Page 1

EDFP110/114/117FPC

Installation/Care/Use Manual

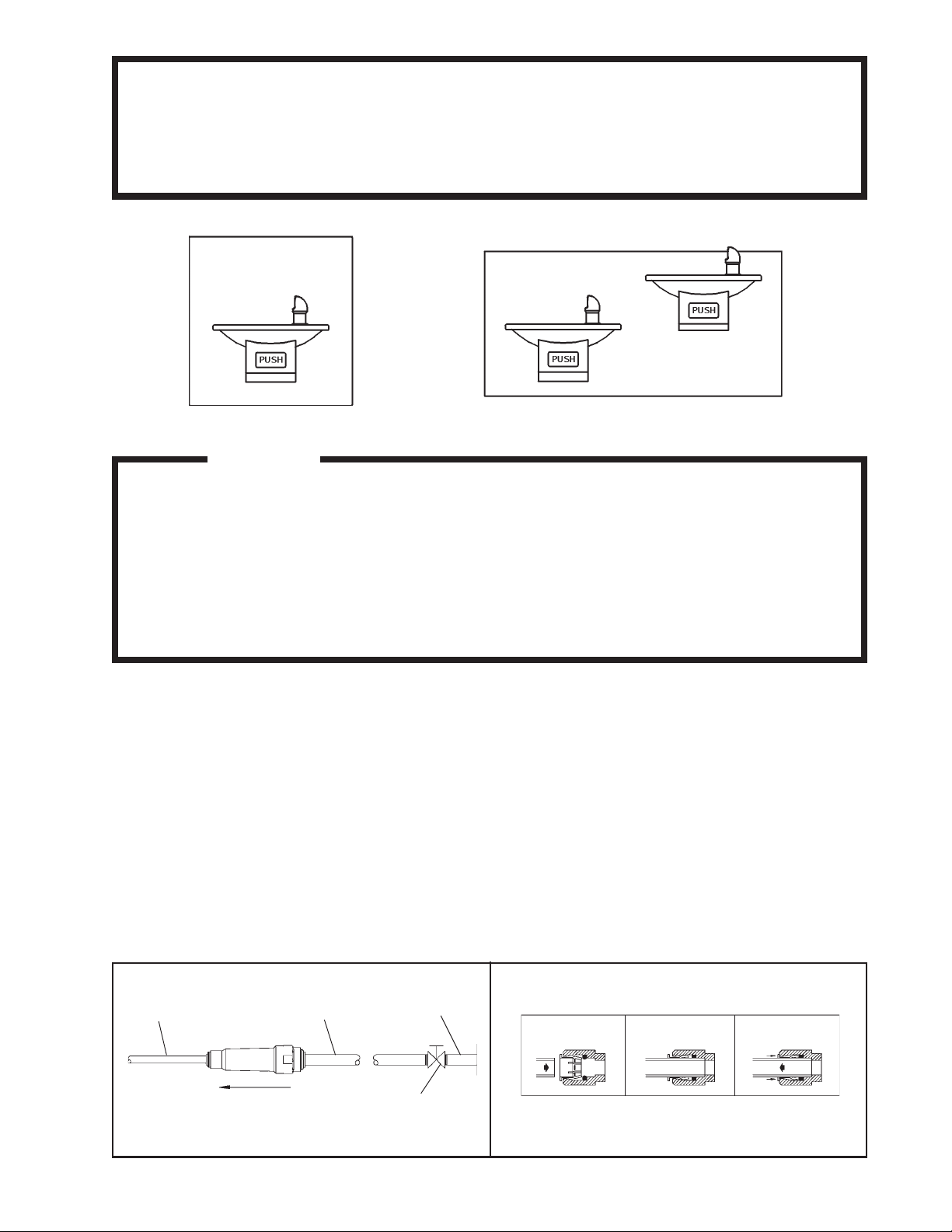

EDFP110FPC EDFP114FPC EDFP117FPC

®

Swirlflo

Installer

T o assure you install this model easily and correctly , PLEASE READ THESE SIMPLE

INSTRUCTIONS BEFORE ST ARTING THE INST ALLATION. CHECK YOUR INST ALLATION FOR COMPLIANCE WITH PLUMBING, ELECTRICAL AND OTHER APPLICABLE

CODES. After installation, leave these instructions inside the fountain for future reference.

This Freeze Resistant Fountain is shipped in two separate cartons. The second carton

contains the Freeze Resistant Package LK616A that is installed on an interior heated

wall. Refer to the Freeze Resistant Package for the rough-in dimensions for installation.

Freeze Resistant Fount ains

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. TO

WA TER LINES IS A COMMON PROCEDURE. THIS GROUNDING MA Y BE IN THE BUILDING OR MA Y

OCCUR A WA Y FROM THE BUILDING . THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK

INTO A FOUNT AIN, CREA TING AN ELECTROLYSIS WHICH CAUSES A METALLIC T ASTE OR AN

INCREASE IN THE METAL CONTENT OF THE WATER. THIS CONDITION IS A VOIDABLE BY USING

THE PROPER MA TERIALS AS INDICA TED. ANY DRAIN FITTINGS PROVIDED BY THE INST ALLER

SHOULD BE MADE OF PLASTIC TO ELECTRICALL Y ISOLA TE THE FOUNT AIN FROM THE BUILDING

PLUMBING SYSTEM.

1/4" O.D. TUBE

WATER INLET

TO COOLER

3/8" O.D. UNPLATED

COPPER TUBE CONNECT

COLD WATER SUPPLY

NOTE: WATER FLOW

DIRECTION

BUILDING WATER

INLET

SERVICE STOP

(NOT FURNISHED)

FIG. 1

PAGE 1

OPERA TION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

FIG. 2

TUBE IS

SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

97030C (Rev. F - 12/04)

Page 2

EDFP110/114/117FPC

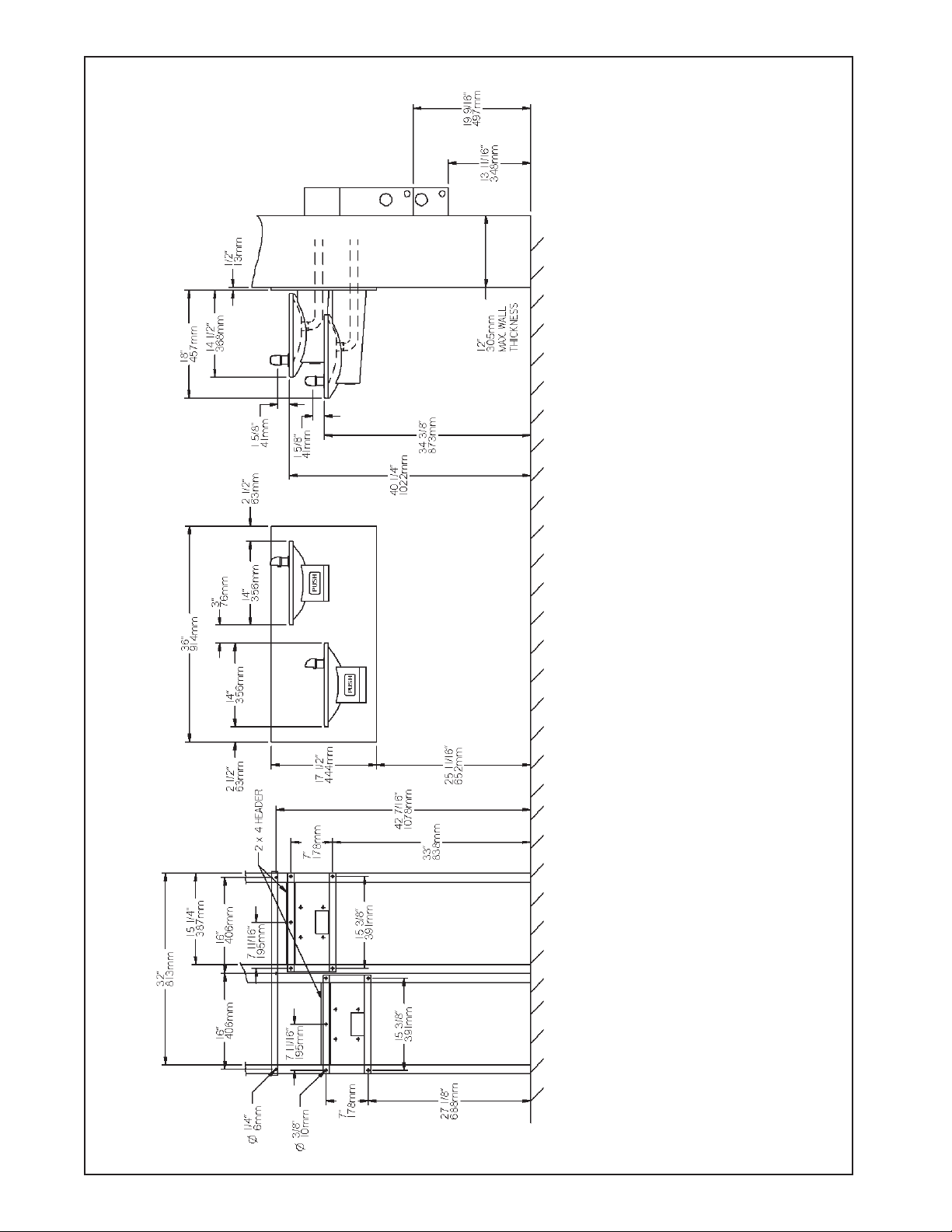

EDFP1 17FPC ROUGH-IN

FINISHED FLOOR *

FIG. 3

97030C (Rev. F - 12/04)

PAGE 2

1. Wall should already be framed for the fountain using dimensions shown in Fig. 3. Shown dimensions pertain to installation location.

These dimensions are required for compliance with ANSI Standard A1 17.1. (and ADA) (Framing shown for reference only).

2. Attach the hanger bracket and panel mounting bracket(s)s to the wall as shown in Fig. 3. Use bolts and flat washers (not provided). Tighten securely.

3. Install the back panel. Place the upper edge of the p anel above the hanger on the wall. Slide the panel down until it engages the hanger . Be sure p anel is

firmly engaged before releasing it.

4. Remove bottom cover(s) from fountain(s) and save the screws. Assemble push rod(s) to fountain(s). See Fig. 6. (Push rods provided with freeze

resistant boxes)

5. Install the fountain(s) to the back p anel and panel mounting bracket(s) using bolt s (provided). T ighten securely .

6. Attach drain tube(s) (supplied with freeze-resistant box) to fountain(s) and cut to required length using the freeze resistant box as a guide.

7. Install freeze resistant box - see box instructions.

8. Install a service stop (not provided) and make water supply connection from the stop to the strainer(s) in the freeze resistant box.

9. Connect fountain water line to freeze resistant box - see box instructions. Replace bottom cover(s).

*NOTE: All dimensions are taken from the finished floor on the side of the wall that the fountain is installed on.

Page 3

EDFP110/114/117FPC

EDFP1 10/1 14FPC ROUGH-IN

FIG. 4

FINISHED FLOOR *

PAGE 3

*NOTE: All dimensions are taken from the finished floor on the side of the wall that the fountain is installed on.

97030C (Rev. F - 12/04)

Page 4

EDFP110/114/117FPC

P ARTS LIST

ITEM

NO.

1

2

3

4A

4B

5A

5B

6A

6B

7

8

9

10

11

12

13

14

15

16

17

NS

NS

NS

* PAR TS ARE SUPPLIED WITH FREEZE RESIST ANT BOX

PART

NO.

21705C

28322C

21810C

21822C

21823C

21845C

21846C

27314C

27315C

98118C

100322740560

15009C

50198C

55001026

70002C

70410C

70426C

75555C

*75559C

75570C

27089C

55000792

27259C

75520C

DESCRIPTION

CLIP-PUSH ROD

BRACKET-PUSH BAR MTG .

PUSH BAR ASSY

FTN BODY&SHELL EDFP1 10C

FTN BODY&SHELL EDFP1 14C

COVER PLATE EDFP1 10C

COVER PLATE EDFP1 14C

PANEL-BACK EDFP1 17FPC

PANEL-BACK EDFP1 10/1 14FPC

BUBBLER ASSEMBL Y

GASKET

NIPPLE ASSY

BUSHING-SNAP

BASIN

SCREW-#10 X .50 HHSM

ROD-PIVOT

SCREW #8-32 X .25 THMS

CLIP -.125 STUD LOCK

PUSH ROD ASSY

SCREW # 10 X .50 PINNED TORX

HANGER BRACKET EDFP1 10/114FPC

HANGER BRACKET EDFP1 17FPC

BRKT ASSY -PANEL MOUNTING

BIT-PINNED TORX

7

8

9

FIG. 5

11

4A, 5A

6A

SEE FIG. 5

SEE FIG. 6

17

4B, 5B

17

10

15

2

16

12

1

3

13

ELKAY MANUFACTURING COMP AN Y • 2222 CAMDEN COURT • OAK BROOK, IL 60523 • 630.574.8484

97030C (Rev. F - 12/04)

14

FIG. 6

FOR PARTS, CONT ACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.323.0620

PAGE 4

Loading...

Loading...