Elliott 445 Series, 445L1752-90, 445L1753-190, 445R1753-190, 445R1752-90 Operating And Maintenance Instructions Manual

445 Series Motors

Models 445L1753-190, 445R1753-190, 445L1752-90, 445R1752-90

Tube & Pipe Cleaners Tube Testers Tube Plugs Tube Removal Tube Installation

Operating and Maintenance Instructions

www.elliott-tool.com

This page intentionally left blank.

Table Of Contents

Introduction .......................................................................................................... 4

Safety Instructions ................................................................................................ 5

Operating Instructions .......................................................................................... 8

Maintenance Instructions ................................................................................... 11

Technical Specications ..................................................................................... 12

Technical Drawings ............................................................................................ 13

Warranty ............................................................................................................. 21

Introduction

Thank you for purchasing this Elliott product. More than 100 years of experience have been employed

in the design and manufacture of our products, representing the highest standard of quality, value and

durability. Elliott tools have proven themselves in thousands of hours of trouble free eld operation.

If this is your rst Elliott purchase, welcome to our company; our products are our ambassadors.

If this is a repeat purchase, you can rest assured that the same value you have received in the past

will continue with all of your purchases, now and in the future.

The Elliott Right Angle Rolling Motor has been designed for the following types of equipment:

Boilers - Firetube

Chillers

Heat Exchangers

Feedwater Heaters

Fin Fan Coolers

If you have any questions regarding this product, manual or operating instructions,

please contact Elliott for immediate service.

Elliott Tool Technologies, Ltd.

1760 Tuttle Avenue

Dayton OH 45403

United States

Phone: +1 (937) 253 6133

Phone: +1 (800) 332 0447

Fax: +1 (937) 253 9189

Email: sales@elliott-tool.com

Web: www.elliott-tool.com

4 Right Angle Rolling Motor

WARNING

Safety Instructions

WARNING

WARNING

WARNING

Read and save all instructions. Before use, be sure everyone that will operate this tool reads

and understands this manual, as well as any labels packaged with or attached to the tool.

Impact-resistant eye protection must be worn while

!

EYE HAZARD:

Wear protective

glasses.

!

NOISE HAZARD:

Wear approved ear

protection in this area.

operating or working near this tool.

For additional information on eye and face protection,

refer to Federal OSHA Regulations, 29 Code of Federal

Regulations, Section 1910.133., Eye and Face Protection

and American National Standards Institute, ANSI A87.1,

Occupational and Educational Eye and Face Protection.

Z87.1 is available from the American National Standards

Institute, Inc. 1430 Broadway, New York, NY 10018.

Personal hearing protection is recommended when

operating or working near this tool.

Hearing protectors are required in high noise areas,

85 dBA or greater. The operation of other tools and

equipment in the area substantially contribute to, and

increase the noise level in the area. For additional

information on hearing protection, refer to Federal

OSHA Regulations Section 1910.95, Occupational Noise

Exposure, and American National Standards Institute,

ANSI S12.6 Hearing Protectors.

Some individuals are susceptible to disorders of the

!

REPETITIVE MOTION:

Repetitive work

motions and/or

vibration can injure

hands and arms.

!

ENTANGLEMENT RISK:

Use minimum hand grip

force consistent with

proper control and safe

operation.

hands and arms when exposed to tasks, which involve

highly repetitive motions and/or vibration.

Those individuals predisposed to vasculatory or

circulatory problems may be particularly susceptible.

Cumulative trauma disorders such as carpal tunnel

syndrome and tendonitis can be caused or aggravated

by repetitions, forceful exertions of the hands and arms.

These disorders develop gradually over periods of weeks,

months and years.

Insure that the operator’s hand will not be wedged or

pinched between the work and the tool when operating.

Right Angle Rolling Motor 5

Safety Instructions (cont.)

CAUTION

CAUTION

• Always wear protective clothing, safety boots, gloves, dust mask, etc, when operating or in an

area where the equipment is being used. This prevents crushing, inhalation and skin exposure

hazards from the equipment and/or lubricant used in the equipment.

• These tools are designed to operate on 90 psi (6.2 bar) maximum air pressure. If the tool is

properly sized and applied, higher air pressure is unnecessary. Excessive air pressure increases

the loads and stresses on the tool parts, sockets, and fasteners and may result in breakage.

Installation of a lter-regulator-lubricator in the air supply line ahead of the tool is recommended.

Only use approved air lubrication.

• Before the tool is connected to the air supply, check the throttle for proper operation (i.e.,

throttle moves freely and returns to closed position). Clear the air hose of accumulated dust and

moisture.

• Be careful not to endanger adjacent personnel. Before removing a tool from service or changing

sockets, make sure the airline is shut off and drained of air. This will prevent the tool from

operating if the throttle is accidentally engaged.

• It is essential for safe operation for any operator of a rolling motor to use good balance, sure

footing, and proper posture in anticipation of a torque reaction. Insure that the operator’s hand

will not be wedged or pinched between the work and the tool when operating. Always use

ambient light to ensure safe operation.

!

When using right angle motors, be sure the throttle is positioned relative to the

right angle head so the throttle will not become wedged against an adjacent

object in the “ON” position due to torque reaction. The angle head may be

repositioned with respect to the lever (on tools with levers) to accommodate

proper location for task. If tool is to be reversed, locate throttle lever in a neutral position that will prevent entrapment. Refer to operating instructions for

additional information.

!

Tools with clutches can stall rather than shut-off if adjusted over maximum

power output of tool, or if there is a drop in air pressure. Operator must then

resist stall torque until throttle is released. ALWAYS use torque reaction bar.

• Higher torque right angle motors are supplied with splined torque reaction mounting plates

which accept torque reaction bars. These bars can be braced against the work, adjacent tubes,

or other suitable points to absorb and relieve the operator of the torque reaction transmitted

by the tool. Tool balance arms are also available to absorb the torque reaction transmitted by

the tool. Due to their squared design, the reaction mounting plates also prevent the motor from

rolling off the work station, preventing further injury. Tool balance arms are also available to

absorb the torque reaction of the tool for improved ergonomic applications if work is accessible.

6 Right Angle Rolling Motor

Safety Instructions (cont.)

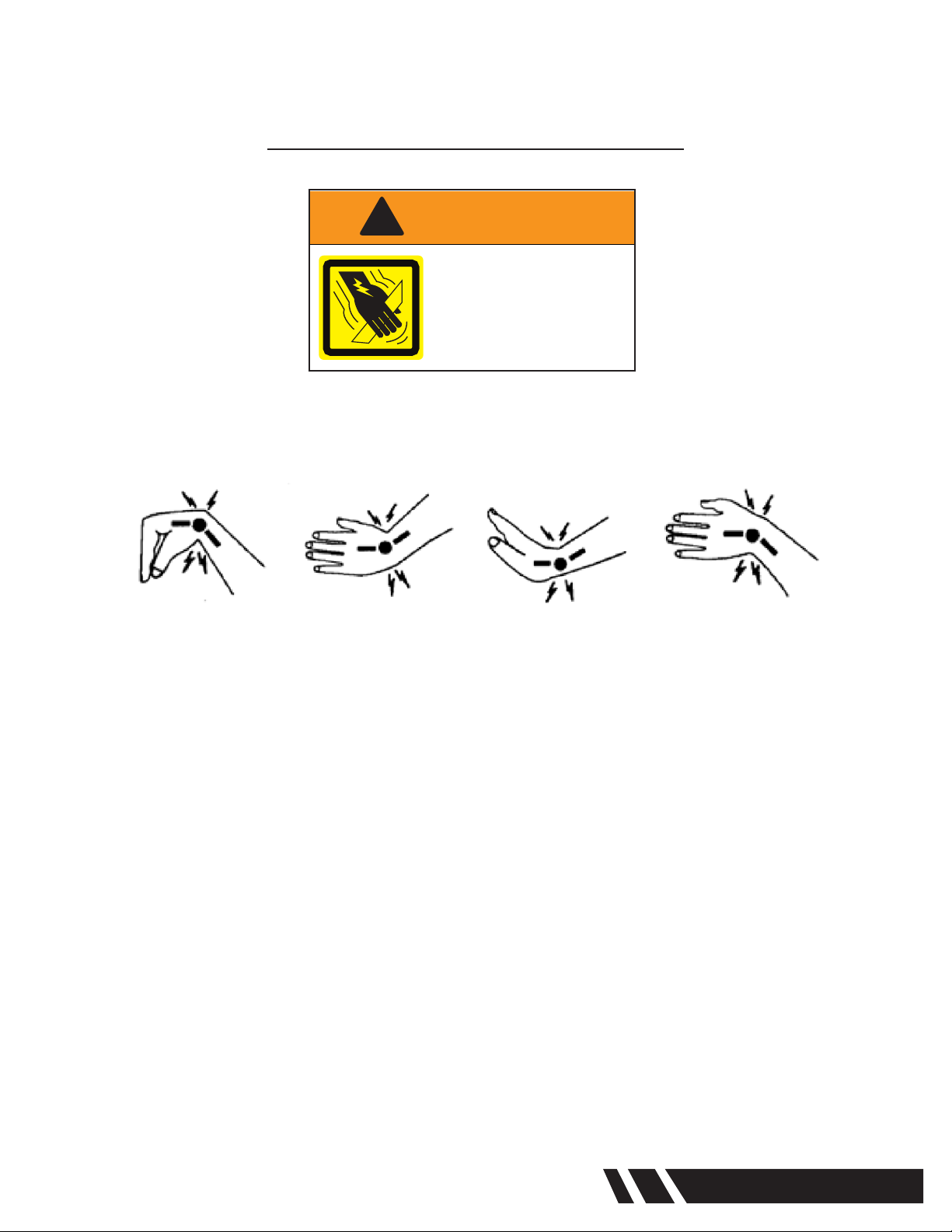

WARNING

!

REPETITIVE MOTION:

Repetitive work

motions and/or

vibration can injure

hands and arms.

Tasks should be performed in such a manner that the wrists are maintained in a neutral position, which

is not exed, hyperextended or turned side to side.

Stressful postures should be avoided and can be controlled through tool selection and work location.

Any user suffering from prolonged symptoms of tingling, numbness, blanching of ngers, clumsiness

or weakened grip, nocturnal pain in the hand, or any other disorder of the shoulders, arms, wrists or

ngers is advised to consult with a physician. If it is determined that the symptoms are job related

or aggravated by movements and postures dictated by the job design, it may be necessary for the

employer to take steps to prevent further occurrences. These steps might include, but are not limited

to, repositioning the workpiece or redesigning the workstation, reassigning workers to other jobs,

rotating jobs, altering work pace, and/or changing the type of tool used so as to minimize stress on the

operator. Some tasks may require more than one type of tool to obtain the optimum operator/tool/task

relationship.

The following recommendations will help reduce or moderate the effects of repetitive work motions

and/or extended vibration exposure:

1. Use a minimum handgrip force consistent with proper control and safe operation.

2. Keep wrists as straight as possible.

3. Keep body and hands warm and dry.

4. Avoid anything that inhibits blood circulation (smoking tobacco, cold temperatures,

certain drugs, etc.)

5. Avoid highly repetitive movements of hands and wrists and continuous vibration

exposure.

Right Angle Rolling Motor 7

Loading...

Loading...