Page 1

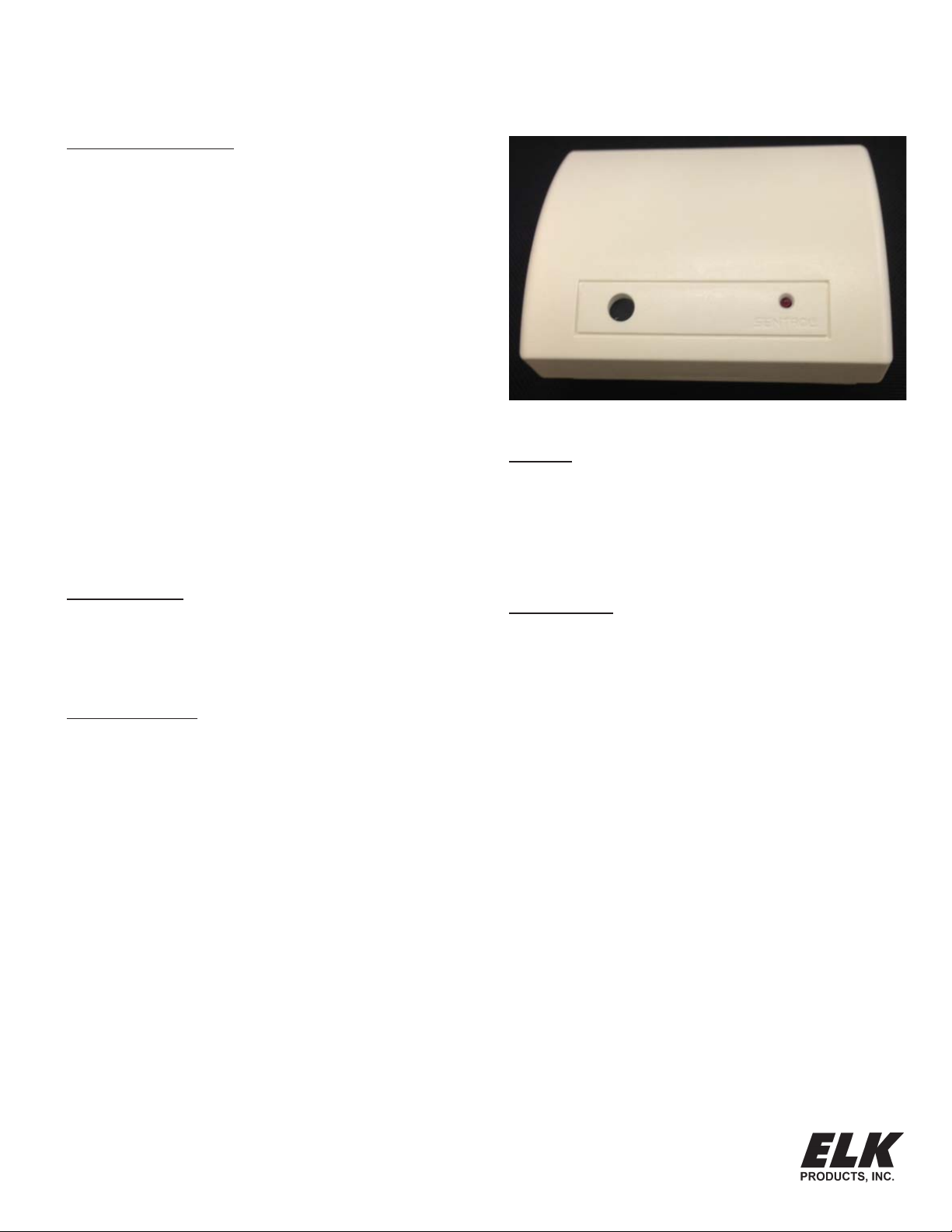

ELK-6040

Wireless Glass Break Sensor

APPLICATION & OVERVIEW

The ELK-6040 Wireless Glass Break Sensor is designed for use with

control/transceivers that accept Elk's two-way technology; such as the

ELK-M1XRFTW. It incorporates many features designed to ensure its

reliable performance.

The 6040 listens for actual patterns of breaking glass across the full

audio band using Pattern Recognition TechnologyTM. The factory set

recognition patterns make it possible to detect the difference between

breaking glass of framed perimeter windows in a building vs. a drinking

glass breaking within a room.

The built-in two-way radio (RF) transmits alarm, supervisory, and low

battery messages to the control/receiver. Each sensor has a unique

TXID number that is enrolled into the control during installation. With its

two-way capability, the sensor listens after every transmission for a

positive acknowledgment from the control. This makes it very energy

efficient since it does not waste energy repeating transmissions unless

they are not acknowledged.

Installation and Setup Guide

A simple hand clap test feature lets the user confirm that the sensor is

operational. A handheld glass break tester (not supplied) can be used

to place the sensor into range and functional test mode.

The product is suitable for use in quiet occupied areas on a perimeter

defined zone. I

and other areas approved by the authority having jurisdiction (AHJ). It

is not intended for use in industrial applications.

ABOUT THIS GUIDE

This Guide describes the installation, operation, and maintenance of this

product. Keep this document in a handy location and refer to it for

answers regarding the products functions or features. Reading this

guide is the only way to learn how to use your product wisely and to

know how to react in the event of an alarm.

PACKAGE CONTENTS

6040 Wireless Glass Break sensor

CR123A Lithium Battery

Mounting Screws and Anchors

Installation Guide

t is intended for residential indoor dwelling unit applications

FEATURES

• Pattern Recognition Technology

• Wireless two-way communication

• Operation Alarm LED - RED (viewable from front)

• RF Acknowledge LED - Bi-Color (viewable with cover off)

• Long life Lithium battery {supplied}

• Low battery trouble signal

• Periodic Supervisory check-in

SPECIFICATIONS

• Dimensions: 4.25"W x 3.13"H x 1.70"D

• Sensor: Omni-directional Microphone, 360° Detection Range

• Detection Range: 20 ft. (6m) x 360°

• Min. Distance from Glass: 4 ft. (1.2m)

• Glass Thickness:

Plate 3/32 to 1/4 in. (2.4 to 6.4mm)

Tempered 1/8 to 1/4 in. (3.2 to 6.4mm)

Wired 1/4 in. (6.4mm)

Laminated 1/8 to 1/4 in. (3.2 to 6.4mm)

• Power: One CR123 3.0 VDC Lithium Bttery

• Quiescent Current: 25 μA (typically)

• Battery Life: 5 years

• RF Frequency: 902 - 928 Mhz channel hopping

• Supervisory check-in interval: ~64 minutes

• Storage temperature: -4 to +140° F (-20 to 60° C)

• Operating Environment: 32° to +120° F (0 to 49° C)

• Relative Humidity: 93% RH (max.), non-condensing

TM

TM

Pattern Recognition Technology is a registered trademark of Edwards,

a UTC Fire and Security company.

For the latest downloadable version of this manual visit our website: http://www.elkproducts.com

ELK-6040 Glass Break Installation Manual Page 1

Page 2

1. GUIDELINES FOR USE

This sensor is a member of a reliable, high-quality product family using

the latest technology available. Please review the information in this

section to ensure you get the most out of the product.

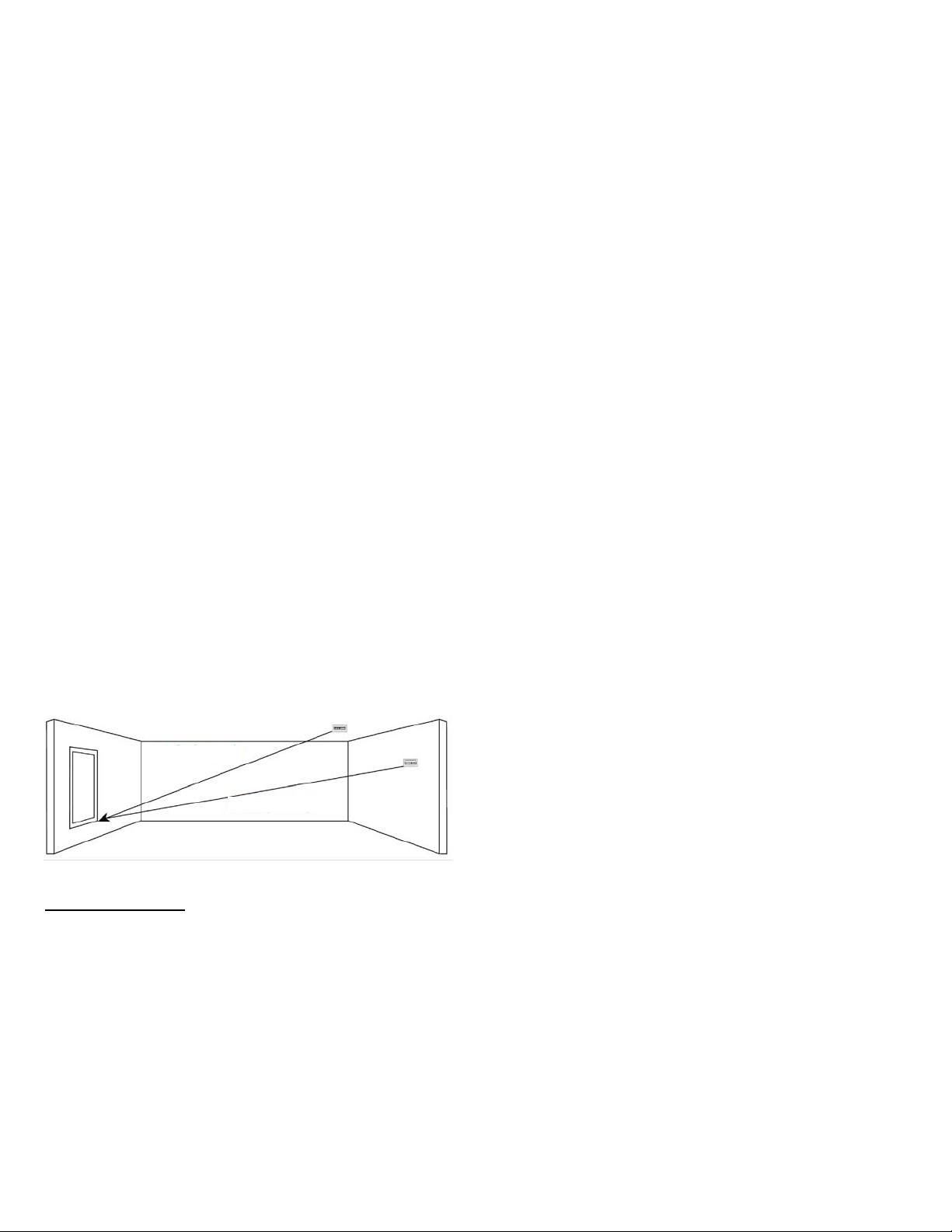

The sensor must always be in direct line of sight of all windows to be

protected. It is not possible for the sensor to consistently detect breaking

glass around corners or in another room.

Wall mount

For wall applications mount the sensor on a wall facing (opposite) the

glass to be protected. Direct line of sight is important. Do not exceed the

max. operating distance. An adjoining perpendicular (90°) wall which

conforms to same criteria may also be used. Orientation of the sensor

(sideways, upside down, etc.) is not critical.

Ceiling mount

For ceiling applications mount the sensor so that it has a direct line of sight

to the glass being protected. However, since sound travels directionally

out from a broken window, a position of around 8 ft. (2.4 m) into the room

provides better detection.

Use the following guidelines to determine the best mounting location:

- Mount the sensor at least 3.3 ft. (1 m) from the windows being

protected and at least 4 ft. (1.2 m) from noise sources such as TVs,

speakers, sinks, and doors.

- Mount the sensor in the direct line of sight of the glass to be protected.

- Mount the sensor in a suitable environment: see specifications for

temperature and humidity ranges..

- Mount the sensor on a stable surface no greater than 25 ft. (7.6 m)

from the farthest point on the glass surface.

- locations exposed to white noise, such as air compressors, etc.

It is recommended that the ELK-6040 be located within 100 feet of the M1

Control or M1XRFTW Transceiver. While an open-air range of 400 feet

or more is possible, adverse indoor and environmental conditions can

significantly reduce the actual transmission range. Small changes to the

sensor's mounting can often make a big difference in transmission range.

DO NOT mount a wireless sensor near metal duct work or other large

metallic surfaces that might shield or adversely affect the RF signals. Prior

to permanent mounting, we recommended a walk test be performed with

the control/transceiver to verify acceptable operation of the wireless

sensor at its intended location.

3. MOUNTING THE SENSOR

This product can be wall mounted or ceiling mounted.

3.1 Disconnect any alarm notification appliances, service related devices,

and extinguishing systems. Functionally test the sensor in its intended

location to verify the communications between it and the M1 Control.

It is very important to confirm that the sensor is within adequate range

of the M1 Control/Transceiver prior to permanently mounting.

Refer to Test Method #3 - Functional Test later in this guide.

- Hold the product in the intended mounting location or temporarily

mount it using some form of removable fastener.

- Confirm that the test signals from the sensor reach the control. If

no signal is received or if the RF signal is low, try relocating the

sensor to another location and retest.

3.2 After testing has been confirmed, mount the sensor and sensor base

2. RECOMMENDED LOCATIONS AND OPERATING RANGE

The sensor is omni-directional, providing 360° coverage. Coverage range

is measured from the sensor to the point on the glass farthest from the

sensor. The sensor can be mounted as close as 3.3 ft. (1 m) from the

glass. The maximum range may vary depending on the type of glass being

protected:

- Plate, tempered, laminated, & wired glass - Mount sensor on

ceiling or the opposite/adjoining wall, maximum range is 20 ft. (6 m).

as follows:

- Remove the screw located in the front.

- Remove the top cover by using a flat bladed tool in the screw

location to pry open the top cover.

- Locate the mounting location and drill holes in base per the

mounting impression in the base.

- Use the anchors and screws to secure the product to the

mounting surface.

3.3 Replace the product’s top cover:

- Snap the top onto the base.

- Replace the screw into the front location.

20 ft. (6m)

4. BASIC OPERATION

This product is equipped with an intuitive normal mode operation.

20 ft. (6m)

LOCATIONS TO AVOID

Improper location can affect the sensitive electronic components in this

product. To avoid causing damage to the product, to provide optimum

performance, and to prevent unnecessary nuisance alarms:

- Avoid rooms smaller than 10 x 10 ft. (3m x 3m).

- Avoid locations where lined, insulating, or sound-deadening drapes

or closed wooden shutters are used.

- Avoid mounting in the corner of a room.

- Do not install the sensor in humid rooms. Excess moisture on the circuit

board can eventually cause a short and a false alarm.

- Avoid locations that might expose the sensor to possible false alarm

sources such as:

- glass airlocks and vestibule areas

- kitchens and bathrooms

- corner mounting

- residential car garages

- small utility rooms

- stairwells

- small acoustically live rooms

Page 2 ELK-6040 Glass Break Installation Manual

- In normal operation, the red LED will generally remain OFF.

- The wake up test will cause the red LED to illuminate two blinks.

- In response to an alarm the red LED will stay ON for approximately

4 seconds. The RF transmitter will send the alarm to the Control.

- In a trouble or maintenance required condition the red LED will not

illuminate in response to the wake up test.

- In a trouble condition such as low battery the sensor will send an

RF transmission to the Control.

Page 3

RF ACKNOWLEDGE LED

This bi-color LED IS located on the bare circuit board near the upper left

side. It provides visual confirmation of the two-way acknowledge

(response) from the control/transceiver and can only be viewed by

removing the sensor cover.

GREEN blink = Sensor successfully transmitted a violation (alarm) and

that signal was received and acknowledged by the transceiver. A

green blink is not provided for a sensor restore transmission..

ORG/RED blink = Sensor was not successful and did not get

acknowledged by the transceiver. POSSIBLE CAUSES: a) the Control

or M1XRFTW is powered off. b) the M1XRFTW is not enrolled with

control. c) the sensor is not enrolled. d) the distance between the

sensor and the transceiver is too great. Check the following:

A. Verify that the M1 Control is powered on.

B. Verify that the M1XRFTW Transceiver is powered on and that it is

enrolled with the M1.

C. Verify that the sensor is properly enrolled.

D. Trip another wireless sensor to see it can successfully communicate.

E. If above steps are OK, temporarily move the failed sensor closer

to the transceiver and retest. If sensor successfully communicates

at the closer range then it may be necessary to:

5. INSTALLING / REPLACING BATTERY

The 6040 sensor uses a single CR123A Lithium battery. The estimated

service life is 5 years in a typical residential installation.

The Battery is supervised for low voltage. When the sensor detects the

voltage has reached 2.6 VDC or less (under load), a Sensor Low Battery

trouble will be transmitted to the control/transceiver. This trouble will be

attached to all future transmissions until a fresh battery is installed.

When the Control indicates that it is time to replace the sensor battery,

remove the old battery and

new battery. This time is necessary to clear and reset the low battery

condition from the sensor memory. After the new battery has been

installed, trip the sensor a couple of times. This should send an "all good"

to the Control and clear the low battery trouble.

Use only approved 3V Lithiums. Replacements can be obtained from any

local Alarm Distributor.

Note: Place the control panel into sensor test mode prior to replacing the

battery. If the control panel is not in sensor test mode during battery

replacement, an alarm condition may be indicated.

WAIT AT LEAST 20 seconds before installing

- Relocate the transceiver to a closer and more central location to this

and all other sensors.

OR

- Purchase and install an additional “remote” transceiver to cover the

area where this sensor was mounted.

RF ACKnowledge LED

RF

STATUS

(ACKnowledge)

ELK-6040

WHT

GRN

BLK

RED

CR123

Lithium

Battery

5.1 Remove the product top cover.

5.2 Remove the old battery and properly dispose of it as recommended

by the battery manufacturer.

5.3 WAIT AT LEAST 20 SECONDS before installing new battery.

5.4 Observe correct polarity when installing the new battery. Insert

the battery positive (+) terminal so that it points towards the (+) symbol

printed on the circuit board. Be careful not to bend or damage the metal

battery holder contacts.

5.5 Replace the top cover.

5.6 Replace the front screw.

5.7 Re-test sensor operation with the control.

Approved 3.0 Lithium Batteries are:

- Panasonic CR123A

- Duracell DL123A

- Varta CR123A.

ELK-6040 Glass Break Sensor with cover removed

Alarm / Activity LED

Sensor Microphone

ELK-6040 Glass Break Installation Manual Page 3

Page 4

ENROLL SENSOR INTO THE CONTROL USING ONE OF THE TWO METHODS BELOW

6. ENROLLING A SENSOR USING THE M1 KEYPAD

6.1 Make sure the M1XRFTW Transceiver is powered and enrolled with

the M1 Control.

6.2 Enter M1 Keypad Installer Programming and go to Menu: 14-

Wireless Setup

6.3 Scroll up to sub-menu:3:Learn Sel Wireless Transmtr and

press Select (right arrow).

6.4 Scroll to and select an unassigned WZone (wireless zone) and

press Learn (right arrow) to enroll.

6.5 Insert the Battery into the sensor when the keypad displays: Push

Transmitter Button and the M1G speaks; “Press transmitter

button for zone xx”). Upon successful enrollment the Keypad will

chime and briefly display the 6 digit TXID printed on the sensor. If

the TXID of the sensor does not display then enrollment was

unsuccessful. To attempt enrollment again you must remove

the battery and wait at least 20 seconds before reinserting.

Rapid-Enroll will auto advance to the next wireless zone in sequence and wait for a new sensor. Repeat the previous step for

each sensor.

6.6 After all wireless sensors are enrolled, press the ELK or Select

Wireless key to stop Rapid-Enroll.

6.7 Set the Loop ID. Scroll to each 6040 wireless zone and press the

HW (left arrow) button. An 8 digit number (TXID in decimal) will

display followed by Loop = 0. Move the cursor to the right (press

RIGHT arrow) and enter a "2" for the Loop ID . This is VERY

IMPORTANT! Press the ELK key to return back to the wireless zone

display. Loop ID informs the M1 how to handle the input transmission.

The 6040 Glass Break sensor MUST be set as Loop "2". NOTE:

The M1 default for all wireless zones is Loop "0".

7. ENROLLING A SENSOR USING ELKRP

7.1 Launch the ElkRP PC software and open the Customer Account file.

7.2 Click the "+" next to Zones (Inputs) to expand the view. Look for

any existing wireless zone groups. If there are none it will be

necessary to add or create a new group. To create a wireless

group, right click on Zones (Inputs) and click New Wireless

Zones. Place a check mark in the box to be added, starting with

Group 2. Click OK. Repeat if more wireless groups are required.

NOTE: The M1 Control requires all expanded zones to be defined

in groups of 16. E.G. Zones 17-32 = Group 2, zones 33-48 = Group

3, etc.

Since the first M1XRFTW Two-Way Transceiver must

always be enrolled at databus address 2 (the first expander),

this means that the first group of wireless sensors should be

defined as group 2. Since M1 allows a maximum of 144 wireless

zones, the last potential wireless zone can never be higher than

Zone 160. If a large number wireless zones is anticipated, it would

be a good idea to avoid conflict with any future Hardwired Zones

in the 17 to 160 range by NOT enrolling any Hardwired Zone

Expanders (M1XIN) at any data bus addresses below 10.

7.3 Double click on Wireless - Group _ (the group just added) and

double click one zone at a time to define the Zone Name, Definition,

Type, Attributes, etc.

7.4 The next step is to enter the sensor's TXID and the other wireless

setup data. This may be done directly from each zone definition

screen (click the Wireless Setup button) OR from the separate

Wireless Setup menu accessed from the folders column.

7.5 Place a check mark in the Enabled box.

7.6 Set Supervision type to "1" (Normal Supervision) for the 6040

Sensor. A setting of "0" means the control will not expect a

supervisory check-in from the sensor. For additional details refer

to paragraph 6.8.

6.8 Set Supervision Type - Set this to "1" (Normal Supervision). Press

the ELK or the Select Wireless key to locate Sub-Menu: 2:Xmit

Transmitter Opt. Scroll to the desired wireless zone and press

Select (right arrow). Scroll to Option 2: Supervision Type and set

it to "1". The control will now expect a supervisory check-in report

every 64 minutes. If set to "0" the control will not expect a

supervisory check-in from the sensor. NOTE: A separate M1 option

sets the number of missed supervisory check-ins before a sensor

is declared missing.

6.9 PIR Auto Restore - DISREGARD

6.10 PROGRAM THE ZONE DEFINITION - This must be done from

Keypad Menu 5 - Zone Definitions.

7.7 PIR Auto Restore - DISREGARD

7.8 Skip to the TXID box and enter the Sensor TXID that is printed on

the small label attached to the sensor.

7.9 Skip to the LOOP box and enter a 2.

7.10 Click Save. Repeat the entire step 4 for each additional Wireless

Zone and Sensor.

7.11 PROGRAM THE ZONE DEFINITION

Page 4 ELK-6040 Glass Break Installation Manual

Page 5

8. TESTING

It is imperative that this sensor be tested during and after installation. In

addition, it should be tested in its installed location at least annually.

WARNING: The M1 Control should be placed into the Walk Test mode

prior to conducting any sensor tests. This will aid in the testing as well

as help prevent false alarms and unintentional central station reporting.

M1 Walk Test mode is activated via Keypad User Menu 3 - Walk Test

Area. As each sensor is tripped the keypad will chime and display the

zone number and name description.

There are two (2) methods for testing this sensor

8.1 Test Method #1 - Wake Up Test

A loud hand clap in the immediate vicinity of the detector is designed to

cause a wake up of the electronics and provide two (2) quick blinks of

the LED for confirmation. This quick test only verifies that the sensor is

receiving power and its microphone and circuitry are working. This test

does not trigger an alarm or cause any RF transmission to the Control and

it does not significantly affect the battery life.

8.2 Test Method #2 - Functional Test

This test requires a UTC 5709C (or equivalent) handheld glass break

tester. The sensor must be placed into a special glass break test mode

using the tester and the steps outlined below.

Note: This sensor is designed to detect the breaking of framed glass

mounted in an outside wall, separating the inside environment from the

outside. The sensor typically does not trip to glass being broken inside

the room or the premises. It should also be noted that breaking of unframed

glass, bottles, etc. typically does not trip the sensor and is definitely not

recommended for testing purposes. The sensor's Pattern Recognition

TechnologyTM is intentionally designed to ignore most false alarm sounds,

including that of glass break testers. In fact, the sensor must be placed

into a special test mode prior to using the glass break tester. This special

test mode disables the glass break pattern processing in the upper and

lower frequencies, restricting the sensor to listening only for the midrange frequencies that the 5709C hand-held tester reproduces. It is the

mid-range frequencies that determine the sensor range.

Activate the sensor's built-in Glass Break tester mode as follows:

A. Turn on the M1 Walk Test mode from the M1 Keypad. This is local only

and will not transmit signals to the monitoring station.

B. Set the 5709C tester to the tempered glass mode setting.

C. Hold the speaker on the handheld tester close to the sensor microphone

and press the test button labeled "Single."

This should cause the sensor to go into alarm and the LED to illuminate

for 2-3 secs. If not, press the test button again.

D. The M1 Walk Test mode should cause the Keypad to beep and display

the zone number/name belonging to this sensor.

G. Press the handheld tester button labeled "Single."

The expected and proper results are:

- The LED on the sensor should illuminate SOLID ON for 4 seconds.

- The M1 Keypad should beep and display the sensor zone number.

If these results do not occur:

- Check the battery strength in the handheld tester. A fresh new

battery in the handheld tester will often improve results.

- Move the sensor mounting location closer to the glass

OR

- Adding additional glass break sensors may be required in order to

to achieve adequate coverage

H. When satisfied with the test results press the " * " button on the M1

Keypad to exit the Walk Test mode. The sensor will automatically return

to normal mode approximately one (1) minute after it hears the last test

activation from the handheld tester. In normal mode the sensor LED

does not blink unless it hears a loud sound. In normal mode the sensor

will not trip to the tester, unless the tester is held very close to the

sensor. Each time the sensor alarms, it also goes into the test mode

for one (1) minute.

Note: Room acoustics can affect the sensor range and even artificially

extend it beyond the specified maximum range during on-site testing. The

maximum range of the sensor has been established for worst-case

conditions. While the sensor might occasionally function at additional

range, it could also miss a breakage event, particularly if the output volume

were minimum. The room acoustic might also change at some future time

and cause the range to be decreased back to its specified range. DO NOT

EXCEED the specified range of the sensor, regardless of what the onsite testing results may show.

E. The LED on the sensor will blink for the one (1) minute duration of the

glass break tester mode. The one (1) minute time will restart with each

activation of the glass break tester.

F. Hold the 5709C Tester near the surface of the glass that is within the

coverage range of the sensor. Aim the speaker at the sensor. Make

sure the tester is at the point on the glass farthest from the detector.

If closed drapes or curtains are present, hold the tester behind them.

NOTE: The 5709C tester has a settings for three (3) types of glass. Set

the tester for tempered or laminated glass unless you are certain that all

the glass to be protected is plate glass.

ELK-6040 Glass Break Installation Manual Page 5

Page 6

9. MAINTENANCE

This product is design for a long service life. While the Control generally

provides indications when it is time to service this product, several annual

and random checks or tests are recommended.

Annual - Perform a Glass Break Functional Test

Random - Visually check that the Alarm LED flashes when

activated by the Wake Up Test

Besides Alarm indications the Control also provides Missing Transmitter

and Transmitter Low Battery indications.

Missing

Transmitter - The supervisory check-in signal from the sensor has

not reached the Control within the assigned

supervisory check interval. This could mean that the

sensor has been removed from the premises, or its

battery has been removed, or that it is experiencing

some other type of fault condition. Technical service

and/or corrective action is required.

Transmitter

Low Battery - The Battery voltage has reached a low voltage

threshold and must be replaced soon in order to

maintain proper operation.

In General

To keep this product in good working order:

- Vacuum or dust the cover of the product once a month to remove

accumulated dust.

- NEVER use detergents or solvents to clean the product. Chemicals

can permanently damage or temporarily contaminate the sensor.

- Avoid spraying air fresheners, hair spray, paint, or other aerosols

near the product.

- NEVER paint the product. Paint will seal the sensor opening and

interfere with proper sensor operation.

10. TROUBLESHOOTING

11. DELETING THE SENSOR FROM THE CONTROL

Deleting a sensor from the Control removes it from being monitored by the

customer’s system. This is not the same as bypassing a sensor. You

should delete a sensor only if it is being permanently removed from the

premises.

To delete a sensor from the Control there are three (3) steps in the Control

programming sections that must be addressed:

11.1 In the Zone Definitions menu locate the zone to which the sensor

belongs and change the Zone definition to "0 - Unused"

11.2 In the Wireless programming menu locate the "Enable Transmitter"

option for the sensor and uncheck (clear) that option.

11.3 In the Wireless programming menu locate the TXID for the sensor

and clear it (make it all zeros).

NOTE: If this sensor's zone was faulted (in a violated state) before it was

deleted then the zone will likely still be faulted. Exiting from the keypad

programming mode generally causes a restart and should clear the fault.

If it does not, power cycling the control is another way to clear it.

LIMITATIONS

While the 6040 Wireless Glass Break sensor is a highly reliable intrusion detection

device, it does not offer guaranteed protection against burglary. Any intrusion

detection device is subject to compromise or failure to warn for a variety of reasons:

Glassbreak sensors cannot consistently detect glass breaking around corners or in

other rooms.

The radio transceiver only provides communications. It does not have anything to

do with detecting the breaking of glass.

The 6040 Wireless Glassbreak is not a Life Safety device.

LIMITED WARRANTY

The 6040 Wireless Glass Break Sensor is warranted to be free from defects and

workmanship for a period of 2 years from date of manufacture. Batteries used with

wireless devices are not warranted. Elk makes no warranty, express or implied,

including that of merchantability or fitness for any particular purpose with regard

to batteries used with wireless devices. Refer to Elk’s website for full warranty

statement and details.

Product does not power up properly or reports low battery

- Check the battery to make sure it is fully seated within the

battery compartment and that the polarity is correct.

- Check the battery voltage (3.0 VDC nominal).

Control Panel does not respond

- Check the control panel programming to verify that the

sensor is enrolled (TXID number) and the zone is defined.

- Check another wireless sensor to see if the control

responds to it.

- Verify that the control and transceiver are powered up and

operating properly.

Alarm/open condition does not restore

- Check the battery and/or battery voltage.

- Does the sensor Alarm LED react to a Walk Up Test? (see

test Method #1 from section 8.1)

If so, remove the sensor cover and perform a Functional

Test (see test method #2 from section 8.2) while observing

the RF Status (ACKnowledge) LED. This will require a UTC

5709C (or equivalent) handheld glass break tester. Each

time the test is performed the RF Status LED should blink

once for the alarm transmission/reply, and a second blink a

few seconds later. This second blink is the sensor restoral

transmission/reply.

- Check the control panel programming to verify that the

sensor is enrolled (TXID number) and the zone is defined.

BATTERY WARNING: Risk of fire, explosion and burns. Do not attempt to

recharge or disassemble. Do not incinerate or expose to heat above 212°

F (100° C). Dispose of used batteries properly. Keep away from children.

FCC AND IC COMPLIANCE STATEMENT:

This device complies with Part 15 of the FCC Rules and Industry Canada License-Exempt RSS

Standards. Operation is subject to the following two conditions: (1) This device may not cause harmful

interference, and (2) This device must accept any interference received, including interference that

may cause undesired operation.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes : (1) l’appareil ne doit

pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique

subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.

ELK-6040 Wireless Glass Break FCC ID: TMAELK-6040

NOTE: ELK PRODUCTS IS NOT RESPONSIBLE FOR ANY CHANGES OR MODIFICATIONS

NOT EXPRESSLY APPROVED BY THE PARTY RESPONSIBLE FOR COMPLIANCE. SUCH

MODIFICATIONS COULD VOID THE USER’S AUTHORITY TO OPERATE THE EQUIPMENT.

IC: 4353A-6040

PO Box 100 3266 US Hwy 70 West

Hildebran, NC 28637

828-397-4200 828-397-4415 Fax http://www.elkproducts.com

Printed in USA

L649 Rev. A 8/7/2014

Page 6 ELK-6040 Glass Break Installation Manual

Loading...

Loading...