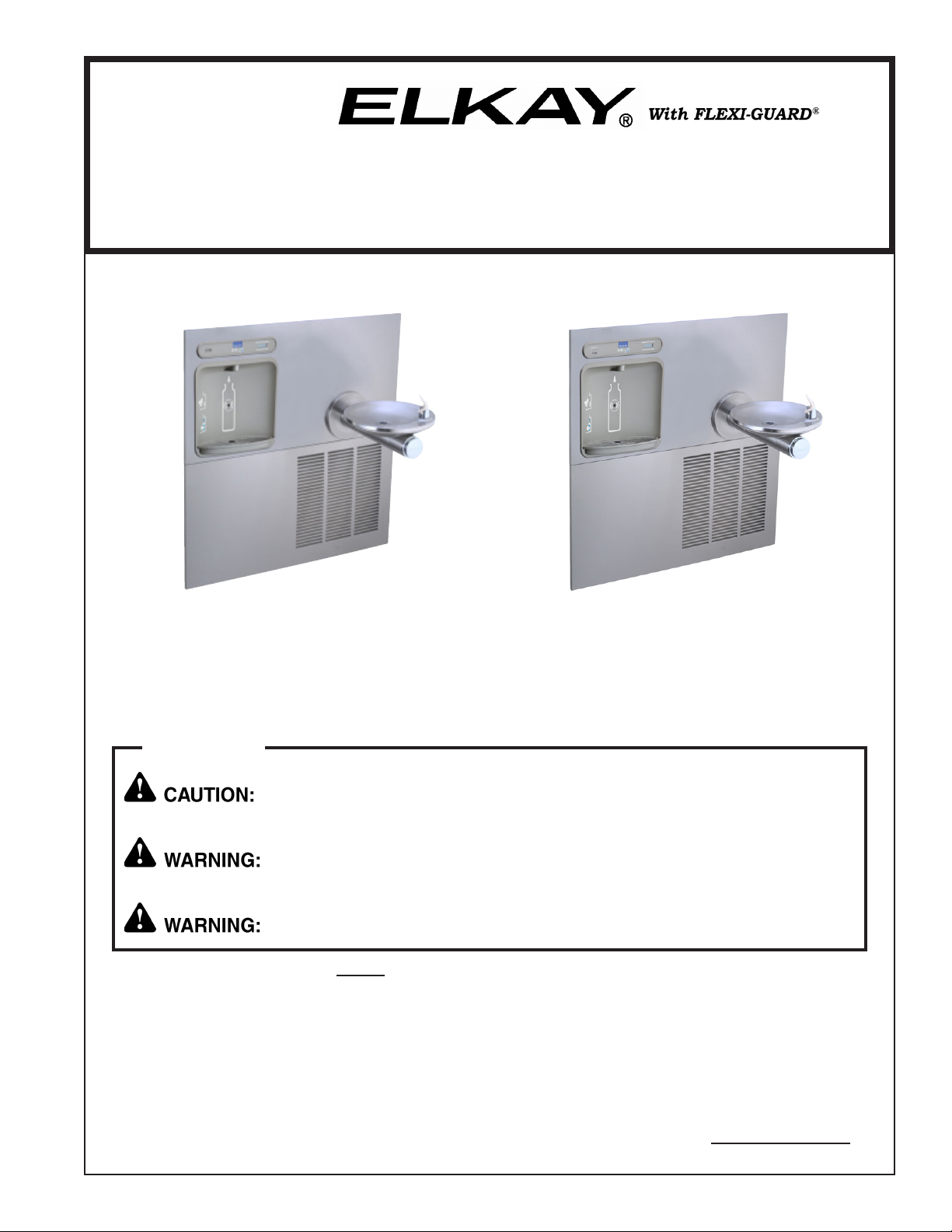

Elkay LZWS-LRPB8-RF Installation Manual

EZWS-ERPB8-RF LZWS-ERPB8-RF

INSTALLATION, CARE & USE MANUAL

SWIRLFLO® Refrigerated Fountains with FLEXI-GUARD® Bubbler

and EZH2O® Bottle Filler

EZWS-ERPB8-RF

LZWS-LRPB8-RF

IMPORTANT

THIS IS AN INDOOR APPLICATION ONLY.

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON.

INSTALLER

Review these instructions before beginning installation. Be sure that installation

conforms to all plumbing, electrical and other applicable codes.

When installation is complete, ensure these instructions are left in the plastic bag

provided inside the installed unit for future reference.

Service to be performed by authorized service personnel only.

NOTE: It is common practice to ground electrical hardware such as telephones, computers and other devices

to available water lines. This can, however, cause electrical feedback in the plumbing circuit, which

results in an “electrolysis” effect occurring in the fountain. This may result in water which has a

metallic taste to it or has a noticeable increase in the metallic content of the water.

When inspecting plumbing circuit, remember the line may be grounded some distance from the

installation, and may occur outside the building or area in which the unit is being installed.

This condition can be avoided (in most cases) by using recommended materials during installation.

Any drain ttings provided by the installer should be made of plastic which will electronically isolate

the fountain from the remainder of the building’s plumbing circuits.

Page 1

0000001059 (Rev. D - 06/16)

EZWS-ERPB8-RF LZWS-ERPB8-RF

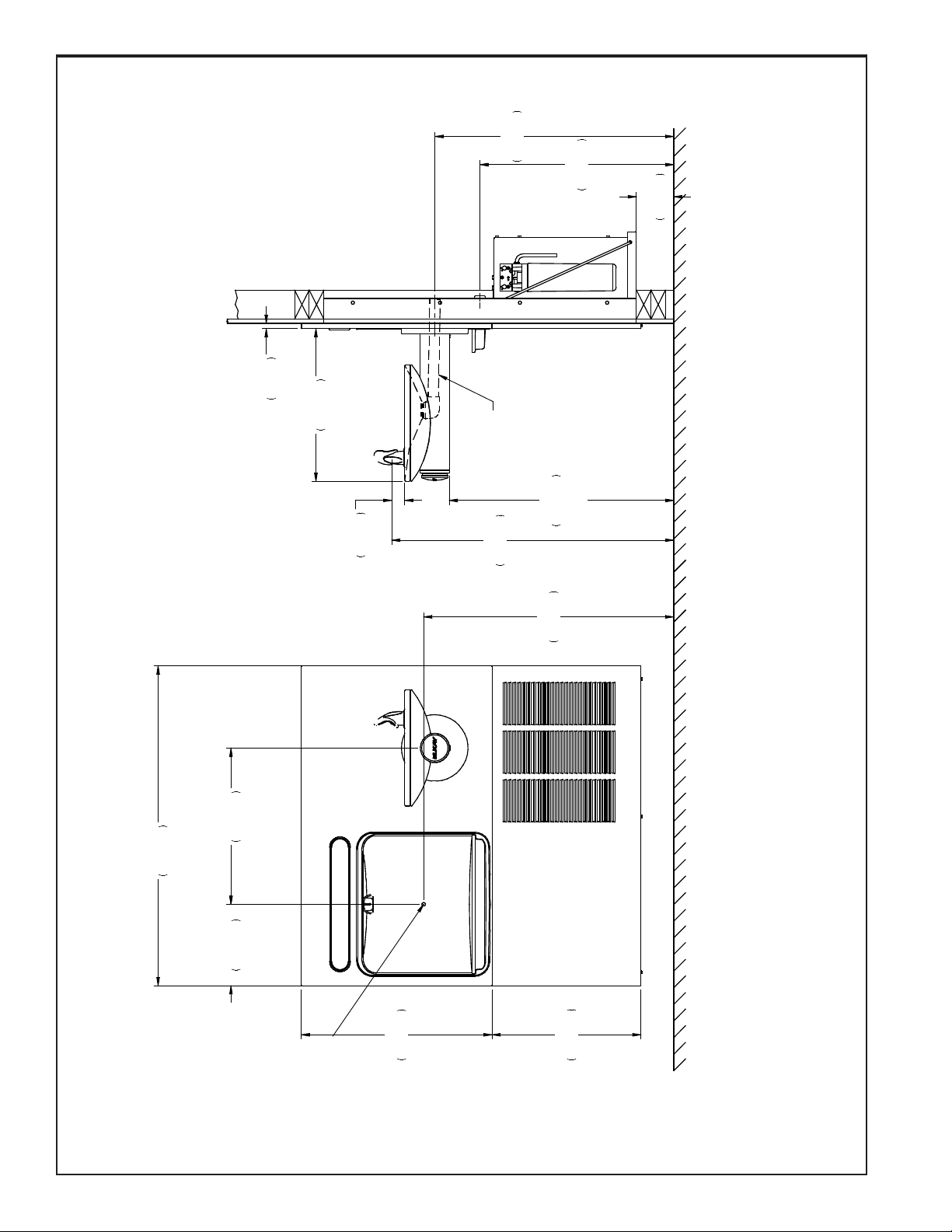

730mm

28 3/4"

23 5/16"

592mm

4 1/2"

114mm

16mm

5/8"

467mm

18 3/8"

A

Model LZWS-ERPB8-RF

18 13/16"

478mm

38 1/2"

978mm

ADA

686mm

27"

REQUIREMENT

40mm

1 9/16"

33 15/16"

862mm

30 1/16"

764mm

9 13/16"

249mm

0000001059 (Rev. D - 06/16)

22 15/16"

583mm

ACTIVATION

SENSOR

Figure 1 – Rough-in Dimensions

Page 2

455mm

17 7/8"

LEGEND

A = 1-1/4” Waste Tube

**NEW INSTALLATIONS MUST USE GROUND FAULT CIRCUIT INTERRUPTER *GFCI)

EZWS-ERPB8-RF LZWS-ERPB8-RF

BOTTLE FILLER / FOUNTAIN RETRO-FIT CONVERSION

REQUIRED TOOLS AND MATERIALS

These tables show special tools and/or additional materials

(not provided) which are necessary to complete installation

of these units:

Tools Not Provided

Description

Safety Glasses

Gloves

Electric Drill / 5/32” Bit

Wrenches, Crescent Wrench,

Channel Lock Type Pliers

5/16” Nut Driver

Hammer / Center Punch

Sockets & Ratchet Wrench

Quantity

1

1

1

1

1

1

1

1

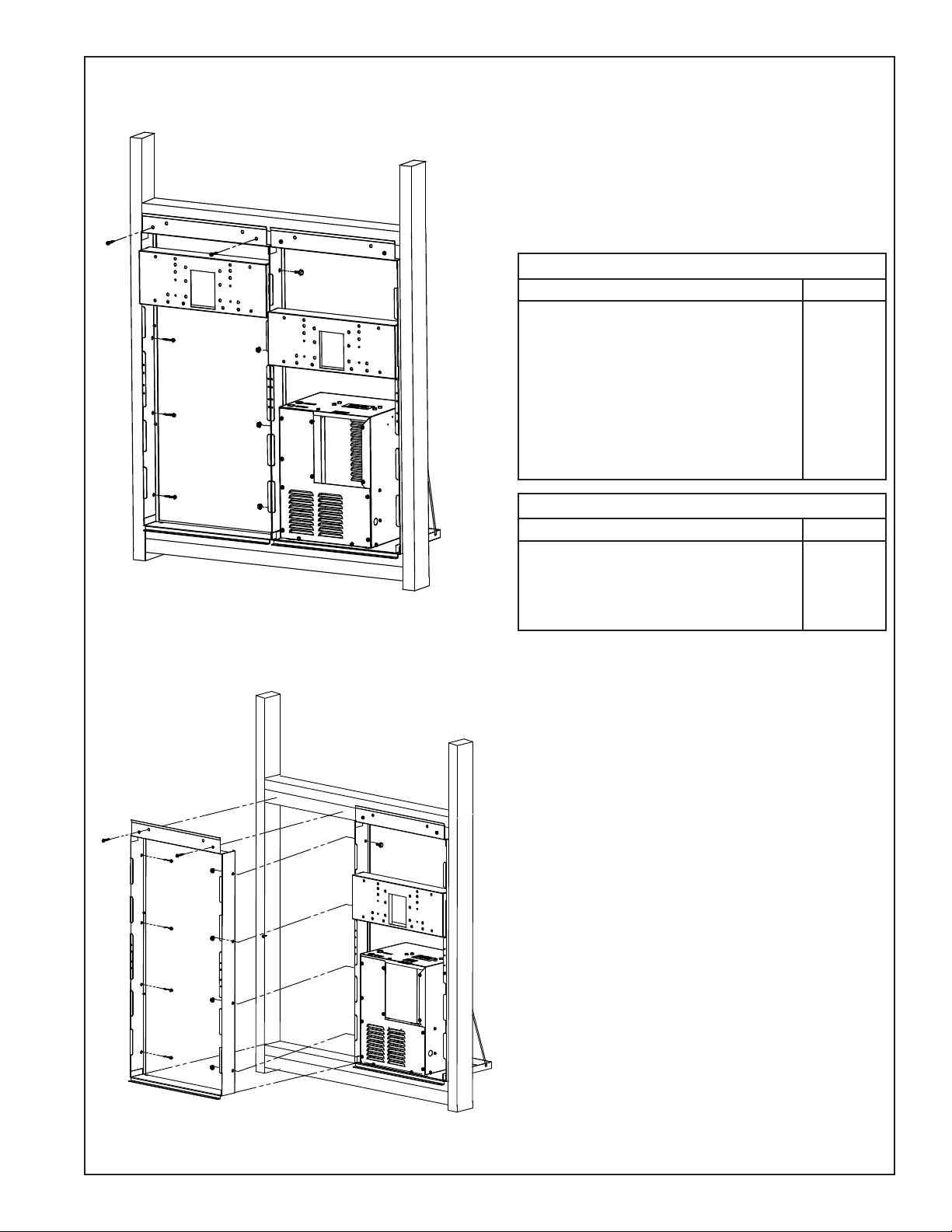

Typical current installation with fountains and panels removed.

Disassemble current Bi-Level Refrigerated fountain installation

Figure 2

Additional Materials Not Included

Item

1

Unplated copper inlet pipe

2

Service Stop/Shut-off Valve

3

90° 1-1/4” Drain Line

4

1-1/4” Tee Drain Line

1. Prepare for conversion. Turn off electrical power and water

supply to existing installation.

2. Disassemble the current installation see (Fig 2).

• Remove existing fountains and plumbing connection lines.

• Remove upper and lower panels

• Remove left hand mounting frame

3. Install new mounting frame into left hand side of wall opening.

• Secure mounting frame to wall opening and adjacent frame.

• Use all fastener holes to secure the frame properly.

Description

Quantity

1

1

2

1

Remove left hand mounting frame, replace with new open frame (included).

Figure 3

Page 3

0000001059 (Rev. D - 06/16)

Loading...

Loading...