Elkhart Products Corporation (EPC) TECTITE Slip Coupling User Manual

GUIDE TO INSTALLATIO

N

Publication Date:

May 15, 2008

OF TECTITE SLIP COUPLINGS

TECTITE Slip Coupling Installation and Specifications Manual

Materials and Material Compatibility

TECTITE slip couplings are designed and manufactured to strict specifications and quality systems.

TECTITE slip couplings are manufactured from Copper or Copper Alloys and utilize EPDM o-ring seals,

Nylon and Acetal plastic components, and a 316 Stainless Steel retaining ring. An ANSI/NSF 61 listed

silicone grease is used to lubricate TECTITE slip couplings.

TECTITE slip couplings are designed for use with ASTM B88 hard drawn and annealed Copper tube, Type K,

L, or M, in the ½” through 1” size range.

All TECTITE slip couplings are designed to operate at temperatures from 0° to 250° F at a maximum working

pressure of 200 psi.

TECTITE slip couplings must not come into contact with household cleaning products, paints, greases, flux,

mineral oils, adhesives, ammonia, nitrates, or other solvent base materials that may be used during or after

installation.

The exterior surface of TECTITE slip couplings should not be painted.

The use of proprietary chemicals to flush pipes during plumbing system startup should be reviewed with an

EPC representative.

Installation

The TECTITE joining system is designed with easy installation in mind. Basic joining and removal procedures

are identical for every type and size of TECTITE fitting.

Revision BB

GUIDE TO INSTALLATIO

N

OF TECTITE SLIP COUPLINGS

Publication Date:

May 15, 2008

TECTITE Slip Coupling Assembly for Copper Tube

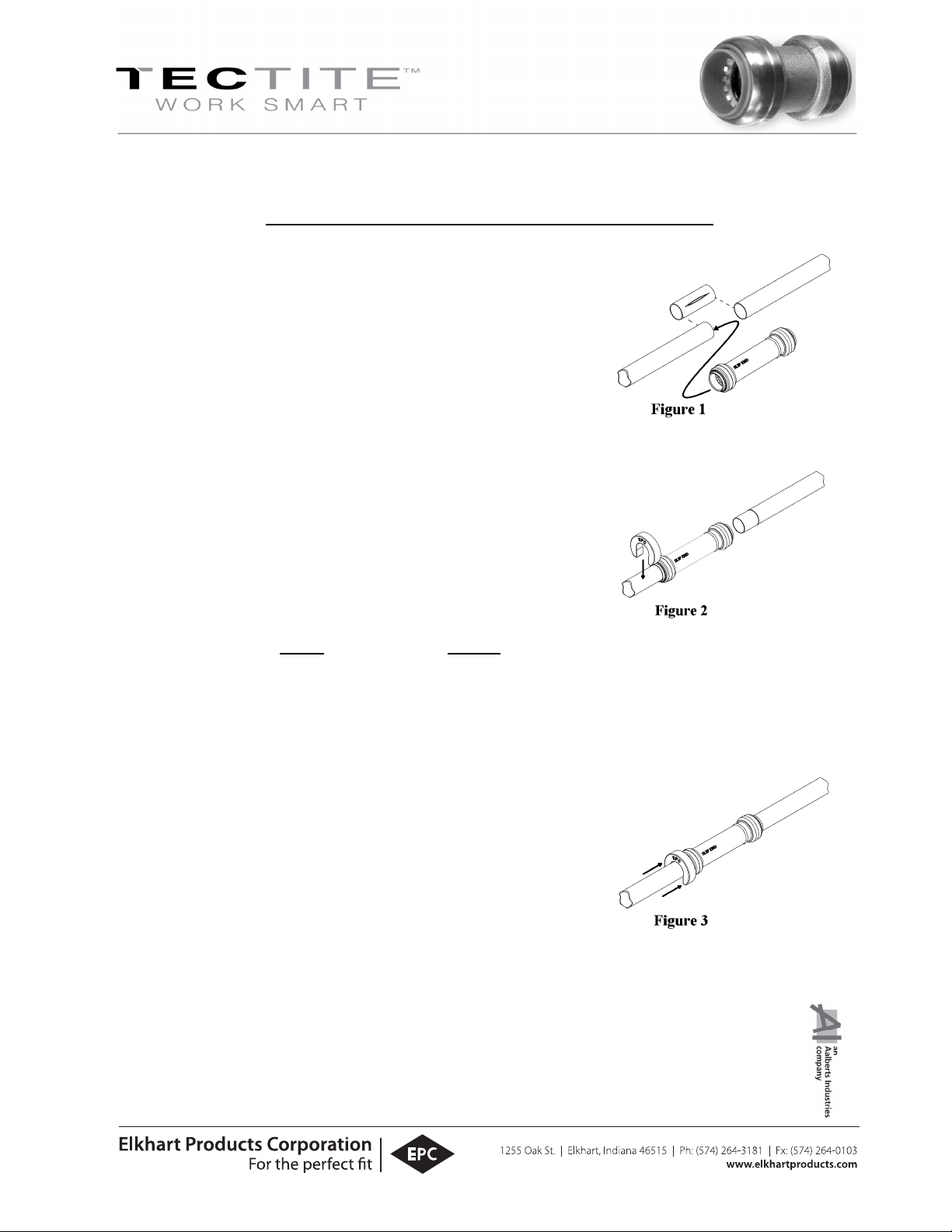

1. Remove a 2” section of the copper tube to be

repaired (Figure 1). Cut the tube using a tube

cutter, the cut should be perpendicular to the

centerline of the tube.

2. Remove burrs by chamfering the tube at the inside

and outside diameters.

3. Install the Slip Coupling by holding the fitting tightly

while inserting the tube straight into the fitting end

marked “SLIP END” with a twisting motion until the

opposite end of the fitting can be aligned with the

other tube end (Figure 2).

4. Mark the insertion depth on the other tube. Insertion

depths are printed on the product packaging or can

be referenced from the table below.

Tube Depth

½ 15/16”

¾ 1-1/8”

1 1-5/16”

5. On the tube already inserted into the coupling, place

a TECTITE Removal Tool around the tube with the

flat side placed in contact with the fitting.

6. Push the removal tool toward the fitting firmly until

the grab ring is compressed. With the removal tool

firmly held in place, use a twisting, and pulling

motion to slide the tube from the fitting, moving the

coupling toward the other tube end (Figure 3).

Revision BB

Loading...

Loading...