Elkhart Brass Unibody Valve User Manual

Valve and Controller Manual

Doc #98311000/Rev. C

TABLE OF CONTENTS

A. Quick Start Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

I. Introduction: Unibody Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

II. Component Identication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1. Bodies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4. Remote Valve Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

III. General Warning and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

IV. Quick Installation Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1. Adapters to Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2. Installation of Actuators to Valve Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

A) Remote, Direct Handle, or Twist Lock Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

B) Rack and Sector Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

C) Gear and Electric Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3. Handle Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2

A) Non-Slow Close Handle Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

B) Slow Close Handle Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4. Slow Close Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

V. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1. Seal Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2. Gear Box Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

VI. Exploded Parts View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ELKHART BRASS MANUFACTURING COMPANY, INC

VII. Introduction: Electric Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3. Specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

VIII. General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1. Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2. Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

IX. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1. Install Control and Display Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2. Install Pressure Sensor (UBEC2, UBEC3, UICS2, E4F, and E6F) . . . . . . . . . . . . . . . . . . 43

3. Install Flow Sensor (UBEC3, E4F, and E6F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

X. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1. Datalink Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2. Primary Control and Display Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3. Remote Control and Display Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4. External Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5. Preset Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6. Flow CAF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7. Set Preprogrammed Valve Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

XI. Programming (UBEC1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

XII. Programming (UBEC2 and UBEC3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

XIII. Programming (UICS2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

XIV. Programming (E3F, E4F, E5F, and E6F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

XV. Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1. Valve Position Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2. Automatic Valve Position Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3. Pressure Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4. Flow Calibration, Single Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5. Flow Calibration, Multiple Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

XVI. Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

XVII. Wiring (UBEC1, UBEC2, UBEC3 and UICS2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

XVIII. Wiring (E3F, E4F, E5F, and E6F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3

800.346.0250 • www.elkhartbrass.com

UBEC AND UICS2 QUICK START INSTRUCTIONS (E1F AND E2F)

1. Wire Harness Diagram

Primary

Controller

12/24 VDC Power Supply

Remote/

Secondary

Controller

2. Valve Position Calibration

NOTE: The valve should be partially open before starting valve position calibration.

SET FULLY CLOSED POSITION

1. Press and hold CLOSE and PRESET buttons.

Release both buttons when the red CLOSED LED

starts to ash.

2. Use the CLOSE button to close the valve.

3. When the valve is fully closed (detected by a high current surge when the valve hits the positive stop), the

CLOSE LED will ash at a faster speed.

4. Press and hold the PRESET (CAF SELECT for UICS2)

button for 5 seconds to accept and exit calibration.

Red LED will stop ashing.

SET FULLY OPEN POSITION

1. Press and hold OPEN and PRESET buttons. Release

both buttons when the green OPEN LED starts to ash.

2. Use the OPEN button to open the valve.

3. When the valve is fully opened (detected by a high

current surge when the valve hits the positive stop), the

last fully opened LED will ash at a faster speed.

4. Press and hold the PRESET (CAF SELECT for UICS2)

button for 5 seconds to accept and exit calibration.

The green fully OPEN LED will stop ashing.

Pressure – Not required unless pressure display is found to be inaccurate. (See page 64)

Flow – Always required with UBEC3 controller. (See page 64-65)

3. Common Error Codes

• F1 – Valve calibration problem

See Valve Position Calibration above.

• F5 – No pressure sensor detected

4

Check sensor harness connections. (See page 68)

• E202 – Invalid program code entered

See Pages 53-61 for programming codes.

• E204 – No signal from sensor

Check harness connections. (See page 68)

NOTE: See page 66 of manual for more diagnostic information.

4. Special Notes

• EB6D Buttery Valves

These valves utilize a high frictional coefcient seat material. This high friction value could result in a high torque

scenario when closing new, dry valves. In the event of a high torque scenario, there is a possibility of the

controller reaching its preset amperage limit, causing the controller LEDs to ash and reset the controller. Once

reset, the controller will function properly. For this reason it is recommended that repeatedly opening and closing of

the valve while dry is avoided.

Note: The above scenario is only possible in the absence of water on the valve seat.

• EBXJ Buttery Valves

1. Press and hold the OPEN and CLOSE buttons for 5 seconds.

2. Enter code 2160

Press OPEN button 2 times to enter 2

Press CLOSE button to move the cursor to the next digit

Press OPEN button 1 time to enter 1

Press CLOSE button to move the cursor to the next digit

Press OPEN button 6 times to enter 6

Result: The PRESSURE display shows 2160.

3. After 3 seconds TYPE1 (standard) or TYPE2 (reverse) shows in the display.

4. Use the OPEN button to toggle between the two.

5. Press the PRESET/CAF SELECT button and hold for 5 seconds to exit and save the programmed parameters.

ELKHART BRASS MANUFACTURING COMPANY, INC

E3F AND E4F QUICK START INSTRUCTIONS

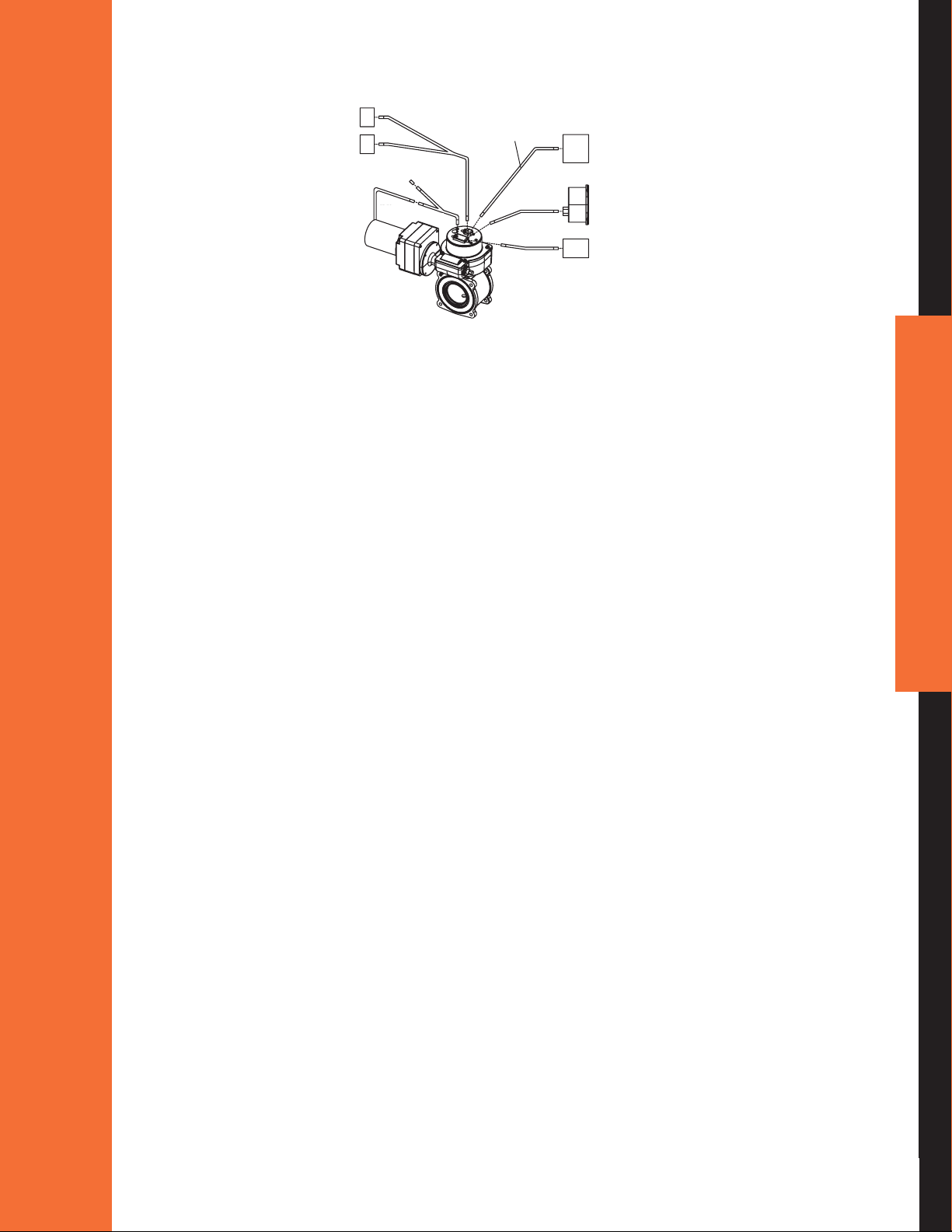

5. Wire Harness Diagram

Can Bus

Wire Not Supplied

12/24 VDC

Power Supply

Motor

Leads

J1939 Data Bus

UBEC Controller

Input Device Options

External

Inputs

Wire Not

Suppplied

Remote Inputs

6. Valve Position Calibration (SEE PAGE 63 OF MANUAL.)

NOTE: The valve should be partially open before starting valve position calibration.

AUTOMATIC POSITION CALIBRATION

1. Press and hold the CLOSE and PRESET buttons for 5 seconds.

2. The valve will cycle through the CLOSED and OPEN positions and nish in the CLOSED position.

AUTOMATIC POSITION CALIBRATION (NO EXTERNAL INPUTS)

1. Supply a 12/24-VDC signal to Pin 5 on the 12-Pin connector.

2. The valve will cycle through the CLOSED and OPEN positions and nish in the CLOSED position.

Pressure – Not required unless pressure display is found to be inaccurate. (See page 64)

Flow – Always required with UBEC3 controller. (See page 64-65)

7. Common Error Codes

• F1 – Valve calibration problem.

See Valve Position Calibration above.

• F5 – No pressure sensor detected.

Check sensor harness connections. (See page 70)

• E202 – Invalid program code entered.

See Pages 62 for programming codes.

• E204 – No signal from sensor.

Check harness connections. (See page 70)

• OPEN and CLOSE LED Flashing – Position Calibration needed.

See Valve Position Calibration above.

NOTE: See page 66 of manual for more diagnostic information.

8. Special Notes

• EB6D Buttery Valves

These valves utilize a high frictional coefcient seat material. This high friction value could result in a high torque

scenario when closing new, dry valves. In the event of a high torque scenario, there is a possibility of the

controller reaching its preset amperage limit, causing the controller LEDs to ash and reset the controller. Once reset,

the controller will function properly. For this reason it is recommended that repeatedly opening and closing of the

valve while dry is avoided.

Note: The above scenario is only possible in the absence of water on the valve seat.

• EBXJ Buttery Valves

1. Press and hold the OPEN and CLOSE buttons for 5 seconds.

2. Enter code 2160

Press OPEN button 2 times to enter 2

Press CLOSE button to move the cursor to the next digit

Press OPEN button 1 time to enter 1

Press CLOSE button to move the cursor to the next digit

Press OPEN button 6 times to enter 6

Result: The PRESSURE display shows 2160.

3. After 3 seconds TYPE1 (standard) or TYPE2 (reverse) shows in the display.

4. Use the OPEN button to toggle between the two.

5. Press the PRESET/CAF SELECT button and hold for 5 seconds to exit and save the programmed parameters.

5

800.346.0250 • www.elkhartbrass.com

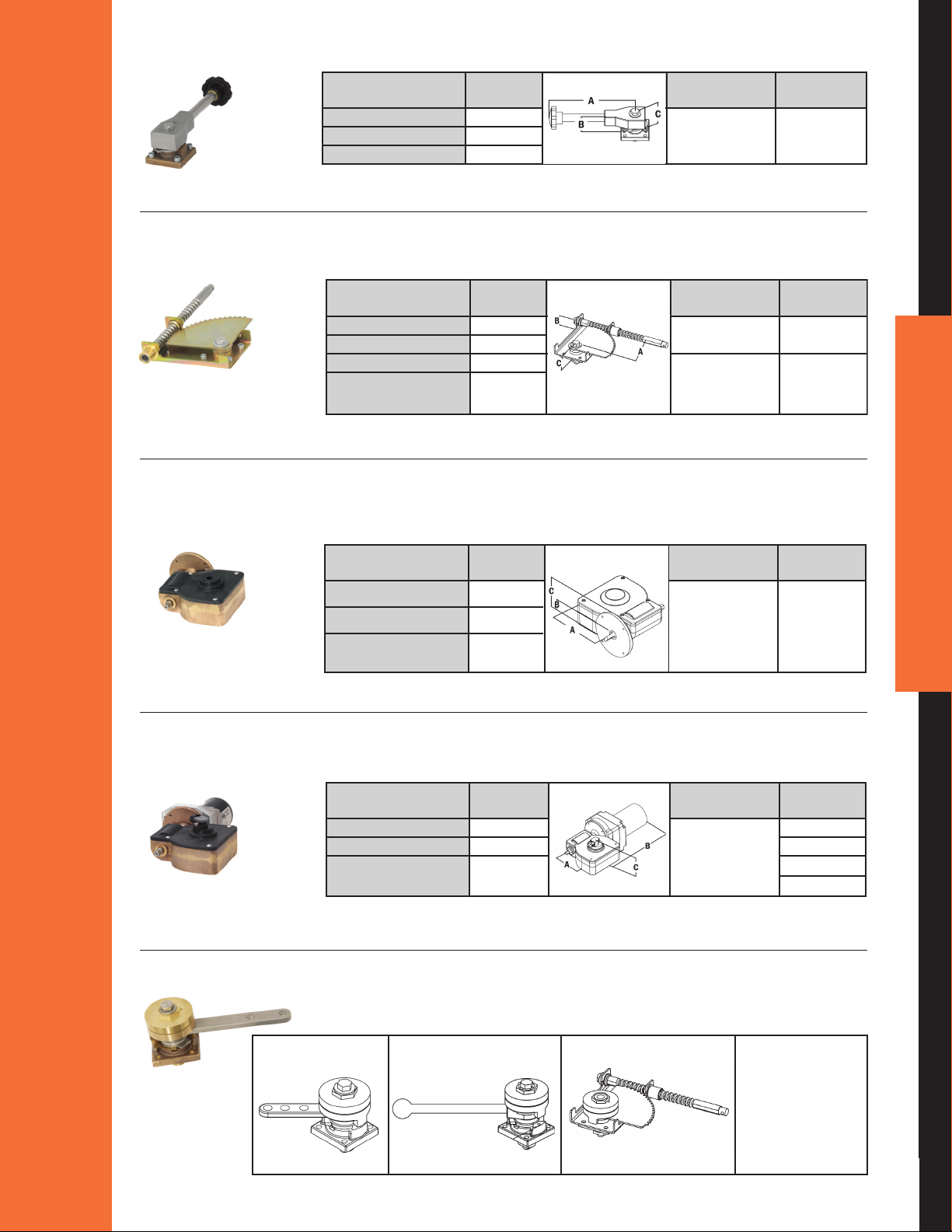

I. INTRODUCTION

Elkhart Brass Unibody apparatus valves are specially designed for reliability, ease of installation and ease

of use.

BALL VALVE

• Unibody Ball Valves are available in 1.5", 2", 2.5", 3", 3.5", and 4" sizes.

• The bodies are constructed of corrosion resistant brass, and the ball is constructed from durable

stainless steel (EB15–EB35) or high strength brass alloy (EB40).

• Dual self-adjusting seats provide bidirectional sealing (EB15-EB35) or single self-adjusting abrasion

resistant unidirectional seat (EB40).

• Adapters (end caps) and pump anges are constructed of either brass or stainless steel requiring no

6

• Swing out construction allows for easy access to internal waterway.

• The patent pending Unibody design allows any actuator assembly to be bolted onto the valve body

• Actuators are interchangeable so that a Unibody Valve may be easily converted to a different actuation

• Durable handles and handle stops ensure dependability, while the handle may be easily changed to

O-rings that could cut or tear during servicing.

without need to break the internal plumbing of the truck.

type without the need to break the waterway.

eight different positions by removing a single bolt.

BUTTERFLY VALVE

• Unibody Buttery Valves are available in 3", 4", 5", 6", and 8" sizes.

• Bidirectional with EPDM seat.

• The buttery valve utilizes either our extreme duty electric actuator or our gear actuator.

Unibody Valves meet or exceed NFPA 1901 Standards.

The electric valve utilizes a three-inch extreme duty motor and gearbox for ultimate reliability.

ELKHART BRASS MANUFACTURING COMPANY, INC

II. COMPONENT IDENTIFICATION

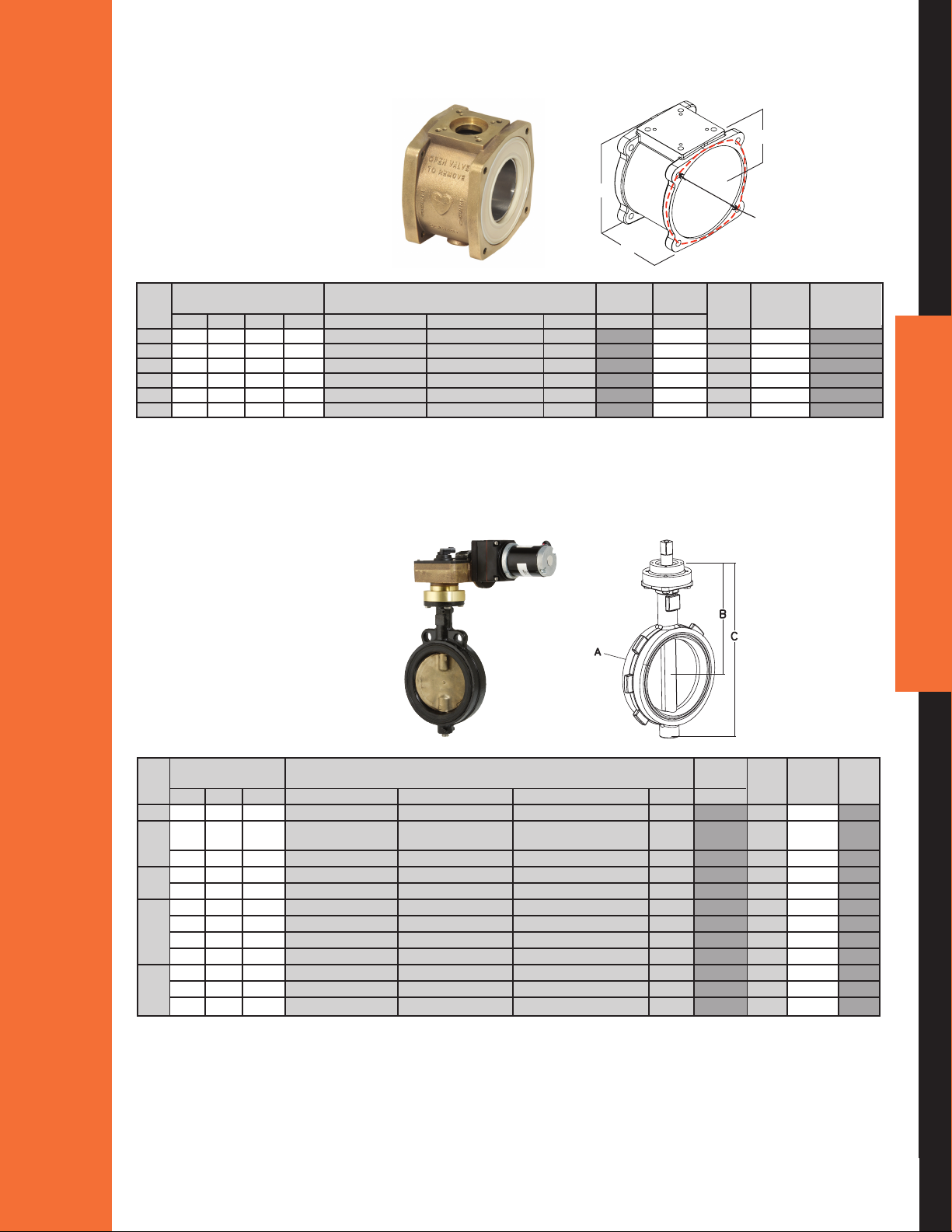

1a. Ball Valve Body

B

B

C

C

D

A

A

DIMENSIONS M ATERIALS BALL RATED CvELKHART Akron

PRESSURE

Size A B C D* Body Ball Seat TYPE (psi) VALUE M O D E L Model

1

1

/

2" 3" 2

2" 3" 2

1

2

/

2" 3

3" 4" 3" 5

1

3

/

2" 4" 3" 5

4" 4" 4

1

/

2" 2

3

/

16" 4

3

/

16" 4

5

/

8" 5

11

/

16" 8

5

1

/

16" 4

/

2" Brass Alloy 844 316 Stainless Steel Hytrel Round 600 139 EB15 7615/7815

5

1

/

16" 4

/

2" Brass Alloy 844 316 Stainless Steel Hytrel Round 600 139 EB20 8620

1

3

/

16" 5

/

8" Brass Alloy 844 316 Stainless Steel Hytrel Round 600 277 EB25 8625

7

1

/

8" 6

/

8" Brass Alloy 844 316 Stainless Steel Hytrel Round 600 510 EB30 8630

7

1

/

8" 6

/

8" Brass Alloy 844 316 Stainless Steel Hytrel Round 600 510 EB35 8635

5

1

/

8" 7

/

8" Brass Alloy 844 316 Stainless Steel Hytrel lat 500 694 EB40 8840

/

/

/

/

* Bolt center diameter

1b. Butterfly Body

8820

8825

8830

8835

7

DIMENSIONS M ATERIALS R ATED CvELKHART Akron

PRESSURE

Size A B C Body W afer Shaft Seat (psi) VALUE M O D E L Model

13

23

3" 1

4"

5"

6"

8" 2

1

2

2

3

2

2

3

2

2

2

2

2

2

/

16" 7

/

16" 8

1

/

8" 8

/

16" 8

1

/

2" 6

/

16" 9

1

/

4" 9

1

/

4" 9

1

/

4" 9

3

/

8" 10

1

/

2" 10

1

/

2" 10

/

32" 11

13

/

32" 12

7

/

16" 13

31

/

32" 13

17

/

32" 13

19

/

32" 14

13

/

32" 11

3

/

16" 15

3

/

16" 15

27

/

32" 17

9

/

16" 18

9

/

16" 18

1

/

8" Cast Iron Aluminum/Bronze 416 Stainless Steel E P D M 250 340 EB3B 7940

15

/

32" Cast Iron Aluminum/Bronze 416 Stainless Steel E P D M 250 660 EB4B 7940/

3

/

8" Carbon Steel 316 Stainless Steel 17-4 PH Stainless Steel PTFE 285 400 EB4J

23

/

32" Cast Iron Aluminum/Bronze 416 Stainless Steel E P D M 250 1080 EB5B 7950

7

/

32" Carbon Steel 316 Stainless Steel 17-4 PH Stainless Steel PTFE 285 650 EB5J

19

/

32" Cast Iron Aluminum/Bronze 416 Stainless Steel E P D M 250 1613 EB6B 7960

13

/

32" Dutile Iron Aluminum/Bronze 416 Stainless Steel E P D M 250 1950 EB6D

1

/

16" Carbon Steel 316 Stainless Steel 17-4 PH Stainless Steel PTFE 285 1050 EB6J

1

/

16" 316 Stainless Steel 316 Stainless Steel 17-4 PH Stainless Steel PTFE 275 1050 EB6JS

11

/

32" Cast Iron Aluminum/Bronze 416 Stainless Steel E P D M 250 3759 EB8B

3

/

16" Carbon Steel 316 Stainless Steel 17-4 PH Stainless Steel PTFE 285 2200 EB8J

3

/

16" 316 Stainless Steel 316 Stainless Steel 17-4 PH Stainless Steel PTFE 275 2200 EB8JS

7945

800.346.0250 • www.elkhartbrass.com

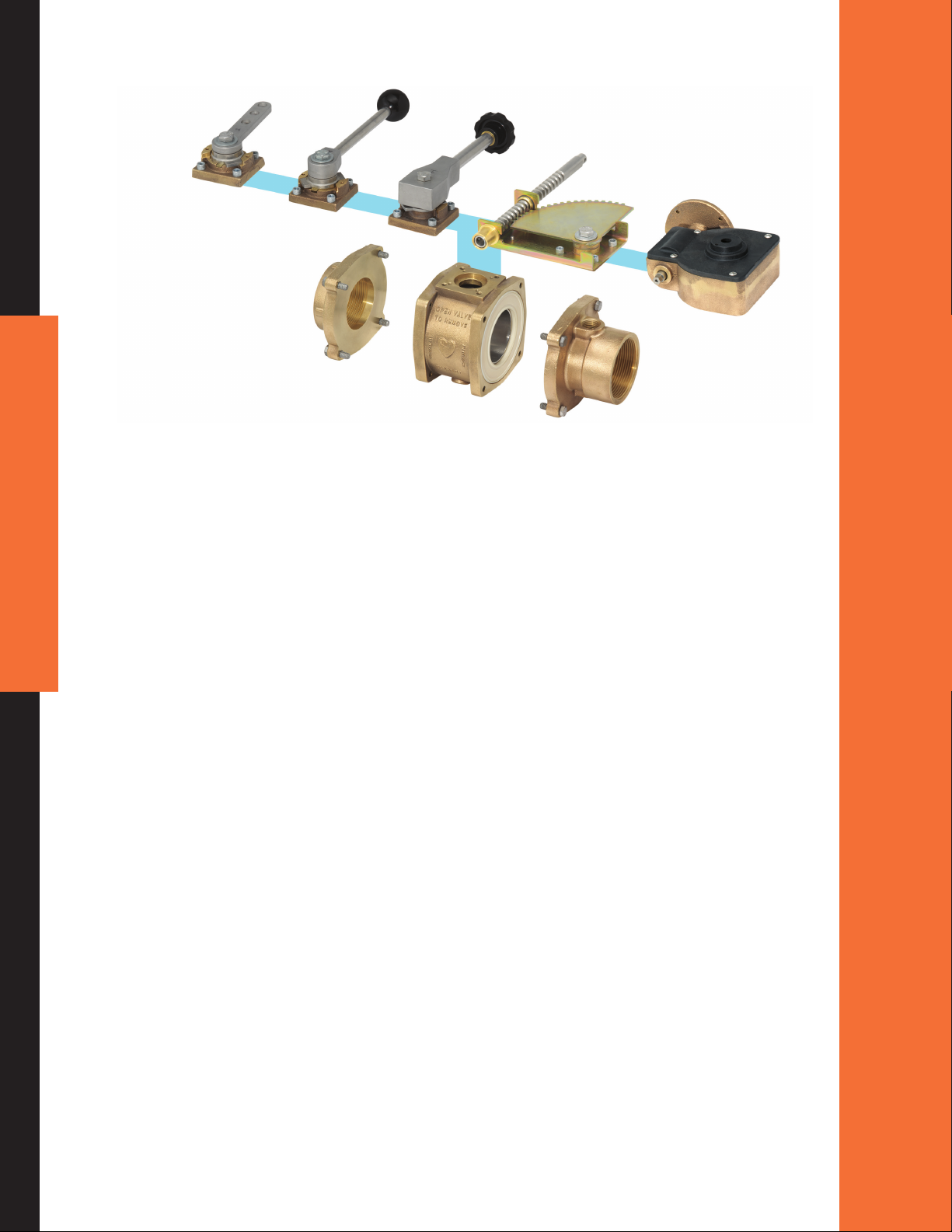

2. Adapters

For complete adapter availability, view the “Unibody Valve Engineering Guide” at www.unibodyvalve.com.

3. Actuators

REMOTEHANDLE

Elkhart Model

Self-Locking Non-Locking

noitpircseDsehcnIsnoisnemiD

8

Handle Length A

(short)

Handle Length A

(long)

Handle Height B 15/

Overall Height C 21/

Overall Height C

DIRECTHANDLE

Handle Length A

(short)

Handle Length A

(long)

Handle Height B 1

Overall Height C 2

Overall Height C

(with slow close)

41/

2"

A

7" Long R2F R4F

Short R1F R3F

C

B

35/

8"

4 esolc wols"

16"

Short with

Long with

R1S R3S

esolc wols)esolc wols htiw(

R2S R4S

noitpircseDsehcnIsnoisnemiD

Elkhart

Mode

5" Short D3F

5

9

/

16"

7

8"

/

1

4"

/

A

C

B

Long D1F

Short with

slow close

Long with

slow close

Short with

5

3

8"

/

chrome cover

Long with

chrome cover

D3S

D1S

D4F

D2F

ELKHART BRASS MANUFACTURING COMPANY, INC

TWISTLOCK

Elkhart

noitpircseDsehcnIsnoisnemiD

Model

Handle Length A 8

15

/

16"

Handle Height B 1

7

/

8 dradnatS" T1F

Overall Height C 3"

B

A

C

Elkhart

noitpircseDsehcnIsnoisnemiD

Model

Handle Length A 8

15

/

16"

Handle Height B 1

7

/

8 dradnatS" T1F

Overall Height C 3"

B

A

C

Elkhart

noitpircseDsehcnIsnoisnemiD

Model

Handle Offset A 4

7

/

8"

Standard S1F

Handle Height B 1

1

/

8"

Overall Height C

1

7

/

8"

Standard with S1S

Overall Height C

3

5

/

16"

slow close

(with slow close)

B

A

C

* For use on the EB6D only.

Elkhart

noitpircseDsehcnIsnoisnemiD

Model

Handle Length A 8

15

/

16"

Handle Height B 1

7

/

8 dradnatS" T1F

Overall Height C 3"

B

A

C

Elkhart

noitpircseDsehcnIsnoisnemiD

Model

Handle Offset A 4

7

/

8"

Standard S1F

Handle Height B 1

1

/

8"

Overall Height C

1

7

/

8"

Standard with S1S

Overall Height C

3

5

/

16"

slow close

(with slow close)

B

A

C

Elkhart

Dimensions Inches Description

Model

Handle Offset A 2

9

/

16"

Handwheels

Handle Height B 1

9

/

16" are ordered G1F

*G2F

Overall Height C 3

7

/

16"

separately.

B

A

C

* For use on the EB6D only.

RACKandSECTOR

Handle Length A 8

Handle Height B 1

Overall Height C 3"

15

16"

/

7

8 dradnatS" T1F

/

A

B

C

noitpircseDsehcnIsnoisnemiD

Elkhart

Model

Handle Offset A 4

Handle Height B 1

Overall Height C

Overall Height C

(with slow close)

GEAR

ELECTRIC

SLOWCLOSE

Dimensions Inches Description

Handle Offset A 2

Handle Height B 1

Overall Height C 3

Manual Offset A 2

Motor Length B 10

Overall Height C (E1F, E2F,

E3F, E4F, E5F, and E6F)

Controllers are ordered separately. * For use on the EB6D only.

7

8"

/

1

8"

/

7

1

8"

/

5

3

16"

/

9

16"

/

9

16" are ordered G1F

/

7

16"

/

9

16"

/

1

4"

/

3

8

4

"

/

noitpircseDsehcnIsnoisnemiD

B

C

A

Standard S1F

Standard with S1S

Elkhart

Model

slow close

Elkhart

Model

C

B

A

Handwheels

separately.

*G2F

9

noitpircseDsehcnIsnoisnemiD

B

A

C

Controllers are

ordered

separately.

Elkhart

Model

E1F

*

E2F

E3F & E4F

*E5F & *E6F

800.346.0250 • www.elkhartbrass.com

Slow close may

be bolted to

remote, direct

and rack and

sector actuators.

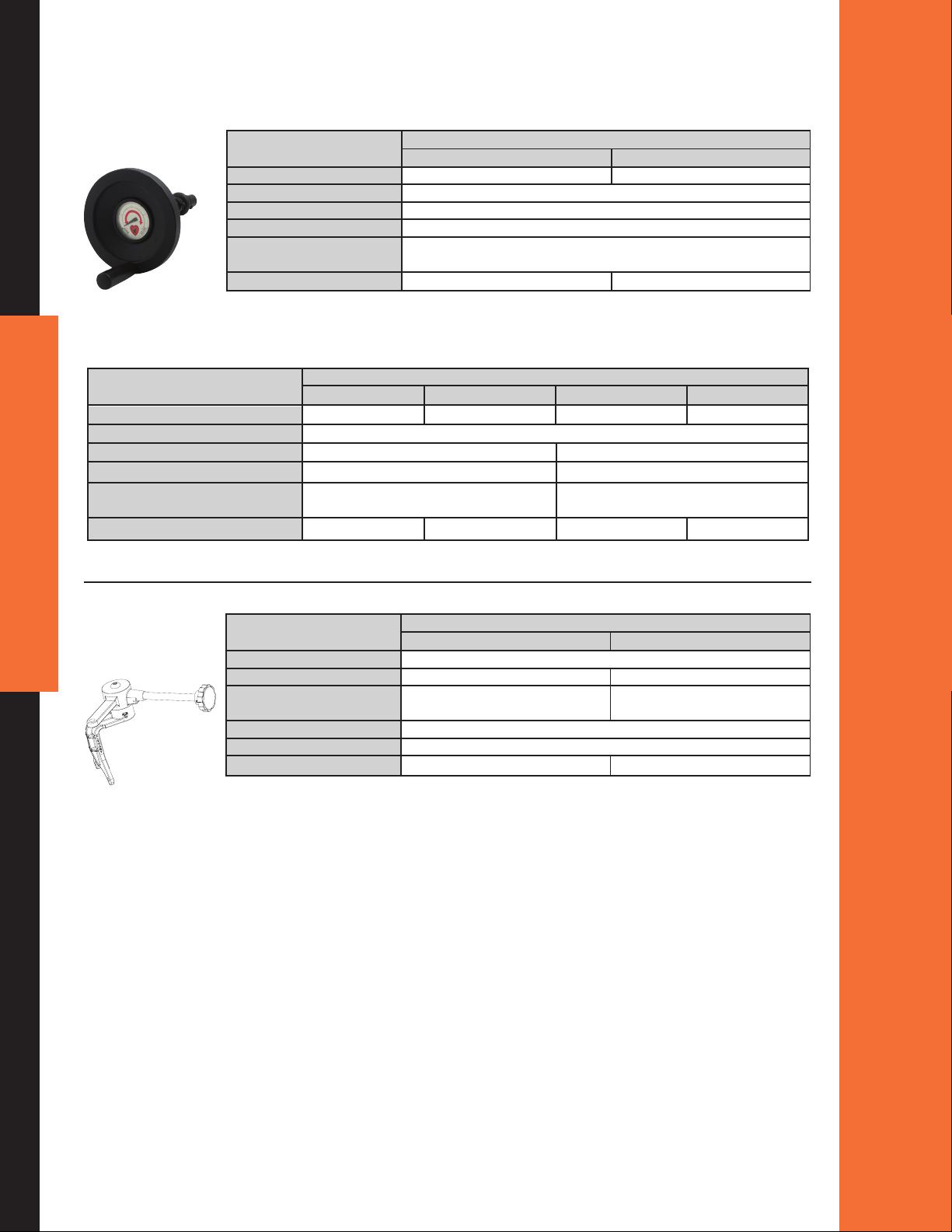

4. Remote Valve Controls

POSITIONINDICATINGHANDWHEEL

MODELS

P 3.6-PWG4-PWGNOITAMROFNI TCUDOR

Handwheel diameter "3.6"4

Material Aluminum

Finish

(specify)

Installation diameter 1.125"

Furnished with

Weight .sbl 5.4.sbl 0.4

swivel joints with protective rubber boots

STANDARDHANDWHEEL

PRODUCT INFORMATION GWR-5 GWR- 6.5 GWD-5 GWD-6.5

Handwheel diameter 5" 6.5" 5" 6.5"

Material Chrome plated brass

Type Panel mount Direct mount

Installation diameter –"521.1

Furnished with

Weight 4. 0 lbs . 6.75 lbs. 2.50 lbs. 5.25 lbs.

Panel bushing and two universal swivel

joints with protective rubber boots

Black or Chrome

Panel bushing and two universal

MODELS

–

10

PIGGY-BACK

REMOTE

CONTROLUNIT

MODELS

Valve compatability For use with the Elkhart Brass Unibody line

Handle gnikcol-noNkcoL-tsiwT

Orientation

(specify)

Material Cast brass with stainless steel handle rod

Length "8"8

Weight .sbl 0.6.sbl 0.6

Dual handle right (A) Dual handle right (A)

U3-CRU2-CRNOITAMROFNI TCUDORP

)B( tfel ro)B( tfel ro

ELKHART BRASS MANUFACTURING COMPANY, INC

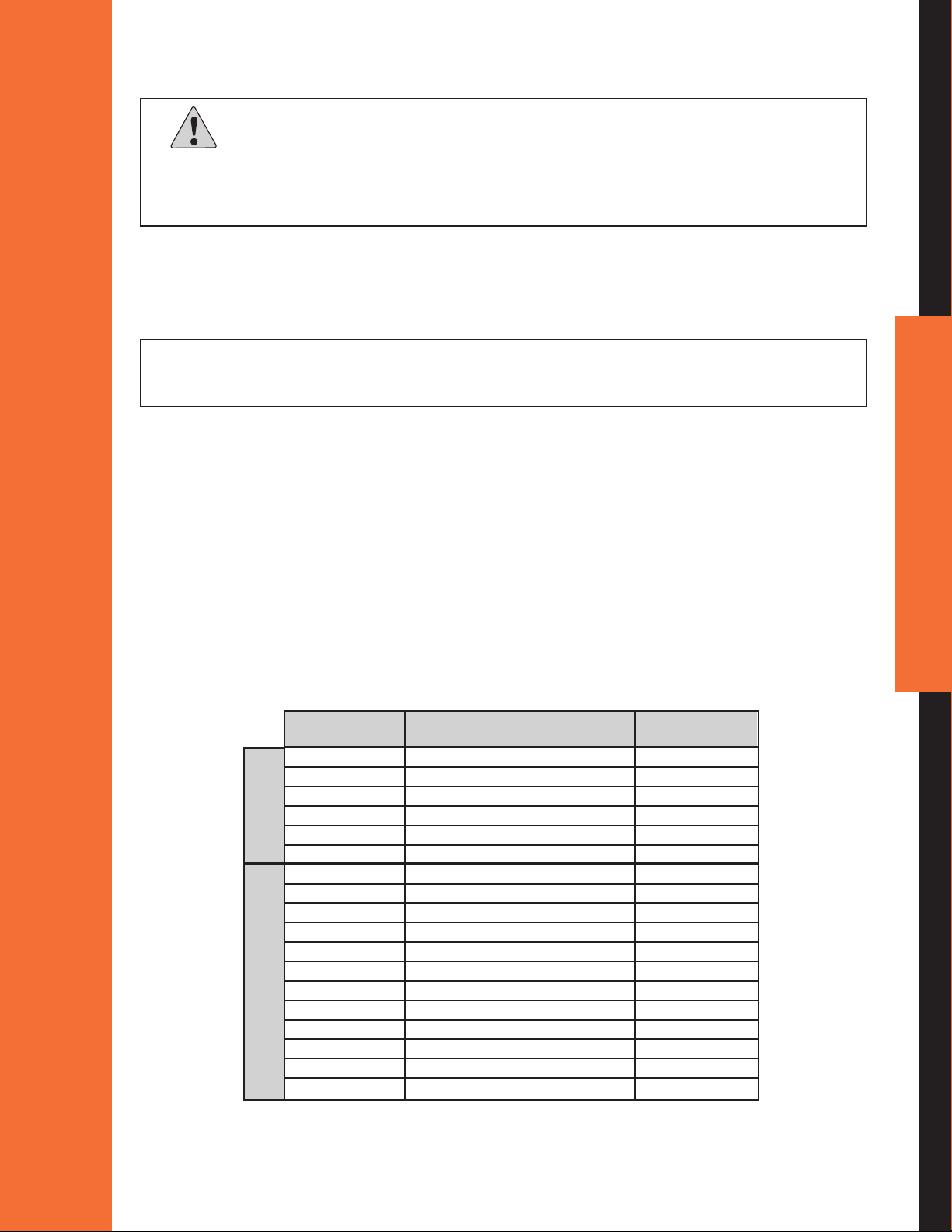

III. GENERAL WARNINGS AND CAUTIONS

Important:

Beforeinstallingandoperatingthisequipment,readandstudythismanualthoroughly.Proper

installationisessentialtosafeoperation.Inaddition,thefollowingpointsshouldbeadheredtoinorder

toassurethesafetyofequipmentandpersonnel.

• All personnel who may be expected to operate this equipment must be thoroughly trained in its safe

and proper use.

• Become thoroughly familiar with the hydraulic characteristics of this equipment.

NFPA1901Standardsspecifyaminimumof3secondsisrequiredtoopenorclosea3”orlargervalve.

• Always open and close valves slowly to avoid water hammer.

• After each use, and on a scheduled basis, inspect equipment per instructions in the maintenance

Section V.

• Keep ngers and hands clear of moving parts.

• Do not use lubrication on the valve ball or seats.

• Do not wrench on the valve body or the opposite adapters.

• Disconnect power before servicing an electric valve.

• Clear debris from waterway before the valve is installed.

• Foreign materials such as metal chips could jeopardize the sealing capability of the valve. Any drilled

holes required in the plumbing should be added, and the chips removed from the waterway, prior to

installation of the valve.

• Do not exceed rated operating pressure for any valve as listed in Table 1.

11

Model Rated Operating Pressure C

Number (psi) Value

EB15 600 139

EB20 600 139

EB25 250 277

EB30 250 510

Ball Valves

Butterfly

EB35 250 510

EB40 250 694

EB3B 250 340

EB4B 250 660

EB4J 285 400

EB5B 250 1080

EB5J 285 650

EB6B 250 1613

EB6D 250 1950

Valves

EB6J 285 1050

EB6S 275 1050

EB8B 250 3759

EB8J 285 2200

EB8S 275 2200

Table 1 – Pressure

v

800.346.0250 • www.elkhartbrass.com

IV. QUICK INSTALLATION GUIDE

1. Adapters to Valve Body

A) Move valve to close position. See Figure 1.

Ball in closed

position

Figure 1

B) Tighten the four 3/8" adapter bolts in an X pattern (see Figure 2). See Table 2 for torque

requirements.

12

Valve Torque

EB15 25-30 ft-lbs

EB20 25-30 ft-lbs

EB25 25-30 ft-lbs

EB30 38-40 ft-lbs

EB35 38-40 ft-lbs

EB40 60-70 ft-lbs

Table 2 – Torque

Figure 2

ELKHART BRASS MANUFACTURING COMPANY, INC

2. Installation of Actuators to Valve Body

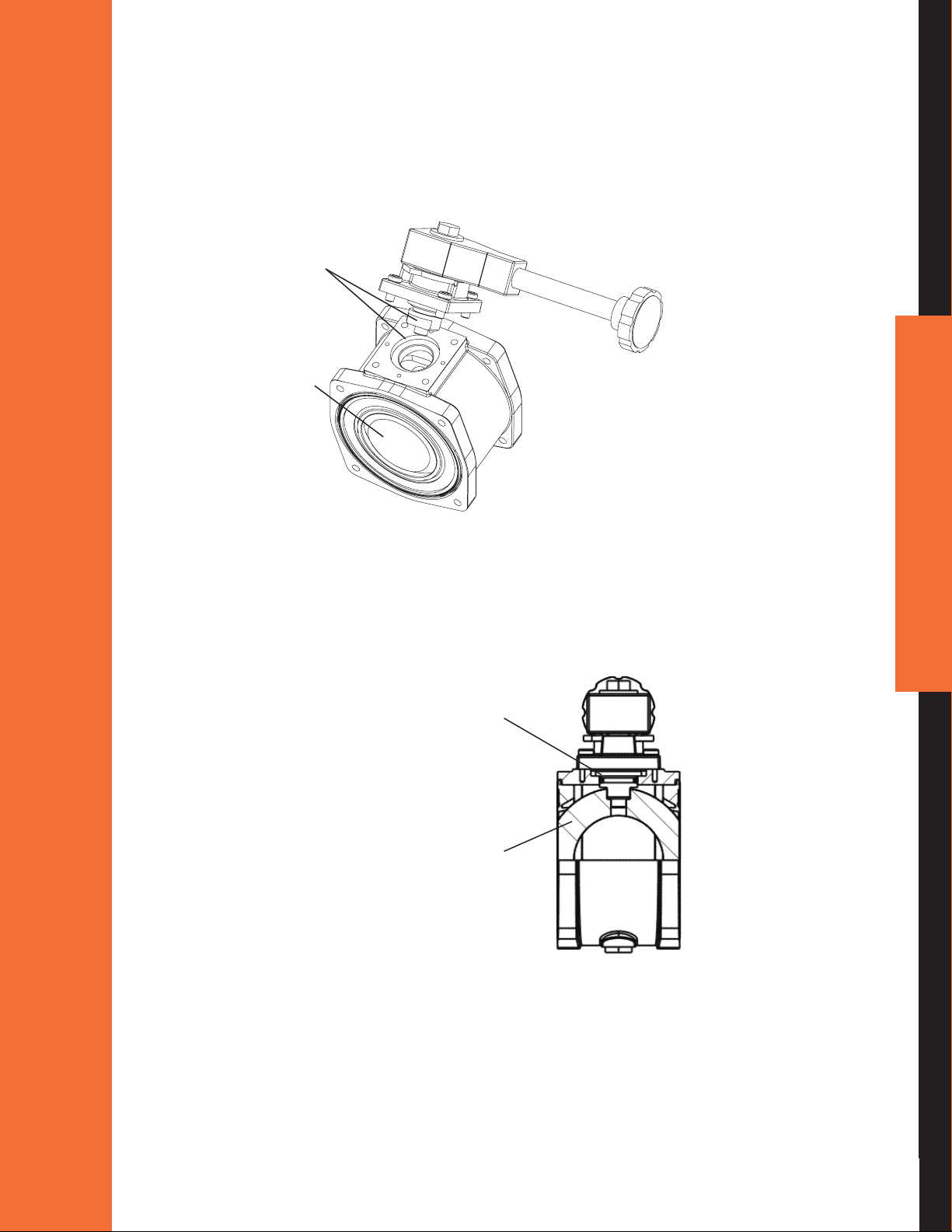

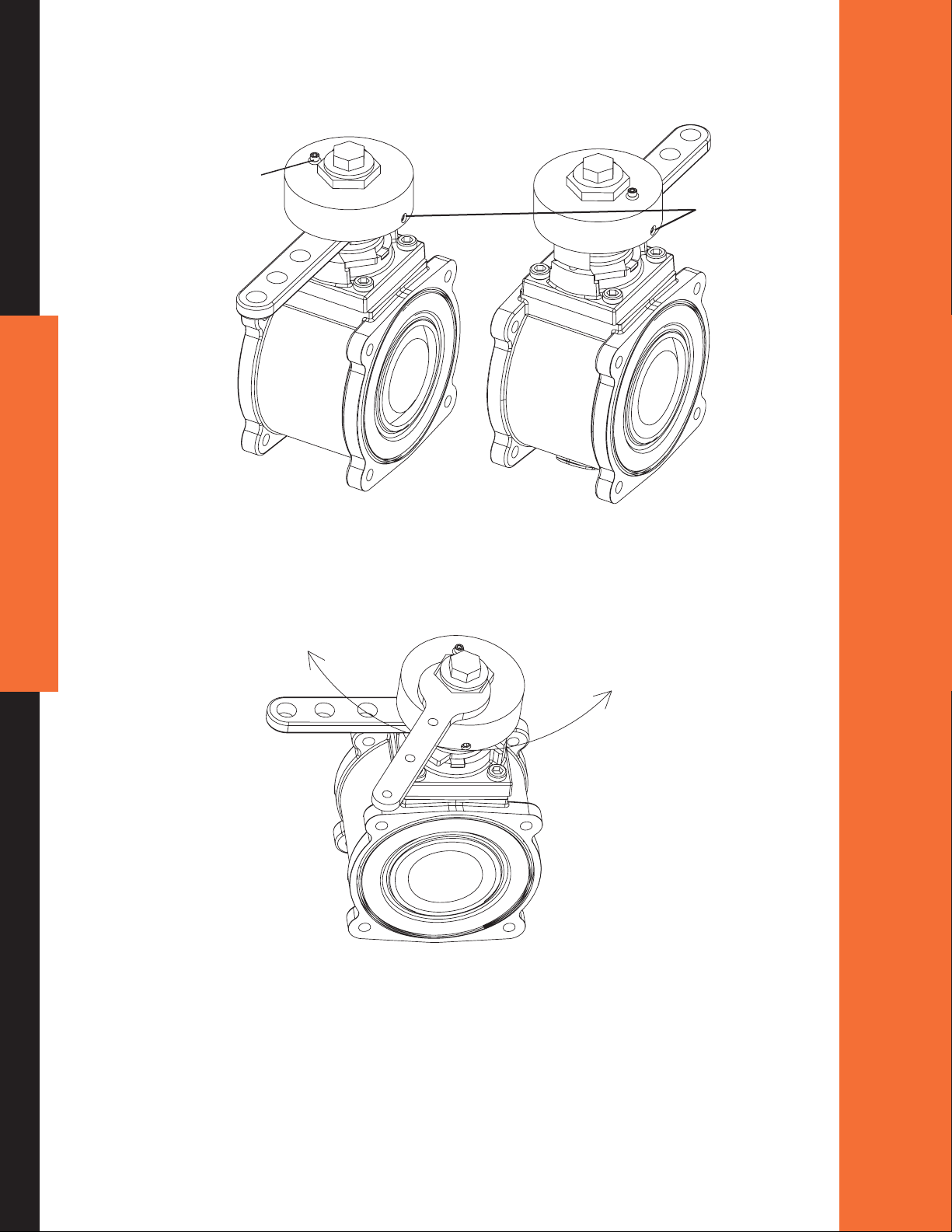

A) Remote, Direct Handle, or Twist Lock Actuator

1. Hold the actuator assembly above valve body assembly and align the actuator shaft

with the slot in the ball as shown. See page 18 Handle Position if the handle requires

new orientation.

Actuator shaft

and slot in

ball align

Ball in closed

position

Figure 3

2. Push the actuator assembly down against valve body assembly and rotate the handle

assembly in both directions slightly while pushing assembly against valve body until

actuator drops into slot in valve ball as shown in Figure 4. There should be no gap

between the actuator assembly and the valve body.

No gap between

actuator assembly

and valve body

Ball in closed

position

Figure 4

13

800.346.0250 • www.elkhartbrass.com

3. Rotate the actuator assembly on valve body until handle stops align with waterway

as shown in Figure 5.

Handle stops align

with waterway

Figure 5

4. Fasten the actuator assembly to valve body by tightening 5/16 socket head cap screws in

an X pattern to a torque of 15 ft-lb.

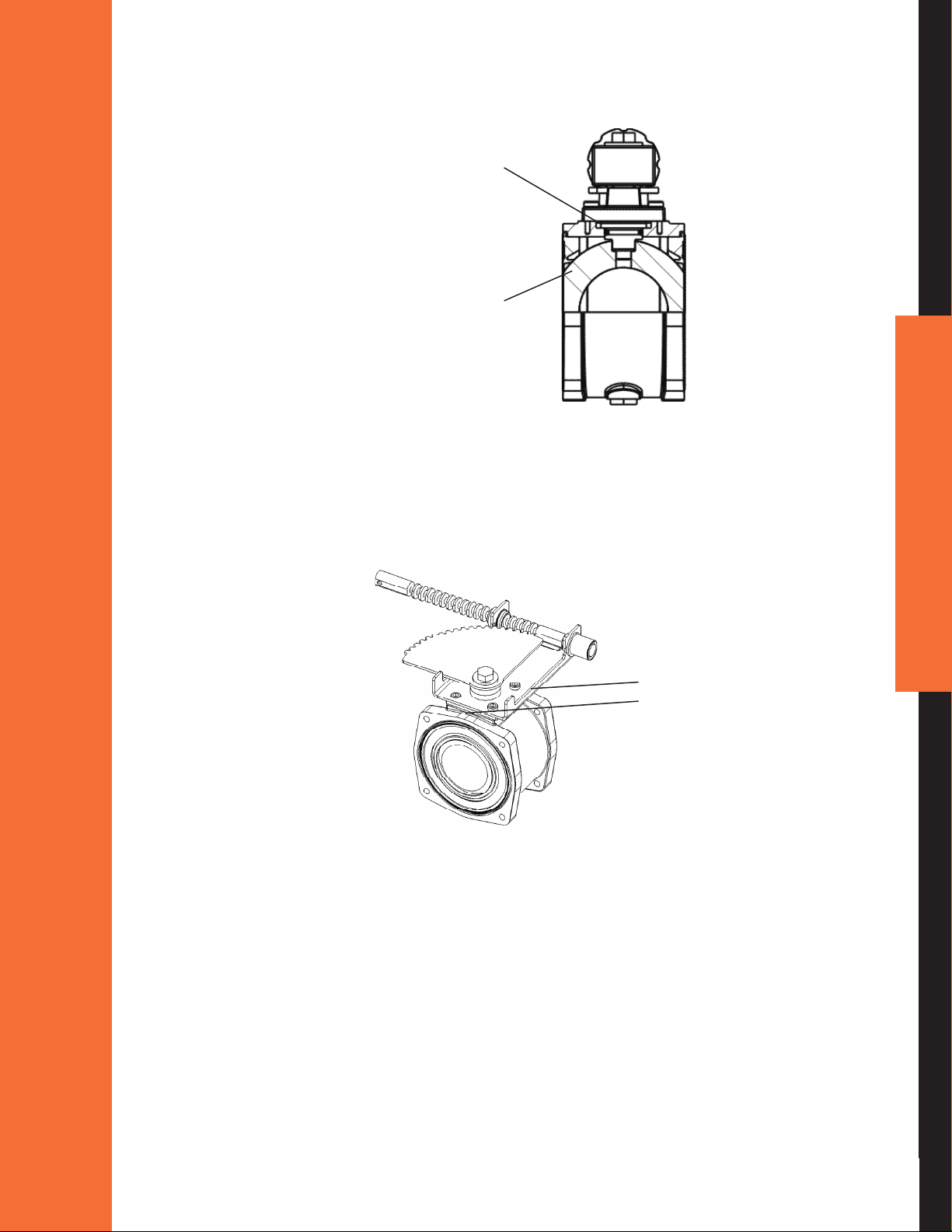

B) Rack and Sector Actuator

1. Hold the actuator assembly above valve body assembly and align the actuator shaft

with the slot in the ball as shown in Figure 6. Ensure that the rst tooth of the rack and

the rst tooth of the section are aligned properly (see Figure 7) or the valve will not

shut completely. Note that the rack and sector actuator assembly can rotate in 90°

increments for different orientations of the actuator assembly.

14

First teeth

together

Actuator shaft

and slot in ball

align

Ball in closed

position

Figure 6 Figure 7

ELKHART BRASS MANUFACTURING COMPANY, INC

2. Push the actuator assembly down against valve body assembly and rotate the assembly

in both directions slightly while pushing assembly against valve body until actuator drops

into slot in valve ball as shown in Figure 8. There should be no gap between the actuator

assembly and the valve body.

No gap between

actuator assembly

and valve body

Ball in closed

position

Figure 8

3. Rotate the actuator assembly on valve body until the rectangular actuator adapter aligns

with the square-mounting surface on the valve body. Ensure the rack is in the proper position when the ball is open, as shown in Figure 9.

Rectangle adapter

aligns with valve

body adapter

Figure 9

4. Fasten the actuator assembly to valve body assembly by tightening 5/16 socket head

cap screws in an X pattern to a torque of 15 ft-lb.

15

800.346.0250 • www.elkhartbrass.com

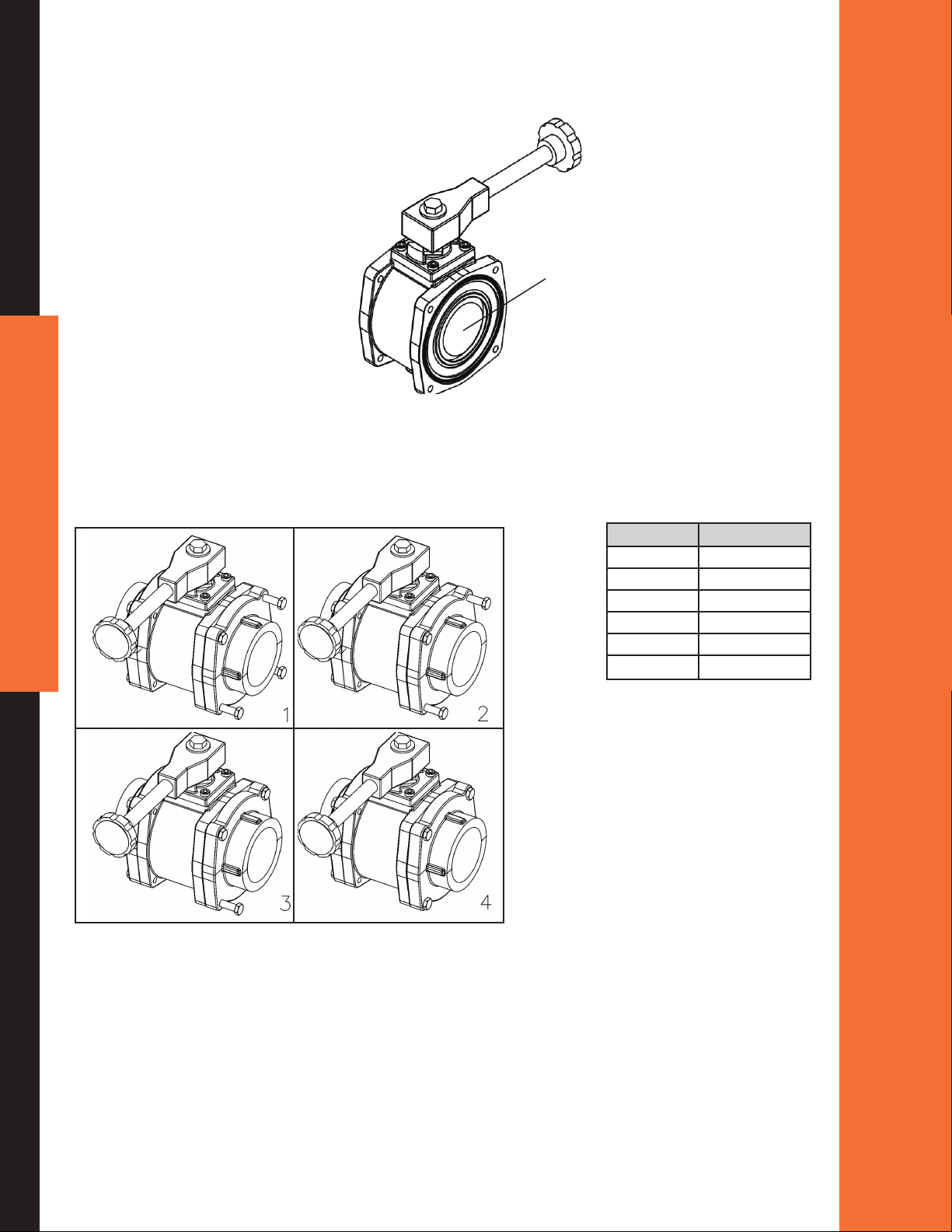

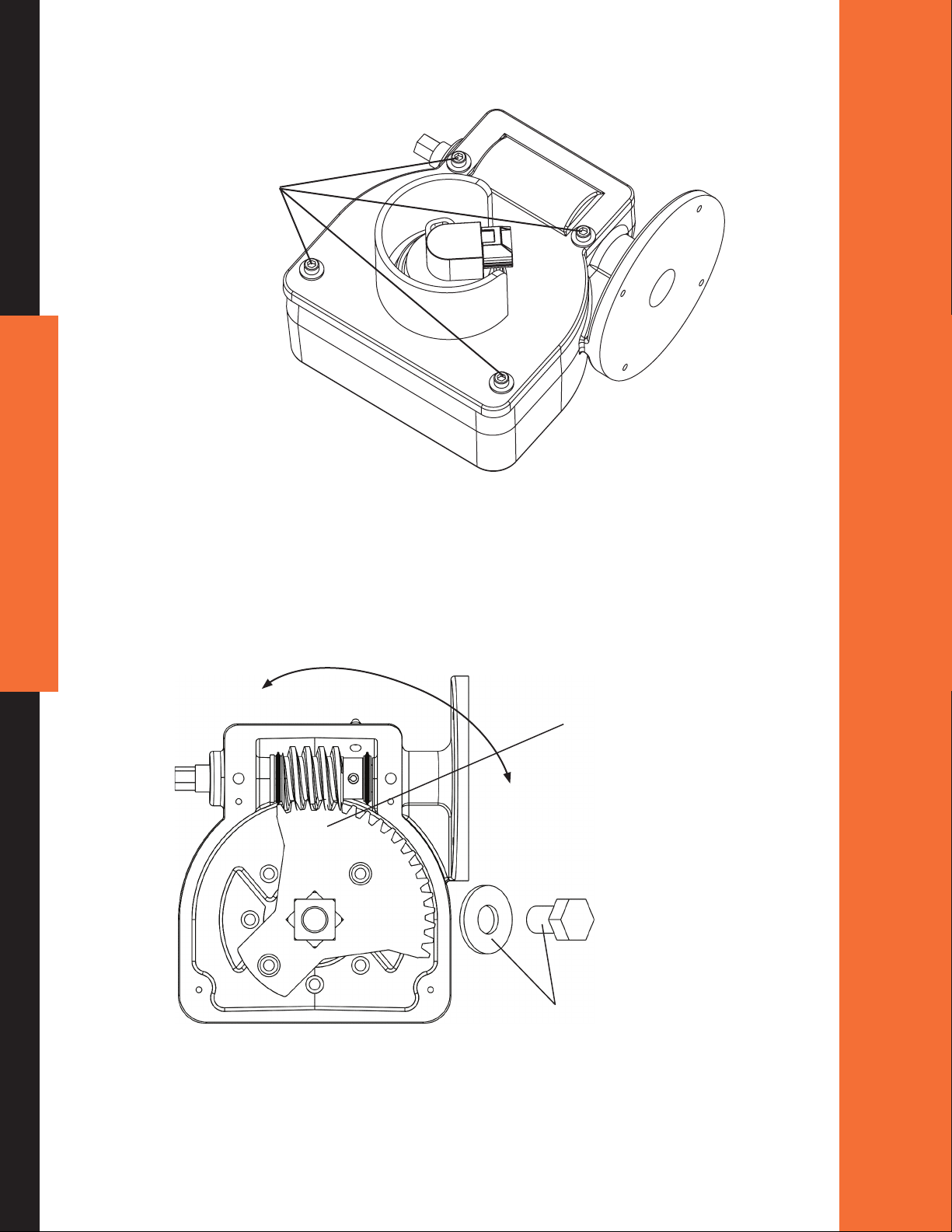

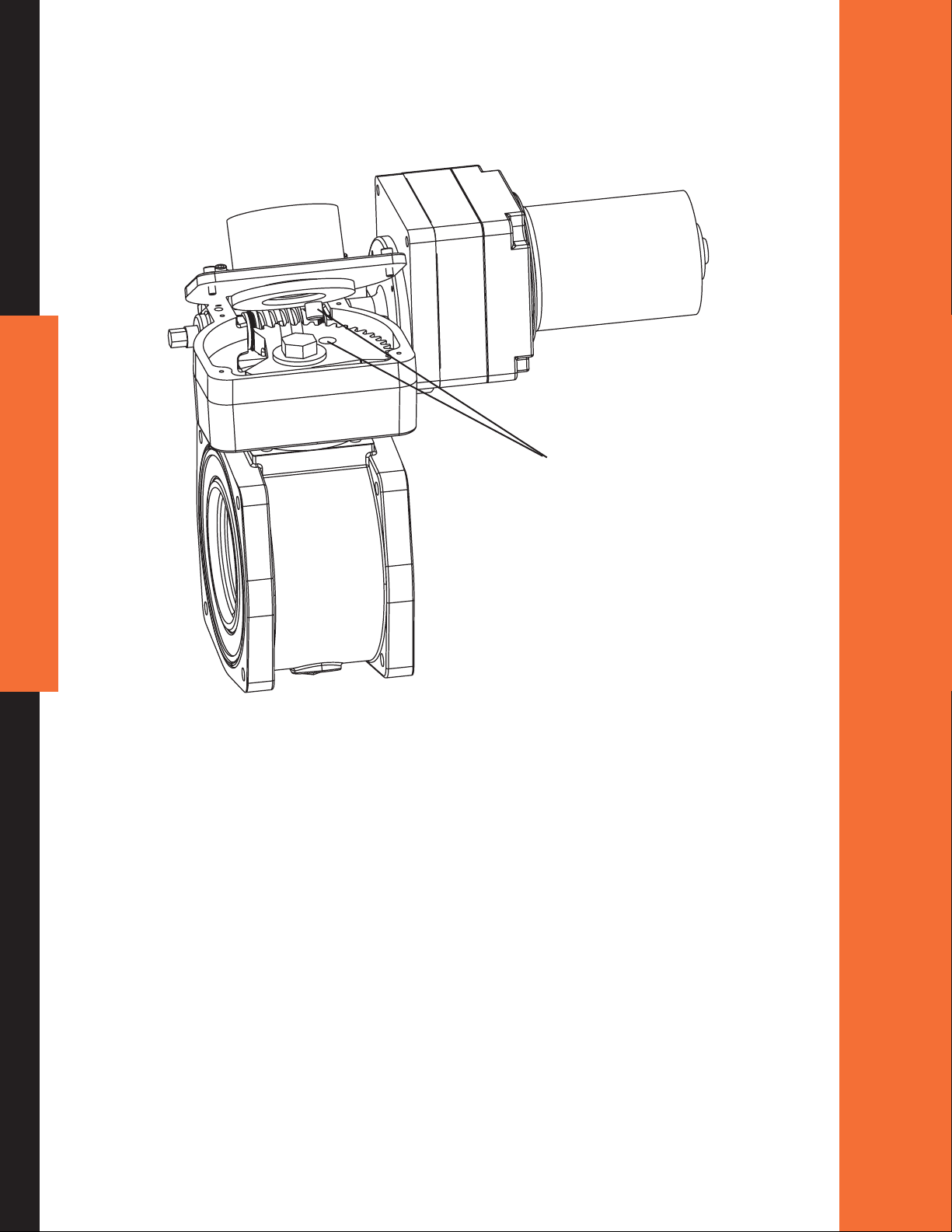

C) Gear and Electric Actuator

1. Disassemble gear case cover from gear case by removing four screws as shown below.

Remove

four

screws

Figure 10

16

2. Remove the 1/2" bolt and washer that locks the actuator assembly in position. Remove

actuator shaft. Remove gear sector and place in the full clockwise position as shown in

Figure 11. This equates to the valve open position for electric actuators on all valves

except EB_J & EB_S buttery valves (The gear sector positions are opposite for the EB_J

and EB_S butterys with electric actuators). This full clockwise position also equates to

the closed position for gear actuators on all valves.

Close(Electric)

Open(GearOP,EB_J&EB_S)

Place gear sector

in full clockwise

position

Open(Electric)

Close(GearOP,EB_J&EB_S)

Figure 11

ELKHART BRASS MANUFACTURING COMPANY, INC

Remove 1/2"

bolt and

washer

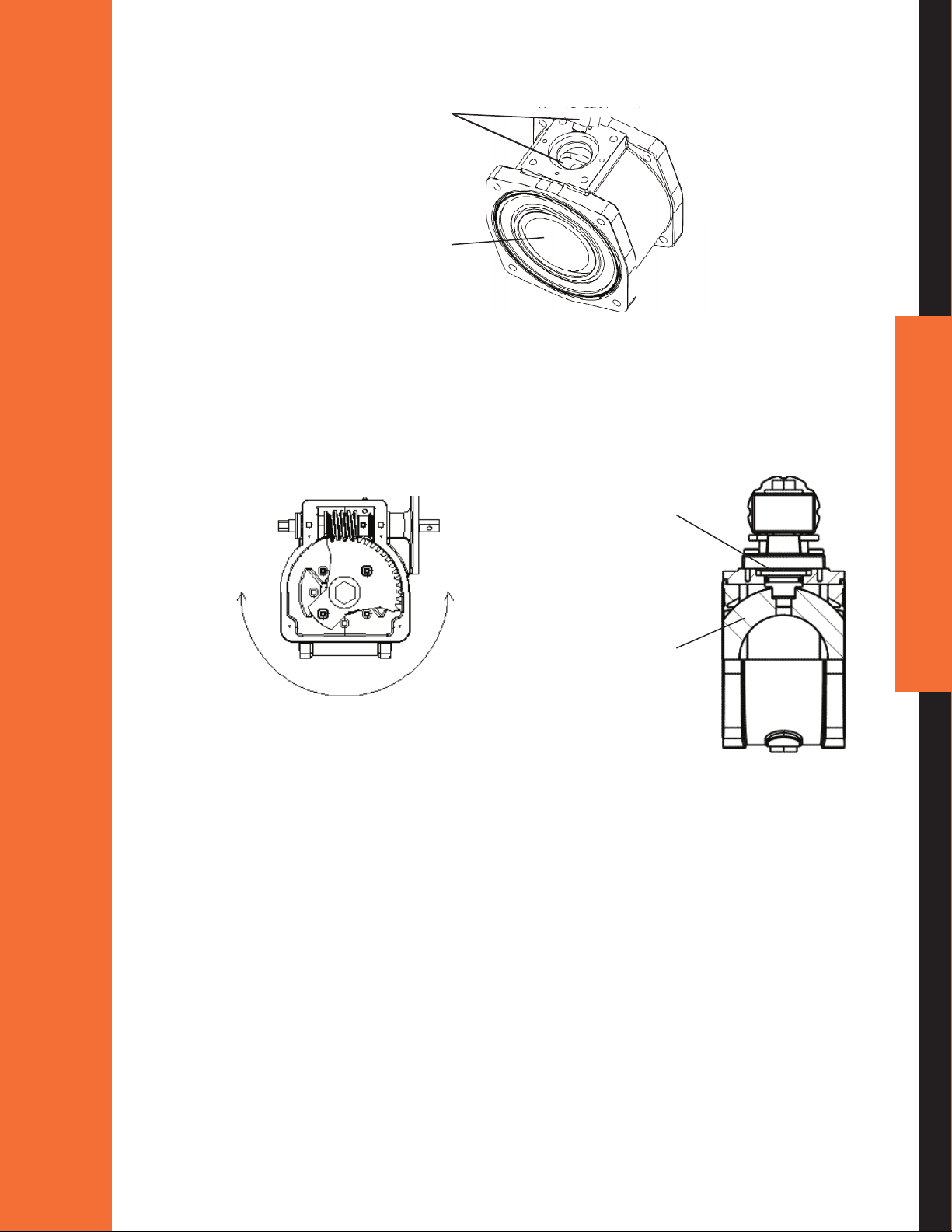

3. Hold the actuator assembly above valve body assembly and align the actuator shaft with

the slot in the ball as shown in Figure 12 for desired gear position on valve body as shown

in Figure 13.

Actuator shaft and

slot in ball align

Ball in closed

position

Figure 12

4. Push the actuator assembly down against valve body assembly and rotate the actuator

assembly in both directions slightly while pushing assembly against valve body until

actuator drops into slot in valve ball as shown in Figure 12. There should be no gap

between the actuator assembly and the valve body as shown below.

No gap between

actuator assembly

and valve body

Ball in closed

position

Figure 13

Figure 14

5. The actuator assembly should be rotated on the valve body until the #10-24 socket head

cap screws line up with the tapped holes on the valve body. The actuator assembly may

be positioned in rotational increments of 45° on the valve body. Replace the 1/2" bolt

and washer that were removed in Step 2. Secure with a thread locker (Blue Loctite #242)

and tighten to 5-7 Ft-Lb.

6. It is recommended to apply a thread locker (Blue Loctite #242) to the screws fastening

the actuator to the valve. Fasten the actuator assembly to valve body assembly by

tightening the #10-24 socket head cap screws in an X pattern to a torque of 5 ft-lb.

17

800.346.0250 • www.elkhartbrass.com

7. On G1F, E3F and E4F assemblies, reattach the gear case cover to the gear case by

replacing the four screws that were removed in Step 1.

8. On E1F (electric) assemblies only, the gear case cover should be re-attached to the gear

case with the sensor shaft engaged into the gear sector. Accomplish this by aligning the

sensor shaft with the gear sector hole nearest the worm gear as shown below.

Sensor shaft aligns

with gear sector

18

Figure 15

9. Push the gear case cover on to the gear case so that the sensor actuator engages in

the hole on the gear sector, then rotate the gear case cover on the gear case so that

the holes in the gear case cover line up with the tapped holes in the gear case. Next,

re-attach the screws that were removed in Step 1.

3. Handle Position

The twist lock, remote, and direct handle actuators may easily have the handles repositioned in

45° increments. The following details the handle reposition procedure.

ELKHART BRASS MANUFACTURING COMPANY, INC

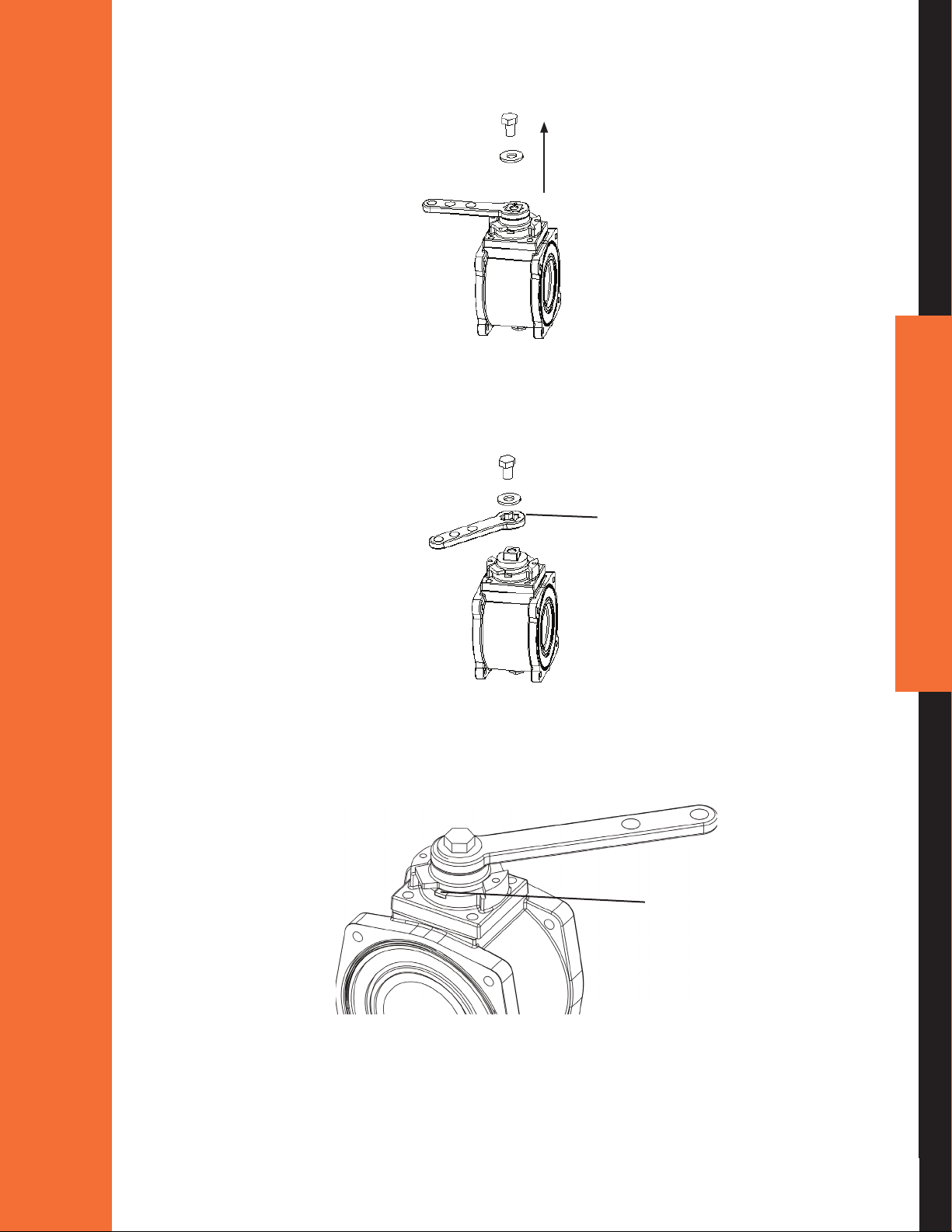

A) Non-Slow Close Handle Positioning

1. Remove the 1/2" bolt and washer that locks the handle in position.

Figure 16

2. The spring-loaded assembly will urge the handle off the actuator shaft. Remove the

handle completely from the shaft and rotate to the desired location in 45° increments.

Remove handle

and rotate in

45° increments

Figure 17

3. Place handle back on actuator shaft in new location and reattach washer and 1/2" bolt.

While tightening bolt, ensure that the stop plate tabs line up with slots in adapter plate

as shown.

Bearing break tab drops

into slot on adaptor plate

19

Figure 18

800.346.0250 • www.elkhartbrass.com

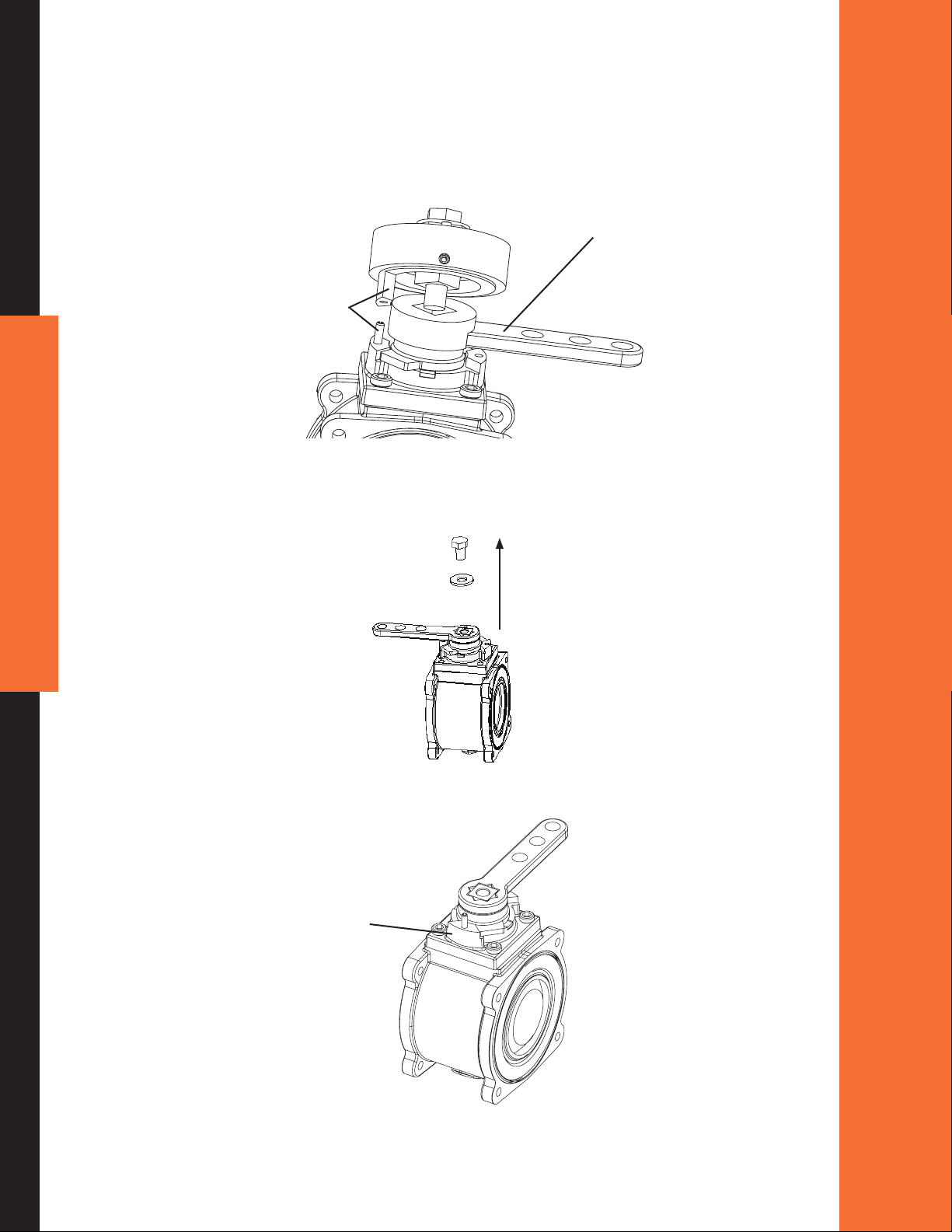

B) Slow Close Handle Positioning

A slow close is available for the R1S, R2S, D1S, D3S and S1S actuators.

1. Properly position the handle. See page 19 - Non-Slow Close Handle Positioning

2. Determine the position of the roll pin alignment. Ensure that the handle will not be

obstructed from moving to full open and full close positions when installed.

Handle moves freely

Pin alignment

Figure 19

20

3. Remove the 1/2" bolt and washer that locks the handle in position.

Figure 20

4. Drive the roll pin into an appropriate stop.

Roll pin

Figure 21

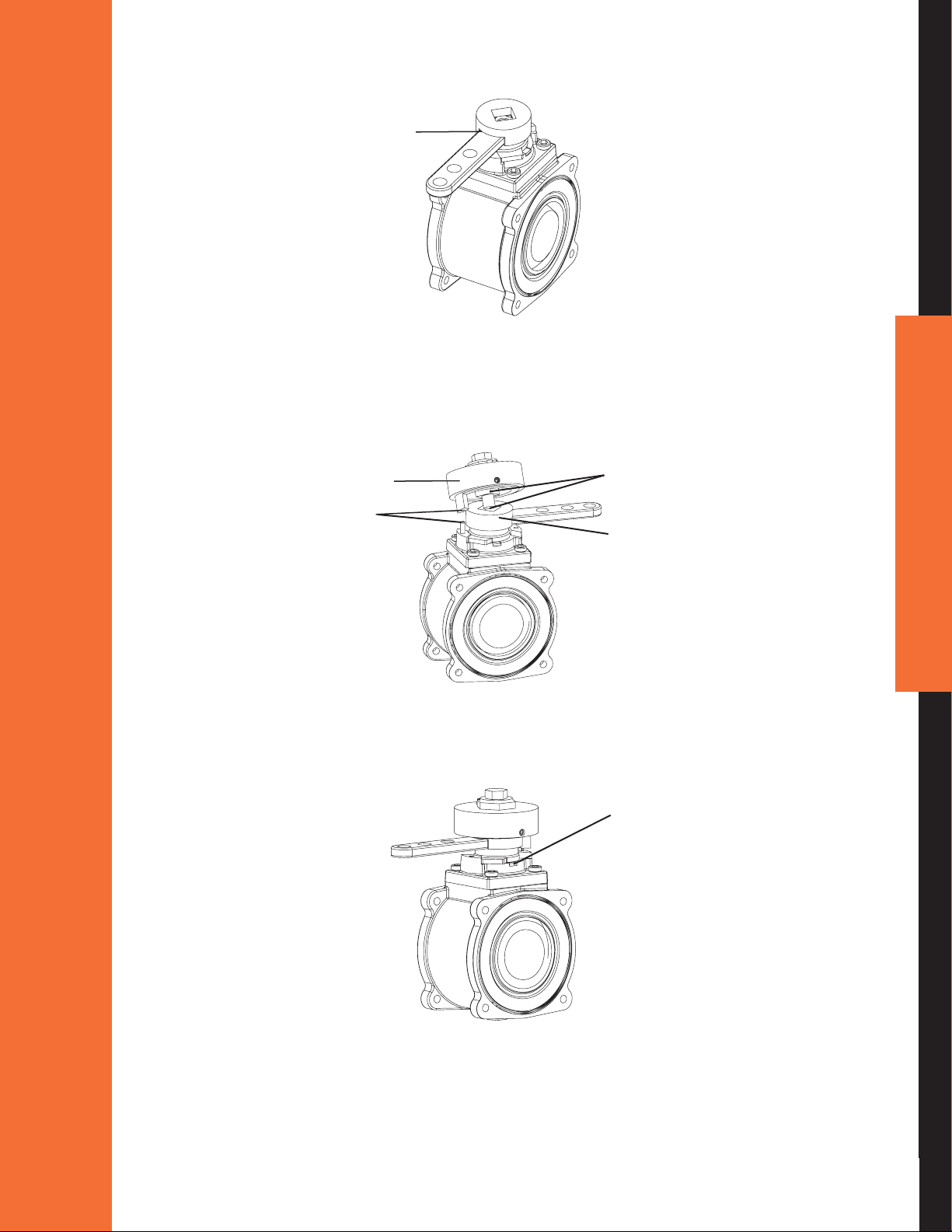

ELKHART BRASS MANUFACTURING COMPANY, INC

5. Place the handle coupler over the handle with the handle lling the slot.

Slot

Figure 22

6. Place the slow close onto the handle coupler. Ensure that the slow close shaft is properly

engaged with the handle coupler. Place entire assembly onto actuator shaft considering

proper handle and drive pin alignment.

Slow Close

Pin Alignment

Shaft Alignment

Handle Coupler

Figure 23

7. Attached washer and new 2" long 1/2" bolt. While tightening bolt, ensure that the bearing

break tabs line up with slots in adapter plate as shown.

Bearing break tab

drops into slot on

adapter plate

21

Figure 24

800.346.0250 • www.elkhartbrass.com

4. Slow Close Adjustment

1. Loosen the socket head cap screw and two set screws.

Cap screw

Figure 25

Set screws

22

2. Use a 1-3/8" wrench to adjust the slow close. (Note that a 3" or larger valve cannot be

actuated to close or open in less than three seconds per NFPA 1901.) Turning the cover

clockwise will reduce the speed at which the valve can be actuated. Turning the cover

counterclockwise will increase the speed at which the valve can be actuated.

Slower

Faster

Figure 26

3. Once proper adjustment has been achieved, tighten the socket head cap screw and both set

screws rmly.

ELKHART BRASS MANUFACTURING COMPANY, INC

V. MAINTENANCE

1. Ball Valve Seal Kits

The Unibody Valve body assemblies require very little maintenance. If it does become necessary

to service a ball valve body, seal kits are available to provide all O-rings and seats required in the

valve assembly.

Additional kits are available that also include the valve ball in the case of severe waterway

debris damage.

Part Number Description Valve Size

02BE ro 51BEtiK laeS00067456

65477000 Seal Kit with Stainless Steel Ball EB15 or EB20

65478000 Seal Kit EB25

65479000 Seal Kit with Stainless Steel Ball EB25

53BE ro 03BEtiK laeS00008456

65481000 Seal Kit with Stainless Steel Ball EB30 or EB35

04BE tiK laeS00028456

Table 3

Swing out instructions for accessing internal waterway.

1. Remove three of the end-cap bolts on each side of the valve away from the desired

swing-out direction.

2. Loosen the remaining two bolts (one on each side of the valve).

3. Rotate the valve out from the end caps pivoting on the remaining two end cap bolts.

4. After servicing the valve, ensure the two seats are secured in the valve body. Rotate the valve back

in line with the end caps.

5. Replace all the end cap bolts and tighten in an X pattern to the torque specied in Table 2 (page 12).

Do not lubricate the valve ball or seats.

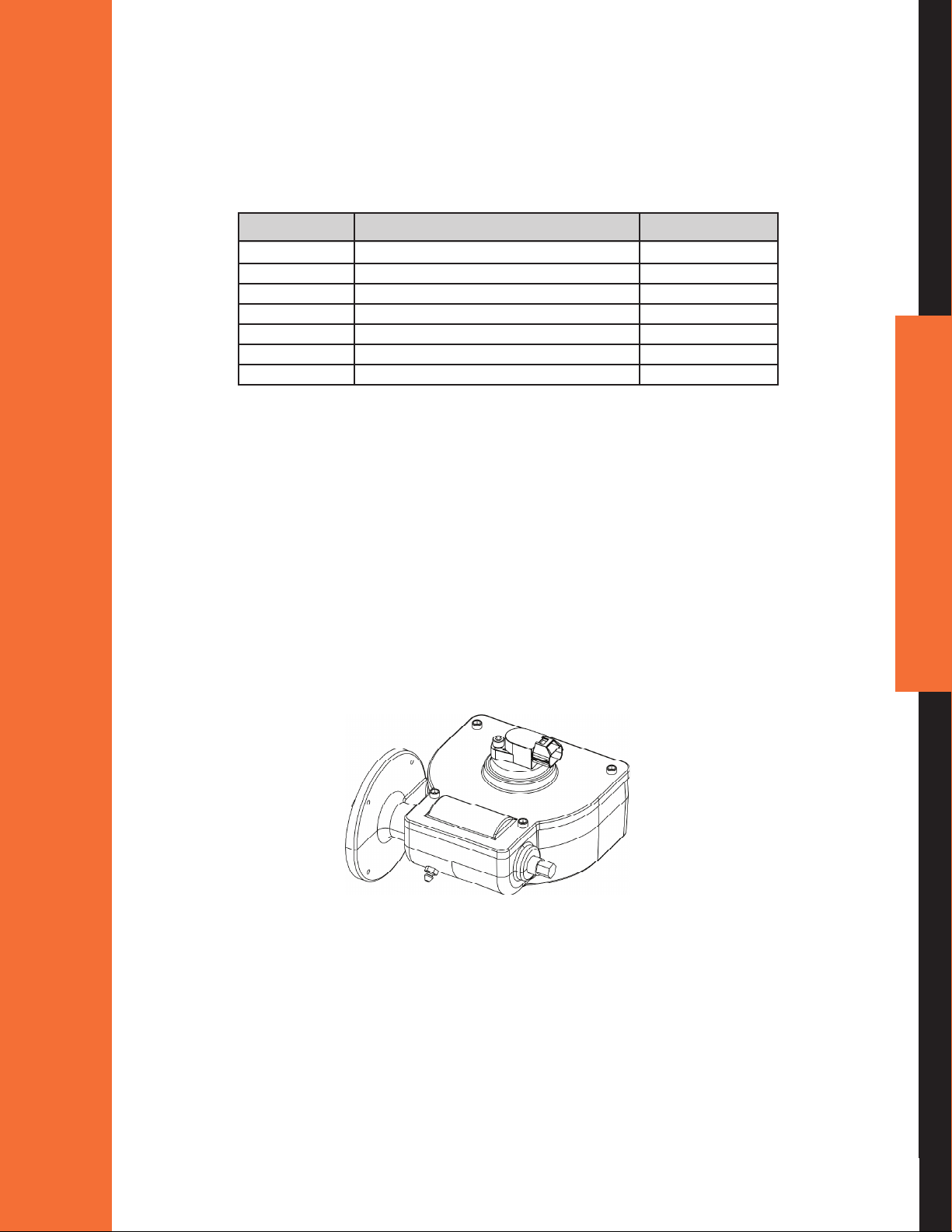

2. Gear Box Lubrication

Gearbox should be greased with petroleum base grease (Mobilux EP2) every six months.

Figure 27

23

800.346.0250 • www.elkhartbrass.com

Loading...

Loading...