Elk 6021 Users Manual

Wireless Mini Door and Window Sensor ELK-6021

Featuring Elk’s Industry Leading Two-Way Supervised Wireless Technology.Featuring Elk’s Industry Leading Two-Way Supervised Wireless Technology.

Featuring Elk’s Industry Leading Two-Way Supervised Wireless Technology.

Featuring Elk’s Industry Leading Two-Way Supervised Wireless Technology.Featuring Elk’s Industry Leading Two-Way Supervised Wireless Technology.

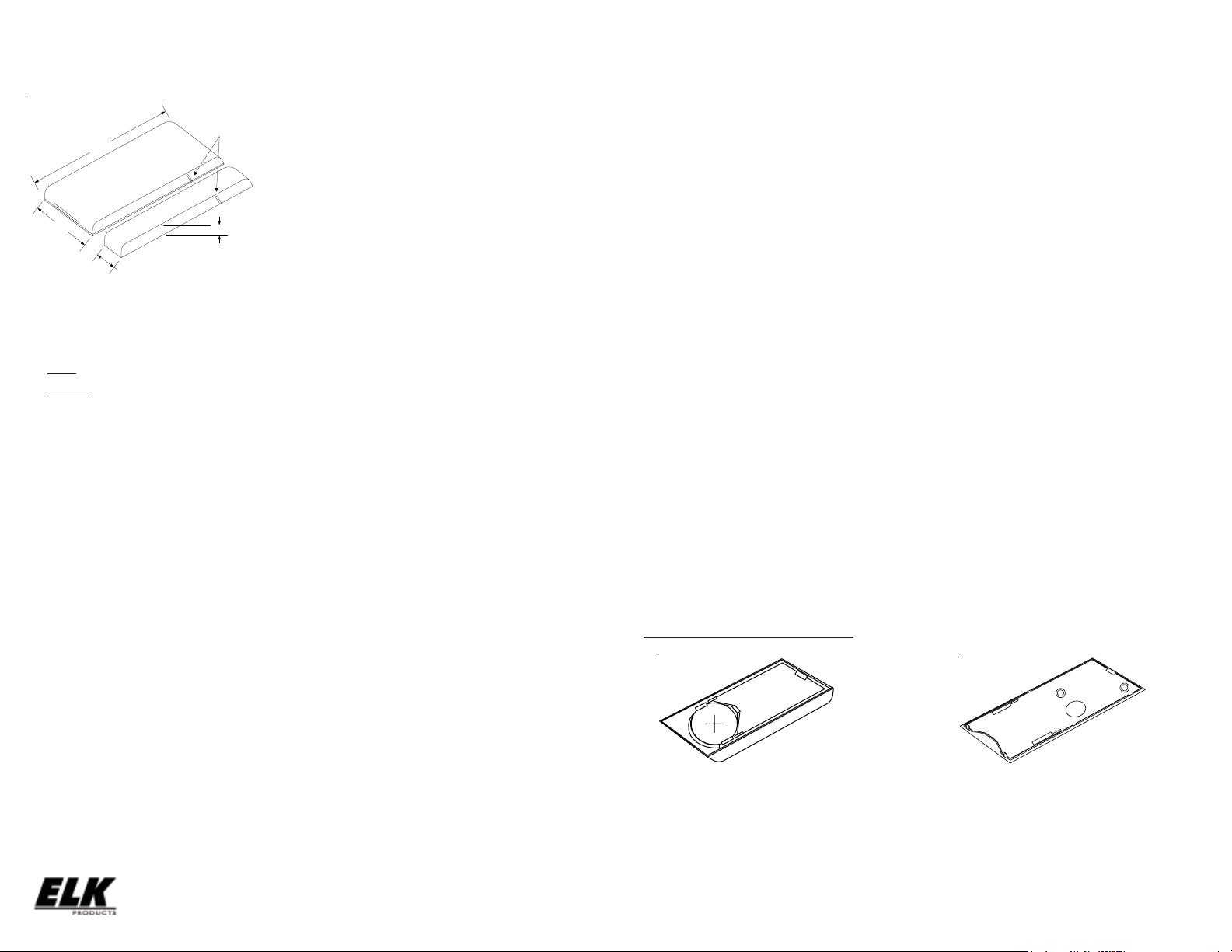

Magnet/

Switch

Alignment

2.37 "

1.11 "

.41 "

Mounting and Installation

Installation Tip: Temporarily mount sensor in its intended location prior to enrollment with the receiver/panel. This helps

ensure the location and mounting orientation are ideal for reliable performance. Mount the sensor permanently after

enrollment and testing. Perform a Walk Test of all sensors before leaving the job.

1. Insert the edge of a coin or flat blade screwdriver in slot and twist to remove front housing from backplate.

2. Do not install the Battery at this time.

3. Doors: Install the sensor backplate on the door frame (jamb) and the magnet on the door. Place the sensor as high up as

possible, but never lower than 12” from the floor. This is to help avoid foot traffic damage.

Windows: Install the sensor backplate on the widest surface (generally the top) of the lower sash and the magnet on the

inside edge of the upper sash where the two meet.

4. Avoid locations of high moisture or where ambient operating temperatures are outside the specifications.

5. The double faced adhesive pads (supplied) are adequate for temporary and many permanent attachments, particularly on

surfaces that cannot be drilled or tapped. However we do recommend the use of the #4 flathead sheet metal screws

(supplied) when possible for a more permanent installation.

7. Be certain that the alignment marks on the sensor and the magnet are aligned and facing each other, and that the gap

between the two does not exceed the maximum operating gap listed in the Specifications.

Like the sensor itself, the magnet accepts double faced adhesive pads. Should you prefer to use screws it will be necessary

to separate the front from the back and drill two 1/8” holes in backplate for screws. Mount the back using #4 flat sheet metal

screws and snap on the front.

IMPORTANT: Low profile wireless sensors generally do not perform well on metal doors, metal jambs, or other metal

surfaces due to the close proximity of sensor’s internal antenna to the metal. If it does become necessary to do so,

we recommend using non-metallic spacers approximately 1/4” thick (wood, plastic, etc.) or thick double faced tape

behind the sensor and the magnet. This will help by spacing the antenna away from the metal surface. Avoid

mounting wireless sensors in close proximity to large metal objects (refrigerators, toolboxes, ductwork, etc.)

Enrolling, Programming, and Testing with M1 Control

1. Enter Keypad Installer Level Programming and navigate to Menu 14 - Wireless Definitions

2. Press the right arrow and scroll or navigate to Option 3 - Learn Wireless Transmitter.

3. Press the right arrow and scroll or navigate to the first desired zone number.

4. Press the right arrow to activate the enroll mode.

The keypad will display Push Transmitter Button and the M1 will speak “Press Transmitter button for zone xx.

5. Immediately insert the transmitter battery. If battery is already installed, remove it and wait 5 seconds, then re-install. A

special enrollment command is sent to the receiver and the battery must be removed long enough for the circuit to recognize

a power on startup.

6. Upon successful enrollment the keypad will briefly display the ID of the new transmitter and M1 will speak “Zone xx

Enrollment.” [If not successful try removing the battery, waiting 5 seconds and re-install again.]

The Transmitter ID (TXID) is 6 hexadecimal digits. The 1st digit will be “A” for a Dr/Wnd sensor followed by 5 digits of

“0” to “F”. Examples: A12345, A9ABCF. This TXID is printed on the sensor and packaging.

The default Loop assignment is “0”, but may also be a 2.

7. The Rapid Enroll feature of M1 will advance to the next zone automatically. M1 will speak “Press Transmitter button for zone

xx (the next zone) and wait for you to install the battery in the next transmitter.

8. For each additional transmitter begin at step 4. When enrollment is completed press the ELK key twice.

9. Navigate to Menu 5 - Zone Definitions and program the Zone Definition for each wireless sensor.

10. Perform a Test of every sensor using the Keypad Walk Test (User Menu 3).

Marks

.24 "

The ELK-6021 Wireless Mini Door & Window Sensor is an

extremely small and low profile sensor. It’s unique design

makes it ideal for use where physical size and esthetics are

important. Applications include: double hung wood or vinyl

windows, entryways, sliding doors, etc. The 6021 is

compatible with Elk’s Two-Way Wireless Technology

Receivers, which currently includes the ELK-M1 model

M1XRFTW. Stand-alone “Slave receivers” with voltage/relay

outputs are also being designed.

Page 1 Page 2

6/13/2011

Using ElkRP Remote Program Software to add Wireless Sensors to M1

1. Install the battery in the Sensor. It doesn’t matter if the sensor is mounted or not-mounted.

2. On the ElkRP Account Details screen open the Wireless Setup.

3. Navigate to the Transmitters tab and double click the desired Zone number.

4. Place a check mark in the Enabled box. Select the desired Supervision type as either: 0=Not Supervised (Keychain Fobs),

1=Normal Supervision (Most Burglary Sensors), 2=Fire Supervision

5. Type in the TxID number of the wireless sensor (printed on the sensor and packaging) and click Save.

6. Program the Loop to be a “0” or “2” ONLY.

7. Navigate to Menu 5 - Zone Definitions and program the Zone Definition for each wireless sensor.

8. Perform a Test of every sensor using the Keypad Walk Test (User Menu 3).

Operation and Testing

Elk’s Two-Way Supervised Wireless Technology ensures faster and more reliable communications as well as improved battery

life. Elk operates in the 900 Mhz band and communicates over multiple frequencies. This is referred to as Spread Spectrum or

Frequency Hopping. The result is more secure communications with much less chance of interference or disruption. In most

cases a sensor only has to transmit a single burst at mid to low power to get a positive acknowledgement from the receiver. If

necessary the sensor can automatically increase its power output should a signal fail to get through.

Confirmation and Setup LED

Following initial installation of the Battery a two color Status LED will become functional for a period of 10 minutes. This LED is

located behind the front cover opposite from the magnet alignment marks. It functions as a setup and diagnostic aid.

Green blink = Sensor has obtained a positive acknowledgement from the Receiver after having transmitted a signal/event.

Red blink = Sensor has made 4 attempts to reach the Receiver but for some reason has not yet gotten an acknowledgement.

SPECIFICATIONS:

Low Profile Dimensions: .25” x 1.125” x 2.375”

Operating Gap (Transmitter to Magnet): .250 nominal

Battery: CR2032 coin cell, 3 volt. Service life of up to 5 years dependent on transmission power level and usage.

Frequency: 902 Mhz - 928 Mhz (frequency hopping over 50 channels)

Supervisor Check-in Intervals: Factory set at ~61 seconds

Transmission Duration (on-time): 50 milliseconds to transmit its data and receive an acknowledgement.

Anti-Jamming: Frequency hopping and short transmission time makes Elk’s sensor difficult to detect or jam.

BATTERY INSTALLATION AND REPLACEMENT

The engraved or printed side of the battery is the positive terminal. It must be installed into the ELK-6021 with the engraved

printing visible. To remove battery carefully wedge the end of a small screwdriver or end of a paperclip under the back edge.

Be carefull not to bend or catch the metal contact leafs or the spring wire that protrudes out from under the battery.

Warning: Do not reverse the battery direction.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

ELK-6021 Mini Door & Window Transmitter FCC ID: TMA ELK-6021

NOTE: ELK PRODUCTS IS NOT RESPONSIBLE FOR ANY CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED

BY THE PARTY RESPONSIBLE FOR COMPLIANCE. SUCH MODIFICATIONS COULD VOID THE USER’S AUTHORITY TO

OPERATE THE EQUIPMENT.

Note: It may be difficult to view this LED under bright sunny conditions.

Each additional Red blink signifies an additional attempt (max. of 12) by the sensor to contact the receiver. Upon a

successful acknowledgement the LED will immediately blink Green. However, if there is no acknowledgement after a

total of 16 attempts the sensor will timeout and go back to an idle mode. During each scheduled supervisory check-in

the sensor will update or report the current state of it’s input to the receiver.

* The Status LED may be re-activated for service or diagnostic purposes by doing the following:

A) Remove and re-insert the battery - This restarts the 10 minute LED status time period.

B) Place the M1 Control into walk test mode (User Menu 3). LED is active throughout the Walk Test time and

enrollment mode, or for 10 minutes after enrollment has ended.

Sensor (inside view) with battery shown

FCC COMPLIANCE STATEMENT:

Sensor Backplate

Loading...

Loading...