Elkay EWF172 Installation Manual

FILTER KIT

EWF112,TWF112 WaterSentry® I KIT (Sediment, Taste & Odor Reduction)

EWF172, TWF172 WaterSentry® VII KIT (Lead, Cyst, Sediment, Taste & Odor Reduction)

These filter kits are designed to be used with the following

Elkay and Cordley/Temprite products.

1. EDG, TDG, EDP, TDP, EDV, TDV Series Point-of -Use

Water Coolers.

2. EBL, TBL, EBV, TBV Series Water Coolers with FV-122

Float Kits.

3. LKH-190 Hot Water Dispensers

4. LK-2156 Dispensing Valve with or without a chiller unit.

5. LK-1141 Bubbler with or without a chiller unit.

6. Independently in an undersink application. For

undersink applications, it is recommended that water

be dispensed through a dedicated valve or faucet

instead of the sink faucet due to the reduced flow

through the filter.

NOTICE: Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

General Installation Instructions

1. These filter kits must be installed in compliance with all

state and local laws and regulations governing the

installation and use of this product. Maximum inlet

water temperature 100°F (38°C).

2. Mount filter head in a suitable location, using the filter

mounting bracket and screws supplied. Allow enough

room under the filter head for installation and removal of

filter cartridge (13" minimum).

3. Connect the cold water supply to the filter through a

shut-off valve and 3/8" O.D. tubing (supplied by the

installer). For ease of servicing, the shut-off valve

should be located within easy reach of the filter.

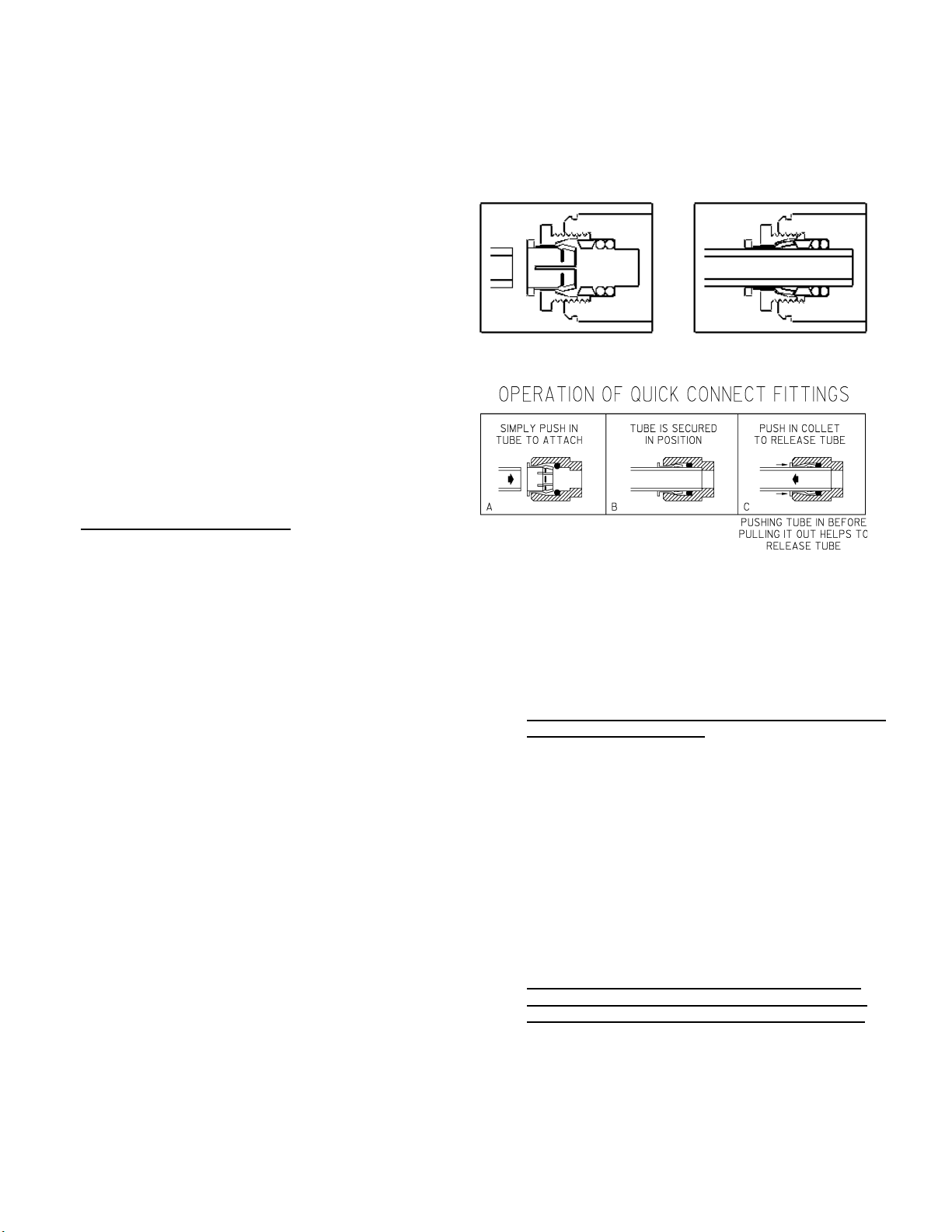

NOTE: The inlet and outlet fitting supplied as

part of the filter head are John Guest Superseal

fittings that accept 3/8" O.D. tubing on the filter

inlet and 1/4" O.D. tubing on the outlet. They may

be used with copper, stainless steel, or semirigid

nylon or polypropylene tubing, with a rated working

pressure equal or greater than encountered in

application. Do not use soft or braided tubing.

4. CAUTION: If supply pressure will ever exceed

100 psi, install a pressure regulator to limit the

inlet pressure to the filter to 100 psi or below.

DO NOT ATTACH HOT WATER LINE TO FILTER.

To make connections on the filter head, loosen locknut.

Push the tube end past both o-rings to a positive stop in

the filter head recess - approx. 1", locknut may have to

be backed out a little more. Screw the locknut hand tight

to seal (See Fig. 1). Ends of tubing must be cut square

and free of burrs and sharp ends that could cut or nick

the o-rings.

5. Connect the outlet of the filter to the inlet of the union

using the 1/4" O.D. poly tubing and 1/4" union supplied.

6. Remove filter from carton, remove protective cap, attach

filter to filter head by firmly inserting into head and

rotating filter clockwise.

FIG. 1

FIG. 2

7. Follow the applicable instructions below for correct

flushing procedure and to complete the installation.

The flushing procedure must be followed to purge air

and fine carbon particles from the sytem.

8. Read and follow instructions for the installation of the

product to be used with the filter kit.

EDP, EDV Series Point-of-Use or EBL, EBV Series water

cooler with FV-122 float kit.

1. If water reservoir contains any water, drain completely

through cold water faucet.

2. Turn on water supply and immediately open cold water

dispensing faucet on cooler, holding faucet open until

approximately 1 gallon of water is dispensed. This

flushing procedure purges air and fine carbon particles

from the filter. When 1 gallon of water has been

purged through the cooler, allow the faucet to close

and the reservoir to fill.

3. Carefully inspect all water connections for leaks.

4. Dispense approximately 1/2 gallon of water through

the hot faucet. Unit is now ready for operation.

LKH-190 Hot Water Dispenser, LK-2156 Dispensing

Valve with or without a chiller tank, LK-1141 Bubbler

with or without a chiller unit, under sink application.

1. Open inlet water supply valve, open dispensing valve

or bubbler and allow approximately 1 gallon of water to

be dispensed. This flushing procedure purges air and

fine carbon particles from the filter.

2. Turn dispensing valve off and carefully inspect all water

connections for leaks.

3. Unit is now ready for operation.

97280C (Rev. C - 3/01)Page 1

Filter Replacement*

1.Turn inlet water valve off.

2.Open dispensing valve to relieve pressure build-up in

the system.

3.Remove filter from head by rotating filter counterclock

wise.

4.Remove new filter from carton, remove protective cap;

cap may be placed on old filter to reduce the chance of

water spilling from filter housing.

5.Attach filter to filter head by firmly inserting into head

and rotating filter clockwise.

*Optional Filter Monitor (Part No. 92640C)

counts gallon usage and provides an audible alert

when filter needs replacement. Alert is sounded only

when water is being dispensed; beeping is not continuous.

Requires 9VDC alkaline battery.

RATED OPERATING CONDITIONS

NOTE: The filter head contains an automatic

shut-off valve that stops the flow of water.

If the filter is removed inadvertently with-

out shutting off the incoming water.

Listed below are filters that will fit into the filter head

supplied with this kit. The labels on the filters are colorcoded as noted. Make certain that the correct filter is

being used for application. See Performance Data

Sheet supplied with each filter for complete list of

claims.

Pressure (Min.)

Flow Rate

Temperature (Min.)

20 PSI (1.5 Kg/cm2)

0.75 GPM

40° F (5° C)

NOTE: Performance will vary depending

on local water conditions.

Table A

REPLACEMENT FILTERS

Filter

ELKAY WaterSentry

®

I

ELKAY WaterSentry® VII

CORDLEY®/Temprite® WaterSentry® I

CORDLEY®/Temprite® WaterSentry® VII

The ELKAY and CORDLEY®/TEMPRITE® WaterSentry® VII conforms to ANSI/NSF Standard 42 for reduction of

Chlorine - Class I, Particulate - Class I, and Taste and Odor; ANSI/NSF 53 for reduction of Lead and Cyst.

NOTE: If the flow exceeds the rated flow rate, install a flow restrictor, Elkay Part No. 50967C, to limit the flow to .5 gpm.

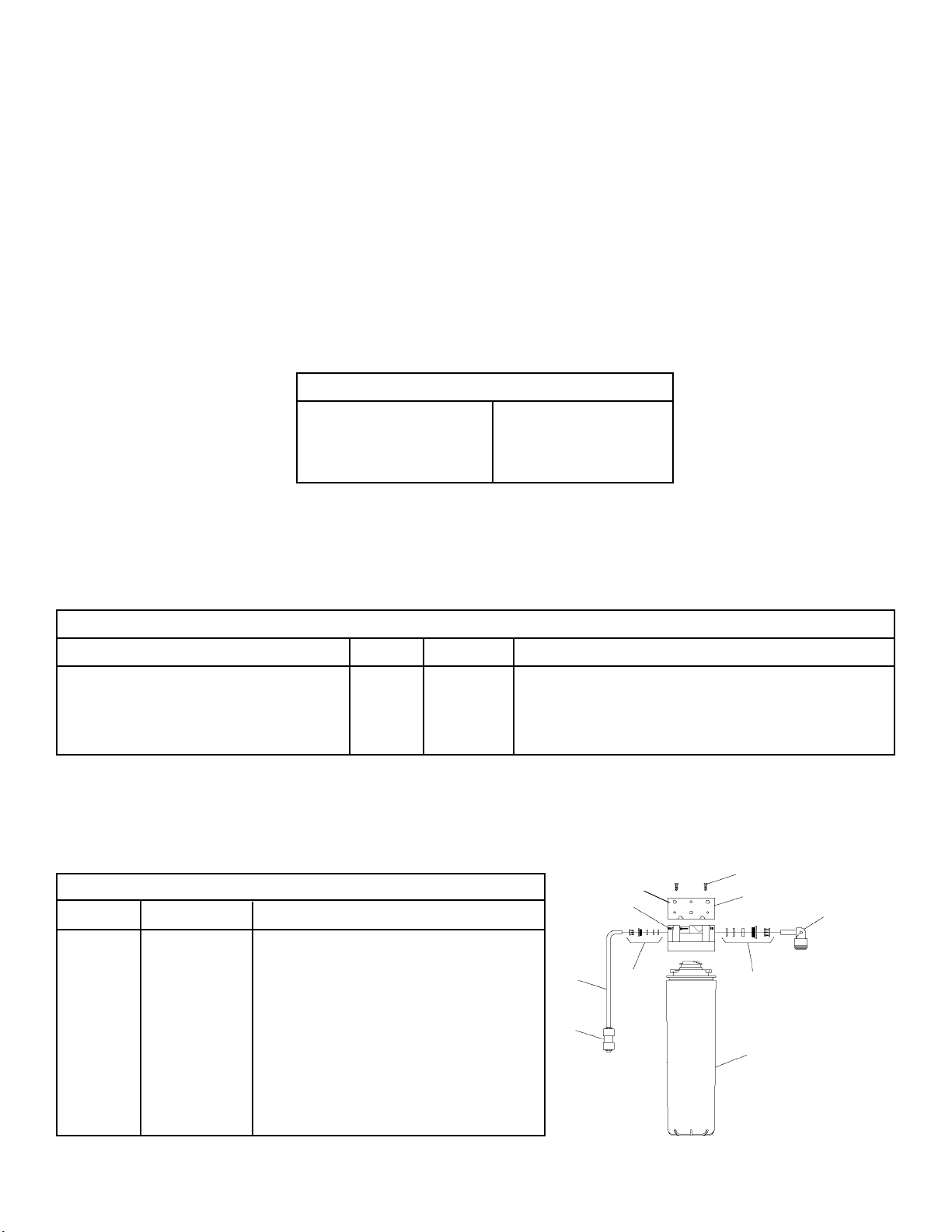

ITEMIZED PARTS LIST

Item No. Part No. Description

Bracket - Filter Mounting

Screw #8-18 x .50 (13mm) LG. HHSM

Filter Head & Bracket Assembly

Screw #8-18 x .75 (19mm) LG. PH

Tubing - Poly 1/4" (6mm) x 24" LG.

Fitting - Superseal 3/8" (10mm)

Fitting - Superseal 1/4" (6mm)

Filter Assembly

Union - 1/4" (6mm)

Elbow Adapter 1/4" x 3/8"

10

1

2

3

4

5

6

7

8

9

22490C

38417002

51469C

70792C

50801C

70823C

70822C

See Table A

70683C

70819C

Part No. Color Code Description

51296C

51299C

55892C

55893C

Light Blue

White

Light Blue

White

Chlorine, Taste, Odor, & Sediment Reduction Filter

Lead, Cyst Reduction, C.T.O. Filter

Chlorine, Taste, Odor, & Sediment Reduction Filter

Lead, Cyst Reduction, C.T.O. Filter

2

3

5

9

7

4

1

10

WHEN

REQUIRED

6

8

* Item No(s). 1, 4, 6, and 7 included with Item No. 3.

97280C (Rev.C - 3/01)

FIG. 3

Page 2

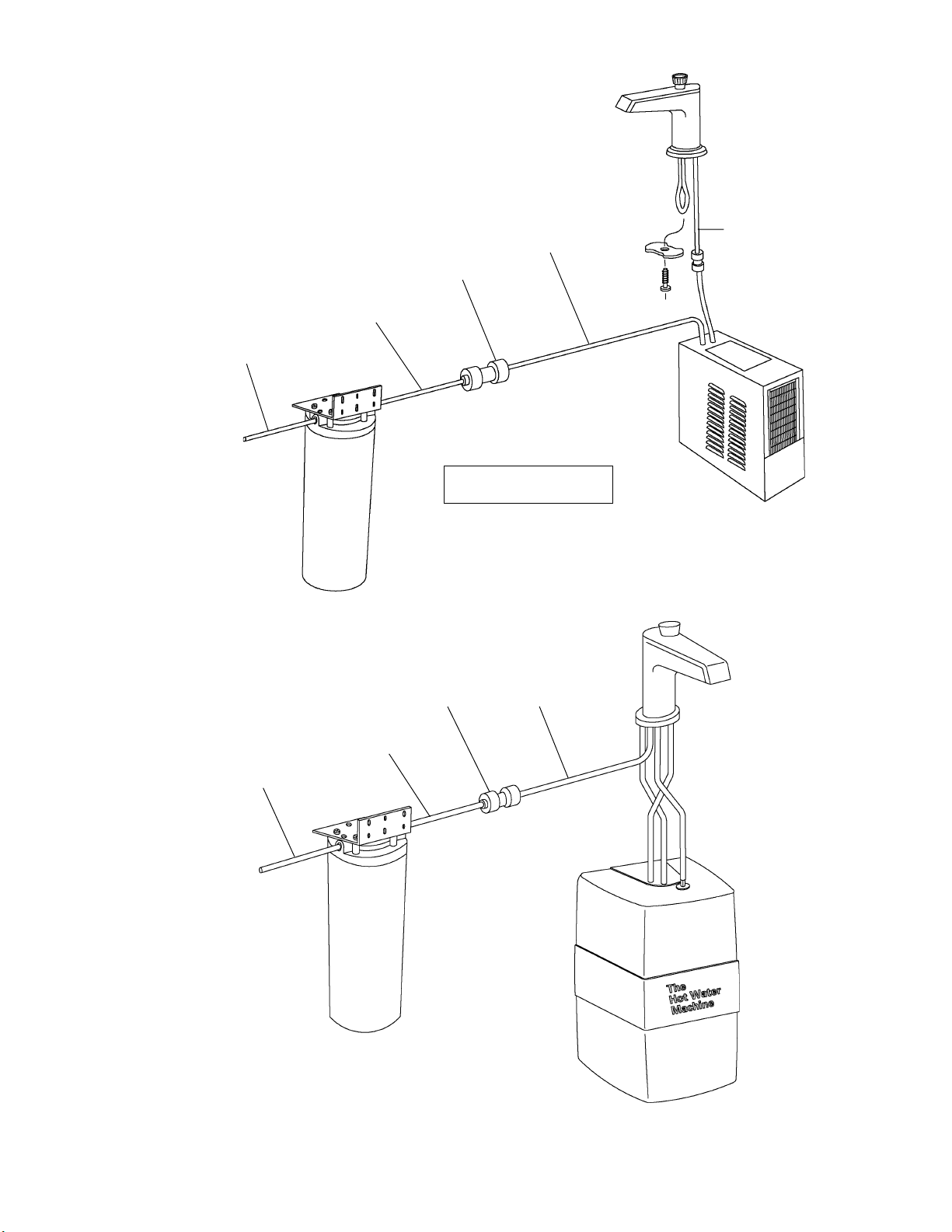

LK-2156 & REMOTE CHILLER

(Alternate LK-2156 alone)

1/4" (6mm)

O.D. TUBING

FROM COLD

WATER SUPPLY

O.D. TUBE

3/8" (10 mm)

(SUPPLIED)

WATER "IN"

TO

REMOTE

1/4" (6mm) UNION

(SUPPLIED)

CHILLER

INSTALLATION WHEN USED

WITH WATER CHILLER

PLUMB FILTER OUTLET

DIRECTLY TO LK-2156 IF NO

CHILLER IS USED

CHILLED

WATER

SUPPLY TO

VALV E

PICTURE OF LKH-190 HOOK-UP

1/4" (6mm)

O.D. TUBING

FROM COLD

WATER SUPPLY

O.D. TUBE

3/8" (10 mm)

(SUPPLIED)

1/4" (6mm) UNION

(SUPPLIED)

WATER "IN"

TO

LKH190

See page 4 for replacement information.

97280C (Rev. C - 3/01)Page 3

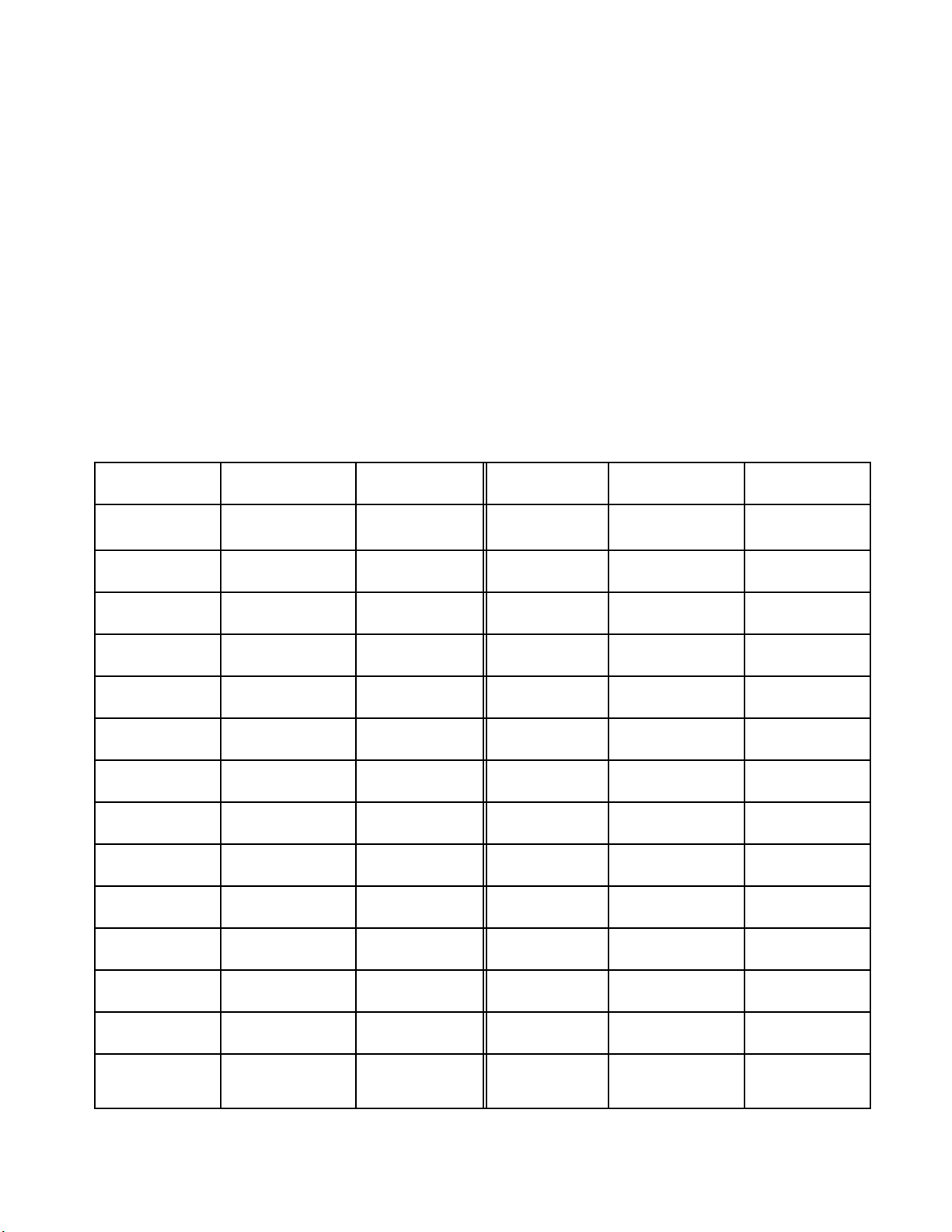

NOTICE

To receive maximum benefit from your ELKAY and CORDLEY®/Temprite®WaterSentry® filters, note the installation

dates below and change according to the following guidelines.

ELKAY WaterSentry® I -- Taste - Odor -Sediment Filter

Change every 2,500 gallons, or once a year -- whichever occurs first.

ELKAY WaterSentry® VII -- Lead/Cyst Reduction Filter

Change every 1,500 gallons, or once a year -- whichever occurs first.

CORDLEY®/Temprite®WaterSentry® I -- Taste - Odor -Sediment Filter

Change every 2,500 gallons, or once a year -- whichever occurs

first.

CORDLEY®/Temprite® WaterSentry® VII -- Lead/Cyst Reduction Filter

Change every 1,500 gallons, or once a year -- whichever occurs

first.

- - KEEP THIS SHEET IN A HANDY LOCATION - -

DATE

INSTALLED

MODEL

(TYPE OF FILTER)

SERVICE

PERSON

DATE

INSTALLED

MODEL

(TYPE OF FILTER)

SERVICE

PERSON

97280C (Rev.C - 3/01)

ELKAY MANUFACTURING COMPANY 2222 CAMDEN COURT OAK BROOK, IL 60523 630.574.8484

FOR PARTS, CONTACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.323.0620

Page 4

Loading...

Loading...