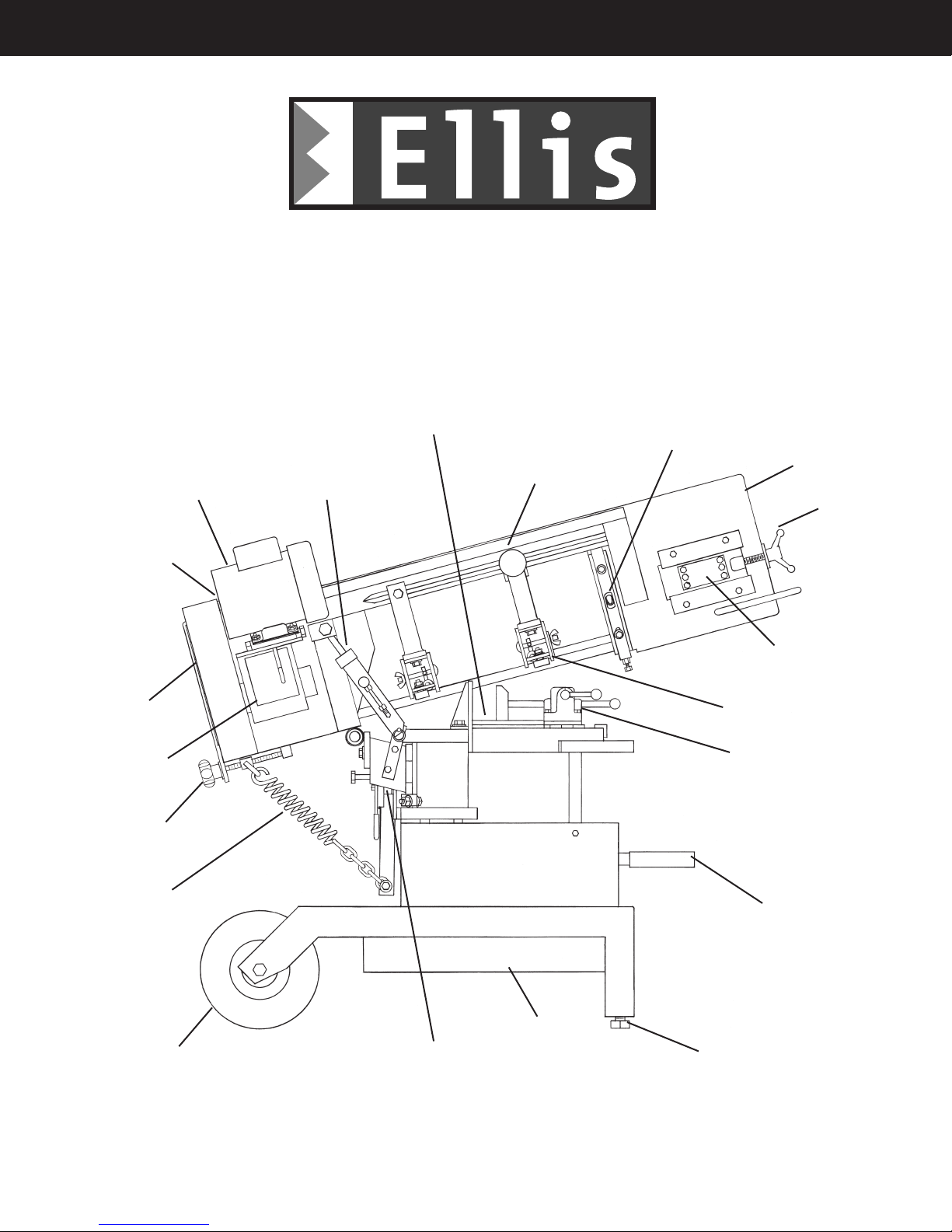

Motor

Drive Wheel

End

PARTS C ATALOG 2H

M

FG

. C

OMPANY

, I

NC

.

Mitre Band Saw

Installation and Operating Instructions

Note: Not all saw parts are shown in this booklet

Replaceable Aluminum Saw Table

Automatic Shut-Off Switch

Hydraulic Feed

Control

Moveable Guide Arm

Idler Wheel End

T-Handle

Blade Tension

Adjustment

Pulley Box

Speed

Reducer

Head Weight

Adjustment

Compensating

Spring Assembly

Cart Wheel

Bearing Carrier Assembly

Idler Spindle

Adjusting Plate

Blade Guide

Assembly-Idler

Vise

Telescoping Handle

with Grip

Chip Tray

Adjustable Legs

107 W. Railroad Street • P.O. Box 930219 • Verona, WI 53593-0219

Phone: (608) 845-6472 • Fax: (608) 845-5199 • www.ellissaw.com

1-800-383-5547

PARTS CATALOG

Page 2

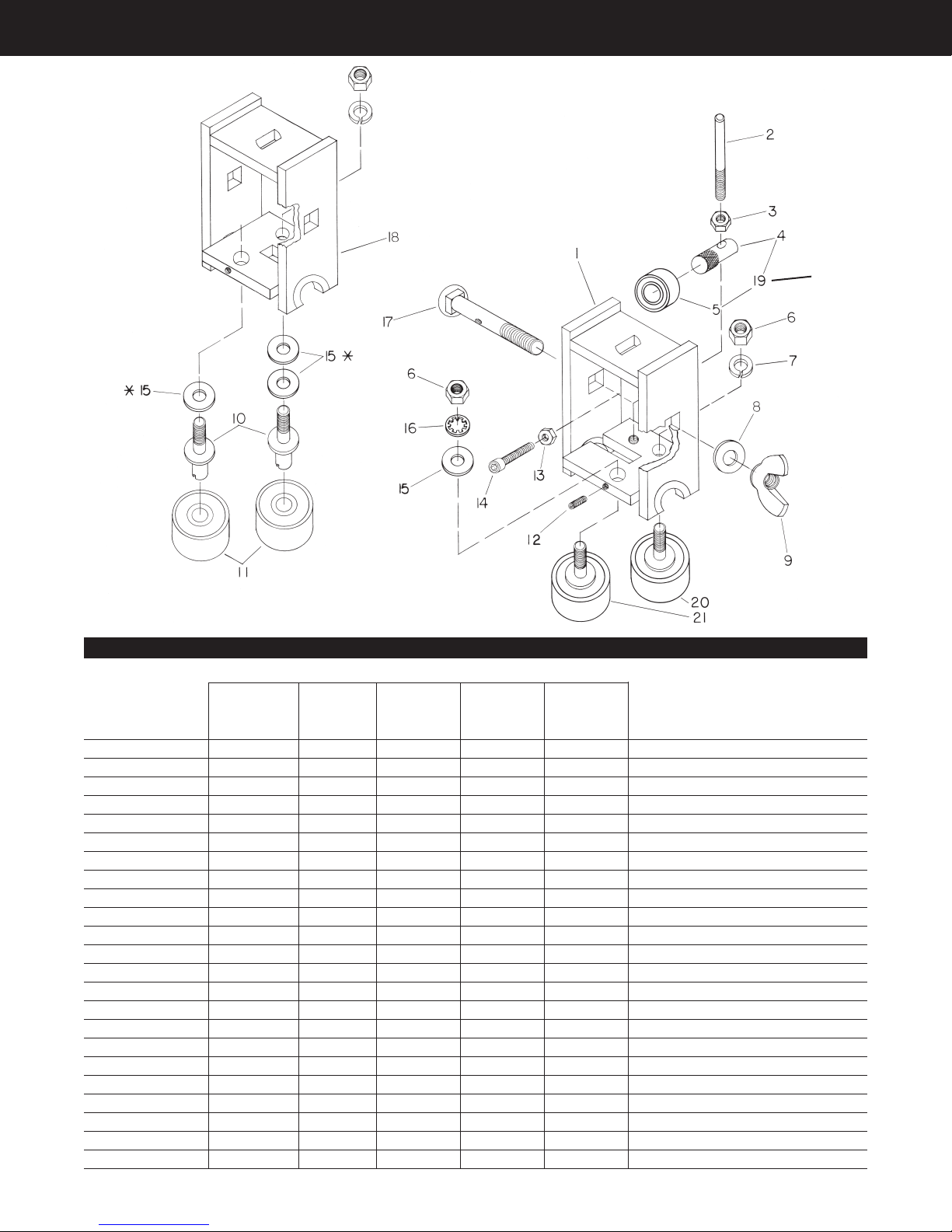

B LADE G UIDE

Complete

Assembly

Bearing Only

90H

Item No. Description

Complete Assy. 9016DC 5370 5539 5720 5732 Blade Guide Assembly, Drive End

Complete Assy. 9016IC 5371 5519 5721 5733 Blade Guide Assembly, Idler End

1 9016I 5391 5588 5588 5981 Housing Assembly, Idler

2 5541 5541 5541 5541 5541 Adjustment Stud, Bearing Plate

3 4260 4260 4260 4260 4260 1/4-20 Hex. Nut

4 6066 6066 6066 6066 5999 Spindle, Pressure Bearing

5 4499 4499 4499 4499 4522 Ball Bearing, Pressure

6 4260 4260 4266 4266 4279 Nut, Hex.

7 4336 4336 4337 4337 4343 Lock Washer, Spring

8 4310 4310 4310 4310 4311 Flat Washer, SAE

9 4271 4271 4271 4271 4270 Wing Nut or Stop Nut

10 5389 5389 5587 6074 6073 Spindle, Guide Bearing

11 4522 4522 4502 4502 4515 Ball Bearing, Guide

12 4140 4140 4140 4140 8-32 x 3/8 Set Screw

13 4258 4258 4258 4258 4260 Hex. Nut

14 4155 4155 4155 4155 4137 Socket Head Cap Screw

15 4304 Flat Washer, 3/16 or 1/4 Std.

16 4355 4355 4356 4356 4343 Lock Washer

17 5374 5374 5542 5542 6056 Guide Clamping Bolt

18 9016D 5390 5540 5540 5982 Housing Assembly, Drive

19 9012 9012 9012 9012 5996 Pressure Bearing Assembly

20 5406 5406 6730 6742 6747 Stationary Guide Bearing Kit

21 5407 5407 6732 6743 6747 Adjustable Guide Bearing Kit

*On all saws, except for the Model 4000, the stationary and adjustable kits are the same except for items 6, 16, and 15 which are included with

the adjustable kits. On the Model 4000 there is no adjustable kit. Therefore, use part number 6747 for both bearing kits on the Model 4000.

1100

Blade Guide Assembly

Part Number For Models

900

1000

1200

1440

1500

Complete

Assembly

1600

1800

2000

3000 4000

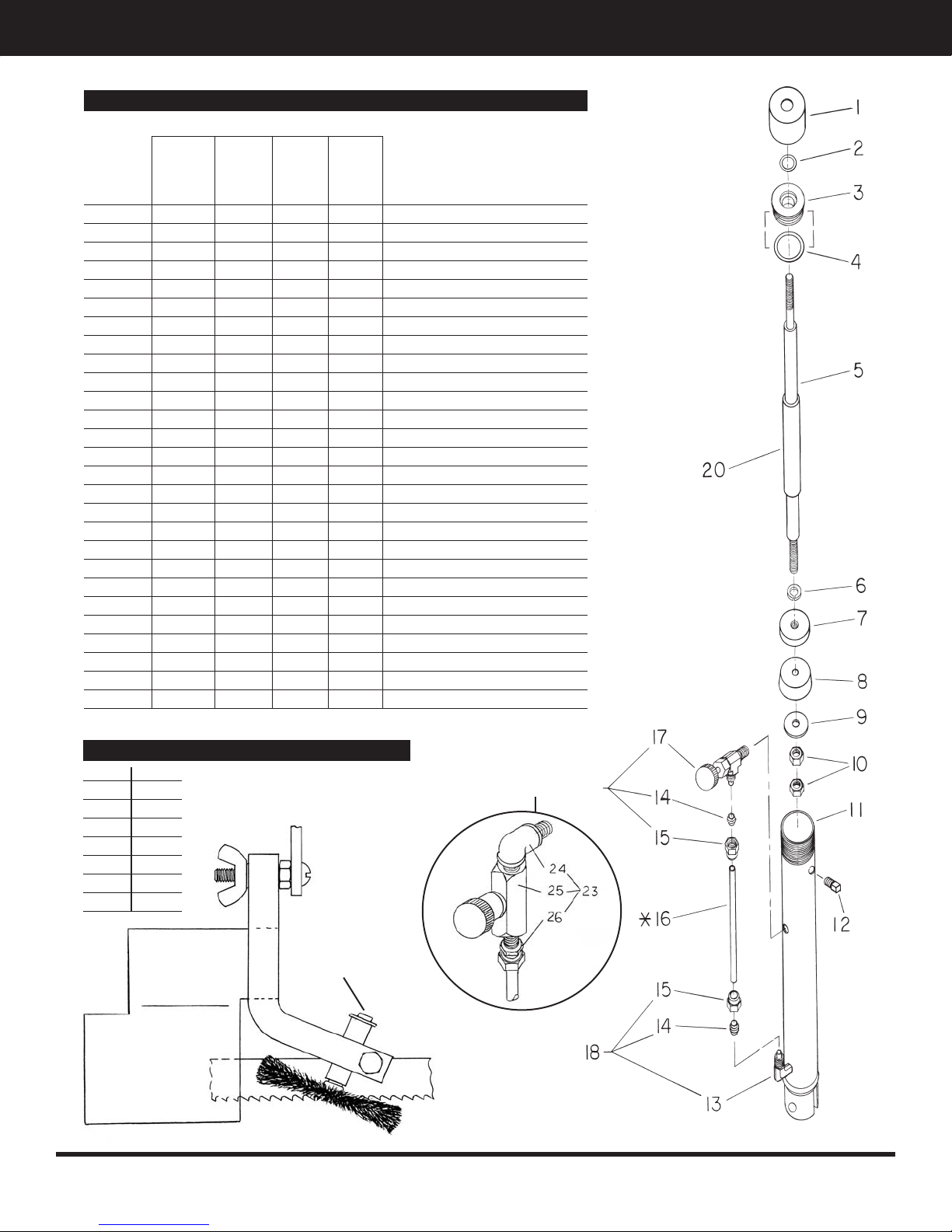

H YDRAULIC F EED C ONTROL

Hydraulic Feed Control Assembly

Part Number For Models

90H

900

1000

Item No. Description

Assy. 5355 5506 5708 5777 Hydraulic Feed Control Assembly

1 5529 5529 5529 5529 Cap

2 4950 4950 4950 4950 O-Ring-Shaft

3 5532 5532 5532 5532 Sealing Washer, Top

4 4951 4951 4951 4951 O-Ring-Cylinder

5 5361 5530 5530 5766 Shaft

6 4337 4337 4337 4337 Lock Washer, 5/16

7 5531 5531 5531 5531 Sealing Washer, Bottom

8 5533 5533 5533 5533 Leather Cup

9 5534 5534 5534 5534 Washer-Special

10 4266 4266 4266 4266 Nut, Hex. Jam, 5/16-24

11 5362 5528 5528 5767 Cylinder

12 4743 4743 4743 4743 Plug, Oil Fill

13 4730 4730 4730 4730 Male Elbow - Tube Fitting

14 4732 4732 4732 4732 Sleeve

15 4729 4729 4729 4729 Nut

16 5363 5590 5711 5706 Tube, 1/4 Dia. Plastic

17 4731 4731 Needle Valve-Tube Fitting

18 4728 4728 4728 4728 Male Elbow Assembly

19* 4727 4727 Needle Valve Assembly

20 5356 5749 5749 5748 Travel Stop Tube

21 6702 6702 6702 6702 Rebuilding Kit

22 5707 5707 Remote Needle Valve Assembly

23* 4808 4808 Flow Needle Valve Assembly

24 4735 4735 Elbow, Male to Male

25 4734 4734 Flow Needle Valve

26 4736 4736 Straight Fitting

*19 and 23 are interchangeable.

1100

1200

1500

1600

1800

1440

2000

3000

4000

Page 3

Saw Pivot Arm Assembly

1100 5393

1200 5393

1500 5685

1600 6350

1800 6366

2000 6350

3000 6366

4000 6366

Chip Brush Assembly

Part No. 5550

Ellis Mfg. Company, Inc. 107 W. Railroad Street • P.O. Box 930219 • Verona, WI 53593-0219

Phone: (608) 845-6472 • Fax: (608) 845-5199 • www.ellissaw.com

23 or 19

Page 4

1

Mitre Head Locking Handle

ALL MODEL SAWS

Item Part

No. No. Description

1 4966 Mitre Head Locking Handle

2 4311 Flat Washer

Press center button to reset ratchet in Handle

Idler Wheel and Bearing Assy.

With Vulcanized Rubber

Part Number For Models

90H

900

1000

1100

1200

5365 5788 5849 Idler Wheel & Bearing Assy.

1440

1500

1600

1800

2000

3000

4000

Description

2

Bearing Carrier Assembly

Part Number For Models

1100

Item

No. Description

90H

1000

1 4500 4510 4514 Carrier Guide, 4 Reqd.

2 4499 4522 4522 Thrust Ball Bearing, 2 Reqd.

1200

1500

1600

1800

2000

3000

4000

Drive Wheel With

Vulcanized Rubber

Part Number For Models

90H

900

1000

1100

1200

5367 5740 5775 Drive Wheel With Rubber

1440

1500

1600

1800

2000

3000

4000

Description

I NSTALLATION & OPERATION

CAUTION:

changing the blade or making any other repair or adjustment to the saw.

1. Visually inspect machine for hidden shipping damage.

2. As part of the receiving inspection, check for broken ball

bearings on the bearing carrier assembly. This is the assem-

IMPORTANT Model 2000, 3000 and 4000 owners note: The shut off rail was removed

for shipping. You must mount the rail on the machine table before using the saw.

Disconnect power supply cord from power source before

Installation Instructions

bly that the saw swivels on for miter cuts. CHECK ALL SIX

BEARINGS. Two are located in the groove under the

degree plate. See illustration on page 4.

Vertical Sawing Position

Page 5

NOTE: Model 1800 only – before raising the head on the

Model 1800, remove the head weight adjustment handwheel and install the 6021 T-Nut. Attach the threaded

vertical support bar (6022) tightly to the rear of the drive

housing. See the chart on page 8. Adjust, if needed, to

square blade with the vertical table.

1. Pull hydraulic pin at bottom of hydraulic. Disengage compensating spring assembly. Head is now free to raise to vertical position. Raise head up and over center. Hold head

and gently let it move up to vertical position. DON’T LET

THE HEAD DROP! See illustration on page 8, or video.

Removing and Replacing Blade

Call 1-800-383-5547 for experienced help in selecting the

proper saw blades for your application.

1. Disconnect power supply cord from power source.

2. Raise saw head assembly until blade clears the back of the

table. Close hydraulic valve to lock in position.

3. Open the covers of the idler and drive wheels.

4. Pivot the chip brush to horizontal position and lock in place.

5. Loosen blade tension T-handle sufficient to release the blade

around the wheels. Pull blade out of the blade guide bearings.

6. Brush chips from blade guide bearings and housings. Wipe

bearing surfaces clean. Check that all bearings are running free.

7. Check that the guide bearings are set correctly for the new

blade thickness. Use a feeler gauge that is one thousandth of

an inch thicker than the blade. This is the best method because

it does not rely on judgement.

A saw blade can also be used as a gauge, but it must be new.

After the blade has been installed and under proper tension,

check for proper spacing. Twist the blade at the idler and drive

wheel side of the respective guide bearing housings. There

should not be any noticeable motion of the blade on the other

side of the guide bearings. Reset the gap to correct fit.

8. Place the new blade over the idler and drive wheels with the

teeth facing toward you. The blade should run under the

guides. The teeth should point out toward you and the tips of

the teeth should point toward the motor end of the saw.

A fast check is to compare the blade (as you place it over the

idler wheel) with the decal on the top of the saw head. Check

to make sure the blade is on both orange wheels.

2. Slide the vertical saw table into the blade and against the

back of the horizontal table. Secure with the screwless vise

or C-clamps. Adjust the drive end of the blade guide assembly, if necessary, to provide support for that end of the vertical table.

3. Attach the vertical blade guard on the moveable guide arm

and secure with wing nut supplied.

4. Position moveable arm as close to work as possible.

9. By turning the T-Handle, apply tension to the blade until all

slack is removed from the blade or the blade is pulled in a

straight line across the top of the saw from wheel to wheel.

Grasp the blade on each side of the guides and twist the

blade. Push down on the teeth with your thumbs and roll the

back of the blade between the guide bearings. Proper tension

is 1-1/2 to 2 full turns (360) of the T-Handle.

10. Proper blade tension is reached by grasping the T-Handle and

applying one full turn (360) on the tension handle. You can

use the casting number on the handle as a reference point.

Reconnect the power supply. Turn the saw on for a couple of

revolutions to square the blade on the wheels. Turn the saw

off. Now put the second full turn of tension on the T-Handle.

Turn the saw on again for a few revolutions. Turn the saw

off. Check the tracking of the blade on the wheels. On saws

with a 9" wheel the blade runs centered on the wheels. On

saws with 12" and 14" wheels the teeth of the blade should

be sticking out past the edge of the wheel. The teeth should

not be on the rubber of the idler or drive wheels. If the blade

is not tracking properly then the idle wheel needs to be

adjusted. If you think the idle wheel needs to be adjusted, call

the factory at 1-800-383-5547 for assistance.

11. Check the blade tension by setting the guide housings about

8" apart then grasp the blade between the fingers and thumb

halfway between the guide housings. With a rotating or

twisting motion of the hand the blade should deflect no more

than 1/8".

A video is available showing the proper procedure for

removing and replacing blades, saw adjustments, troubleshooting and maintenance. If you did not receive a

video with this machine or would like another copy, call

the factory.

Page 6

I NSTALLATION & OPERATION

Troubleshooting Crooked Cuts

1. Check blade for worn or broken teeth and replace if needed.

2. Check to make sure that the number of teeth per inch on the

blade fit the application. As a rule, only 6 to 12 teeth should

be in contact with the workpiece.

3. Check the head pressure on the saw. The compensating

spring tension should be 8 pounds with the blade 1" above

the table, coming down with the hydraulic valve open.

4. Check the blade tension. Review the proper blade tension

procedure under “Removing and Replacing Blade” on page

5, item 10.

5. Check the space between bearings of both guide bearing

assemblies. It should be only .001" over the thickness of a

Saw Adjustments

(If above steps did not eliminate crooked cuts)

1. Squaring blade with back of saw table.

Raise the head up 1/8" and hold in place with the hydraulic

valve. Place a 6" square against the table back and move the

head until the blade is exactly 90 degrees from the table

back. Lock the head in position. Check that the POINTER

points to zero (0 degrees) on the degree plate. If the pointer

does not point to zero, bend the pointer so that it lines up to

0 degrees. The saw is now adjusted to cut from front to back

accurately at 90 degrees and at all angles.

2. Square blade with top of saw table.

Use a blade aligning tool of the “clip on” or magnetic type to

attach to the blade. Set a 6" square on the table top with the

blade vertical and touching the aligning tool. These test

new blade. As an example, a .033" feeler gauge would be

used to set the guides for a .032" thick blade.

6. Check the blade tracking on the idler and drive wheels.

9" solid wheels: blade in center of wheels

12" spoked wheels: 3/4" wide blade should have teeth

protruding from the side of the wheel about 1/8", and

the 1" wide blade about 1/4".

14" spoked wheels: 1" and 1-1/4" wide blades should

have teeth protruding 1/4" to 5/16" from side of wheel.

7. Check to make sure that the blade guide assemblies are not

too far apart. Set the idler blade guide closer to the work to

provide greater support for the blade.

measurements should be made with the tools kept as close as

possible to the guide bodies. If the blade is not square with

the table, the guide bearing plate needs to be adjusted to

bring the blade into alignment. See illustration of Blade

Guide Assembly on page 2.

First the wing nut, Item 9 in the illustration, must be loosened. Next, loosen nut, Item 13. The adjustment to the bearing plate is set using the cap screw, Item 14. If the adjustment requires that the cap screw be backed out, the adjustment stud, Item 2, must be manually pushed so it is in contact with the cap screw. When the blade is aligned parallel

with the square, tighten the wing nut to lock the bearing

plate in position. Hold the cap screw from turning and lock

nut, Item 13, against the guide clamping bolt.

The V-belt must be changed on the pulleys to change speeds.

For HIGH speed, place the belt in the largest pulley on the

motor shaft and the smallest on the reducer shaft.

Replacement of Hydraulic Oil

The hydraulic cylinder can be filled on the saw or in a bench

vise.

THE SHAFT MUST BE FULLY PUSHED IN BEFORE

STARTING TO FILL.

A good clean machine is easy to operate and promotes safety.

1. Keep areas clean by brushing chips from table grooves,

guide bodies, idler and drive wheels, pivot shaft hinge area

and turntable grooves.

2. Oilite bushings in pivot shaft should be oiled annually.

Blade Speeds

For MEDIUM speed, the middle pulley is used on both shafts.

For LOW speed, the smallest pulley on the motor shaft is used

with the largest on the reducer.

1. Remove pipe plug from near top of cylinder.

2. Fill with light weight hydraulic oil until oil flows back out of

hole. Replace pipe plug.

Maintenance

3. Check oil level in hydraulic. Proper level is at pipe plug hole.

4. Oil in wormgear should be checked every 90 days. FILL TO

PROPER LEVEL AT PLUG, BELOW THE BREATHER

VENT, using 80 to 140 weight gear oil.

Air Tube Between

Solenoid And

Air Nozzle

Power Cord To

Receptacle On

Band Saw

A IR C OOLING

Page 7

Saw Blade

Connect To

Shop Air

Air Cooling System

Part Number

For Voltage Rating

Item No. Description

Sys. 5922 5932 Air Cooling System-Complete

1 5925 5925 Valve and Nozzle Assembly

2 4730 4730 Elbow Fitting

3 4733 4733 Needle Valve

4 4744 4744 Nipple

5 5923 5923 Mounting Bar*

6 5924 5924 Nozzle Cap

7 4970 4970 Blow Gun

8 4969 4969 Air Hose Assembly

9 5903 5912 Solenoid Valve Assembly-Complete

10 5904 5913 Solenoid and Cord Assembly

11 5926 5926 Tubing, .25 OD, 5 Feet

12 4015 4015 Bolt, Hex. Head 5/16-18 x 1-1/4

120

230

Air Supply Tube

ENLARGEMENT

OF AIR NOZZLE

Only

* For saw Model 4000 use mounting bar 5928

A CCESSORIES

Page 8

Heavy Duty Support Stands

Saw Model Unit No. Roller Only Length Width Roller Dia. Height

3000 - 4000 6227 6198 5ft 20" 2.38" 24"

1800 - 2000 6228 6198 5ft. 20" 2.38" 22.5"

3000 - 4000 6225 6193 5ft. 12" 2.38" 24"

1800 - 2000 6229 6193 5ft. 12" 2.38" 22.5"

Clamping of Support

Under Saw Table

6252

Adjustable Gauge

With Micro Adjuster,

Support Stand,

2 Rollers

5750

2

Vertical Table

and Blade Guards

Order by Saw Model Number.

Table sold with blade guard.

Description/Item

Vertical Table #9374 ✔✔

Vertical Table #5661 ✔

Vertical Table #6040 ✔

Blade Guard #6041 ✔✔✔✔

T-Nut #6021* ✔

Vertical Support Bar #6022 ✔

* Replace Head Weight Adjustment Handwheel with 6021 T-Nut

6222

Part Number For Models

90H

900

1100

1200

1500

1

1600 1800

6200

Stock Support

6240

Second Roller

Stand Assembly

One Roller

Stock Support Stand

Description/Item

Stock Support Stand

with adjustable gauge and 6252

micro-adjuster – 2 rollers

Adjustable gauge and 6222 5750

micro-adjuster only

Roller only 6181 —

1-5/8" Dia. x 12" long

Micro-Adjustable

Gauge Detail

Part Number For Models

90H 1200

900 1500

1000 1600

1100 1800

2000

3000

4000

See Heavy Duty

Support Stands and/or

adjustable gauge with

micro-adjuster

Single Stock Stand

Description Part No.

Single Stock Stand 6185

Self Supporting Adjustable

Roller Only 6193

2" diameter x 12"

Loading...

Loading...