Ellies FBIC3000VA/24V, FBIC3000VA/48V, FBIC5KV4880 User Manual

3000VA Inverter Charger

FBIC3000VA/24V & FBIC3000VA/48V User Manual

Please read this guide carefully before using this product

CONTENTS

Important Safety Instructions 1

1. General Information 1

2. Installation Instructions 4

3. Interface Instruction 7

4. Protection 14

5. Troubleshooting 14

6. Maintenance 15

7. Technical Specifications 16

Notes 17

Important Safety Instructions

Please reserve this manual for future review.

• Please reserve this manual for future review. This manual contains all instructions about safety, installation and

operation for the inverter/charger.

• Read carefully all the instructions and warnings in the manual before installation.

• Non-safety voltage exists inside the inverter/charger, users must not dismantle it by itself in order to avoid personal

injury, contact professional maintenance personnel of our company in need of maintenance.

• Keep the inverter/charger out the reach of children.

• Do not place the inverter/charger in a damp, oily, inflammable and explosive or a severe environment with a large amount

of dust accumulation.

• The utility input and AC outp

ventilated places, it’s shell may produce heat during operation.

• It is suggested to install appropriate external fuses/breakers.

• Make sure switching o all connections with PV array and the fuse/breakers close to battery before inverter/charger

installation and adjustment.

• Make sure all connections remain tight to avoid excessive heat from a loose connection.

• It’s an o-grid inverter/charger, not for on-grid system.

• This inverter/charger can only be used singly, parallel or in series connections will damage the devices.

ut with high voltage, don’t touch wire connections. Install the inverter/charger in well

1. General Information

1.1 Overview

The UPower series is a new type of the inverter/charger combining with solar & utility charging and AC output, which adopts

a multi-core processor design and advanced MPPT control algorithm,

reliability and high industrialization standard. It oers four charging modes including Solar priority, Utility priority, Solar and

Utility & Solar; two output modes for Battery and Utility, meeting the various application demands.

The up-to-date optimized MPPT tracking technology is adopted for the PV charging modules. It can quickly track the

maximum power point of the PV array in any environment and acquire the maximum energy of solar panel in real time;

The advanced control algorithm is adopted for AC-DC charging modules that realize fully digitalized double closed-loop

control for voltage

DC charging voltage/current is continuously adjustable in a certain range, and the complete input/output protection

functions can oer stable and reliable charging and protection for the battery.

The DC-AC inverter modules are based on full digital and intelligent design. It adopts the advanced SPWM technology,

outputs the pure sine wave and converts 24/48VDC to 220/230VAC suitable for AC loads of household appliances, electric

tools, commercial units, electronic audio and video devices etc.

The product adopts 4.2 inch LCD display design, which real-time displays the operational data and running state of the

system. The comprehensive electronic protection function guarantees more safe and more stable operation of the system.

and current, with high control precision, small volume. The input range of AC voltage is wide, the output

and has the features of high response speed, high

Features

• Adoption of the advanced SPWM technology, with pure sine wave output.

• Fully digitalized voltage and current double closed-loop control.

• Advanced MPPT technology, with eciency no less than 99.5%.

• Four charging mode: Solar priority, utility priority, utility & solar and solar only.

• Two OUTPUT mode: Battery and utility.

• LCD design that enables dynamic display of system running data and operating state.

• Provided with common interface and advanced interface.

• Multiple LED indicators that instantly indicate the operating state of the system.

• 2P circuit breaker provided at the utility input end.

• Independent control of AC output by AC OUT button.

• Battery temperature compensation function.

• Extensive electronic protection.

1.2 Characteristics

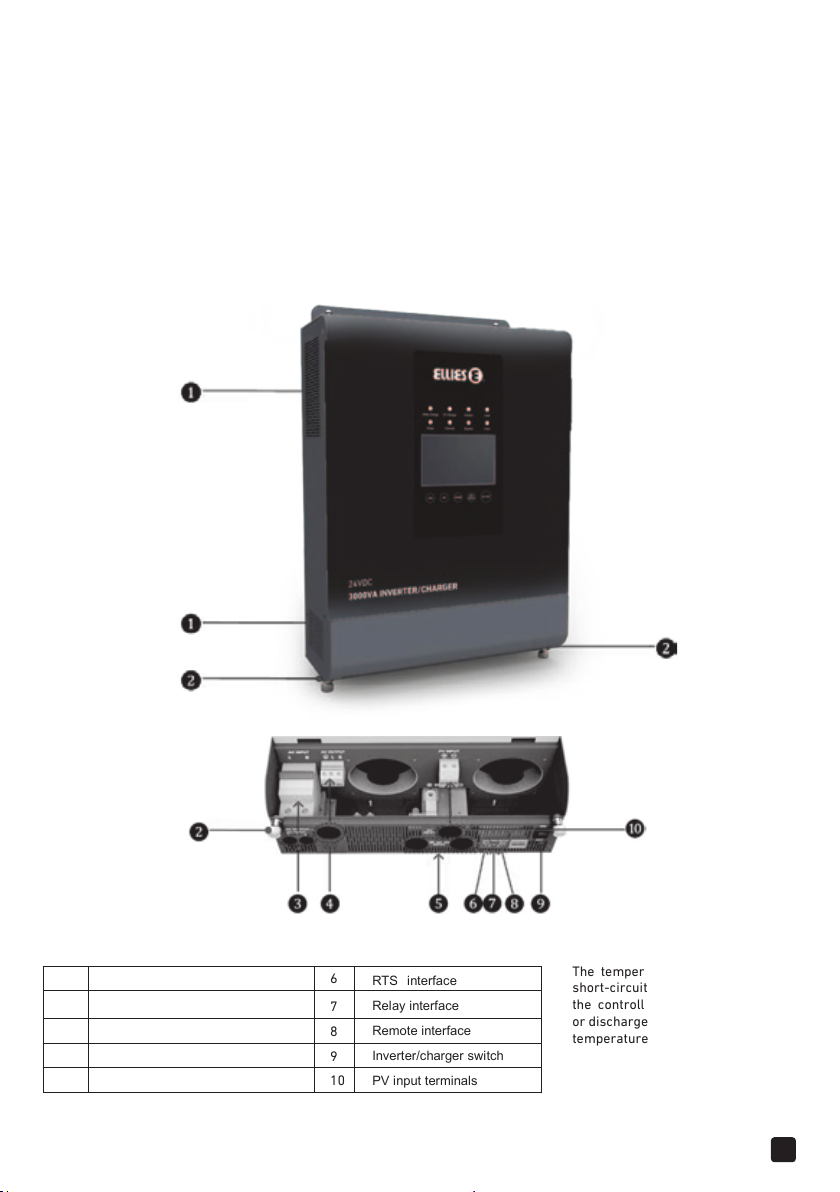

Figure 1 Product appearance

1

Ventilation RTS

Captive screw (2 pcs) Relay interface

2

AC output terminals Remote interface

3

Utility input terminals Inverter/charger switch

4

Battery input terminals PV input terminals

5

6

7

8

9

10

interface

The temperature sensor

short-circuited or damaged,

the controller will be charged

or discharged at the default

temperature 25 ºC.

2

1.4 Schematic Diagram for Connections

Warning:Confirm the AC load power compatible with the power of the

inverter/charger, AC load selected exceeding the maximum output power

of inverter/charger is prohibited.

3

2. Installation Instructions

2.1 General Installation Notes

• Please read the entire installation instructions to get familiar with the installation steps before installation.

• Be very careful when installing the batteries, especially flooded lead-acid battery. Please wear eye protection, and have

fresh water available to wash and clean if any contact with battery acid

• Keep the battery away from any metal objects, which may cause short circuit of the battery.

• Explosive acid battery gases may come out from the battery during charging, so make sure ventilation condition is good.

• Ventilation is highly recommended if mounted in an enclosure. Never install the controller in a sealed enclosure with

flooded batteries! Battery fumes from vented batteries will corrode and destroy the controller circuits.

• Lead-acid battery is only recommended, other kinds please refer to the battery manufacturer.

• Loose connections and corroded wires may result in high heat that can melt wire insulation, burn surrounding materials,

or even cause fire. Ensure tight connections and use cable clamps to secure cables and prevent them from swaying in

motion.

• Battery connection may be wired to one battery or a bank of batteries. The following instructions refer to a singular

battery, but it is implied that the battery connection can be made to either one battery or a group of batteries in a battery

bank.

• Select the system cables according to 5A/mm2 or less current density in accordance with Article 690 of the National

Electrical Code, NFPA 70.

• For outdoor installation, keep out of the direct sunshine and rain infiltration.

• High voltage still exists inside the inverter/charger after switching o the power switch, do not turn on or touch the

internal units, conduct the associated operation only after discharging the electric capacity.

• Do not place the inverter/charger in a damp, oily, inflammable and explosive or a severe environment with a large amount

of dust accumulation.

• Prohibit reverse connection at DC input end otherwise it may damage the equipment or unpredictable danger will occur.

The utility input and AC output are of high voltage, do not touch the wire connetion.

2.2 Wire Size & Breaker

The wiring and installation methods must follow all national and local electrical code requirements.

Recommended wire and circuit breaker of PV

Model PV wire size

FBIC3000VA/24V

FBIC3000VA/48V

10mm

6mm

2

/8AWG

2

/10AWG

Breaker

—

2P

—

2P

63A

32A

NOTE: When the PV modules connect in series, the open circuit voltage of the PV array must not exceed max.

PV input voltage at 25Cenvironment temperature.

Recommended wire of Utility

Model Utility wire size

FBIC3000VA/24V

FBIC3000VA/48V

6mm2/10AWG

2

6mm

/10AWG

NOTE: The utility input has the circuit breaker already and there is no need to add any more.

Recommended wire and circuit breaker of battery

Model Battery wire size Breaker

FBIC3000VA/24V

FBIC3000VA/48V

Type of circuit breaker is selected based on non-independent connection of inverter at the battery end

NOTE:

where there is no antherinverter connected.

2

/2AWG 2P— 200A

35mm

2

/6AWG 2P— 100A

16mm

4

Recommended

FBIC3000VA/24V

FBIC3000VA/48V

wire and circuit breaker for AC output

Model AC w ire size Breaker

NOTE: The wire size used for connection is for reference only, use thicker wires to lower the voltage drop

and improve the system performance when the distance between the whole solar system components is far.

2

4mm

/12AWG 2P— 16A

2

4mm

/12AWG 2P— 16A

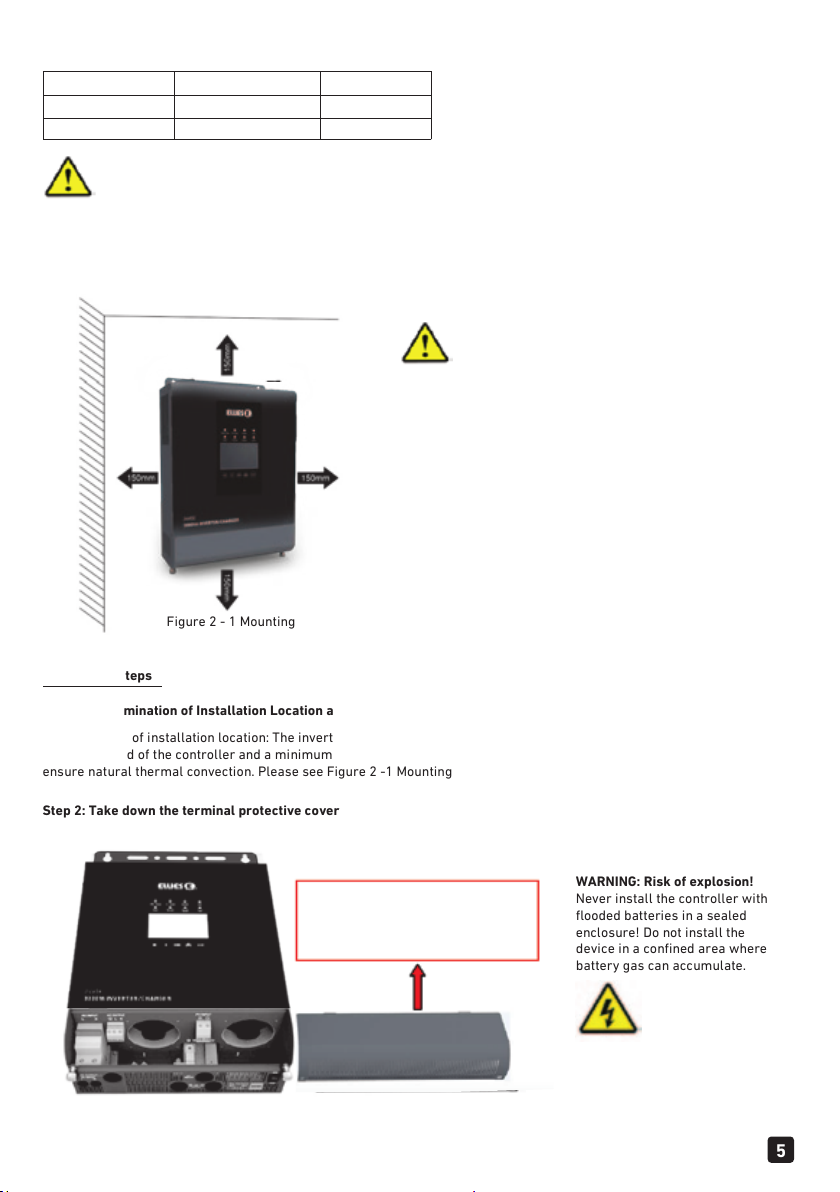

2.3 Mounting

NOTE: The above wire and the circuit breaker size

are for recommended use only, please choose the

suitable wire and circuit breaker according to the

practical situation.

Installation Steps

Step 1: Determination of Installation Location and Heat-dissipation Space

Determination of installation location: The inverter/charger shall be installed in a place with sucient air flow through the

dissipation pad of the controller and a minimum clearance of 150 mm from the upper and lower edges of the controller to

ensure natural thermal convection. Please see Figure 2 -1 Mounting

Step 2: Take down the terminal protective cover

Figure 2 - 1 Mounting

Screw o the screws and take

down the terminal protective cover

of the inverter/charger before

wiring.

WARNING: Risk of explosion!

Never install the controller with

flooded batteries in a sealed

enclosure! Do not install the

device in a confined area where

battery gas can accumulate.

6

5

Loading...

Loading...