Page 1

1

UBEC 1AT AUTO TANK Fill System

1302 WEST BEARDSLEY AVE • ELKHART, IN 46514 • 574-295-8330 • 800-346-0250 98330000 REV A

© 2012 ELKHART BRASS MFG. CO., INC. • WWW.ELKHARTBRASS.COM

08899155 & 08899156

Installation, Operation, & Setup Instructions

Page 2

2

TABLE OF CONTENTS

PRODUCT SAFETY INFORMATION 3

MONITOR CALLOUT DRAWING 4

OVERVIEW 5

INSTALLATION INSTRUCTIONS 7

TankVision Display Module 7

AUTO TANK Control Module 8

Pressure Sensor 9

Control Valve 10

CALIBRATION 11

Overview 11

Calibration Steps 12

OPERATIING INSTRUCTIONS 14

Theory 14

Modes 14

Valve Position Indicators 15

Operational Check 15

SPECIFICATIONS 17

WIRING 18

To view the most current parts list, drawings, or demonstrations of common EXM commands,

please visit www.elkhartbrass.com

Page 3

3

PRODUCT SAFETY INFORMATION

All personnel who may be expected to operate this equipment must be thoroughly trained in its safe

Important: Before installing and operating this equipment, read this manual

thoroughly. Proper installation is essential to safe operation.

and proper use.

Become thoroughly familiar with the hydraulic characteristics of this equipment.

Always open and close valves slowly to avoid water hammer.

After each use, and on a scheduled basis, inspect equipment per instructions in the maintenance

section.

Keep fingers and hands clear of movings parts.

Disconnect power before servicing and electric valve or electric valve controller.

Use only mild dish soap to clean the controller.

Any modifications to the electrical will destroy the NEMA 4 rating and void warranty coverage of the

enclosure and all components within.

SYSTEM INFORMATION:

SERIAL NUMBERS:__________________________________________________________________________

KIT DETAILS:

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Page 4

4

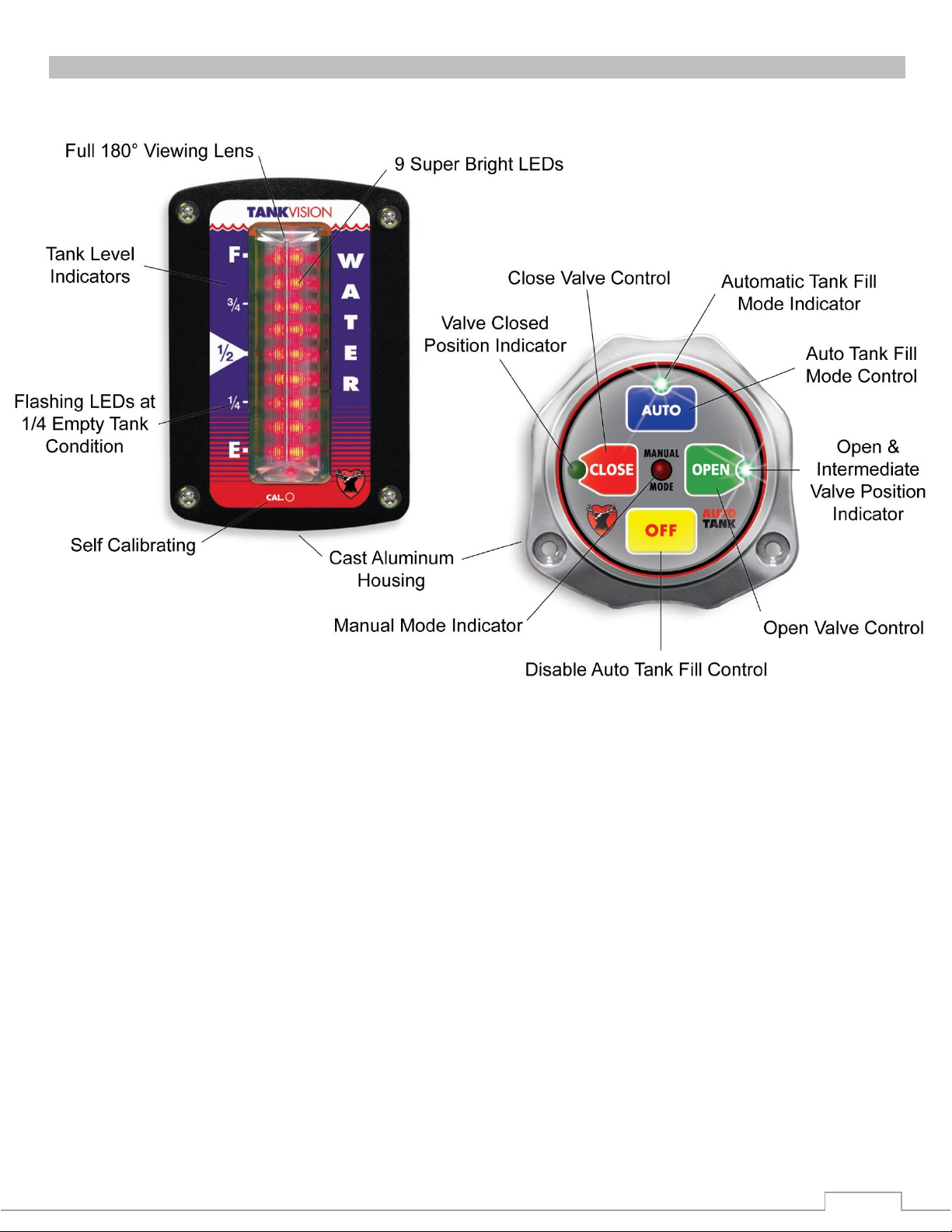

SYSTEM CALLOUT

Figure 1: AUTO TANK System

Display & Control Modules

Page 5

5

OVERVIEW

The AUTO TANK System is designed to work with around-the-pump foam systems where there is a

need to fill the water tank and maintain low pressure at the pump intake while pumping foam.

Normal operations would require pressurized water from a hydrant or pumper in relay to be connected

to the input of the pump. During foam operations excessive pressure at the input side of the pump can

cause the foam system to operate at partial capacity or fail to inject foam. This limits foam system

operations to the amount of water in the tank. When pressurized supply water flow is controlled the

AUTO TANK system, the water volume in the tank of a pumper is automatically maintained. Low

pressure water is available at the input side of the pump continuously to extend foam system

operational capabilities

Features

Maintains tank water volume between 50% and 95% full (P/N 08899155), or between 75% and

100% full (P/N 08899156)

Controls water flow for any GPM rate

For use with tanks over a 500 capacity

Self-Calibrating for any shape or size tank

Automatic or manual control

Components

TankVision Display Module

AUTO TANK Control Module

Pressure Sensor

Elkhart E3F Unibody Control Valve (Sold Separately)

All necessary component harnesses

TankVision Display Module

The tank volume display module is waterproof and has dimensions of 4.4 inches high by 3 inches

wide. An output signal from a pressure sensor mounted on the tank is input to the display module. It is

processed and the volume of liquid in the tank is shown on the 9 LED display. An output from the

display module controls the opening and closing of the control valve when the automatic mode is

selected.

AUTO TANK Control Module

The control module provides an interface between the TankVision display module and the valve. It has

four push buttons that allow the operator to select the mode of operation. The control module also has

automatic tank fill and manual valve control indicators. The open and close LEDs provide valve

position feedback.

The controller for P/N 08899155 stays in manual or automatic mode until changed. The controller for

P/N 08899156 powers up in automatic mode even if it was in manual mode when powered down.

Page 6

6

Pressure Sensor

The pressure sensor is mounted on a side of the tank near the bottom. It provides a signal that is

proportional to the volume of liquid in the tank to the input of the primary display module. The

electrical connector is waterproof and molded into the pressure sensor housing.

The pressure sensor is used on tanks between 1 and 10 feet in vertical height.

Control Valve

The E3F electric actuator is utilized for control of the tank fill valve. The AUTO TANK control module

communicates to the E3F electric actuator via the J1939 data bus. It can be mounted on any standard

sized Unibody valve.

NOTE: An Elkhart control valve is not included with the AUTO TANK Fill System, and must be

purchased separately.

Page 7

7

INSTALLATION INSTRUCTIONS

TankVision Display Module

Figure 2: Display Module Dimensions

Note: It is recommended to mount the display at eye level for accurate tank level readings.

1. Measure and mark mounting location for display module panel cutout and mounting screw holes.

Make sure there is a clearance behind the panel for the display and cables before cutting holes.

Refer to Figure 2 below.

2. Cut out a 4” by 2 1/8” hole and drill four (4) holes (clearance or tapped) for 6-32 mounting

screws.

3. Place Display Module in position and secure with four (4) screws.

4. Connect the Display Module cables and wires. (Please refer to Wiring Section on page 17)

Page 8

8

AUTO TANK Control Module

Figure 3: Control Module Dimensions

1. Measure and mark mounting location for cutout and mounting screw holes. Make sure there is

clearance for the module and cables before cutting hole. Refer to Figure 3 below.

2. Cut out a 2 ¾” diameter hole and drill two (2) holes (clearance or tapped) for 10-32 mounting

screws.

3. Place control module in position and secure with two (2) screws.

4. Connect the cables and wires. (Please refer to Wiring Section on page 18)

Page 9

9

Pressure Sensor

Figure 4: Pressure Sensor Dimensions

The pressure sensor is mounted on one of the tank sides approximately 2 inches from the bottom. The

pressure sensor can only be utilized for tanks between 1 and 10 feet in vertical height. Installation of

the pressure sensor in tanks larger than these limits could result in permanent damage to the sensor.

Note: When mounting the pressure sensor on a tank with thin walls (less than 3/8”), it is recommended

that the tank wall be reinforced at the sensor mounting location.

1. Measure and mark mounting location for sensor (Mounting hole should be approximately 2” from

bottom of tank). Make sure there is clearance for sensor and cable before drilling hole. Refer to

Figure 4 below.

2. Drill and tap a ¼-18 NPT hole.

3. Apply sealant around base and threads of pressure sensor.

4. Screw sensor into hole.

5. Connect sensor cable. (Please refer to Wiring Section on page 17)

Page 10

10

Control Valve

Installation instructions for the control valve can be found in the Unibody Valve and Controller Manual

(Document P/N 98311000). After installing the control valve, connect the AUTO TANK Control Module

to the control valve using the supplied harness. Please see Wiring section on page 18.

Note: Be sure to perform an automatic position calibration on the control valve after installation. This

procedure can be found on page 13.

Note: The AUTO TANK Fill Controller is intended to be used only with Elkhart Unibody control valves

that utilize an E3F electric actuator. Do no attempt to use with any other control valve, doing so could

result in damage to the Controller and will void the warranty.

Page 11

11

CALIBRATION

The TankVision has unique calibration programs that enable it to be used on tanks of all shapes and

OVERVIEW

sizes.

Note: The standard pressure sensor is limited to a max tank height of ten (10) feet.

Magnet Sensor

The calibration programs are accessed by activating the CAL. Magnet sensor that is located at the

bottom on the front of the display module. The sensor is activated by placing the north pole of a small

magnet in close proximity of the sensor. (The sensor will not respond to the south pole of the magnet).

The magnet is then moved about 1” away, this will produce an electronic signal that is similar to a

button being released. If the LEDs in the display do not change try moving the magnet farther away

from the sensor.

In these procedures the term ‘swipe’ will mean to move the magnet up to and then away from the

magnetic sensor at the bottom of the display.

Non-Linear Calibration

The first program is a non-linear calibration procedure that can be used for any shape or size tank.

This procedure must to be used for irregular shape tanks (e.g.: T-shape, oval, elliptical, tank with

through hole, etc.). The program compares the pressure in the tank, as the tank fills at a steady rate, to

time. This provides for very accurate displays.

Linear Calibration

The second program is a linear calibration procedure that can only be used when the tank volume is

proportional to the height. This would include square or rectangular shape tanks with no irregularities.

It is quick way of calibrating a tank to an empty tank, takes the difference and divides it into eight

equal volume displays.

Full Tank Correction

This program is for use to fine tune the tank display after a non-linear or linear calibration procedure

has been completed. It would only be needed in cases where one type of liquid is used for calibration

when a different liquid would normally be in the tank. For example, this would allow the basic

calibration of a foam tank to be done using water and then the calibration would be fine tuned when

the tank is filled with foam concentrate.

Control Valve Position Calibration

This calibration will automatically adjust the AUTO TANK Control Module to the E3F control valve

position. This process must be done in order for the AUTO TANK Controller to function properly.

Page 12

12

CALIBRATION STEPS

Non-Linear Calibration

This non-linear calibration procedure can be used for any shape or size tank. The calibration process

requires that the tank be empty at the start of the procedure and the filled at a steady rate of flow.

1. Empty the tank.

2. Apply power to the display module.

3. Swipe the magnet three (3) times to enter calibration mode (Non-Linear).

Result: Top three (3) display LEDs flash on and off.

4. Fill the tank at a steady rate of flow.

Note: once the calibration process is activated, the flow rate of liquid into the tank must remain

constant for the procedure to be accurate.

5. When the tank is full stop the flow.

6. Swipe the magnet three (3) times to set the calibration into memory.

Note: The program only acts on three (3) swipes to set the calibration into memory, or eight

swipes to terminate calibration mode. If a wrong entry is made, wait six seconds and it will clear.

7. After six (6) seconds the calibration process will terminate and all the LEDs will be lit to show that

the tank is full.

To exit calibration mode, swipe the magnet eight (8) times. The top eight (8) display LEDs will turn on,

calibration mode terminates, and no program data is changed.

Linear Calibration

This linear calibration procedure can only be used for square or rectangular shape tanks with no

irregularities. The calibration process requires that the tank be full at the start of the procedure.

1. Fill the tank. (Do not fill up into the fill tower)

2. Apply power to the Display Module.

3. Swipe the magnet four (4) times to enter calibration mode (Linear).

Note: Once the calibration process is activated, there is a six (6) second timeout. Do no wait more

than six (6) seconds to move from step 3 to step 4.

4. After three (3) seconds, swipe the magnet four (4) times to set the calibration into memory.

5. After six (6) seconds the calibration process will terminate and all the LEDs will be lit to show that

the tank if full.

To exit calibration mode, swipe the magnet eight (8) times. The top eight (8) display LEDs will turn on,

calibration mode terminates, and no program data is changed.

Full Tank Correction

This fine calibration procedure is used to fine tune the tank display after a non-linear or linear

calibration has been completed. The calibration process requires that the tank be full at the start of the

procedure and the display shows 75% or more.

Page 13

13

1. Fill the tank. (Do not fill up into the fill tower)

2. Apply power to the Display Module.

3. Swipe the magnet five (5) times to enter calibration mode (Full Tank).

Note: Once the calibration process is activated, there is a six (6) second timeout. Do no wait more

than six (6) seconds to move from step 3 to step 4.

4. After three (3) seconds, swipe the magnet five (5) times to set the calibration into memory.

5. After six (6) seconds the calibration process will terminate and all the LEDs will be lit to show that

the tank is full.

To exit calibration mode, swipe the magnet eight (8) times. The top eight (8) display LEDs will turn on,

calibration mode terminates, and no program data is changed.

Control Valve Position Calibration

A valve position calibration must be performed prior to operation. This calibration can be initiated

through the AUTO TANK Control Module by making use of the following steps:

1. Hold the OPEN and CLOSE buttons for ten (10) seconds until the AUTO light begins to flash.

2. Hold the AUTO light for five (5) seconds to initiate the automatic valve position calibration. During

this process the MANUAL mode LED will flash.

3. When the calibration process is complete, the CLOSE LED will turn on and stay lit.

Page 14

14

OPERATING INSTRUCTIONS

The AUTO TANK system is designed to automatically maintain the water volume in the tank of a

THEORY

MODES

pumper. It is more specifically designed to be used on tanks that supply water to around-the-pump

foam systems.

System Operating Parameters

The minimum size of the pumper tank is 500 gallons. There is no maximum tank size.

There is no minimum pump discharge flow rate. The maximum discharge flow rate is 500 GPM.

An Elkhart E3F electrically actuated ball valve is required.

The supply water flow rate at the input to the tank must be at least 20% above the pump

discharge flow rate.

The supply water must enter the tank through the fill tower to avoid potential over pressurization

of the tank, or pressure surges through the tank as the valve is opened and closed. Plumb from

the valve to the tank fill tower.

With all the system parameters met and operating in the automatic mode, the AUTO TANK system P/N

08899155 will keep the tank between 50% and 95% full, and AUTO TANK system P/N 08899156 will

keep the tank between 75% and 100% full.

For efficient operation around-the-pump foam proportioning systems should be operated with low

pump intake pressure, less than 20 PSI. During normal operations pressurized water from a hydrant or

pumper in relay would be connected to the input of the pump. This excessive pressure at the input side

of the pump can cause the foam system to operate at partial capacity, fail to inject foam, or allow

water to enter the foam tank. The UBEC-1AT system continuously fills the tank as required so that low

pressure water is available at the input side of the pump.

During operations a supply line from a pressurized source of water (hydrant or pump in relay) is

connected to the input side of the control valve. A dedicated line connected from the output side of the

valve to the fill tower feed water to the tank. The TankVision display monitors the water in the tank. It

sends a signal to the control module to indicate a low or full level. In auto mode the control module

then sets the position of the valve as needed.

The control module allows the operator to select the automatic, manual, or off mode of operation.

On power-up the controller for system P/N 08899155 initializes to the same mode of operation it was

in when power went off, and system P/N 08899156 initializes in automatic mode even if it was in

manual mode when power went off.

No operator input is required for the TankVision to be operational. When power is on, the display will

be operating. The signal from the pressure sensor is processed and the volume of liquid in the tank

shows on the display.

Page 15

15

During all modes of operation the TankVision display functions normally and the volume of water in

VALVE POSITION INDICATORS

OPERATIONAL CHECK

the tank is shown on the 9 LED display.

All 9 LEDs are on when the tank is full. Each LED goes off starting at the top and working down as

the liquie in the tank decreases.

The bottom two (2) LEDs flash when the tank is less than ¼ full.

All 9 LEDs rapidly down-chase when the tank is almost empty.

Automatic Mode

Pressing and holding the AUTO button puts the system in the automatic mode and the green LED

comes on. The opening and closing of the valve is controlled by the control module on the control

valve. The valve stays closed until the tank water level goes below 50% or 75% (depending on your

system). The valve then opens fully and allows supply water to flow into the tank. When the tank is

refilled to approximately 95% or 100% (depending on your system) the valve will close. The valve takes

approximately 7 seconds to move from fully closed to fully open or from fully open to fully closed. The

valve cycles as needed during operations to maintain the water volume in the tank.

Manual Mode

Pressing the OPEN or CLOSE button puts the system into the manual mode and the MANUAL MODE

LED comes on. In the manual mode, the opening and closing of the valve is controlled by the OPEN

and CLOSE buttons.

Off (Valve Shut) Mode

Pressing the OFF button closes the valve.

The TankVision display functions normally and the volume of water in the tank is shown on the 9 LED

display.

Solid Close – CLOSED LED is lit when valve is fully closed.

Solid Open – OPEN LED is lit when valve is fully opened.

Flashing Open – OPEN LED is flashing when valve is anywhere between fully open and fully closed.

Note: For this check, the input to the AUTO TANK system control valve does not have to be connected

to a water source. The tank can be filled at the fill tower by any method that is convenient. (This will

check the operation of the AUTO TANK system, but it will not verify the plumbing between the valve

and tank)

1. Fill the tank with water and apply power to the AUTO TANK system.

2. Press the OPEN and CLOSE buttons.

Result: The valve and the indicating lamps follow the switch position.

3. Press the OPEN button to open the valve.

4. Press the AUTO button.

Page 16

16

Result: The system is put into automatic mode, the green LED comes on, and the valve closes.

5. Drain water from the tank.

Result: The display shows tank volume. When it reaches 50% or 75% (depending on your system)

the valve opens.

6. Stop draining water and refill tank.

Result: The display shows tank volume. When it reaches 95% or 100% (depending on your

system) the valve closes.

Page 17

17

SPECIFICATIONS

System Requirements

Tank Size:

o Min 500 Gallons

o Max No Maximum (Less than 10 vertical feet tall)

Total Discharge flow rate:

o Min 0 GPM

o Max 500 GPM

Supply Water flow rate into tank:

o Min 20% above discharge flow rate

o Max No Maximum

TankVision Display Module

Supply Voltage: 9-30 VDC

Supply Currant: 0.25 AMP Max

Dimensions: 4.4” x 3.0”

Housing: Waterproof Cast Aluminum

Indicators: 9 Super Bright LEDs

Viewing Angle: 180°

AUTO TANK Control Module

Supply Voltage: 9-30 VDC

Supply Currant: 0.25 AMP Max

Dimensions: 3.25” x 3.25”

Pressure Sensor

Housing: Stainless steel with ¼-18 NPT for mounting

Sensor: Ceramic Diaphragm

Pressure Range: 1-5 PSI (Maximum tank height: 10 feet)

Excitation Voltage: 5 VDC

Page 18

18

WIRING

Figure 5: Display Module Wiring Diagram

Supplied Harness (P/N 37069000)

Supplied Harness

(P/N 37068000)

Page 19

19

Figure 6: Conrtol Module Wiring Diagram

Page 20

ELKHART BRASS

1302 WEST BEARDSLEY AVE

P.O. BOX 1127

ELKHART, IN 46514

PHONE: 574-295-8330 • 800-346-0250

FAX: 574-293-9914

WWW.ELKHARTBRASS.COM

© ELKHART BRASS MFG. CO., INC. 2012

UBEC 1AT AUTO TANK FILL SYSTEM

08899155 & 08899156

INSTALLATION, OPERATION, & SETUP INSTRUCTIONS

98330000 REV. A

Loading...

Loading...