Ellis 6000 Instruction Manual

1-800-383-5547 • EllisSaw.com

EllisSaw.com

1-800-383-5547

P.O. Box 930219 • Verona, WI 53593-0219

GENERAL OPERATING & SAFETY INSTRUCTIONS

* READ INSTRUCTIONS BEFORE USE *

CAUTION: Disconnect power supply cord from power source when doing repair work or changing belt.

To avoid personal injury: Always wear safety glasses or a face shield.

Always wear gloves and protective clothing.

Wear a dust mask or respirator as required.

Wear hearing protection as required.

UNPACKING AND SETUP

First, check machine over for any shipping damage. After the

belt grinder is uncrated, remove any tapes, straps or packing

material from the grinder. A light weight hand truck can be

used to move it around the shop. The motor end should be toward the operator as the grinder is tipped back onto the truck.

SAFETY PRECAUTIONS, FEATURES &

OPERATING INSTRUCTIONS

1. When using the grinder, basic safety precautions should

always be followed to reduce risk of re, electrical shock

and personal injury. Read WARNING section!

2. Use caution, be alert and maintain a balanced stance at all

times while operating the Grinder. The abrasive belt rotates

at 5000 surface feet per minute (SFM) and will cause

serious injury if contacted directly.

3. The belt grinder is equipped with a red emergency stop button, Item 11 (E-Stop). Push the button

down to stop the grinder. To release it, turn the

button clockwise.

4. The grinder also has an On-O switch, Item

12. Pushing the green button starts

the grinder; pushing the red button stops it.

5. In case of a power outage during operation,

the grinder will not restart when the power

returns. The green button has to be pushed.

6. Always keep children away.

Caution: Once the grinder has been turned o , the belt will still

be in motion until it stops on its own.

START-UP

1. Plug power cord into 115V AC 60 HZ single phase power

receptacle.

2. Check to see that the red emergency stop button is in the

upright position, otherwise turn it clockwise.

3. Check the belt alignment by turning the grinder on and

o quickly. Watch to see that the belt is centered on the

contact wheel. If not, read the next section:

“Belt Tension, Alignment and Adjustment.”

Note: Possible damage could occur to the belt and grinder if

the belt tracks o center.

Visit our website, EllisSaw.com, for

video instruction and more information

2

or contact Ellis for a DVD.

E-Stop

EllisSaw.com

1-800-383-5547

BELT TENSION, ALIGNMENT & ADJUSTMENT

1. The sliding tube assembly, Item 18, must be fully extended

to provide the correct belt tension. Lock the belt release

hand wheel rmly to maintain proper belt tracking.

2. If the belt is tracking o the contact wheel toward the

right, turn the belt alignment knob, Item 17, clockwise

slowly until the belt tracks directly over the contact wheel.

3. If the belt tracks o toward the left, the belt alignment

knob should be turned slowly counter-clockwise to bring

the belt back in alignment.

Note:

When making belt alignment adjustments, the belt

should be in motion.

BELT CHANGE

1. Switch motor o and unplug the grinder. Wait until belt

has stopped moving.

2. Turn the belt release handle, Item 15, counter-clockwise

as you face the hand wheel to unlock the sliding tube assembly, Item 18.

3. Grasp the belt release lever, Item 16, and pull back as far as

the sliding tube assembly, Item 18, is allowed to go. Hold

lever and lock Item 18 in this position by retightening the

belt release hand wheel.

4. Grasp the lower right hand corner of the hinged side cover

and lift it up to rest on the hinge stop. Slide the belt o .

5. Check the new belt carefully. Do not use a belt with a

nicked or cut edge or with handling damage.

6. Use only a 2–1/2” wide belt. A wider or narrower belt could

cause damage to the contact wheel or the belt.

7. Look for an arrow marked on the inside surface of the new

belt. The contact wheel and drive wheel rotate in a counter

clockwise direction. Not all belts have an arrow, but if one

is marked on the belt, the arrow must point in the direction

the belt will be traveling. See Item 2 in the manual which

indicates the direction of the arrow. Center the new belt on

the contact wheel and drive wheel.

8. Close the cover.

9. Hold the belt release lever to keep the sliding tube assembly, Item 18, from jumping forward while releasing it with

the release hand wheel. Allow Item 18 to move forward

as far as it will go. Lock it in position with the release hand

wheel.

10. Check the belt alignment as described in the “Start-up”

section.

WARNING

• Use the grinder in a well ventilated area. The dust

created when grinding some materials can be

harmful. Dust masks are strongly recommended to

minimize dust inhalation.

• Sparks from the grinder could ignite ammable

materials and fumes. Keep these materials at a

safe distance from the grinder.

• Do not remove cover and guards on the machine

while doing grinding operations.

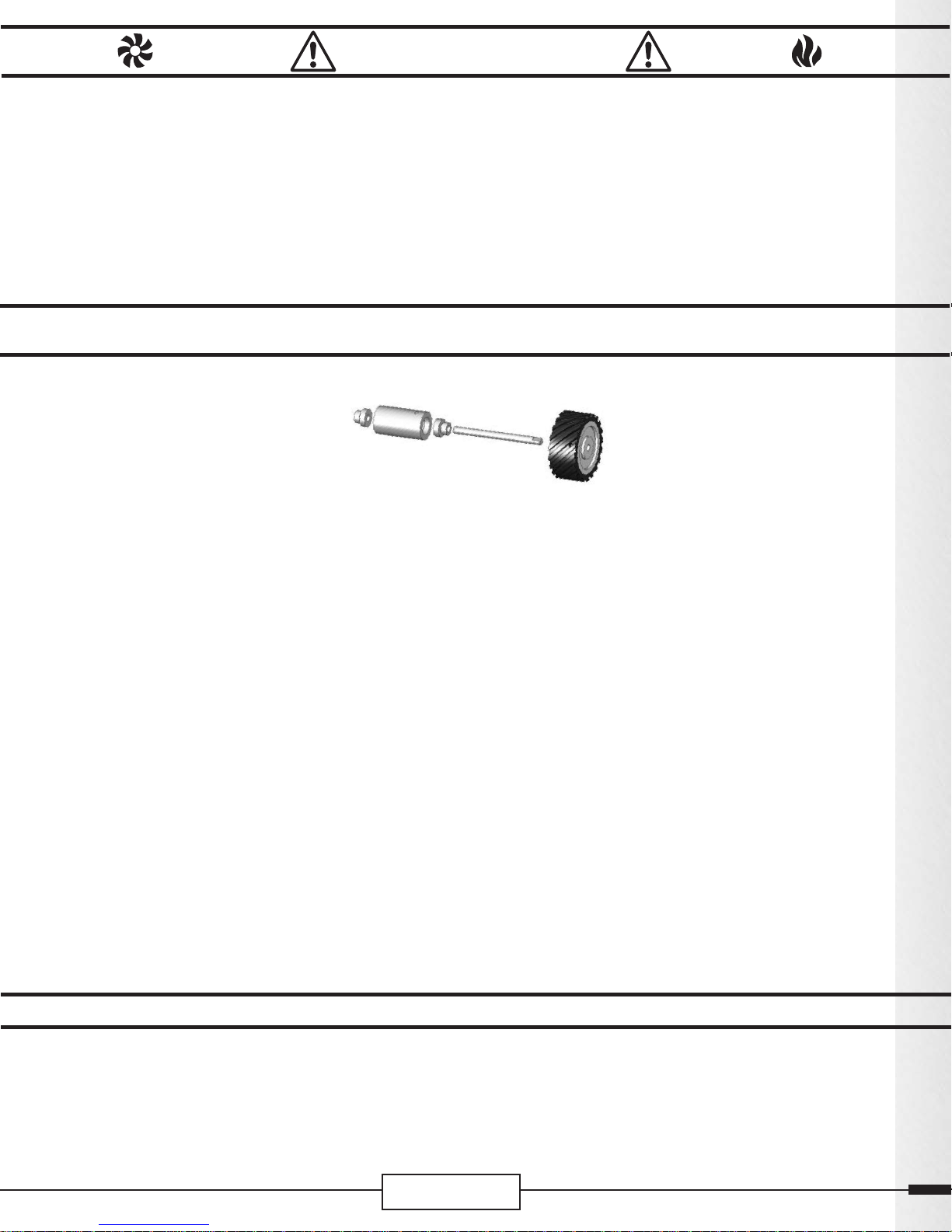

Contact Wheel, Spindle and Bearing Replacement

1. To remove the bearings, rst remove the

contact wheel, Item 26, by loosening

the set screw with a 5/32 inch hex

key wrench. Refer to the parts catalog

illustration.

2. Next remove the socket head cap screw

and the adapter hex bolt, Items 19 & 21, and the

lock washers, Item 20, that secure Item 22 to Item 18.

Use a 5/16 inch hex key wrench. Set these aside for reassembly.

3. Slide the bearing housing assembly out and place on a

work bench.

4. Loosen the set screw on each bearing collar, using a 1/8

inch hex key wrench.

5. Slide the spindle out of the bearing housing. You may

need to twist the collars and tap gently on the end of

the spindle.

6. Remove the old bearings with a punch or similar tool.

Tap the bearing out from the opposite end.

7. When replacing the new bearings use an arbor press or

tap the bearing into the housing with a hammer. Take

care not to damage the bearing. Press or tap only on the

outer ring of the bearing.

8. Slide the spindle into the bearings so that the end at the

rear of the housing is going to be ush with the bearing

collar. If the spindle does not t, remove the burrs on

the spindle with a ne le.

9. Place the collars over the spindle and bearings. Rotate

each collar individually on its bearing in the direction

GRINDING TECHNIQUES

• Check that the drive and contact wheels are running true and are free of damage. Worn or damaged parts should be replaced immediately.

• Check a new belt for nicks or cuts along its edge.

Do not use if damage is evident.

• Use extreme caution when grinding magnesium.

Magnesium dust can ignite. Have a bucket of sand

close by to extinguish a re.

that the belt turns. That is, a counter-clockwise

rotation as you face the contact wheel end

of the spindle. Tighten the set screw us-

ing a 1/8 inch hex key wrench. Then

use a center punch and place it in the

countersunk hole on the collar. Tap

the punch lightly with a hammer so the

collar is “set” in the counter-clockwise motion. Repeat

with the other collar.

10. Replace the bearing housing assembly, Item 22.

a. Place the bearing housing assembly, Item 22,

into the Sliding Tube Assembly, Item 18, and line

up the threaded holes on Item 22 with the holes

in Item 18.

b. Place a lock washer, Item 20, over an adapter hex

bolt, Item 19. Insert the bolt, Item 19, into the

top hole in Item 18. Start the bolt into Item 22,

but only to depth of 1 or 2 threads. Repeat this

procedure for the bottom hole.

c. Turn the top bolt and bottom screw (Items 19

& 20), alternately, equal turns, until the lock

washers are compressed solid. Item 22 should be

centered within Item 18.

11. Replace contact wheel

Place contact wheel, Item 26, on the spindle with the

set screw side on the outside. Tighten the set screw

on the contact wheel hub, using a 5/16 inch hex

wrench.

Hand Held Grinding

All grinding should be done below the centerline of the

contact wheel because it will be easier to hold the work and

minimize chatter. Present the workpiece to the contact wheel

in an upward motion to improve cutting and to draw the

hands away from the abrasive belt.

EllisSaw.com

1-800-383-5547

Platen Grinding

The platen is designed for grinding at surfaces using light

pressure.

Tool Grinding

Use the tool rest, part # 7075, for accurate grinding such as

drill bits, chisels, etc.

3

Loading...

Loading...