Page 1

| Instruction Manual |

Page 2

Page 3

1

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the

following:

This sewing machine is designed and manufactured for household use only.

Read all instructions before using this sewing machine.

DANGER

—

To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug

this sewing machine from the electric outlet immediately after using and before

cleaning.

WARNING

—

To reduce the risk of burns, re, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used

by or near children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if

it has been dropped or damaged, or dropped into water.

Return this sewing machine to the nearest authorized dealer or service center for examination,

repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of this

sewing machine and foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep ngers away from all moving parts. Special care is required around the sewing machine

needle and/or cutting blade.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area, such as

threading the needle, changing the needle, threading the bobbin or changing the presser foot, and

the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or

when making any other adjustments mentioned in this owner’s manual.

SAVE THESE INSTRUCTIONS

Please note that on disposal, this product must be safely recycled in accordance with relevant

National legislation relating to electrical/electronic products. If in doubt please contact your

retailer for guidance. (European Union only)

For Europe only:

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be made

by children without supervision.

For outside Europe (except U.S.A and Canada):

This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Page 4

2

TABLE OF CONTENTS

ESSENTIAL PARTS

Names of Parts ............................................................3-4

Standard Accessories .................................................... 4

Accessory Storages ....................................................... 5

Protection Flaps ............................................................. 6

• Opening and closing protection aps ........................... 6

• Detaching the protection aps ..................................... 6

• Attaching the protection aps ...................................... 6

• Free-arm sewing .......................................................... 6

GETTING READY TO SEW

Connecting the Power Supply ..................................... 7-8

Using the foot control ..................................................... 7

Before Using Your Sewing Machine ............................... 7

Operating Instructions: ................................................... 7

Using the start/stop button ............................................. 8

Controlling Sewing Speed .............................................. 8

Speed control slider ..................................................... 8

Foot control .................................................................. 8

Machine Operating Buttons ....................................... 9 -10

Start/Stop button .......................................................... 9

Reverse button ............................................................. 9

Auto-lock button ........................................................... 9

Needle up/down button .............................................. 10

Thread cutter button ................................................... 10

Stitch width adjusting button ...................................... 10

Stitch length adjusting button ..................................... 10

LCD Display ...................................................................11

Touch Panel ...................................................................11

Arrow keys ...................................................................11

Numeral keys ...............................................................11

Direct pattern selection keys .......................................11

Thread cut memory key ...............................................11

Elongation key .............................................................11

Set key .........................................................................11

Lockout key .................................................................11

Selecting the Patterns .................................................. 12

Direct pattern selection .............................................. 12

Presser Foot Lifter ........................................................ 13

Changing the Presser Foot .......................................... 13

Removing and Attaching the Foot Holder .................... 13

Adjusting the Needle Thread Tension ......................14-15

Straight stitch balanced tension ................................. 14

Zigzag stitch balanced tension ................................... 15

Dropping or Raising the Feed Dog ............................... 16

Changing the Needle.................................................... 17

Fabric, Thread and Needle Chart ................................. 17

Bobbin Winding ....................................................... 18 -20

Removing the bobbin ................................................. 18

Setting the spool ........................................................ 18

Winding the bobbin .................................................... 19

Inserting the bobbin.................................................... 20

Threading the Machine................................................. 21

Needle Threader .......................................................... 22

Drawing up the Bobbin Thread .................................... 23

Setting Mode ........................................................... 24-26

Buzzer sound setting .................................................. 24

Needle stop position setting ....................................... 24

Key position adjustment setting ................................. 25

Resetting all to default ................................................ 26

BASIC SEWING

Straight Stitch Sewing .................................................. 27

Starting to sew............................................................ 27

Securing seams .......................................................... 27

Cutting threads ........................................................... 27

Auto Thread Cutting ..................................................... 28

Changing Sewing Direction .......................................... 28

Sewing from the Edge of Thick Fabric ......................... 28

Using Seam Guides ..................................................... 29

Turning Square Corners ............................................... 29

Altering the Needle Drop Position ................................ 30

Altering the Stitch Length ............................................. 30

Variety of Straight Stitches ...................................... 31-32

Lock-a-matic Stitch ..................................................... 31

Locking Stitch ............................................................. 31

Triple Stretch Stitch .................................................... 31

Stretch Stitch .............................................................. 32

Sculpture Stitches ...................................................... 32

Zigzag Stitch ................................................................. 33

Altering the stitch width .............................................. 33

Altering the stitch length ............................................ 33

Variety of Overcasting Stitches .................................... 34

Multiple Zigzag Stitch ................................................. 34

Knit Stitch ................................................................... 34

Super Overlock Stitch................................................. 34

Attaching Elastic ........................................................... 35

Buttonholes .............................................................36-43

Square Buttonhole................................................. 37-39

Altering the buttonhole width .................................... 39

Altering the buttonhole density ................................. 39

Round-end and Fine Fabric Buttonhole ..................... 40

Keyhole Buttonhole .................................................... 40

Stretch Buttonhole and Antique Buttonhole ............... 40

Corded Buttonhole ..................................................... 41

Welted Buttonhole ................................................. 42-43

Darning Stitch ............................................................... 44

Tacking ......................................................................... 45

Eyelet ............................................................................ 46

Zipper Sewing ......................................................... 47-49

Blind Hemming ............................................................. 50

Button Sewing .............................................................. 51

Rolled Hem ................................................................... 52

Gathering ...................................................................... 53

DECORATIVE STITCHES

Patchwork ..................................................................... 54

Angle scale on the needle plate ................................. 54

Shell tuck ...................................................................... 54

Lingerie Stitch ............................................................... 55

Applique ....................................................................... 55

Pintucks ........................................................................ 56

Fringing......................................................................... 56

Drawn Work .................................................................. 57

Cross Stitch .................................................................. 57

Corded Trim .................................................................. 58

Single Cord For Gathering Heavy Fabric ..................... 58

Fagoting ........................................................................ 58

French Knots ................................................................ 59

Scallop Stitch ................................................................ 59

Smocking ...................................................................... 59

Stippling Stitch.............................................................. 60

Clasp Stitch .................................................................. 60

Satin Stitches ............................................................... 61

Elongation ratio .......................................................... 61

Decorative Stitches ...................................................... 61

CARE OF YOUR MACHINE

Cleaning the Hook Race and Feed Dog ...................... 62

Installing the Bobbin Holder ......................................... 62

Correcting Distorted Stretch Stitch Patterns ................ 63

Problems and Warning Signals .................................... 64

Troubleshooting ............................................................ 65

Stitch Chart ................................................................... 66

EC DECLARATION OF CONFORMITY ....................... 67

Page 5

3

r t

y

u

!3

i

!1

o

!4

!5

!0

!6

!7

!8

!9

@0

@1

@2

@3

@4

@5

@6

@7

@8

#0

#0

q w e

!2

#1

#2

q

w

e

r

t

y

u

i

o

!0

!1

!2

!3

!4

!5

!6

!7

!8

!9

@0

@1

@2

@3

@4

@5

@6

@7

@8

@9

#0

#1

#2

#3

#4

#5

#6

#7

#8

#9

$0

$1

$2

$3

$4

ESSENTIAL PARTS

Names of Parts

LCD display

Stitch width adjusting buttons

Stitch length adjusting buttons

Start/stop button

Reverse button

Auto-lock button

Needle up/down button

Thread cutter button

Speed control slider

Touch panel

Thread tension dial

Accessory drawer

Protection aps unlock button

Protection aps release lever

Bobbin winder stopper

Bobbin winder spindle

Accessory storage

Stitch reference chart

Thread take-up lever

Thread guide (B)

Bobbin winder thread guide (B)

Bobbin winder thread guide (A)

Retractable thread guide

Threading chart

Top cover

Thread guide (A)

Spool pin

Spool thread guide

Face cover

Protection aps

Lower thread guide

Needle clamp screw

Needle bar thread guide

Needle

Presser foot

Hook cover release button

Hook cover plate

Needle plate

Feed dog

Foot holder

Setscrew

Lever

Needle threader

Buttonhole lever

#3

NOTE:

Design and specications are subject to change

without prior notice.

NOTE:

To carry the sewing machine, hold the carrying handle

with your hand, and support the sewing machine with

the other hand.

@9

#5

#7

#8

#9

$0

$3

$4

$1

$2

#4

#6

Page 6

4

$5

$6

$7

$8

$9

%0

%1

%2

%3

Feed adjusting screw

Drop feed lever

Carrying handle

Handwheel

Power switch

Foot control jack

Machine inlet

Presser foot lifter

Thread cutter

q w e r

t y u i

o !0 !1 !2

!3 !4

!5

$5

$6

$7

$8

$9

%0

%1

%2

%3

Standard Accessories

No. Part Name Part No.

1 Zigzag foot A (Set on the machine) 832523007

2 Zipper foot E 808852003

3 Satin stitch foot F 82 2 8 04118

4 Automatic buttonhole foot R 753801004

5 Blind hemming foot G 82 0 817015

6 Rolled hem foot D 820809014

7 Cording foot H 820819006

8

Spool holder (large) (Set on the

machine)

809810002

9 Spool holder (small) 80 9 8110 03

10 Bobbin X 4 (1 set on the machine) 102261103

11 Assorted needle set 540401026

12 Seam ripper (Buttonhole opener) 647808009

13 Lint brush 802424004

14 Screwdriver 653802002

15 Instruction book 809850509

16 Foot control case 809814109

17 Foot control 04 3 27113 3

18 Power cable*

U.S.A and Canada 85651900 4

U.K. 830377008

Australia 830314018

Continental Europe 830335004

!6

!7 !8

*The power cable included may differ from the illustration.

Page 7

5

Accessory Storages

Accessories can be stored in the accessory storage

and the accessory drawer.

Open the top cover to access the accessory storage.

Open the protection ap (front) and pull the tab on the

right side of the ap to open the accessory drawer.

CAUTION:

When you store the foot control inside the closed

aps, follow the instructions below to avoid damage

to product and injury to person.

• Do not place anything that may be caught

between aps and machine body when closing

the aps.

• Do not carry the machine with the foot control

placed inside of the aps.

• Do not turn the handwheel when the foot control

is placed on the free arm.

Page 8

6

Protection Flaps

•Openingandclosingprotectionaps

To open the protection aps, slide the protection ap

release lever q to the right.

To close the protection aps, fold the rear and front

aps w e, then fold the left ap r until it snaps to

the both aps.

q Protection aps release lever

w Protection ap (front)

e Protection ap (rear)

r Protection ap (left)

q

w

e

r

•Detachingtheprotectionaps

To detach the protection aps, push down the

protection ap unlock button, and pull the protection

aps away from the machine as illustrated.

t Protection aps unlock button

•Attachingtheprotectionaps

To attach the protection aps, push the protection

aps, inserting the hook into the hole until it snaps into

the machine.

•Free-armsewing

Free-arm sewing is useful for darning socks and

mending the knee or cuff areas.

t

NOTE:

Do not carry the machine with the protection aps

open.

Page 9

7

q

w

e

t

u

y

r

i

GETTING READY TO SEW

WARNING:

While in operation, always keep your eyes on the

sewing area and do not touch any moving parts such

as the thread take-up lever, handwheel or needle.

Always turn off the power switch and unplug from the

power supply:

- when leaving the machine unattended.

- when attaching or removing parts.

- when cleaning the machine.

Do not place anything on the foot control.

ConnectingthePowerSupply

Usingthefootcontrol

Turn off the power switch.

Pull the foot control cord from the foot control.

Insert the pin connector into the jack.

Insert the machine plug into the power inlet.

Insert the power supply plug into the wall outlet.

Turn on the power switch.

q Power switch

w Pin connector

e Jack

r Machine plug

t Power inlet

y Power supply plug

u Wall outlet

The foot control sign will be displayed when the foot

control is connected to the machine.

i Foot control sign

BeforeUsingYourSewingMachine

Before using your sewing machine for the rst time,

place a scrap of fabric under the presser foot and run the

machine without thread for a few minutes. Wipe away any

oil which may appear.

Operating Instructions:

The symbol “O” on the switch indicates the “off” position

of the switch.

Foot control model 21371, YC-485-EC-1 or 4C-339JM is

used with this sewing machine.

FortheU.S.AandCanadaonly:

For appliances with a polarized plug (one blade wider

than the other): To reduce the risk of electric shock, this

plug is intended to t in a polarized outlet only one way.

If it still does not t, contact a qualied electrician to

install the proper outlet. Do not modify the plug in any

way.

NOTE:

Do not pull the cord of foot control beyond the red

marker on the cord.

NOTE:

The machine will be initialized when turning on the

power switch. Do not touch the machine while the

machine is being initialized.

Page 10

8

q

e

t

r

w

Usingthestart/stopbutton

Turn off the power switch.

Insert the machine plug into the power inlet.

Insert the power supply plug into the wall outlet.

Turn on the power switch.

q Power switch

w Machine plug

e Power inlet

r Power supply plug

t Wall outlet

y Start/Stop button

NOTE:

The start/stop button does not work when the foot

control is connected.

ControllingSewingSpeed

Speed control slider

Sewing speed can be varied by the speed control slider

according to your sewing needs.

To increase sewing speed, move the slider to the right.

To decrease sewing speed, move the slider to the left.

Foot control

Depress the foot control to start the machine.

The further down you press on the foot control, the faster

the machine runs.

The maximum sewing speed can be varied by the speed

control slider.

y

NOTE:

The machine will be initialized when turning on the

power switch. Do not touch the machine while the

machine is being initialized.

Page 11

9

q

w

e

MachineOperatingButtons

q Start/Stopbutton

Lower the presser foot lifter.

Press this button to start or stop the machine.

The machine starts running slowly for the rst few

stitches, and it then runs at the speed set by the speed

control slider.

The machine runs slowly as long as this button is being

pressed.

NOTE:

The start/stop button cannot be used when the foot

control is connected to the machine.

w Reversebutton

•Whenfollowingstitchpatternsareselected;

The machine will sew in reverse as long as the

reverse button is pressed. Release the button to sew

forward.

When the machine is stopped and foot control is

disconnected, the machine will sew in reverse slowly

as long as the reverse button is pressed. Release the

button to stop the machine.

•Whenanyotherstitchesareselected;

If you press the reverse button when sewing any other

patterns, the machine will immediately sew locking

stitches and automatically stop.

There will be particular functions of the reverse button

when patterns shown above are selected. Refer to

pages 31, 44 and 45 for instructions.

•Whenfollowingstitchpatternsareselected;

e Auto-lockbutton

•Whenfollowingstitchpatternsareselected;

Press the auto-lock button to sew a locking stitch

immediately. The machine will automatically stop.

•Whenanyotherstitchesareselected;

Press the auto-lock button to sew a locking stitch

at the end of current pattern. The machine will

automatically stop.

Page 12

10

u Stitchwidthadjustingbutton

Press “ ” or “ ” to change the stitch width or needle

drop position o, depending on the selected stitch

pattern. Refer to pages 30, 33 and 39.

i Stitchlengthadjustingbutton

Press “ ” or “ ” to change the stitch length !0 of the

selected pattern. You can also adjust the buttonhole

density, the evenness of darning, and the size of eyelet

with this button. Refer to pages 30, 33 and 39.

r

t

r Needleup/downbutton

Press the needle up/down button to bring the needle up

or down.

t Threadcutterbutton

Press the thread cutter button to trim the threads after

sewing.

The thread cutter mark will blink y while the machine

cuts the threads.

NOTE:

The thread cutter button does not function:

- directly after turning on the power.

- after being pressed 3 times in a row.

Use the thread cutter on the face cover if the thread is

#30 or thicker (refer to page 27).

u i

y

o

!0

Page 13

11

q

LCD Display

w

e r

NOTE:

Magnetic or electrostatic interference may cause the

LCD display to icker.

Do not use the machine near appliances that generate

a magnetic eld or an electrostatic eld such as

microwave ovens.

The LCD display shows following information when the

machine is turned on.

q Identication letter of the recommended foot

w Stitch pattern number

e Stitch width

r Stitch length

TouchPanel

w qe

r

t

y

u

i

(q and w)Arrowkeys

Press “ ” q or “ ” w to select the stitch pattern, or turn

the page in the setting mode (refer to pages 12 and 24-26 ).

e Numeralkeys

Enter a 2-digit number to select the desired stitch pattern

(refer to page 12).

r Directpatternselectionkeys

You can select stitch patterns 00, 06, 12 and 16 directly

by pressing the corresponding direct pattern selection

key (refer to page 12).

t Threadcutmemorykey

To cut the threads automatically after locking stitches,

press the thread cutter memory key t (refer to page 28).

y Elongationkey

Press this key to elongate satin stitch patterns (refer to

page 61).

u Setkey

Press this key to enter the machine setting mode for

customizing the machine settings (refer to page 24-26).

i Lockoutkey

Press this key to lockout the machine when threading the

machine, replacing the accessories etc.

To reduce the risk of injury, all the buttons and keys are

deactivated.

To unlock the machine, press this key again.

Page 14

12

SelectingthePatterns

Enter the 2-digit number of the desired stitch pattern with

the corresponding numeral keys.

To refer available stitch patterns for this sewing machine,

check the stitch chart or the stitch chart in this manual on

page 66.

q Stitch chart

q

•Usingnumeralkeys

Example:Toselectstitchpattern72

z Turn the power switch on.

x Press the numeral keys on the touch panel.

First press key 7 and then press key 2.

c Now pattern 72 is selected.

z

x

c

Direct pattern selection

You can select the following stitch patterns directly by

pressing the corresponding direct pattern selection keys.

e

e Direct pattern selection keys

•Usingarrowkeys

You can use arrow keys to select your desired patterns.

To select the desired stitch pattern, press the either of

arrow keys until the desired pattern is displayed.

w Arrow keys

w

Page 15

13

RemovingandAttachingtheFootHolder

CAUTION:

Turn OFF the power switch or press the lockout key

to lockout the machine before detaching or attaching

fo ot hol der.

Removingthefootholder

Remove the setscrew by turning it counterclockwise with

a screwdriver.

Attachingthefootholder

Align the hole in the foot holder with the threaded hole in

the presser bar.

Fit the setscrew into the hole.

Tighten the setscrew by turning it clockwise with the

scr ewdr iver.

q Setscrew

w Foot holder

e Hole

r Threaded hole

q

e

r

w

q

e

we

Presser Foot Lifter

The presser foot lifter raises and lowers the presser foot.

You can raise the foot about 1/4˝ (0.7 cm) higher than the

normal up position for easy removal of the presser foot,

or to help you place thick material under the foot.

q Presser foot lifter

w Normal up position

e Highest position

ChangingthePresserFoot

CAUTION:

• Turn OFF the power switch or press the lockout

key to lockout the machine before changing the

foot.

• Do not push the lever down when removing the

presser foot.

• Always use the proper foot for the selected pattern.

The wrong foot can cause the needle to break.

Each foot is marked with an identication letter.

q Identication letter

r

e

w

q

Removingthepresserfoot

Raise the needle to its highest position by turning the

handwheel counterclockwise. Raise the presser foot, and

press the lever on the back of the foot holder.

w Lever

Attachingthepresserfoot

Place the selected presser foot so that the pin on the foot

lies just under the groove in the foot holder.

Lower the presser bar to lock the foot into the place.

e Groove

r Pin

w

Page 16

14

AdjustingtheNeedleThreadTension

Straightstitch balancedtension

The ideal straight stitch has threads locked between two

layers of fabric, as illustrated (magnied to show detail).

If you look at the top and bottom of the seam, notice that

the stitches are evenly balanced.

q Needle thread (top thread)

w Bobbin thread (bottom thread)

e To loosen

r To tighten

When adjusting the needle thread tension, the higher the

number, the tighter the top thread tension.

Results depend on:

- stiffness and thickness of the fabric

- number of fabric layers

- type of stitch

q

w

e

r

r

q

w

t

e

Tension is too loose

The needle thread shows through on the wrong side of

the fabric, and the stitch feels bumpy. Turn the dial to a

higher number to tighten the needle thread tension.

q Needle thread (top thread)

w Bobbin thread (bottom thread)

e To tighten tension

r Right side (top side) of fabric

t Wrong side (bottom side) of fabric

r

q

w

t

e

Tensionistootight

The bobbin thread shows through on the right side of the

fabric, and the stitch feels bumpy. Turn the dial to a lower

number to loosen the needle thread tension.

q Needle thread (top thread)

w Bobbin thread (bottom thread)

e To loosen tension

r Right side (top side) of fabric

t Wrong side (bottom side) of fabric

Page 17

15

Zigzagstitchbalancedtension

For an ideal zigzag stitch, the bobbin thread does not

show on the right side (top side) of the fabric, and the

needle thread shows slightly on the wrong side (bottom

side) of the fabric.

See the illustrations for the correct appearance.

To match this appearance, adjust the needle tension as

necessary.

Balanced tension

Minimize the amount of needle thread visible on the

wrong side (bottom side) of the fabric without causing

excessive puckering, or causing the bobbin thread to

show on the right side (top side) of the fabric.

Results vary with fabric, thread and sewing conditions.

q Right side (top side) of fabric

w Wrong side (bottom side) of fabric

q w

q w

q w

Tensionistootight

The corner of each zigzag pulls together on the right side

of the fabric

q Right side (top side) of fabric

w Wrong side (bottom side) of fabric

Tension is too loose

The corner of each zigzag point pulls together on the

wrong side of the fabric.

q Right side (top side) of fabric

w Wrong side (bottom side) of fabric

Page 18

16

q w

DroppingorRaisingtheFeedDog

The drop feed lever is located underneath the free arm

bed on the back of the machine.

To drop the feed dog, push the lever in the direction of

the arrow q.

To raise the feed dog, push the lever in the direction

of the arrow w, as illustrated, and turn the handwheel

toward you.

The feed dog must be up for normal sewing.

Viewfromtherear

Page 19

17

ChangingtheNeedle

CAUTION:

Turn OFF the power switch or press the lockout key to

lockout the machine before changing the needle.

Raise the needle to its highest position by turning the

handwheel counterclockwise, and lower the presser

foot.

A loose needle or a loose screw may cause machine

malfunction or needle to break.

Loosen the needle clamp screw by turning it

counterclockwise. Remove the needle from the needle

clamp.

Insert a new needle into the needle clamp with the at

side to the rear. When inserting the needle into the

needle clamp, push it up as far as it will go.

Tighten the needle clamp screw rmly by turning it

clockwise.

q Needle clamp screw

w Flat side

To see if the needle is in good condition, place the at

side of the needle onto something at (needle plate, glass

etc.). The gap between the needle and the at surface

should be consistent. Never use a bent or blunt needle.

A damaged needle can cause permanent snags or runs

in knits, ne silks and silk-like fabrics.

q

w

Fabric Thread Needle

Fine

Lawn

Georgette

Tric o t

Organza

Crepe

Silk #80-100

Cot t on #80 -10 0

Synthetic #80-100

#9/65-11/75

Blue tip needle

Medium

Sheeting

Jersey

Broadcloth

Fleece

Silk #50

Cotton #50-80

Synthetic #50-80

#11/ 75 -14 / 9 0

Heavy

weight

Denim

Tweed

Coating

Quilting

Silk #30-50

Cotton #40-50

Synthetic #40-50

#14 / 9 0 -16/ 10 0

Fabric,ThreadandNeedleChart

• For general sewing, use needle size 11/75 or 14/90.

• A ne thread and needle should be used for sewing

lightweight fabrics, so the fabric will not be marred.

• Heavy fabrics require a needle large enough to

pierce the fabric without fraying the needle thread.

• Always test the needle size on a small scrap of the

fabric that will be used for actual sewing.

• In general, use the same thread for the needle and

bobbin.

• When sewing stretch fabrics, very ne fabrics and

synthetics, use a blue tip needle. The blue tip needle

effectively prevents skipped stitches.

NOTE:

1 x blue tip needles (#11/75), 2 x #11/75 needles and 2

x #14/90 needles are included in the needle case (Part

No. 540401026).

Page 20

18

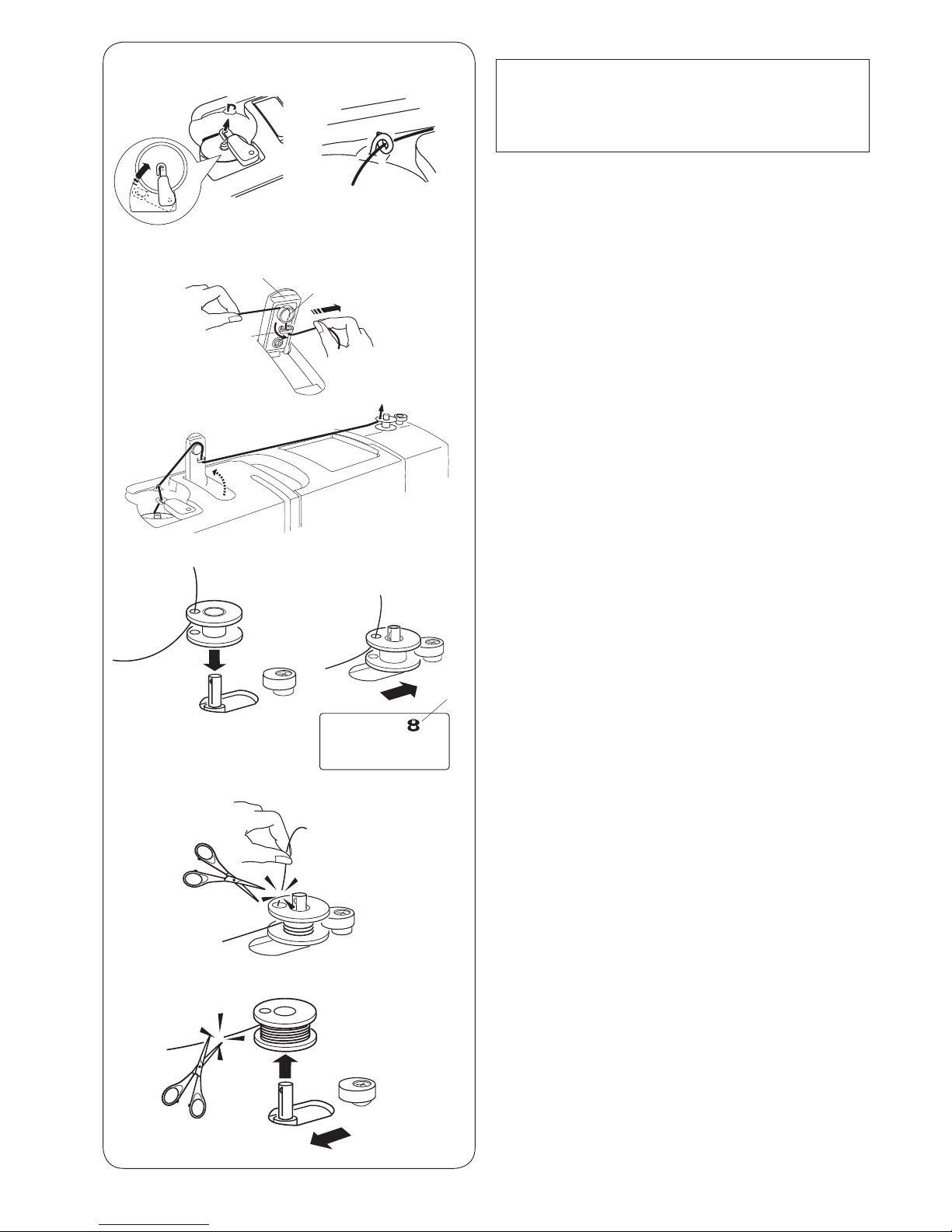

Settingthespool

z Turn the spool thread guide t as illustrated, and the

spool pin y will lift up.

WARNING

Do not lean over the top of spool pin when turning the

spool thread guide. The spool pin pops up and it may

strike your face.

t Spool thread guide

y Spool pin

BobbinWinding

Removingthebobbin

Gently slide the hook cover release button q to the right

and remove the hook cover plate w.

Lift out the bobbin.

q Hook cover release button

w Hook cover plate

e Bobbin

q

w

t

y

u

o

x

c

z

u

y

x Place a spool of thread on the spool pin with the

thread running off counterclockwise.

Draw the thread from the spool about 4˝ (10 cm) of

thread. Attach the large spool holder u.

u Large spool holder

i Slit

c Press the spool holder u rmly against the spool of

thread, and then push down the spool pin y to lower

the spool until it is locked in the bottom.

* The small spool holder o is used with narrow or small

spools of thread.

o Small spool holder

NOTE:

If a rimless spool may not let thread out smoothly,

place the spool on the spool pin in up position and do

not use the spool holder so the spool can rotate freely.

NOTE:

If there is a slit i on the spool of thread, be sure to

place the spool with the slit end up.

i

NOTE:

Make sure there is no gap between the spool holder

and spool rim, otherwise the thread can get tangled.

NOTE:

Use the “J” plastic bobbins for horizontal hook (marked

with “J” r). Using other bobbins, such as pre-wound

paper bobbins, may cause stitching problems and/ or

damage to the bobbin holder.

r

e

Page 21

19

Windingthebobbin

NOTE:

• Set the speed control slider at its fastest position

for bobbin winding.

• Close the retractable thread guide e after the

bobbin winding.

z Turn the spool thread guide as illustrated.

Draw the thread from the spool and pass it through

the spool thread guide.

x Pass the thread through the thread guide (A).

c Raise the retractable thread guide.

Guide the thread around the bobbin winder thread

guide (A) q and (B) w as illustrated.

v Pass the thread through the hole in the top of the

bobbin from the inside to outside.

b Put the bobbin on the bobbin winder spindle.

n Push the bobbin to the right. The bobbin mark r

appears on the LCD display.

m With the free end of the thread held in your hand,

start the machine. Stop the machine when bobbin has

wound a few layers, and then cut the thread close to

the hole in the bobbin.

, Start the machine again. When the bobbin is fully

wound, it will stop automatically. Stop the machine

and return the bobbin winder to its original position

by moving the spindle to the left. Cut the thread as

shown.

z x

v

b n

r

m

,

c

q

w

e

Page 22

20

Insertingthebobbin

CAUTION:

Turn OFF the power switch or press the lockout key to

lockout the machine before inserting the bobbin and

threading the bobbin holder.

z Place a bobbin in the bobbin holder w with the thread

running off counterclockwise.

q End of thread

w Bobbin holder

x Guide the thread into the rst notch e on the front

side of the bobbin holder.

e Notch

c Draw the thread to the left, sliding it between the

tension spring blades.

v Continue to draw the thread lightly until the thread

slips into the second notch r. Pull out about 4˝ (10

cm) of thread.

r Notch

b Attach the hook cover plate. Check the threading by

referring to the diagram t shown on the hook cover

plate.

t Threading diagram

y End of thread

z

x

c

v

b

q

e

r

t

w

y

Page 23

21

ThreadingtheMachine

Raise the presser foot. Press the needle up/down button

q to raise the thread take-up lever to its highest position.

q Needle up/down button

CAUTION:

Turn OFF the power switch or press the lockout key to

lockout the machine before threading the machine.

z Turn the spool thread guide w in the direction of arrow

as illustrated.

Pass the end of the thread through the spool thread

guide w.

x Pass the thread through the thread guide (A) e.

q

w

z

x

c

v

b

z x

c v

b n

e

r

t

y

n

m

u

i

c Draw the thread around the thread guide (B) r.

v Draw the end of the thread down around the check

spring holder t.

b Firmly draw the thread up from right to left over the

take-up lever, and down into the take-up lever eye y.

n Pass the thread through the lower thread guide u.

Slide the thread behind the needle bar thread guide

on the left i.

m Thread the needle from front to back, or use the

needle threader (see page 22).

m

Page 24

22

NOTE:

The needle threader can be used with a #11 to #16

needle or a blue tipped needle. Thread sizes 50 to 90

are recommended.

NeedleThreader

CAUTION:

Turn OFF the power switch or press the lockout key to

lockout the machine when using the needle threader.

z Lower the presser foot. Press the needle up/down

button q to raise the needle to its highest position.

Press the lockout key or turn the power switch off.

Pull down the needle threader knob w as far as it will

go. The hook e comes out through the needle eye

from behind.

q Needle up/down button

w Knob

e Hook

x Draw the thread from guide (a) r to guide (b) t and

under the hook e. Draw the thread up along the right

side of guide (b) t and slip the thread in between

guide (b) and the holder plate y.

e Hook

r Guide (a)

t Guide (b)

y Holder plate

c Raise the knob in the direction of the arrow, drawing

the thread loop through the needle.

u Thread loop

v Pull the thread through the needle eye.

w

e

y

t

e

r

z

x

c

v

u

q

Page 25

23

DrawinguptheBobbinThread

z Raise the presser foot. Hold the needle thread lightly

with your left hand.

x Press the needle up/down button q twice to lower

and raise the needle to pick up the bobbin thread.

q Needle up/down button

c Pull both threads 10 to 15 cm (4˝ to 6˝) under and

behind the presser foot.

q

z

x

c

Page 26

24

Buzzer sound setting

The buzzer sound can be turned on or off using the

buzzer sound setting.

Enter the setting mode.

The default buzzer sound setting is “ON”.

To turn the buzzer sound off, press the stitch length

adjusting button “ ” q, and the “oF” mark will blink.

Setting Mode

Press the set key q to enter the machine setting mode

for customizing the machine setting.

The LCD display will show “01”, “on” (ON) and “oF” (OFF),

and the “on” mark will blink.

Each time you press the arrow key w, the mode

number changes, and you can set the following machine

functions as follows:

e

Mode number

r

Buzzer sound setting

t

Needle stop position setting

y

Key position calibration

u

Resetting all to default

Press the set key q to apply the machine settings and

exit the machine setting mode.

q

w

e

r

t

y

u

q

w

To turn the buzzer sound on, press the stitch width

adjusting button “ ” w, and the “on” mark will blink.

* Caution buzzer sound cannot be turned off.

Needle stop position setting

You can set the needle position to up or down when the

machine stops.

Enter the setting mode.

Press the right arrow key q to select the needle stop

position setting.

The default up/down needle position setting is “dn” (down).

To change the needle position to up, press the stitch

width adjusting button “ ” w, and the “uP” mark will

blink.

To change the needle position to down, press the stitch

length button “ ” e, and the “dn” mark will blink.

e

w

q

NOTE:

Customized machine settings will not apply if you turn

off the machine while in the machine setting mode.

Page 27

25

Keypositionadjustmentsetting

You can adjust the key position when you think the key

sensor is off from the actual key position.

Enter the setting mode.

Press the right arrow key q twice to select the key

position adjustment setting.

The key position adjustment screen appears and “oF”

(OFF) mark is shown on the screen.

Press the stitch width adjusting button “ ” w to activate

the key position adjustment setting.

The “oF” mark changes to “on” (ON) and “P1” is shown

on the LCD display.

z

x

c

v

b

n

z With a seam ripper, press q on the touch panel of

your machine.

x “P2” will be shown on the LCD display. Press the w

on the touch panel.

c “P3” will be shown on the LCD display. Press the e

on the touch panel.

v “P4” will be shown on the LCD display. Press the r on

the touch panel.

b “P5” will be shown on the LCD display. Press the t on

the touch panel.

w

q

•Keypositioncalibration

n The screen will back to the setting screen with a

buzzer sound.

NOTE:

To cancel the calibration, press the stitch width

adjusting button “ ”. The “oF”(OFF) mark is shown on

the screen and the calibration will be canceled.

Page 28

26

Resetting all to default

The following customized settings can be reset to the

default settings (factory settings).

• Buzzer sound

• Needle stop position

• Key position adjustment

Enter the setting mode.

Press the right arrow key q 3 times to select the

resetting all to default mode.

Press the stitch length adjusting button “ ” w.

The “y” (YES) and “n” (NO) mark appears on the screen.

Press the stitch width adjusting button “ ” e under the “y”

mark to reset the machine to the factory setting.

Press the stitch length adjusting button “ ” w under the

“n” mark to cancel the resetting.

w

we

q

Page 29

27

q

StraightStitchSewing

q Stitch pattern: 00 or 03

w Needle thread tension: 2 to 6

e Presser foot: Zigzag foot A

NOTE:

When sewing with the satin stitch foot F or buttonhole

foot R, pull the thread to the left to hold the thread.

Startingtosew

Raise presser foot and position the fabric next to a seam

guide line on the needle plate. Lower the needle to the

point where you want to start.

Pull the thread toward the rear and lower the presser

foot.

Press the start/stop button or depress the foot control to

start sewing.

Gently guide the fabric along a seam guide line letting

the fabric feed naturally.

q Start/stop button

BASIC SEWING

4

q w e

Securing seams

For fastening the ends of seams, press the reverse

button and sew several reverse stitches.

The machine sews in reverse as long as you press and

hold the reverse button.

w Reverse button

Press the reverse button once when sewing the lock-amatic stitch (pattern 01) or locking stitch (pattern

02) and the machine will lock the stitches off and stop

automatically.

Cuttingthreads

To cut the threads after nishing sewing, press the

thread cutter button. The needle bar automatically rises

after trimming the threads.

After cutting the thread, you can start sewing without

drawing up the bobbin thread.

e Thread cutter button

To use the thread cutter on the face cover, remove the

fabric and draw it to the back.

Pull the threads up and slip them between the thread

cutter and face cover from behind.

Pull the threads toward you to cut.

r Thread cutter

w

e

r

NOTE:

Use the thread cutter on the face cover to cut

specialized or thick threads (#30 or thicker).

Page 30

28

AutoThreadCutting

To cut the threads automatically after locking stitches,

press the thread cutter memory key.

The thread cutter icon appears on the LCD display.

q Thread cutter memory key

w Thread cutter icon

When buttonhole, tacking, darning or eyelet is selected,

the machine will cut the threads automatically after

sewing is nished.

Press the auto-lock button or reverse button to cut the

threads automatically after locking stitches when other

stitch is selected.

NOTE:

Use the thread cutter on the face cover if the thread is

30 or thicker.

q

w

ChangingSewingDirection

Stop the machine.

Raise the presser foot.

Pivot the fabric around the needle to change the sewing

direction as desired.

Lower the foot and start sewing in a new direction.

NOTE:

Lower the needle by pressing needle up/down button if

the needle stop position is set at up position.

w

q

SewingfromtheEdgeofThickFabric

The black button on the zigzag foot locks the foot in the

horizontal position.

This is helpful when starting sewing from the far edge of

thick fabrics or sewing across a hem.

Lower the needle into the fabric at the point where you

wish to start sewing.

Lower the foot while pushing the black button in. The foot

is locked in the horizontal position to avoid slipping.

The button is released automatically after sewing a few

stitches.

q Black button

w Thick fabrics

Page 31

29

Turning Square Corners

When sewing with fabric edge at 5/8˝ seam guide, to

turn a square corner so that sewing continues at same

distance from edge.

Stop the machine when front edge of fabric reaches the

cornering guide lines y.

Raise the presser foot and turn the fabric

counterclockwise 90°.

Lower the presser foot, and begin stitching in the new

direction.

y Cornering guide

NOTE:

Lower the needle by pressing needle up/down button

if the needle stop position is set at up position.

y

Using Seam Guides

The seam guides on the needle plate and the hook cover

plate help you to measure seam allowance.

The numbers on the needle plate indicate the distance

from the center needle position in inches and millimeters.

q Center needle position

The front seam guides are marked at 1/4˝, 3/8˝ and

5/8˝ from the center needle position.

w Front seam guide at 1/4˝

e Front seam guide at 3/8˝

r Front seam guide at 5/8˝

The angle scales are marked at 45, 60, 90 and 120

degrees.

Use the angle scales when seaming patchwork pieces

(refer to page 54).

t Angle scales

y Cornering guide

y

w

e

r

y

t

q

Page 32

30

(7.0)

(3.5)(0.0)

AlteringtheNeedleDropPosition

The needle drop position can be altered for straight stitch

patterns 00 to 04 and 52 to 54.

Press the “ ” sign on the stitch width adjusting button to

move the needle to the left.

Press the “ ” sign on the stitch width adjusting button to

move the needle to the right.

q Stitch width adjusting button

q

AlteringtheStitchLength

The stitch length can be altered.

Press the “ ” sign on the stitch length adjusting button to

increase the stitch length.

Press the “ ” sign on the stitch length adjusting button

to decrease the stitch length.

q Stitch length adjusting button

w Stitch length

q

w

w

Page 33

31

Lock-a-maticStitch

q Stitch pattern: 01

w Thread tension dial: 2 to 6

e Presser foot: Zigzag foot A

LockingStitch

q Stitch pattern: 02

w Thread tension dial: 2 to 6

e Presser foot: Zigzag foot A

TripleStretchStitch

q Stitch pattern: 04

w Thread tension dial: 2 to 6

e Presser foot: Zigzag foot A

q

q

4

q w e

Use this stitch to secure the beginning and the end of a

seam with backstitching.

When you reach the end of the seam, press the reverse

button once. The machine will sew four reverse stitches,

four forward stitches, and then stop sewing automatically.

q Reverse button

4

q w e

This unique stitch is used where an invisible locking

stitch is needed.

Lower the needle close to the front edge of the fabric.

The machine will sew several locking stitches in place

and continue sewing forward.

When you press the reverse button at the end of the

seam, the machine will sew several locking stitches in

place, then stop sewing automatically.

q Reverse button

This strong, durable stitch is recommended when

both elasticity and strength are necessary in order

to insure comfort and durability. Use it to reinforce

areas such as crotch and armhole seams. Also use for

extra reinforcement when constructing items such as

backpacks.

4

q w e

VarietyofStraightStitches

Page 34

32

This stitch is a narrow stretch stitch designed to

eliminate puckering on knit fabrics and bias seams, while

permitting the seam to be pressed completely open at.

Use this stitch for seaming ne fabrics.

SculptureStitches

q Stitch pattern: 53 or 54

w Thread tension dial: 3 to 6

e Presser foot: Satin stitch foot F

StretchStitch

q Stitch pattern: 05

w Thread tension dial: 3 to 6

e Presser foot: Zigzag foot A

4

q w e

You can achieve a lovely hand-worked look when

topstitching suits, blazers, jumpers, and denim outts

with these stitches.

4

q w e

Page 35

33

The zigzag stitch is one of the most useful and versatile

stitches.

It is used for overcasting, mending, appliqué, and also

used as a decorative stitch.

NOTE:

Use interfacing when sewing on stretch fabrics such

as knit, jersey or tricot.

ZigzagStitch

q Stitch pattern: 06 or 07

w Thread tension dial: 3 to 7

e Presser foot: Zigzag foot A

Alteringthestitchwidth

Press the “ ” sign on the stitch width adjusting button to

increase the stitch width.

Press the “ ” sign on the stitch width adjusting button to

decrease the stitch width.

q Stitch width adjusting button

w Stitch width

The stitch width of pattern 06 can be changed without

changing its center needle position (M) e.

e Center needle position

The stitch width of pattern 07 can be changed without

changing its right needle position (R) r.

r Right needle position

Alteringthestitchlength

Press the “ ” sign on the stitch length adjusting button

to increase the stitch length.

Press the “ ” sign on the stitch length adjusting button

to decrease the stitch length.

q Stitch length adjusting button

w Stitch length

4

q w e

q

e

w

r

q

w

Page 36

34

MultipleZigzagStitch

q Stitch pattern: 08

w Thread tension dial: 3 to 7

e Presser foot: Zigzag foot A

This stitch is used to nish a raw edge of synthetics and

other stretch fabrics that tend to pucker.

Sew along the fabric edge leaving an adequate seam

allowance.

After sewing, trim off the seam allowance closer to the

stitches.

This stitch is also excellent for darning and mending

tears.

4

q w e

This industrial inspired overlock stitch is excellent for

assembling and nishing fabrics together in one step.

Apply ribbing to knits and garment retains its shape.

Elna invented this stitch in 1982.

Place the fabric edges together under the presser foot

next to the right side edge of the presser foot.

q Edge of fabric

SuperOverlockStitch

q Stitch pattern: 12

w Thread tension dial: 3 to 6

e Presser foot: Satin stitch foot F

4

q w e

q

Place your fabric to allow a 5/8˝ (1.5 cm) seam. Trim

excess close to the stitching. Be careful not to cut the

stitches.

KnitStitch

q Stitch pattern: 09

w Thread tension dial: 3 to 6

e Presser foot: Zigzag foot A

4

w eq

VarietyofOvercastingStitches

Page 37

35

AttachingElastic

q Stitch pattern: 15

w Thread tension dial: 1 to 4

e Presser foot: Satin stitch foot F

Mark the elastic into quarters. Match those to the center

front, center back and side seams, and pin the elastic to

the fabric.

Place the elastic under the foot and stitch into place while

stretch the elastic evenly.

4

w eq

Page 38

36

Buttonholes

The following 7 types of buttonholes are available.

q Squarebuttonhole

This buttonhole is widely used on medium to heavy

fabrics.

w Round-endbuttonhole

This buttonhole is used on ne to medium weight fabrics,

especially for blouses and children’s clothes.

e Finefabricbuttonhole

This buttonhole is rounded at both ends and is used on

ne, delicate fabrics such as ne silk.

r Keyholebuttonhole

The keyhole buttonhole is widely used on medium to

heavy fabrics. It is also suitable for larger and thicker

buttons.

t Stretchbuttonhole

This buttonhole is suitable for stretch fabrics. It can also

be used as a decorative buttonhole.

y Antiquebuttonhole

Resembles a “Hand Worked” buttonhole ideal on ne

fabrics featured in Heirloom sewing or for couture

fashions.

u Weltedbuttonhole(Boundbuttonhole)

This is a template pattern for the hand-sewn welted

buttonhole.

q w e r t y u

Page 39

37

z

e

r

t

The size of a buttonhole is automatically set by placing a

button in the rear of automatic buttonhole foot R.

The button holder of the foot takes a button size of 1 cm

(3/8˝) to 2.5 cm (1˝) in diameter.

When selecting the buttonholes, the LCD display advise

you to lower the buttonhole lever.

NOTE:

It is sometimes necessary to change buttonhole size

to match certain heavy or specic fabrics and threads.

Make a test buttonhole on an extra piece of the fabric

to check your settings.

The preset width of the buttonhole is suited for

ordinary buttons.

Apply an interfacing to stretch or ne fabrics.

Sewing

z Pull the button holder to the back, and place the

button in it. Push it together tightly on the button.

q Button holder

NOTE:

If the button is extremely thick, make a test buttonhole

on an extra piece of the fabric.

If it is difcult to t the button through the test

buttonhole, you can lengthen the buttonhole by pulling

the button holder back a little. The length of the

buttonhole will be increased.

w Extra gap

x Press the needle up/down button to raise the needle.

Attach the automatic buttonhole foot R snapping the

pin into the groove of the foot holder.

You may lift the presser foot lifter to the extra lifted

position when placing the automatic buttonhole foot

under the foot holder.

Raise the presser foot.

e Groove

r Pin

c Draw the needle thread to the left through the hole of

foot. Mark the buttonhole position on the fabric and

place it under the buttonhole foot. Lower the needle at

the starting point by turning the handwheel.

t Starting point

q

w

x

c

SquareButtonhole

q Stitch pattern: 16

w Thread tension dial: 1 to 4

e Presser foot: Automatic buttonhole foot R

4

w eq

Page 40

38

v

!2

!2

!2

i

i

i

y

v Lower the presser foot and pull the buttonhole lever

down as far as it will go.

y Buttonhole lever

NOTE:

The reference lines on the buttonhole foot can be

used as a positioning guide.

Make sure there is no gap between the slider and

stopper, otherwise the buttonhole will be out of

position or there will be a sewing gap.

u No gap

i Starting point

o Reference lines

!0 Slider

!1 Stopper

!2 Sewing gap

u

b Start sewing while pulling the needle thread lightly to

the left. After sewing a few stitches, free the thread

and continue sewing.

NOTE:

If you start sewing without pulling down the buttonhole

lever, the LCD display will show a warning and

the machine will stop after a few stitches. Pull the

buttonhole lever down and start sewing.

b

i

o

!0

!1

Page 41

39

Alteringthebuttonholewidth

Press the “ ” sign on the stitch width adjusting button to

increase the buttonhole width.

Press the “ ” sign on the stitch width adjusting button to

decrease the buttonhole width.

q Stitch width adjusting button

NOTE:

The buttonhole width can be adjusted from 2.5 to 7.0.

n The buttonhole is sewn in the sequence as shown.

When the buttonhole is nished, the machine will stop

automatically with the needle in the up position.

Doublelayerbuttonhole

To make a sturdy buttonhole, sew another layer of

buttonhole stitches over the previous stitches.

After the buttonhole is nished, do not raise the foot or

buttonhole lever, simply start the machine again.

n

m

,

!3

!4

m Remove the fabric and place a pin just below the

bartack to prevent accidentally cutting the stitches.

Cut the opening with the seam ripper.

!3 Pin

!4 Seam ripper

, When buttonhole sewing is nished, push the

buttonhole lever upward as far as it will go.

y Buttonhole lever

y

Alteringthebuttonholedensity

Press the “ ” sign on the stitch length adjusting button

to decrease the buttonhole density.

Press the “ ” sign on the stitch length adjusting button

to increase the buttonhole density.

q Stitch length adjusting button

NOTE:

The buttonhole density can be adjusted from 0.2 to 0.8.

NOTE:

If the fabric is not feeding smoothly when sewing

a double layer buttonhole, increase the buttonhole

densit y.

q

q

Page 42

40

Round-endandFineFabricButtonhole

q Stitch pattern: 17 and 18

w Thread tension dial: 1 to 4

e Presser foot: Automatic buttonhole foot R

Sewing procedure is the same as square buttonhole.

The buttonhole width can be varied from 2.5 to 5.5.

The stitch density can be varied from 0.2 to 0.8.

KeyholeButtonhole

q Stitch pattern: 19

w Thread tension dial: 1 to 4

e Presser foot: Automatic buttonhole foot R

Sewing procedure is the same as square buttonhole.

The buttonhole width can be varied from 5.5 to 7.0.

The stitch density can be varied from 0.3 to 0.8.

Use the seam ripper and an eyelet punch to open the

buttonhole.

q Eyelet punch (not provided with the machine)

q

StretchButtonholeandAntiqueButtonhole

q Stitch pattern: 20 and 21

w Thread tension dial: 1 to 4

e Presser foot: Automatic buttonhole foot R

The machine will sew the front bartack and left row rst.

The machine will sew the back bartack and right row,

then it stops automatically.

The stitch width can be varied from 2.5 to 7.0.

The stitch density can be varied from 0.5 to 1.0 (Stretch

buttonhole), 0.5 to 2.5 (Antique buttonhole).

4

w eq

4

w eq

4

w eq

Page 43

41

z Use the same procedure as the square buttonhole

sewing. Set the stitch width to match the thickness of

the cord used.

With the buttonhole foot raised, hook the ller cord on

the spur at the back of the buttonhole foot. Bring the

ends toward you under the buttonhole foot, clearing

the front end.

Hook the ller cord into the forks on the front of the

buttonhole foot to hold them tight.

Lower the needle into the garment where the

buttonhole will start, and lower the foot.

q Spur

w Forks

x Start the machine and sew the buttonhole.

Each side of the buttonhole and the bartacks will be

sewn over the cord.

Remove the fabric from the machine, and cut the

sewing threads only.

e Needle thread

r Bobbin thread

c Pull the loose ends of the ller cord to tighten it.

Thread the each end of the cord through a handsewing needle. Then draw the both ends to the wrong

side of the fabric and knot.

NOTE:

Cut the ller cord at both ends, if the ller cord is

stitched on the fabric and cannot be pulled.

z

x

c

q

w

e

r

CordedButtonhole

q Stitch pattern: 16

w Thread tension dial: 1 to 4

e Presser foot: Automatic buttonhole foot R

4

w eq

Page 44

42

q

w

w

q

e

e

r

q

e

r

e

w

z

x

c

v

b

n

WeltedButtonhole

q Stitch pattern: 22

w Thread tension dial: 1 to 4

e Presser foot: Automatic buttonhole foot R

A welted buttonhole is made by stitching a strip or patch

of fabric to the buttonhole.

Welted buttonholes are particularly suitable for tailored

garments, but are not recommended for sheer or delicate

fabrics where the patch might show through or add bulk.

z Baste a patch to the garment fabric with the right

sides together.

q Wrong side of patch

w Right side of garment fabric

x Select pattern 22.

Sew the welted buttonhole on both fabrics together.

Cut the buttonhole opening as illustrated then pull the

patch out through the slit to the other side.

q Wrong side of patch

w Right side of garment fabric

e Right side of patch

c Pull out the patch until the right side of the patch is

showing. Use an iron to press both corner ends until

they are squared off.

e Right side of patch

r Wrong side of garment fabric

v Fold back each side of the patch to form buttonhole

lips.

q Wrong side of patch

e Right side of patch

b Press both folds with an iron.

e Right side of patch

r Wrong side of garment fabric

n Baste both edges of the seam with a needle and

thread by hand.

w Right side of garment fabric

4

q w e

Page 45

43

r

t

q

r

w

e

r

u

y

u

y

u

y

u

m

,

.

⁄0

⁄1

⁄2

⁄3

m Fold over the length of the garment fabric, sew back

and forth beside the original seam to secure aps of

the patch.

r Wrong side of garment fabric

t Sew back and forth

, Fold over the end of fabric and sew back and forth

three times over the triangular end.

q Wrong side of patch

w Right side of garment fabric

r Wrong side of garment fabric

. The patch should be cut 1 to 1.5 cm (7/16˝ – 5/8˝)

away from the hole. The corners should be cut

rounded off as shown.

e Right side of patch

r Wrong side of garment fabric

⁄0 Place the facing on the wrong side of the garment

fabric. Mark the 4 corners with pins as shown.

y Facing

u Garment fabric

⁄1 Turn all the layers over and cut the buttonhole opening

on the facing in the same way as step x.

Four marker pins show you the corner points on the

facing. Fold back each ap between the facing and

patch.

y Facing

u Garment fabric

⁄2 Stitch around the opening with a needle and thread as

shown.

y Facing

u Garment fabric

⁄3 The welted buttonhole is complete.

u Garment fabric

Page 46

44

DarningStitch

q Stitch pattern: 23

w Thread tension dial: 3 to 6

e Presser foot: Automatic buttonhole foot R

q

w

e

r

w

y

u

z x c v

Sewingashorterdarning

To sew a darning shorter than 2 cm (3/4˝), rst stop the

machine after sewing the required length y, then press

the reverse button t.

The required length y has been determined.

Start the machine again and continue sewing until the

machine stops automatically.

t Reverse button

y Required length

u Starting point

Sewingasame -sizeddarning

Simply start the machine to sew another darning at the

same size.

NOTE:

To reset the size of the darning, select the other stitch

pattern and reselect the darning stitch.

Adjustingtheevennessofdarning

Correct the evenness of the darning as follows:

“d5” is the default setting value.

When the right side of the darn is lower than the left side,

press the “ ” sign on the stitch length adjusting button q

to set the value to “d6” to “d9”, and make the darn even.

When the left side of the darn is lower than the right side,

press the “ ” sign on the stitch length adjusting button q

to set the value to “d1” to “d4”, and make the darn even.

q Stitch length adjusting button

Startingtosew

z Attach the automatic buttonhole foot R and pull the

button holder q all the way out.

Draw the needle thread to the left through the hole of

foot.

q Button holder

x Place the fabric under the foot, and lower the needle

at the starting point w. Then lower the foot.

w Starting point

c Start the machine. The machine will sew locking

stitch, 16 rows of darning, locking stitch again and

stop automatically.

v Turn the fabric and repeat sewing in different direction.

e 2 cm (3/4˝)

r 0.7 cm (9/32˝)

4

w eq

q

t

Page 47

45

Tacking is used to reinforce pockets, crotches and belt

carriers where extra strength is needed.

Tacking

q Stitch pattern: 24

w Thread tension dial: 3 to 6

e Presser foot: Satin stitch foot F

q

w

r

r

Startsewing

Start the machine and sew until the machine stops

automatically. The machine will sew a tacking 1.5 cm

(5/8˝ ) long.

q 1.5 cm (5/8˝)

Sewingashortertack

To sew a tack shorter than 1.5 cm (5/8˝), rst stop the

machine after sewing the required length, then press the

reverse button.

The tack length has been determined.

Start the machine again and continue sewing until the

machine stops automatically.

w Required length

e Reverse button

r Tack length

Sewingasame -sizetacking

Simply start the machine to sew another tack at the same

size.

NOTE:

To reset the size of the tacking, select the other stitch

pattern and reselect the tacking.

4

w eq

e

Page 48

46

Adjustingtheshapeofaneyelet

Correct the shape of the eyelet as follows:

“L3” is the default setting value.

If the eyelet gap overlaps, press the “ ” sign on the stitch

length adjusting button to make the darn even.

If the eyelet gap opens, press the “ ” sign on the stitch

length adjusting key to make the darn even.

q Stitch length adjusting button

NOTE:

The shape can be adjusted within L1 to L5.

Eyelet

q Stitch pattern: 25

w Thread tension dial: 1 to 4

e Presser foot: Satin stitch foot F

The eyelet is used for belt holes etc.

Startingtosew

Lower the needle at the starting point and lower the

presser foot. Start the machine.

The machine will stop automatically when completed.

q Starting point

Open the eyelet with an awl, eyelet punch or pointed

scissors (an awl, eyelet punch or pointed scissors are not

provided with the machine).

q

4

w eq

q

Page 49

47

Place the right sides of the fabric together.

Attach the zigzag foot and seam up to the end of the

zipper opening, with a 2 cm (13/16˝) seam allowance.

Reverse the stitch to fasten the seam.

Manually increase the stitch length to 5.0 and baste the

zipper opening with the thread tension loosened to 1-3.

t End of the zipper opening

y 2 cm (13/16˝)

u Basting

i Reverse stitches

o Seam stitches

Fabricpreparation

Add 1 cm (3/8˝) to the zipper length. This is the overall

opening size.

q Right side of the fabric

w 1 cm (3/8˝)

e Opening size

r Zipper length

t End of the zipper opening

ZipperSewing

q Stitch pattern: 00

w Thread tension dial: 1 to 4

e Presser foot: Zigzag foot A

Zipper foot E

Attachingthezipperfoot

Fit the pin on zipper foot E to the groove on the foot

ho l der.

q Groove

w Pin

(A): To sew the left side of the zipper, attach the zipper

foot with the pin on the right-hand side.

(B): To sew the right side of the zipper, attach the zipper

foot with the pin on the left-hand side.

t

y

o

q

w

e r

i

u

q

w

(A) (B)

t

4

w eq

Page 50

48

Startsewing

z Fold back the left seam allowance. Turn the right seam

allowance under to form a 0.2 to 0.3 cm (1/8˝) margin.

Place the zipper teeth next to the fold and pin in place.

Set the stitch length and thread tension back to the

original setting.

q 0.2 to 0.3 cm (1/8˝) margin

w Zipper teeth

e Fold

r End of the zipper opening

t Opening size

z

x

c

q

r

e

t

x Attach the zipper foot E with the pin on the right hand

side.

Lower the foot onto the topside at the end of the

zipper opening so that the needle pierces the fabric

next to the fold and the zipper tape.

c Sew through all layers next to the fold.

Stop the machine 5 cm (2˝) before the foot reaches

the slider on the zipper tape.

Lower the needle slightly into the fabric.

Raise the foot and open the zipper to clear the slider.

Lower the foot and stitch the remainder of the seam.

y Slider

u 5 cm (2˝)

y

u

w

CAUTION:

Be sure that the needle does not strike the presser

foot or zipper teeth when the zipper foot is attached.

Page 51

49

v Close the zipper and spread the fabric open at with

the right side facing up.

Attach the Zigzag foot A.

Adjust the stitch length to 5.0, stitch width to 3.5 (default

value) and the thread tension dial to 1-3.

Baste the opened fabric and zipper tape together.

i Basting stitch

o Zipper tape

i

o

v

b

n

m

b Attach the zipper foot E with the left pin.

Adjust the stitch length and the stitch width to default

value, and thread tension dial to “4”.

Backstitch across the end of the opening 0.7-1 cm

(3/8˝) and turn the fabric 90 degrees.

!0 0.7-1 cm (3/8˝)

CAUTION:

Be sure that the needle does not strike the presser

foot or zipper teeth when the zipper foot is attached.

n Stitch through the garment and zipper tape, guiding

the zipper teeth along the side edge of the foot.

Stop the machine 5 cm (2˝) before the foot reaches

the slider on the zipper tape. Lower the needle into

the fabric, and raise the foot. Remove the basting

stitches.

!1 5 cm (2˝)

!2 Basting stitches

!2

!1

!0

!3

m Open the zipper, then lower the foot and stitch the

remainder of the seam.

After sewing is nished, remove the basting stitches

on the upper fabric.

!3 Basting stitches on upper fabric

Page 52

50

q w

z Use the same color thread as the fabric.

On heavy weight fabrics that ravel, the raw edge

should be overcast rst.

Fold the hem, as illustrated.

q Heavy weight fabric

w Light weight fabric

e Wrong side of the fabric

r

y

t

r

t

y

x There is a sliding guide screw on the blind hem foot

that allows you to control where the needle pierces