ElMod Fusion ECO, Fusion PRO, Fusion PRO Rev.F Detailed Installation Instructions And User Manual

ElMod Fusion ECO & Fusion PRO Rev.F

Detailed installation instructions and user manual

Before installation always read carefully all these instructions.

We congratulate on your purchase of the ElMod Fusion, the innovative and universal full-option-solution for different types of vehicles.

The ElMod Fusion enhances your model by true to scale movement, extensive weapon-, lighting- and other functions combined with

simple installation. All functions right down to the last detail may be easily adjusted on your Windows® or Apple® Computer or an

Android® Smartphone or Tablet by over 100 parameters which are logically grouped and explained in detail. By ongoing

improvements and software updates, which may be easily applied at home within few minutes, you bought a future-proof product.

Scope of delivery

Before starting the installation, check the scope of delivery for completeness.

• ElMod Fusion PCB

• volume control rotary knob with cable

• cable for the RC receiver

• plug with for connecting to the battery

• plug for connecting up to two drive motors

• cable for connecting to the loudspeaker

• microSD card (already plugged-in on the PCB)

• USB dongle and an USB cable for connecting to the computer

• ElMod Fusion PRO only: housings and cables for assembly of up to 5 external light sources

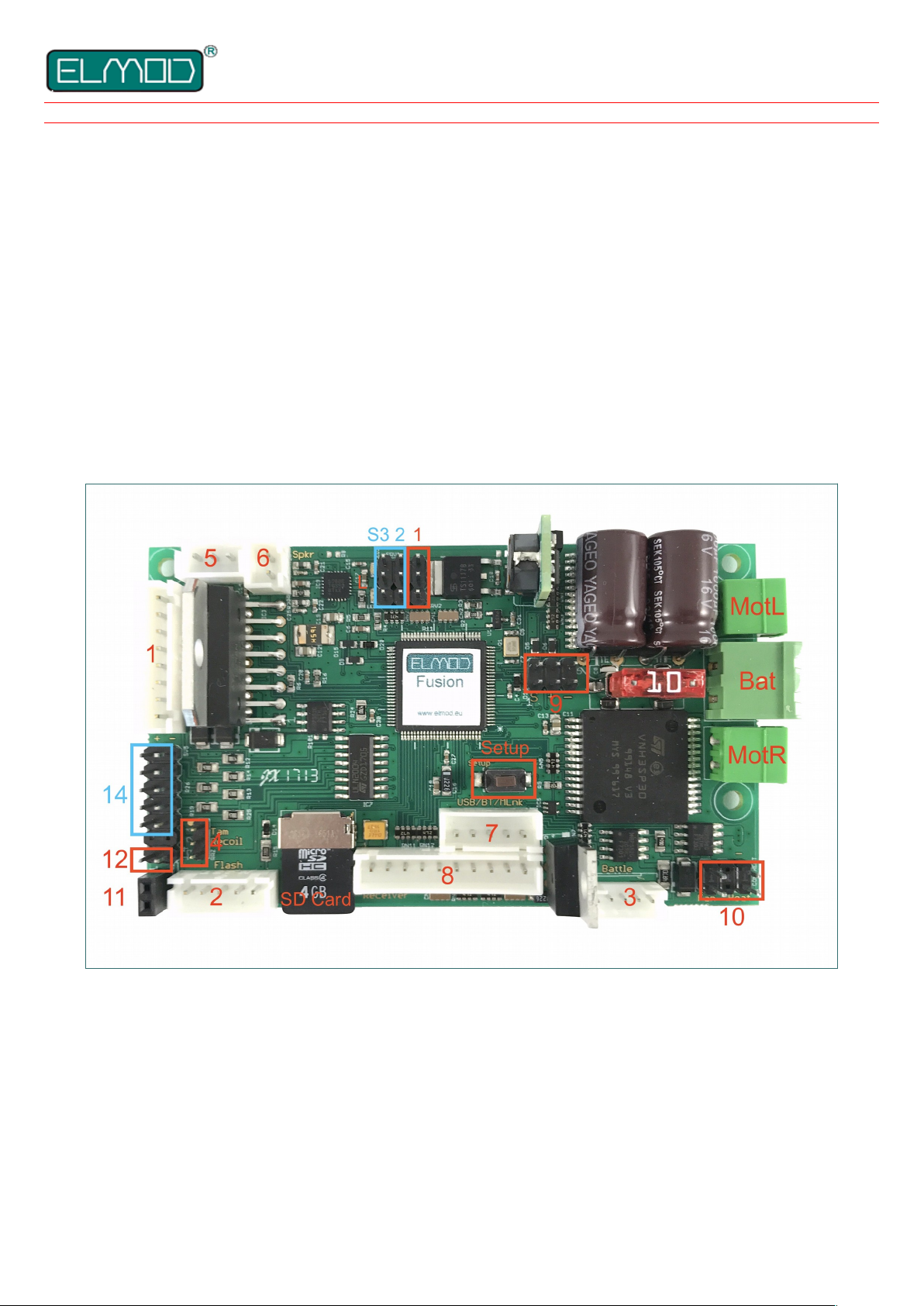

Fusion ECO and Fusion PRO

Bat battery connector

MotR connector for the right motor

MotL connector for the left motor

Sw pushbutton for the setup, firmware update and reset

S1 servo connectors

L status LEDs

SD microSD card

1 turret connector (HengLong®)

2 muzzle flash connector (Taigen®, HengLong®)

3 connector for IR battle functions

4 connector for the Tamiya® barrel recoil mechanics

5 connector for the volume control rotary knob

6 connector for the loudspeaker

7 connector for the USB dongle and ElMod BT adapter

8 connector for the RC receiver

9 connectors for external motor drivers

10 connector for a smoke unit

11 connector for Taigen®, HengLong

®

recoil/shot mechanics

12 connector for Taigen®, HengLong

®

recoil servo pcb

additively Fusion PRO (marked blue)

14 connector for additional lights

S2,S3 servo 2 & 3

Hint: all connectors are marked and described on the bottom side of the PCB.

- 1 - © ElMod - 19-09-02

In this paragraph the installation is described step by step. It is essential that each step is accomplished correctly and completely.

Wrong or improper connection may cause malfunction or damage and/or destruction of the electronics, the installed components or

the model. Please contact the support of your dealer if you have further questions regarding the installation.

Connection of the power supply

• connect the red cable with the + terminal and the black cable with the – terminal of the battery plug.

Incorrect connection causes the destruction of the electronics!

• keep the cable length as short as possible in order to prevent interferences

The following battery types are supported:

Variant Battery type Cells Voltage under voltage shut down

ECO/PRO NiMh/NiCd 6 7,2 V 6 V

ECO/PRO NiMh/NiCd 7 8,4 V 7 V

ECO/PRO NiMh/NiCd 8 9,6 V 8 V

PRO NiMh/NiCd 9 10,8 V 9 V

PRO NiMh/NiCd 10 12 V 10 V

ECO/PRO LiPo 2S 7,4 V 6,4 V

PRO LiPo 3S 11,1 V 9,6 V

PRO Pb - 12V 10V

ECO/PRO LiIon 2S 7,4 V 6 V

PRO LiIon 3S 11,1 V 9 V

If the battery voltage drops below a certain threshold, the protective under voltage shut down will be activated. The voltage value

depends on the used battery type as listed in the table.

If the battery voltage exceeds a maximum value, the protective over voltage shut down will be activated.

The protective shut down (under voltage and over voltage) deactivates all functions of the ElMod Fusion. The engine turns off and the

vehicle cannot be operated any more. The announcement "Low Battery" or "Voltage too high" follows via loudspeaker every 5

seconds and the red status LED shows an error state (see chapter "Status LEDs").

The factory setting is NiMh/NiCd-battery 7,2V (6 cells). If another battery type is used, it has to be set in the configuration software,

otherwise the under voltage protection shut down won't work correctly.

If any other battery type as listed is used, a proper function cannot be guaranteed.

The warranty is void if higher voltage than allowed is used!

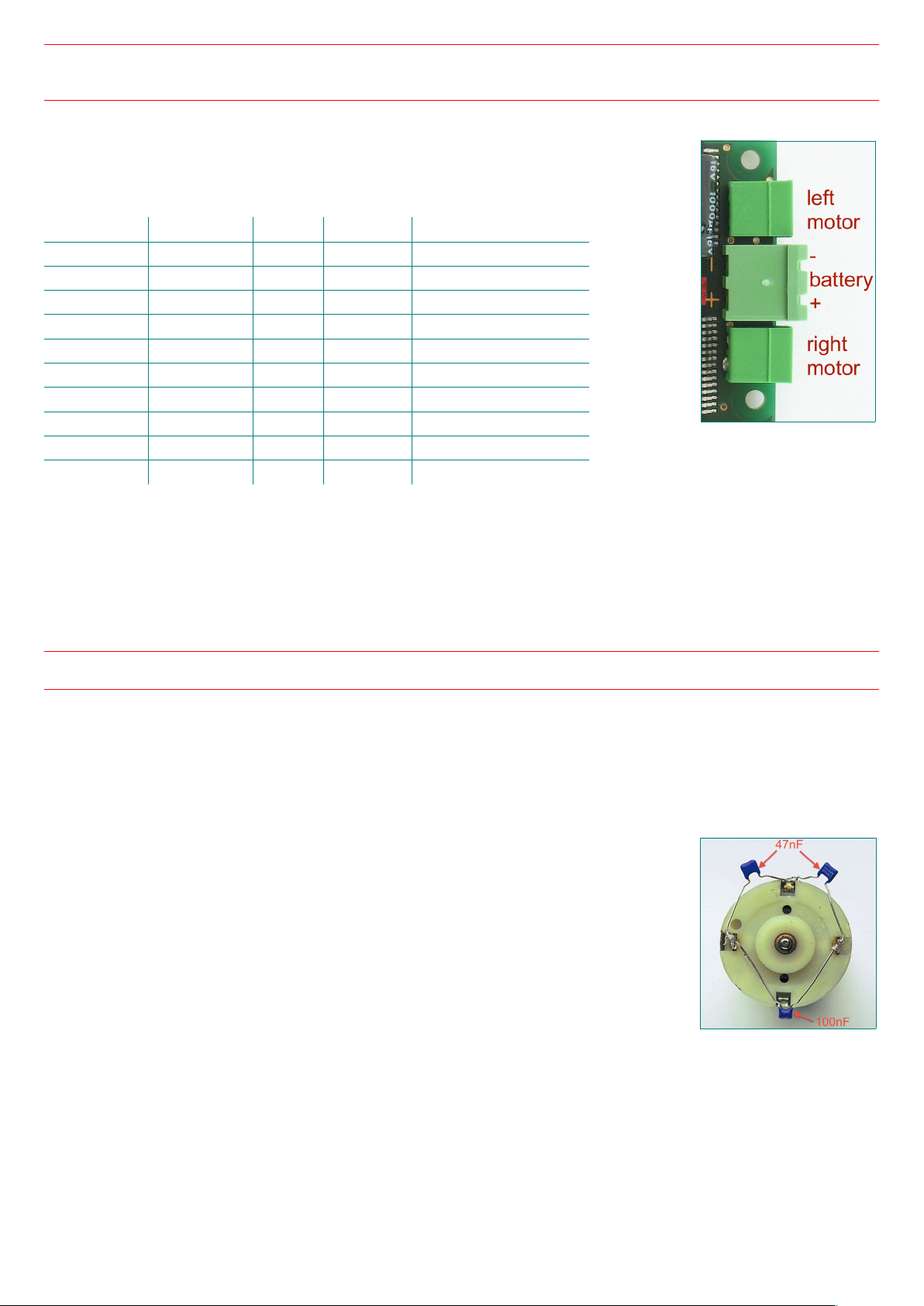

Connection of the drive motors (integrated drivers)

The ElMod Fusion supports one or two DC motors for the main drive. Brushless motors and motors with an extra high current

consumption may be used optionally by commercially available external drivers (see next chapter). It is not possible to operate

integrated and external drivers simultaneously.

The maximum current consumption of the drive motors is internally limited to 30 A peak. The allowed permanent load is 10 A. The

motor drivers need no further cooling. They are protected against short circuit and overload.

• attach the motor wires for the right drive to the connector MotR

• attach the motor wires for the left drive to the connector MotL

• for vehicles with only one drive motor use one of the two connections

• it makes no difference which cable (+/- of the motor) is connected to which screw of the

corresponding terminal

• keep the cable length as short as possible in order to prevent interferences! For additional

interference protection the motor cables can be twisted.

• IMPORTANT! The motors must be interference-suppressed. This is accomplished with the use of

three capacitors as shown in the figure. Many motors are interference-suppressed already. Please

check this by asking the producer or distributor of your motors.

For checking the correct wiring of the motors proceed as follows:

• make sure that the driving shaft is free to rotate and the model cannot move uncontrollably

• connect a fully charged battery to the electronics and connect the power supply in accordance with section "connection of the

power supply"

• please wait for 3-4 sec. until the blue LED starts blinking constantly

• press and hold the setup pushbutton

• the motors start rotating after around 3 seconds. The motors are connected correctly if the left one is rotating slightly slower than

the right one

• every few seconds the motors change their rotation. Release the button when the chains or wheels rotate forward. Now the motors

- 2 - © ElMod - 19-09-02

are set up correctly.

• when only one motor is attached proceed accordingly. Release the button when the motor rotates forward.

Connection of the drive motors (external drivers)

Commercially available external drivers may be connected directly to the ElMod Fusion. The operating type (internal/external drivers)

must be set by the ElMod App (tab "drive", parameter "motor drivers"). It is not possible to operate integrated and external drivers

simultaneously. The external drivers are connected with the connectors 9. The black ground wire of the

drivers points to the right edge of the PCB (towards the battery connector).

Smoke generator

The smoke generator is connected to the connector for the smoke generator (connector 10).

• if the smoker generator provides two wire operation only (combined fan and heater), attach it to the fan

labeled connector

• if the smoker generator provides four wire operation (separated fan and heater wires), attach the fan

wires and the heater wires to the respective connector

• the polarity of the connectors are printed on the board

Turret functions

The ElMod Fusion provides a HengLong® compatible 8-pin turret terminal (connector 1). It is used by the

turret rotation motor, gun elevation motor, main gun trigger motor, front lighting and muzzle flash of the

main MG.

• an optional adapter allows the use of a Tamiya® turret. The functions turret rotation, main gun elevation and also main lighting and

muzzle flash of the main MG are supported

• an optional cable offers the connection of a turret with a different wiring to the ElMod Fusion board.

The voltage on all turret components is always equal to the voltage of the battery. If you plan to use motors with lower voltage, reduce

the setting for maximum speed in the ElMod App of the corresponding motor. For example the maximum speed of a 7.2 V motor in a

12 V tank should not excess 60% (60% of 12V = 7,2V).

Also keep in mind that the maximum current per motor must not exceed 2 A. Higher current may destroy the electronics.

Shot function

In principle, all HengLong®/Taigen® shot systems are operable as soon as the 8-wire turret cable is

attached to connector 1. In this case the shot function is active as long as the trigger is actuated.

Depending on the assignment of the plugs and the settings in the ElMod App, this basic function can be

extended. The corresponding parameter "Recoil Type" in the ElMod App can be found in the "Weapons"

tab.

• Setting Standard corresponds to the basic setting (turret cable only). If the ground cable of the shot

system is also connected to the negative pole of the battery, the firing mechanism automatically

returns to its initial position after the trigger is released.

• Setting Airsoft is suitable for the firing mechanism for plastic balls. The shot sound sounds at the same

time as the ball is fired. For this purpose, one more cable must be connected in addition to the 8-wire

turret cable and the ground wire. The white-orange cable from the switch for the position of the

shooting mechanism has to be attached to connector 12. The orange wire points to the edge of the

board (mark "O" at the bottom of the board).

• Setting Airsoft with recoil is suitable for tanks with a firing mechanism for plastic balls AND

simultaneous recoil mechanics via a turret built-in control electronics with a servo. The wiring is the same as for the airsoft shot

function. Additionally electronics for the recoil mechanics has to be attached to connector 11. Plus and minus are marked on the

board and correspond to the red or black wire of the cable.

• Setting Tamiya Recoil is intended for the Tamiya® recoil mechanics. For this the connector of the mechanics has to be attached to

connector 4. The white cable faces the marking (golden dot) on the upper side of the board.

If your cabling differs from the one described here or if you are unsure, please contact your dealer's support! Errors in the wiring can

damage or destroy the electronics of the tank or the ElMod circuit board!

A further possibility to simulate the barrel recoil is the use of a dedicated servo with the appropriate mechanics. Details are described

in this section Servos. The servo recoil is independent of the setting "Recoil Type" in the ElMod App.

Muzzle flash

The HengLong®/Taigen® Xenon flash or the HengLong® muzzle flash LED are equipped with a 5-pin plug and has to be connected to

connector 2. The Tamiya® Xenon flash is not supported. If an LED is used, the flash may be weak depending on the type of LED. The

ElMod LED Flash Booster provides a bright LED flash in this case.

- 3 - © ElMod - 19-09-02

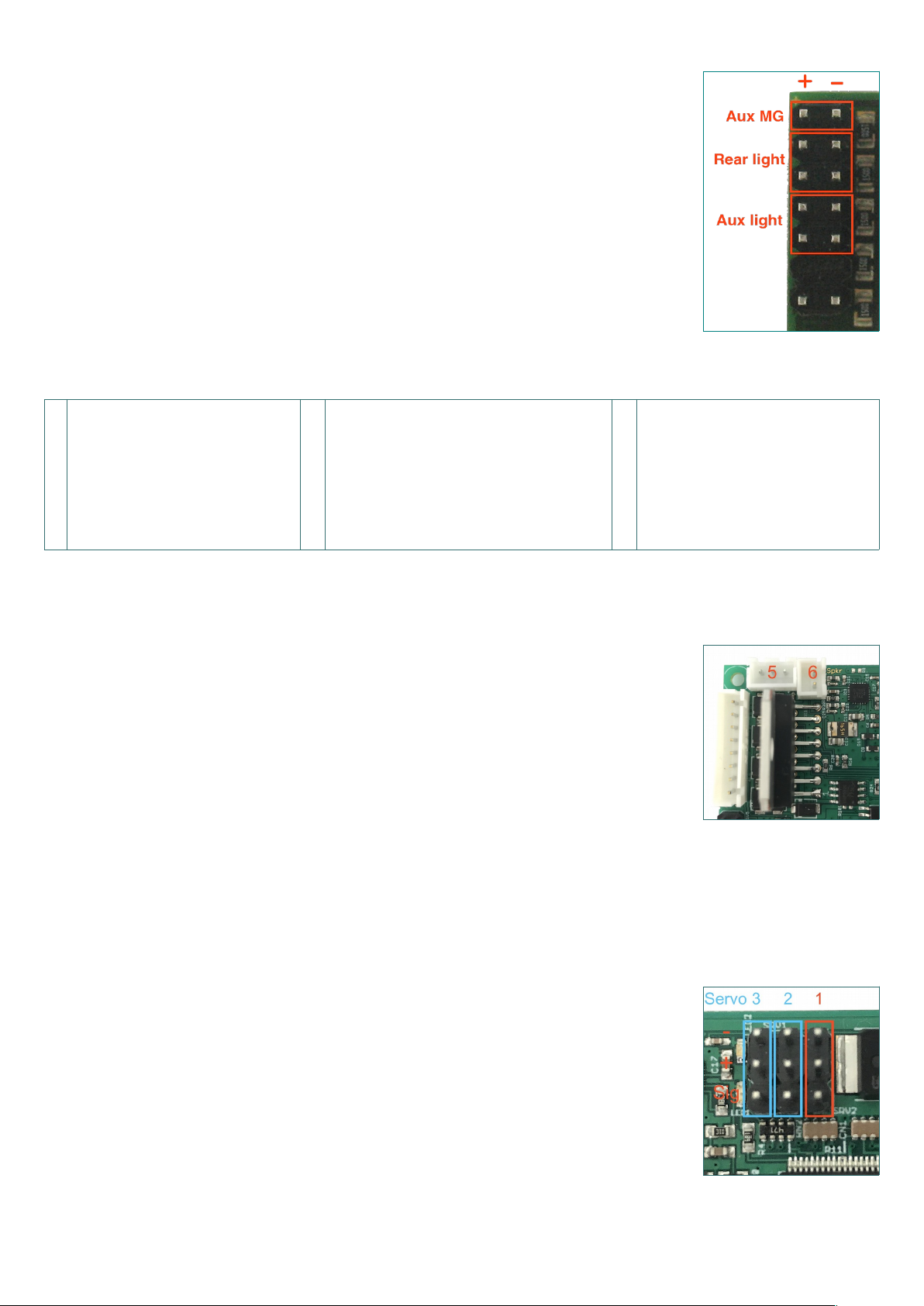

Light functions

The ElMod Fusion is able to control several light channels:

• front light (white LEDs) and MG muzzle flash (ultra bright white LED) on the HengLong® turret

connector (turret and weapon functions)

• xenon or LED muzzle flash of the main gun and muzzle flash of the MG (see chapter turret and

weapon functions)

• ElMod Fusion Pro provides further light sources:

• one ultra bright white LED for muzzle flash of the auxiliary MG

• one or two red LEDs for combined rear and brake lights. The rear light is controlled together with the

front light. The brake light is active independently of the state of the main/rear light.

• one or two white LEDs for auxiliary light (e.g. camo light)

All light outputs are short circuit protected and current limited.

Pin assignment

Turret (connector 1) Muzzle flash (connector 2) Battle (connector 3)

from top from left von links

o

o

o

o

o

o

o

o

motor turret rotation

motor turret rotation

motor elevation

motor shot

common motor elevation and shot

Light common +

main light muzzle flash MG -

o

o

o

o

o

not used

not used

power supply – (LED and xenon flash)

signal + (LED and xenon flash)

power supply + (xenon flash only!)

o

o

o

o

o

signaling LEDs cathode

sensor signal

ground

IR sender cathode

+5V power supply

Sound: installation and connection

• plug the provided volume rotary knob to connector 5

• the ElMod Fusion PRO also provides the option to control the main volume by the radio. To activate

this feature the appropriate parameter has to be set in the ElMod App to "external" (tab "sound

volume", parameter "main volume control"). In this case the volume control knob on connector 5 will

be deactivated.

• connect the loudspeaker's cable with the output of a suitable 8 Ohm loudspeaker (connector 6). The

loudspeaker's polarity (+/-) makes no difference at this. We recommend the Visaton® FRS7-8 speaker

(loud, high pitch) or Visaton® FRS8-8 (quieter, lower/deeper pitch)

• for the best possible sound experience install the loudspeaker in an insulated airtight chassis with as

large volume as possible

• check the correct fitting of the micro SD card. If the card is not well fitted or its contents is faulty, the

sounds cannot be played.

• connect a fully charged battery to the ElMod Fusion and wait 3-4 sec. until the blue LED starts blinking constantly

• now tap the setup button. The call "battle mode..." is played. Tap several times more on the setup button until you hear "battle

mode off".

• if you cannot hear the call, please check if the volume is set too low

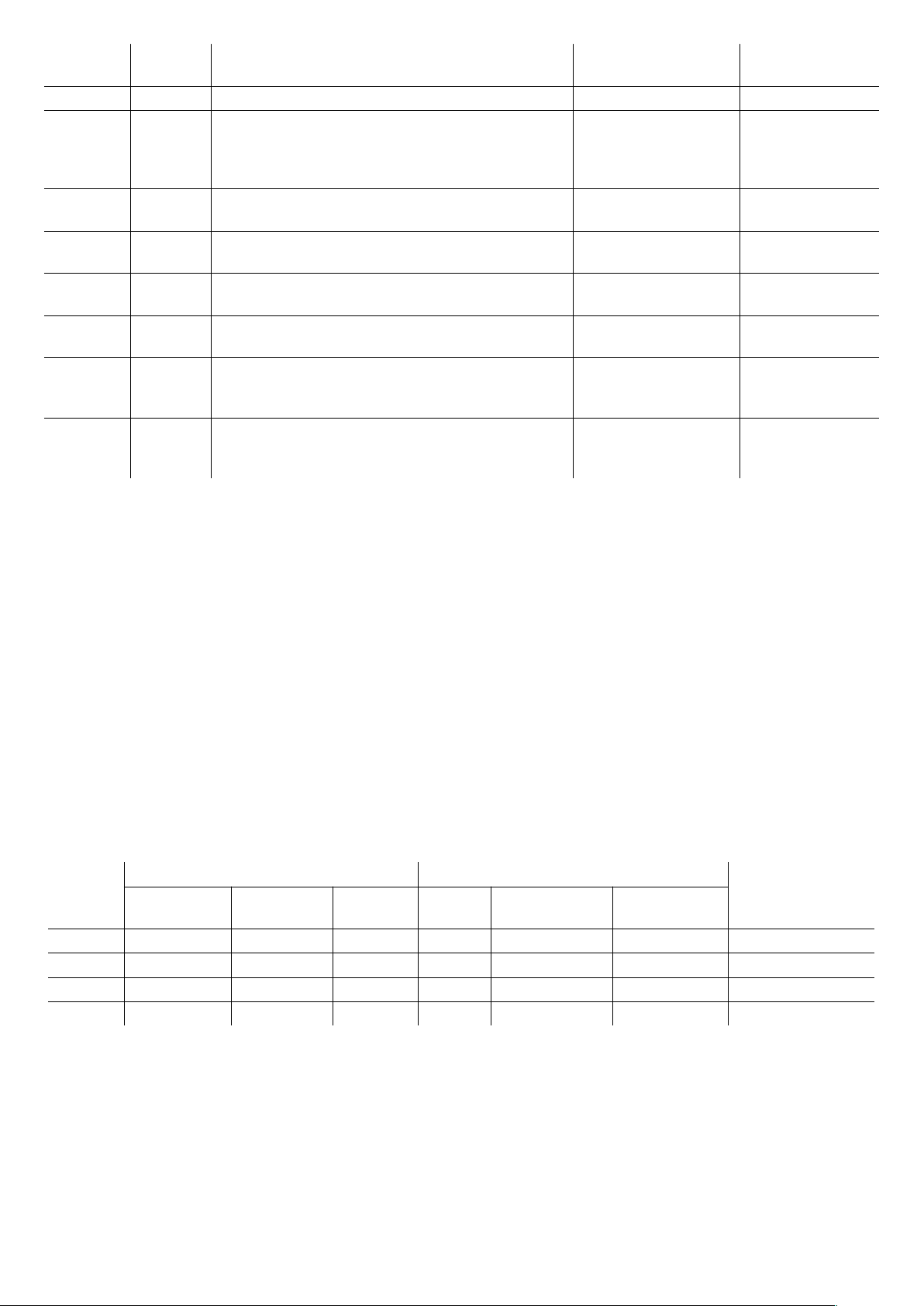

Servos

Depending on the type of your ElMod Fusion one servo (ElMod Fusion ECO) or three servos (ElMod

Fusion PRO) may be driven. The servos are power supplied by the board. The maximum current is 0,8 A

(ElMod Fusion ECO) or 1,5 A (ElMod Fusion PRO). The servos are connected so that the ground line

points to the upper edge of the PCB (see image).

Each servo may be assigned to one of the functions listed below. The same function may be assigned to

several servos simultaneously but every instance of this function may be configured independently (e.g.

for the control of three steering axles of a truck with different steering lock angle). For each function the

servo lock angle may be reversed or limited (right and left side separate). This is useful if the attached

mechanic has a smaller movement clearance as the servo's side arm). By two other parameters each

function may be further adjusted (see table).

- 4 - © ElMod - 19-09-02

function

module

type

effect param 1 (0-100%) param 2 (0-100%)

barrel recoil ECO/PRO barrel recoil after firing the main gun retraction speed extraction speed

steering ECO/PRO steering axle

speed dependent

steering lock angle (0% -

off, 100% - no steering

on max. speed)

-

elevation PRO

vertical movement of the main gun. The larger the stick

deflection the faster the movement

max. speed

elevation,

modern

PRO

as above. After each shot the barrel moves to the reload

position

max. speed

duration of reloading

in 0.1 secs

traversion PRO

horizontal movement of the main gun. The larger the

stick deflection the faster the movement

max.speed

turret

rotation

PRO turret rotation with an external ESC - -

hatch

function

PRO

simulation of an open/close function. On: servo moves

to the end position. Off: servo moves to the origin

position

opening speed closing speed

radar/wiper

function

PRO

wipe function. On: servo moves between both end

positions, Off: servo moves back and remains in the

starting position

speed of the "to"

movement

speed of the "fro"

movement

The hatch and radar function are auxiliary functions that are activated by the special functions on the radio (see chapter "function

control"). E.g. the commander's hatch may be attached to servo 1, AA radar to servo 2 and the driver's hatch to servo 3, the functions

are triggered as follows:

• switch on channel 5 must be positioned to auxiliary functions

• left lever to the left for activation/deactivation of the first servo's function (commander's hatch)

• left lever to the top for activation/deactivation of the second servo's function (radar)

• left lever to the right for activation/deactivation of the third servo's function (driver's hatch)

IR battle functions

The ElMod Fusion provides a Tamiya® Battle Unit compatible battle function. The configuration takes by tapping on the setup button.

Each tap changes the currently active setting which are:

• "battle mode light tank"

• "battle mode middle tank"

• "battle mode heavy tank"

• "battle mode test setting". If active, you may trigger a hit by nearly any infrared remote control.

• "battle mode off". This setting should be selected, when you do not use the battle function.

The selection of the vehicle's type affects its behavior during the battle. These features are listed in the following table:

setting

Hit count Time in seconds

Mushroom blinks

after power up

slight slow

down*

strong slow

down*

destruction

reload

time

invulnerability

after a hit

delay until

resurrection

test mode 1 3 6 3 2 5 4x

light 1 2 3 3 15 15 1x

middle 1 4 6 5 12 15 2x

heavy 1 5 9 9 10 15 3x

* reduction of the maximum velocity of the vehicle

The ElMod Fusion indicates specific events with four sounds:

• a fanfare after switching on with activated battle function and after each resurrection. The vehicle stays invulnerable for several

seconds (see table: reload time).

• reloading sound. Until this sound is heard you cannot fire again.

• metal impact after a hit. The vehicle stops and cannot be operated for two sec.

• an explosion during vehicle's destruction. The vehicle cannot be operated for the interval shown in the table (delay until

resurrection).

- 5 - © ElMod - 19-09-02

Loading...

Loading...