Page 1

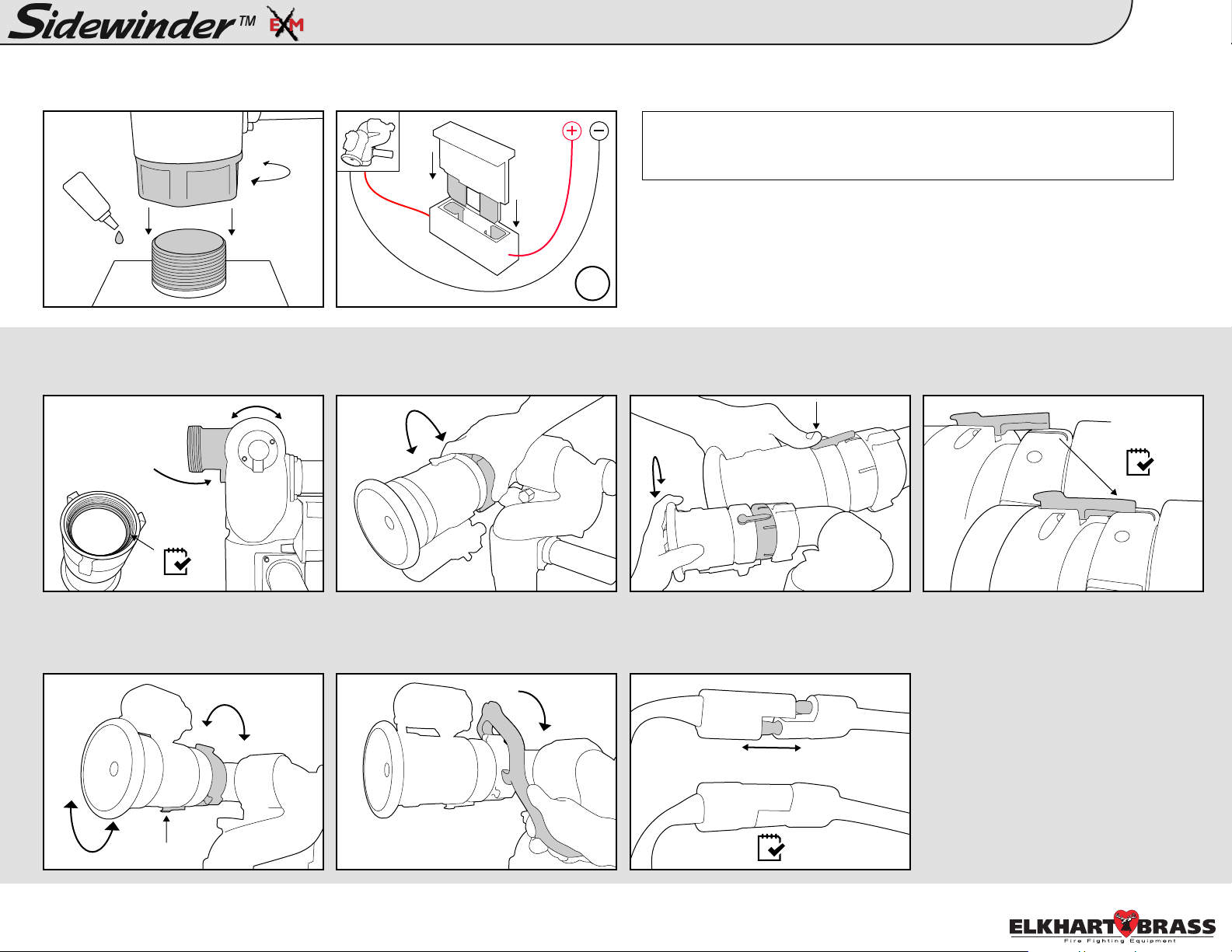

1.

A. Tighten Sidewinder EXM monitor to

base using Loctite 592 thread sealant or

equivalent.

2.

A. Position monitor discharge elbow

parallel to ground. Ensure gasket is

inside nozzle swivel.

90°

Typical Pumper Truck Install Guide:

B. Add a 20A(12VDC)* fuse between

RED controller lead and positive power

lead.

B. Hand tighten nozzle to monitor using

swivel end piece.

*10A(24VDC)

NOTE: We recommend using 16 AWG for monitor power and ground. See

Sidewinder EXM monitor installation guide on page 9 of the manual for

length to gauge recommendations.

16g

C. Adjust flow by pressing down on

locking lever and rotating nozzle to

desired flow setting.

Monitor & Nozzle

MONITOR

D. Confirm that locking lever is snapped

securely into position.

1

E. Loosen swivel and reposition nozzle

so the locking lever is on the very

bottom; 6 o’clock position.

3.

Confirm that all connections are tight and all electrical connections have been reconnected. If installing additional components,

such as controllers, you may choose to double check the connections after everything has been installed.

F. Tighten swivel using a spanner

wrench to ensure a secure connection.

G. Connect nozzle and monitor two-way

connectors.

NOZZLE

98326020 Rev. Rel

Page 2

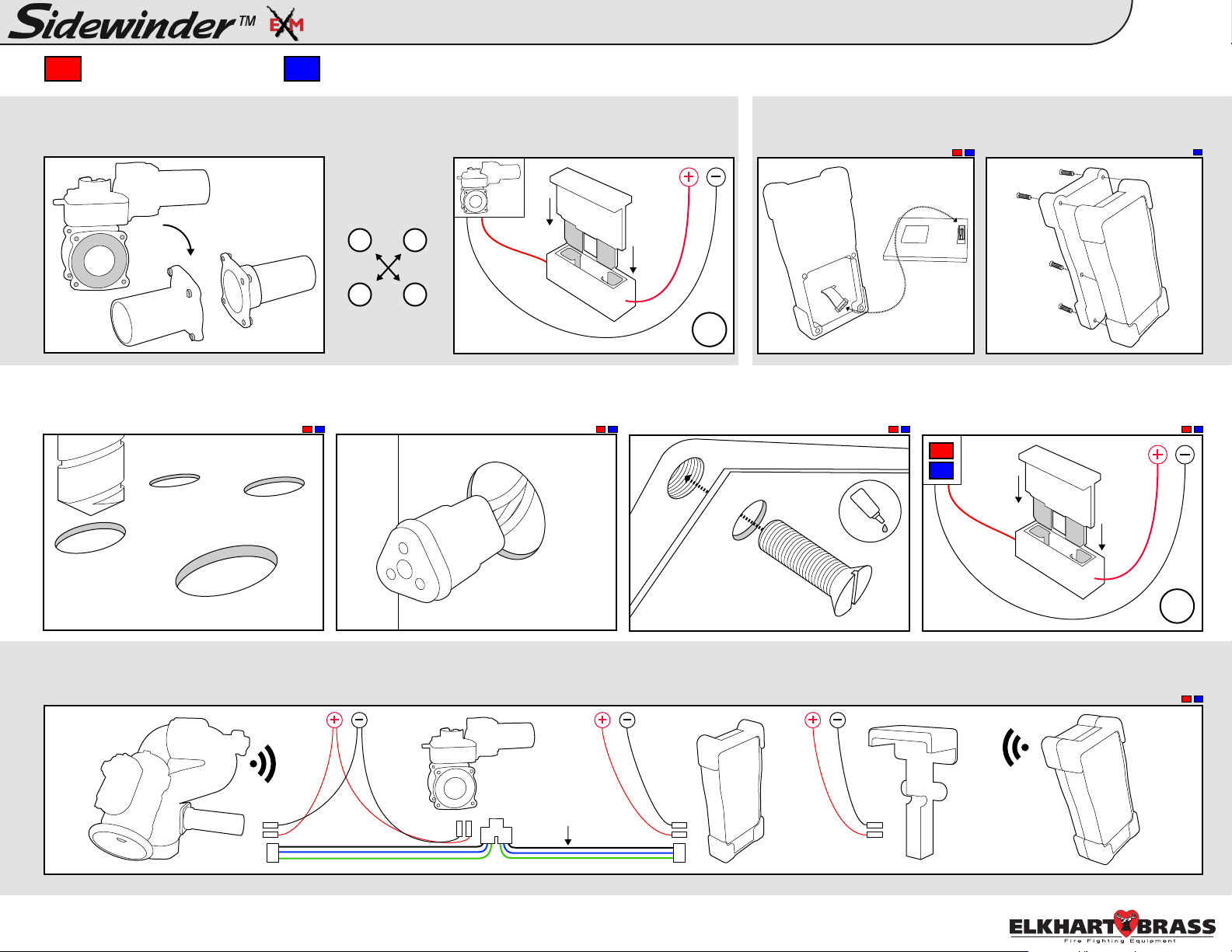

Typical Pumper Truck Install Guide:

Control Components & Accessories

2

- Panel Mount Controller Handheld Controller / Docking Station

A. Install valve into plumbing. Torque

4.

adapter bolts to spec using torque specs

to the right.

A. Follow mounting templates on page

5.

30 of the instruction manual for hole

diameters and dimensions.

-

B. Add a 30A(12VDC)* fuse between

RED controller lead and positive power

lead.

*15A(24VDC)

Tighten Adapter

Bolts using a

cross pattern

1 3

4 2

25-30 ft-lbs

B. Drill holes for CAN network and

power cables for each components’

leads behind each component.

RF Installation - The RF

Module will be upside down

when installed correctly.

16g

C. Mount components to panel using

10-24 x 1/2” screws. Use Loctite 242 or

equivalent.

Connect power and attach

battery pack to Handheld

controller.

D. Add a 1A (12VDC)* fuse between

red component lead and positive power

*.5A (24VDC)

lead.

7/32” dia.

unless noted

A. Connect entire CAN network together using 18-22 AWG. Ensure every component connected to the CAN network is connected in between 2 end components that

6.

have CAN termination. Please refer to the BLUE, GREEN, and BLACK lines as the CAN wires below.

CAN

Network

Wires

Before continuing please follow the steps on page 14 of the Sidewinder EXM instruction manual outlining the

Monitor Configuration Tool.

98326020 Rev. Rel

18g

Page 3

NOTE: You will

AUX

OSC

OPEN

CLOSE

OSC

FOG

CLOSE

OPEN

CLOSE

need to calibrate

the valve before

use. While you

are NOT in

setup mode,

press and hold

<Preset> and

<Close> for

approximately 5

seconds. The

valve will

a u to m a t ic a l l y

start to calibrate

itself.

The following

steps are

optional (O).

Pressing the

<Osc> button will

cycle through the

monitor speed

options:

LEDs - Ver / Hor

0 - Fast / Fast

1 - Slow / Fast

2 - Fast / Slow

3 - Slow / Slow

Move monitor to

desired position,

then press <Fog>

and <Osc> at the

same time to

store a stow

position.

Stow position

must be within

allowed limits of

travel.

3

Typical Pumper Truck Install Guide:

CALIBRATE VALVE

PRESET

SET MONITOR SPEED

(O)

SET STOW POSITION

(O)

OPEN

Press and hold

<Stream> and

<Fog> until

yellow status

LED on controller

and blue status

LED on monitor

box turn on.

From a Joystick

Controller, press

and hold <Aux>

and <Preset>

until LEDs turn

on.

Move monitor to

the left limit and

press <Close>.

Move monitor to

the right limit and

press <Open>.

Maximum Travel

limits will give

approx 175° of

travel from the

c a l i b r a t e d

horizontal forward

position in either

direction.

Pressing <Open>

and <Close> at

the same time

will clear travel

limits, keep out

areas, and the

stow position.

4 5

STATUS POWER

L

CLEAR ALL

C

E

L

PRESET

A

R

A

L

L

Setup Mode

R

This step is

required (R).

Aim monitor at

center forward

“zero” position.

Hold <Preset>,

then press and

hold <Left> or

<Right> until

status LED on

monitor blinks &

returns to solid.

Takes about a

second.

Lower Left:

Move to top/right

corner of the

lower left zone,

hold <Preset>,

press <Close>,

and release both.

Lower Right:

Move to top/left

corner of the

lower right zone,

hold <Preset>,

press, <Open>,

and release both.

Press and hold

<Stream> and

<Fog> on the

panel mount and

<Aux> and

<Preset> on the

joystick until the

status LEDs turn

off.

21

8

CALIBRATE HORIZONTALENTER SETUP MODE

(R)

OPEN

SET KEEP-OUT ZONESSET TRAVEL LIMITS

(O)(O)

Lower Right Zone:

Top left corner

Lower Left

Zone

0°

Lower Left Zone:

Top right corner

Lower Right

Zone

Right Travel LimitLeft Travel Limit

EXIT SETUP MODE

STATUS POWER

3

6

7

98326020 Rev. Rel

Page 4

Typical Pumper Truck Install Guide:

Button Press Logic: Panel Mount & Handheld Panel Mount Layout:

To Stow

Hold <Fog> and <Osc> until monitor begins to stow.

Button Press Logic

4

To Oscillate

Press the <Osc> button at both extremities of the desired oscillation

pattern.

Horizontally Vertically Two Axis Oscillation

NOTE: You can manually control nozzle position while in a single

axis oscillation. Example: Up and Down will allow you to manually

control the vertical axis while in a horizontal oscillation. Any

direction in a two axis oscillation will stop the oscillation.

Left, Right, Up, Down

These function normally

Fog & Straight Stream

These function normally

Valve Open & Close

These function normally

Valve Preset

Opens or closes valve to a predetermined position

Power LED

OSC

USB Port (Covered)

Status LED

FOG

Straight Stream

Monitor Directional

Control Buttons

AUX

Valve Position LEDs

Open

To Change Valve Preset

Open or close the valve to the desired position. Press and hold the

<Preset> button until the preset light blinks (approx 10 seconds).

Valve Auto Travel

To auto travel OPEN, hold the <Open> button, then press <Close>, and

release both. The valve should fully open automatically. To CLOSE,

hold the <Close> button, then press <Open>, and release both.

BUTTON LOGIC

Preset

Close

PANEL MOUNT

98326020 Rev. Rel

Loading...

Loading...