1

Technical Support: +44(0)23 9269 6638 (option 3) PAK200574_01K May 2016 ©2016 ELMDENE INTERNATIONAL LTD

27.6 Vdc Switch Mode Power Supply for Fire – EN54-4:1997 +A1 +A2

STX2410-E Optional BATT-BOX-65

STX2410-H

F

EATURES

The STX2410-x is an EN54-4:1997 +A1 +A2 approved power supply ideal for use in Fire control

Systems. Its regulated 27.6V dc output will supply a total of 10 Amps continuous into the load, whilst

also enabling battery charging. (7.2 Amps Load with 65Ah batteries, 10 Amps with 18Ah batteries).The

power supply output features electronic short circuit protection under both mains and standby

battery operation. Maximum battery life is assured through continuous active battery monitoring and

the use of a three stage charger, comprising bulk, absorb and temperature compensated final float

phase depending upon battery condition. Once fully charged the product operates in Eco power

saving mode, whereby the batteries are charged for 4 hours in every 24 hour period while still being

continuously monitored. This reduces wasted energy in charging already fully charged batteries and

extends their working life. Deep discharge protection prevents premature battery failure when

operating from standby for extended periods. Two sets of volt free solid state relay fault output signal

(i) loss of mains and (ii) battery fault, charger fault and loss of output. In addition there is an RS232

serial interface that can provide diagnostic and fault reporting information to supervisory systems.

• Certified by UL to EN54-4:1997 +A1 +A2.

• Up to 10 A current to load at 27.6V dc nominal regulated output.

• Charging capability to support 18, 38 or 65Ah batteries with intelligent load enhancement.

• Electronic overload protection shuts down output until overload or short circuit is removed.

• Battery Monitor detects battery missing, low battery, short-circuit or reverse connection or

circuit impedance (Ri) in excess of 300mΩ caused by connector or wiring corrosion within

4hours..

• Battery charging circuit is energised only when a battery is correctly connected and the battery

voltage is greater than 14 V.

• No loss of output during automatic connection of battery to load on loss of mains.

• Deep discharge protection disconnects battery from load when battery voltage falls to 21 V.

• Fault indicator LED (Yellow) flashes on detection of output fault, battery fault, charger fault and

mains failure.

• Mains indicator LED (Green) showing mains present.

• RS232 serial interface for fault reporting and diagnostics interface to OEM equipment.

Elmdene International Ltd

Tel: +44(0)23 9269 6638

3 Keel Close, Interchange Park, Fax: +44(0)23 9266 0483

Portsmouth, Hampshire, PO3 5QD, UK

Web: www.elmdene.co.uk

0843-CPR-0216

14

2

Technical Support: +44(0)23 9269 6638 (option 3) PAK200574_01K May 2016 ©2016 ELMDENE INTERNATIONAL LTD

S

PECIFICATION

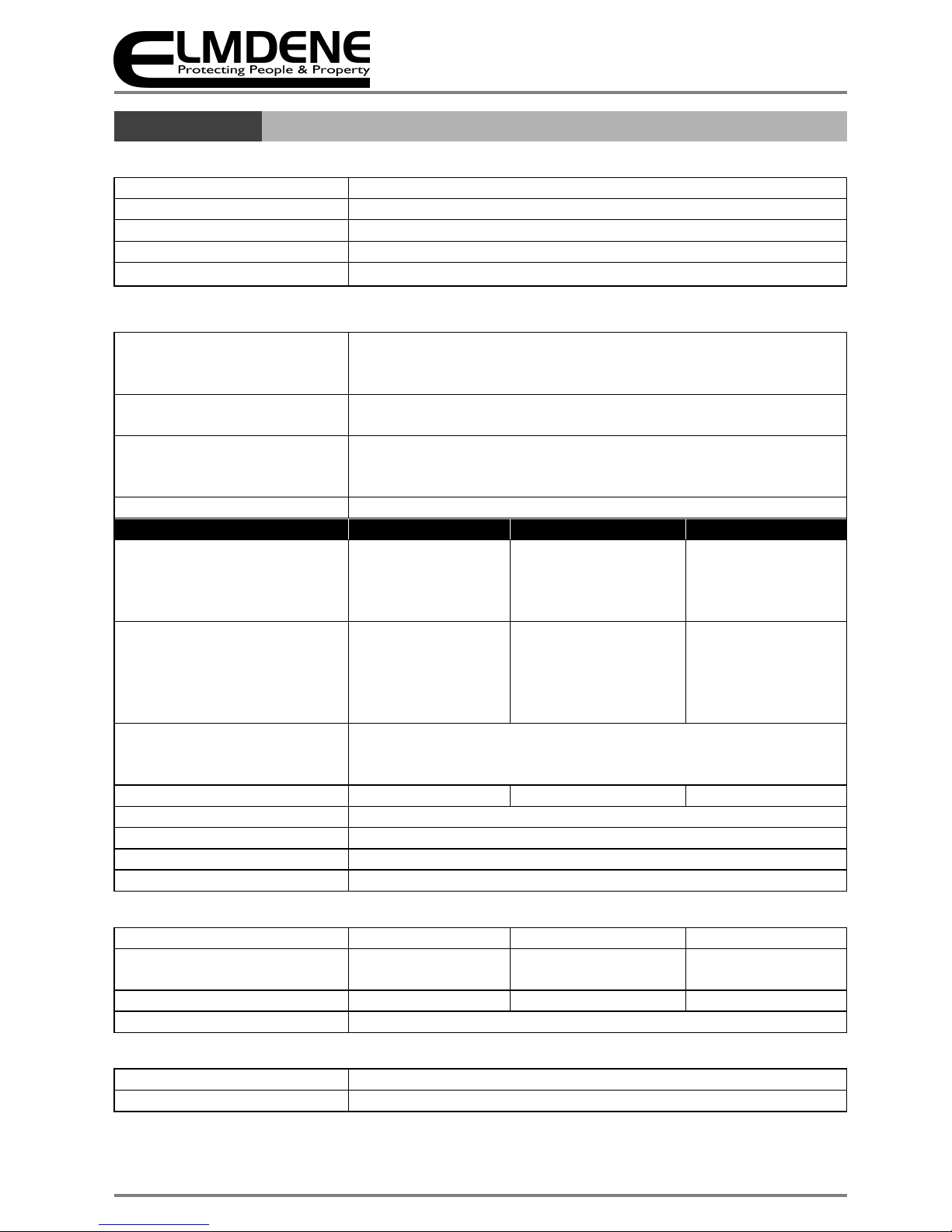

Mains Input

Rated Voltage

110 – 240V

ac

Frequency

50 Hz

I

nput current

<

4.0 Amps at full load

Inrush current

30

A Max at 25 °C 110V

ac for 10

ms

Fuse

T4.0 A, 20 mm, 250V

ac HRC

Output

Voltage at full load

Mains power

Battery standby

26.0 – 28.5 Vdc (range) (27.6 V nominal)

18 – 26.0 Vdc

Ripple

<100 mV pk

– pk max

@ Rated Voltage

Fuse

Load

Battery

F10.0 A

F10.0 A

Overload

Electronic shutdown at 15

A until overload or short circuit removed

Battery mode selected

17/

18 Ah

38 Ah

65 Ah

Continuous Output Current

No charging (Imax B)

With charging (Imax A) – 220V

With charging (Imax A) – 110V

10.0 A

10.0 A

8.5 A

10.0 A

8.0 A

7.5 A

10.0 A

7.2 A

6.5 A

Battery Capacity

eg

- PowerSonic model

- Yuasa model

- Interlogix model

2 x 17

/18

Ah 12 V

PS12170

NP17-12

BS131N

2 x 38 Ah 12 V

PS12380

NP38-12

2 x 65 Ah 12 V

PS12650

NP65-12

BS133N

Battery Charging

Constant current bulk charging to 80% capacity within 24 hours

Float charging to 100% within 48 hours

Eco charging and check every 2 hours – (for 20 minutes)

Constant current charge

0.7 A

1.6 A

2.6 A

Low battery thresho

ld voltage

23 V

Deep discharge protection

Threshold voltage

– 21 V

Quiescent current

– no load

30 mA

Quiescent current

– batt cut off

0 mA

Mechanical

Product

Reference

STX2410

-E

STX2410

-H

BATT

-

BOX-65

Enclosure Dimensions

w x h x d (mm)

400 x 420 x 80 420 x 420 x 180 450 x 535 x 245

Weight (kg)

excluding battery

6.4 9.7 12.9

Material

1.2mm steel white powder coated

Environmental

Temperature

– Operating

-10 to +40°C (operating) 75% RH non

-

condensing

Temperature

- Storage

-20 to +80°C (storage)

3

Technical Support: +44(0)23 9269 6638 (option 3) PAK200574_01K May 2016 ©2016 ELMDENE INTERNATIONAL LTD

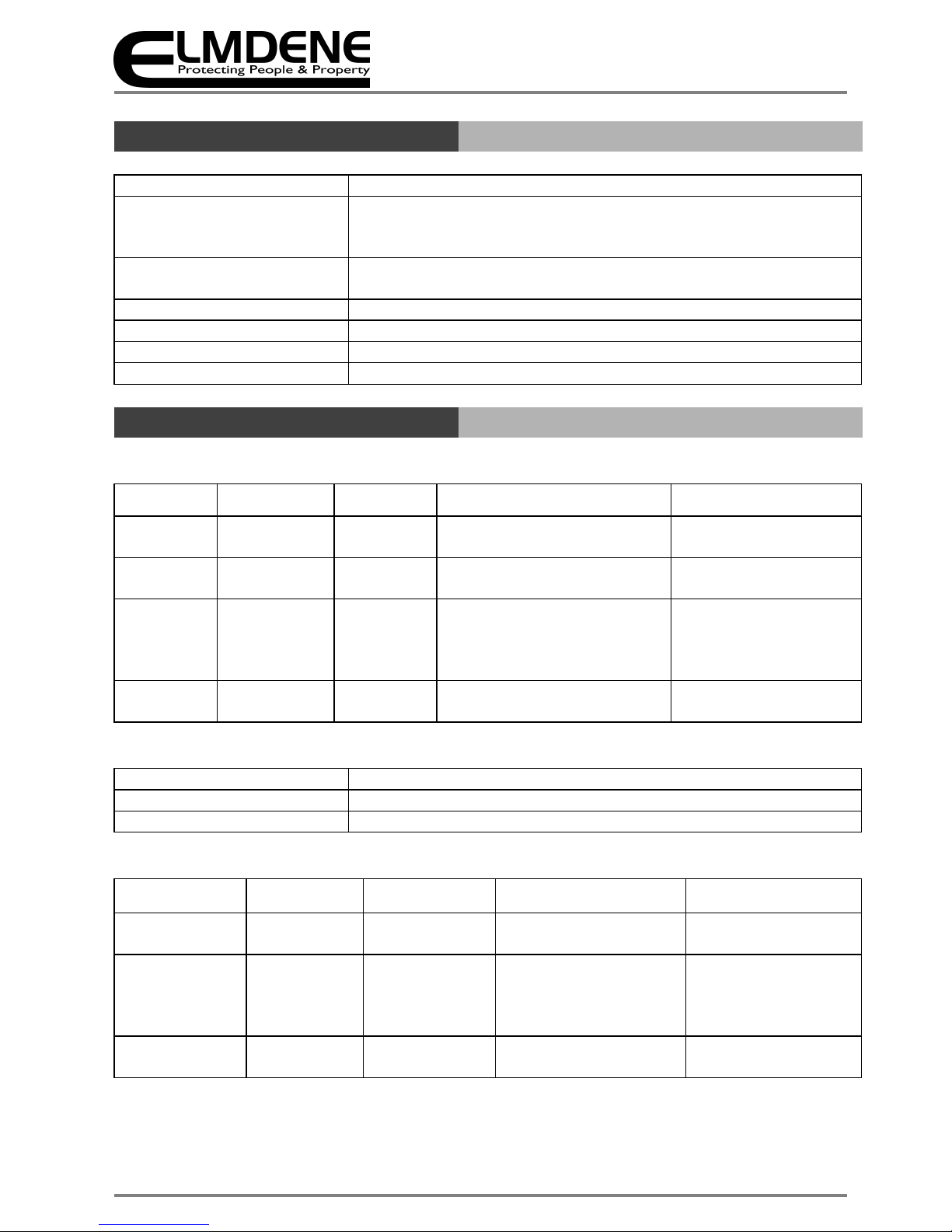

C

ONNECTIONS

Load Output ++ /

-- Screw terminals

Voltage output to load

GEN

PSU Fault

(normally

closed contact)

0.10 A @ 60

V

dc 16

Ω solid state relay contact

s, volt free

Open if Mains failed and battery voltage < 23V or fault PSU fault

condition, (see below)

EPS Fault (normally closed

contact)

0.10 A @ 60

V

dc 16

Ω solid state relay contacts, volt free

Open if loss of mains for > 10 seconds

Temperature sensor

Therm

istor input from supplied battery terminal

therm

istor.

BATT + /

- Connection to b

ack up battery using supplied battery lead

FAN +/

- Not used

RS232 serial interface

4

pin header

S

IGNALLING AND DIAGNOSTICS

Fault Outputs

EPS Fault GEN Fault Condition Possible Cause Action

C

LOSED

C

LOSED

Normal

operation

Mains present

Battery healthy

None

O

PEN

C

LOSED

Standby

Mode

Mains lost

Battery driving load

Investigate loss of mains

C

LOSED

O

PEN

Fault

Present

Blown fuses

Battery fault

Overload

Internal fault

Investigate fault source

using diagnostic LED

Rectify fault where

possible

O

PEN

O

PEN

PSU

Shutdown

Mains lost

Standby battery exhausted

Restore mains as soon

as possible

LED Indication

YELLOW

LED

Fault LED

GREEN LED

Mains supply On

DIAGNOSTICS

Diagnostic LED (Not visible through front panel)

Fault Diagnostic table – Front panel - User

Yellow LED

Fault

Green LED

Mains

Condition Possible Cause Action

OFF ON

Normal

operation

Mains present

Battery healthy

None

F

LASH

C

ONTINUOUS

ON or OFF Fault

Blown fuses

Battery fault

Overload

Internal fault

Contact service

engineer

1 P

ULSE

OFF Standby Mode

Mains lost

Battery driving load

Investigate loss of

mains

4

Technical Support: +44(0)23 9269 6638 (option 3) PAK200574_01K May 2016 ©2016 ELMDENE INTERNATIONAL LTD

Fault Diagnostic table – Internal - Engineer

Orange

LED

Diagnostic

Green LED

Mains

Condition Possible Cause Action

OFF

ON

Normal

operation

Mains present

Battery fully charged

None

OFF

Standby

Operation

Mains Lost. No faults present

Battery driving load

Investigate loss of mains

F

LASH

C

ONTINUOUS

ON or OFF No output

Output fuse blown

Output overload

Output short circuit

Check and replace

output fuse

Disconnect output load

and test load

1 P

ULSE

ON

Battery

Charging

No faults active

Battery charging normally

but

< 90% of full charge

None

2 P

ULSES

ON No Battery

Battery disconnected

Battery fuse blown

Battery heavily discharged

Check battery

connections

Check battery fuse

Check battery condition

Replace battery if aged

OFF

Low Battery

Volts

Standby Mode

Battery almost discharged

Restore mains

3 P

ULSES

ON or OFF Battery Fault

High impedance in battery

connection

Battery internal fault

Check battery

connections for

corrosion. Replace

battery if aged

4 P

ULSES

ON or OFF Charger Fault

Internal failure of battery

charger

Return to manufacturer

5 P

ULSES

ON or OFF

Battery

Temperature

Probe Fault

Battery temperature monitor

disconnected or damaged

PSU running in Safe Mode

Check temperature

sensor connections and

condition of sensor.

Replace if suspect

O

N

C

ONTINUOUS

ON or OFF Internal Fault

Software fault detected

PSU running in Safe Mode

Return to manufacturer

I

NSTALLATION

This unit is only suitable for installation as permanently connected equipment. The PSU is NOT SUITABLE for

external installation. This product (PSE) is designed for the use in automatic fire detection and fire alarm systems. If

it is used as power supply equipment for control and indicating equipment, the PSE shall be installed no further

than 10cm from the CIE, and close coupled by conduit.

This unit must be fed from a mains power source having a separate (approved) disconnect device and fitted with a

fuse or other over-current protection device rated at 5 A maximum. Ensure that the disconnect device used has

appropriate earth fault protection to the applicable standard.

Where the PSU is used to provide power to a fire alarm circuit, the mains isolation and disconnect device should be

provided solely for this purpose and be suitably marked “FIRE ALARM – DO NOT TURN OFF”. All cabling should meet

national and local fire system installation regulations, e.g. FP200 type cable for high integrity installations.

Where the PSU is used for other applications, it should be installed according to all relevant safety regulations

applicable to that application.

5

Technical Support: +44(0)23 9269 6638 (option 3) PAK200574_01K May 2016 ©2016 ELMDENE INTERNATIONAL LTD

Where the PSU Fault and EPS Fault outputs are used, they should only be connected to circuits having voltages less

than 60 Vdc.

Cable Sizing

1) Mains input cable must be to the applicable standard with a 5 A or greater current capacity, i.e. 0.75 mm2

nominal conductor area, having a minimum operating voltage of 300/500 Vac.

2) The low voltage output cable must be sized to carry the rated load current to the devices connected to the

PSU.

3) Mains input and low voltage output cables should be routed to use different entry / exit holes in the case.

Bushes should be used to protect cable sheaths from chafing. Ensure that these bushes are correctly sized

(i.e. close fitting with respect to cable sizing). Note that the bushes should meet a minimum flammability

specification of UL94 HB.

4) All cabling should be securely fastened in position using a cable tie through the saddles provided.

Mounting – E box – 17 or 18 Ah

5) The E box is designed to support two 17 or 18 Ah batteries and as such weighs a total of 19.5 Kg when

loaded. Ensure that wall fixings are appropriate to support this weight.

6) The product should be mounted no further than 10 cm from the control and indicating equipment, close

coupled by conduit if it is being used to power the CIE directly.

7) Fix to wall or other support structure in correct orientation i.e. with hinge on left hand side, using screws

of sufficient size and length through the mounting holes.

8) Protect the battery terminals from any metal surfaces during installation as shorting of the terminals is

extremely hazardous.

9) Knock-outs are provided in the case for mating with external trunking or conduit.

10) Ensure that all unused holes (on the rear of the case) are sealed to prevent the ingress of damp and dust.

Figure 1 – E Box and Battery mounting

Mounting – BATT- BOX – 65 Ah

11) The Battery box is used for 65 Ah batteries is designed to be floor mounted. DO NOT suspend from a wall.

12) It is important that the battery box and the PSU are co-located as shown, and connected using the

provided extended 3 metre cable.

13) A fixing bracket is provided to secure the Battery Box to the wall to prevent it moving away from the wall.

6

Technical Support: +44(0)23 9269 6638 (option 3) PAK200574_01K May 2016 ©2016 ELMDENE INTERNATIONAL LTD

Figure 2 – E Box and Battery box mounting

Mounting – H Box – 38 Ah

14) The H box is designed to handle and support two 38 Ah batteries and as such weighs a total of

approximately 40 Kg when loaded. Ensure that wall fixings are appropriate and designed to support this

weight.

15) The product should be mounted no further than 10 cm from the control and indicating equipment, close

coupled by conduit if it is being used to power the CIE directly.

16) Fix to wall or other structure in correct orientation i.e. with hinge on left hand side, using screws of

sufficient size and length through the mounting holes.

17) Protect the battery terminals from any metal surfaces during installation as shorting of the terminals is

extremely hazardous.

18) Knock-outs are provided in the case for mating with external trunking or conduit.

19) Ensure that all unused holes (on the rear of the case) are sealed to prevent the ingress of damp and dust.

Figure 3 – H Box and Battery box mounting

Floor

Spacing

Spacing shall be greater

than 20 mm and less

than 300 mm

Fit conduit

between

boxes

7

Technical Support: +44(0)23 9269 6638 (option 3) PAK200574_01K May 2016 ©2016 ELMDENE INTERNATIONAL LTD

C

OMMISSIONING

Mains Power Up

1) With no external connections made to the PSU, connect the mains input wires to the terminal block,

ensuring that the mains isolator (disconnect device) is open. Fasten wiring in place with cable tie to

saddle. Note: Equipment must be earthed.

2) Apply mains input. Ensure that the green Mains LED illuminates and that the yellow Fault LED flashes after

approximately 20s (indicating a disconnected battery).

3) Disconnect the mains power.

Load Output and Remote Signalling

4) Connect the EPS and PSU Fault outputs to the appropriate inputs of control equipment if remote fault

monitoring is required.

Figure 4 – Power, Load and Battery connections

5) Connect the load (output) wiring as shown in Figure 4. Cable tie to saddle provided (adjacent to exit hole).

6) Re-apply mains. Verify that the green Mains LED illuminates and the yellow Fault LED flashes after

approximately 20 s (disconnected battery).

7) If connected, verify that the EPS Fault monitor shows a closed contact and the PSU Fault monitor shows an

open contact.

8)

Perform a full functional test of system including full alarm condition

.

9) Disconnect the mains supply.

Figure 5 – Terminal labels

To Load

L E N

n/c |GEN| EPS|TMP|+ - | + + - | FAULT |Sens|Bat| O/P

L E N

AC in

BATTERY | DIAG| OUTPUT LOAD

FUSE | LED| FUSE

Main input

Fuse

8

Technical Support: +44(0)23 9269 6638 (option 3) PAK200574_01K May 2016 ©2016 ELMDENE INTERNATIONAL LTD

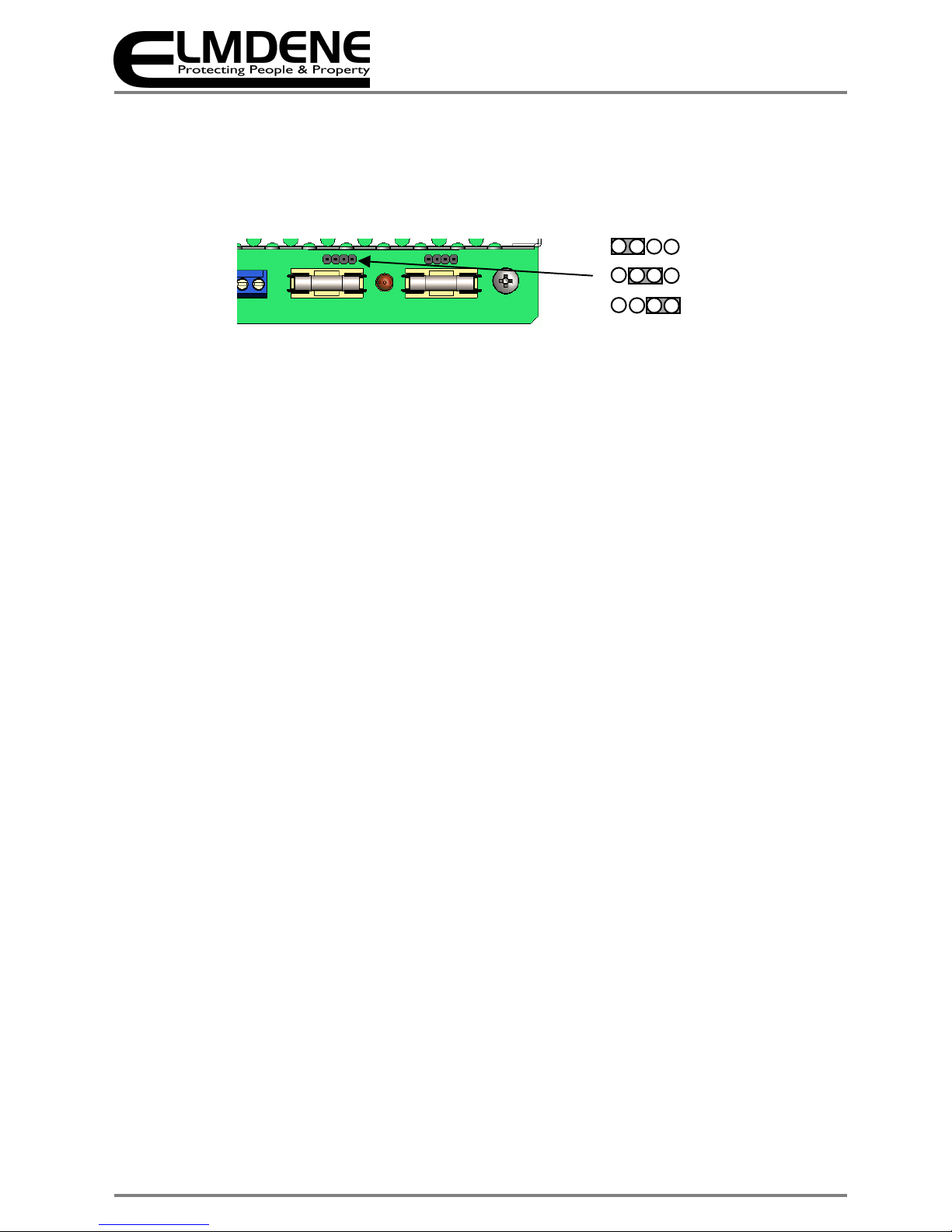

Standby Battery

10) Select the Battery type by placing the link (above the Battery fuse) in the appropriate location to

select (17/18 Ah, 38 Ah or 65 Ah) batteries. This changes the maximum bulk charge current, and

therefore enables higher load current to be used when smaller batteries are required. Put the link

on the left hand two pins for 17/18 Ah, the middle pins for 38 Ah and the right hand two pins for 65

Ah batteries.

Figure 6 – Standby battery size selection links

11) Mount the appropriate batteries as shown above. Where a dual box solution is used all cabling

between the two boxes should be routed to use separate case entry/exit holes from other cabling

and use suitable bushes to protect the cables.

12) Connect the two 12 V standby batteries in series using the single cable provided. Connect the

negative of one battery to the positive of the other. DO NOT CONNECT the other two battery

terminals to each other.

13) Connect the free Positive and Negative terminals of the batteries to the PCB terminals Batt+ and

Batt - using the cables provided. See Figures 4 & 5.

14) Connect the battery temperature sensor (two white wires) to the PCB terminals TMP Sens. See

Figure 5.

15) If the batteries are housed remotely, replace the battery lead assembly (including battery

temperature sensor) with an extended length assembly, provided with the Battery box (Ensure the

temperature sensor and battery connections are made according to figure 5.

16) Re-apply the mains power and verify that the yellow Fault LED stops flashing after about 20 s

(battery connection detected). Verify that the remote GEN PSU Fault monitor shows a closed

contact.

17) Disconnect the mains power. Verify that the green Mains LED extinguishes and the yellow Fault LED

starts to pulse (indicating that the PSU is running from its standby batteries).

18) If connected, verify that the EPS Fault monitor shows an open contact and the PSU Fault monitor

shows a closed contact.

19) Perform a full functional test of system including full alarm condition. Verify that the standby

batteries can support the system load. Note: ensure batteries have sufficient charge.

Final

20) Reconnect the mains. Verify that the green Mains LED illuminates and the yellow Fault LED

extinguishes.

21) If connected, verify that the EPS Fault monitor shows a closed contact and the GEN PSU Fault

monitor shows a closed contact.

22) Close cover and secure using fastening screws provided.

17/ 18 Ah

38 Ah

65 Ah

9

Technical Support: +44(0)23 9269 6638 (option 3) PAK200574_01K May 2016 ©2016 ELMDENE INTERNATIONAL LTD

O

PERATING INSTRUCTIONS

In the event of loss of mains, a battery fault or a GEN fault, the corresponding Fault signal contacts will open.

If the output of the PSU fails, the cause of the failure should be investigated e.g. short circuit load,

connection of a deeply discharged battery. The fault should be rectified before restoring power to the PSU. If

any of the fuses require replacing, ensure the correct fuse rating and type is used.

M

AINTENANCE

Maintenance

This unit is intended for use by Service Personnel only. There are NO USER SERVICEABLE parts inside.

There is no regular maintenance required of the PSU other than periodic testing, and replacement of the

standby battery. Reference should be made to the battery manufacturer's documentation to determine

typical/expected battery life with a view to periodic replacement of the battery.

D

IAGNOSTICS

Local Diagnostics

Green LED On = Mains Present

Yellow LED Fault Diagnostics according to table:

Yellow LED

(fault)

Green LED

(mains)

Status

OFF ON Normal: Battery fully charged

One short flash

every second

ON Normal: Battery charging but not fully charged

Flashing:

1second On

1 second Off

ON

Fault:

Output fuse or battery fuse blown, or

battery missing

OFF Fault: No mains, output fuse blown

One short flash

every 3 seconds

OFF Fault: No mains, battery supplying load.

OFF OFF

Fault:

No mains

, No output

, Batteries

disconnected or completely discharged

10

Technical Support: +44(0)23 9269 6638 (option 3) PAK200574_01K May 2016 ©2016 ELMDENE INTERNATIONAL LTD

C

OMPLIANCE

This power supply unit meets the essential requirements of the following EU Directives:

CPR: 305/2011 EU EMC: 2014/30/EU Low Voltage: 2014/35/EU WEEE: 2012/19/EU RoHS2: 2011/65/EU

Functional standard: EN54-4:1997 +A1 +A2

Environmental Class II

Certification Body: Underwriters Laboratory

Declaration of Performance DOP2014/08

DOP2014/09

D

ISPOSAL OF PRODUCT AT END OF LIFE

This product falls within the scope of EU Directives 2012/19/EU Waste Electrical and Electronic Equipment

(WEEE) and 2013/56/EU (Battery). At the end of life, the product must be separated from the domestic

waste stream and disposed via an appropriate approved WEEE disposal route in accordance with all national

and local regulations.

Before disposal of the product, any batteries must be removed, and disposed separately via an appropriate

approved battery disposal route in accordance with all national and local regulations. Package used batteries

safely for onward transport to your supplier, collection point or disposal facility.

Caution: Risk of fire or explosion

if bare battery wires are allowed to touch.

See Specification for battery type information. The battery is marked with the crossed out wheelie bin

symbol, which may include lettering to indicate cadmium (Cd), lead (Pb), or mercury (Hg).

For more information see: www.recyclethis.info

The packaging supplied with this product may be recycled.

Please dispose of packaging accordingly.

0843

Elmdene International Ltd 3 Keel

Close Portsmouth PO35QD

14

0843-CPR-0216

EN54-4:1991997 +A1 +A2

Power Supplies intended for use in

fire detection and fire alarm

Loading...

Loading...