Elkay ECU8-3 Installation Manual

ECU8-1, ECU8-2, ECU8-3

Installation Instructions

Refrigeration Packages

INSTALLATION

1. Insure proper ventilation. In fully recessed drinking fountains be sure condenser faces louver panel and is

within 1/2" (13 mm) of louver panel when panel is in place.

2. Water inlet is 3/8" (10 mm) O.D. tube connector. Contractor to supply connections as required.

3. Connecting lines to be made of copper. Thoroughly flush all lines to remove all foreign matter before

connecting to cooler.

4. Connect cooler to building supply with a shut-off valve and install a 3/8" (10 mm) water line between the valve

and cooler. Remove burrs from outside of water line. Insert water line into bulkhead union until it reaches a

positive stop, approximately 3/4" (19 mm).

5. Electrical: Make sure power supply is identical in voltage, cycle, and phase to that specified on cooler serial

plate. Never wire the compressor directly to the power supply.

IMPORTANT! INSTALLER PLEASE NOTE:

The grounding of electrical equipment such as telephone, computers, etc., to water lines is a common procedure.

This grounding may be in the building, or may occur away from the building. This grounding can cause electrical

feedback into a water chiller, creating an electrolysis which causes a metallic taste or an increase in the metal

content of the water. This condition is avoidable by using the proper materials indicated below. Drain fittings which

are provided by the installer should be plastic to electrically isolate the chiller from the building plumbing system.

START-UP

1. Open supply line valve.

2. Purge all air from all water lines by operating bubbler valve of fountain to which cooler is connected. A steady

stream flow assures that all air is removed.

3. Rotate fan blade to assure proper clearance and free action.

4. Connect to proper electrical power.

TROUBLE SHOOTING & MAINTENANCE

Temperature Control: Factory-set for 50°F water (± 5°) under normal conditions. For colder water, adjust screw

on item no. 5.

Ventilation: Cabinet louvers and condenser fins should be periodically cleaned with a brush, air hose, or vacuum

cleaner. Excess dirt or poor ventilation can cause no cold water and compressor cycling on the overload

protector.

Lubrication: Motors are lifetime lubricated.

Actuation of Quick Connect Water Fittings: Cooler is provided with lead-free connectors which utilize an o-ring

seal. To remove tubing from the fittings, relieve water pressure, push in on gray collar while pulling on the

tubing. To insert tubing, push tube straight into fitting until it reaches a positive stop, approximately 3/4.

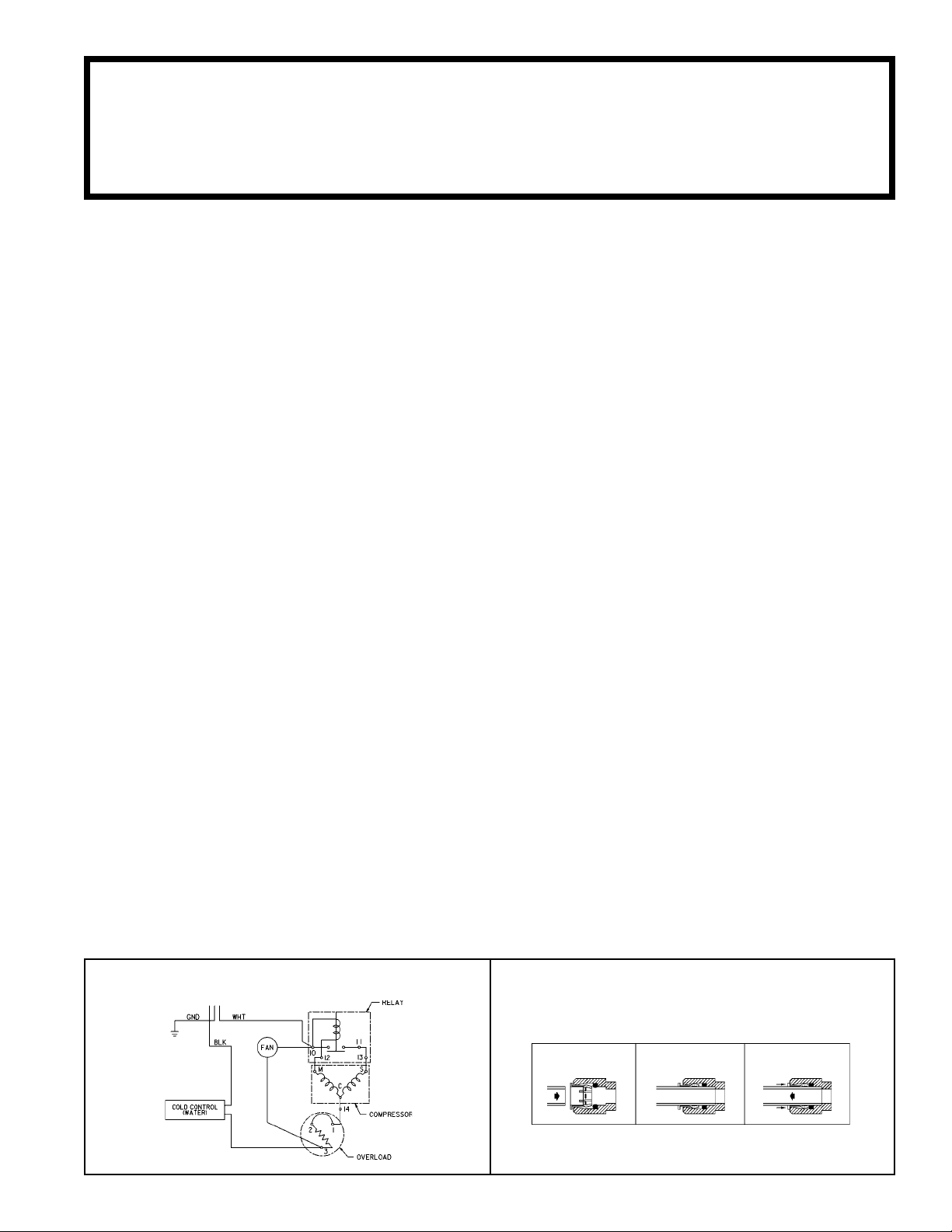

WIRING DIAGRAM

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

96645C (Rev. E)

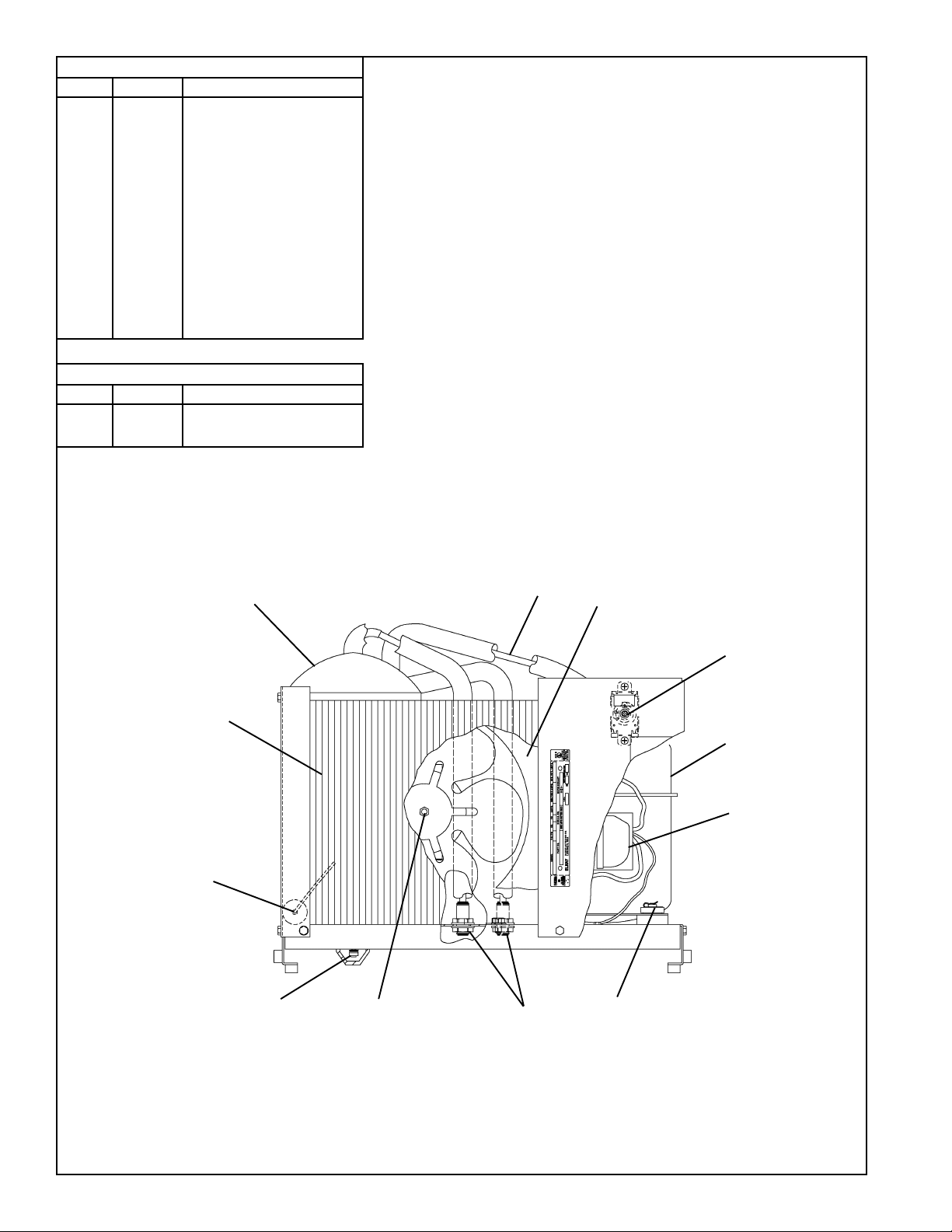

ECU8-1, ECU8-2, ECU8-3

PARTS LIST

ITEM NO.

1

2

3

4

5

6*

7

8

9

10

11

12

13

14

15

16

17

18

NS

PART NO.

66421C

50189C

66263C

70841C

31513C

35767C

31025C

19037000

101516143550

100806740570

20282C

31490C

70018C

30664C

66202C

66305C

70767C

70772C

31504C

EVAPORATOR

SHROUD

HEAT EXCHANGER

UNION - BULKHEAD

COLD CONTROL

COMPRESSOR SERV. PAK

OVERLOAD/RELAY ASSY

CLIP - COMPRESSOR MTG

STUD - COMPRESSOR MTG

GROMMET - COMPRESSOR MTG

BRACKET - FAN MTG

FAN MOTOR

NUT

FAN BLADE

DRIER

CONDENSER

EVAPORATOR RETAINING CLIP

EVAPORATOR DRAIN PLUG

POWER CORD

DESCRIPTION

220/240 50/60HZ PARTS LIST

ITEM NO.

PART NO.

6*

7

15

35763C

31024C

31430C

COMPRESSOR SERV. PAK

OVERLOAD/RELAY ASSY

FAN MOTOR

*INCLUDES RELAY & OVERLOAD. IF UNDER WARRANTY REPLACE

WITH SAME COMPRESSOR USED IN ORIGINAL ASSEMBLY.

NOTE: ALL CORRESPONDENCE PERTAINING TO ANY OF THE ABOVE

WATER COOLERS OR ORDERS FOR REPAIR PARTS MUST INCLUDE

MODEL NO. AND SERIAL NO. OF COOLER, NAME AND PART NO. OF

REPLACEMENT PART.

DESCRIPTION

15

16

1

3

2

5

6

7

11, 12, 13, 1417, 18

4

8, 9, 10

96645C (Rev. E)

FOR PARTS, CONTACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.323.0620

ELKAY MANUFACTURING COMPANY2222 CAMDEN COURTOAK BROOK, IL 60523630.574.8484

Loading...

Loading...