Page 1

Magic Module

ELK-MM443 - Field Programmable Controller

Elk Development Software

Covers Software Release Version 5.1 – 16384 bytes of program memory.

Note: MM443

Magic Modules were shipped with 16384 bytes of program memory as of August 1, 2000 .

$10.00

Note: Specifications and features may change without notice. All rights are reserved by Elk Products, Inc.

Dallas iButton is a trademark of Dallas Semiconductor Inc., Dallas, Texas

PO Box 100

3266 US Hwy. 70 West

Hildebran, NC 28637 USA

828/397-4200 FAX 828/397-4415

http://www.elkproducts.com Email: info@elkproducts.com

Elk Products, Inc 1 Magic Module Instructions, Rev. 5.3 L391

Page 2

Introduction

The Magic Module family of low cost field programmable controller modules offers a unique controller and

data acquisition product line to markets not normally using such technology due to cost and complexity.

The ELK - MM220 is a two digital input two-relay output low cost programmable controller.

program the MM220.

computer. The code is then downloaded to the MM443 via a RS-485 data bus and programmed into re-programmable

Electrically Erasable Programmable Read Only Memory (EEProm memory). The MM220, a low cost stand-alone

version, is programmed from the MM443. Up to 31 MM443’s may be data bussed together and controlled from an

optional PC computer. Inputs and outputs may be read and controlled from the PC. The MM443 has a two way X-10

interface for transmitting commands to and receiving commands from X-10 Power Line Carrier Devices. Also an

optional interface is available for reading the Dallas iButton, and the 26 bit Wiegand Prox Card ID devices for

identification and access control applications.

Programs for the MM443 family may be written with an automatic Code Writer, which constructs programs

from a visual question list into a lower level Intermediate Code. The Intermediate Code, known as SIMPLE

like high level language that compiles the Intermediate Code into code byte’s that the micro processor reads out of

reprogrammable EEProm memory and executes the code through a built in operating system. The latest updates to

the Elk Product’s Magic Module Development Software are available at: www.elkproducts.com.

The Savoy MM220S & MM443S are available using the Savoy Automation “Cyberhouse” home automation

graphical software development system. Cyberhouse enables the user to either use the Magic Module system

standalone or connected to a PC for whole house and advanced network control. Savoy software to program the

Magic Module is available on the CD that accompanies the MK400S Development Kit. Additional Savoy Cyberhouse

information and software is available from www.savoyautomation.com/elk.

Components Available:

The ELK - MM443 is a four analog input, four relay output programmable controller that is also used to

The Magic Module is programmed by way of a code editor and software module simulator on a personal

, is a Basic-

• MK400 - Starter Development Kit for MM443S Magic Module.

• MK410 - Pre-programmed X-10 Transceiver. Four inputs, four relay outputs, sends and receives X-10.

• MK420 - Pre-programmed access control with 10 Dallas iButton’s.

• MM220 - 2 digital inputs, 2 relay outputs, stand-alone.

• MM443 - 4 analog inputs, 4 relay outputs, RS-485 data bus, X-10, Dallas iButton.

• MM443S - MM443 with Savoy Software.

• MM447 - MM443 Magic Module, MV-480 Voice Module, ML8 Caddx Interface; fits in Caddx Control Box.

• MV480 - 400 Channel Recordable Voice Annunciator - 480 seconds record time, RS-485 data bus.

• MB485 - RS-232 Serial Port to RS-485 Data Bus. Connects a PC to the RS-485 data bus.

• MK485 - Everything in the MK400S except the MM443S Magic Module

• MC100 - Real Time Clock - Plugs into the MM443 to give real time clock capability; Includes battery.

• MA100 - Dallas iButton Reader Interface and iButton Reader - Interfaces Dallas iButton to MM443.

Includes MA110 and MA190.

• MA101 - Package of 10 Dallas iButton’s.

• MA110 - iButton Reader and stainless steel faceplate.

• MA190 - iButton Reader Interface and cord.

• MT100 - Magic Module Remote Temperature Probe.

• MA290 -26 bit Wiegand Reader Interface for prox cards, with cord to Magic Module MM443.

• ML8 - Caddx Security Control Data Bus Interface

• 930 - Door Bell Interface, Telephone Ring Interface to the Magic Module and other automation

equipment.

Elk Products, Inc 2 Magic Module Instructions, Rev. 5.3 L391

Page 3

Table Of Contents

INTRODUCTION ............................................................................................................................................ 2

MAGIC MODULE MM443.......................................................................................................................................................................5

MM443 FEATURES ...................................................................................................................................... 5

MM443 SPECIFICATIONS ............................................................................................................................. 5

MM443 DESCRIPTION.................................................................................................................................. 6

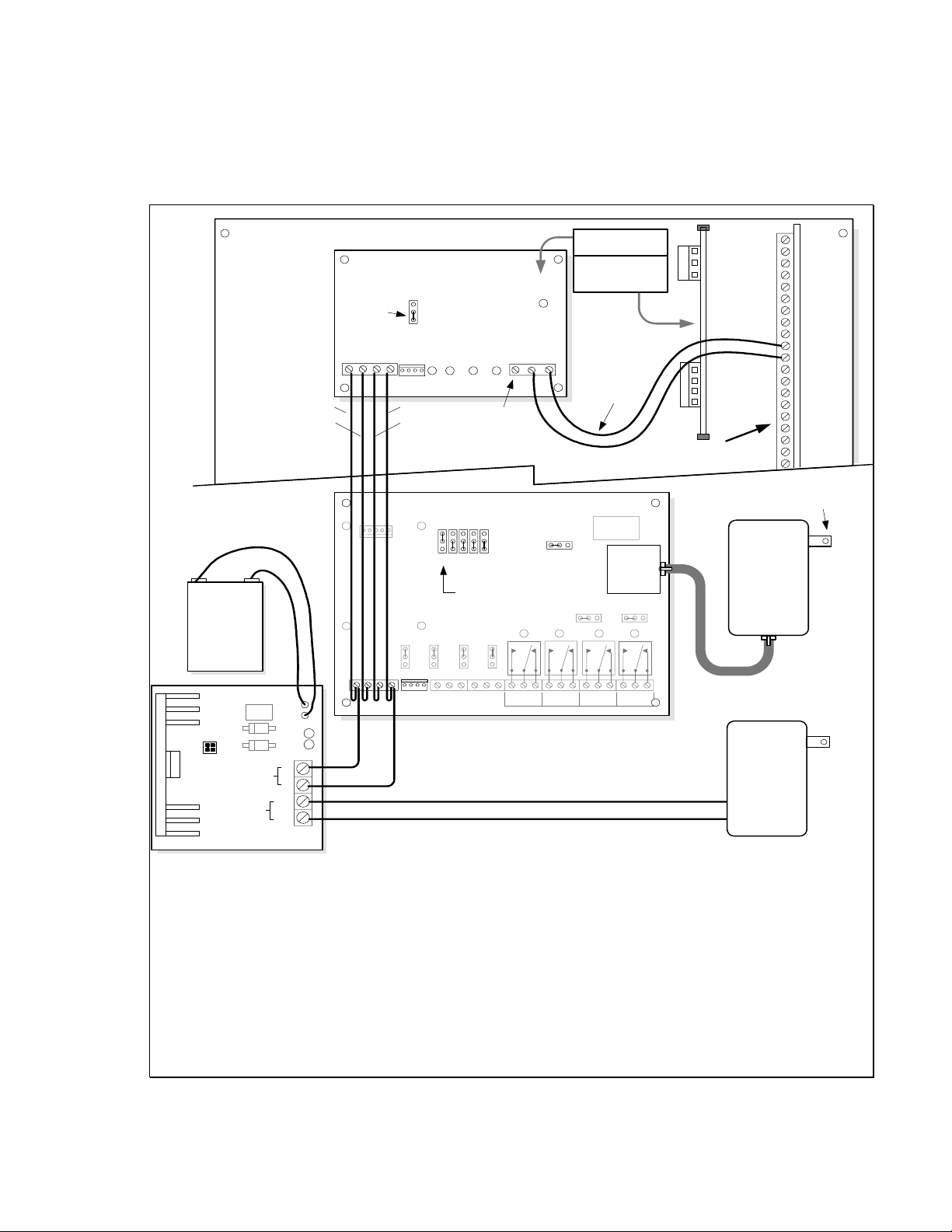

MM443 HOOKUP DIAGRAM......................................................................................................................... 7

MM443 MAGIC MODULE INPUT HOOKUP OPTIONS SCHEMATIC ................................................................. 7

MM443 MAGIC MODULE LAYOUT .............................................................................................................. 8

MV120 (32 CHANNELS) & MV480 (400 CHANNELS) RECORDABLE VOICE ANNUNCIATORS.................... 10

Features ................................................................................................................................................. 10

Specifications......................................................................................................................................... 10

Hookup................................................................................................................................................... 10

MV120 / MV480 PC Board Layout.ELK-129 Hookup ......................................................................... 11

ELK-129 Hookup................................................................................................................................... 12

ML8 – MAGIC MODULE TO CADDX NX8 FAMILY DATA BUS INTERFACE ........................................................................13

ML8 HOOKUP 1 ......................................................................................................................................... 14

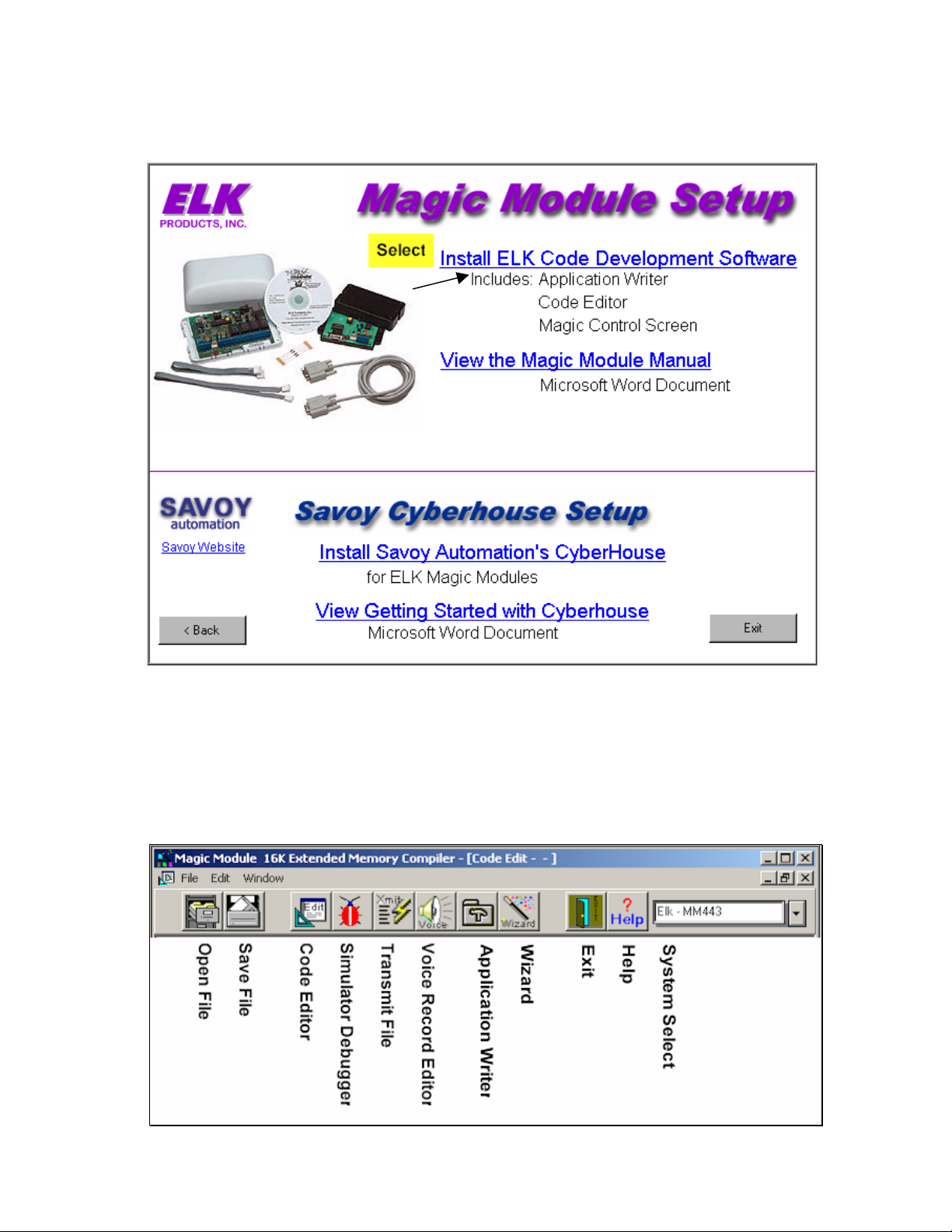

MAGIC MODULE CODE DEVELOPMENT PROGRAMS..............................................................................................................15

PC SYSTEM REQUIREMENTS:..................................................................................................................... 15

MAIN MENU............................................................................................................................................... 16

APPLICATION WRITER –....................................................................................................................................................18

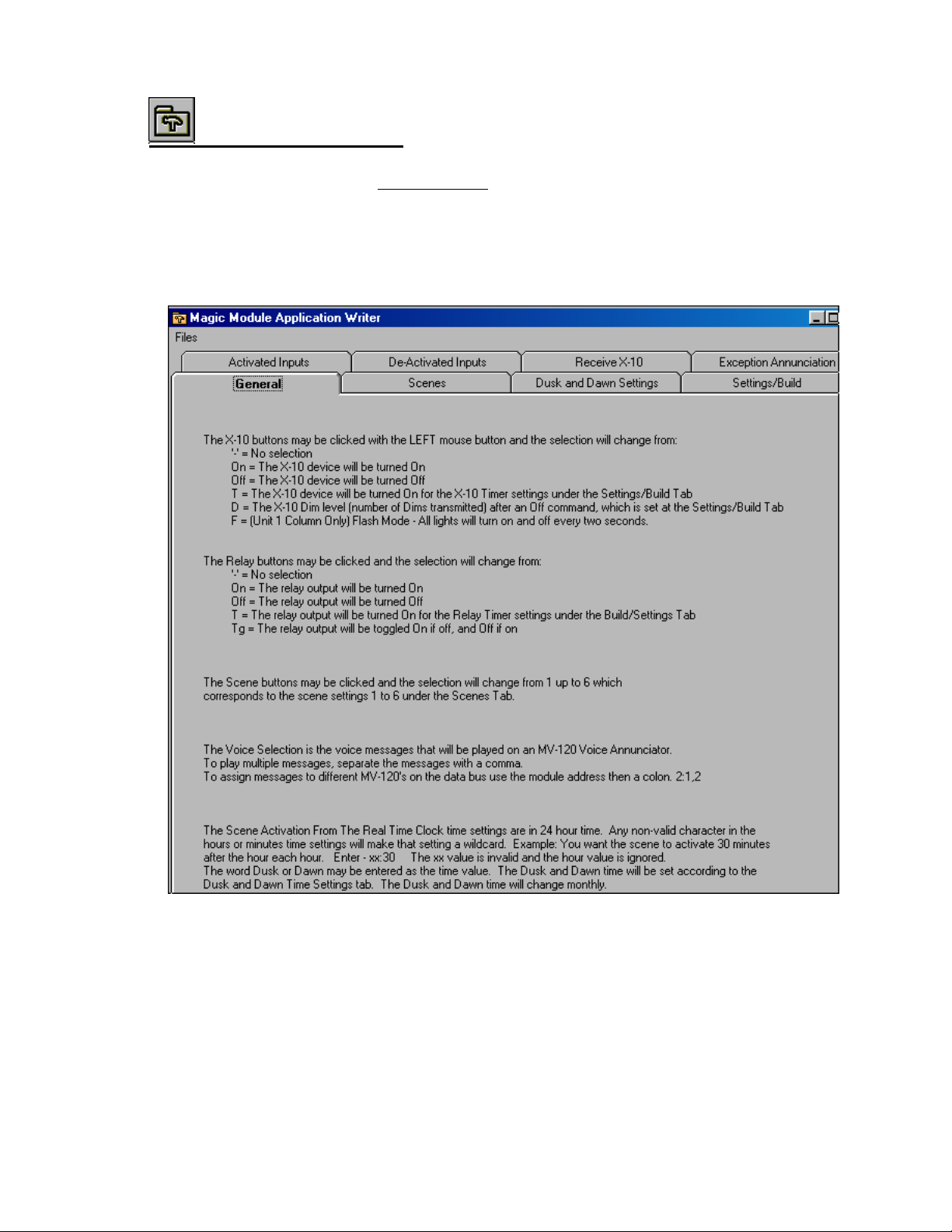

General Tab........................................................................................................................................... 18

Scenes Tab ............................................................................................................................................. 18

Dusk and Dawn Settings Tab................................................................................................................. 20

Activated Inputs Tab .............................................................................................................................. 21

X-10 Click Buttons –.............................................................................................................................. 22

Relay Click Buttons –............................................................................................................................. 22

Scene Click Buttons –............................................................................................................................. 22

Voice Channels – ................................................................................................................................... 22

De-Activated Inputs Tab ........................................................................................................................ 23

Receive X-10 Tab................................................................................................................................... 23

Exception Annunciation......................................................................................................................... 24

Settings / Build Tab................................................................................................................................ 25

CODE EDITOR............................................................................................................................... 29

WRITING CODE .......................................................................................................................................... 30

Right Mouse Click (in Code Editor program area)............................................................................. 31

Event Programming Description........................................................................................................... 32

CODE WRITER............................................................................................................................................ 33

Input Event............................................................................................................................................. 34

Timer Event............................................................................................................................................ 35

X-10 Receive Event ................................................................................................................................ 36

Data Bus Receive Event......................................................................................................................... 37

Dallas iButton Reader or 26 Bit Wiegand Reader (Prox Card)............................................................ 38

X-10 Transmit ........................................................................................................................................ 39

Data Bus Transmit................................................................................................................................. 41

Real Time Clock (RTC) Event................................................................................................................ 43

ASCII Text String Transmission............................................................................................................. 44

File - Drop Down Menu in Code Editor................................................................................................ 45

Edit - Drop Down Menu in Code Editor................................................................................................ 45

Elk Products, Inc 3 Magic Module Instructions, Rev. 5.3 L391

Page 4

Window - Drop Down Menu in Code Editor ......................................................................................... 45

SIMULATOR - DEBUGGER..................................................................................................................................................47

Simulation Screen .................................................................................................................................. 47

Simulate Registers.................................................................................................................................. 48

Program Control.................................................................................................................................... 49

TRANSMIT/REMOTE CONTROL......................................................................................................................................50

Setup....................................................................................................................................................... 50

Transmit Screen ..................................................................................................................................... 51

Disassembly of Magic Module Code ..................................................................................................... 54

VOICE PLAY/RECORD SCREEN - .....................................................................................................................................55

MV120 (MV480) VOICE PLAYER/RECORDER - TYPE 4............................................................................. 55

WIZARD -.................................................................................................................................................................................57

SIMPLE PROGRAMMING LANGUAGE ........................................................................................................ 58

SIMPLE Intermediate Code Command Summary.................................................................................. 63

DATA BUS PROTOCOL................................................................................................................................67

ML8 CADDX TO MAGIC MODULE DATA BUS CONVERTER....................................................................................................68

CADDX NX8 FAMILY CONTROLS TO ML8 MAGIC MODULE INTERFACE.................................................... 68

COMMUNICATOR ACTIVATION................................................................................................................... 74

EventType............................................................................................................................................... 74

Contact ID Communicator Activation:.................................................................................................. 75

PhoneSelector........................................................................................................................................ 75

ContactIDCodes..................................................................................................................................... 75

SIA Format Communicator Activation:................................................................................................. 77

SIA Transmission Codes ........................................................................................................................ 77

Real Time Clock:.................................................................................................................................... 80

MM220 - MAGIC MODULE.................................................................................................................................................................81

MM220 FEATURES .................................................................................................................................... 81

MM220 SPECIFICATIONS ........................................................................................................................... 81

MM220 DESCRIPTION................................................................................................................................81

MM220 INPUT SCHEMATIC........................................................................................................................ 82

MM220 COMPONENT BOARD LAYOUT...................................................................................................... 82

EXAMPLE PROGRAMMING...............................................................................................................................................................83

TRAINER1 EXAMPLE PROGRAM ................................................................................................................. 83

TRAINER2 EXAMPLE PROGRAM ................................................................................................................. 84

Example Program “Trainer2”............................................................................................................... 88

FIVE YEAR LIMITED WARRANTY...................................................................................ERROR! BOOKMARK NOT DEFINED.

ADDITIONAL PRODUCTS.................................................................................................... ERROR! BOOKMARK NOT DEFINED.

Elk Products, Inc 4 Magic Module Instructions, Rev. 5.3 L391

Page 5

Magic Module MM443

MM443 Features

• Four analog or digital inputs

• Four relay outputs (two relay outputs may be jumper programmed for transistor open collector output at

100 milliamps max.)

• 16384 program bytes using SIMPLE programming language

• Four (4) Counters, range 0 to 255

• Four (4) Timers, range 1/10 second to over 255 hours

• Networked to optional PC and up to 31 other Magic Module’s through a RS-485 data bus.

• X-10 Power Line Carrier Interface. PL513, PSC04 (Transmit Only), or TW523, PSC05 (Two Way).

Analog transmission Magic Module to Magic Module and Preset Dim Commands.

• Dallas iButton Reader with optional MA100 or MA290 interface, or 26 bit Wiegand Prox Card Reader

with MA200 interface.

• Automatic Code Writer code development

• Programs the MM220 (two input, two relay output)

• Emulates MM220 for code development

• 130 SIMPLE Language Instructions

• Program stored in non-volatile EEProm memory

• Plastic white ABS enclosure with cover. 6.5 in. X 4 3/8 in. Mounts to single or double gang electrical

box. Optional DIN Rail Mounting. PCB mounts into 4 inch SnapTrack.

MM443 Specifications

• Magic Module RS-485 Data Bus Type 3

• Operating Voltage - 9.6 to 15 Volts DC

• Operating Current - 10 mA. Nominal, 130 mA. Maximum

• Operating Temperature - 32F to 122F (0C to 50C)

• Environment - Indoor non-condensing

• 4 - Analog inputs - 0 to 13.6 volts, with jumper programmable 2k pull up resistor to 12 V, or 2k pull down

resistor to ground. May be left floating. Software programmable hi and lo threshold levels per input makes it

easy to setup end-of-line resistor circuits.

• Input impedance (floating input) - 100K ohms

Elk Products, Inc 5 Magic Module Instructions, Rev. 5.3 L391

Page 6

• Four (4) Outputs - Four Relays - 12 Amps at 120VAC or 28VDC; 12 Amps at 240VAC general purpose; 7

Amps at 277VAC general purpose; ¼ hp at 120VAC; Two relay outputs may be configured as open collector

transistor outputs - 100 mA. Maximum.

• X-10 Interface - PL513, PSC04 or TW523, PSC05 (jumper selectable) - 4 wire RJ-11 telephone style female

connector on PCB

• Auxiliary Programming Connector J1 - 5 pin Methode style male connector (interfaces to cable Elk Part #

WO11A), .1” spacing, to MM220

• RS-485 Data Bus - up to 32 different device loads. Maximum length - 4000 feet

• Optional Real Time Clock (Elk Part # ELK-MC100)

MM443 Description

Usage - MM443 may be used as a stand alone field programmable controller in a vast array of applications

from timers, door controllers, simple process controllers, multiple zone security controls, etc. or as a networked

controller with up to 31 other modules connected on a common RS-485 data bus.

Inputs - Four analog or digital inputs with programmable low and high level switching thresholds accepting

input voltages directly up to 13.6 volts DC. Higher voltages can be used by using resistors on the input as a voltage

divider. Each input is jumper programmable for a 2K ohm input resistor pulled to 12VDC, ground, or no resistor input

voltage bias. The input loop response time may be adjusted with the set INxFilter command in 1/10-second

increments from 100 milliseconds to 25.5 seconds.

Outputs - Four form C relay outputs with contacts rated at up to 12 amps. Two relay outputs are jumper

programmable (JP11 & JP12) to switch the output through an open collector NPN transistor (100 ma maximum)

instead of the relay for higher speed applications such as flashing LED’s where the click of the relay is not desired.

Timers - Four timers ranging from 100 milliseconds to over 255 hours. Each timer is set in the program and

automatically counts down to zero. An if statement checks for the timer to be equal to zero (= 0) or not equal to zero

(not= 0) where the program will jump to a new statement.

Counters - Four counters with a range from 0 to 255 counts can be set, incremented, or decremented by the

program. An if compares the counter value with a variable value for =, not =, >=, or <, where the program will jump to

a new statement.

X-10 Powerline Interface - Connects to a X-10 PL513, PSC04 for transmit only or TW-523, PSC05 for

transmit and receive through a four conductor RJ-11 telephone style cable. Jumper JP10 selects between the PL-513,

PSC04 (one way) or the TW-523, PSC05 (two way) interface. The UVAL (unit value) and FVAL (function value) is set

when a X-10 transmission is received and matches the X-10 House Code (RHOUSE). The RHouse Code may be

different for each Magic Module on the Data Bus.

RS-485 Data Bus - The PC may send control commands to outputs and request status from the inputs on the

MM443. The modules may send commands and status requests to other magic modules as needed by the program.

Example: Module 1 will turn on its relay output 1 (Light switch) when Module 2’s input 1 (motion detector) is high.

Module 1 may also send an X-10 “Lights On” command to all X-10 modules to turn on lights. The combinations are

endless!

Excellent articles are available from National Semiconductor’s Website on wiring the RS-485 data bus at:

www.national.com/an/AN/AN-979.pdf

www.national.com/an/AN-1057.pdf

Programming - MM443 connects to a PC by way of the RS-485 data bus. The program is transferred from

the PC to the MM443 using the PC’s serial port and a RS-232 to an RS-485 converter box (ELK Part # MB485). Once

programmed, the Magic module may be disconnected from the data bus or the PC may be turned off. Two softwareprogramming interfaces are available: The SIMPLE programming language from ELK Products, Inc. (Basic Language

type programming), and the Savoy Cyberhouse Programming Language (Graphical Rules type programming).

Reset - In the event that a defective program has been loaded into the MM443 memory and the data bus can

no longer be accessed for reprogramming, the module’s program memory can be cleared and reset by shorting the

solder pads located at “TP1” and powering up the module. If TP1 remains shorted upon power up, MM443 will enter a

factory test mode. The factory test mode enables testing of the module. TP1’s short must be cleared for the input

loops to function. If any input (1 thru 4) goes to a high state the corresponding relay (1 thru 4 ) will activate. If TP1 is

shorted while the program is running, the module will be placed into the “STOP” mode and program execution will

cease. Data Bus response will continue.

Elk Products, Inc 6 Magic Module Instructions, Rev. 5.3 L391

Page 7

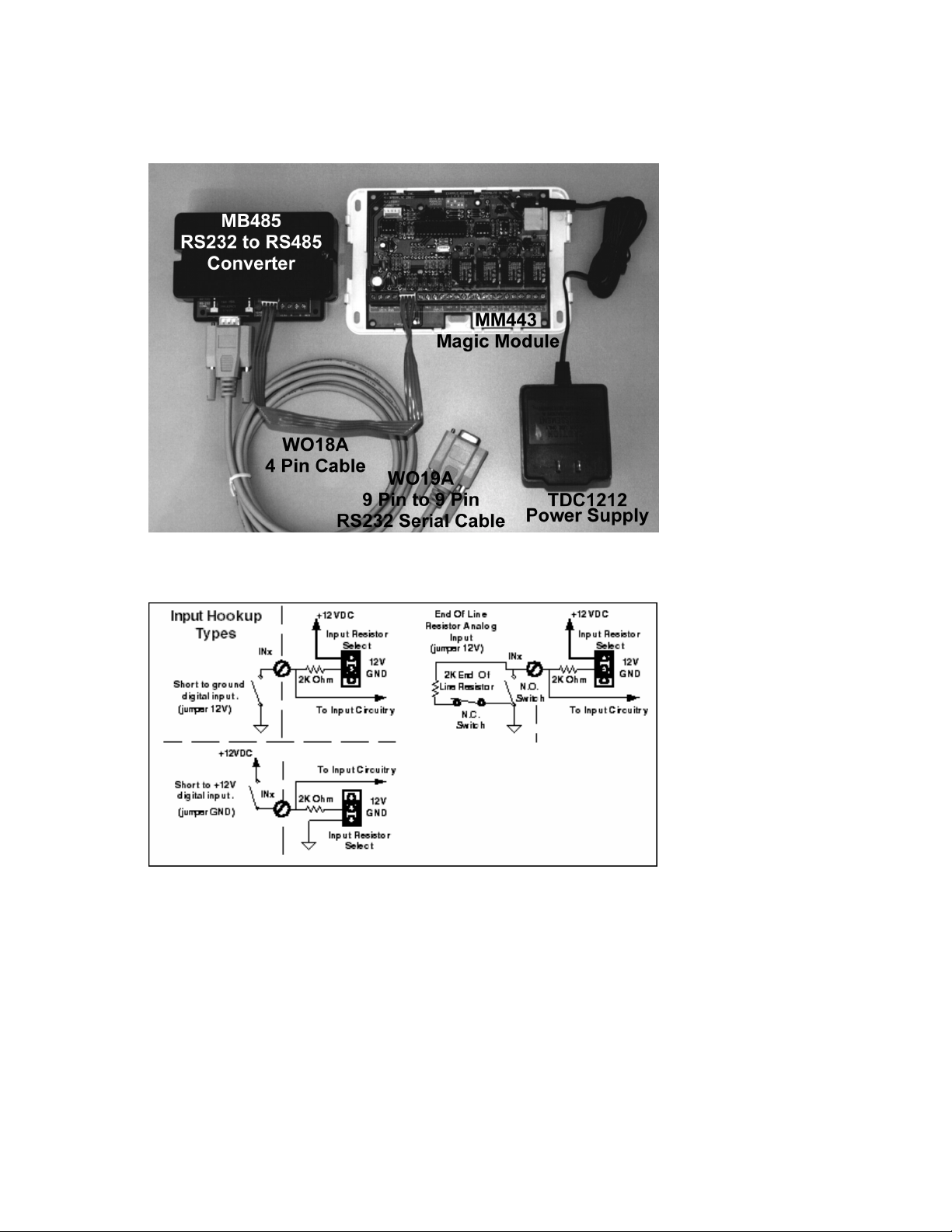

MM443 Hookup Diagram

MK400(S) Magic Module Development Kit Hookup

MM443 Magic Module Input Hookup Options Schematic

The inputs may be used as:

1. Normally Open Short to ground. Set JP1 thru JP4, according to the input, to the “+12V” pull up setting.

2. Normally Open Short to +12VDC. Set JP1 thru JP4 to the “GND” pull down setting.

3. End Of Line Resistor (EOLR) at 2000 ohms with Normally Open contacts across the resistor and/or

Normally Closed contacts in series with the resistor. Set JP1 thru JP4 to the “+12V” pull up setting.

4. Analog Voltage Input between 0 to 13 VDC. Remove the JP1 thru JP4 jumper. Use the if Inx <= value

to select what to do next in the program according to the input voltage level.

Note: A well-regulated power supply is required if reading analog input levels.

Elk Products, Inc 7 Magic Module Instructions, Rev. 5.3 L391

Page 8

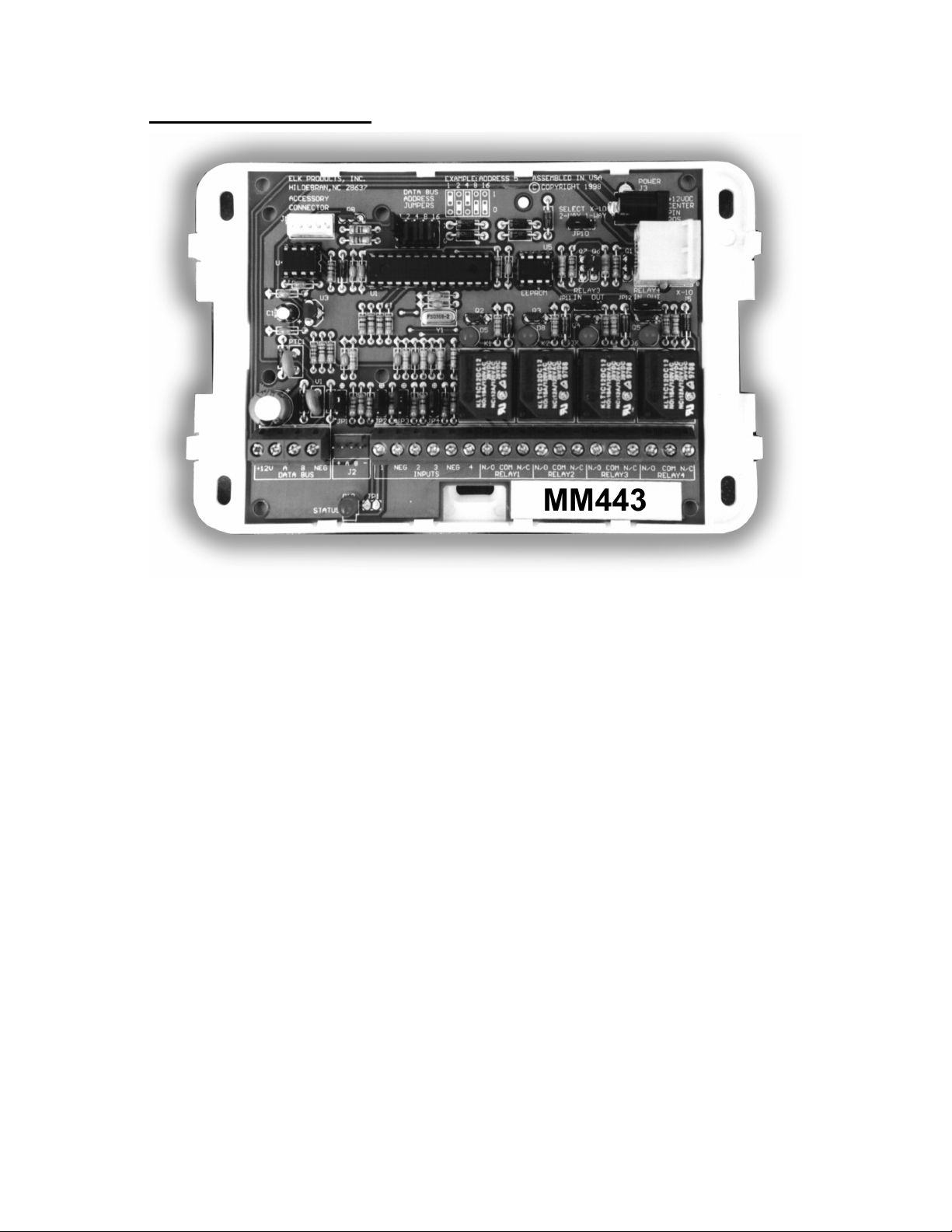

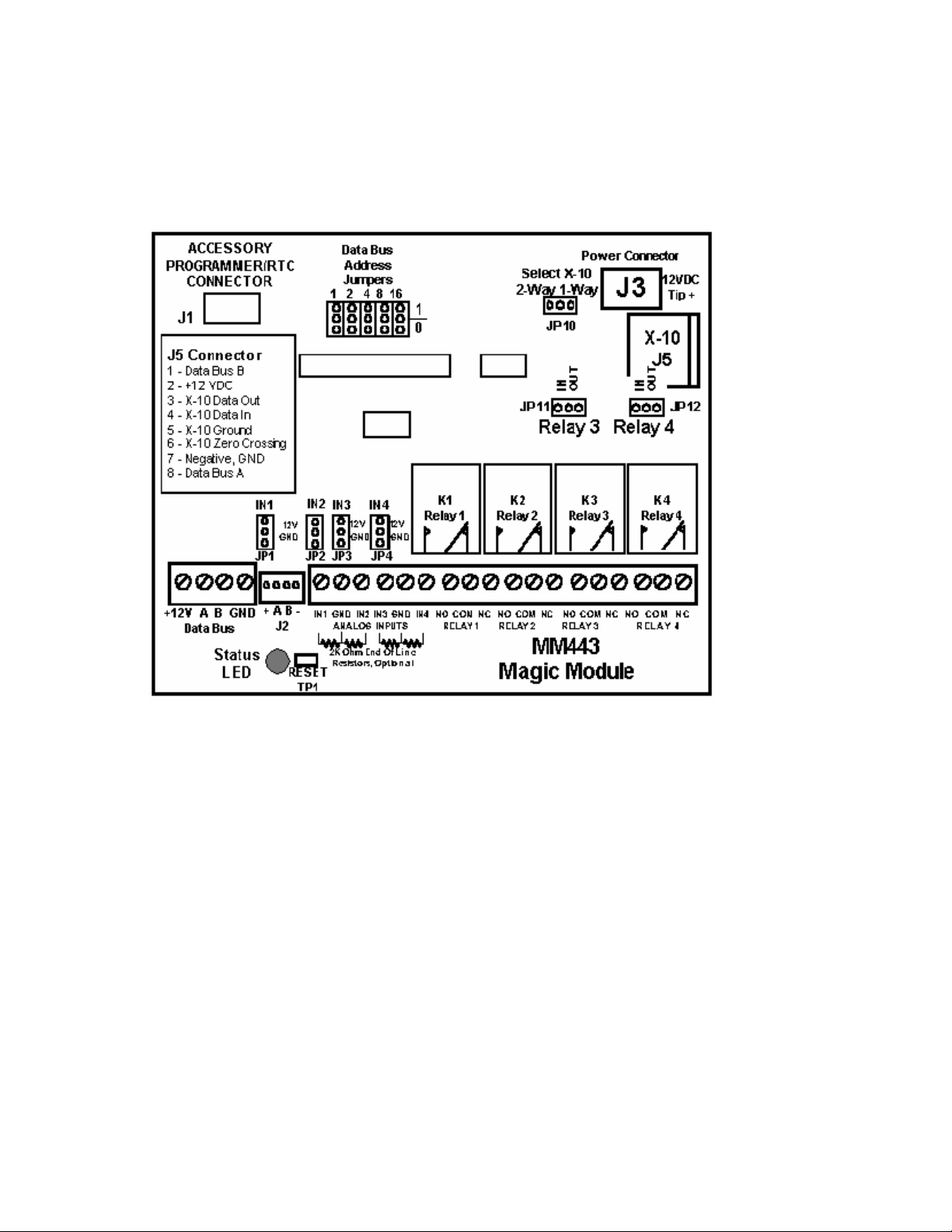

MM443 Magic Module Layout

+12 VDC may be supplied at four (4) locations on the MM443 Magic Module PC Board:

1. RS-485 Data Bus Terminals 1 and 4.

2. RS-485 Data Bus Jumper Header J2, Pins 1 and 4.

3. J-5 Eight-Pin Telco Type Connector, Pins 2 and 7.

4. J3 Power Connector for plug in power supply, center +12VDC.

Terminal Description:

1. +12VDC, minimum 100 milliamps. Will vary according to equipment connected to the Magic Module.

2. Data Bus A - RS-485 data bus. All “A” terminals must be connected together when the data bus is in use.

3. Data Bus B - RS-485 data bus. All “B” terminals must be connected together when the data bus is in use.

4. Ground - Common ground or power supply negative terminal.

5. IN1 - Input 1 terminal.

6. Ground - Common ground or power supply negative terminal. Used as the return terminal for the Input.

7. IN2 - Input 2 terminal.

8. IN3 - Input 3 terminal.

9. Ground - Common ground or power supply negative terminal. Used as the return terminal for the Input.

10. IN4 - Input 4 terminal.

11. NO - Relay 1 Normally Open Contact.

12. COM - Relay 1 Common Contact.

13. NC - Relay 1 Normally Closed Contact.

14. NO - Relay 2 Normally Open Contact.

15. COM - Relay 2 Common Contact.

16. NC - Relay 2 Normally Closed Contact.

17. NO - Relay 3 Normally Open Contact.

18. COM - Relay 3 Common Contact.

19. NC - Relay 3 Normally Closed Contact.

20. COM - Relay 4 Common Contact.

21. NC - Relay 4 Normally Closed Contact.

Elk Products, Inc 8 Magic Module Instructions, Rev. 5.3 L391

Page 9

JP11 and JP12 select Relay 3 and Relay 4 contacts In and Out of circuit. If JP11 (Relay 3) or JP12 (Relay 4)

is set to “Out” then the COM relay contact will pull to ground by a 100 milliamp maximum current transistor. This can

be used for low current circuits such as LED’s or buzzers in which the clicking of the relay would be annoying.

Data Bus Address Jumpers:

Each Magic Module connected to the RS-485 data bus must have a unique address set on each Magic Module. This

address is set on the Magic Module PC Board with five (5) jumpers. The address is set with a binary code, each

jumper has a value:

Jumper 1 (left jumper) = 1

Jumper 2 = 2

Jumper 3 = 4

Jumper 4 = 8

Jumper 5 = 16

By placing the appropriate jumper(s) in the upper or 1 position, the address setting may be set by adding up the

jumper values.

Example: Set data bus address 5.

Jumper 1 and jumper 3 will be placed into the “1” position. Add up the value: 1 + 4 = 5.

Set data bus address 17.

Jumper 1 and jumper 5 is placed into the “1” position. Add up the value: 1 + 16 = 17.

Note: After changing the data bus address jumper settings, the power

must be turned off and turned back on before the new jumper settings

will take effect.

Elk Products, Inc 9 Magic Module Instructions, Rev. 5.3 L391

Page 10

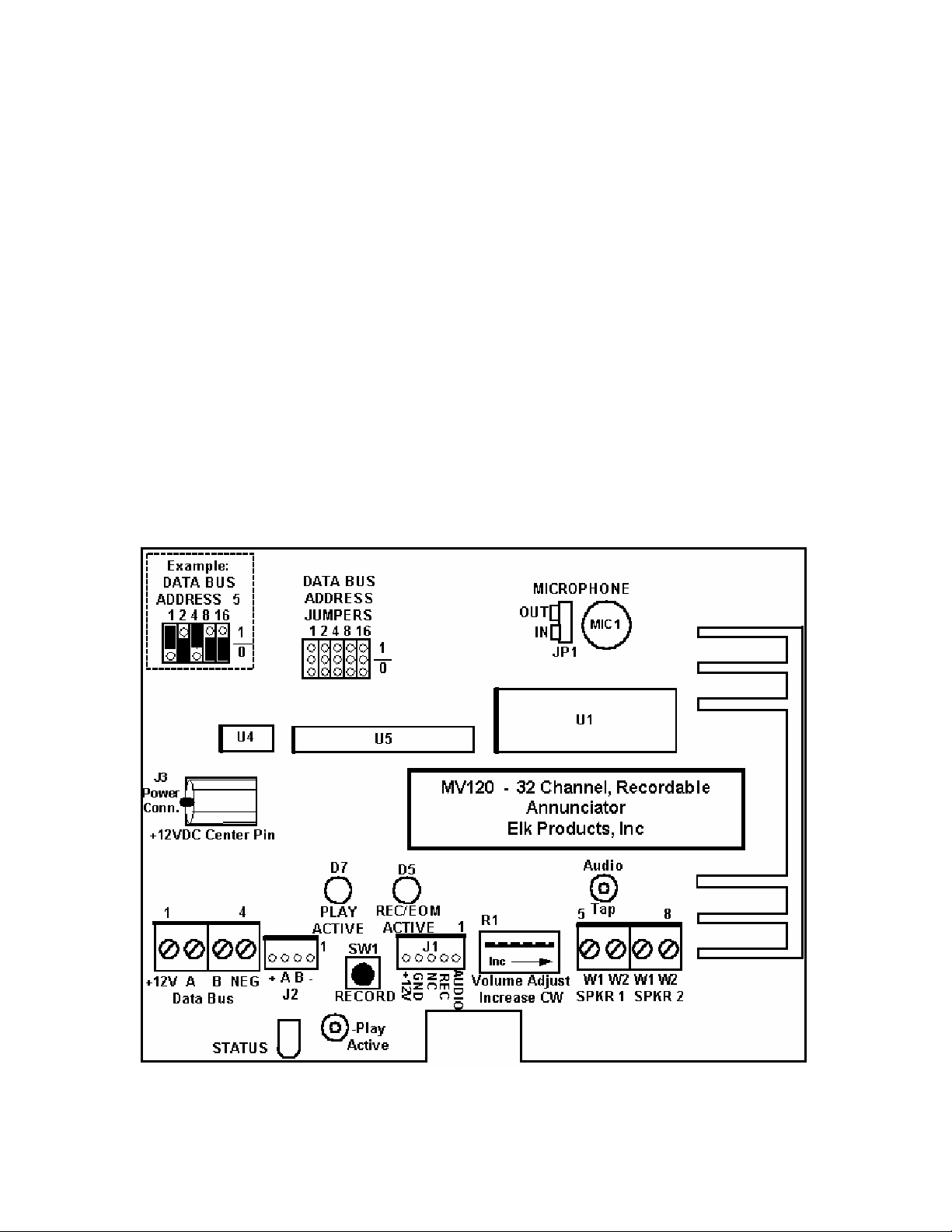

MV120 (32 Channel) & MV480 (400 Channel) Recordable Voice

Annunciators

The MV480 is a MV120 with extended record time of 480 seconds and a total of 400 channels. Each channel’s record

time is 1.2 seconds.

Features

• Controlled from the MM443 Magic Module or compatible controllers.

• 32 individually addressable message channels on MV120, 400 channels on MV480.

• 120 seconds maximum record time on MV120, 480 seconds on the MV480).

• Any message can be any length up to the maximum record time.

• 31 MV120 or MV480s may be networked on the Magic Module RS-485 Data Bus

• Built-in microphone or download a computer wave file using the ELK-129 computer interface.

• Record and playback controlled from a PC computer.

• Adjustable volume control.

• Output for direct connection to audio amplifiers.

• 24-Watt built-in audio amplifier.

• Two speaker connections

Specifications

• 10.25 to 15 Volts DC, well regulated. Note: Low cost plug in DC power supplies may not work due to AC hum

present on the power supply. Recommended: Elk-624 Power Supply with ELK-B1240 standby battery.

• Temperature 20 degrees F. to 122 degrees F, non-condensing. Contact the factory if to be used in extended

temperature environments.

• Maximum current draw at full volume: 1.25 amps. Adjust volume for desired maximum current draw.

• Maximum output speaker load 4 ohms.

• RS-485, simplex data bus. Two Data, two power, +12VDC & NEG.

• Type 4 Magic Module, Addressed from 1 to 31. Address 0 = global non-responding address.

Hookup

Power Supply – The MV120 (MV480) may be power from any of four different locations on the printed circuit board.

1. J3 Power Connector – Plug in a well regulated +12VDC power supply into the connector. The center

conductor is +12V. 2.1mm ID X 5.5mm OD Female plug on the power supply.

2. Terminals 1 & 4 – Terminal 1 is +12VDC and terminal 4 is Negative.

3. Connector J2 – Pin 4 is +12VDC and pin 1 is Negative.

4. Connector J1 – Elk-129 Computer audio programming connector, Pin 4 is Negative. Connect one of the

AC Transformer inputs on the ELK-129 to terminal 1 on the MV120 (MV480) to provide +12VDC to the

internal circuitry on the ELK-129.

Data Bus Connection - The RS-485 Data Bus may be connected in two locations:

1. Terminals 2 & 3 – Terminal 2 is “A” side of the data bus. Terminal 3 is “B” side of the data bus.

2. Connector J2 – Pin 3 is “A” side of the data bus. Pin 2 is “B” side of the data bus.

Note: Data Bus “A” must connect to Data Bus “A” on other modules and Data Bus “B” must connect

to Data Bus “B” on other modules for proper operation of the Data Bus.

Speaker Connection – Two 8 ohm speaker connections are available at Terminals W1 & W2 SPKR1 and W1& W2

SPKR2. When an 8-ohm speaker is connected to both terminals, an effective 4-ohm speaker load is placed on the

amplifier. The speakers may also be wired in series to add more speakers to the system. To connect the MV120

(MV480) to a low level line input going into another audio amplifier, turn the volume all the way down, then turn it up until

the audio level into the other amplifier is satisfactory.

Note: Maximum speaker load on the audio amplifier is 4 ohms.

Jumper Selection – There are two sets of jumpers that should be configured before use of the MV120 (MV480).

Elk Products, Inc 10 Magic Module Instructions, Rev. 5.3 L391

Page 11

1. MIC, JP1 – Microphone enable – If the on board microphone is to be used to record messages; the

jumper at JP1 must be set to the “IN” position (IN Circuit). If the ELK-129 Computer Interface is to be

used to record messages, the jumper at JP1 should be in the “OUT” position (OUT of Circuit).

2. Data Bus Address Jumpers – Each voice module must be set to its own individual data bus address.

The address is set with 5 jumpers. There are two settings, 0 or 1, for each jumper. When the jumper is

in the 0 position, its value is equal to 0. When it is set to the 1 position, its value is shown above the

jumper: 1, 2, 4, 8, 16. Add up the jumpers in the 1 position to see the data bus address setting.

Example: jumper 1 is set to the 1 position; jumper 4 is set to the 1 position. Add the values: 1 + 4 = 5

the data bus address = 5. If a jumper is missing, its value will be 0.

Play Active SolderPad – The solder connection is pulled to ground by a transistor when the MV120 (MV480) is

playing a message. It may be connected to an ELK-924 Relay to trigger other equipment. The maximum current draw

at the solderpad is 50 milliamps.

Audio Tap SolderPad – A low level audio signal may be taken to another audio amplifier from this solder pad.

RECORD Button – When the MV120 (MV480) has been given a record command from the computer, the record

button should be pressed and held during the recording session. Speak clearly into the on board microphone. When

the button is released, the message just recorded will be played. If the record button is not pressed within 45

seconds, the MV120 will return to normal operating mode and cancel the record request. Pressing the RECORD

Button without a record command issued from the computer will play the last message recorded or the first message if

no recording has taken place.

Status LED - blinking – The status LED blinks when the MV120 is in normal operation.

On continuous – The status LED will be ON continuous when a record command is received from

the PC computer. The status LED will return to blinking within 45 seconds if the record button is not

pressed on the MV120 (MV480).

MV120 / MV480 PC Board Layout.

Elk Products, Inc 11 Magic Module Instructions, Rev. 5.3 L391

Page 12

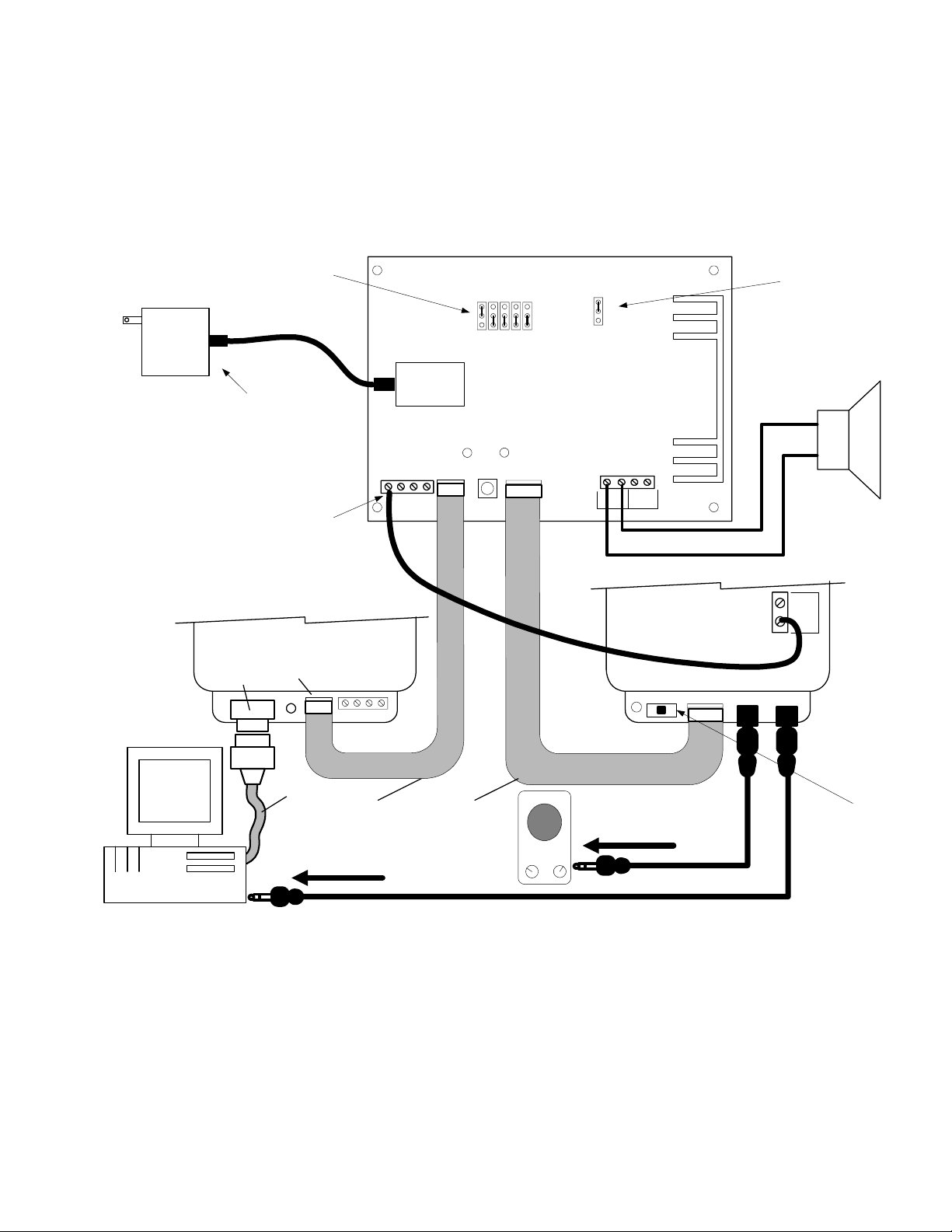

ELK-129 Hookup

The ELK-129 Computer Interface connects a computer sound card to the MV120 (MV480) Voice Module so that

WAV files or other audio files may be downloaded to the MV120 (MV480). See the ELK-129 instructions for

further information.

Recording Hookup for MV120/MV480 to ELK-129

SET TO THE

CORRECT

ADDRESS

+12 VOLT

DC PLUG IN

POWER

SUPPLY

USE A FILTERED AND REGULATED

12 VDC @ 1.2A POWER SUPPLY

(ELK-T1212 RECOMMENDED)

TO POWER THE ELK-129, CONNECT

FROM THE MV120 "+" TERMINAL TO

THE ELK-129 12VAC INPUT AS SHOWN

(DO NOT CONNECT A 12VAC

TRANSFORMER TO THE ELK-129)

THE MB485 IS POWERED FROM THE MV120

THROUGH THE 4 PIN RIBBON CABLE

ELK-MB485

P1

RS-485 DATA BUS

CONNECTOR

RS-232 SERIAL

PORT CONNECTOR

ELK-MV120/MV480 VOICE MODULE

OUT

MIC

IN

POWER

124816

1

0

DATA BUS

ADDRESS

JUMPERS

MOVE "MIC"

JUMPER TO THE

"OUT" POSITION

8 OHM SPEAKER

J3

SW1

J2 J1

BA

-

+

W1 W2 W1 W2

SPKR2

SPKR1

12

VAC

INPUT

ELK-129

AUDIO OUT AUDIO INSW1 J1

-

+

BA

PC

9

PIN

SERIAL

CABLE

4 PIN

RIBBON

CABLE

5 PIN

RIBBON

CABLE

To Amplified

Speakers

SWITCH TURNED

OFF, LED STAYS

To Sound Card

Line Out

Elk Products, Inc 12 Magic Module Instructions, Rev. 5.3 L391

LEAVE THIS

ON WHEN

POWERED

Page 13

ML8 – Magic Module To Caddx NX8 Family Data Bus Interface

The ML8 Interface (ELK-ML8) connects to the data bus of the Caddx NX Control using only 2 wires. Data received

from the control is mapped to 16 collection flags. Changes to these flags are broadcasted over the Magic Module data

bus. In addition, 240 bits of data from the NX8 Control may be interrogated on demand by the Magic Module. In order to

program the 16 collection flags or develop a Home Control or Automation application, a Magic Module Programmers Kit

(ELK-MK485) is needed which includes the Elk Application Writer. There is also a ready to install kit "Home Control Lite"

available which includes a programmed Magic Module, ML8 Interface, plus a Magic Voice (ELK-MV480) 400 channel

recordable voice annunciator.

See ML8 Hookup on next page.

INSTALLATION

Step 1. Disconnect all power to the Caddx NX Security Control and the ELK Magic Module.

Mount the ML8 Interface using the enclosed self-adhesive foam tape or two of the special NX enclosure slide

Step 2.

Step 3. Connect the ML8 Interface, Caddx NX Control, and Magic Module as per ML8 Hookup on next page.

Step 4. After all wiring connections are complete, apply power to the NX Security Control and Magic Module.

Step 5. Use the Magic Module "Code Writer" or "Application Writer" software to setup the 16 collection flags and

LEDs

RCV = Blinks when the NX Control is transmitting information to the ML8 Interface

STATUS = Blinks slowly when the Control Keypad data bus is operational.

PWR = On when the ML8 Interface is receiving Power.

rails available separately from Caddx.

NOTE: ML8 Hookup on next page shows no connection to terminal +V on the ML8 Interface. The

Magic Module source is powering the unit. To power the ML8 Interface and/or Magic Module from the

Caddx NX, connect a wire from +V to the Caddx Keypad POS terminal. Be certain that the maximum

combined current draw including any keypads or auxiliary devices does not exceed the ratings

published with the control. The ML8 Interface and one Magic Module draw 55mA idle or 185mA with

all relays active. A Magic Voice Module will add an additional 70mA idle and up to 500mA when

active with 3/4 volume setting.

develop the desired operation program. The Software includes a manual and on-line help screens.

XMIT = Blinks when information is being transmitted to or received from a Magic Module

Elk Products, Inc 13 Magic Module Instructions, Rev. 5.3 L391

Page 14

ML8 Hookup 1

*

CADDX NX4/6/8 ALARM CONTROL

RS-485 BUS

(4 WIRES)

+

*

BATTERY

-

ELK-1240

JP1 ON

JP2 OFF

Do Not Move Jumpers

JP1

JP2

DC OUTPUT

AC

TRANSFORMER

*

ELK-624 12V POWER SUPPLY

+

-

AC

AC

RED

GREEN

-

+

LEDS

LINK INTERFACE

ELK-ML8

Leave in the

NORMAL

Position

J1

BA

+

BATTERY

AC DC

Mount the ELK-ML8

Interface Here

Or

Mount using

Optional Rails Here

JP1 MODE

AUX

NORMAL

NEGB+12V A

RCV

XMIT

J1

BLACK

YELLOW

*

ELK-MM443 MAGIC MODULE

124816

JP2JP1

PWRSTATUS

See Step 3 for +V

Optional Hookup

DATA BUS

ADDRESS

JUMPERS

SET TO ADDRESS 1

JP4

JP3

D5

not used

DATANEG+V

SELECT X-10

2-WAY 1-WAY

K1

JP10

K2

TO

CADDX

KEYPAD BUS

(2 WIRES)

POWER

J3

X-10 and

DALLAS

Interface

RELAY 4

RELAY 3

IN OUT

K3

-

NOCOMNC

1-2

J2

NOCOMNC

4

3

-

RELAY 1

NOCOMNCNO COMNC

RELAY 2 RELAY 3

Items noted with * must be purchased separately

J5

IN OUT

K4

RELAY 4

DATA

NEG

+V

NEG

B DATA

A DATA

+12 VOLTS

CADDX NX ALARM

CONTROL BOARD

* X-10

POWERLINE

INTERFACE

MODEL:PSC05

*

Transformer

16.5 VAC

40 VA

ELK-TRG1640

TO AC POWER

RECEPTACLE

2 WAY

KP DATA

KP COM

KP POS

Required

only for

Applications

using X-10

Devices

Elk Products, Inc 14 Magic Module Instructions, Rev. 5.3 L391

Page 15

Magic Module Code Development Programs

PC System Requirements:

• Windows 95 or 98, minimum suggested Pentium 75 Mhz

•

16 meg Ram

•

50 meg Hard Drive Space

•

CD Drive for program installation

•

RS-232 Serial Port

•

Display 800 X 600 X 16 bit SVGA or greater

•

Mouse

•

Optional soundcard for wave file programming of the MV120 (MV480) with the ELK-129

There are two types of development software available:

Elk Products, Inc. Development Software

Written using a code editor and automatic Code Writer in a “Basic Language Like” structure called SIMPLE.

This programming environment is familiar to experienced programmers. The Elk version offers program

simulation and debug capabilities.

Savoy Automation, Inc. Development Software

Savoy Automation software offers standalone Magic Module applications or the Magic Module can be

connected to a PC server for advanced network and whole house home automation applications tying together

other equipment into a unified automation system.

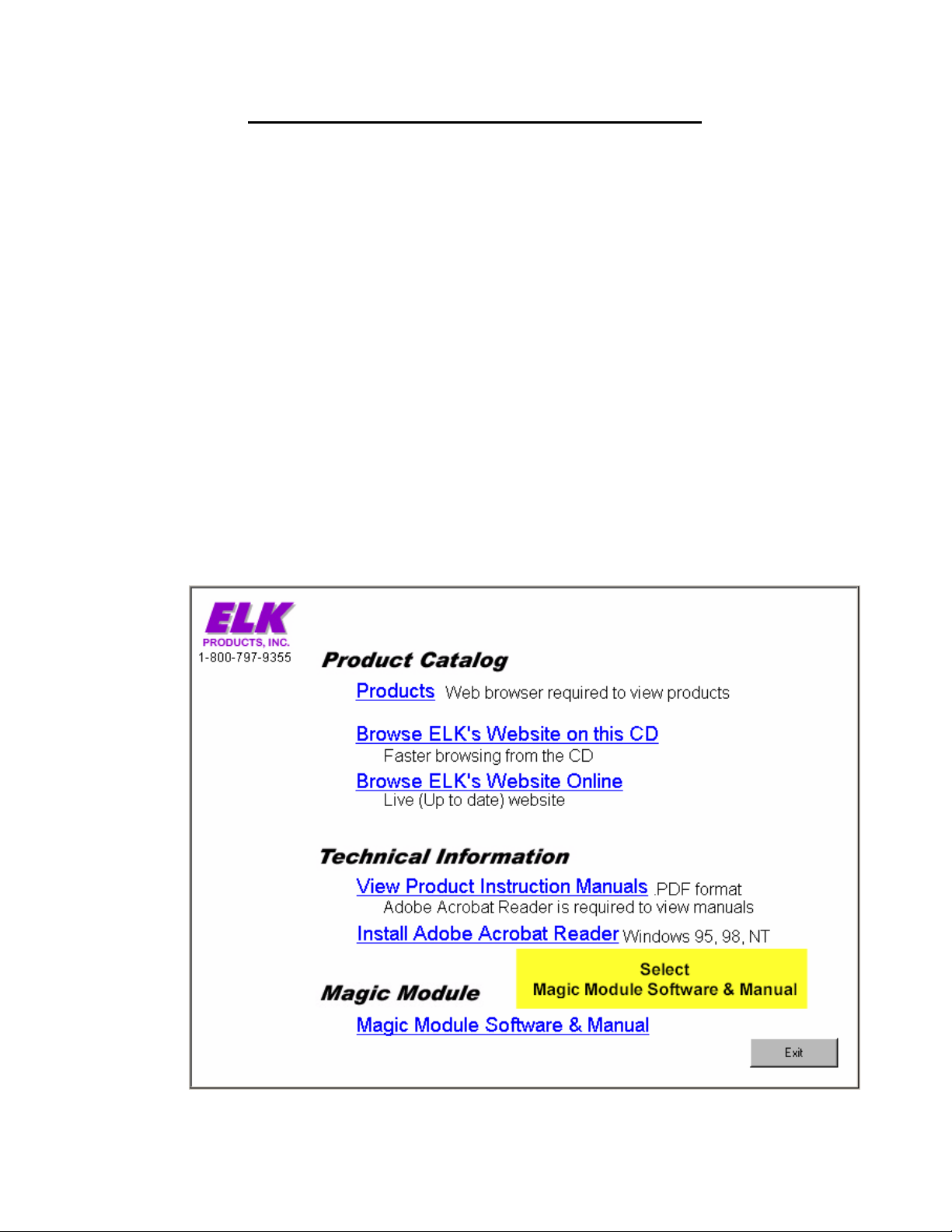

Software Development Installation CD

Insert the ELK Software Development CD into your CD Drive and follow the directions. If the following screen

does not show up, from the Explorer window select the CD Drive, then the autorun.exe program on the CD.

Elk Products, Inc 15 Magic Module Instructions, Rev. 5.3 L391

Page 16

Both versions of software are available on the CD that comes with the Magic Module MK443S Software Development

Kit.

CD Startup Screen

Main Menu

After starting the Magic Module Code Development Software, the Main Menu will appear. From this window you may

choose which program to run:

Elk Products, Inc 16 Magic Module Instructions, Rev. 5.3 L391

Page 17

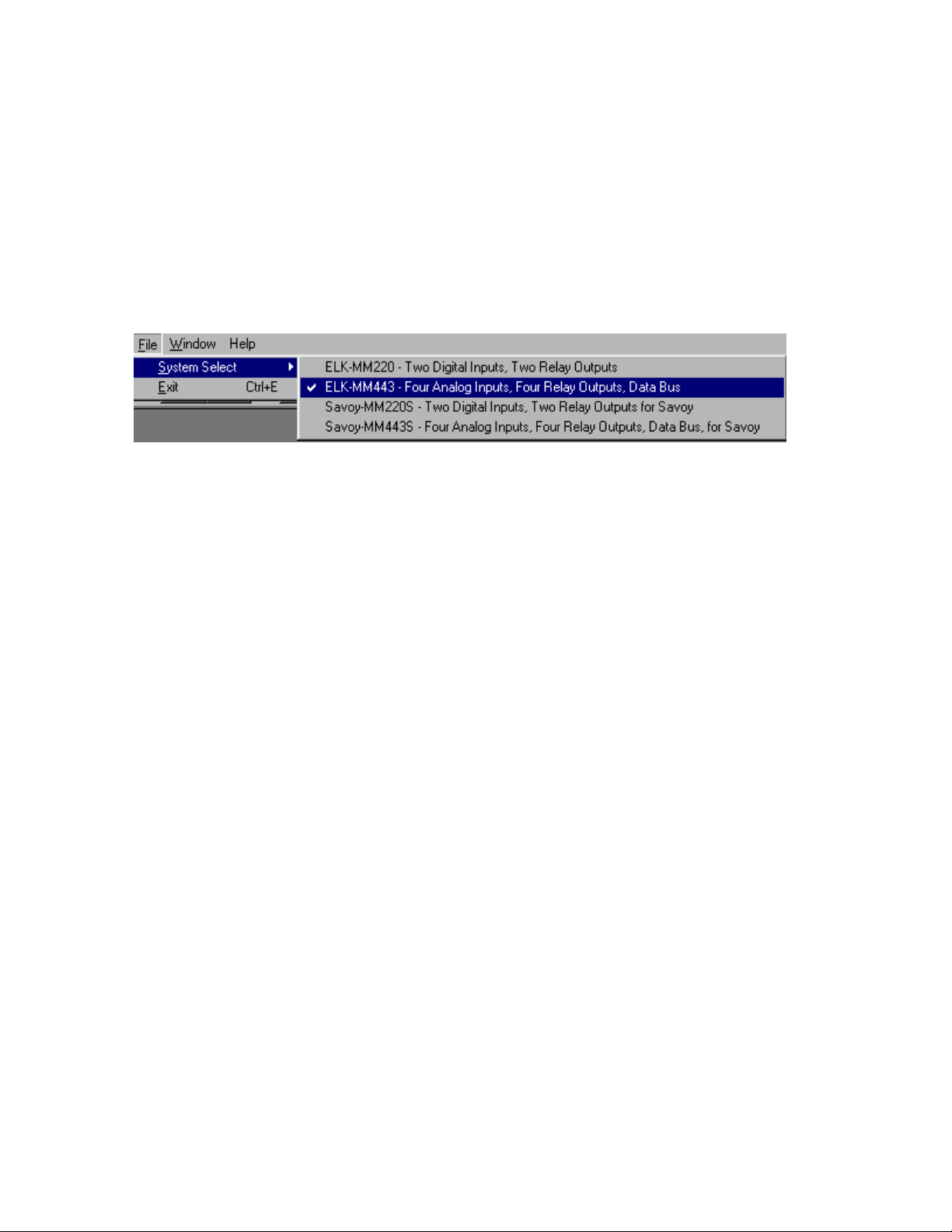

System Select:

Four systems are available to select:

1. ELK-MM220 Two digital input, two relay outputs, stand alone.

2. ELK-MM443 Four analog inputs, four relay outputs, data bus, X-10, Dallas iButton capability.

3. Savoy-MM220S Two digital input, two relay outputs, stand alone for Savoy’s Cyberhouse software.

4. Savoy-MM443S Four analog inputs, four relay outputs, data bus, X-10, Dallas iButton capability for Savoy

Cyberhouse software.

File / System Select, then the system selection. Note: The initial program screen must be displayed with no

Select

other screens open to execute the “System Select” function.

Elk Products, Inc 17 Magic Module Instructions, Rev. 5.3 L391

Page 18

Application Writer –

The Application Writer is designed for

automation features of the MM443 Magic Module simply by clicking buttons on the Application Writer Screens. This

allows quick programming and customization of a very powerful and inexpensive home automation system.

The Application Writer may use the Caddx NX4, NX6, or NX8 Security Control as 16 inputs to the Magic Module by

using the ELK ML8 Caddx To Magic Module Data Bus Converter.

The Application Writer writes a Magic Module .src file from the buttons that the installer selects. Further

customization may be added with the

non-programmers to be able to program and utilize many of the home

Code Editor.

General Tab

The General Tab provides Help information on how to use the Application Writer.

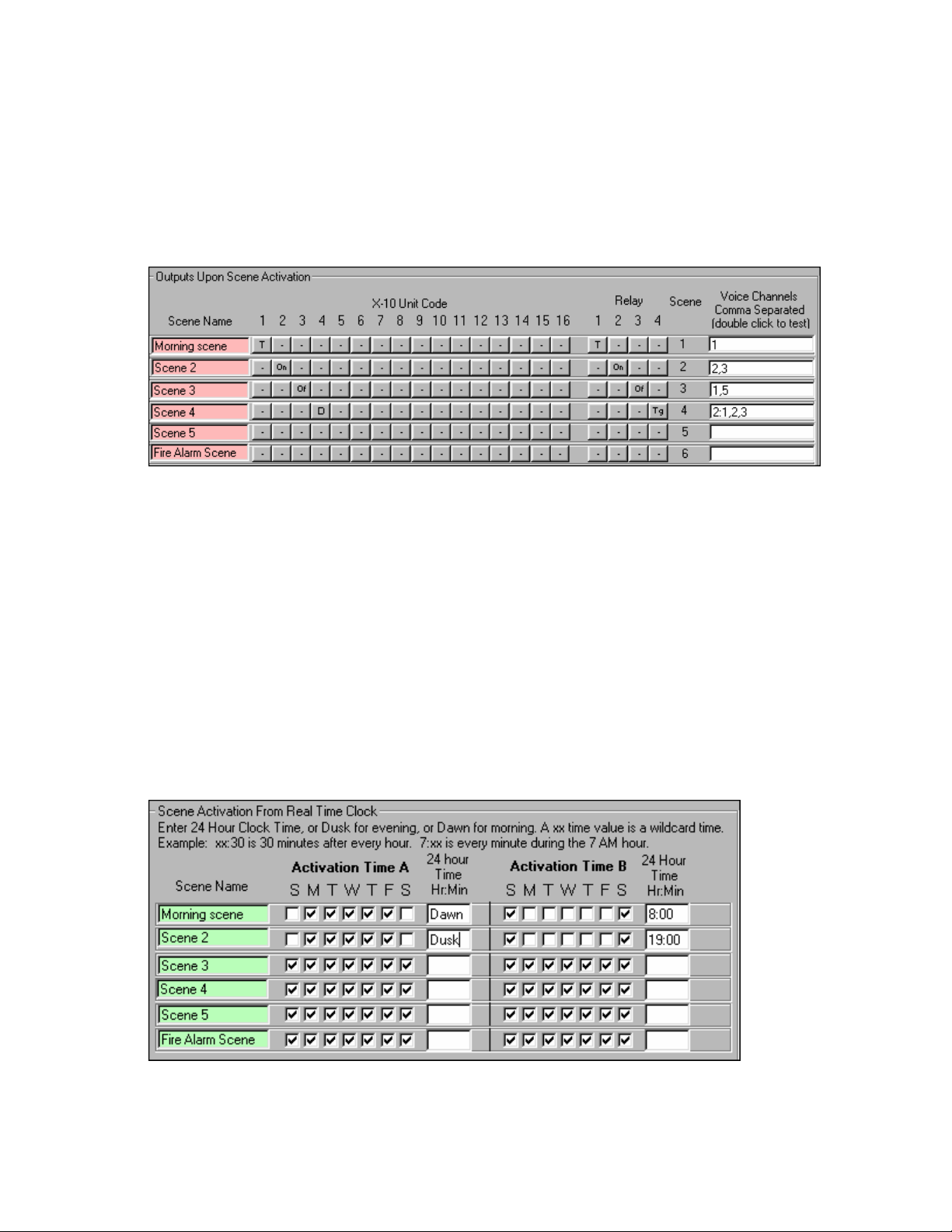

Scenes Tab

Scenes may be described as lighting, relay, or voice setting that is triggered from an input or a time of day.

Example 1: Define Scene 1 as the Morning Scene. The kitchen and bedroom lights turn on. The coffee maker turns

on. The HVAC changes to the morning mode and a voice command is triggered to tell everyone to get out of the bed.

Elk Products, Inc 18 Magic Module Instructions, Rev. 5.3 L391

Page 19

Example 2: Define Scene 6 as the Fire Alarm Scene. When triggered from the Caddx Security Control. All the lights

turn on. The HVAC turns off. A repeating voice message tells everyone to leave the premise and assemble in the

front of the house. The message is recorded with the mothers voice to calm the children.

The Scene Names may be edited like the “Input” names.

The Voice Channels and the Click Buttons for the X-10 Unit Codes and Relays function the same as

described on the

“Activated Input” Tab.

Scene Activation From Real Time Clock –

If the Caddx Security Control is used, the real time clock time comes from the Caddx Control. Otherwise, install an

ELK MC-100 Real Time Clock Module onto the MM443 Magic Module for the real time clock operation.

The 6 Scenes may be triggered from the real time clock. Two time settings are available for each Scene:

Activation Time A and Activation Time B. Each Activation Time has the option of selecting which day during the

week that the scene will activate. If the Day Of The Week selection box is checked, the real time clock will activate the

scene on that day when the time of day is reached.

Note: All times are in 24 hour time: 00:00 is midnight, 3 PM is 15:00. The scene is checked every minute for all the

times that could set the scene.

A wildcard time is available for special activations by using “xx” as the hour or minute time.

Example 1: “xx:45” will activate the scene 45 minutes past every hour.

Example 2: “18:xx” will activate the scene every minute during the 6 PM hour.

Example 3: “xx:xx” will activate the scene every minute.

Example 4: “Dusk” and “Dawn” will reference the settings in the “Dusk and Dawn Settings” Tab.

Elk Products, Inc 19 Magic Module Instructions, Rev. 5.3 L391

Page 20

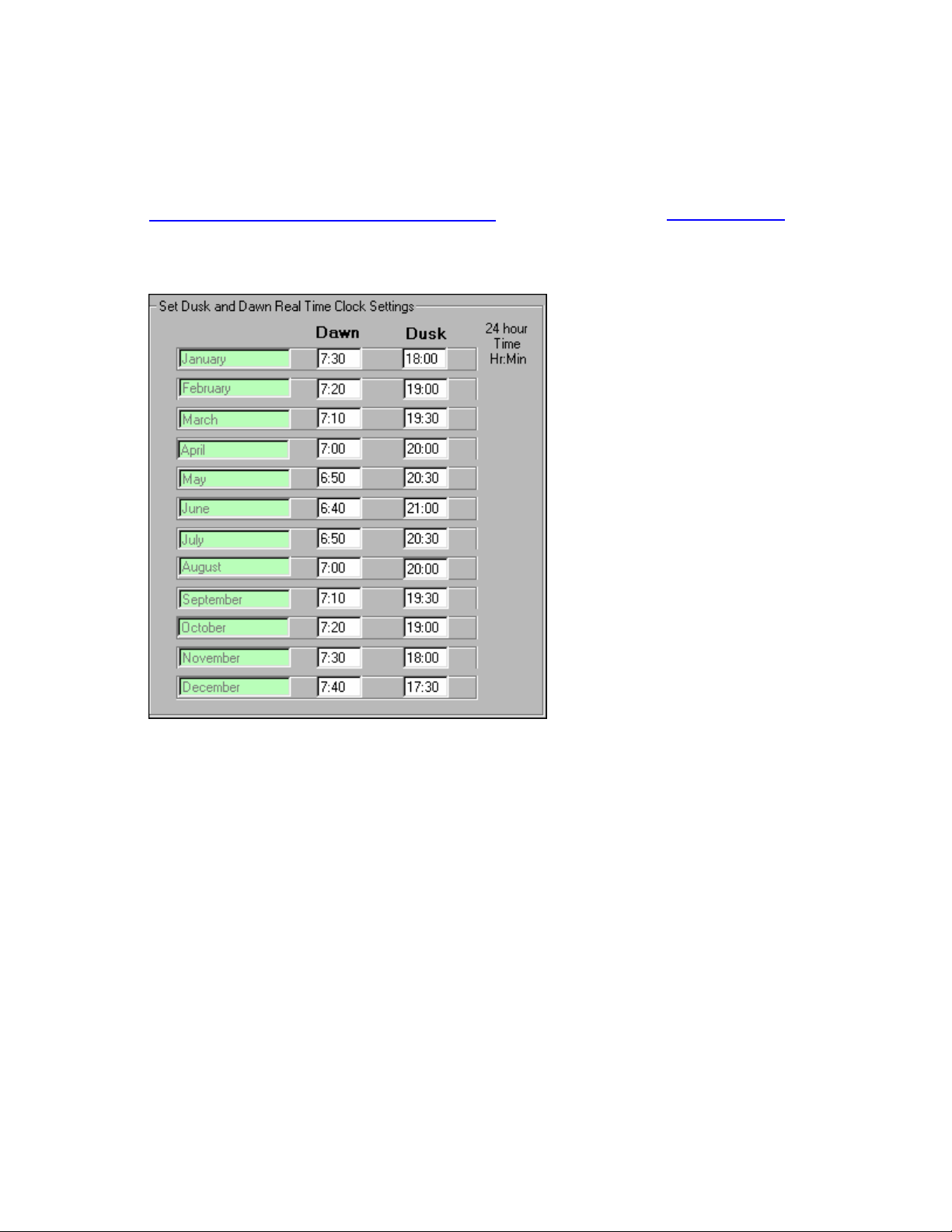

Dusk and Dawn Settings Tab

To turn items on and off at dusk and dawn, the time settings are adjusted on a monthly basis. Insure that the

dusk and dawn time setting for your area are correct. Remember day light savings time corrections. The time is

always set in a 24-hour format. Example: 5 pm = 17:00.

Dusk and Dawn settings may be downloaded from the Internet at:

http://www.mindspring.com/~cavu/sunset.html or referenced through http://www.cavu.com/

These Dusk and Dawn time settings are used in the

section under the

Scenes Tab.

Scene Activation From Real Time Clock settings

Elk Products, Inc 20 Magic Module Instructions, Rev. 5.3 L391

Page 21

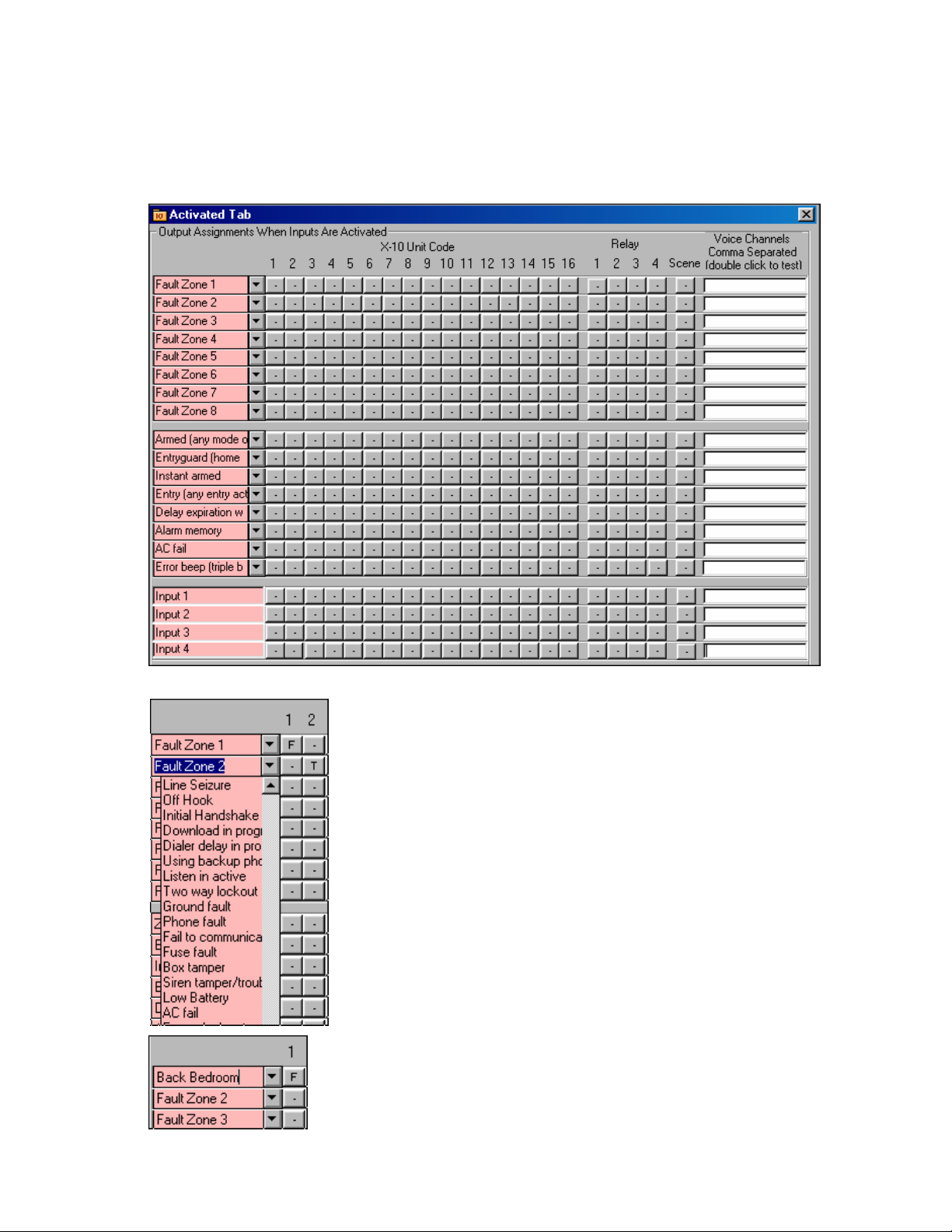

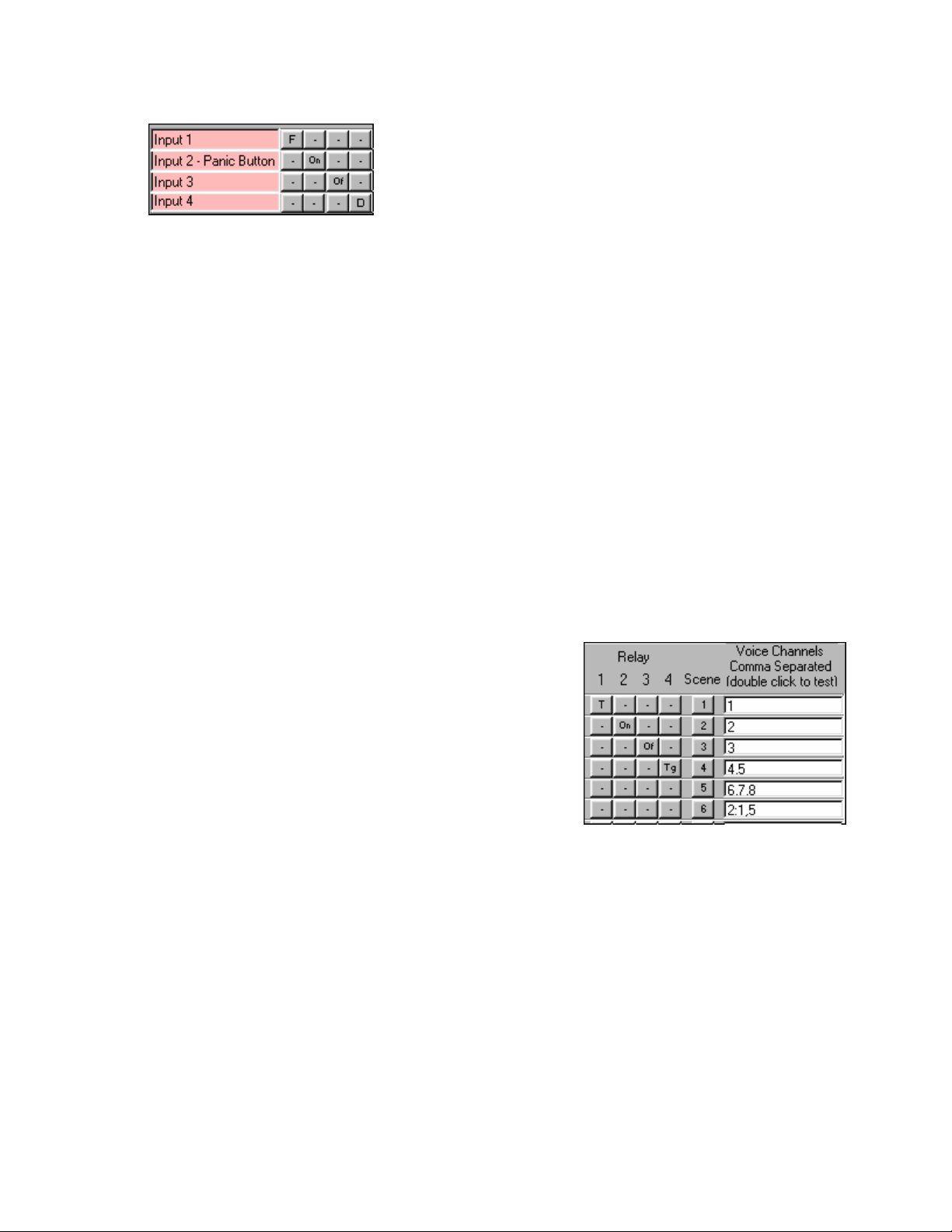

Activated Inputs Tab

Activated Inputs – What do you want the Magic Module to do when the input is triggered on or goes into an active

state? Up to 16 X-10 Unit Codes may be controlled with Flash, On, Off, Dim and Timed On, the four (4) relay outputs

on the Magic Module may be controlled, up to 6 Scenes may be controlled, and the MV120 Voice Annunciator may

speak multiple voice messages.

The first 16 positions in the left input column are the Caddx NX8, 6, or 4 Security

Control Inputs. The programmer can select from 240 different data inputs from

the Caddx Security Control in each of the 16 positions. Just click on the down

arrow to the right of each box and select the input desired. See the

Description Section for further explanation of the Caddx inputs

The input description may also be changed to help the programmer remember what

the input is used for. When the input descriptions under the Activated Inputs are

changed, then all the other input descriptions associated with that input would also be

changed

name will be displayed.

. If the cursor hovers over the input description, the original input

Caddx Input

.

Elk Products, Inc 21 Magic Module Instructions, Rev. 5.3 L391

Page 22

The four (4) analog inputs to the Magic Module are available at the bottom

left of the screen. Up to 16 X-10 Unit Codes may be controlled with Flash,

On, Off, Dim and Timed On, the four (4) relay outputs on the Magic Module

may be controlled, up to 6 Scenes may be controlled, and the MV120

Voice Annunciator may speak multiple voice messages. When the input

descriptions under the Activated Inputs are changed, then all the other

input descriptions associated with that input would also be changed.

Note: The Click Buttons for X-10, relays, scenes, and voice

annunciation operate the same on all screens

X-10 Click Buttons –

To select a function on the X-10 Unit Codes that correspond to an input, click the button with the mouse. The button

caption will change as follows:

“-” No selection. No code will be generated for that input and output.

1.

2. “T” – Turn the X-10 device on for the time setting under the “Settings/Build” Tab and “X-10 Timer Setting”.

The timer range is from two seconds to 255 hours.

command, so do not use a one second timer setting.

3. “On” – Turn the X-10 device on.

“Of” – Turn the X-10 device off.

4.

“D” – Dim the X-10 device. First the device is turned off, then the number of X-10 Dim commands that are

5.

set in the “Settings/Build” Tab and “X-10 Dim” setting are transmitted. Ten (10) Dims will go to half

brightness.

“F” – Available in the X-10 Unit 1 column only. All 16 X-10 Unit codes will turn the lights on and off every

6.

two seconds until an X-10 “Off” command is issued. This can be used when an alarm is tripped to alert the

neighbors or the police.

Note: It takes two seconds to send the X-10

Relay Click Buttons –

To select a relay output function on the Magic Module that corresponds to an input, click the button with the mouse.

The button caption will change as follows:

“-” No selection. No code will be generated for that input and

1.

output.

“T” – Turn the relay output on for the time setting under the

2.

“Settings/Build” Tab and “Relay Timer Setting”. The timer range

is 1/10 of a second to 255 hours

“On” – Turn the relay output on.

3.

“Of” – Turn the relay output off.

4.

5.

“Tg” – Toggle the relay’s on/off state. If the relay output is on,

turn it off. If the relay output is off, turn it on.

Scene Click Buttons –

To select a Scene that corresponds to an input, click the button with the mouse. The button caption will change from 1

to 6, which corresponds to Scenes 1 to 6 as described under the “Scenes” Tab.

Voice Channels –

To select and speak a Voice Channel that corresponds to an input on the MV120 (MV480) Voice Annunciator that

connects to the Magic Module Data Bus, type in the voice channel (1 to 32 MV120, 1 to 240 MV480). If multiple voice

messages are to be concatenated together, separate them with commas.

Example: 1,2,3,4. By default the voice commands are sent out onto the data bus with a global address of “0”. This

will command all voice modules to say the same voice channels on each module. Should you want to direct the voice

command to a particular MV120 on the data bus, precede the voice commands with the MV120 (MV480)’s Data Bus

Address then a colon. Example: 2:4,5 this will command the MV120 with a data bus address 2 to say voice channels

4 and 5. Double clicking the voice channel text box will immediately send the voice channels to the MV-120 (MV480)

to test the voice messages.

Elk Products, Inc 22 Magic Module Instructions, Rev. 5.3 L391

Page 23

De-Activated Inputs Tab

De-Activated Inputs – What do you want the Magic Module to do when the input is restored to a normal or non-alarm

state? Up to 16 X-10 Unit Codes may be controlled with On, Off, Dim and Timed On, the four (4) relay outputs on the

Magic Module may be controlled, up to 6 Scenes may be controlled, and the MV120 (MV480) Voice Annunciator may

speak multiple voice messages.

Note: All Click Buttons work the same as the

Activated Inputs Tab.

Receive X-10 Tab

Up to 16 received X-10 signals from X-10 Unit Code 1 – 16 may be combined with any X-10 function code to

create a unique received code. When the unique X-10 Code is received other X-10 devices may be controlled, the

four relays may be controlled, Scenes may be triggered, and voice messages may be announced.

The click buttons all have the same operation as described in the

The received House Code is set under the

Code may be any one-house

code from “A” to “P”.

Settings/Build tab, Received House Code. The received House

Activated Inputs Tab.

Example above:

When X-10 Unit Code 1, Function On is received, turn on and time Unit 1 for the time set under the

Settings/Build tab. Turn on X-10 Unit 2, turn on relay 1 for the time set under the Settings/Build tab, turn on relay 2,

and speak voice channels 1 and 2 through the MV120 (MV480) Voice Annunciator.

When X-10 Unit Code 2, Function Off is received, turn off X-10 unit 3. When X-10 Unit Code 3, Function Dim

is received, Dim X-10 Unit Code 4.

Elk Products, Inc 23 Magic Module Instructions, Rev. 5.3 L391

Page 24

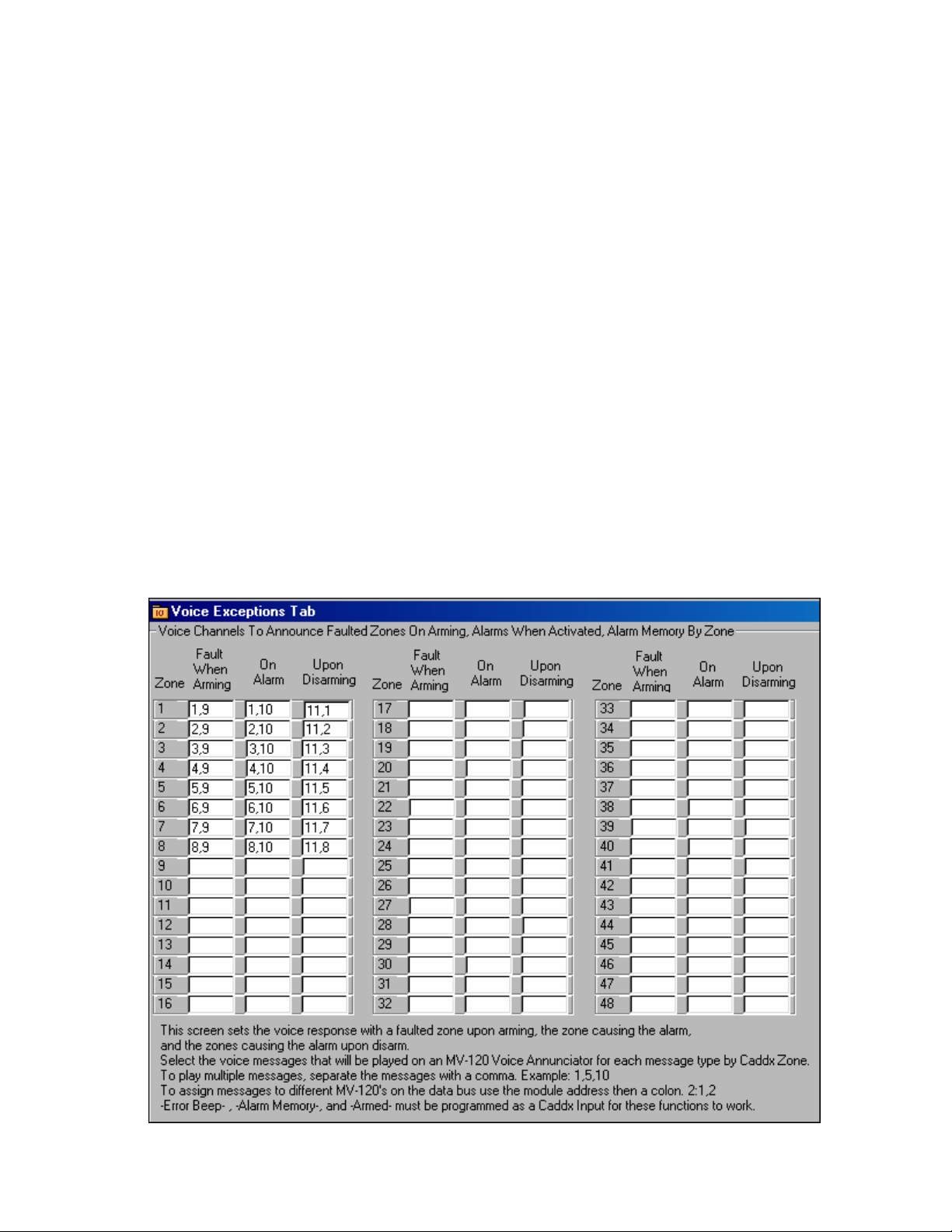

Exception Annunciation

categories:

Insert the Voice Channels to speak into the corresponding zone and annunciation type columns text box with

each voice channel separated by commas. The voice channel input range is from 1 to 32.

By default all voice transmissions are to a global address of “0”. To direct the voice transmission to a specific

MV120 Voice Module, enter the MV120’s data bus address followed by a colon (:) then the voice channel to speak:

2:1,2.

Channels are programmed using the

to the front door, so program channel 1 as “Front Door” and so forth through zone 8 describing each zone with a voice

message.

Program voice channel 9 as “is open”.

Program voice channel 10 as “triggered the alarm”.

Program voice channel 11 as “an alarm was caused by the”.

When the “front door” is open and arming the alarm is attempted, “front door is open” will be annunciated.

When the “front door” causes an alarm, “front door triggered the alarm” will be annunciated. Then upon

disarming the control, “an alarm was caused by the front door” will be annunciated.

Exception Voice annunciation by the ELK MV120 (MV480) may be programmed to speak in three (3)

Fault When Arming: Upon arming and one or more of the Caddx Security Control Zone

1.

2.

3.

Example below:

Program the MV-120 (MV480) voice channels 1 through 8 with the zone description. The Voice

inputs are violated or open. Make sure one of the Caddx Inputs on the

programmed as an

On Alarm: When the Caddx Security Control goes into alarm, the zone input(s) that

caused the alarm will be annunciated. Make sure one of the Caddx Inputs on the

Activated Tab is programmed as an

Upon Disarming: If an alarm has been triggered during that arming cycle, the alarmed

zone(s) will be annunciated. . Make sure one of the Caddx Inputs on the Activated Tab is

programmed as an

Voice button in the ELK Code Development Software. For example zone 1 goes

Error Beep (triple beep).

Alarm Memory.

Armed (any mode of armed).

Activated Tab is

Elk Products, Inc 24 Magic Module Instructions, Rev. 5.3 L391

Page 25

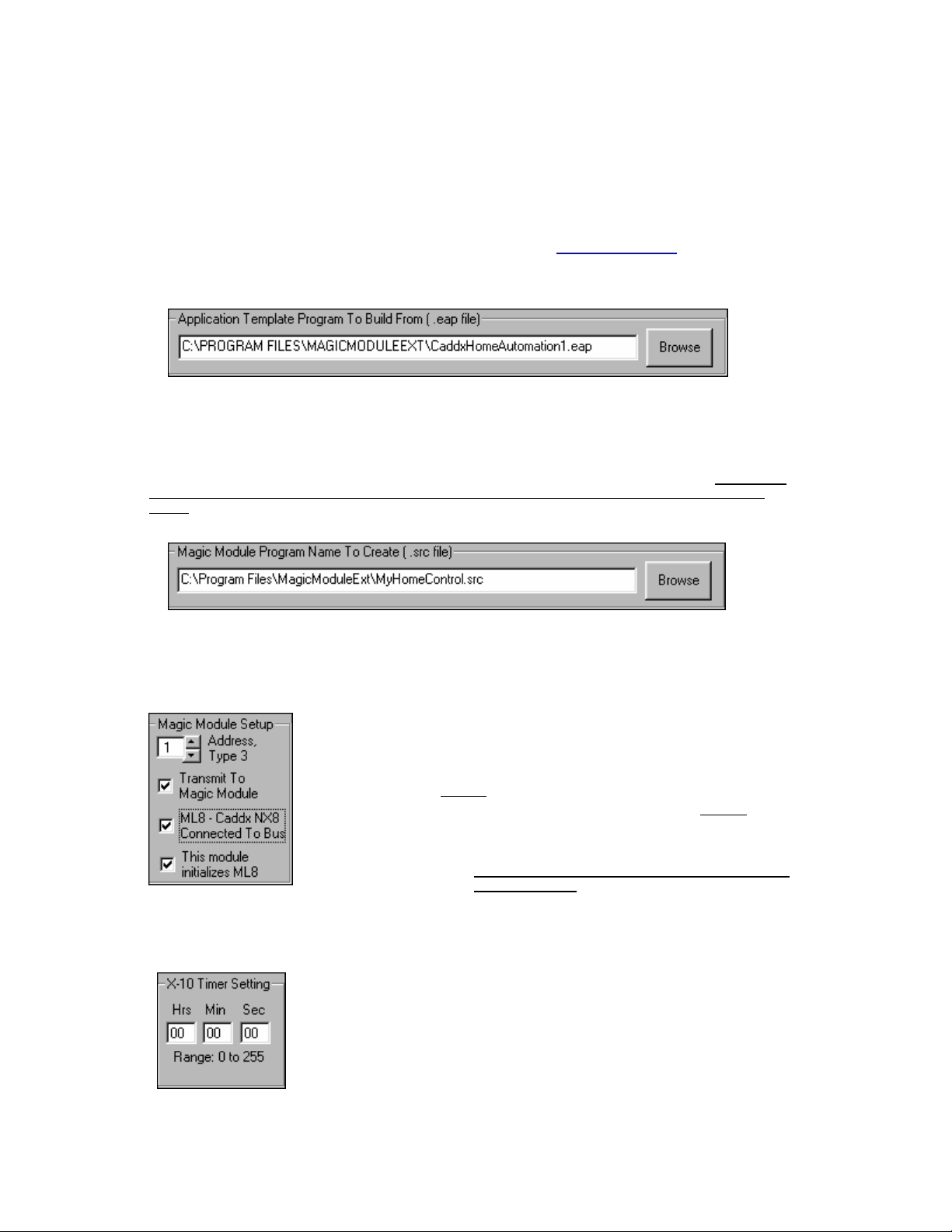

Settings / Build Tab

Application Template Program To Build From

The Application Writer uses a pre-built template program with a file type of .eap to reference as it builds the

program. The “CaddxHomeAutomation1.eap” program should be used as a template to build all programs. As more

template programs are developed, they will be available on our website at www.elkproducts.com

work properly if the .eap template program has been modified.

Note: Do Not Modify The “CaddxHomeAutomation1.eap”. Compilation of the .src program may not

.

Magic Module Program Name To Create

The Application Writer will create a new program with a file type of .src. This program may be named anything

that you would like to call it. The program may also be edited with the ELK Code Development Editor.

Code Editor custom features and operations that are not available through the Application Writer may be

added.

Through the

Magic Module Address

After the Application Writer finishes building the new program into an .src file, the file

will be automatically transmitted to the Magic Module that is addressed by the

Module Address

bus address set on the Magic Module.

If no Magic Module is connected to the computer or transmission to the Magic

Module is not desired, uncheck

If a ML8 – Magic Module to Caddx Data Bus Interface is not used, uncheck

– Caddx NX8 Connected To Bus

X-10 Timer Setting

If any X-10 Unit Code Settings Click Buttons display a “T” for Timer, the X-10 device

will be turned

the timer expires

button, the timer will be restarted for all devices that have been turned on with a “T” click

button.

The timer settings are in Hours (Hrs), Minutes (Min), and Seconds (Sec). The value

range of each time setting is 0 to 255 hours, minutes, and seconds.

NOTE: A time setting should not be less than two (2) seconds since a X-10 message

requires two seconds to transmit.

window. Make sure the address set into the window matches the data

the Transmit To Magic Module checkbox.

checkbox.

If a ML8 is used and this program is to initialize the ML8,

check the

Note: Only one Magic Module on the data bus should

initialize the ML8.

On for the timer setting that is in the X-10 Timer Setting and turn off when

. Should the timer be started by another X-10 device with a “T” on the click

“This module initializes ML8” checkbox.

Magic

the ML8

Elk Products, Inc 25 Magic Module Instructions, Rev. 5.3 L391

Page 26

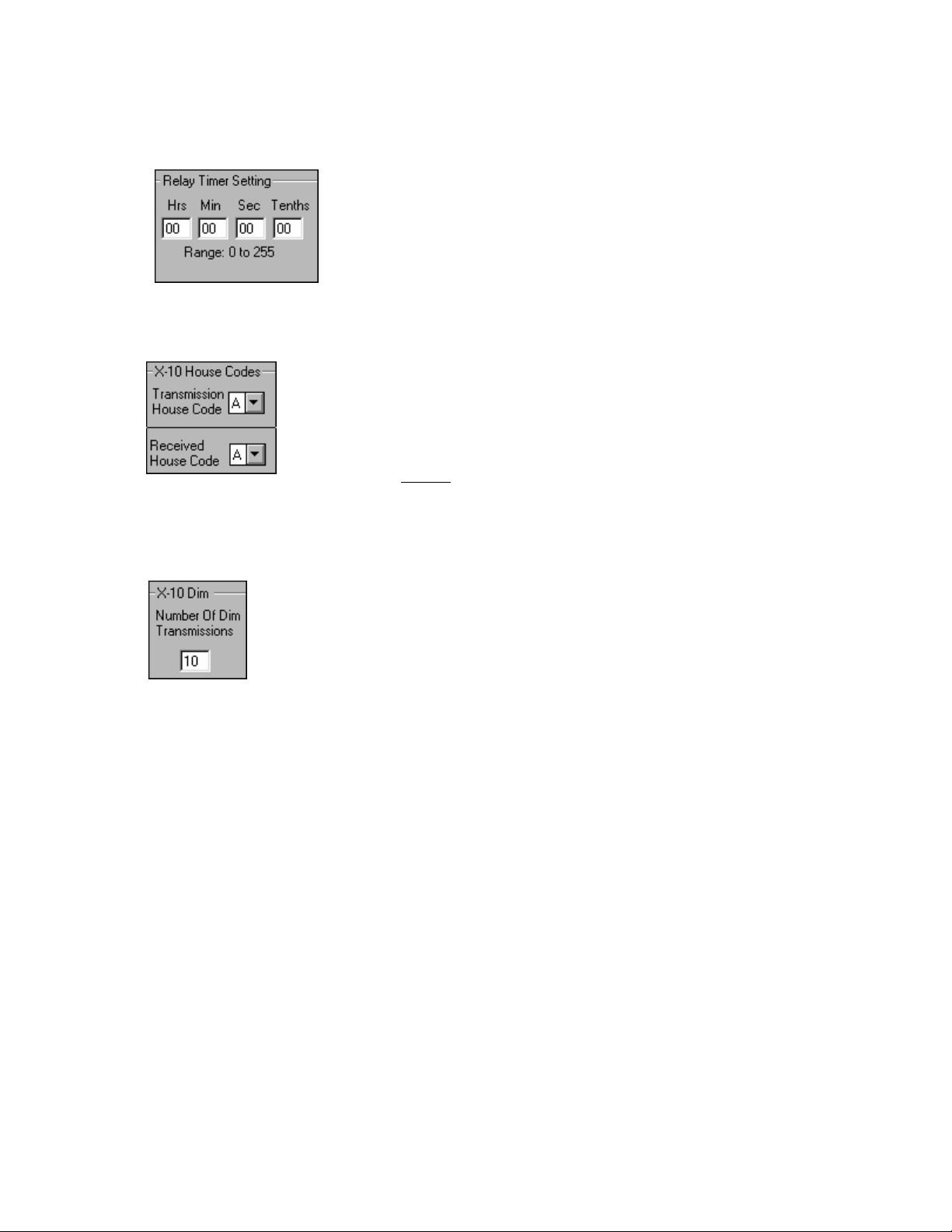

Relay Timer Setting

X-10 House Codes

Module, the

Received House Code must be set to the same house code that is being transmitted from a X-10 device.

X-10 Dim

If a X-10 Unit Code Click Button is set to “D”, the X-10 module will be turned Off, then

the number of X-10 Dim Transmissions set in

Ten (10) transmissions are about ½ brightness, 20 transmissions will turn the lamp on most X-10

modules off.

If any Relay Click Buttons display a “T” for Timer, the relay will be turned On for

the timer setting that is in the

expires. Should the relay timer be started by another relay with a “T” on the click

button, the timer will be restarted for all devices that have been turned on with a “T”

click button.

The relay timer settings are in Hours (Hrs), Minutes (Min), Seconds (Sec), and

Tenths of Seconds (Tenths). The value range of each time setting is 0 to 255 hours,

minutes, seconds, and tenths of seconds.

Each X-10 device is associated with a

devices from talking to your neighbor’s X-10 devices.

There is a

devices in you house. The X-10 device such as a X-10 lamp module must have its House

Code set the same as the Transmission House Code. One X-10 House Code is available for

transmission using the Application Writer, however all 16 House Codes may be used with

modifications to the .src file using the ELK Development Software’s Code Editor.

If you are receiving

Transmission House Code with which you send commands to the X-10

Relay Timer Setting and turn off when the timer

House Code. This helps to keep your X-10

X-10 House Codes to trigger other functions in the Magic

X-10 Dim will be transmitted to the X-10 module.

Elk Products, Inc 26 Magic Module Instructions, Rev. 5.3 L391

Page 27

Hardwire Input Activation

Each of the four-hardwire inputs on the Magic Module may be configured as to how the input will be triggered

active. If the High or Low click boxes are selected the input will switch from a Hi to Lo state or Lo to Hi state at

approximately 6 volts.

Hardwire input switch hookups:

Normally Closed Switch: A normally closed security switch is closed when the magnet has closed

the switch or the door is closed. This is the most widely used type of security switch. This type of switch can be

supervised because all the switches are wired in series and if any switch opens, the entire loop opens. When this type

of switch is connected across the input terminal and negative, the hardwire input activation will be

voltage at the input terminal goes high to +12 VDC.

Normally Open Switch: A normally open security switch’s contacts are open when the magnet is

near the switch or the door is closed. This type of switch is wired in parallel and cannot be supervised from someone

cutting the wire. When this type of switch is connected across the input terminal and negative and the switch closes,

the hardwire input activation will be

If the

end of the switch loop between the input terminal and negative on the Magic Module, the four selections are:

End Of Line Resistor check box is selected and a 2000-ohm end of line resistor is connected at the

1.

2.

3.

4.

Make sure the input selection jumpers, JP1 to JP4, on the Magic Module are set to the “+12V”

setting.

Low. Therefore the voltage at the input terminal goes low to 0 volts.

High – The input will trigger active when the input voltage exceeds the high threshold

setting in the program which is set by the Application Writer at approximately 8 volts, or

when the input loop connected to the hardwire input terminal and negative opens.

Low – The input will trigger active when the input voltage drops below the low threshold

setting in the program, which is set by the Application Writer at approximately 4 volts, or

when the input loop connected to the hardwire input terminal and negative shorts.

In Range – The input will trigger active when the input voltage is between the low and

high threshold settings, 4 and 8 volts, or the end of line resistor is installed and the input

loop is not faulted.

Out Of Range – The input will trigger active when the input voltage is above the high

threshold setting, 8 volts, or below the low threshold setting, 4 volts. This is the option

that would normally be used for a burglar alarm input when the input loop faults open or

shorted.

High, where the

Elk Products, Inc 27 Magic Module Instructions, Rev. 5.3 L391

Page 28

Reset All Values

Build Application

Open/Save Settings

All buttons and settings are cleared to factory default.

Application Writer reads all click button settings and text fields and writes the Magic

Module .src program. The program may be changed and additional software features

added with the ELK Code Development Software Editor.

When exiting the Application Writer Program, all values will be saved in the

Windows registry and will be reloaded the next time the program is loaded.

The program settings may be saved to a disk file and reloaded later using the

“File” at the top of the Application Writer Screen.

Elk Products, Inc 28 Magic Module Instructions, Rev. 5.3 L391

Page 29

Code Editor

via the Code Transmitter Program.

The Code Editor edits and builds the intermediate code so that it can be transmitted to the Magic Modules

Program Listing Columns:

Add - Memory address of program line expressed in hexadecimal.

1.

C1 - Program code byte 1. The first byte of a code byte command. Expressed in hexadecimal.

2.

C2 - Program code byte 2. The second optional byte of a code byte command. Expressed in hexadecimal.

3.

C3 - Program code byte 3. The third optional byte of a code byte command. Expressed in hexadecimal.

4.

C4 – Program code byte 4. The fourth optional byte of a code byte command. Expressed in hexadecimal.

5.

Label - Designates an address position in the program for a goto, jmp, call, if, or event to redirect the program

6.

to.

Command - The 13 commands that direct the program to function:

7.

7.

8.

9.

10.

Directive - The directing part of the command that selects components such as inputs, outputs, counters, and

timers. Not all commands require the Directive part of the command.

Compare - The comparison part of the command that holds the comparison value. Not all commands require the

Compare part of the command.

Goto - The if command redirects the program to a new address identified by a Label and stored in the Goto

column.

Comment - The user may comment the program line to help explain what the program is doing. Up to 150

characters may be typed into the comment field. If the command is a

visible. If the Wizard button is pressed, the text “Wiz- What is “ is inserted into the comment line. The user may

add or modify the command line to explain the question that will be asked if the

Wizard program allows for quick editing of lines of code without knowing how the program works.

set command, the Wizard button will be

Wizard program is used. The

Elk Products, Inc 29 Magic Module Instructions, Rev. 5.3 L391

Page 30

Writing Code

Each line of code is written by filling in the appropriate blocks in the Code Edit Line. By clicking the down

arrow to the right of each block, a menu list of the available selections drops down. Click on the desired selection and

it will be placed into the Code Edit Line.

Insert

Program Line will then be placed into the Code Edit Line where changes may be made. After

changes are made, place the Code Edit Line back into the program by clicking on the Program Line

where the Code Edit Line should be

placed before the highlighted line.

Replace

Edit Line should be

highlighted line.

Compile

be sent to the Magic Module Controller. If any errors are found during the compilation, the red

ERROR flag will be displayed along with the address in hexadecimal where the error occurred.

Comments

A line of code may be commented by typing the comments into the comment line. If the command is a “set”

command the “Wizard” button will be displayed. If the Wizard button is clicked, the comment field will start with “Wiz-“.

This will allow the Wizard Program to make changes to that line of code.

Any line in the program may be edited by “Double Clicking” the Program Line. The

Inserted. Click on the Insert button. The edited code will be

After changes are made to the Code Edit Line, click on the Program Line where the Code

Replaced. Click on the Replace button. The edited code will replace the

After editing the program, press the Compile button to regenerate the code bytes that will

Code Space

memory. This memory is stored in a non-volatile EEProm memory.

Elk Products, Inc 30 Magic Module Instructions, Rev. 5.3 L391

The amount of memory space available to store program instructions. There are 16384 bytes of program

Page 31

Save Label

A label may be added to the label list to be used later without having to type the label

name again.

Right Mouse Click (in Code Editor program area)

Copy - Highlighted Program Lines are copied to a clipboard for storage.

Cut - Highlighted Program Lines are cut from the program and copied to a clipboard for storage.

Delete - Highlighted Program Lines are deleted from the program.

Insert - Insert the Code Edit Line before the highlighted Program Line.

Paste - Insert the program lines stored from a copy or cut into the program before the highlighted Program Line.

Replace - Replace the highlighted program line with the Code Edit Line.

Code Writer - Provides several programs for automatically writing application program subroutines and initialization

setup. See

Comment/Uncomment - The program lines that are highlighted will be commented out of the program with a single

quote as the first character of the Command instruction. A null will be placed into the program code at that location. If

the code is already commented out, it will be

program. The single quote comment should not be confused with the semicolon “;” comment that is used to add

comments to the line for documentation or line spacing.

Insert; Comment - Inserts a comment line at the highlighted Program Line. The single “;” must be the only character

in the Command field. The comment field may be edited to add text for explanation. No other commands may be

present in any other fields. Use the

New / Build Structure - Starts a new program and gives the option to automatically build the program structure with a

title, description area, initialization area, program area, subroutine area, and data area. This provides a starting

template to make programming easier.

Code Writer section.

Uncommented and the normal program code will be compiled into the

Comment/Uncomment to temporarily remove a line of program code.

Open - Opens an existing file to be edited.

Save - Saves a file that has been edited and previously saved with the Save As button.

Save As - Initially saves an edited file and allows for renaming the file to a new name. This should always be

used before the

Transmit -

Magic Module that is set in the address field on the Transmit Screen.

Save button is used to initialize the file name.

Provides a shortcut to get to the Transmit Screen to send the file that is being edited out to the

Elk Products, Inc 31 Magic Module Instructions, Rev. 5.3 L391

Page 32

Event Programming Description

Events are occurrences that trigger the program to call a subroutine. When the subroutine is finished,

denoted by the

The following occurrences can generate an Event:

At the beginning of a program the event must be declared with a “set” command. The “set” command will include the

event name such as “EvtTMR1” for timer 1 event and the label where the event subroutine is located. At the end of

the subroutine a “return” command must be inserted.

Example: Toggle relay 1 on or off every 5 seconds:

begin set EvtTMR1 TimEvt ;setup timer 1 Event at label “TimEvt”

loop jmp loop ;loop forever waiting on an event to occur

; ;when Timer 1 counts down to 0 the event is triggered

;

TimEvt set OUT1 toggle ;alternate relay 1 on or off

set T1SEC 5 ;WIZ- set delay time in seconds.

return ;return from the Event

Note: if “WIZ-“ is entered as the first characters in the comment field of a “set” command, the Wizard Program will

allow the value to be changed easily. Try running the Wizard Program with the example above.

return statement, program execution continues at the next program location before the event occurred.

1. Timer 1 reaches 0. (

2. Timer 2 reaches 0. (

3. Timer 3 reaches 0. (

4. Timer 4 reaches 0. (

5. Input 1’s analog value has moved past the high or low threshold settings. (

6. Input 2’s analog value has moved past the high or low threshold settings. (

7. Input 3’s analog value has moved past the high or low threshold settings. (

8. Input 4’s analog value has moved past the high or low threshold settings. (

9. X-10 message is received.

FVAL will hold the Function value upon entering the subroutine. (EvtRX-10

10. Real Time Clock (RTC) minute has passed. Once a minute a RTC Event will occur. (

11. RS-485 data bus message has been received. This occurs when a message with the proper type and

address has been received on the data bus. (

12. RS-485 data bus has been lost. (

13. Local Temperature has changed by at least one-degree celcius. (

Dallas iButton read enabled. (EvtTKey) A Dallas iButton or 26-bit Wiegand reader can be read

14.

through the optional MA100 or the MA290 access reader interface, which plugs into connector J5. Use

Code Writer to automatically write the program code. UVAL = ID number, FVAL = reader number:

the

0 = reader 1, 1 = reader 2

EvtTMR1)

EvtTMR2)

EvtTMR3)

EvtTMR4)

EvtIN1)

EvtIN2)

EvtIN3)

EvtIN4)

RHOUSE must be set with the house code. UVAL will hold the Unit value;

EvtRTC)

EvtRXBus)

EvtNoBus)

EvtTEMP)

call TimEvt ;initialize Timer1 to 5 seconds

Elk Products, Inc 32 Magic Module Instructions, Rev. 5.3 L391

Page 33

Code Writer

The Code Writer uses a graphical user interface to answer questions and then generates

the program according to the questions answered. Note: Additional tabs may show up on your software and will be

fully supported in the future.

There are eight (8) categories for the Code Writer to use for automatically writing Magic Module Program

Code:

1. Input Event

2. Timer Event

3. Receive X-10 Event

4. Data Bus Receive Event

5. Dallas iButton Reader or 26 bit Wiegand ( Prox Card)

6. X-10 Transmit

7. Data Bus Transmit Event

8. Real Time Clock Event

SIMPLE code into

Elk Products, Inc 33 Magic Module Instructions, Rev. 5.3 L391

Page 34

Input Event

Each of the four (4) analog inputs can generate an event (or sometimes called an interrupt) when the input

level crosses either the high or low threshold level. From the factory these levels are set at 126 for the high level and

125 for the low level and the input acts as a digital input with the input either being high or low with no InRange

(between high and low thresholds) area. To generate the code follow the three-step setup:

Step 1 -

• Input Select - Selects input ( IN1 to IN4). If the input has already been used the selection will be grayed out and

cannot be selected.

• Input Description - Describes what the input will be used for. Example: Front Door, Kitchen Door, and Tank

Level. This code will be added to the comment field. A description longer that 20 characters will be truncated.

• Filter Time - The input filter time is in 1/10-second increments with a range from 1 to 255 (1/10 second to 25.5

seconds). The input filter time is sometimes call loop response time. It is the amount of time the input must

remain in the High, Inrange, or Low state before it is recognized as being in that state before generating an event.

Because the processor only increments the timer every 1/10 of a second, the filter time will have a +/- 100

milliseconds resolution, a value less than 2 or 2/10 of a second should not be used to insure a minimum of 100

milliseconds filter time. A value of 0 will disable the filter time.

Step 2 -

• Set Thresholds In Code - When checked the Code Writer will place the custom high and low input thresholds

into the code. Move the high and low slider bar to the desired voltage setting. An input level above the High

Threshold setting is interpreted as a high state. An input level between the High Threshold and the Low

Threshold is interpreted as an InRange state. An input level below the Low Threshold level is interpreted as a

Low state.

Step 3 -

• Skip If - Checks for the inputs to be in the High state, InRange state, not InRange state, and Low state. If true

the subroutine will be skipped.

Input Event Label - Code Writer automatically selects labels to be inserted into the program code. Normally this field

should not be changed.

Elk Products, Inc 34 Magic Module Instructions, Rev. 5.3 L391

Page 35

Timer Event

Each of the four (4) timers on the MM443 can generate an event when the timer counts down to zero. Follow

the three steps for programming the event:

Step 1 -

• Timer Select - Selects timer (Timer1 to Timer4). If the timer has already been used, the selection will be grayed

out and cannot be selected.

• Timer Description - Describes what the timer will be used for. Example: Exit Delay, Alarm Timer, And Relay On

Timer. This code will be added to the comment field. A description longer that 20 characters will be truncated.

Step 2 - Optional

• Tenths Second Set - Set the tenths of a second value. Range 0 to 255 (0 to 25.5 seconds).

• Seconds Set - Set the seconds value. Range 0 to 255 (0 to 255 seconds).

• Minutes Set - Set the minutes value. Range 0 to 255 (0 to 255 minutes).

• Hours Set - Set the hours value. Range 0 to 255 (0 to 255 hours).

Any combination of tenths, seconds, minutes, and hours may be entered. When all the timer settings count

down to zero, the event will be triggered.

Step 3 - Optional

• Preload Time In Setup Area - When the program starts, the timers will be initialized as set if the checkbox has

been checked.

• Reload Time In Event Subroutine - When the timer event is activated, the timers will be reloaded in the timer

event subroutine if the checkbox has been checked.

Timer Event Label - Code Writer automatically selects labels to be inserted into the program code. Normally this field

should not be changed.

Elk Products, Inc 35 Magic Module Instructions, Rev. 5.3 L391

Page 36

X-10 Receive Event

This program sets up MM443 to receive X-10 power line transmissions using a TW-523, PSC05 two-way X-10

module plugged into J5 X-10 port.