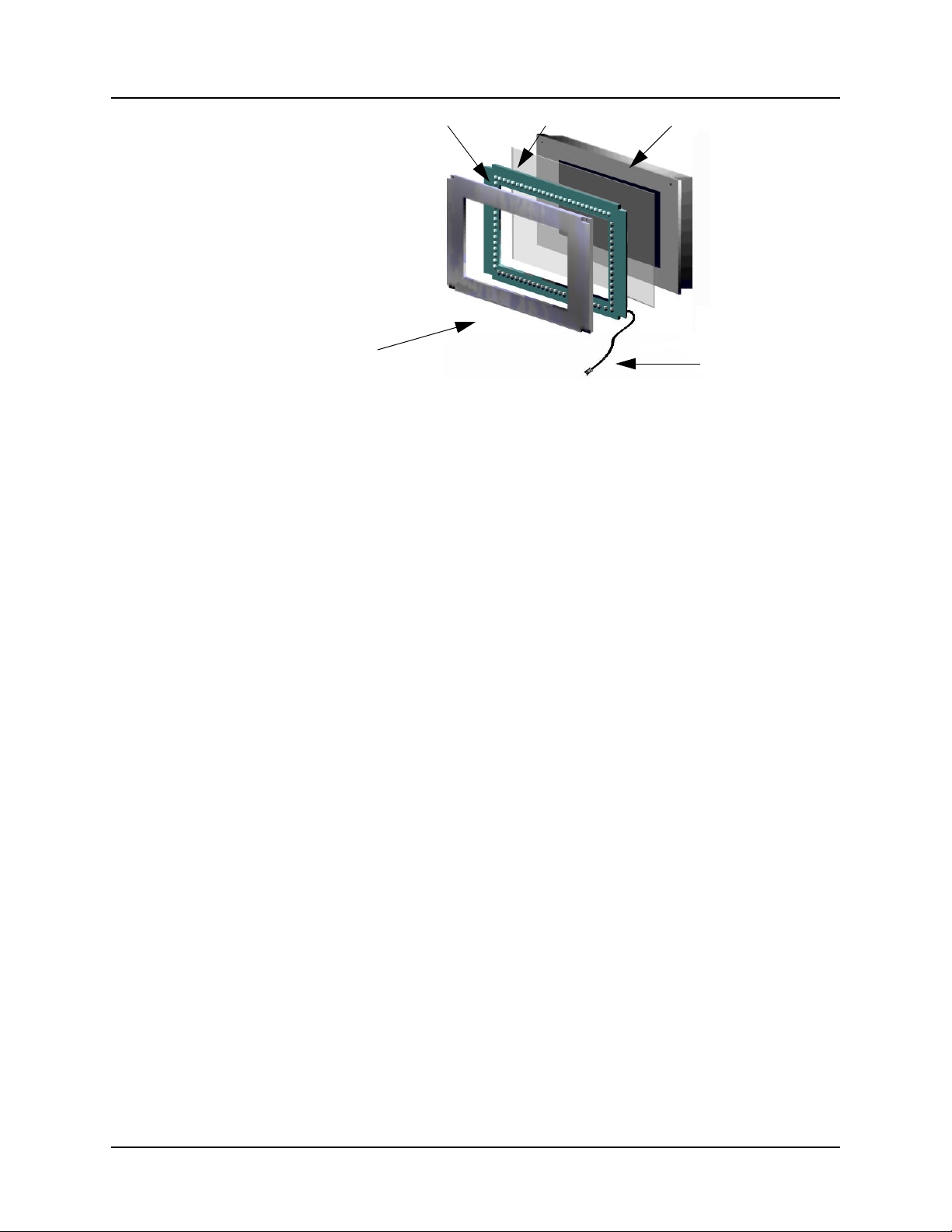

The IR-transparent protective bezel used by Carroll Touch’s standard

modular flat panel touch systems, shown in Figure 1-2, is vacuum

formed from polycarbonate resin. This same resin in transparent grades

is used to form the standard touch system filter.

From a wide spectrum of possible manufacturing materials,

polycarbonate was chosen because it is rugged, IR-transparent and

thermoformable. Indeed, this material is so impact resistant that it is

used for bulletproof glass. Polycarbonates maintain their physical

strength far past 100° C, even under impact testing.

Modular touch system filters with special optical properties such as

polarization, anti-glare and anti-reflection are available from Carroll

Touch. Polarizing filters are more sensitive to temperature extremes

than polycarbonate filters. Contact Carroll Touch for options and

details.

Polycarbonate Chemical Resistance

Certain combinations of chemical environments, temperature, and

stress can adversely affect thermoplastic parts made from

polycarbonate resin. For this reason, lubricants, gaskets, O-rings,

cleaning solvents, or any other material that may come in contact with

the finished part should be carefully evaluated under end-use

conditions for compatibility.

Polycarbonate resin is generally stable to water, mineral acids and

organic acids.

Testing of the polycarbonate resins used in the manufacture of Carroll

Touch touch system components has yielded the results shown in Table

3-1. However, interpretation of the test results is somewhat subjective.

If a material is found to be incompatible in a short term test, it will

usually be incompatible in the field. The converse, however, is not

always true. Favorable performance is no guarantee that actual end-use

conditions have been duplicated.

Caution

The results of these tests should be used as a guide only. We

recommend that you test production parts under true end-use

conditions.

3-2 Modular Flat Panel Mounting and Environments Guide

Page 24

CARROLL TOUCH Chapter 3 - Bezel/Filter Assembly

Table 3-1. Effects of Chemical Classes on Polycarbonates

Chemical Class Effects

Acids No effect under most common conditions of concentration and temperature.

Alcohols Generally compatible at low concentration and room temperature. Higher concentrations

and elevated temperatures results in etching and attack, evidenced by decomposition.

Alkalis Generally compatible at low concentration and room temperature. Higher concentrations

Aliphatic Hydrocarbons Generally compatible.

Amines Surface crystallization and chemical attack. Avoid.

Aromatic Hydrocarbons Partial solvents and severe stress cracking agents (i.e., xylene, toluene). Avoid.

Detergents and Cleaners Mild soap solutions are compatible. Avoid strong alkaline materials.

Esters Cause severe crystallization. Partial solvents. Avoid.

Halogenated Hydrocarbons Solvents. Avoid.

Ketones Cause severe crystallization and stress cracking. Partial solvents. Avoid.

Silicone Oils and Greases Generally compatible up to 185° F. Avoid those that contain aromatic hydrocarbons.

and elevated temperatures results in etching and attack, evidenced by decomposition

Polycarbonate is dissolved by the following substances:

Chloroform Dioxane Methylene chloride Pyridine

Cresol Ethylene dichloride

Polycarbonate may not be resistant to the following substances:

Acetaldehyde Butyric acid Ethane tetrachloride Phosphorous trichloride

Acetic acid (concentrated) Carbolic acid Ethylamine Propionic acid

Acetone Carbon disulphide Ethyl ether Sodium sulfide

Acrylonitrile Carbon tetrachloride Ethylene chlorohydrin Stryrene

Ammonium fluoride Caustic potash sol (5%) Formic acid (concentrated) Sulfuryle chloride

Ammonium sulfide Caustic soda sol. (5%) Freon (refrigerant and propellant) Tetrahydronapthalene

Benzene Chlorobenzene Nitrobenzene Thiophene

Benzoic acid Cyclohexanone Nitrocellulose lacquer Toluene

Benzyl alcohol Cyclohexane Phenol Xylene

Bromobenzene Dimethyl formamide Phosphorous hydroxy chloride

Polycarbonate has limited resistance to the following substances:

Cyclohexanol Hydrochloric acid (concentrated) Nitric acid (concentrated) Sulphuric acid (concentrated)

Gasoline Milk of lime (CaOH)

Modular Flat Panel Mounting and Environments Guide 3-3

Page 25

Chapter 3 - Bezel/Filter Assembly CARROLL TOUCH

At room temperature, polycarbonate is resistant to the following

substances:

Acetic acid (20%) Cyclohexane Milk Salt solution (10%)

Aluminum chloride Decahydronapthalene Mineral heating oil Silicone oil

Aluminum sulphate Diesel oil Mineral water Silver nitrate

Ammonium chloride Ethyl alcohol (96%) Mustard Soap (soft & hard)

Ammonium nitrate Fish oil Nickel sulphate Sodium bicarbonate

Ammonium sulphate Floor polish Nitric acid (10% & 20%) Sodium bisulphate

Antimony trichloride Formic acid (10%) Oleic acid Sodium bisulphite

Arsenic acid (20%) Formalin (30%) Orange juice, peel Sodium carbonate

Axle oil Gasoline (low aromatic) Oxalic acid Sodium chlorate

Beer Glazier’s putty Paraffin oil Sodium chloride

Borax Glycerine Pentane Sodium hypochlorite

Brake fluid Glycol Petrol Sodium sulphate

Butyl alcohol Grapefruit peel, juice Petroleum ether Spindle oil

Calcium chloride Gypsum Phosphoric acid, concentrated Stannous chloride

Calcium nitrate Hydrochloric acid (10% & 20%) Potassium aluminum alum Sulphur

Castor oil Hydrogen peroxide (30%) Potassium bichromate Sulphuric acid (10% & 20%)

Cement Hydrofluoric acid (20%) Potassium bromate Tartaric acid (30%)

Chlorinated lime paste Ink Potassium bromide Tincture of iodine

Chlorinated lime sol. (2%) Iron chloride Potassium chloride Tomato juice, concentrate

Chrome alum Iron sulphate Potassium nitrate Transformer oil

Chromic acid (20%) Insulating tape Potassium perchlorade Trichloroacetic acid

Citric acid (40%) Isoamyl alcohol Potassium permanganate Turpentine

Cocoa Lactic acid Potassium persulphate Vacuum pump oil

Coffee Linseed oil & varnish Potassium sulphate Vinegar

Cognac Liqueur Propyl alcohol Vodka

Compressor oil Magnesium chloride Rapeseed oil Water

Copper chloride Magnesium sulphate Refined oil Wine

Copper sulphate Manganese sulphate Rum Zinc chloride

Cuprous chloride Mercuric chloride Salad oil Zinc sulphate

3-4 Modular Flat Panel Mounting and Environments Guide

Page 26

4

O

Sealing and

Sealing and Coating

Coating

nce an application environment is analyzed, most customers find

that they will be able to use Carroll Touch modular flat panel

touch systems without any adaptation. However, in some instances, it

may be necessary to enhance the standard touch system with additional

sealing or conformal coating.

This chapter discusses the following topics:

• Sealing.

• Coating.

Modular Flat Panel Mounting and Environments Guide 4-1

Page 27

Chapter 4 - Sealing and Coating CARROLL TOUCH

Sealing

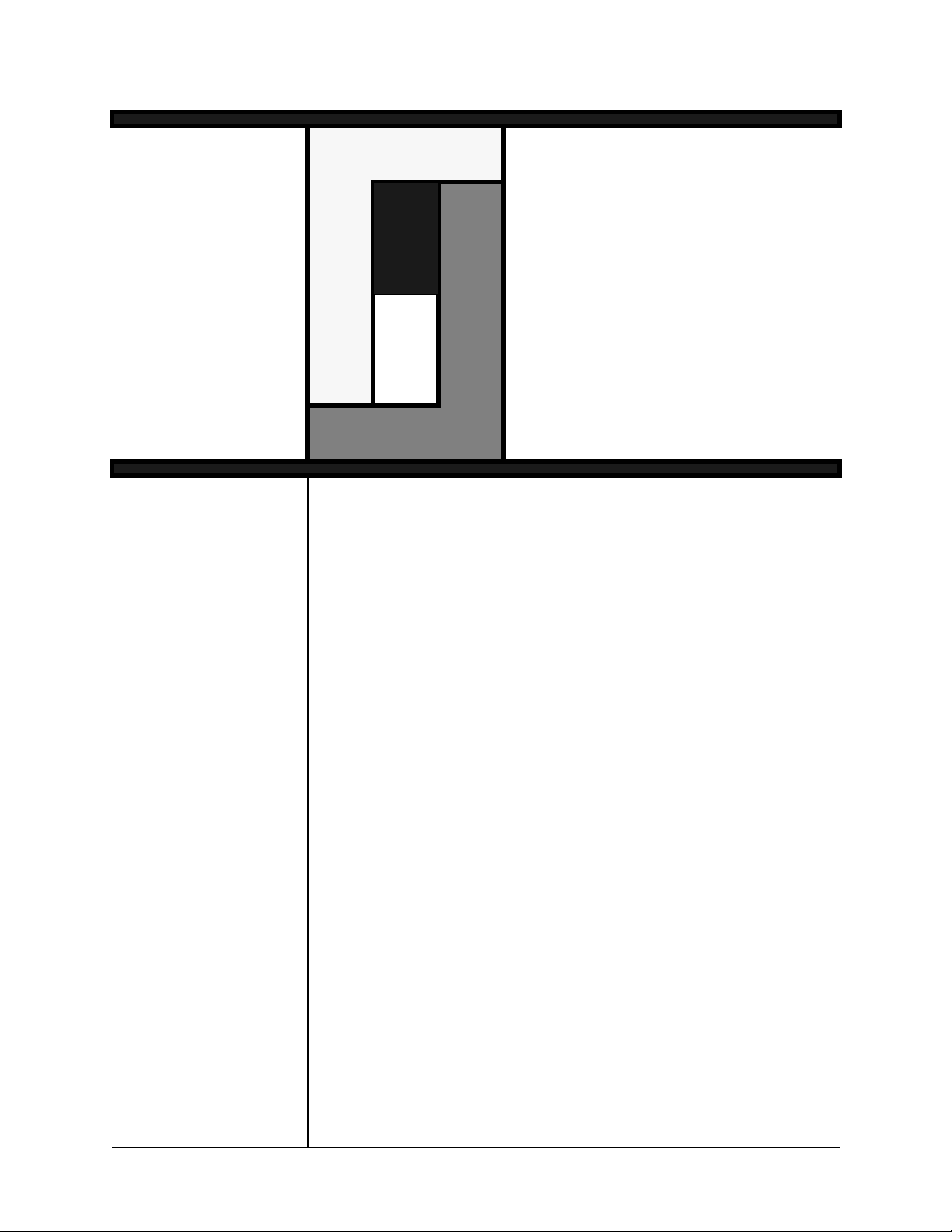

As shown in Figure 4-1, the modular flat panel touch system is sealed

by the application of gasketing material or sealant between the two

contact edges of the IR-transparent protective bezel and the filter. This

seal provides adequate protection against accidental exposure to

liquids, such as that involved in cleaning or spillage.

Figure 4-1. Modular Flat Panel Touch System Sealing

Modular bezels are fitted with gasket material at the factory. Carroll

Touch offers enhanced sealing with assorted sealants and gasket

materials as a custom service.

With CRT touch systems, gasketing is the preferred method, since it

allows easy disassembly and efficient access for cleaning and

maintenance of the touch system. The amount of cleaning required is

dependent on the amount of dust or moisture in the environment and the

quality of the seal. Unlike CRT monitors, flat panels do not attract dust.

Therefore, the buildup of dust in the interior of a modular flat panel

touch system does not occur.

Gasket material characteristics that must be considered are

compression resilience (how the material bounces back after

compression), and moisture and chemical resistance. Recommended

gasket materials are polyester, urethane, and silicone.

Polyester and urethane are available as open cell or closed cell

materials. Open cell polyester and urethane cost less than silicone.

Closed cell sealing material is preferred in environments containing

moisture or chemicals. Polyester and urethane are resistant to ozone,

oxidation and hydrocarbons and can withstand wide temperature

variations.

4-2 Modular Flat Panel Mounting and Environments Guide

Page 28

CARROLL TOUCH Chapter 4 - Sealing and Coating

Silicone is an environmentally inert material available in sponge or

solid form. It is recommended for application environments that

involve electrostatic discharge, severely caustic or actively corrosive

chemicals, high moisture, broad temperature ranges, oxidation, or

acids.

Coating

In the case of certain high density or high current circuits, or in harsh or

explosive environments where the intent is to prevent corrosion,

erosion, arcing or sparking, or in the face of critical service issues

where the failure of a circuit could cause loss of human life, conformal

coating is used as a second method to seal a circuit. Carroll Touch has

used conformal coating only rarely in the past for extremely ruggedized

or military applications.

Conformal coating is a polyurethane resin insulating compound that is

sprayed on or washed over the printed circuit board assembly during

the manufacturing process. It may be required in outdoor information

systems, shipboard applications, industrial environments, or wherever

moisture or corrosives must be prevented from entering the system.

Conformal coating is the ultimate seal for the touch system, providing

an excellent environmental shield from fungus, thermal shock,

moisture and chemicals such as sulphuric acid.

Modular Flat Panel Mounting and Environments Guide 4-3

Page 29

Chapter 4 - Sealing and Coating CARROLL TOUCH

4-4 Modular Flat Panel Mounting and Environments Guide

Page 30

CARROLL TOUCH Glossary

Glossary

ambient light The level of light to be found in the physical environment of a

given touch application, normally measured in lux or footcandles.

axis (x-axis, y-axis) The two dimensions that make up the touch coordinate system.

The x-axis (horizontal) is composed of the vertical physical

beams or opto-pairs (the physical x-axis). The y-axis (vertical) is

composed of the horizontal physical beams or opto-pairs (the

physical y-axis).

beam The infrared light transmitted by an IR LED and received by a

phototransistor, which are set opposite each other in the touch

frame.

bezel The IR-transparent plastic protective housing of the modular flat

panel touch frame, which is fastened to the filter.

broken beam A beam in which the infrared light level received by the

IR-sensitive phototransistor falls below a threshold value set by

the touch system firmware. In normal operation, this is due to the

user’s finger obstructing the beam path from the LED to the

phototransistor. However, broken beams may also result from a

defective LED, phototransistor, or other touch system hardware,

and from other obstructions of the beam path. See also beam.

host (host system) The computer system to which the IR touch system is added.

MDI See modular digital interface (MDI).

modular digital interface

(MDI)

opto-matrix frame A rectangle, each side of which is comprised of a circuit board.

opto-pair The LED/phototransistor combination that transmits and receives

touch controller The circuitry and firmware necessary to interpret touch data for a

The frame-to-controller interface created by confining all analog

functions to the frame. The MDI makes a standard touch frame

controller-independent and reduces the touch system cabling

requirement to a simple 8-pin standard phone cable up to six feet

long.

Two adjacent circuit boards contain banks of IR LEDs, while the

second two contain banks of complementary phototransistor

receivers. The horizontal boards contain the banks of opto-pairs

that make up the x-axis of the touch screen. The vertical boards

contain the banks of opto-pairs that make up the y-axis of the

touch screen.

an IR beam. See beam.

host computer.

Modular Flat Panel Mounting and Environments Guide GL-1

Page 31

Glossary CARROLL TOUCH

touch frame The portion of the modular touch system that consists of the

opto-matrix frame, the IR-transparent protective bezel and the

modular digital interface (MDI).

touch system The collection of all the components that are necessary to detect a

touch and report it to the host. This collection usually consists of

the touch frame or screen, protective bezel, and touch frame

controller.

GL-2 Modular Flat Panel Mounting and Environments Guide

Page 32

CARROLL TOUCH Index

Index

A

altitudes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ambient light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3, 1-5, 1-6

anti-glare filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

anti-reflection filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

anti-shock/vibration mounting technique . . . . . . . . . . . . . . . . . . . 2-6

application environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

arcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

B

bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2, 1-6, 3-2, 4-2

C

chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3, 1-4, 4-2, 4-3

commercial aircraft, mounting techniques in . . . . . . . . . . . . . . . . 2-6

conformal coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

D

dust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6, 4-2

E

effects of chemicals on polycarbonate resin . . . . . . . . . . . . . . . . . 3-2

electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

environmental factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

erosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

F

filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2, 3-2, 4-2

fluorescent light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

G

gasket materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2, 4-3

gasket properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Modular Flat Panel Mounting and Environments Guide IN-1

Page 33

Index CARROLL TOUCH

H

heat dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3, 1-4

I

industrial or medical mounting technique . . . . . . . . . . . . . . . . . . 2-7

infrared radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2, 1-5

L

light emitting diodes (LEDs) . . . . . . . . . . . . . . . . . . . . . . . . .1-2, 1-6

M

modular digital interface (MDI) . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3, 1-4, 4-2, 4-3

mounting technique

anti-shock/vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

industrial or medical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

NEMA 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

simple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

N

NEMA 4 mounting technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

O

opto-matrix frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

opto-pairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

oxidation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2, 4-3

ozone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

P

particulate contaminants . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3, 1-6

phototransistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2, 1-6

physical beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

polarizing filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

polycarbonate resins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4, 3-2

polycarbonate resins, resistance to various substances . . . . . .3-2, 3-3

polycarbonate resins, testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

IN-2 Modular Flat Panel Mounting and Environments Guide

Page 34

CARROLL TOUCH Index

polyester gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

polyurethane resin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

powder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

S

sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6, 2-2, 2-7, 4-2

shock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3, 1-4, 2-6

silicone gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

simple mounting technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

smoke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

sparking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

sunlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

surgical operating room, mounting techniques in . . . . . . . . . . . . 2-7

T

temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

touch systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

U

urethane gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

V

vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3, 1-4, 2-6

Modular Flat Panel Mounting and Environments Guide IN-3

Page 35

Index CARROLL TOUCH

IN-4 Modular Flat Panel Mounting and Environments Guide

Page 36

CONTACTING CARROLL TOUCH:

Carroll Touch (512) 244-3500Switchboard

2800 Oakmont Drive (800) 386-8241Toll Free

Round Rock, Texas 78664 (512) 388-5643Order Assistance

(512) 388-5509Technical Support

(512) 244-7040Fax

http://www.carrolltouch.com (512) 388-5668Bulletin Board (14400K,N81)

Loading...

Loading...