TouchSystem

Programmer's

Guide

CARROLLTOUCH

TOUCHPRODUCTS

ancompanyAMP

Touch System

Programmer’s

Guide

CARROLL TOUCH

TOUCH PRODUCTS

an AMP company

August 1996

Part #: 2970-0011-01-Rev A

Copyright

Copyright ©1996 Carroll Touch. All rights reserved.

Trademarks

Smart-Frame is a trademark of Carroll Touch, Round Rock, Texas.

IBM and PC are trademarks of International Business Machines

Corporation.

All other brands and product names are trademarks of their respective

owners.

Disclaimer

Carroll Touch has a policy of continually improving products as new

technology becomes available. Carroll Touch reserves the right to make

changes and improvements to the specifications of this equipment at

any time without notice.

Carroll Touch has made every attempt to ensure that the information in

this document is accurate and complete. Carroll Touch assumes no

liability for any damages that result from the use of this manual or the

equipment it documents. Carroll Touch reserves the right to make

changes to this document at any time without notice.

CARROLL TOUCH Table of Contents

Table of Contents

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1. Introduction to Infrared Touch Systems . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Touch Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Touch Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Interpolating Touch Coordinates. . . . . . . . . . . . . . . . . . . . 1-3

Reporting Touch Coordinates . . . . . . . . . . . . . . . . . . . . . . 1-4

Failed Beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Criteria for Failing a Beam . . . . . . . . . . . . . . . . . . . . . 1-5

Failed Beam Timing Parameters . . . . . . . . . . . . . . . . . 1-5

Criteria for Unfailing a Beam . . . . . . . . . . . . . . . . . . . 1-7

Failed Beam Reports . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2. Introduction to Guided Wave Touch Systems . . . 2-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Touch Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Touch Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

EEPROM File and Parameters . . . . . . . . . . . . . . . . . . . . . 2-3

3. General Programming Issues . . . . . . . . . . . . . . . . 3-1

Hardware Configurations . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Built-In Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

External Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Application Program Interface . . . . . . . . . . . . . . . . . . 3-4

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Floating Point Calibration Program Design . . . . . . . . 3-7

Floating Point Calibration Examples. . . . . . . . . . . . . . 3-8

HBC I/O Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Sending a Touch Command to the HBC . . . . . . . . . . . 3-9

Receiving Touch Data from the HBC . . . . . . . . . . . . 3-10

Polling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Interrupt Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Resetting the HBC. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

i

Table of Contents CARROLL TOUCH

4. Smart-Frame Protocol . . . . . . . . . . . . . . . . . . . . . . 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

SFP and SFP-II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Types of SFP Commands . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Communication Commands . . . . . . . . . . . . . . . . . . . . 4-3

Reporting Method Commands. . . . . . . . . . . . . . . . . . . 4-3

Touch Mode Commands . . . . . . . . . . . . . . . . . . . . . . . 4-4

Information Request Commands. . . . . . . . . . . . . . . . . 4-5

System Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Touch System Initialization. . . . . . . . . . . . . . . . . . . . . . . . 4-7

Resetting the Touch System . . . . . . . . . . . . . . . . . . . . 4-7

Power Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Dedicated Reset Signal . . . . . . . . . . . . . . . . . . . . . 4-7

Break (Hardware Detected). . . . . . . . . . . . . . . . . . 4-7

HBC Hardware Reset Register . . . . . . . . . . . . . . . 4-8

Break (Firmware Detected) . . . . . . . . . . . . . . . . . . 4-8

Reset (45H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Performing the Autobaud/Autoparity Sequence . . . . . 4-8

Checking for Touch System Errors . . . . . . . . . . . . . . . 4-9

Setting the Reporting Method and Touch Mode . . . . 4-10

Touch System Initialization Examples . . . . . . . . . . . . . . 4-10

Using Autobaud/Autoparity . . . . . . . . . . . . . . . . . . . 4-10

Using a Fixed Baud Rate. . . . . . . . . . . . . . . . . . . . . . 4-11

Using the HBC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Using an SBC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Compatibility Issues/Programming Tips. . . . . . . . . . . . . 4-12

Number of Processors Independence . . . . . . . . . . . . 4-13

Firmware Version Independence. . . . . . . . . . . . . . . . 4-13

Frame Size Independence . . . . . . . . . . . . . . . . . . . . . 4-13

Touch System Response Time Independence . . . . . . 4-13

SFP Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Autobaud/Autoparity Delay Time. . . . . . . . . . . . . . . 4-14

Maximum Command Completion Time . . . . . . . . . . 4-14

Reset Time/Diagnostics Completion Time . . . . . . . . 4-14

SFP Programming Examples. . . . . . . . . . . . . . . . . . . . . . 4-14

5. Smart-Frame Protocol II . . . . . . . . . . . . . . . . . . . . 5-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Extensibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Modal Protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Backward Compatibility . . . . . . . . . . . . . . . . . . . . . . . 5-4

Types of SFP-II Functions. . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

ii

CARROLL TOUCH Table of Contents

Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Validation Layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Interpretation Layer. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Validation Layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Interpretation Layer. . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Reporting Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Report Transfer Mode . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Error Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Invalid Command Number . . . . . . . . . . . . . . . . . . . . 5-12

Invalid Parameter Value . . . . . . . . . . . . . . . . . . . . . . 5-13

Unsupported Feature . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Invalid Byte Count. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Not Enough Parameters. . . . . . . . . . . . . . . . . . . . . . . 5-17

Too Many Parameters . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Overloaded Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Shared Parameters between SFP and SFP-II. . . . . . . . . . 5-19

Touch Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Report Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

6. Touch Application Program Interface (TAPI) . . 6-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Installing a TAPI Driver . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

SBC Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

HBC Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

RS-232 Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Determining if a TAPI Driver Is Installed. . . . . . . . . . . . . 6-7

Calling TAPI Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Touch System Initialization Using a TAPI Driver . . . . . . 6-8

TAPI Programming Examples. . . . . . . . . . . . . . . . . . . . . . 6-9

7. CTKERN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Touch Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Calibration and Scaling Examples. . . . . . . . . . . . . . . . . . . 7-5

Temporal Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Methods for Interfacing CTKERN and an Application

Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Polling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Interrupt Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

iii

Table of Contents CARROLL TOUCH

Loading the CTKERN Driver . . . . . . . . . . . . . . . . . . . . . . 7-9

Command Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Determining If the CTKERN Driver Is Installed . . . . . . 7-13

Calling CTKERN Functions . . . . . . . . . . . . . . . . . . . . . . 7-13

CALIB.EXE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Command Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Calibrate Mono, EGA, VGA Video Modes . . . . 7-16

Calibrate Other Video Modes . . . . . . . . . . . . . . . 7-17

Edit Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Delete Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

CALIB.DAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

CTKERN Programming Examples . . . . . . . . . . . . . . . . . 7-20

8. Dynamic Link Library (DLL) Functions . . . . . . . 8-1

Calling Windows Driver DLL Functions . . . . . . . . . . . . . 8-2

A. Smart-Frame Protocol Command Reference . . . A-1

Add_Exit_Point_Modifier (29H) ()) . . . . . . . . . . . . . .A-5

Clear_Touch_Report_Buffer (3DH) (=) . . . . . . . . . . .A-6

Continuous_Mode (27H) (’) . . . . . . . . . . . . . . . . . . . .A-7

Coordinate_Reporting (23H) (#) . . . . . . . . . . . . . . . . .A-8

Echo_Off (21H) (!) . . . . . . . . . . . . . . . . . . . . . . . . . .A-10

Echo_On (20H) (SPACE) . . . . . . . . . . . . . . . . . . . . .A-11

Enter_Point_Mode (25H) (%) . . . . . . . . . . . . . . . . . .A-12

Exit_Point_Mode (28H) (() . . . . . . . . . . . . . . . . . . . .A-13

Get_Configuration_Report (33H) (3) . . . . . . . . . . . .A-14

Get_Error_Report (32H) (2) . . . . . . . . . . . . . . . . . . .A-15

Get_Failed_Beam_Report (36H) (6). . . . . . . . . . . . .A-19

Get_Firmware_Version_Report (34H) (4) . . . . . . . .A-21

Get_Frame_Size_Report (37H) (7) . . . . . . . . . . . . . .A-23

Get_One_Report (46H) (F) . . . . . . . . . . . . . . . . . . . .A-24

Get_State_Report (47H) (G) . . . . . . . . . . . . . . . . . . .A-25

Hardware_Flow_Control_Off (42H) (B). . . . . . . . . .A-27

Hardware_Flow_Control_On (41H) (A). . . . . . . . . .A-28

Report_Transfer_Off (43H) (C) . . . . . . . . . . . . . . . .A-29

Report_Transfer_On (44H) (D). . . . . . . . . . . . . . . . .A-30

Reset (45H) (E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-31

Run_Diagnostics (3AH) (:) . . . . . . . . . . . . . . . . . . . .A-32

Scan_Reporting (22H) (”) . . . . . . . . . . . . . . . . . . . . .A-33

Software_Reset (3CH) (<). . . . . . . . . . . . . . . . . . . . .A-34

SwitchToSFP-II (65H) . . . . . . . . . . . . . . . . . . . . . . .A-35

Touch_Scanning_Off (2BH) (+) . . . . . . . . . . . . . . . .A-37

iv

CARROLL TOUCH Table of Contents

Touch_Scanning_On (2AH) (*) . . . . . . . . . . . . . . . .A-38

Tracking_Mode (26H) (&) . . . . . . . . . . . . . . . . . . . .A-39

B. Smart-Frame Protocol II Function Reference . . B-1

GetConfiguration (11H) . . . . . . . . . . . . . . . . . . . . . . .B-3

GetCoordinateRanges (10H) . . . . . . . . . . . . . . . . . . . . B-8

GetProtocolVersion (65H). . . . . . . . . . . . . . . . . . . . .B-10

GetTouchState (01H). . . . . . . . . . . . . . . . . . . . . . . . . B-12

SetReportProperties (21H) . . . . . . . . . . . . . . . . . . . . B-14

SetReportTransferMode (22H) . . . . . . . . . . . . . . . . . B-19

SetTouchModes (20H) . . . . . . . . . . . . . . . . . . . . . . . B-24

SwitchToClassicSFP (64H). . . . . . . . . . . . . . . . . . . . B-29

C. TAPI Function Reference . . . . . . . . . . . . . . . . . . . C-1

CheckForReports (3) . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

GetCommunicationParameters (4) . . . . . . . . . . . . . . . C-4

GetReports (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

GetTAPIDriverConfiguration (6) . . . . . . . . . . . . . . . .C-7

GetUserEventHandlerParameters (8) . . . . . . . . . . . . . C-8

Reset (0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

SendCommand (1). . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

SetCommunicationParameters (5). . . . . . . . . . . . . . . C-11

SetSBCFrameSize (40H). . . . . . . . . . . . . . . . . . . . . . C-13

SetUserEventHandler (7). . . . . . . . . . . . . . . . . . . . . .C-14

D. CTKERN Function Reference . . . . . . . . . . . . . . . D-1

GetCalibrationTableEntry (7) . . . . . . . . . . . . . . . . . . .D-5

GetCommunicationParameters (22) . . . . . . . . . . . . . .D-7

GetCTKERNDriverConfiguration (20). . . . . . . . . . . .D-8

GetCurrentCalibrationModeAndParameters (5) . . . . .D-9

GetCurrentScalingModeAndParameters (10) . . . . . .D-10

GetTAPIDriverConfiguration (19) . . . . . . . . . . . . . .D-11

GetTemporalFilterModeAndParameters (16) . . . . . .D-12

GetTouchState (1) . . . . . . . . . . . . . . . . . . . . . . . . . . .D-13

GetTouchSystemStatus/Configuration (17) . . . . . . .D-15

GetUserEventHandlerModeAndParameters (25) . . .D-16

GetZ-AxisScalingModeAndParameters (13) . . . . . .D-17

Reset (0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-18

SendSmart-FrameProtocolCommand

AndGetReport (18) . . . . . . . . . . . . . . . . . . . . . . . .D-20

SetCalibrationMode (3). . . . . . . . . . . . . . . . . . . . . . .D-22

SetCalibrationParameters (4). . . . . . . . . . . . . . . . . . .D-23

SetCalibrationTableEntry (6) . . . . . . . . . . . . . . . . . .D-24

SetCommunicationParameters (21). . . . . . . . . . . . . .D-26

SetScalingMode (8). . . . . . . . . . . . . . . . . . . . . . . . . .D-28

v

Table of Contents CARROLL TOUCH

SetScalingParameters (9). . . . . . . . . . . . . . . . . . . . . .D-29

SetTemporalFilterMode (14). . . . . . . . . . . . . . . . . . .D-31

SetTemporalFilterParameters (15) . . . . . . . . . . . . . .D-34

SetTouchState (2) . . . . . . . . . . . . . . . . . . . . . . . . . . .D-36

SetUserEventHandlerMode (23) . . . . . . . . . . . . . . . .D-37

SetUserEventHandlerParameters (24). . . . . . . . . . . .D-39

SetZ-AxisScalingMode (11) . . . . . . . . . . . . . . . . . . .D-40

SetZ-AxisScalingParameters (12) . . . . . . . . . . . . . . .D-41

E. Dynamic Link Library (DLL) Function Reference E-1

DisableMouse (11) . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

DisableTouch (12). . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

EnableMouse (9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

EnableTouch (10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

GetMouseInfo (13) . . . . . . . . . . . . . . . . . . . . . . . . . . . E-7

GetTemporalFilterInfo (18). . . . . . . . . . . . . . . . . . . . . E-8

GetTouchInfo (14). . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

GetTouchStateandCoord (5) . . . . . . . . . . . . . . . . . . . E-10

InitializeTouch (16). . . . . . . . . . . . . . . . . . . . . . . . . . E-11

SetCalibInfo (7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-12

SetTemporalFilterInfo (17) . . . . . . . . . . . . . . . . . . . . E-14

SetTouchEvents (8) . . . . . . . . . . . . . . . . . . . . . . . . . . E-16

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .GL-1

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IN-1

vi

CARROLL TOUCH Table of Contents

List of Figures

Figure 1-1. Infrared Touch Frame . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Figure 1-2. Beam Averaging - Example 1 . . . . . . . . . . . . . . . . . . 1-3

Figure 1-3. Beam Averaging - Example 2 . . . . . . . . . . . . . . . . . . 1-4

Figure 2-1. Guided Wave Touch Screen . . . . . . . . . . . . . . . . . . . 2-2

Figure 3-1. Built-In Smart-Frame Controller Hardware . . . . . . . 3-2

Figure 3-2. RS-232 Controller Hardware (Modular IR Touch

Systems) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-3. SBC and HBC Hardware (Modular IR Touch

Systems) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-4. Touch Control Software . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-5. Touch Calibration Screen . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 7-1. Touch System to Application Communication . . . . . 7-3

Figure 7-2. Calibration Mode Fixed or Automatic and Scaling

Mode Fixed or Automatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Figure 7-3. Calibration Mode Fixed or Automatic and Scaling

Mode Disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Figure 7-4. Calibration Mode Disabled and Scaling Mode

Fixed or Automatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Figure 7-5. Calibration Mode Disabled and Scaling Mode

Disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Figure 7-6. Calibration Main Menu Screen . . . . . . . . . . . . . . . . 7-15

Figure 7-7. Calibration Menu Screen . . . . . . . . . . . . . . . . . . . . . 7-16

Figure 7-8. Calibration Target Screen . . . . . . . . . . . . . . . . . . . . 7-16

Figure 7-9. Calibration Other Video Mode Screen #1 . . . . . . . . 7-17

Figure 7-10. Calibration Other Video Mode Screen #2 . . . . . . . 7-17

Figure 7-11. Calibration Other Video Mode Screen #3 . . . . . . . 7-18

Figure 7-12. Calibration Manual Edit Menu Screen . . . . . . . . . 7-19

Figure 7-13. Calibration Exit Prompt Screen . . . . . . . . . . . . . . . 7-19

Figure B-1. Flow Diagram for Report Transfer Mode . . . . . . . . B-19

Figure D-1. Temporal Filter Spatial Box Size . . . . . . . . . . . . . .D-32

vii

Table of Contents CARROLL TOUCH

viii

CARROLL TOUCH Table of Contents

List of Tables

Table 1-1. Failed Beam Timing Parameters . . . . . . . . . . . . . . . . . 1-5

Table 3-1. HBC I/O Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Table 3-2. Status Register Bit 0 Values . . . . . . . . . . . . . . . . . . . 3-10

Table 3-3. Status Register Bit 1 Values . . . . . . . . . . . . . . . . . . . 3-10

Table 4-1. SFP Communication Commands . . . . . . . . . . . . . . . . 4-3

Table 4-2. SFP Reporting Method Commands . . . . . . . . . . . . . . 4-4

Table 4-3. SFP Touch Mode Commands . . . . . . . . . . . . . . . . . . . 4-4

Table 4-4. SFP Information Request Commands . . . . . . . . . . . . . 4-5

Table 4-5. SFP System Commands . . . . . . . . . . . . . . . . . . . . . . . 4-6

Table 4-6. SFP Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Table 6-1. TAPI Error Messages and Explanations . . . . . . . . . . . 6-6

Table 7-1. CTKERN Error Messages . . . . . . . . . . . . . . . . . . . . . 7-10

Table A-1. SFP Commands in Alphabetical Order . . . . . . . . . . .A-3

Table A-2. SFP Commands in Numerical Order . . . . . . . . . . . . .A-4

Table A-3. Smart-Frame Protocol Error Report Error Codes . . .A-16

Table A-4. Touch System Default Settings . . . . . . . . . . . . . . . .A-34

Table B-1. SFP-II Functions in Alphabetical Order . . . . . . . . . . . B-2

Table B-2. SFP-II Functions in Numerical Order . . . . . . . . . . . .B-2

Table B-3. ComponentTypes, AttributeTags and

AttributeValues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Table C-1. TAPI Functions in Alphabetical Order . . . . . . . . . . . . C-2

Table C-2. TAPI Functions in Numerical Order . . . . . . . . . . . . . C-2

Table C-3. Typical BL/BH Register Contents . . . . . . . . . . . . . . . C-7

Table D-1. CTKERN Functions in Alphabetical Order . . . . . . . .D-3

Table D-2. CTKERN Functions in Numerical Order . . . . . . . . . .D-4

Table D-3. Typical BX Register Contents . . . . . . . . . . . . . . . . . .D-8

Table D-4. Typical BL/BH Register Contents . . . . . . . . . . . . . .D-11

Table E-1. Windows Driver DLL Functions in

Alphabetical Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Table E-2. Windows Driver DLL Functions in

Numerical Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Table E-3. Definition of Touch Events . . . . . . . . . . . . . . . . . . . E-17

ix

Table of Contents CARROLL TOUCH

x

WelcomeWelcome

s computers become a part of daily life, a technology that makes

A

them easier to use has become a necessity. Carroll Touch provides

the solution through the power of touch.

Thank you for your purchase of a Carroll Touch product and welcome

to Carroll Touch.

Purpose

Audience

Organization

This Programmer’s Guide is designed to:

• Give an overview of the touch technologies used by Carroll Touch,

with a particular emphasis on hardware and software information

(such as calibration and initialization) needed by programmers.

• Define the use and functions of the Smart-Frame Protocol, the

Smart-Frame Protocol II, the Touch Application Program Interface

(TAPI) driver, the CTKERN application interface, and the

Windows driver dynamic link libraries (DLLs).

This guide is designed for the programmer or software engineer who

integrates Carroll Touch touch systems with host computer systems.

Chapter 1, “Introduction to Infrared Touch Systems,” is an overview of

Carroll Touch infrared touch system hardware and operating principles.

Touch System Programmer’s Guide xi

Welcome CARROLL TOUCH

Chapter 2, “Introduction to Guided Wave Touch Systems,” is an

overview of Carroll Touch guided wave touch system hardware and

operating principles.

Chapter 3, “General Programming Issues,” includes information on

programming topics that apply to all Carroll Touch touch systems, such

as calibration and HBC I/O registers.

Chapter 4, “Smart-Frame Protocol,” gives an overview of the SFP

firmware protocol, including a discussion of command and report

types, initialization, timing, and programming tips and examples.

Chapter 5, “Smart-Frame Protocol II,” gives an overview of the SFP-II

firmware protocol, which extends the capabilities of SFP by offering

support of z-axes and higher resolution. Explanations of command and

report formats are included.

Chapter 6, “Touch Application Program Interface (TAPI),” includes an

overview of the TAPI software functions, and TAPI driver installation

and initialization information.

Chapter 7, “CTKERN,” includes an overview of the CTKERN

software functions, CTKERN driver installation, and parameters. It

also discusses the operation of the CTKERN calibration program

(CALIB.EXE).

Chapter 8, “Dynamic Link Library (DLL) Functions,” describes how to

use the DLL function calls to the Carroll Touch Windows driver.

Appendix A, “Smart-Frame Protocol Command Reference,” gives the

specifications for each SFP command and report.

Appendix B, “Smart-Frame Protocol II Function Reference,” gives the

specifications for each SFP-II function.

Appendix C, “TAPI Function Reference,” gives the specifications for

each TAPI function.

Appendix D, “CTKERN Function Reference,” gives the specifications

for each CTKERN function.

Appendix E, “Dynamic Link Library (DLL) Function Reference,”

gives the specifications for each Windows driver DLL.

xii Touch System Programmer’s Guide

CARROLL TOUCH Welcome

Conventions

For clarity, this guide uses certain conventions to visually distinguish

different types of information. The conventions are:

• Bold is used to emphasize a word or phrase, including definitions

of important concepts.

MALL CAPITAL LETTERS (such as SPACE or ENTER) indicates a

• S

key on the keyboard.

• Courier font indicates file names, directory names, messages

displayed by the computer, parameters in command lines, and

information to be typed by the user.

• Italics indicate a command, function name, or mode (such as

Debug Mode).

• Reports (such as the Touch Coordinate Report) and menus (such as

the Configuration Menu) use initial capital letters.

• Courier italic font indicates a variable in a command line

for which you must substitute a value.

• Hexadecimal numbers in text are identified with capital H; for

example, 1BH is the hexadecimal value 1B. Command and report

formats and examples reproduce numbers as they appear on the

screen and thus do not use the H convention.

• Information of particular importance or actions that may have

undesirable results if performed improperly are included under the

headings

Note and Caution.

Touch System Programmer’s Guide xiii

Welcome CARROLL TOUCH

xiv Touch System Programmer’s Guide

1

Introduction to

Introduction to

Infrared Touch

Infrared Touch

Systems

Systems

his chapter gives an overview of Carroll Touch scanning infrared

T

touch systems, and covers the following topics:

• Overview.

• Touch Frames.

• Touch Controllers.

• Interpolating Touch Coordinates.

• Reporting Touch Coordinates.

• Failed Beams.

Touch System Programmer’s Guide 1-1

Chapter 1 - Introduction to Infrared Touch Systems CARROLL TOUCH

Overview

A Carroll Touch infrared touch system consists of a touch controller and

touch frame or a combined touch frame and controller. The touch

system uses scanning infrared (IR) beam technology to detect operator

input. Generating an invisible grid of IR light beams in front of the host

video display screen, the touch system reports touch input when the IR

light field is interrupted by a stylus (typically a finger). This input can

be used by a touch application just as similar applications use input from

pointing devices such as a mouse, light pen or trackball.

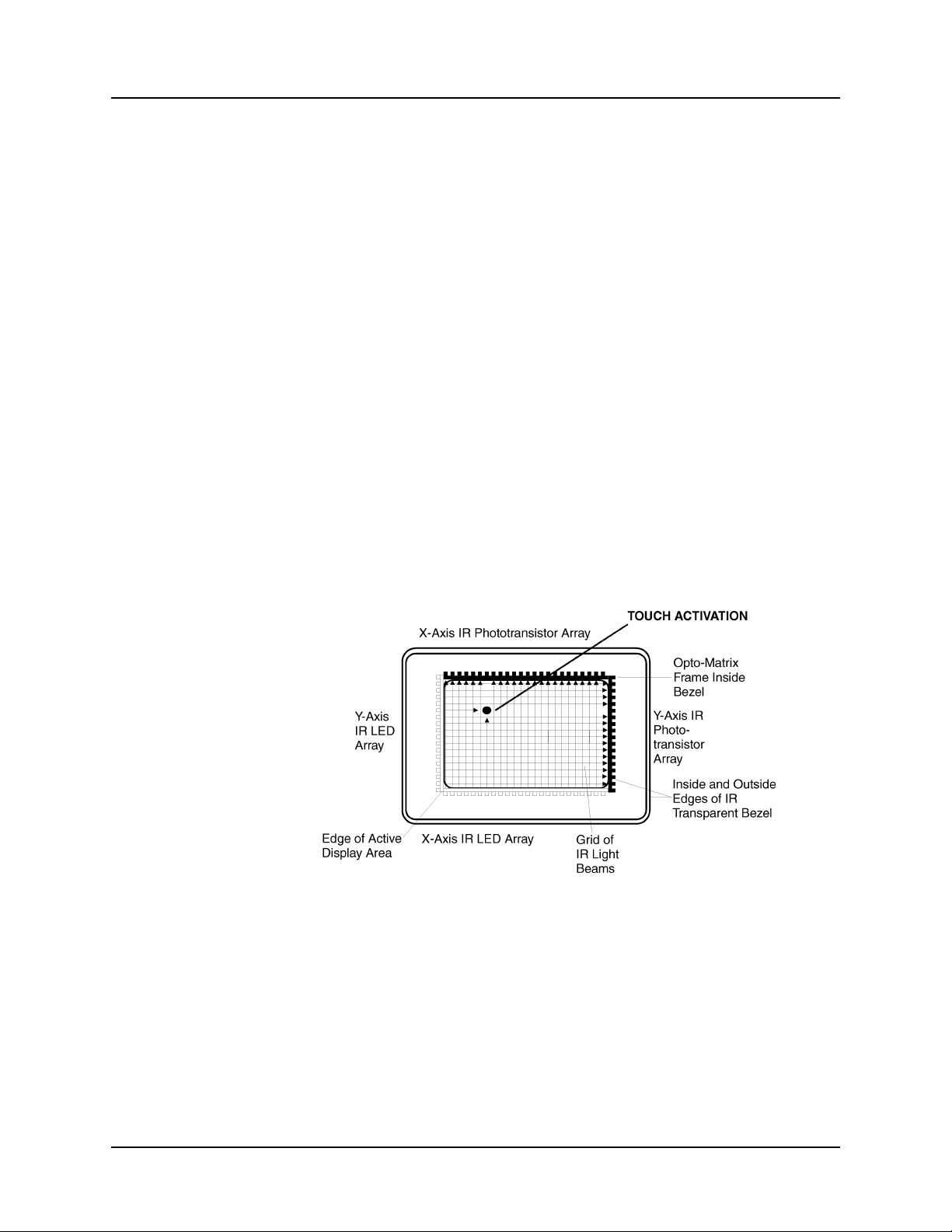

Touch Frames

The typical Carroll Touch touch frame is a thin, flat rectangle comprised

of four joined printed circuit boards (PCBs). Two adjacent PCBs contain

arrays of IR light emitting diodes (LEDs), while the other two PCBs

contain arrays of phototransistor/receivers. Each IR LED and the

phototransistor opposite it is called an opto-pair. The IR LED of each

opto-pair emits an IR light beam that is detected by the phototransistor.

The x-axis and y-axis arrays of opto-pairs are pulsed sequentially to

create a grid of IR beams, as shown in Figure 1-1.

Figure 1-1. Infrared Touch Frame

A beam, or a beam pair, consists of an IR LED and phototransistor

directly across from each other in the touch frame.

Touch Controller

The touch controller is the circuitry required to create and monitor the

IR grid. A sequence of electrical pulses is sent to the LEDs to create the

1-2 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 1 - Introduction to Infrared Touch Systems

grid of IR beams in front of the video display surface. This grid of IR

beams is the touch active area.

When a stylus enters the touch active area, light beams are obstructed at

a particular location on the grid. The touch frame then transmits to the

controller a list that indicates which beams have been interrupted. The

controller converts this list into an x, y coordinate that identifies the

location of the touch. The x, y coordinate data is transmitted to the host

processor via the PC bus or the RS-232 serial port and is then processed

and used by the application program.

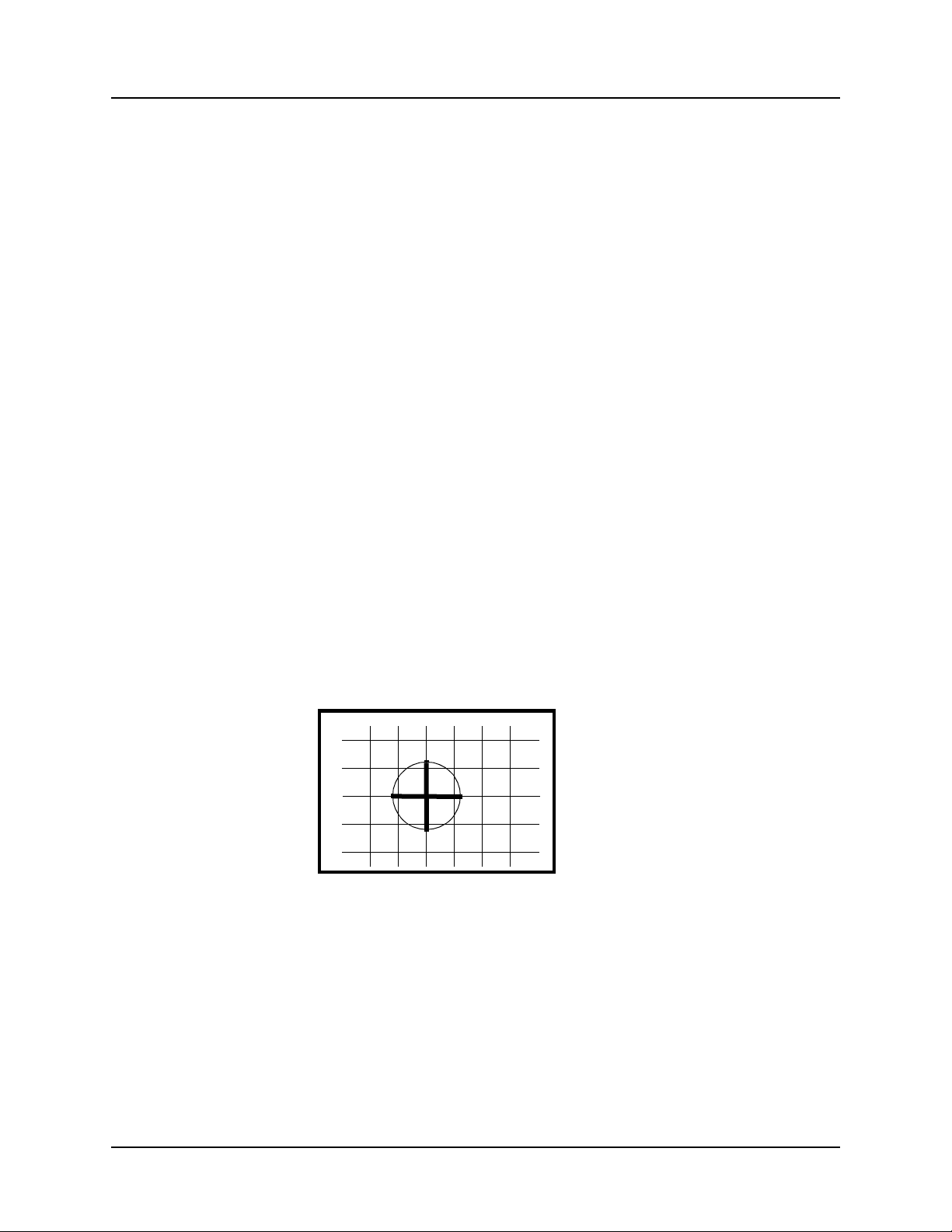

Interpolating Touch Coordinates

To achieve finer resolution than the physical IR beam grid provides,

Carroll Touch IR touch systems interpolate a virtual beam between each

pair of physical beams. The physical beams are assigned even numbers

(0, 2, 4, and so on). The virtual beams are assigned odd numbers (1, 3,

5, and so on). The combination of physical beams and virtual beams

results in a set of logical beams.

The coordinate system formed by the logical beams is called the logical

coordinate system. The origin of the logical coordinate system (0, 0) is

located in the upper left corner of the display. When multiple beams are

interrupted, the touch system averages them and reports one x, y logical

coordinate pair to the host, a process known as beam averaging.

Examples of beam averaging are shown in Figures 1-2 and 1-3.

02 04 0806 1000

00

02

04

06

08

4,4

Figure 1-2. Beam Averaging - Example 1

In Figure 1-2, beams 2, 4, and 6 are interrupted on both the x- and

y-axes. The logical coordinate pair reported to the host is 4, 4.

Touch System Programmer’s Guide 1-3

Chapter 1 - Introduction to Infrared Touch Systems CARROLL TOUCH

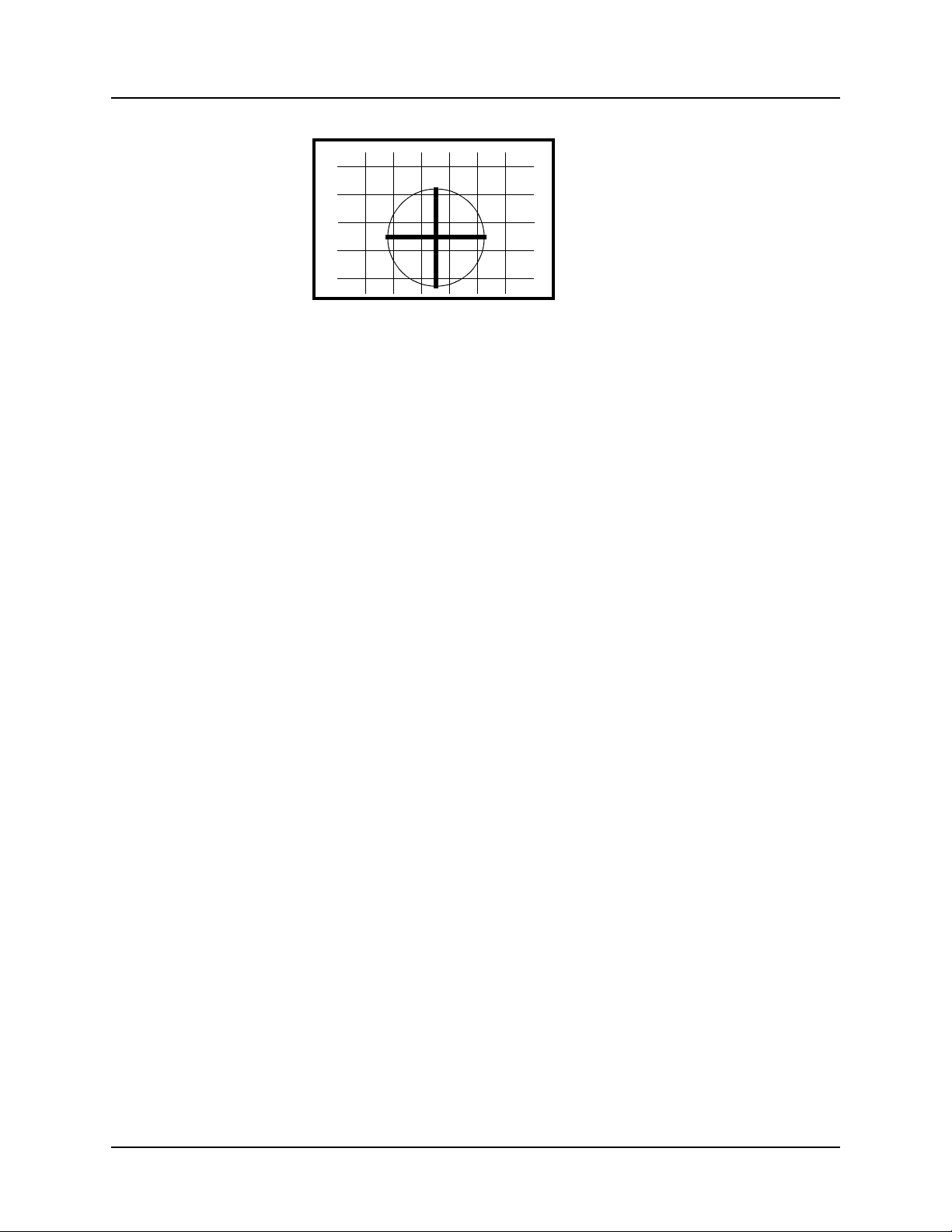

02 04 0806 1000

00

02

04

06

08

5,5

Figure 1-3. Beam Averaging - Example 2

In Figure 1-3, beams 2, 4, 6, and 8 are interrupted on both the x- and

y-axes. The logical coordinate pair reported to the host is 5, 5.

Reporting Touch Coordinates

For a touch to be reported, at least one x beam and one y beam must be

interrupted. If no beams are interrupted in either the x- or y-axis, the

touch is ignored.

The lowest logical coordinate reported for any axis on any touch frame

is zero. The maximum logical coordinate that may be reported for a

given touch frame axis may be determined from the number of physical

beams on that touch frame axis as follows:

Failed Beams

Maximum logical coordinate = 2 x (number of physical beams - 1)

For example, on a frame that has 40 x-axis beams and 30 y-axis beams,

the maximum logical coordinates for the frame are:

Maximum logical x coordinate = 2 x (40 - 1) = 78

Maximum logical y coordinate = 2 x (30 - 1) = 58

Therefore, the reported coordinates would range from 0 to 78 on the

x-axis and from 0 - 58 on the y-axis.

Carroll Touch touch systems have incorporated into their firmware a

mechanism for detecting defective beam pairs and removing them from

consideration when determining the location of a stylus within the touch

frame. This failed beam mechanism provides a measure of fault

tolerance for the touch system so that, in the event of an opto-component

1-4 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 1 - Introduction to Infrared Touch Systems

failure, the touch system simply suffers a localized loss of resolution in

one coordinate axis, rather than being completely inoperable.

Criteria for Failing a Beam

The touch system considers a beam to be interrupted if the IR light level

at the phototransistor is below a threshold level. A beam is considered

failed if it appears to be interrupted for a given period of time.

The touch system detects failed beams:

• During power up.

• When the touch system is reset using the SFP Reset (45H)

command or BREAK.

• When the touch system diagnostics are run using the SFP

Run_Diagnostics (3AH) command.

• While the touch system is scanning the beams during normal

operation.

In the first three cases, the time required to fail a beam is less than one

second. In the last case, the time required to fail a beam is determined

by the failed beam timing parameters.

The touch system maintains a table of beams that have been determined

to have failed.

Failed Beam Timing Parameters

The values for the various failed beam timing parameters are different

for ASIC-based touch systems and non-ASIC-based touch systems, as

shown in Table 1-1.

Table 1-1. Failed Beam Timing Parameters

Parameter

Valid Touch Fail Time 59 - 62 sec. 225 - 270 sec.

Non-Contiguous Touch Fail Time 2.2 - 4.4 sec. 10 - 20 sec.

ASICBased

Non-ASICBased

Single Axis Touch Fail Time 2.2 - 4.4 sec. 10 - 20 sec.

Unfail Time 2.2 - 4.4 sec. 10 - 20 sec.

A touch system is probably ASIC-based if it is a modular touch system,

or an invasively integrated Smart-Frame with a five switch

Communication Parameters jumper block on the frame. If you are

Touch System Programmer’s Guide 1-5

Chapter 1 - Introduction to Infrared Touch Systems CARROLL TOUCH

unsure whether your system is ASIC-based and if you need to know the

values of the failed beam timing parameters, use the touch system

diagnostics software (CTDIAG) to observe the amount of time required

to fail beams that are interrupted by a valid touch.

Table 1-1 gives a range of values rather than a specific value because the

touch system firmware checks for failed beams at a regular interval (2.2

seconds or 10 seconds). A beam that appears to be interrupted just after

the firmware checks takes longer to fail than a beam that appears to be

interrupted just before the firmware checks.

Note

Custom touch systems may have different values for the failed

beam timing parameters from those given in Table 1-1.

During normal operation, with the touch system scanning the beams, a

beam is considered failed if it is interrupted for the amount of time

specified by the Valid Touch Fail Time parameter and if the pattern of

interrupted beams appears to indicate a valid touch with a single stylus.

(A touch is considered valid if there appears to be one and only one

region of contiguous interrupted beams in each coordinate axis.) Thus,

a single stylus that remains stationary within the touch screen for the

Valid Touch Fail Time causes beams to be failed.

If beams are interrupted on only one axis of the touch frame, the

interrupted beams are failed in the amount of time specified by the

Single Axis Touch Fail Time parameter.

For any other pattern of interrupted beams, such as more than one region

of interrupted beams in an axis, the interrupted beams are failed in the

amount of time specified by the Non-Contiguous Touch Fail Time

parameter. Thus, multiple styli that remain stationary for longer than the

Non-Contiguous Touch Fail Time result in beams being failed, as do

non-contiguous touches.

For example, if you place a piece of tape over the opto-devices in one

axis of the touch screen, the beams obstructed by the tape are determined

by the touch system firmware to be failed and are added to the failed

beam table only after the amount of time specified by the Invalid Touch

Fail Time parameter has elapsed. If you then remove the tape, the time

specified in the Unfail Time parameter must elapse before the beams are

considered unfailed by the touch system firmware.

1-6 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 1 - Introduction to Infrared Touch Systems

Criteria for Unfailing a Beam

If a failed beam appears not to be interrupted for the amount of time

specified by the Unfail Time parameter, it is unfailed and removed from

the failed beam table by the touch system firmware.

Failed Beam Reports

Two SFP commands can be used to generate reports related to the failed

beam status of the touch system: Get_Error_Report (32H) and

Get_Failed_Beam_Report (36H). See Appendix A, “Smart-Frame

Protocol Command Reference,” for details on these commands.

Touch System Programmer’s Guide 1-7

Chapter 1 - Introduction to Infrared Touch Systems CARROLL TOUCH

1-8 Touch System Programmer’s Guide

2

T

Introduction to

Introduction to

Guided Wave

Guided Wave

Touch Systems

Touch Systems

his chapter gives an overview of Carroll Touch guided wave touch

systems and covers the following topics:

• Overview.

• Touch Screens.

• Touch Controllers.

• EEPROM File and Parameters.

Touch System Programmer’s Guide 2-1

Chapter 2 - Introduction to Guided Wave Touch Systems CARROLL TOUCH

Overview

A Carroll Touch guided wave touch system consists of a touch

controller and touch screen. The touch system uses guided acoustic

wave (GW) technology to detect operator input for a variety of

applications. Generating invisible acoustic waves, the touch system

reports touch input when the wave motion is attenuated by a stylus

(typically a finger). This input can be used by a touch application just as

similar applications use input from pointing devices such as a mouse,

light pen or trackball.

Touch Screens

Guided acoustic wave technology is based on transmitting acoustic

waves through a glass overlay placed over the display surface. A

transducer mounted on the edge of the glass emits an acoustic wave. The

wave travels along the reflector array, is redirected across the overlay to

the reflecting edge, and returns to the array where it is reflected back to

the transducer. The first reflector will send a signal back first, then the

second, and so on, as shown in Figure 2-1.

Figure 2-1. Guided Wave Touch Screen

Touch Controllers

The touch controller is the circuitry required to create and monitor the

acoustic waves. A sequence of electrical pulses is sent to the transducer

located in the upper left of the glass overlay to generate the acoustic

waves. The area covered by the acoustic waves is the touch active area.

2-2 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 2 - Introduction to Guided Wave Touch Systems

When a stylus enters the touch active area, acoustic waves are attenuated

at that location on the overlay. The touch screen then transmits to the

controller information indicating the location of the attenuated waves.

The controller converts this information to an x, y coordinate that

identifies the location of the touch. The x, y coordinate data is

transmitted to the host processor via the controller and is then processed

and used by the application program.

EEPROM File and Parameters

Guided wave touch screens use an electrically erasable programmable

read-only memory (EEPROM) chip. An associated file stores the values

of the EEPROM parameters that control many features of the touch

screen. The following EEPROM values may be displayed, modified,

saved, and restored:

• Touch sensitivity.

• Touch active region.

• Transducer corner.

• Coordinate origin corner.

• Transducer orientation.

• Touch refresh time.

• No touch refresh time.

• Temporal filter space.

• Temporal filter time.

Touch System Programmer’s Guide 2-3

Chapter 2 - Introduction to Guided Wave Touch Systems CARROLL TOUCH

2-4 Touch System Programmer’s Guide

3

General

General

Programming

Programming

Issues

Issues

his chapter includes information that may apply to any Carroll

T

Touch touch system. It discusses the following topics:

• Hardware Configurations.

• Calibration.

• HBC I/O Registers.

Touch System Programmer’s Guide 3-1

Chapter 3 - General Programming Issues CARROLL TOUCH

Hardware Configurations

There are two major types of Carroll Touch controller configurations:

built-in controllers (used in infrared Smart-Frames) and external

controllers (used in modular infrared and guided wave touch systems).

Built-In Controllers

An infrared Smart-Frame touch system has controller electronics

built onto the touch frame itself. The Smart-Frame touch system

communicates directly with the host computer through the host serial

port. Figure 3-1 illustrates the built-in Smart-Frame controller hardware.

Built-in

Controller

(Infrared

SmartFrame)

RS-232 Cable

Host PC

Figure 3-1. Built-In Smart-Frame Controller Hardware

The Smart-Frame communicates serially with the host computer using a

selectable baud rate (300, 600, 1200, 2400, 4800, 9600, 19,200 or

autobaud) and parity (odd, even, none, autoparity). Default values for

the standard Smart-Frame are autobaud and autoparity.

External Controllers

External controllers connect to the touch system via the Modular Digital

Interface (MDI) cable in modular infrared touch systems or an 8-pin

mini-DIN sensor cable in guided wave systems. The MDI cable carries

digital signals, while the mini-DIN sensor cable carries analog signals.

A modular infrared touch system consists of any one of a number of

IR-transparent protective bezels that house and protect a touch frame,

matched with any one of three modular touch controllers: the software-

3-2 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 3 - General Programming Issues

based controller (SBC), hardware-based controller (HBC), and RS-232

controller. A guided wave touch system uses HBCs or RS-232

controllers. Figure 3-2 illustrates the RS-232 controller hardware.

External

Controller

(Guided Wave

or Modular IR

Touch Frame)

MDI/Sensor Cable

RS-232

Controller

RS-232 Cable

Host PC

Figure 3-2. RS-232 Controller Hardware (Modular IR Touch Systems)

The RS-232 controller is a PCB that has its own protective housing and

requires an external power supply. The RS-232 controller

communicates with the modular touch frame via the MDI cable and with

the host computer through the host serial port.

The RS-232 controller communicates serially with the host computer

using a selectable baud rate (300, 600, 1200, 2400, 4800, 9600, 19,200

or autobaud) and parity (odd, even, none, autoparity). Default values for

the RS-232 controller are autobaud and autoparity.

Figure 3-3 illustrates the SBC and HBC controller hardware. The SBC

and HBC are PCBs that fit into an expansion slot of an IBM-compatible

PC, communicating with and drawing power for the touch system

directly from the host through the PC bus. Both controllers

communicate with the modular touch frame via the MDI cable.

The SBC and HBC communicate with the host via several I/O registers.

The SBC and HBC also support interrupt-driven communications.

Touch System Programmer’s Guide 3-3

Chapter 3 - General Programming Issues CARROLL TOUCH

Modular

IR Touch

Frame

Modular

IR Touch

Frame

MDI Cable

SBC

Controller

Card

Host Host

PC PC

HBC

Controller

Card

SBC(TAPI)

Driver

SBC TAPI Driver

PC Bus I/O Ports

Software Interrupt

Figure 3-3. SBC and HBC Hardware (Modular IR Touch Systems)

Application Program Interface

As shown in Figure 3-4, application programs may interface with

Smart-Frame systems and systems using the HBC or RS-232 controller

directly via the Smart-Frame Protocol. Smart-Frame systems and

systems using the RS-232 controller are identical in terms of software.

Both communicate using the Smart-Frame Protocol via the RS-232

serial interface. Systems using the HBC communicate with the

application program using the Smart-Frame Protocol via the HBC I/O

registers. For more details about the I/O registers, see “HBC I/O

Registers” later in this chapter. The SBC cannot use the Smart-Frame

Protocol directly because the SBC has no processor on board. The

Smart-Frame Protocol is discussed in Chapter 4, “Smart-Frame

Protocol.”

As also shown in Figure 3-4, application programs may interface with

Smart-Frame systems and systems using the SBC, HBC, or RS-232

controller using the Smart-Frame Protocol via a Touch Application

Program Interface (TAPI) driver. This is the same Smart-Frame

Protocol used when interfacing directly to the touch system hardware.

3-4 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 3 - General Programming Issues

A

P

CTKERN

P

L

I

SMART-FRAME

C

PROTOCOL (VIA TAPI)

A

T

I

SMART-FRAME

PROTOCOL (DIRECT)

O

N

TAPI TAPI TAPI

RS-232

DRIVER

CTKERN

HBC

DRIVER

SBC

DRIVER

M

P

R

O

G

R

A

SMARTFRAME

MDI

RS-232

CONTROLLER

HBC

CONTROLLER

FRAME

SBC

CONTROLLER

Figure 3-4. Touch Control Software

There are three TAPI drivers: the SBC driver, the HBC driver, and the

RS-232 driver. The RS-232 driver works with Smart-Frames as well.

Each TAPI driver communicates with the touch system using the

hardware interface appropriate for the touch system, and with the

application program using the TAPI functions that are accessed via a

software interrupt. The TAPI interface is the same regardless of which

TAPI driver is used. This means that you may make an application touch

system hardware-independent by interfacing at the TAPI driver level

rather than directly to the touch system hardware. The TAPI software

functions are discussed in Chapter 6.

Figure 3-4 also shows that application programs may interface with

Smart-Frame systems and systems using the SBC, HBC, or RS-232

controller via the CTKERN driver. The CTKERN driver communicates

with the touch system using the TAPI driver appropriate for the touch

system, and with the application program using the CTKERN functions,

which are accessed via a software interrupt. CTKERN is a DOS driver

that provides calibration and scaling support, as well as easy-to-use

touch state reporting. CTKERN also features an installable user event

handler that allows interrupt-driven communication with the application

program. The CTKERN functions are discussed in Chapter 7.

Touch System Programmer’s Guide 3-5

Chapter 3 - General Programming Issues CARROLL TOUCH

TOUCH_MAX_Y

Calibration

The size of the display area of the video monitor frequently does not

match the size of the touch active area of the touch frame. The touch

active area is usually larger than the display area. The relationship of

touch and video coordinates is shown in Figure 3-5. In addition, the

display area on most video monitors may actually shift position or drift,

while the touch active area remains constant. To establish and maintain

alignment of the touch active area with the active display area, the touch

screen must be calibrated. A calibration procedure such as the one that

follows identifies the touch coordinates of the extreme outside corners

of the video image displayed on the monitor and derives calibration

parameters that may then be used to convert touch coordinates into

video coordinates.

0

0

0

0

VIDEO_MAX_Y

TOUCH_MAX_X

VIDEO_MAX_X

Figure 3-5. Touch Calibration Screen

It is strongly recommended that a calibration program be included in any

touch application or driver. Touch applications or drivers should not use

hard-wired values that are specific to a particular touch frame and

monitor. Use of a calibration program takes care of variations in monitor

image size and location and allows touch applications to be used on

different sizes of monitors and/or touch systems without modifying the

touch application or driver.

This calibration must be performed at least once for each physical touch

screen/video monitor pair. This procedure produces four calibration

parameters that should be stored by the host computer in some form of

nonvolatile storage, which lets the calibration be performed only once.

3-6 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 3 - General Programming Issues

Once calibration is completed, the host software may use the calibration

parameters to convert touch coordinates into video coordinates (pixel

coordinates). These may then be used in the remainder of the host

software.

Some monitors do not maintain a constant video image size and

placement for all of the video modes that they support. For this reason,

the calibration should be performed using the same video mode as the

touch application in order to assure an accurate calibration.

Floating Point Calibration Program Design

When designing a program to calibrate the touch screen, include the

following steps:

1. Prompt the user to touch the upper left corner of the video screen.

2. Save the coordinates returned as TOUCH_UL_X and

TOUCH_UL_Y.

3. Prompt the user to touch the lower right corner of the video screen.

4. Save the coordinates returned as TOUCH_LR_X and

TOUCH_LR_Y.

A good way to prompt the user to touch the corners is to draw a

border around the edge of the screen and prompt the user to touch

each point using a target in the respective corner and text centered

on the screen.

5. Calculate the four calibration parameters as follows:

OFFSET_X = TOUCH_UL_X

OFFSET_Y = TOUCH_UL_Y

SCALE_X = VIDEO_MAX_X / (TOUCH_LR_X -

TOUCH_UL_X)

SCALE_Y = VIDEO_MAX_Y / (TOUCH_LR_Y -

TOUCH_UL_Y)

6. Save the four calibration parameters to a nonvolatile storage area, if

available. If none is available, the calibration procedure must be

followed each time the system is powered up.

The floating point calibration procedure is now complete. In your

application program, convert the touch coordinates reported by the

touch system into the equivalent video coordinates with these equations:

VIDEO_X = SCALE_X * (TOUCH_X - OFFSET_X)

VIDEO_Y = SCALE_Y * (TOUCH_Y - OFFSET_Y)

Touch System Programmer’s Guide 3-7

Chapter 3 - General Programming Issues CARROLL TOUCH

You may also want to limit VIDEO_X and VIDEO_Y to the ranges

defined by VIDEO_MAX_X and VIDEO_MAX_Y. It is recommended

that the touch coordinates be converted to video coordinates

immediately upon their receipt from the touch system, and that video

coordinates be used in the remainder of the application program.

Floating Point Calibration Examples

If the coordinates resulting from calibration of a system with 640 x 480

resolution are:

TOUCH_UL_X = 10

TOUCH_UL_Y = 7

TOUCH_LR_X = 150

TOUCH_LR_Y = 110

and the system has a resolution of 640 x 480:

VIDEO_MAX_X = 639

VIDEO_MAX_Y = 479

the four calculated calibration parameters are:

OFFSET_X = 10

OFFSET_Y = 7

SCALE_X = 639 / (150 - 10) = 4.5643

SCALE_Y = 479 / (110 - 7) = 4.65

Following are three examples of how to solve for different values of

VIDEO_X and VIDEO_Y:

If TOUCH_X = 7 and TOUCH_Y = 10, then:

VIDEO_X = 4.5643 * (10 - 10) = 0

VIDEO_Y = 4.65 * (7 - 7) = 0

If TOUCH_X = 60, and TOUCH_Y= 80, then:

VIDEO_X = 4.5643 * (60 - 10) = 228

VIDEO_Y = 4.65 * (80 - 7) = 339

If TOUCH_X = 150, and TOUCH_Y= 110, then:

VIDEO_X = 4.5643 * (150 - 10) = 639

VIDEO_Y = 4.65 * (110 - 7) = 479

3-8 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 3 - General Programming Issues

HBC I/O Registers

Overview

The HBC communicates with the PC through the PC bus via three

consecutive I/O registers. The base address of these I/O registers is set

by the I/O address jumpers on the HBC board, and may be set in

increments of 16 to any I/O address between 200H and 3F0H inclusive.

The three I/O registers are defined in Table 3-1.

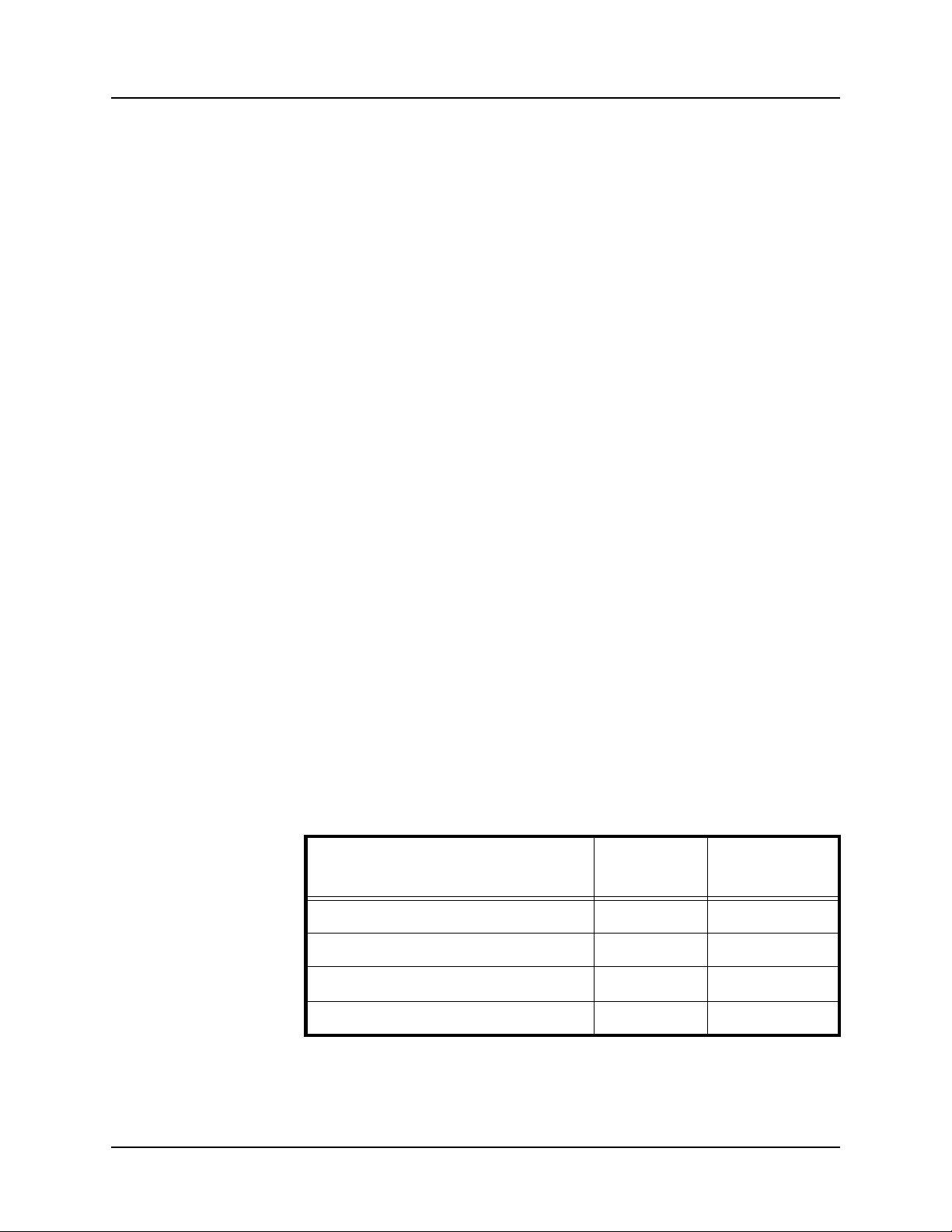

Table 3-1. HBC I/O Registers

I/O Address Name

I/O Base

Address

I/O Base

Address + 1

I/O Base

Address +2

The touch controller may be used in polling mode or in interrupt mode.

In polling mode, the application software must check the Status

Register before sending or receiving data. In interrupt mode, the

application software must check the Status Register when sending data

to the touch controller, but may install an interrupt handler to receive

data from the touch controller. The interrupt number used is set by the

interrupt number jumpers on the HBC board, as described in the HBC

installation instructions. When using polling mode, set these jumpers to

none to prevent the HBC from generating any interrupts.

Data Register R/W Used to send commands to

Status

Register

Hardware

Reset Register

Read/

Write

and receive reports from

the touch controller.

R Used to check the touch

controller communications

status (i.e. ready to receive

commands, reports

available).

W Used to reset the touch

controller.

Description

Sending a Touch Command to the HBC

The procedure used to send a touch command to the HBC is the same

for both interrupt mode and polling mode.

Before sending a command to the touch controller, you must first

perform an I/O read of the Status Register (Base Address + 1). Bit 0 of

the Status Register indicates whether the touch controller is ready to

Touch System Programmer’s Guide 3-9

Chapter 3 - General Programming Issues CARROLL TOUCH

receive a command or whether it is busy. Table 3-2 shows the values of

Bit 0 of the Status Register.

Table 3-2. Status Register Bit 0 Values

Bit 0 Description

0 Touch controller ready to receive command.

1 Touch controller busy.

If Bit 0 of the Status Register is 0, you may send a command to the touch

controller by performing an I/O write to the Data Register (Base

Address). If Bit 0 of the Status Register is 1, do not send a touch

command to the touch controller.

Receiving Touch Data from the HBC

The procedure used to receive data from the HBC differs depending on

which communication mode you are using.

Polling Mode

When using polling mode, the application software polls the Status

Register (Base Address + 1) to check if touch data is available in the

Data Register (Base Address).

Before reading the Data Register, you must first perform an I/O read of

the Status Register. Bit 1 of the Status Register indicates whether there

is touch data available in the Data Register. Table 3-3 shows the values

of Bit 1 of the Status Register.

Table 3-3. Status Register Bit 1 Values

Bit 1 Description

0 Touch data available.

1 No touch data available.

If Bit 1 of the Status Register is 0, you may receive a byte of touch data

by performing an I/O read of the Data Register. If Bit 1 of the Status

Register is 1, there is no data available in the Data Register.

3-10 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 3 - General Programming Issues

Interrupt Mode

When using interrupt mode, the touch controller uses a PC hardware

interrupt to notify the application software that touch data is available in

the Data Register (Base Address). When the display is touched with

touch enabled, or an information request command is received by the

touch system, the touch system sends touch data to the Data Register.

The HBC then interrupts the host computer, indicating that data is

available in the Data Register. The application software’s interrupt

handler should perform an I/O read of the Data Register to receive a byte

of touch data from the touch system.

Resetting the HBC

The procedure to perform a hardware reset on the HBC is the same for

both interrupt and polling communication modes. To cause a hardware

reset of the touch controller, perform an I/O write to the Hardware Reset

Register (Base Address + 2).

Note that the value of the data byte written to the Hardware Reset

Register does not matter.

Touch System Programmer’s Guide 3-11

Chapter 3 - General Programming Issues CARROLL TOUCH

3-12 Touch System Programmer’s Guide

4

Smart-Frame

Smart-Frame Protocol

Protocol

his chapter gives an overview of the SFP firmware protocol,

T

including a discussion of command and report types, initialization,

timing, and programming tips and examples.

The chapter discusses the following topics:

• Overview.

• SFP and SFP-II.

• Types of SFP Commands.

• Reports.

• Touch System Initialization.

• Touch System Initialization Examples.

• Using an SBC.

• Compatibility Issues/Programming Tips.

• SFP Timing.

• SFP Programming Examples.

See Appendix A, “Smart-Frame Protocol Command Reference,” for

the specifications of each Smart-Frame Protocol command.

Touch System Programmer’s Guide 4-1

Chapter 4 - Smart-Frame Protocol CARROLL TOUCH

Overview

The Smart-Frame Protocol (SFP) regulates communication between

the touch system and the application program.

Smart-Frame Protocol commands are used to:

• Initialize the touch system.

• Establish host-to-touch communications.

• Select the touch system reporting and operating modes.

• Request special reports.

• Manage report transfer.

• Execute diagnostic functions.

SFP and SFP-II

The SFP, defined in 1985, is currently used by most Carroll Touch

touch systems, but will eventually be supplanted by Smart-Frame

Protocol II (SFP-II) on newer touch systems.

The SFP is implemented as a modal protocol, meaning that, even if a

touch system supports both the SFP and SFP-II, it can only support one

protocol at a time and, during that time, cannot accept commands from

the other protocol. To switch between protocols, use the

SwitchToSFP-II (65H) SFP command and the SwitchToClassicSFP

(64H) SFP-II function.

Types of SFP Commands

Smart-Frame Protocol commands are grouped into five logical

categories:

• Communication commands.

• Reporting method commands.

• Touch mode commands.

• Information request commands.

• System commands.

SFP commands may be invoked with either a hexadecimal code or an

ASCII code, and many of the commands have associated reports. To

issue a command under the Smart-Frame Protocol, simply type its

function number. An SFP command example is 32, the hexadecimal

code for the Get_Error_Report (32H) command.

4-2 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 4 - Smart-Frame Protocol

Communication Commands

Communication between the touch system and the host computer can

be regulated by hardware or software flow control. Communication

commands are shown in Table 4-1.

Table 4-1. SFP Communication Commands

Command Name

Hardware_Flow_Control_On 41H A None

Hardware_Flow_Control_Off 42H B None

Report_Transfer_Off 43H C None

Report_Transfer_On 44H D None

Get_One_Report 46H F varies

Hardware flow control regulates the transmission of data from the

touch system to the host and from the host to the touch system by using

RS-232 control signals. To enable and disable this type of data flow

control, use the Hardware_Flow_Control_On (41H) and

Hardware_Flow_Control_Off (42H) commands.

Software flow control regulates transmission of data from the touch

system to the host on a report-by-report basis. To implement this type

of data flow control, use the Report_Transfer_On (44H) command,

Report_Transfer_Off (43H) command, or the Get_One_Report (46H)

command.

Hex

Code

ASCII

Code

Associated

Report

The default flow control method is software flow control.

Reporting Method Commands

Reporting methods determine the form in which data is sent from the

touch system to the host. Both the desired reporting method and touch

mode should be selected before turning touch system scanning on,

although they may also be changed with scanning on. The commands

used to select the reporting method are shown in Table 4-2.

Touch System Programmer’s Guide 4-3

Chapter 4 - Smart-Frame Protocol CARROLL TOUCH

Table 4-2. SFP Reporting Method Commands

Command Name

Hex

Code

ASCII

Code

Associated

Report

Scan_Reporting 22H “ Scan Report

Coordinate_Reporting 23H # Touch Coordinate Report

Add Exit Coordinate

Point Report

Non-Contiguous

Coordinate Report

Scan reports present interrupt beam data with no software interpretation

and are used for diagnostic and testing purposes. Coordinate reports

present interrupt beam data in the form of x, y (x-axis, y-axis)

coordinate pairs for application processing.

Touch Mode Commands

Touch mode commands select the conditions under which touch

coordinates are reported when the reporting method is set to coordinate

reporting. Touch mode commands are shown in Table 4-3.

Table 4-3. SFP Touch Mode Commands

Command Name

Hex

Code

ASCII

Code

Associated

Report

Enter_Point_Mode 25H % Touch Coordinate Report

Tracking_Mode 26H & Touch Coordinate Report

Continuous_Mode 27H ‘ Touch Coordinate Report

Exit_Point_Mode 28H ( Touch Coordinate Report

Add_Exit_Point_

29H ) Touch Coordinate Report

Modifier*

*Add Exit Point is a modifier that is used with other touch modes. It is not a stand-alone touch

mode.

To change the touch mode, simply send the touch mode command that

selects the new touch mode. For example, to change from Enter Point

Mode to Tracking Mode, send the Tracking_Mode (26H) command.

4-4 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 4 - Smart-Frame Protocol

Changing the touch mode clears the Add Exit Point modifier. To

disable the Add Exit Point modifier without changing the current touch

mode, simply send the desired touch mode command again.

For example, to select Tracking Mode with Add Exit Point, send the

Tracking_Mode (26H) command followed by the

Add_Exit_Point_Modifier (29H) command. To deselect Add Exit Point

and remain in Tracking Mode, send the Tracking_Mode (26H)

command again.

Information Request Commands

Information request commands query the touch system for system

status reports, such as error, configuration, firmware version, failed

beam, frame size, and state reports. Information request commands are

shown in Table 4-4.

Table 4-4. SFP Information Request Commands

Command Name

Get_Error_Report 32H 2 Error Report

Get_Configuration_Report 33H 3 Configuration Report

Get_Firmware_Version_

Report

Get_Failed_Beam_Report 36H 6 Failed Beam Report

Get_Frame_Size_Report 37H 7 Frame Size Report

Get_State_Report 47H G State Report

Hex

Code

34H 4 Firmware Version

ASCII

Code

Associated

Report

Report

System Commands

System commands control all touch system functions such as

initialization, software reset, diagnostics, and scanning. The system

commands are shown in Table 4-5.

Touch System Programmer’s Guide 4-5

Chapter 4 - Smart-Frame Protocol CARROLL TOUCH

Table 4-5. SFP System Commands

Reports

Command Name

Echo_On 20H Space None

Echo_Off 21H ! None

Touch_Scanning_On 2AH * None

Touch_Scanning_Off 2BH + None

Run_Diagnostics 3AH : Error Report

Software_Reset 3CH < None

Clear_Touch_Report_Buffer 3DH = None

Reset 45H E None

SwitchToSFP-II 65H SFP-II Protocol

Hex

Code

ASCII

Code

Associated

Report

Version Report or

Error Report

An SFP report has the following format:

header reportbytes trailer

The trailer is always FF. An example of a report returned from the

Get_Error_Report (32H) command is:

F8 00 FF

F8 is the header, 00 indicates no errors, and FF is the trailer. An

example of a touch coordinate report is:

FE 35 2D FF

FE is the header; 35 and 2D are the x, y touch coordinates; and FF is

the trailer.

4-6 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 4 - Smart-Frame Protocol

Touch System Initialization

To initialize a touch system that uses the Smart-Frame Protocol, take

the following steps:

1. Reset the touch system.

2. Perform the autobaud/autoparity sequence, if appropriate, then the

software reset command.

3. Check for any errors that may have been detected.

4. Set the desired reporting method and touch mode.

Details on each step are in the following sections.

Resetting the Touch System

The following methods may be used to reset the touch system. Be sure

to use a method that is appropriate for the touch system being used.

Power Cycle

This method resets everything. For touch systems that communicate

serially, Clear To Send (CTS) is deasserted (negative voltage) to

indicate that the touch system is busy until the touch system is ready to

accept commands. For serial touch systems that have their

communication parameters set to autobaud/autoparity, this occurs

when the touch system enters the autobaud sequence by sending breaks.

Dedicated Reset Signal

On some Smart-Frame systems, a dedicated reset signal line is present.

If present, this signal is on pin 8 of the 2 x 5 pin communication

connector that is on the frame. To reset the touch system, deassert this

pin by applying negative voltage for a minimum of 10 ms. This type of

reset is equivalent to cycling the power to the touch system. This signal

is not present on the modular RS-232 controller.

Break (Hardware Detected)

For touch systems that use the modular RS-232 controller, a break of at

least 400 ms resets the touch system. To send a break of 400 ms, set the

Transmit Data (TD) signal to the “space” condition (positive voltage),

wait 400 ms, and set the TD signal back to the “mark” condition

(negative voltage). For PC systems, the “Set Break” bit in the Line

Control Register of the 8250 USART chip is used to set and/or clear the

break condition. This type of reset is equivalent to cycling the power to

the touch system.

Touch System Programmer’s Guide 4-7

Chapter 4 - Smart-Frame Protocol CARROLL TOUCH

HBC Hardware Reset Register

For touch systems that use the modular HBC, writing any value to the

HBC Hardware Reset Register (Base Address +2) resets the touch

system. This type of reset is equivalent to cycling the power to the touch

system.

Break (Firmware Detected)

For all touch systems that communicate serially, a break of at least

150ms resets the touch system. To send a break of 150ms, set the

Transmit Data (TD) signal to the “space” condition (positive voltage),

wait 150ms, and set the TD signal back to the “mark” condition

(negative voltage). For PC systems, the “Set Break” bit in the Line

Control Register of the 8250 USART chip is used to set and/or clear the

break condition. This type of reset is equivalent to cycling the power to

the touch system, except that Clear To Send (CTS) is not affected if

hardware flow control was not enabled before the reset.

Reset (45H)

This Smart-Frame Protocol command resets everything. If the touch

system communicates serially and hardware flow control is enabled,

CTS is deasserted (negative voltage) to indicate that the touch system

is busy until the touch system is ready to accept commands. For serial

touch systems that have their communication parameters set to

autobaud/autoparity, this occurs when the touch system enters the

autobaud/autoparity sequence by sending breaks. If hardware flow

control is disabled, Clear To Send (CTS) is not affected. This type of

reset is equivalent to cycling the power to the touch system, except that

the Clear To Send (CTS) is not affected if hardware flow control was

not enabled before the reset. Also, if the touch system communicates

serially but is set to use a fixed baud rate and parity (not

autobaud/autoparity), or if the touch system uses the HBC, the touch

system sends a Power Up Report (F1 FF) when it is ready to receive

commands.

In all cases, the touch system is ready to receive commands within one

second after the reset occurs. Touch applications must delay for one

second after resetting the touch system. In cases where a break is sent,

the one second time does not begin until the break is released.

Performing the Autobaud/Autoparity Sequence

If you are using a touch system that communicates serially and is set to

use autobaud/autoparity, you must perform the autobaud/autoparity

4-8 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 4 - Smart-Frame Protocol

sequence to allow the touch system to establish baud rate and parity that

is used by the host.

To perform the autobaud/autoparity sequence, the host must send five

ASCII carriage returns (CR - 0DH) followed by a delay of at least

100ms after each carriage return. The touch system uses these carriage

returns to determine the baud rate used by the host. When the touch

system has determined the baud rate of the host, it stops sending breaks

to the host; the host need not send additional carriage returns after this

occurs. The simplest method, however, is for the host to send five

carriage returns with delays and ignore the breaks sent by the touch

system. This is the recommended method.

Regardless of whether or not the touch system uses autobaud/

autoparity, the host must send a Software_Reset (3CH) command

followed by a delay of at least 100ms. This clears the touch system

buffers and resets the touch system parameters listed in Table 4-6 to

their defaults. If autobaud/autoparity is being used, this also establishes

the parity being used by the host.

Table 4-6. SFP Default Settings

System Parameters Default Setting

Touch Scanning Off

Reporting Method Coordinate reporting

Touch Mode Tracking Mode

Add Exit Point Modifier Off

Report Transfer Off

Hardware Flow Control Off

Checking for Touch System Errors

To confirm that the initialization sequence was successful, determine

the status of the touch system by sending the Get_Error_Report (32H)

command. The Error Report that is returned lists any errors detected by

the touch system. Since report transfer has not been enabled yet, the

host must enable it so that the touch system can transmit the Error

Report. This is accomplished by sending the Report_Transfer_On

(44H) command to the touch system before sending the

Get_Error_Report (32H) command.

Touch System Programmer’s Guide 4-9

Chapter 4 - Smart-Frame Protocol CARROLL TOUCH

The contents of the Error Report vary according to whether the touch

system has a single processor or dual processors.

If the touch system did not detect any errors, the Error Report appears

as follows:

F8 00 FF Reports no errors for single processor

systems.

F8 00 00 FF Reports no errors for dual processor

systems.

If the touch system detects errors, the 00 byte is replaced by an error

code count, followed by error codes. These error codes are identified in

the Get_Error_Report (32H) documentation in Appendix A.

If the Error Report is not received by the host, there is a communication

error. Run the initialization sequence again or send the Echo_On (20H)

command to determine the source of the communication problem.

Setting the Reporting Method and Touch Mode

The host may now complete the initialization sequence and enable

touch system scanning. It should send the appropriate Smart-Frame

Protocol commands to set the desired reporting method and touch

mode, send any other parameters (such as hardware flow control, and

so forth), then send the Touch_Scanning_On (2AH) command.

Touch System Initialization Examples

The following examples represent the recommended initialization

sequences for various touch system hardware configurations.

Using Autobaud/Autoparity

To initialize a touch system that communicates serially and uses

autobaud/autoparity, use the following initialization sequence:

1. Send a 400ms break. You may send a Reset (45H) command

instead, but this only works if the touch system has previously

been set to receive commands at the current baud rate and parity

and is not recommended.

2. Wait one second for the touch system to complete its power-on

testing.

4-10 Touch System Programmer’s Guide

CARROLL TOUCH Chapter 4 - Smart-Frame Protocol

3. Send five carriage returns (CRs - 0DH) with a 100ms delay after

each CR.

4. Send the Software_Reset (3CH) and delay 100ms.

5. Send the Report_Transfer_On (44H) command, followed by the

Get_Error_Report (32H) command.

6. Read the Error Report sent by the touch system. If the report is

received correctly and indicates no errors, the touch system is