ELMETRON CX-401 User Manual

WATERPROOF

MULTIFUNCTION

METER

CX- 401

USER’S MANUAL

WATERPROOF

MULTIFUNCTION METER

CX-401

Before use please read the instruction carefully!

TABLE OF CONTENT

I. Introduction

1. Exploitation notices 4

2. The characteristic of the meter 5

3. What is the meter designed for 6

4. Outside view 7

5. Switching the meter on and off 10

6. Preparation to work 11

6.1. Choosing the kind of temperature compensation 11

6.2. Changing the resolution of the measurement 12

II. pH measurement

7. Preparation of the pH electrode 14

8. Calibration of the pH electrode 15

8.1. Introducing the pH values of the buffer solutions 17

8.2. Automatic change of the pH value of buffer solution 19

8.3. The actions during calibration 21

8.4. Calibration with automatic temperature compensation 24

8.5. Calibration with manual temperature compensation 26

9. Changing the electrode and checking it’s condition 26

9.1. Checking the electrode’s condition 26

10. pH measurement 27

10.1. Measurement with automatic temperature compensation 27

10.2 Measurement with manual temperature compensation 28

11. Notices about the temperature compensation and interpretation of the results 29

III. Conductivity and salinity measurement

12. Basic information about the conductivity measurement 32

13. Preparation to work 33

13.1. Choosing the unit 34

13.2. Entering the W

14. Choice and maintenance of the conductivity cell 36

14.1 The cell choice 36

14.2 The conductivity cell maintenance 37

15. Calibration 38

15.1 Calibration without the sample solution 38

15.2 Calibration with use of sample solution 39

16. The simplified way of determining the α coefficient 41

17. Entering the α coefficient value 42

18. The conductivity measurement 43

18.1. The measurement without temperature compensation 43

18.2. The measurement with temperature compensation 44

18.3. The measurement with manual temperature compensation 45

coefficient 35

TDS

- 2 -

19. Salinity and TDS measurement 46

19.1. Salinity measurement with conversion to NaCl or KCl content 47

19.2. Determining the W

19.3. The measurement of salinity with conversion to TDS 48

IV. Oxygen concentration measurement

coefficient 48

TDS

20. Basic information about dissolved oxygen measurement 50

21. The oxygen sensor 52

22. Entering the parameters 52

22.1. Changing the number of probe 52

22.2. Changing the unit 53

22.3. Salinity influence compensation 53

22.4 Automatic compens. of the atmospheric pressure influence 56

23. Calibration of the oxygen probe 57

24. Oxygen concentration measurement 59

24.1. Measurement with automatic temperature compensation 60

24.2. Measurement with manual temperature compensation 60

V. Atmospheric pressure measurement

25. Atmospheric pressure measurement 62

VI. ORP (mV) and temperature measurement

26. ORP (voltage) measurement 64

27. Temperature measurement 64

VII. Other

28. Clock, date, auto switch off function 66

28.1. Time display 66

28.2. Date display 66

28.3. Auto off function 66

28.4. Checking the battery condition 67

28.5. Setting the time and date 67

29. Storage and readout of the results 68

29.1. Storing or printing 68

29.2. Parameters of storing and reading from the memory 68

29.3. Storing the single measurements in the memory 70

29.4. Storing the measuring series 70

29.5. Reviewing of the results 71

29.6. Deleting the stored results 71

30. Printouts on the printer 72

30.1. Printout of the result – single or serial 72

30.2. Printout of the results stored in the memory 73

31. Power source and changing the battery 73

32. Co-operation with the PC 74

34. Technical data 75

33. Equipment 78

I. Introduction

- 3 -

1. EXPLOITATION NOTICES

- 4 -

Dear User!

We present you a device distinguished by accuracy according to the technical

data and by a high stability of the displayed results. We believe that the

measurements will not cause you any trouble and that the meter will operate

without any inconvenience. Wide range of additional functions requires

careful reading of the manual in other case some of the features may stay

unused or using the meter may cause you a troubles.

The employing of good-quality electrodes cells and probes and their replacing

after a suitable time ensures obtaining of high measuring parameters. We want

to call your attention to the fact, that this equipment has a much shorter working

life than the meter. Typical symptoms of an improper operation of the electrode

are deterioration of final result stability, it’s flowing as well as a higher

measuring error. Part of the users has problems, arising from employing

electrodes not being preconditioned before the measurement or making

the measurements without removing the shielding ring from the liquid

junction or taking measurements with a plugged junction. To avoid this

situation it is necessary to choose the proper kind of electrode for solutions

which are going to be measured ex. special electrodes for the sewage, liquids

with deposits, meat cheese etc. Therefore, if you observe improper operation of

the device, please take control measurements with another electrode or check

the used electrode with another pH-meter. Generally the deterioration of the

meter work is caused by the electrode and not by the meter.

In case of conductivity measurements it is important to choose the cell with right

constant K value for the measuring range. Wrong selection may cause larger

error occur, similar situation occurs during measurements with automatic

temperature compensation with incorrectly introduced α coefficient.

Accuracy of the dissolved oxygen measurements depends on the sensor

calibration and regular maintenance which consist in replacing the membranes,

electrolyte and cleaning the electrodes. Lack of correct maintaining of the

sensor after some time will make measurements impossible. Please turn

your attention to the fact that stabile measurement is possible only with

simulated or natural measured water flow.

The essential feature of our products is their low failure frequency. However if

your meter will fail, our firm immediately performs its warranty repair.

We wish you a pleasant and trouble-free work with our meter.

- 5 -

2. THE CHARACTERISTICS OF THE METER

The multifunction meter CX-401 belongs to the newest generation of measuring

devices which offer wide range of additional functions. The meter ensures high

accuracy and repeatability of the readings. Two kinds of power source: battery

and power adapter enable work in field and long-lasting measurements in the

laboratory. The newest generation electronic elements used in the meter made

it’s memory independent to power supply and have ensured very low power

consumption what greatly increases the operation time on 1 battery. The meter

is equipped with large custom LCD display, which enables simultaneous

observing of the measured function, temperature value and additional symbols

which make working easier. Waterproof housing makes working in difficult

conditions possible. Small size and weight make the meter very handy

especially during the field work.

Main features of the CX-401 are:

- high accuracy and stability of the reading;

- automatic and manual temperature compensation;

- pH electrode calibration in 1 to 5 points;

- automatic recognition of pH buffers and standards;

- imposed values of standard solutions with possibility of changing their value;

- option of automatic introduction of temperature correction on the value of pH

buffer solutions (NIST norm);

- information about the condition of the pH electrode;

- storing of three characteristics of electrodes in each function;

- wide range of conductivity measurement with 6 automatically switched

subranges (autorange);

- counting the conductivity to salinity in NaCl or KCl according to real

dependence to conductivity;

- possibility of introducing the TDS coefficient;

- calibration of the conductivity cell by introducing the constant K or on sample

solutions;

- function of determining the constant K of cell;

- automatic compensation of the salinity influence on the oxygen

measurement using the conductivity measurement function;

- measurement and automatic compensation of the atmospheric pressure

influence on the dissolved oxygen concentration;

- internal datalogger for 200 measurements with time date and temperature;

- taking series of measurements with set time interval;

- RS-232 output

- possibility of printing the measurement results or values stored in the

memory on standard printer with use of interface;

- Information about the battery condition;

- automatic switch off function after time set by the user;

- 6 -

3. WHAT IS THE METER DESIGNED FOR

Waterproof multifunction meter CX-401 is precise and easy to use meter

designed for hydrogen ion concentration measurements in pH units, Oxidation

Reduction Potential (mV) conductivity, in µS/cm or mS/cm, dissolved oxygen in

water in % of saturation or mg/l and atmospheric pressure measurement in hPa.

The meter may be also used for accurate temperature measurement of solutions

and air in °C.

The conductivity measurement result may be also displayed in concentration

units (g/l or %) counted to NaCl, KCl or TDS. Waterproof housing enables work

in difficult weather conditions or in humid environment.

Multifunction CX-401 meter is being used in food, chemical, pharmaceutical and

energetical industries, in water treatment stations, laboratories, agriculture,

universities, scientific laboratories etc.

The meter is prepared to work with all types of combination pH electrodes and

conductivity cells, with wide constant K range, equipped with BNC-50 connector.

It is possible to connect the meter with two electrodes (pH measuring and

reference) by special adapter offered as additional equipment. CX-401 co-

operates with Pt-1000 temperature probe with Chinch connector.

The meter may collect up to 200 measurements taken as single or series of

measurements with set time interval. RS-232 output enables connecting the

meter wit a PC for sending the data or through special EI-401 interface with

standard printer, what enables printing the data collected in the memory or

current results of the measurement.

In case of necessity of collecting series longer than 200 results it is possible to

use special software offered by our company.

Caution: interface EI-401, which enables connecting the meter with standard

printer and special software for collecting series of measurements on a PC is

offered as additional equipment.

- 7 -

4. OUTSIDE VIEW.

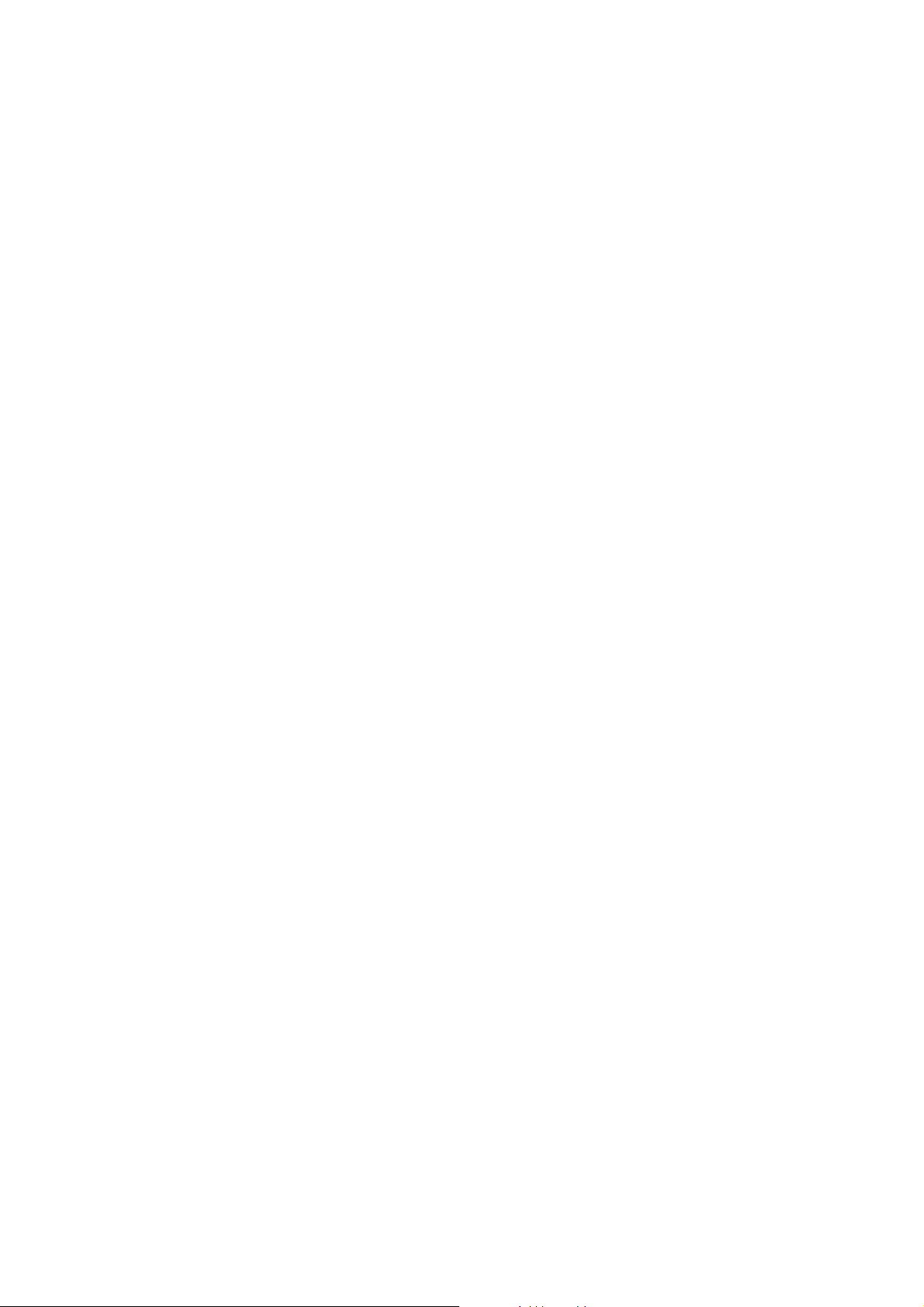

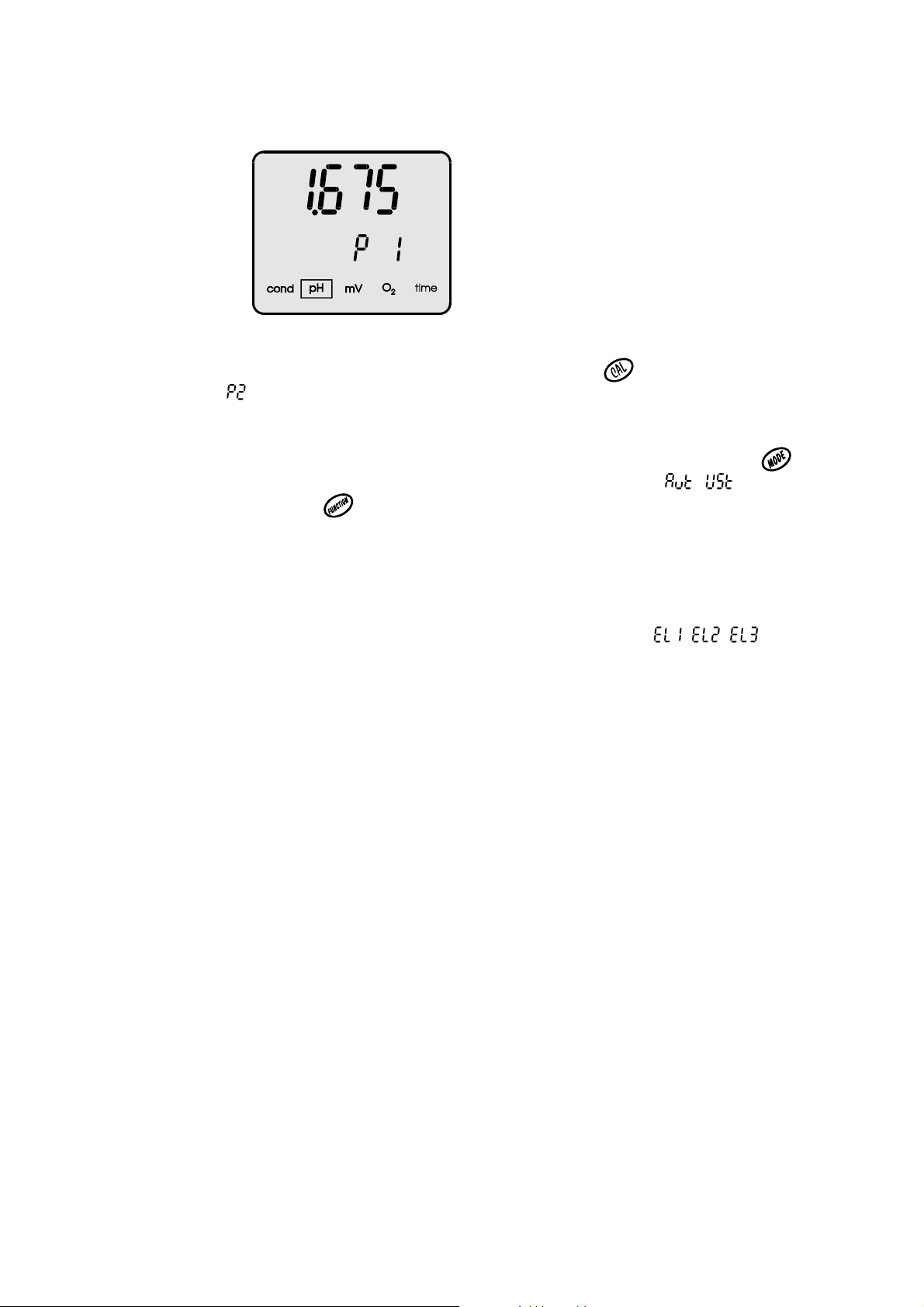

On the front wall of the meter there is a LCD display (pic. 1) on which

depending on the chosen function following symbols are displayed:

- result of the conductivity or salinity measurement;

- result of the pH measurement in pH units;

- result of the mV measurement in mV;

- result of the oxygen measurement in % or mg/l

- time and date.

Choosing the function by

right symbol in the lower part of the display: cond (conductivity), pH, mV, O

button is signalised by displayed frame round the

or

2

time.

Simultaneously with the result a measured temperature value is displayed in oC.

Symbols of the units are displayed by the results. In the oxygen measurement

mode there is possibility of reading the atmospheric pressure value.

Pic. 1.

Beside the temperature value a symbol for automatic temperature

compensation is displayed or for manual. CAL symbol on the left side of the

display informs that the meter is in calibration mode.

After pressing the

button all parameters introduced by the user are

displayed and also the value of atmospheric pressure measurement (in oxygen

measurement function). If the battery should be changed a

.symbol is

displayed.

The keyboard (pic. 2) placed under the display is used for switching the meter

on and off, choosing the measuring function, calibration, entering the

parameters, printing and storing the results in the memory.

- 8 -

The keyboard has the keys as follows:

- to change the function, and switch the meter on, off.

- short pressing in MODE/P.CAL mode enables choosing points of

calibration to change their value.

- longer pressing of this button enters the calibration mode (CAL symbol

displayed). Short pressing in this mode confirms the calibration result.

- after pressing this button the result is stored, the measuring series

starts or printing begins.

- after longer pressing of this button the stored results reviewing is

possible.

- chooses the entered parameter.

, - buttons used for entering the parameters

In upper wall of the meter there are inputs with below given symbols.

F - BNC-50 connector for connecting the combination pH

electrode, Redox electrode or the oxygen probe

F1 - BNC-50 for connecting the conductivity cell

t - Chinch input to connect the temperature probe

RS - RS-232 input for connecting with PC or printer

P - Power adapter input 9V

- 9 -

Pic. 2.

- 10 -

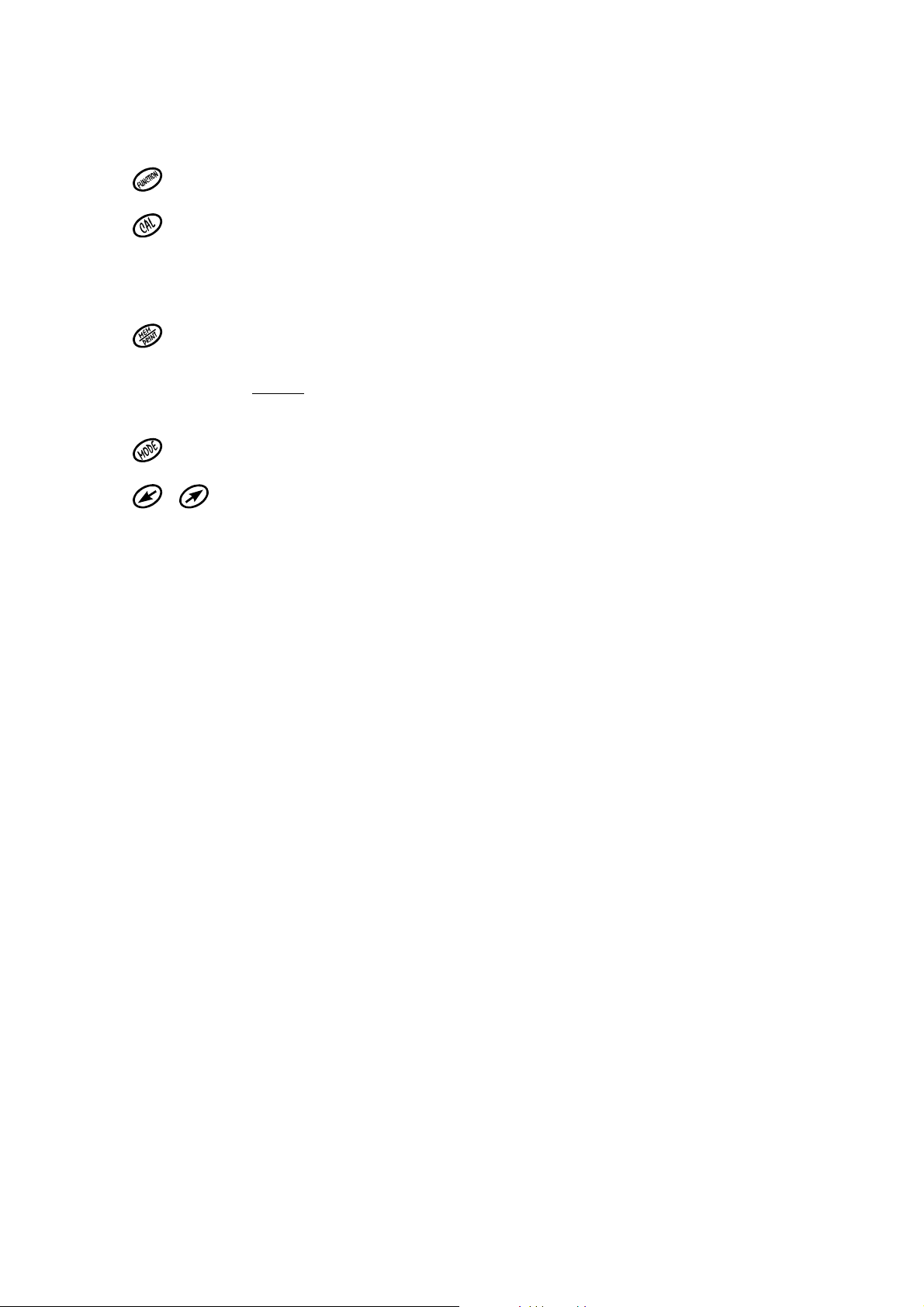

5. SWITCHING THE METER ON AND OFF

The meter is switched on by pressing the

button. The meter tests the

memory and display on which all symbols are displayed.

Pic. 3

If the test was successful, after about 1.5 s the meter switches it self

automatically to the measuring mode, in which it was switched off. If a sign

will be displayed it means that the meter has lost the factory settings and

requires the service repair. If after the 1,5 s all symbols will be continuously

displayed it informs that the calibration parameters of electrodes or cells were

lost.

After pressing the button the meter will take standard characteristics:

- shift = 0 pH, characteristic slope = 100% for pH electrode;

- constant K = 1.000 cm

- shift = 0% O

, characteristic slope = 100% O2 for oxygen sensor.

2

-1

for conductivity cell;

And will enter the measuring mode. It will be necessary to calibrate the

conductivity cell, pH and oxygen electrodes.

The meter is switched off by pressing and longer holding of the

button till

displaying of the symbol. In case of working on the batteries to save them

the meter switches it self automatically off after the time set by the user from

last pressing of any button. Way of introducing the time is described in the

paragraph number 21. This function is switched off for the time of calibration,

taking the series of measurements, printing the memory content and work with

the power adapter.

- 11 -

6. PREPARATION TO WORK

Before starting the work one should:

- join the power adapter plug to the P input, if work with the power adapter is

planned;

- to BNC-50 input F join the ready to work combination pH electrode, redox

electrode or the dissolved oxygen sensor;

- to BNC-50 input F1 join the conductivity cell;

- in case of using the temperature probe it should be connected with the chinch

temperature input t;

- In case of printing or work with PC join the interface El-401 or cable CP-4XX –

PC with RS input

- switch the meter on by pressing the button.

CAUTION: during pH measurements the conductivity cell has to be

disconnected from the meter or removed from the measured

solution in which the pH electrode is immersed.

6.1. Choosing the kind of temperature compensation

The meter switches it self to the automatic temperature compensation mode

automatically after joining the temperature probe, after disconnecting it the

meter enters the manual temperature compensation mode. In ATC mode near

the displayed temperature a symbol appears. Manual temperature

compensation is indicated by symbol near the value entered by the user, it

may be changed using or keys.

- 12 -

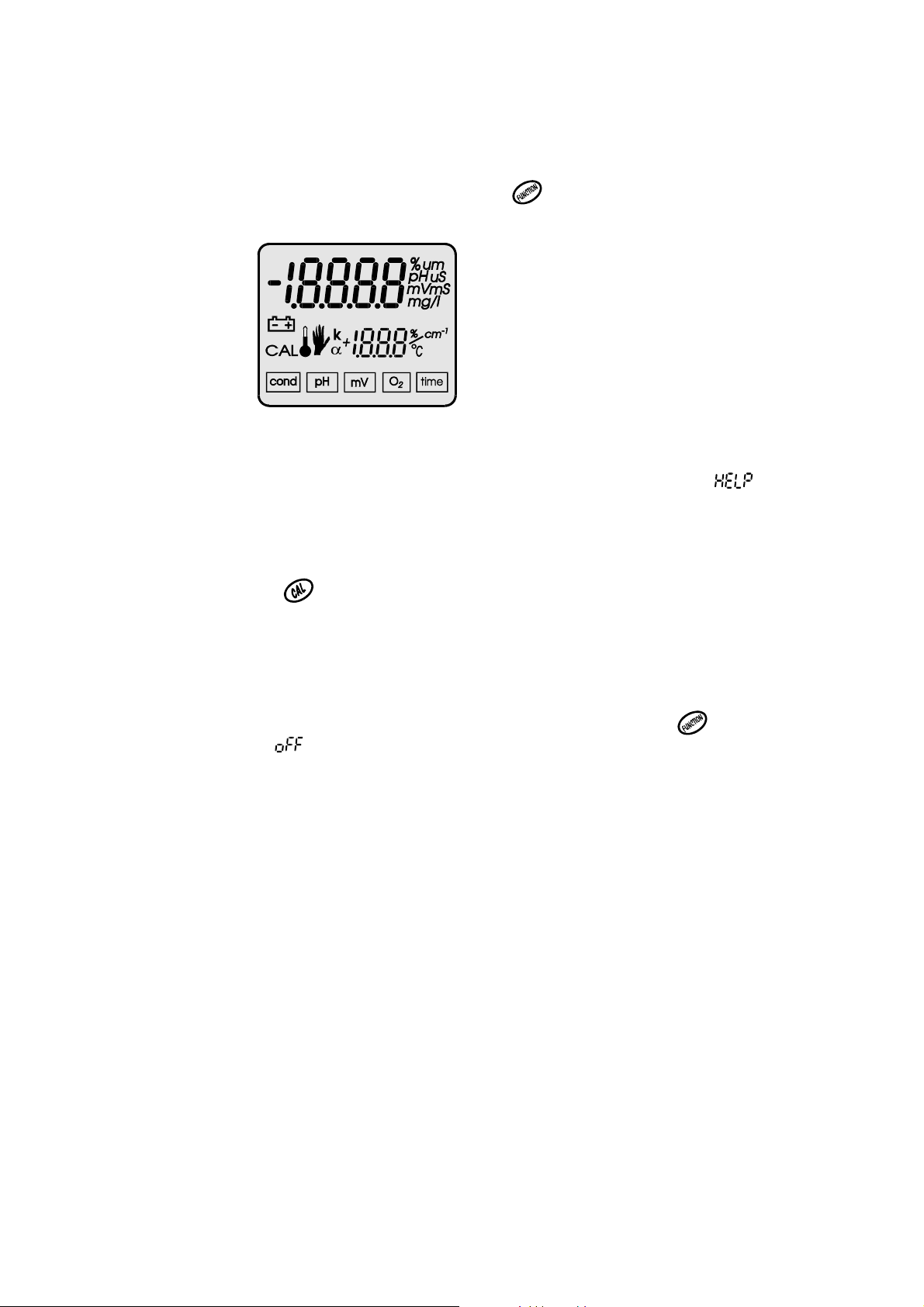

6.2. Changing the resolution of the measurements

The measurement results may be displayed with chosen resolution. To change

it one should:

- in the measuring mode press the button, a (resolution) sign will be

displayed. (Pic. 4)

- Using keys or one may choose:

- (low) resolution of the measurement;

- (high) resolution of the measurement.

Pic. 4

For the pH measurement:

- resolution of the measurement 0.01 pH;

- resolution of the measurement 0.001 pH.

For the conductivity measurement:

- resolution of the measurement 3½ digits;

- resolution of the measurement 4½ digits.

For the oxygen measurement:

- resolution of the measurement 1% or 0,1mg/l;

- resolution of the measurement 0.1% or 0.01 mg/l.

Return to the measurement mode by pressing

button.

- 13 -

II. pH measurement

- 14 -

7. PREPARATION OF THE pH ELECTRODE

The electrode should be prepared to work according to the producer

instructions. If the instructions weren’t given please follow the steps:

- new electrode should be put into distilled water or in saturated KCl solution

for about 5 hours:

- Before starting the measurements protecting rings (if used in this kind of

electrode) should be removed. The ring placed on the junction – lower part

of the electrode should be moved up along the electrode’s body and the

upper, which protects the KCl refilling hole, down along the body.

Removing the lower ring is essential, in other case the electrode won’t

measure.

Upper ring should be removed during measurements of high temperature

solutions or to protect the junction during measurements in solutions with

deposits or oils;

- during measurements in laboratory it is advisable to use an electrode holder;

- after every measurement the electrode should be washed in distilled water;

- excess of liquid on the electrode should be removed by gentle touching the

glass with a tissue paper;

- after work the electrode should be stored in one of the above given solutions.

The protecting rings should be moved on the junction and upper hole;

- in case of long breaks between the measurements the electrode should be

stored, after drying, in the packaging;

- after taking the electrode of the package the eventual deposit should be

removed using water;

- before using the electrode it should be placed in distilled water for about 2

hours;

- if the construction of the electrode enables refilling the electrolyte, it should

be controlled and refilled periodically by the upper hole in the electrode’s

body (usually as the electrolyte a KCl solution is used).

CAUTION: storing of the electrode in distilled water shortens it’s life time and

may cause shifting of the zero point.

- 15 -

8. CALIBRATION OF THE pH ELECTRODE

Before starting the measurement with new electrode, after long-lasting using, or

before making measurements which require higher accuracy the electrode

connected with the meter should be calibrated. Results of measurements done

without calibration will have a great error. The calibration is done on the buffer

solutions. It depends on comparing pH value of the buffer solutions with the

value displayed by the meter and next automatic introduction of correction

which is taken into consideration during measurements. The calibration should

be periodically repeated because during work the parameters of the electrode

are changing what influences the accuracy. The frequency of this procedure

depends on the demanded accuracy, number of the measurements carried out,

conditions in which the electrode was used, temperature and value of the

measured solutions. When the highest accuracy is required it is recommended

to use sample solutions with certificates. In technical usage buffer solutions are

used with lower accuracy but mostly with total values ex. 2.00 pH; 4.00 pH etc.

In this manual to make it easier a buffer solution name was used for both buffer

and sample solutions. For accurate measurements it is necessary to use fresh

good quality buffers.

The first action taken before the calibration is entering the values of used pH

buffer solutions to the meter’s memory. This should be done before the first

calibration and repeated in case of changing the used buffers to other values.

During the calibration after immersing the pH electrode and temperature probe

the meter automatically detects the value of the used buffer, if it was earlier

stored in the meter’s memory.

There is possibility of calibration in minimum 1 buffer solution and maximum in 5.

The more points of calibration is used the higher is the accuracy in the whole

measuring range.

- 16 -

Calibration in one buffer solution can’t ensure high accuracy. If only one buffer

solution is used it’s value should be close to the forecasted value of measured

solution. If the required accuracy isn’t very high and the measurements will be

done in the whole range the one point calibration should be done with buffer

solution close to 7.00 pH. Thanks this the so called zero electrode shift will be

eliminated. In other points a standard characteristic will be taken from the

meter’s memory. This characteristic corresponds with theoretical efficiency of

the pH

electrode

If measurements are done both in acids and alkalis and the measurements are

not done at the ends of measuring range it is enough to calibrate the electrodes

in 3 buffer solutions with values in range given in table 2 – calibration points 2, 3

and 4. In case of accurate measurements in the whole range it is recommended

to calibrate the electrode in all 5 points given in the table. IN CX-401

characteristic of the electrodes is approximated linearly between the calibration

points.

Starting the calibration under one of the electrode numbers does not

remove the set buffer values, but irreparably removes the electrode

characteristic stored under this number.

There is no possibility of calibrating only one point, leaving the rest of

data from the last calibration.

CX-401 enables independent storing of 3 characteristics of pH electrodes. This

feature is especially useful when fast replacing of the electrodes is necessary or

when it was broken. Those electrodes should be earlier calibrated and brought

into memory under following symbols , , .

- 17 -

The order of using the buffer solutions is freely chosen.

The user may choose two independent ways of action:

1. enter the value of pH buffer solutions depending on the actually used

buffers, in the range given for each point of calibration;

2. use the values of pH sample solutions entered to the memory by the

manufacturer. Those values are in conformity with the NIST norm. This

type of calibration switches on the automatic correction introduction

connected with the change of sample solution along with temperature

changes.

Choosing the second option makes the calibration much easier. The user

doesn’t need to warm up or cool down the sample solutions to the temperature

given by the user. This option includes some simplifications and when very high

accuracy is required it shouldn’t be used. The meter stores independently 5

values of the buffers for each of the calibration modes described above.

8.1. Introducing the pH values of buffer solutions.

Values of the buffer solutions set by the producer in the meter’s memory are

given in the table 1.

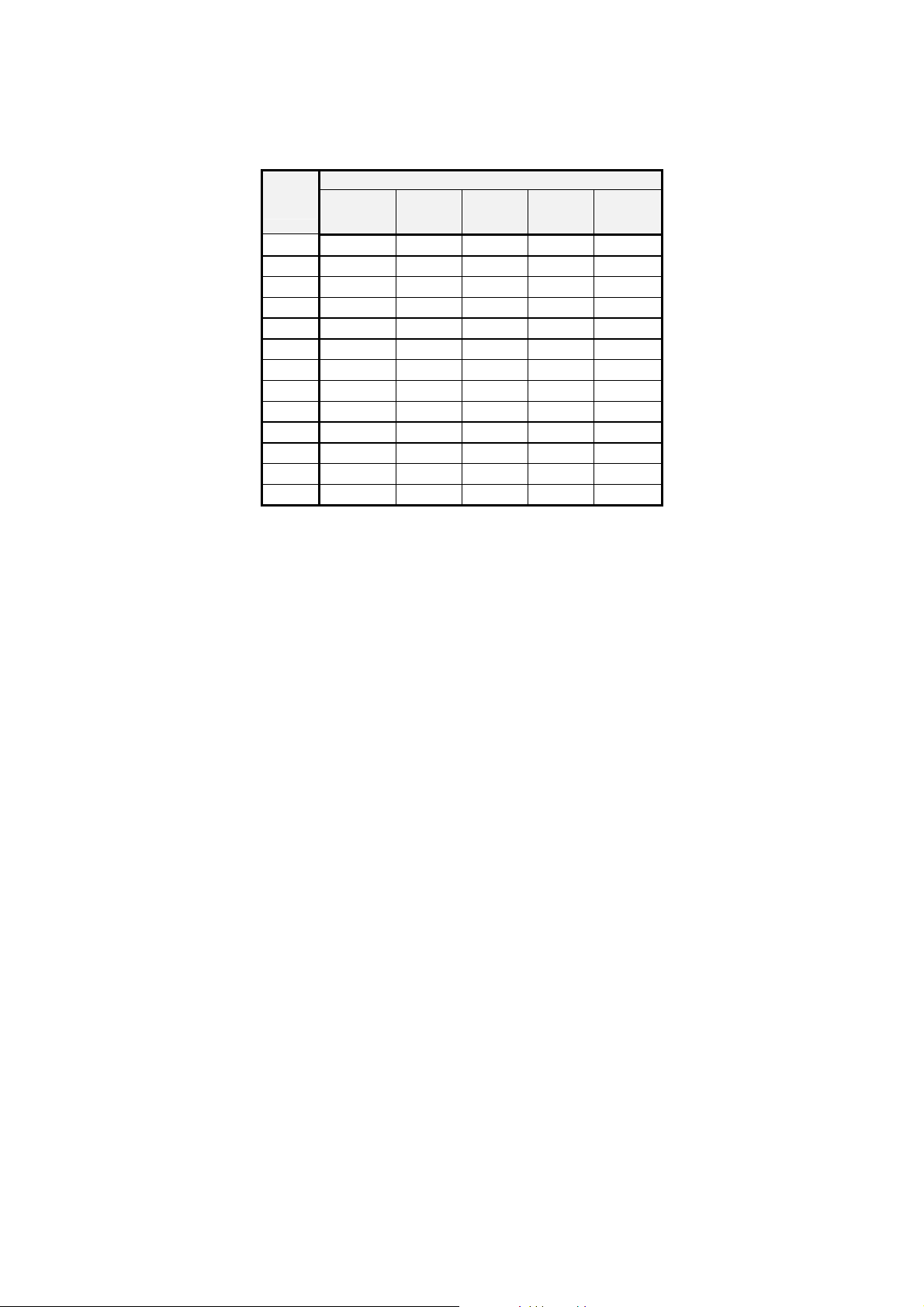

Point of

Calibration

Resolution

0,001

Resolution

0,01

1 1,675 1,68

2 4,002 4,00

3 6,881 6,88

4 9,225 9,22

5 12,627 12,63

Table 1

If the values of used buffer solutions are different than the given above the user

may change the set values.

- 18 -

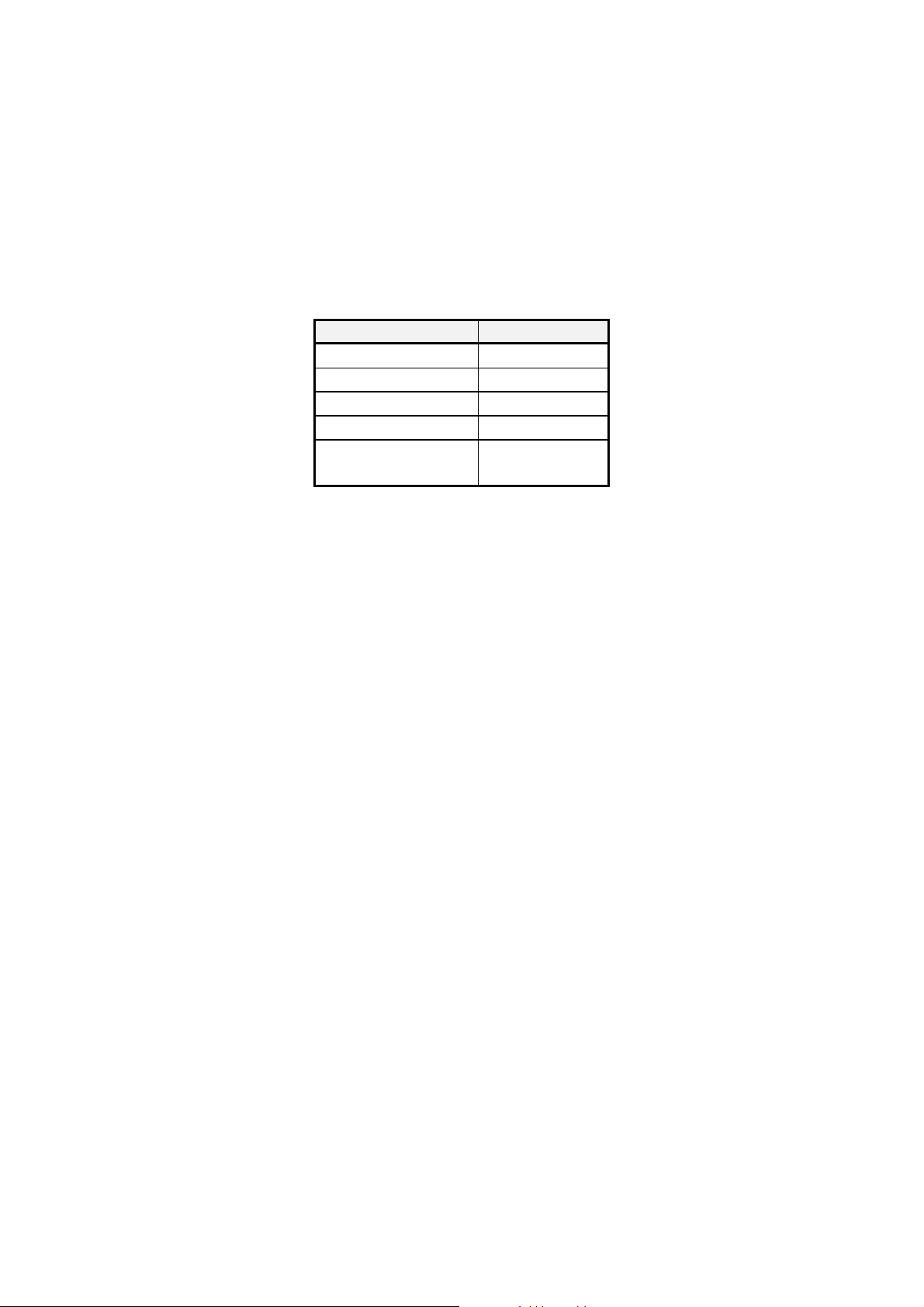

Range of possible changes is given in the table 2. There is possibility to

introduce the values of buffer solutions with two or three decimal places.

The meter doesn’t allow for introducing pH values in ranges other than

those given in the table 2.

Table 2.

Calibration point Range

1

2

3

4

5

0,800 ÷ 2,100

3,900 ÷ 4,100

6,800 ÷ 7,100

8,900 ÷ 9,400

11,500÷

14,000

The values of pH buffer solutions entered by the users are stored in the

meter’s memory till their changing to others.

Some of the sample solutions made according to norms may differ between on

the third decimal place. In very accurate measurements the user may not use

the mode with values of sample solutions according to NIST, but the mode

which enables changing the values of stored buffers. Before calibration one has

to change them to the accurate value of used sample.

The range of introducing the pH values of the buffer solutions in the individual

points of calibration is quite wide what enables to use buffer solutions with

values which differ from the ones set by the producer. For example buffers with

value 2,00 pH; 7,00 pH; 9,00 pH; and 12,00 pH may be used. In every case the

introduced buffer solution will be automatically recognised by the meter.

- 19 -

Together with the temperature change value of the pH buffer solution changes.

The producers often give the values of the solutions in few temperatures. This

data may be used and the meter may be calibrated in other temperature than

20 oC, by introducing to the meters memory value of the buffer which responds

to the chosen temperature.

8.2. Automatic change of the pH value of buffer solution.

In this mode 5 constant sample solution values, according to NIST, are used. In

the meter’s memory a table with dependence between the temperature

and pH values for this 5 sample solutions is stored. This dependence is

showed in the table 3. Those values are taken into consideration when the

calibration is done in other temperatures. Values between the points are

approximated linearly.

The highest accuracy may be obtained only when the pH values of the buffer

solutions are identical as in the table.

If there are some differences between the values given in the table and values

given by the producer of buffer solutions, one should judge weather the error

which will occur during calibration with automatic correction of the value won’t

be to big. If yes one should resign from using this option.

The range of the temperatures, taken into consideration during introducing the

correction, is 0 to 60 oC, and can’t be exceeded.

Table 3.

- 20 -

Temp.

0

C

1

oxalate 2 phthalate3 phosphate4 di-sodium

Kind of buffer solution

tetraborate

calcium

hydroxide

0 1.666 4.003 6.984 9.464 13.423

5 1.668 3.999 6.951 9.395 13.207

10 1.670 3.998 6.923 9.332 13.003

15 1.672 3.999 6.900 9.276 12.810

20 1.675 4.002 6.881 9.225 12.627

25 1.679 4.008 6.865 9.180 12.454

30 1.683 4.015 6.853 9.139 12.289

35 1.688 4.024 6.844 9.102 12.133

40 1.694 4.030 6.838 9.063 11.984

45 1.700 4.047 6.834 9.038 11.841

50 1.707 4.060 6.833 9.011 11.705

55 1.715 4.075 6.834 8.985 11.574

60 1.723 4.091 6.836 8.962 11.449

5

- 21 -

8.3. The actions during calibration

One should:

a. Choose the resolution with which the buffer solution value will be introduced.

Depending on the fact weather the buffer solutions have the pH value given

with 2 or 3 decimal places one should choose the right resolution.

Using button choose the pH function, next press the button a

(resolution) sign will be displayed.

Using or buttons choose:

- (low) resolution of the measurement 0.01 pH;

- (high) resolution of the measurement 0.001 pH.

b. Choose the electrode number under which the parameters of calibration will

be stored.

Press the

button, than using or

buttons choose the electrode

number (symbols , , ), under this number the calibration results will

be stored. Above the electrode number following signs will be displayed:

- under this number there is no characteristic stored and producers

values are provided.

- under this number there are values of last calibration stored.

- the last calibration showed that the electrode is loosing it’s

efficiency and in short time it’s calibration won’t be possible

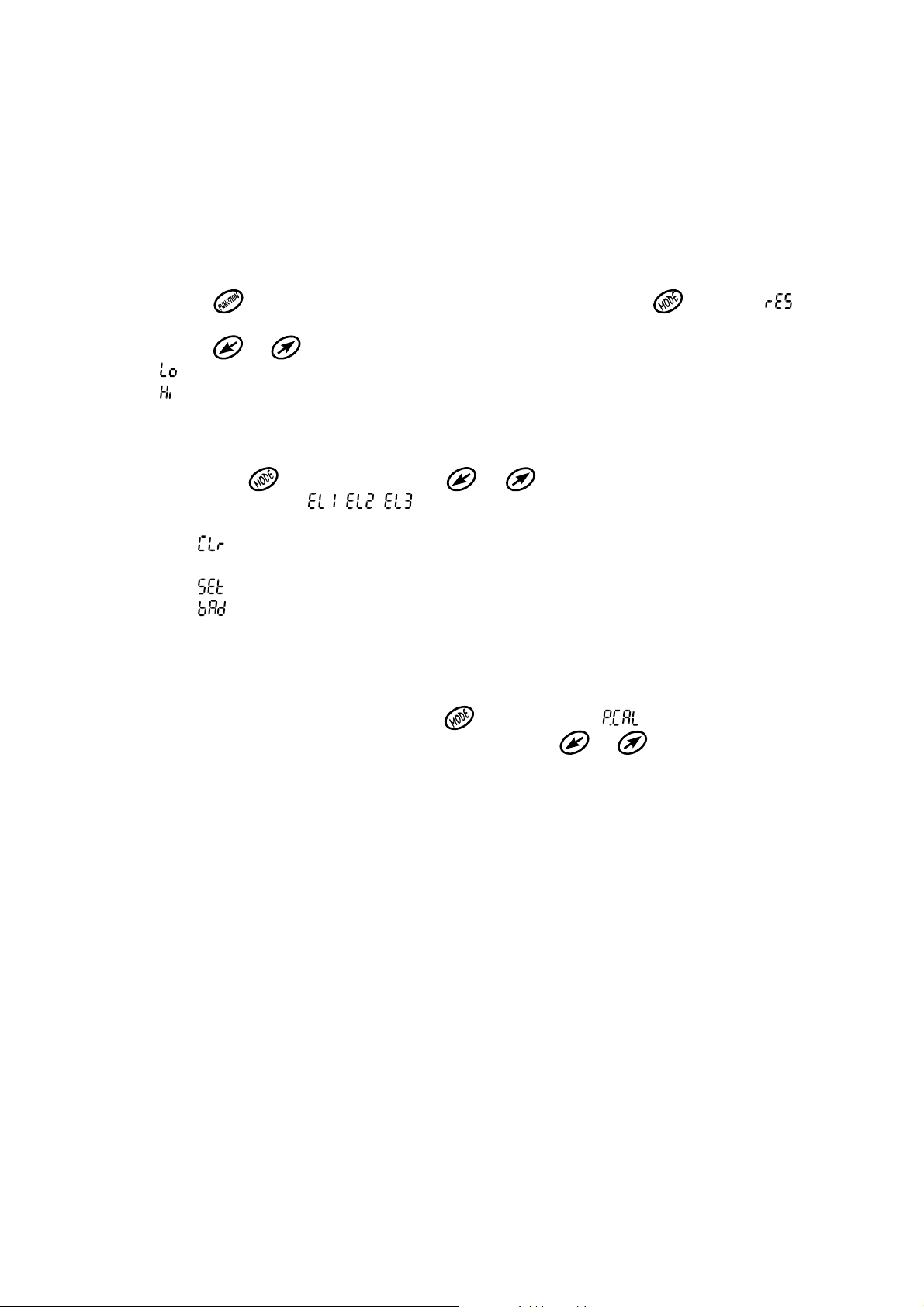

c. Choose or block the function of automatic correction of the change of pH

value of buffer solution with the temperature.

To do so one should press the button than a symbol (points of

calibration) will be displayed, (pic. 5) next using or

buttons choose:

- 22 -

– automatic change of the stored pH value of the buffer solution by

it’s temperature change according to table 3.

– setting the value of the buffer solution in the range given in table 3.

Pic. 5

After choosing the symbol one should press the button and start the

calibration in buffer solutions according to point e and chapter 8.4.

After choosing the act according to the point d.

d. After choosing the (user setting) symbol one should start checking and

eventually changing the stored values of calibration points. To do so one

should press the button. In the lower row a symbol will be displayed,

point one of calibration, and in the upper row value of the buffer. (pic. 6) If

one uses buffer solution with value a bit different than this displayed one,

using or

buttons bring the displayed value to the value of used

buffer solution.

Range of changes for each calibration points is given in the table 2.

- 23 -

Pic. 6.

To pass to the second point of calibration press the button in the lower

row a , symbol will be displayed (point 2) and in the upper row the stored

in this point value of buffer solution. When checking or changing the value

in the next steps please follow the instructions given above.

After the end of introducing the pH values of buffer solutions using the

button return to the choosing the calibration points mode ( / ,) or by

next pressing the enter the pH measuring mode.

During next calibrations if the values of the previously used buffer

solutions haven’t changed the actions described in this point may be

omitted.

e. Prepare the electrode for work acting according to it’s producer instructions,

than mark it with the number chosen in the meter (symbols , , ).

- connect the prepared combination electrode and temperature probe to the

right connectors (F and t) in the meter (pic. 2);

- if the function of automatic correction of the influence of temperature on

pH value of the buffer solution isn’t used measure the temperature of the

buffer solutions and bring it to the temperature given by it’s producer, so to

reach the value set in the meters memory. The order of using the buffer

solutions may be chosen freely.

Loading...

Loading...