1 UM/SWHM/V3/0115

User Manual

PREPAID METER

THREE PHASE | SINGLE PHASE

www.elmeasure.com

2 UM/SWHM/V3/0115

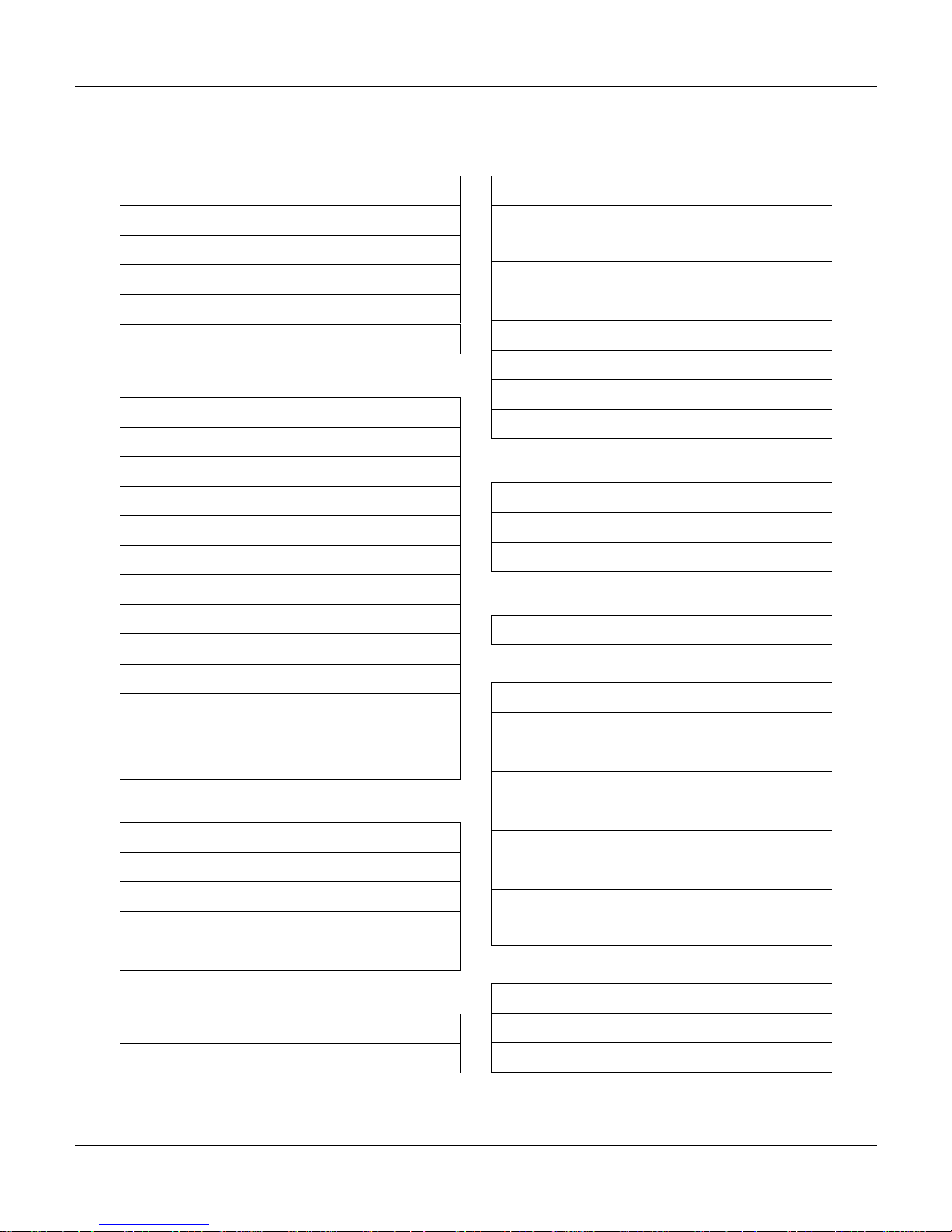

Table of Contents

1 INTRODUCTION 3

1.1. IMPORTANT INSTRUCTIONS 3

1.2. ABOUT THIS GUIDE 4

1.3. PREPAID METER UNIQUE FEATURES 4

1.3.1. BENEFITS OF PREPAID METER 4

1.3.2. APPLICATIONS OF PREPAID METER 5

2. INSTALLATION 5

2.1. SAFETY WARNINGS 5

2.2. WIRING THE PREPAID METER 7

Wire the Dual Input 9

Wire the Digital Inputs (Max.4) 9

Wire the Communication (RS485) 9

Wire the Remote Unit 9

2.3. INSTALLING THE METER 9

2.3.1 INSTALLING A METER IN A NEW LOCATION 10

2.3.2 REPLACING AN EXISTING METER 10

2.3.3 INSTALLING THE SIM CARD INTO THE

DEVICE (GSM/GPRS METERS) 11

2.3.4 INSTALLING THE REMOTE UNIT 11

3. PREPAID METER CONFIGURATION 12

3.1. PREPAID METER PRODUCT DESCRIPTION 12

Physical Description 12

Models & Display parameters of Prepaid meter 14

3.2. PREPAID METER OPTIONS 14

4. PREPAID METER OPERATION 15

4.1. KEY FUNCTIONS 15

4.2. Wi-Fi RESET OPTION 16

4.3. PROGRAMMING GUIDE FOR 3PHASE

(PE5120)/1PHASE (PE5121) PREPAID METER 16

4.4. PREPAID OPTIONS 19

RF based 19

GSM/GPRS based 20

WI-FI based 20

RS485 with Aggregator 21

4.5. PREPAID FUNCTIONS 22

5. FEATURES OF PREPAID METER 23

5.1. COMMON FEATURES 23

5.2. OPTIONAL FEATURES 24

6. TECHNICAL SPECIFICATIONS 24

7. COMMUNICATION 26

7.1. COMMUNICATION OPTIONS 26

7.1.1. RS485 26

7.1.2. SMARTCARD 26

7.1.3. GSM/GPRS 27

7.1.4. WI-FI 28

7.1.5. REMOTE UNIT 28

7.2. COMMUNICATION REGISTER MAP FOR PREPAID

METER 29

8. TROUBLESHOOTING 30

9. DISCLAIMER 31

3 UM/SWHM/V3/0115

1. INTRODUCTION

A Prepaid Energy Meter enables power utilities and the maintenance team to collect electricity bills

from the consumers prior to its consumption. The prepaid meter is not only limited to Automated

Meter Reading [AMR] but is also attributed with prepaid recharging ability and information exchange

with the utilities pertaining to customer’s consumption details.

The idea of prepaid metering will be very important for the new research fields of Micro-grid and Smart

Grid and is an inevitable step in making any grid smarter than it is now. Prepaid is a plan that deducts

usage charges and any fixed charges from account balance each day. Consumer is expected to take

responsibility.

This Unique

product termed as Contactless prepaid energy meter developed

by Elmeasure, is

probably the

first of its kind in the Indian meter manufacturing

history. T he design is completely

microcontroller based thus provides effective solution

to th

e electrical

service providers.

T

he action

required

by

the

service provider is just

to install

the meter and further activities involve only

the

consumer,

which

then

is a very simple

procedure to be followed. It is sufficient for the

service provider

to have

only

one man power or n o man p ower to recharge the meter as per the consumer's

requirement. This is not only limited to power and energy, Elmeasure devices also can integrate gas

and water meter with the different inlets of the house and deduct the balance based on consumption.

The meters can be networked with RS485, GSM/GPRS. The unique data communication enables the

secured recharging of the meter. Elmeasure has developed ELNet PPS software which enables the

customer to recharge the meters 24x7 using the payment gateway without even visiting the service

provider.

The microcontroller acquires signals from the metering element(s), processes them and calculates

values of measured energy or gas and water. The results are stored in registers for particular tariffs.

The microcontroller also generates pulses for the LED and, enables two-way communication via the

RS485 and drives the LCD and the control outputs.

1.1. IMPORTANT INSTRUCTIONS

This Unit is meant to be installed on electrical panels for measurement / analysis / control of

electricity. It should be installed only by qualified, competent personnel who have the

appropriate training and experience with high voltage and current devices.

DANGER

Failure to observe the following may result in serious injury or death

! During normal operation of the Unit, hazardous voltages are present on its terminal strips.

Follow standard safety precautions while performing any installation or servicing work (i.e.

removing PT fuses, shorting CT secondary’s, etc.)

! Voltage inputs including auxiliary supply must be protected by fuses in each circuit.

! Under no circumstances should the current input to the Unit be disconnected while current is

flowing in the primary circuit of the Current Transformer on the line.

4 UM/SWHM/V3/0115

CAUTION

For reliable operations establish input connections for voltage, Current and

Aux. supply through spade lugs crimped to wire ends

! The front panel of the Unit lists the voltage and current limits that may be applied to various

terminals. Application of inputs beyond these limits may result in permanent damage to the Unit

and will render the warranty void.

1.2. ABOUT THIS GUIDE

This document describes the Features of prepaid meter, Installation, Operation, Technical

Specifications and Communication options. It is intended for use by metering administrators,

installers, and meter technicians.

1.3. PREPAID METER UNIQUE FEATURES

• User friendly Prepaid Energy Metering Solutions

• Money based recharging. No separate recharging for EB and DG

• Integration of Gas and Water with the electrical parameters thereby, extending the flexibility

for the user to budget expenses

• Threshold point of kVA separately for EB and DG programmable to the individual customers

with the ON/OFF profiling to save the equipment in the house

• Direct current measurement 10/ 60A (default) for Single or three phase measurements

• Charging the meter with credit revenue through secured communication

• Elmeasure encryption is added on top of this to provide the better security

• Emergency credit for the selected customer

• Remote ON / OFF load by the service provider

• Pulse data collection from up to four external devices, such as gas or water meters, with

tamper monitoring included (optional feature)

• LED pulse outputs for accuracy verification of kWh

• Meter can be manufactured with kWh and kVAh

• Signal relay for control of external contactor or other devices, with activation linked to the

currently active tariff period or controlled by remote command (optional feature)

• Visual blinking on display indication to customer for low balance, over voltage, over KVA etc

• Remote Display Unit allowing customer to recharge and monitor consumption

• Elmeasure prepaid meter has great optional feature i.e. individual phases on for DG (R, Y, B or

RYB or No DG). This feature can avoid ACCL to individual houses.

• Optional Battery-backed Real Time Clock (RTC) to maintain time accuracy and tamper detection

during power outages.

1.3.1. BENEFITS OF PREPAID METER

• Improved operational efficiencies: The prepaid meters are likely to cut the cost of meter

reading as no meter readers are required. In addition, they eliminate administrative hassles

associated with disconnection and reconnection

5 UM/SWHM/V3/0115

!

• Reduced financial risks: Since the payment is up-front, it reduces the financial risk by

improving the cash flows and necessitates an improved revenue management system

• Better customer service: The system eliminates billing delay, removes cost involved in

disconnection/reconnection, enables controlled use of energy, and helps customers to save

money through better energy management

•

The whole process of billing can be centralized

•

Cost of manpower for billing / collection is reduced or Nil

•

This avoids the hassles of human intervention as there is no need to enter the data into the

meter. This makes the system more users friendly

•

Displays balance Energy in the meter, thus enabling the consumer to plan when to recharge

•

The smart recharge software (ELNet PPS) running in the service room

has

the option of

deducting

the common

lighting

charges/maintenance

charges either fixed for a month or

based on the amount of

area occupied

1.3.2. APPLICATIONS OF PREPAID METER

• Large scale development by utilities for Residential and Commercial connections

• Sub-metering in Apartments, Shopping malls and Building complexes

• Convenient mode of payment in housing colonies

• As a second meter between utility meter and distribution board for housing tenants

• Selective deployment by utilities in regions with poor credit history

• Electricity supply for vendors, contractors and temporary connections

2. INSTALLATION

2.1. SAFETY WARNINGS

Before you install and operate your meters, it is important to be familiar with all regulatory

agency, manufacturer, and utility industry safety precautions. Observe these safety

precautions during all steps of meter installation, operation, and service. Failure to comply

with these precautions, or with specific warnings or instructions elsewhere in this guide,

violates safety standards of design, manufacture, and the intended use of the meter.

Elmeasure assumes no liability for failure to comply with these requirements.

The information presented in this guide is intended to be an aid to qualified metering

personnel. It does not replace the extensive training necessary to handle metering equipment

in a safe manner.

Safety Warning: Any work on or near energized meters or other metering

equipment presents the danger of electrical shock. Only qualified electricians and

metering specialists should be authorized to work with the meters, in accordance

with local utility safety practices, utility requirements, and other safety precautions

as dictated by local code, regulations, or statutes.

6 UM/SWHM/V3/0115

!

INCOMING INSPECTION

Before the meter is installed, visual inspection, for any damage in the process of

transportation, has to be carried out.

Safety Warning: Return damaged meters and components to Elmeasure do not

attempt to repair the damage. The meter has no user-serviceable parts. Any

attempt to remove or repair internal parts voids the meter warranty.

REPACKING

If the meter has to be returned to the supplier, repack the unit in the packing in which it was

supplied.

OPTIMUM FIELD CONDITIONS

For the reliability and better life of the product the unit has to be operated at moderate

temperatures and humidity. The meter is designed to work from -5 to 60 degree C and

humidity of 95% RH non condensing.

STORAGE

In case if the meter is not installed after receiving, it has to be stored in a dry place in the

original packing material.

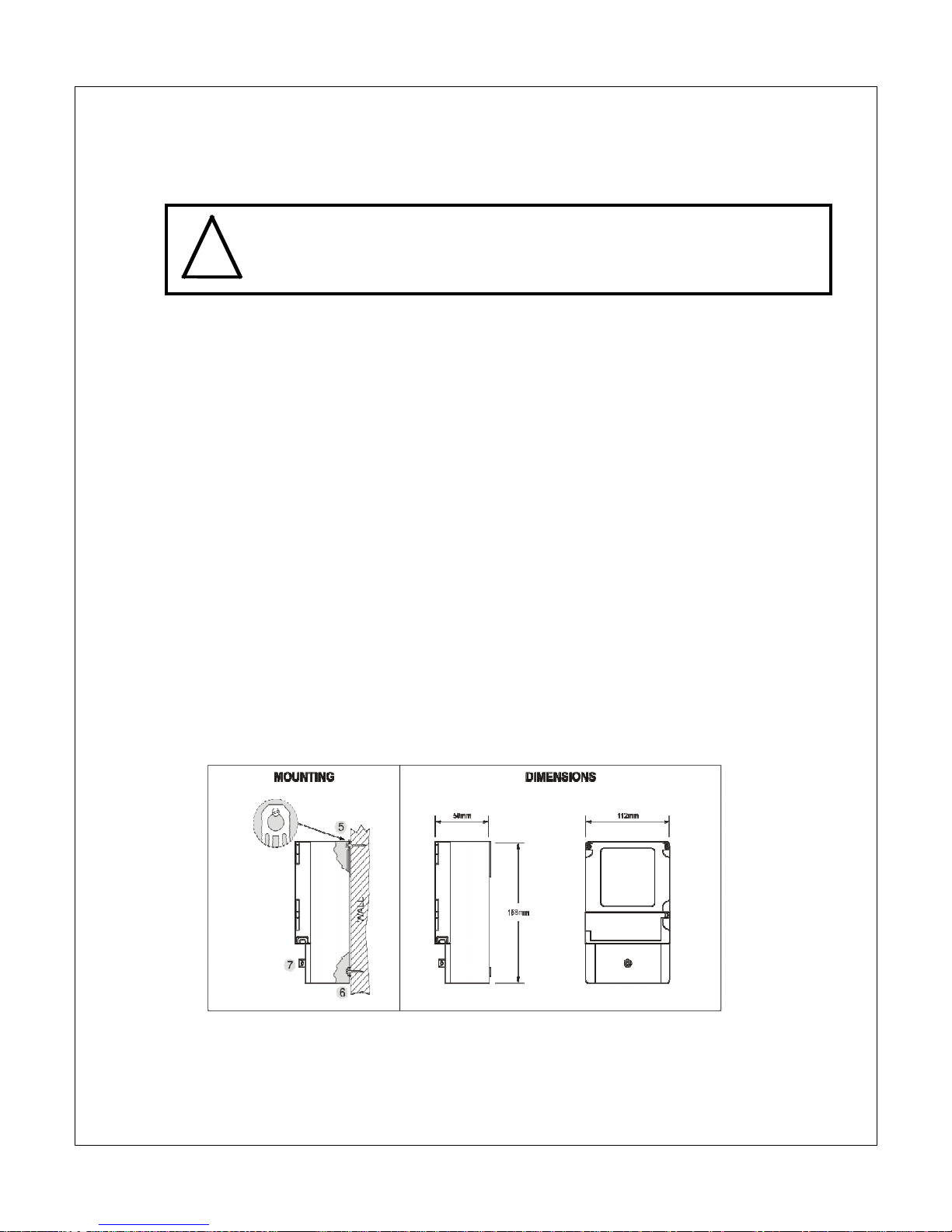

MOUNTING

Figure shows the location of the meter mounting holes. The Mount the Prepaid Energy Meter in

a dry location free from corrosive vapours. To mount the Unit: In the real panel side we have wall

mountable clamp, by using that mount the prepaid meter on the wall.

Fig. 1: Drawing for Single phase mounting details

7 UM/SWHM/V3/0115

Fig. 2: Drawing for Three phase Mounting details

Mounting:

The front bezel of the basic model is molded plastic. Bezel dimensions are 160 x

112 mm (Depth 58mm behind bezel) for single phase prepaid meter and 173 × 262 mm (Depth

82mm behind the bezel) for three phase prepaid meter.

EXTRA PRECAUTIONS

Make sure of supply voltage, supply current and configuration. Wrong connection can severely

damage the instrument, which is not covered under our warranty.

We recommended installing necessary protective device along with the meter like circuit

breaker / Fuse/ MCB/ Switch/ Isolator to take care of unexpected faults.

CONNECTION

The meter uses a polycarbonate casing and so is a good insulator. Hence it DOES NOT HAVE

ANY EARTH TERMINAL.

Terminal cover is to be used to protect the meter terminals from being tampered with. As soon

as the connections are made the terminal block has to be covered and sealed by terminal

cover. It can be fixed using two sealable screws.

VENTILATION

No specific ventilation is recommended. Meter is capable of working satisfactory at Ambient

between -5 to 60 degree C.

2.2. WIRING THE PREPAID METER

The inputs to be connected to the Prepaid Energy Meter are clearly indicated on the Front Panel.

Connect the Voltage inputs: For LT Models (415 V AC L-Nominal), connect the voltage inputs

directly to the terminals. For HT Models, the inputs should be from the secondary of the Potential

Transformer. In a 3-wire system, the Neutral terminal is not connected. In a 4-wire system, the

neutral may or may not be connected to the terminal marked ‘N’.

8 UM/SWHM/V3/0115

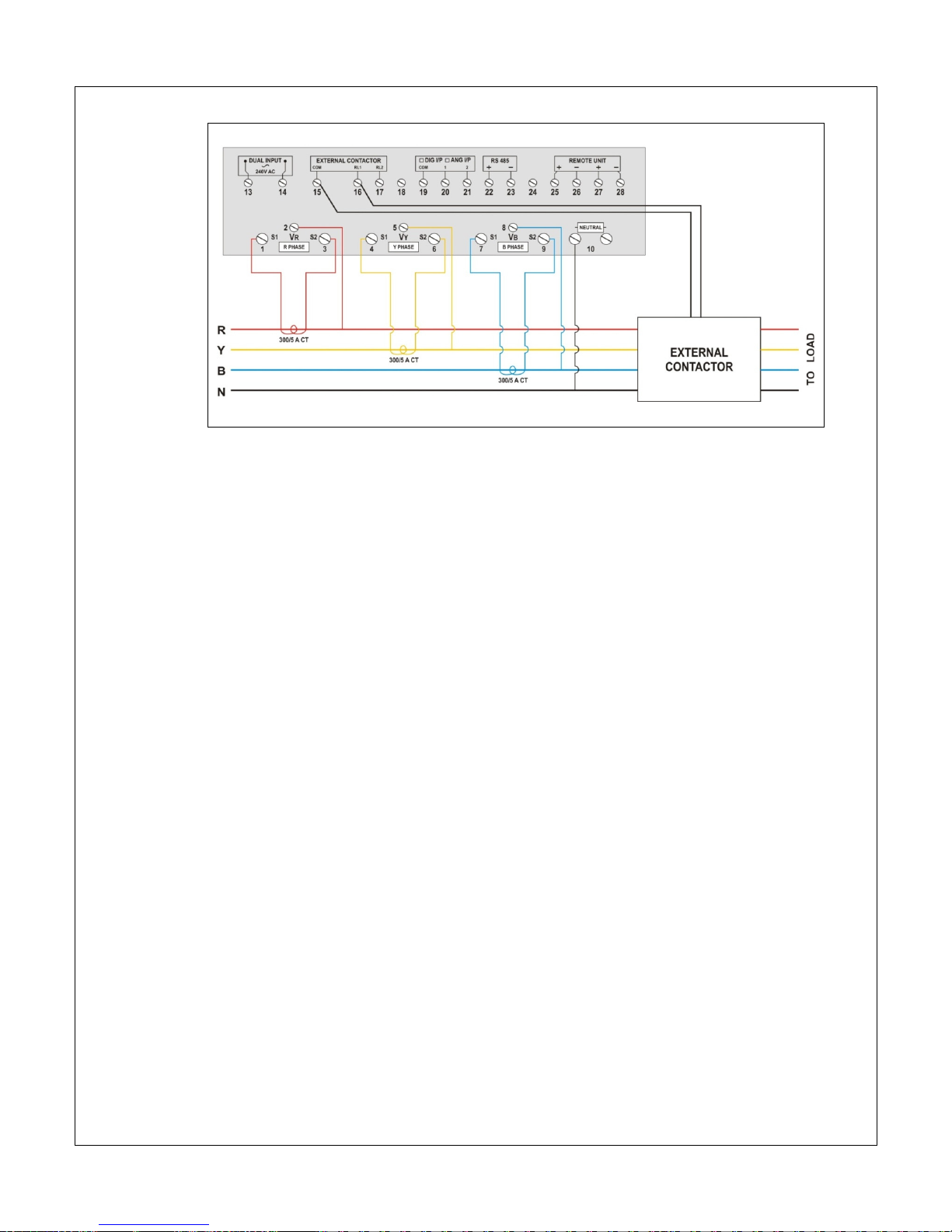

Connect the Current inputs: It is important to maintain the direction of the current flow from S1

to S2. If this reversed in one or more phases, the Power computation will be negative in the

corresponding element(s). Though the computation is internally corrected to an equivalent

positive value, it is not advisable to leave a reversal of current flow uncorrected.

It is important to adhere to phase relationships. Current ‘IR’ must correspond to the phase

that has the Voltage connected to the ‘VR’ terminal. The same holds good for current inputs ‘IY’

and ‘IB’. If the current and voltage inputs are swapped, the Power and Energy computations may

be erroneous.

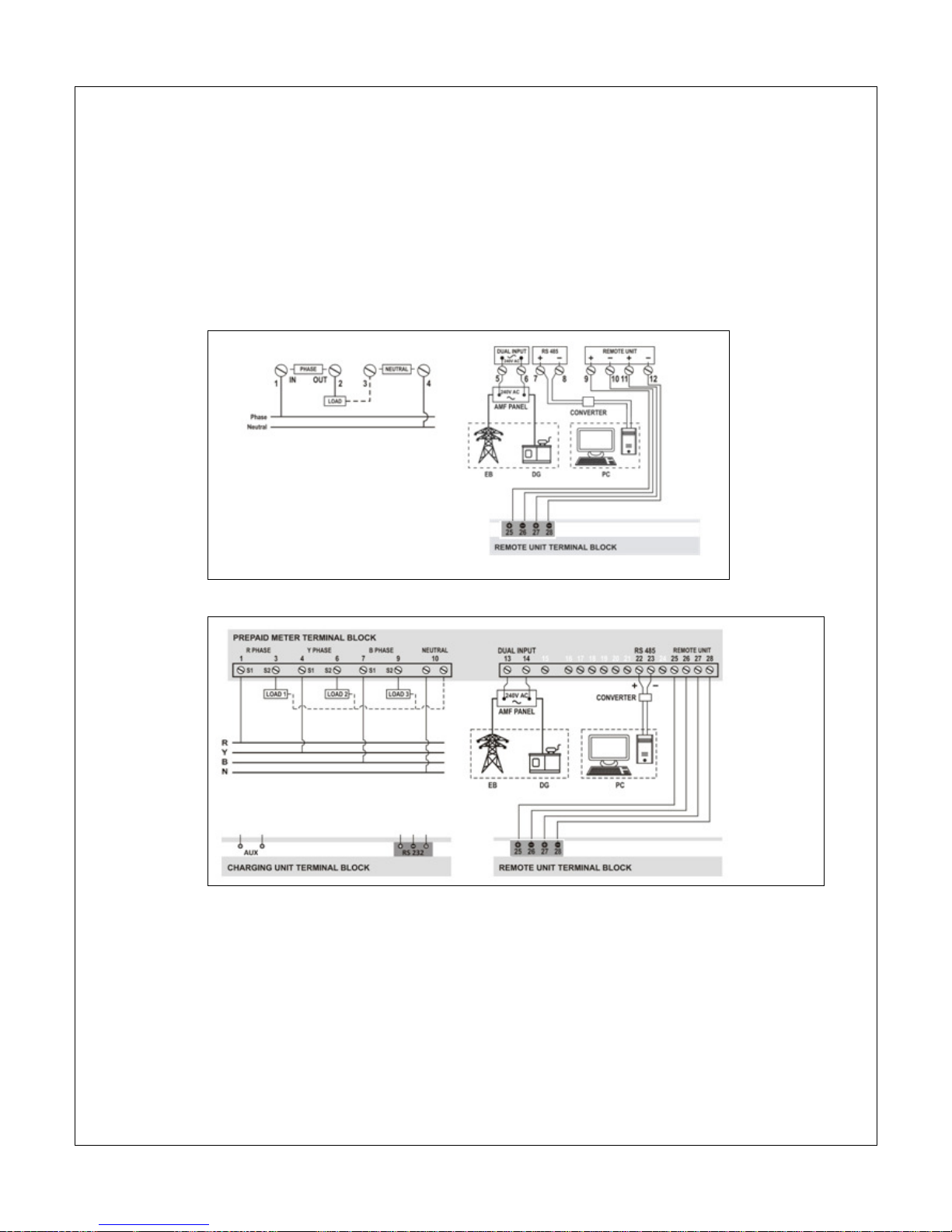

Fig. 1: Connection diagram for Single Phase Prepaid Energy Meter

Fig.2: Connection diagram for Three Phase Prepaid Energy Meter (Whole current

measurement)

9 UM/SWHM/V3/0115

Fig. 3: Connection diagram for CT Operated Three Phase Prepaid Energy Meter

Wire the Dual Input

The Unit is capable of monitoring electricity consumed from two separate sources. One of these could

be the supply from the electricity authorities while the other could be from the in-house generator. For the

meter to recognize that the supply is from the alternate source, the meter requires a voltage input

between 240 V AC that should go live when the supply is from the alternate source as shown in Fig 2.

Wire the Digital Inputs (Max.4)

Integration of Gas and Water with the electrical parameters thereby, extending the flexibility for the

user to budget expenses. The four digital inputs, any gas and water meter can be configured. It is

important to program the price / Pulse in the corresponding ElNet PPS.

Wire the Communication (RS485)

The Prepaid Energy Meter is equipped with an RS-485 Serial Communication Port or GSM/GPRS and

operates on the MODBUS-RTU protocol.

Wire the Remote Unit

The Prepaid Energy Meter is equipped with Remote Unit; it has four terminals, two terminals for 5V

supply to Remote Unit and two terminals for RS485 communication to Remote Unit.

2.3. INSTALLING THE METER

The device should be installed in a place where it will not be at risk of damage or near any

unauthorized current connection. The sealing of the distributor housing is recommended. The

producer is not responsible for any damage caused by improper assembly, service and product

maintenance.

10 UM/SWHM/V3/0115

2.3.1. INSTALLING A METER IN A NEW LOCATION

To install the Elmeasure’s prepaid meter in a new location:

• Remove the terminal cover from the meter

• Install the meter in an upright position, using mounting hardware that is appropriate for the

type of surface material

•

Connect the line and load wires to the meter terminals, being careful to use the correct

phase, neutral, and line/load configuration

• Turn the supply line power to the meter on

• Test each phase line terminal of the meter to make sure power is on to each phase, and that

the neutrals are connected to the proper terminals

• Test the load terminals of the meter to make sure power is available to each phase of the

load.

• Check the display for proper operation of the meter

• Replace the terminal cover. Apply a seal to the sealing screw if necessary or desired. The

installation is complete

2.3.2. REPLACING AN EXISTING METER

To install the Elmeasure’s prepaid meter in a existing meter location:

Precaution: Make sure the existing meter and Elmeasure meter mounting mechanism is same.

•

Turn off the line power to the existing meter

Caution: Test existing meter terminals to be sure the voltage is off.

• Remove the line and load wires from the existing meter terminals. Make sure you label the

wires, or have a method to identify the line and load wires of each phase, R, Y, B, and neutral,

for proper installation in the new meter

• Remove the old meter

• Install the Elmeasure’s prepaid meter in the same location as the previous meter, using

mounting hardware that is appropriate for the type of surface material

• Inspect the line and load wires to make sure they are not damaged or frayed. (Replace if

needed.)

• Connect the line and load wires to the meter terminals, being careful to use the correct

phase, neutral, and line/load configuration

• Turn the supply line power to the meter on

• Test each phase line terminal of the meter to make sure power is on to each phase, and that

the neutrals are connected to the proper terminals

• Test the load terminals of the meter to make sure power is available to each phase of the

load.

• Check the display for proper operation of the meter

• Replace the terminal cover. Apply a seal to the sealing screw if necessary or desired. The

installation is complete

11 UM/SWHM/V3/0115

2.3.3. INSTALLING THE SIM CARD INTO THE DEVICE

(GSM/GPRS METERS)

GSM/GPRS based prepaid meters SIM holder having two symbols on the downside. Down symbol for

opening the SIM holder and up symbol for locking the SIM holder.

•

Open the SIM holder by click down symbol of the SIM holder

• Insert the SIM into the holder

• Lock the

SIM holder by click up symbol of the SIM holder

2.3.4. INSTALLING THE REMOTE UNIT

• Connect the Remote unit power supply and RS485 terminals to Prepaid meter Remote Unit

terminals as shown in the connection diagrams

• Connect the EB/DG input to Prepaid meter and output of prepaid meter connected to load

Fig.1: Connection diagram for single phase prepaid energy meter with remote and charging unit

12 UM/SWHM/V3/0115

Fig2: Connection diagram for three phase prepaid energy meter with remote and charging unit

3. PREPAID METER CONFIGURATION

3.1. PREPAID METER PRODUCT DESCRIPTION

Physical Description

FRONT:

The front panel of prepaid meter contains the two parts:

1. Display

2. Wiring Diagram

The Display part has one row of six digits/characters each, with auto scaling Kilo, Mega, and

minus indications. Two smart keys make navigating the parameters very quick and intuitive

for viewing data and configuring the prepaid meter.

The Display part of front panel contains the following indicators and controls:

7-segment LED display: One row of alphanumeric displays, six digits each, displays all

parameters simultaneously. For every second the display updated.

Indicators: One row has Kilo, Mega and Minus indicators, Electricity Board, Old energy and

DG indicators, communication indicator, and for Digital inputs 4 indicators(T1,T2,T3,T4) as

shown in the front panel figure.

Keys: Two smart keys to scroll through the display pages.

7-segment LED display:

One row, six digits, segment LED display. The Energy meter

displays the parameter name prominently right on the large, alphanumeric readouts. In

Energy all the 6 digits contains the value of parameters. In Power, Basic first 4 digits

correspond to Value and remaining 2 digits corresponds to Name.

13 UM/SWHM/V3/0115

The Indicators-Kilo, Mega, Minus, COM and 4-D/I

LED indications for prepaid meter

LED Status

Meaning

KILO ON

Kilo

MEGA ON

Mega

MINUS(

-

) ON Lag

MINUS(

-

) OFF

Lead

EB ON

Meter displays EB energy

OLD ON

Old energy values for EB and DG separately

DG ON

Meter displays DG energy

EB LED

Blinking

Meter is running in EB

DG LED Blinking

Meter is running in DG

T1 ON

Gas meter1

T2 ON

Water meter1

T3 ON

Gas meter2

T4 ON

Water meter2

W1 WIFI Status

W2 WIFI Status

W3 WIFI Status

W4 WIFI Status

COM ON

Meter Communication with software

The second part of front panel of prepaid meter is wiring diagram as shown in the section 2.2

KILO

Kilo: When lit, indicates that the reading is in Kilo (103). 10,000 is

displayed as 10.00 K.

MEGA

Mega: When lit, indicates that the reading is in Mega, (106). 10,000 K

is shown as 10.00 M. and 1.0 M as 1000 K.

MINUS

Minus

: When lit

, indicates that the

read

ing is negative. When PF

(power factor) is lead (capacitive load): Both PF and VAR (reactive

power) sign will be negative. When current is reversed: W (active

power) of that particular phase is negative.

EB:

EB indicator blinking indicates that meter running on electricity

coming from Electricity board.

OLD

OLD:

OLD indictor indicates the old energy values for both EB and DG

separately.

DG:

DG indicator blinking indicates that meter running on Digital

Generator.

COM

: Communication indicator indicates the meter communic

ating

with the software or not.

D/I (T1, T2, T3, and T4): These four LEDs represent gas and water

meters connected to the prepaid meter.

Pulse output:

This is the blinking LED indicates the load pattern. It

produces 1000 pulses / kWh for 10/60A meter.

(W1, W2, W3, and W4):

These four LEDs represent WIFI status. These

four LEDs intermittent on and off wifi reset condition, W1 and W3 not

connected to the access point, W3 for Wifi communication.

14 UM/SWHM/V3/0115

Models and Display parameters of Prepaid meter

Model

Display Parameters

PE5120

– Three phase Prepaid meter with

internal contactor

•

Credit left in kWh Units(balance)

• Cumulative kWh(EB & DG)

• Digital Inputs(for Gas and Water meters)

Cumulative Old KWh(EB & DG)

• Digital Inputs Old (for Gas and Water meters)

• Voltage(Average & phase wise)

• Current(Average & phase wise)

• Frequency

• Watts(Average & phase wise)

• VA(Average & phase wise)

• PF(Average & phase wise)

PE5121

– Single phase prepaid meter with

internal contactor

•

Voltage

• Current

• Frequency

• Watts

• VA

• PF

• Cumulative kWh

• Cumulative kWh(EB & DG)

• Credit left in kWh Units(balance)

• Digital Inputs (for Gas and Water meters),

Cumulative Old KWh (EB & DG), Digital Inputs

old (for Gas and Water meters)

3.2. PREPAID METER OPTIONS

• Three phase PE5120, Single phase PE5121

• RS485 to connect to the remote terminals

• Postpaid or Prepaid

• Dual Source

• Direct Current 5/20A, 10/60A (default), 20/80A and CT operated---/5A

• Remote display unit enables the individual customer to monitor consumption

• With RTC option

• GSM / GPRS option

• Integration of Gas and Water (Up to 4 channel for 5120 and up to 3 channel in for PE5121) with

the electrical parameters thereby, extending the flexibility for the user to budget expenses

15 UM/SWHM/V3/0115

4. PREPAID METER OPERATION

The meter is suitable for Three-phase four wire (PE5120)/ Single Phase 2 wire system (PE5121).

Meter measures electrical energy consumed and decrements the available credit register in accordance

with the energy consumption-KWh or kVAh. The available credit register is incremented as and when

payment is made. Meter continuously calculates the balance credit against the consumption.

As the balance credit decreases beyond the pre-defined level, a switch (latching relay) is used to

disconnect the supply to the load. Meter display starts blinking when the credit balance falls to a

programmed value.

Over voltage (OVER.VOL) Tripping: This is the unique feature from the Elmeasure meter to protect the

equipment when the over voltage occurs. When the Line voltage is more than programmed value the

prepaid meter trips the load, thus protecting the house hold equipments. This replaces the need for

over voltage relays in individual houses.

Over.KVA (EB or DG): Elmeasure meters have the unique feature to program the set limit for

consumption when it is operating on EB and DG in terms of kVA. When the consumption is above the

set value then the LOAD gets disconnected for a span of 1 minute (programmable through

configuration) after which the LOAD gets connected for the SET DELAY time to see the load is reduced

and if the consumption is still higher it trips the load for the 2nd delay time (programmable) and this

process gets repeated with the different programmable delay time until the consumption is reduced.

DG SELECTION: Elmeasure prepaid meter has great optional feature i.e. individual phases on for DG (R,

Y, B or RYB or No DG). This feature can avoid ACCL to individual houses.

COMMUNICATION SETTINGS:

4.1. KEY FUNCTIONS

Smart Keys

Operating the energy meter is easy, using the two smart keys to navigate through the display

pages. The display shows where you are headed.

Protocol Modbus RTU

Data bits 8

Baud rate 9600 Baud, User set 1200 to 19200

Range:1200, 2400, 4800, 9600, 19200

Normal use: 9600 Baud

Noisy, EMI, RFI, long data cable: 4800/2400 Baud

Short cable (< 300 meters or 975 feet): 19200 Baud

Parity Even/odd/no

Device ID

1

Stop bit

1

16 UM/SWHM/V3/0115

Smart Keys Functionality

Key In SET (Programming) mode

In RUN (Measurement) mode

UP

To select the value and accept the

value.

To scroll pages in upward direction to look at

different parameters.

DOWN

To edit t

he value/system type

down-ward in edit mode and scroll

through the parameters.

To scroll pages in downward direction to

look at different parameters

4.2. Wi-Fi RESET OPTION

Step Actions

Display Reads

Range/Options/Comments

1 Press UP & DOWN keys

together to enter SETUP

[SETUP]

2 Press DOWN key

Row: 0000 PW with first

digit “0” blinking

3 Press DOWN key

until it

reaches the first digit to

“9”.

PASSWORD =

9900

(default/factory set).

If any other password is already set

using DOWN key to set the right

password

Press DOWN key

R o w : S A V E “Y”

Row : “Y” blinking.

If “n”(no) is selected then Meter

enters into RUN mode without

reset WiFi module. If “Y” is selected

meter enters in to wifi reset mode .

4.3. PROGRAMMING GUIDE FOR 3PHASE

(PE5120)/1PHASE (PE5121) PREPAID METER

Step Actions

Display Reads

Range/Options/Comments

1 Press UP & DOWN keys

together to enter SETUP

[SETUP]

2 Press DOWN key

Row: 0000 PW with first

digit “0” blinking

3 Press DOWN key

until it

reaches the first digit to

“1”.

PASSWORD =

1000

(default/factory set).

[PASSWORD = 9900

For wifi reset ]

If any other password is already set

using DOWN key to set the right

password

4 Press UP key four times to

accept the password.

Row: 2056 Yr

( RTC year)

2056 Yr ( Default)

Defines the RTC year setting.

5 Press UP key to select the

RTC year.

Row: 2056 Yr

“56” will start to blink and

it can be edited using

DOWN key.

Egg: Year need to be set as 2014 so

press the Up key, the selected

mode will start to blink i.e. “56” and

change the selected mode to “14”

using DOWN key.

6 Press UP key to select the

RTC year

Row: 2014 Yr

Default: 2056

Program Range for RTC year :2012

-

2056

If year is set 2014, display return to

RTC year acceptance.

17 UM/SWHM/V3/0115

7 Press DOWN key to go to

the next parameter

Row: 01.01. d

Defines the Month & Date of the

clock.

First two digits define the month

selection & another two digits

mention the date.

8 Press the UP key to select

the Month & Date

Row: 01. 01. d (default).

First two digits blinking

which is “month”

selection can be edited

using down key.

Selected mode will blinks and it can

be set to the desired range using

Down key.

Eg: Month need to be set April , set

the selected blink value as “04”

using DOWN key

9 Press UP key to accept the

edited value for month.

Row: 04.01. d

Second digit blinking

which is “Date” selection,

it can be edited using

DOWN key. Press UP key

to accept the edited

value.

10 Press DOWN key to go to

the next parameter

Row: 00.01. t ( Default)

It defines the RTC time settings.

It is in HH:MM format.

11 Press the UP key to select

the Hour & Minute.

Row: 01.01. t

Follow the procedure

steps 8 & 9 for set the

Hour & minute.

12 Press DOWN key to go to

the next parameter

Row: 52.00 Eb (Default in

3phase).

17.50 Eb(Default in single

phase)

Over KVA EB

It defines the over KVA tripping

value for Eb.

Range: up to 9999 Mega

13 Press UP key to select the

over KVA value.

Row: 52.00 Eb.

First digit starts blinking

can be edited using

DOWN key.

(selected mode blinks)

14 Press UP key

to accept the

edited value for first digit.

Row: 52.00 Eb

Second digit blinking, can

be edited using DOWN

key. Press UP key to

accept the edited value.

Continue the same

method until fourth digit.

Program range for Over KVA: 52.00

Kilo- 9999.0 Mega.

15 Pr

ess UP key

Row: 52.00 K Eb.

Decimal point blinking. It

can be set at appropriate

location using DOWN key.

Ascertain the correct

scale (Kilo, Mega) is

selected. Press UP key to

accept the edited value.

Egg. To set 11.00 K.

Set first four digits (1100) as

explained above. Press DOWN key

to place decimal point at

appropriate location with

respective LED (kilo, Mega)

indication.

18 UM/SWHM/V3/0115

16 Press DOWN key to go to

the next parameter

Row: ryb dG. (Default)

Phase selection in DG

(only in 3 phase meter)

It defines which

phase needs to be

work in DG.

Ranges: ryb,r,y,b

17 Press UP key to select the

edited value.

Row: ryb dG.

Selected mode blinks and

select any of the phase

selection as mentioned in

the range using DOWN

key. Press UP key to

accept the selected mode.

18 Pr

ess DOWN key to go to

the next parameter

Row : display 285.0 O.V

(over voltage)

285.0 O.V (Default)

Defines the over voltage settings

between Line to neutral.

Range: 80-310 V

19 Press UP key to select the

over voltage value

Row: 285.0 O.V (Over

Voltage)

First digit blinking can be

edited using DOWN key.

(selected mode blinks)

20 Press UP key to accept the

edited value for first digit.

Row : 285.0 O.V

Second digit blinking, can

be edited using DOWN

key. Press UP key to

accept the edited value.

Continue the same

method until fourth digit.

Program Range for Over Voltage :

80V to 310V

If value set is above this limit,

display returns to the maximum O.V

value acceptable.

21 Press DOWN key to go to

the next parameter

Row: 5.000 d.t (Delay

Time). Follow the

procedure as described in

steps 5 & 6

5.000 (default)

It defines the delay time for relay

tripping

Range: 1-180 sec

22 Press DOWN key

Row : 9600.b (Baud rate)

Communication Speed

(9600-Default / factory

set)

Defines the Baud rate Option:

2400, 4800, 9600, 19.2k.

23 Press DOWN key

Row : EVEn P (Parity)

Even/ Odd/ None

Even

(even)/ Odd( odd)/ No( No

parity)

(Internal Communication error

Check)

24 Press DOWN key

Row : 1.000 Id( Device ID)

1.000 (Default)

Defines the ID.

Communication identification

Number. Option :1- 247

25 Press DOWN key

Row:

------ (Password).

User Programmable

password, range 1000 to

9999.

If the password is forgotten the

meter will be reset and calibrated

at factory only.

20 Press DOWN key

Row : rESO E.S (Energy

Selection) rESO (Default)

Option: resolution/counter

(rESO/COUN).Energy value format

i.e., the energy accumulated in the

meter to be displayed in resolution

or counter format

19 UM/SWHM/V3/0115

21

Press DOWN key

Row : 5.000 A.t. ( Auto

scroll time)5.000 (

Default)

Range: 1 to 10 seconds

Display increment during auto

scroll.

22 Press DOWN key

R o w : S A V

E

Row 2: “Y” blinking.

If “n”(no) is selected then Meter

enters into RUN mode without

memorizing any edited Values in

the setup

The List of parameters that can be configured and the range is given below

Sl. No.

Parameter

Default setup

Range

1 Ove

r Voltage(L

-

N) [ O.V ]

285.0

80V-310V

2 Over KVA

52.00

52-

999K

3 Individual phases change on DG

RYB R (or) Y (or) B (or) RYB

(or) No DG

4 Delay Time [d.t]

5.000

1-

180s

5 Baud rate [b]

9600

2400 to 19.2k

6 Parity(P)

EVEn

Even/ Odd/ no

7 Device Id (I d)

1.000

1.000 to 247.0

8 Password

1000

1000 to 9999

9 Energy selection mode [E.S]

rESO rESO /COUΠ

10 Display increment time during auto scroll [A.t]

5.000

1 to 10 seconds

Enabling and Disabling of Auto scrolling:

Enabling Auto Scrolling: Press DOWN key continuously for 5 seconds or until display shows EnAb.Au

for downward scrolling. The auto scrolling will be enabled automatically when the meter is OFF and

ON.

Disabling Auto Scrolling: Press UP/DOWN key to disable auto scrolling. Display shows dlSA.Au and

returns to normal mode.

4.4. PREPAID OPTIONS

RF based

• Secured Encrypted RF Smart Card based recharging

• Elmeasure encryption also added for improving the security

• Can have multiple card- one with low value charged for emergency

• Over KVA tripping when the meter is running in DG (programmable through the smart card)

• Reconnection time is programmable-10sec, 1 min, 10 min, 2 hrs. monthly fixed charges based

on KVA/KW

• RTC option available: Holiday and night time cutoff prevention, Grace amount can be set from

factory, Option of programming for non tripping during week end

20 UM/SWHM/V3/0115

GSM/GPRS based

• Recharging with the secure authentication code and secure reply

• Meter with Real Time Clock (RTC option)

• Sends power outage & power resumption timings with date & time stamp after the power

resumes to the server

• Response for all the successful, failure recharge with the reasons

• Force ON and OFF the load through SMS (Resets with the power cycle)

• Remote configuration of unit cost (cost per KWh) and the slab wise cost

• Remote Configuration of change in Threshold, Negative balance, Tariff in the secure mode

• Initiate the SMS when balance reaches the 20% or 15% of the threshold value

• Information like profiling, recharge history can be available through smart mobile applications

• Avoids Remote display

WI-FI based

• Recharging with the secure authentication code and secure reply

• Meter with Real Time Clock (RTC option)

• Sends power outage & power resumption timings with date & time stamp after the power

resumes to the server

• Response for all the successful, failure recharge with the reasons

21 UM/SWHM/V3/0115

• Remote configuration of unit cost (cost per KWh) and the slab wise cost

• Remote Configuration of change in Threshold, Negative balance, Tariff in the secure mode

• Initiate the message when balance reaches the 20% or 15% of the threshold value

• Information like profiling, recharge history can be available through smart mobile applications

• Avoids Remote display

RS485 with Aggregator

• Cost effective solution

• Aggregator collects information and transfer data through Ethernet/Wifi/USB/GPRS to the

server

• ELNet billing software for profiling

Aggregator-AG 1000

Aggregator AG1000 is a web based high end data concentrator and All-In-One multi protocol

communication interfacing unit that supports the Modbus protocol and has different types of

communication channels. Introduction of the Aggregator allows for flexibility to cater to wired

or wireless environments with built in storage, providing the end user with a robust solution of

Energy Management. One of the major advantages of AG1000 is the data storage capacity of

upto 64GB which can be transferred to a remote server at pre-defined time intervals that

allows for built in data redundancy. Data for 64 devices recording 62 parameters each at 1 min

intervals can be stored for up to 5 years. The same data can be directly viewed and can also can

22 UM/SWHM/V3/0115

be pushed to the cloud with the built in web server software, enabling the user to collect and

monitor the system without the system without geographical boundaries. Communication

channels of RS485, Ethernet, Wi-Fi, Zigbee and GPRS (2G & 3G) are available in the unit.

Key Features:

• Rugged construction meet harsh industrial environments

• Data reliability improved through redundancy

• Isolated communication channels for better safety and reliable operation

• Data can be pushed to the cloud server for integration with customer end applications

• Flexible installation can be configured to match the customer requirements

• Remotely monitoring- generate alarms in case of any error

• Signal strength notification for easy installation and maintenance

• Compact construction –Din rail and wall mountable

Communication channels available in AG1000:

• RS485 with Isolated wired

• Ethernet wired

• Wi-Fi wireless

• Bluetooth Wireless

• Zigbee Wireless

• GPRS (2G & 3G) wireless

4.5. PREPAID FUNCTIONS

• Advanced collection of revenue before electrical power consumption.

• Charging the meter with credit revenue through multiple options (Smart card or Wired or

GSM/GPRS).

• The loaded revenue decrements based on the rate of electricity at that time (Currency/unit),

which may change from time to time.

• Provides visible and audible alarm to the user when the credit balance falls to a particular value

at the meter as well as at the remote display unit (Optional).

• Secured transactions, bill and report generation.

• The implementation of prepayment accounting functions can be separated into credit and

charge functions. The credit functions include:

1. Token credit function

2. Emergency credit function

Two types of charge functions are implemented:

1. Consumption-based tariff charges

2. Time-based auxiliary charges

23 UM/SWHM/V3/0115

Token credit function:

Token Credit function deals with managing credit registers according to credit token transfer.

When credit transfer is accepted, the values of “Available Credit Register” and “Total Purchase

Register” are increased for the amount credit transferred.

Emergency credit function:

Emergency credit function is used in situations when “Available Credit Register Value” approaches

or goes under zero. For this purpose, three parameter objects are implemented:

1. Emergency Credit Initial Limit

2. Emergency Credit Limit

3. Emergency Credit Threshold

“Emergency Credit Initial Limit” is used once after meter installation for the purpose of enabling

the customer to make the first buy (or transferring the first credit from the management centre).

It defines the credit value which is available when emergency credit is first selected by the

customer.

“Emergency Credit Limit” defines the credit value which is available after the value of “Available

Credit Register” reaches zero and the customer selects the emergency credit.

“Emergency Credit Threshold” defines the positive value of “Available Credit Register” at which

the meter begins to notify the customer that the credit will expire. When the value of “Available

Credit Register” falls below the value of “Emergency Credit Threshold”, the meter starts

notification.

5. FEATURES OF PREPAID METER

5.1. COMMON FEATURES

• User friendly, compact wall mounting design

• Dual source measurements up to 80A whole current/CT operated

• Currency based recharging for EB, DG, Gas and Water (Up to 4), pricing can be programmed

independently

• No separate EB and DG recharging

• Displays and communicates balance, VLL, VLN, A, F, W, PF, VA, KWh EB and DG, Gas and Water

input pulse

• Tripping of EB or DG consumption at pre-determined set point for protection and effective use

of energy

• Current Limiting facility for DG/EB separately

• History of recharge

• Protect your equipment against overload/over voltage/harmonics

24 UM/SWHM/V3/0115

• Selection of DG powers either 3phase or single phase programmable at site- replaces ACCL &

minimize wiring complexity

• Over voltage protection at 285v default (programmable at site)

• Display blinks in the frequent interval to indicate low balance

• EB to DG to EB changeover through 240V AMF / RS485 communication

• For DG phase wise (R or Y or b or RYB or No DG)

• EB over consumption limit

• Programmable Time delay

• 4DI (except RF) / 2DI

• Programmable alarm value to blink the display

5.2. OPTIONAL FEATURES

• Optional RTC

• Monthly (on programmable day)/Weekly (on day of the week) /Daily (on time) deduction

programmable

• 14 programmable holidays

• 2 programmable Weekend holidays (can be programmed to any 2 days or 1day)

• Happy Hours (can be programmed to any time of the day)

• Service provider can Force off and on the load

• Emergency credit to take of residence / occupants even with zero balance

• Programmable 4 slab based on the tariff

• Programmable 2 TOD based on the time (slab programmable independently)

6. TECHNICAL SPECIFICATIONS

The following table gives the Technical Specifications of the prepaid single phase meters PE5121 /

Three phase energy meter PE5120.

Parameter

Range

Connection

Single Phase,2 wir

e, PE5121 / Three phase, 4wire,

PE5120

Accuracy

Class 1 (Default) IEC 61036, CBIP 88

Sensing / Measurement

True RMS, 1 Sec update time, 2 Quadrant Power &

Energy

Voltage

Burden

External Fuse Rating

80-

240V Phase to Neutral

5VA Max.

60A

Current

Basic

Current I

b

= 10A

Maximum Current I

max

= 60A

25 UM/SWHM/V3/0115

Frequency

50Hz ± 5 %

Pulse Constant

1000 pulses/Kwh

Display Resolution

1 Rows, 6 digits (10mm height)

Operating Temperature

-

10o C to +55

o

C (14

o

F -

131o F)

Storage Temperature

-

25o C to +70

o

C (-13o F -

158o F)

Humidity

5% to 95% non condensing

Communication

RS 485 serial channel connection Industry standard

Modbus RTU protocol

Baud rate

2400 bps to 19200 bps (preferred 9600 bps)

Isolation

2000 volts AC isolation for 1 minute between

communication and other circuits

Gas/Water input option

Factory configurable Digital input with Maximum

Frequency 3Hz for up to 4 channel or Analog Input

4-20mA or 0-20mA for 2 channel programmable at

field or 1-10DC voltage

Weight (appox.) unpacked

670 gms for PE5121 /

1650 for PE5120

Shipping(packed)

750 gms for PE5121 / 1750 for PE5120

Dimensions(mm)

160 × 112 mm (Depth 58mm behind bezel)

The following table gives the Technical Specifications of the Prepaid Three phase meters (PE5120) CT

operated meter.

Parameter

Range

Connection

3 Phase,4 wire, PE5120 CT operated

Accuracy

Class 1 (Default) IEC 61036, CBIP 88

Sensing / Measurement

True RMS, 1 Sec update time, 2 Quadrant Power & Energy

Input voltage (Measurement)

4 voltage inputs(VR,VY,VB,VN)

Programmable 110 or 415VLL Nominal(Range 80 to 550VLL),

Primary Programmable up to 999kV

Burden

External Fuse Rating

0.2VA Max. per phase

2A

Input Current(Measurement)

Current Inputs (AR,AY,AB) 50mA

-

6A(Field programmable 1A or

5A) , Primary Programmable up to 99kA for CT operated one.

Overload

Burden

10VA Max. Continuous, 50A max. for 3 sec.

0.5VA Max. per phase

CT PT Ratio Max

2000MVA programmable

Display Resolution

1 Rows, 6 digits (10mm height)

26 UM/SWHM/V3/0115

Humidity

5% to 95% non condensing

Operating Temperature

-10o C to +55

o

C (14

o

F -

131o F)

Storage Temperature

-25o C to +70

o

C (-13o F -

158o F)

Communication

RS 485 serial channel connection, Industry standard. Modbus

RTU protocol.

Baud rate

2400 bps to 19200 bps (preferred 9600 bps)

Isolation

2000 volts AC isolation f

or 1 minute between communication

and other circuits

Gas/Water input option

Factory configurable Digital input with Maximum Frequency

3Hz for up to 4 channel or Analog Input 4-20mA or 0-20mA for

2 channel programmable at field or 1-10DC voltage

Weight

3 phase: Unpacked

-

1650 gms, Packed 1850gms

Dimension Bezel

173 × 262 mm (Depth 82mm behind bezel)

7. COMMUNICATION

7.1. COMMUNICATION OPTIONS

7.1.1. RS485

The RS-485 bus standard is one of the most widely used physical layer bus designs in

industrial applications. The key features of RS-485 that make it ideal for use in industrial

communications and the applications are

• Bi directional communication in the single pair of twisted cables

• Multiple Driver can be connected to the same bus

• Differential communication makes it work for long distance upto 3000 feets or

approximately 900 meters (depending on the cable and environment)

7.1.2. SMARTCARD

A smart card, chip card, or integrated circuit card (ICC) is any pocket-sized card with

embedded integrated circuits.

The benefits of smart cards are directly related to the volume of information and applications

that are programmed for use on a card. A single contact/contactless smart card can be

programmed with multiple banking credentials, medical entitlement, driver’s license/public

transport entitlement, loyalty programs and club memberships to name just a few. Multifactor and proximity authentication can and has been embedded into smart cards to increase

the security of all services on the card.

27 UM/SWHM/V3/0115

Commercial Applications:

The smart card’s portability and ability to be updated make it a technology well suited for

connecting the virtual and physical worlds, as well as multi-partner card programs.

• Banking/payment

• Loyalty and promotions

• Access control

• Stored value

• Identification

• Ticketing

• Parking and toll collection

7.1.3. GSM/GPRS

GSM (Global System for Mobile communications) is an open, digital cellular technology used

for transmitting mobile voice and data services. GSM supports voice calls and data transfer

speeds of up to 9.6 kbps, together with the transmission of SMS (Short Message Service).

GPRS stands for General Packet Radio Service and is a second generation (2G) and third

generation (3G)--or sometimes referred to as in-between both generations, 2.5G--wireless

data service that extends GSM data capabilities for Internet access, multimedia messaging

services, and early mobile Internet applications via the wireless application protocol (WAP),

as well as other wireless data services.

GPRS was one of the earliest cell phone data access technologies

GPRS is the most widely supported packet-data wireless technology in the world. Like GSM,

GPRS supports international roaming so customers can access data services whether they are

at home or abroad. When users travel to areas that have not yet been upgraded to GPRS,

they still can access many data services via circuit-switched GSM.

Features and benefits of GSM/GPRS Modem

• Designed for use at energy meter

• The modem takes readings at scheduled intervals

• Stored data is transfer in fast mode on request from central station

• SMS to predefined mobile numbers for anomalous events of meter

• Flexibility to enable reading of any type of electronic meters (pre-configured)

• Suitable for HT and LT metering installations

• Modem with built-in wide range power supply

• Sealing provision

• Suitable for wall mounting

• Connection types

o Single meter

o Multiple meters (Secure make) via optional multiplexer interface

• Meter connectivity through

o Optical communication port

o Serial RS232 communication port

o Serial RS485 communication port (for Secure make meters)

28 UM/SWHM/V3/0115

• IP 51 compliant

• Multiple LEDs for Status indication

• SIM card holder (sliding with sealing provision)

GSM/GPRS Specification:

• Works with global Quad band. Can be used with any GSM operators

• GPRS class B mobile station

• Compliant with GSM phase 2/2- class 4 (2W @850/900 MHZ, class1

(1W@1800/1900MHZ))

7.1.4. WI-FI

Wi-Fi is a local area wireless technology that allows an electronic device to exchange data or

connect to the internet using 2.4 GHz UHF and 5 GHz SHF radio waves. These can connect to

a network resource such as the Internet via a wireless network access point. Such an access

point (or hotspot) has a range of about 20 meters (66 feet) indoors and a greater range

outdoors. Hotspot coverage can comprise an area as small as a single room with walls that

block radio waves, or as large as many square kilometers achieved by using multiple

overlapping access points.

Features and benefits of WI-FI

•

Enable staff to carry portable Wi-Fi handsets giving them the ability to work

anywhere, anytime.

•

Using Wi-

Fi enables PDA’s and Laptops to deliver quick and easy access to information

•

Eliminate cellular usage charge.

•

Eliminate cabling and wiring for PC’s

•

Eliminate switches, adapters, plugs, pins, and connectors.

•

Secure networking using the latest secure networking protocols

•

Simplified management software.

•

Radio Frequency sweeping technology that disables rogue and ad hoc wireless devices

not relevant to the network

• Fast roaming and seamless data packet transfer

• Quality of Service or QO

7.1.5. REMOTE UNIT

A Remote Unit (RU) is a microprocessor-controlled electronic device that interfaces objects

in the physical world to a distributed control system by transmitting telemetry data to a

master system, and by using messages from the master supervisory system to control

connected objects.

29 UM/SWHM/V3/0115

Features:

• Elegant design

• Displays all parameters including balance

• No separate power is required

• 100 meter distance from the meter using CAT 5 cable

• Display blinks and buzzer on in the frequent interval to individual

• When idle state remote unit shows balance only

• Manual SET button for re-connection

Applications:

Remote monitoring of functions and instrumentation for:

• Oil and gas (offshore platforms, onshore oil wells)

• Networks of pump stations (wastewater collection, or for water supply)

• Environmental monitoring systems (pollution, air quality, emissions monitoring)

• Mine sites

• Air traffic equipment such as navigation aids (DVOR, DME, ILS and GP)

Remote monitoring and control of functions and instrumentation for:

• Hydro-graphic (water supply, reservoirs, sewerage systems)

• Electrical power transmission networks and associated equipment

• Natural gas networks and associated equipment

• Outdoor warning sirens

7.2. COMMUNICATION REGISTER MAP FOR PREPAID

METER

All the parameters declared in the communication map are float and follows the standard

Modbus RTU protocol. The data can be retrieved individually or together as a block.

Sl. No.

Parameter

Data type

Address

1 Watts Total

float 40101

2 Watts R phase

float 40103

3 Watts

Y phase

float 40105

4 Watts B phase

float 40107

5 Reserved, communicates zero

float 40109

6 Reserved, communicates zero

float 40111

7 Reserved, communicates zero

float 40113

8 Reserved, communicates zero

float 40115

9 PF Ave. (Instantaneous)

float 4

0117

10 PF R phase

float 40119

11 PF Y phase

float 40121

12 PF B phase

float 40123

30 UM/SWHM/V3/0115

13 VA total

float 40125

14 VA R phase

float 40127

15 VA Y phase

float 40129

16 VA B phase

float 40131

17 VLL average

float 40133

18 Vry phase

float 40135

19 Vyb ph

ase float 40137

20 Vbr phase

float 40139

21 VLN average

float 40141

22 V R phase

float 40143

23 V Y phase

float 40145

24 V B phase

float 40147

25 Current Total

float 40149

26 Current R phase

float 40151

27 Current Y phase

float 40153

28 Current B

phase

float 40155

29 Frequency

float 40157

30

Wh EB (if meters is manufactured for Wh), VAh

EB(if the meter is manufactured for VAh)

float 40159

31 Reserved, communicates zero

float 40161

32 Reserved, communicates zero

float 40161

33 Reserved, commu

nicates zero

float 40161

34

Wh DG (if meters is manufactured for Wh), VAh

DG(if the meter is manufactured for VAh)

float 40167

8. TROUBLESHOOTING

CAUTION

During reparation and maintenance, do not touch the meter connecting clamps directly with your

bare hands, with metal, blank wire or other material as you will have the chance of an electricity

shock and a possible chance for health damage.

Turn off and lock out all power supplying the energy meter and the equipment to which it is installed

before opening the protection cover to prevent the hazard of an electric shock.

WARNING

Maintenance or reparations should be performed by qualified personnel familiar with applicable

codes and regulations.

Use insulated tools to maintain or repair the meter.

Make sure the protection cover is in place after maintenance or repair

31 UM/SWHM/V3/0115

Due to programming error, site conditions, some problems can cause the Meter malfunction. The

fault symptoms and their remedial action for correction is given below.

If the display does not turn ON

• Check that there is at least 110 V available in power supply

• Check the link connected or not

Recharging not happening through RS 485

• Check the connectivity for RS485

• Check the meter ID correct or not

• Check the Elnet PPS selection correct or not

Recharging not happening through RF card.

• Check the RF card serial no and meter serial no is correct or not

• Check proper PPS select or not

• Check the RF card recharge properly

Display blinking

• Balance is below the limit

• Load off condition

• Check the balance is zero

• Check the over voltage occur

• Check the over KVA occur

If RS-485 communication does not work:

• Check that the baud rate of the host computer/PLC is the same as Meter

• Check that the device ID of the meter is unique and should not replicate

• Check all communications wiring is complete

• Check that the number of data bits is set to 8, with one stop bit and even parity

9. DISCLAIMER

Sufficient care is taken to provide all information regarding the product but ElMeasure does not

responsible the product which has been damaged due to improper installation, improper handling,

improper connections, neglect, misuse, accident, and abnormal conditions of operation and natural

calamities or acts of god.

Loading...

Loading...