Page 1

ELK-319WS Wireless Window and Shock Sensor

Description

The ELK-319WS is a Supervised, Wireless Window Sensor designed

to detect the opening of a window or vibrations made by an intruder

attempting to break the window. A built-in reed switch monitors

windoe movement and a piezo shock sensor monitors vibrations.

The sensitivity and range of the piezo shock is adjustable.

When the sensor activates it transmits a signal to the control

panel. Additional transmitted signals include: restoral, supervisory,

tamper and low battery (as needed). Sensor is powered by two (2)

replaceable 3-V lithium coin-cell batteries. It is compatible with Elk’s

319MHz Receivers/Panels as well as many other panels that operate

on the 319.5MHz Frequency and adhere to the ITI/Interlogix protocol.

Specications

RF frequency: 319.5 MHz

Compatibility: ELK-319 Panel/Receivers & others that operate on

Freq. 319.5MHz and use the ITI/Interlogix protocol

Battery type: Two (2) 3V lithium coin-cell

(Panasonic or Varta Model CR2032)

OperatingTemp Range: 32 to 120°F (0 to 49°C)

Storage Temp Range: -30 to 140°F (-34 to 60°C)

Relative Humidity: 95% non-condensing

Dimensions 2.25” L x .1.0 x 0.50” in. (L x W x D)

Programming (Enrollment)

The following is a general guideline for programming (enrolling) this

sensor into the receiver or panel. For more detailed steps please

refer to the receiver or panel instructions.

NOTE: THIS SENSOR ENROLLS DIFFERENTLY FROM OTHERS

The reed and piezo shock are two (2) dierent sensors and require

their own TXID identier and zone in the alarm panel.

The TXID printed on the sensor label is for the piezo shock sensor.

The TXID for the reed sensor will be the shock TXID plus 1.

Example: If shock TXID is 0A62CC7 the reed TXID will be A062CC8

1. Power up the sensor by pulling and removing both battery isolator

tabs. DO NOT REMOVE the sensor cover. It will be done in 4.

2. Place the panel into the Program mode and proceed to the

WIRELESS SETUP menu.

3. Select the appropriate zone/sensor location number for the piezo

shock sensor.

4. Start the panel sensor Enroll process. When the panel prompts

to trip the sensor for learning do the following:

- Remove sensor cover to activate the tamper. The panel should

acknowledge the shock has been learned by keypad display and/

or audio alert (depending on panel). If enrollment fails try putting

the cover back on and repeating steps 3 and 4.

5. Advance to next zone/sensor location to enroll the reed switch.

6. Remove both batteries from the sensor.

7. Start the panel Enroll process. When the panel prompts to trip

the sensor for learning do the following:

- Hold the tamper plunger down with one nger while inserting one

of the batteries. The panel should acknowledge the magnetic

reed switch has been learned by keypad display and/or audio

alert (depending on panel). If enrollment does not succeed

remove both batteries and repeating steps 5 thru 7.

NOTE: Loop assignment must be set for “ 2 “ on both sensor zones.

8. Proceed to the zone programming and assign the zone denition

for each enrolled sensor.

9. Exit programming mode when nished.

TM

Interlogix is a registered trademark belonging to United Technologies.

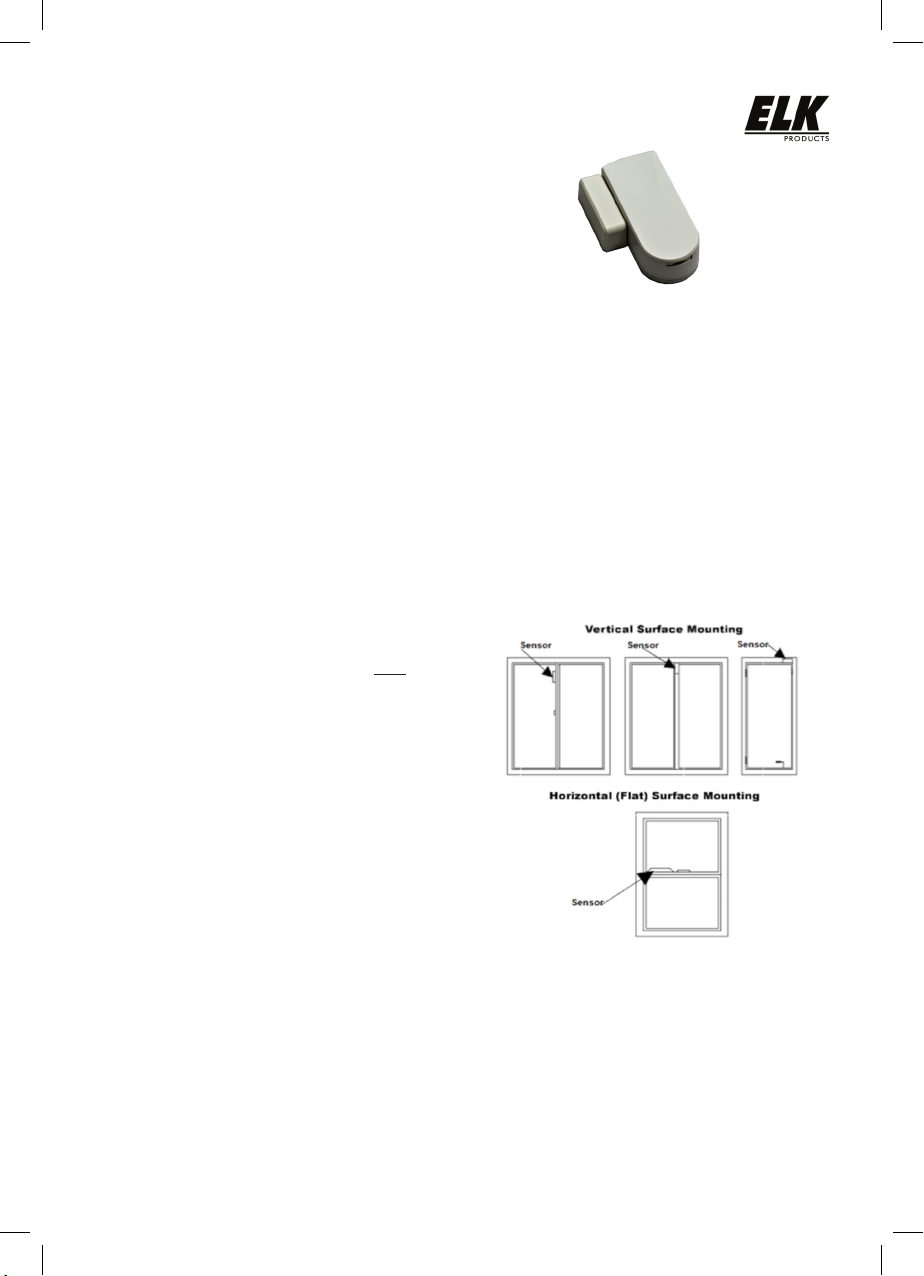

Installation Guidelines

• Sensor should be mounted window frame and magnet on the

moveable part of the window. Sensor is recommend for wood

or vinyl windows only.

• Attaching sensor to a metal surface can negatively aect the

transmit range and magnet gap performance. Some metallic

surfaces may be acceptable if range and gap testing are good.

• Always attach the sensor temporarily at the desired location and

successfully range test with the panel/receiver prior to drilling any

holes or mounting permanently.

• Install the sensor within 100 ft. of the receiver or panel.

• Align magnet directly opposite the top LEFT edge of the sensor

with a gap of 5/16” (8 mm) or less for wood surfaces and 1/4” (6

mm) or less for non-wood surfaces.

Note: Gap between sensor and magnet must never exceed 3/8”.

• After mounting is completed, retest the sensor using the test

procedures which follow.

Mounting the Sensor

Sensor may be mounted using screws or double sided foam tape.

Screws

Separate the sensor and magnet from their mounting bases and

place the bases in the desired location. Secure using the supplied

screws. Re-attach the sensor and magnet onto their bases making

sure the alignment marks on the sensor and magnet are facing

one another.

Double-Sided Tape

It is not necessary to separate the sensor and magnet from their

bases when using double sided tape. Make certain the window

mounting surfaces & surfaces of the sensor and magnet are clean,

smooth and dry.

Page 2

Apply one piece of double sided tape to the bottom of the sensor and

one to the bottom of the magnet. Remove the protective lm and

stick the sensor and magnet in the desired location making sure the

alignment marks on the sensor and magnet are facing one another.

Note: When applying double sided tape apply even pressure across

the entire area to ensure the tape and surface bond.

Testing the Sensor

It is recommend that all wireless sensors be thoroughly walk tested

after installation and programming.

1. Place the panel into the Walk Test mode.

2. Monitor the keypad display as each sensor is tripped. Refer to

the receiver or panel for complete instructions. In some cases

there may be a signal strength indication.

3. Exit Walk Test mode when nished.

Shock LED Functionality

Shock Test mode is entered automatically upon batteries insertion.

The shock LED is only functional during test mode. The LED

activates on shock activation and goes out upon shock restoral.

Test mode remains on until cover is replaced or tamper is pressed.

In order to restart the shock test both batteries must be removed

and re-installed.

Note: Shock LED also serves as a Low battery indicator and will

ash until batteries have been replaced. Device also transmits low

battery signal to the control panel.

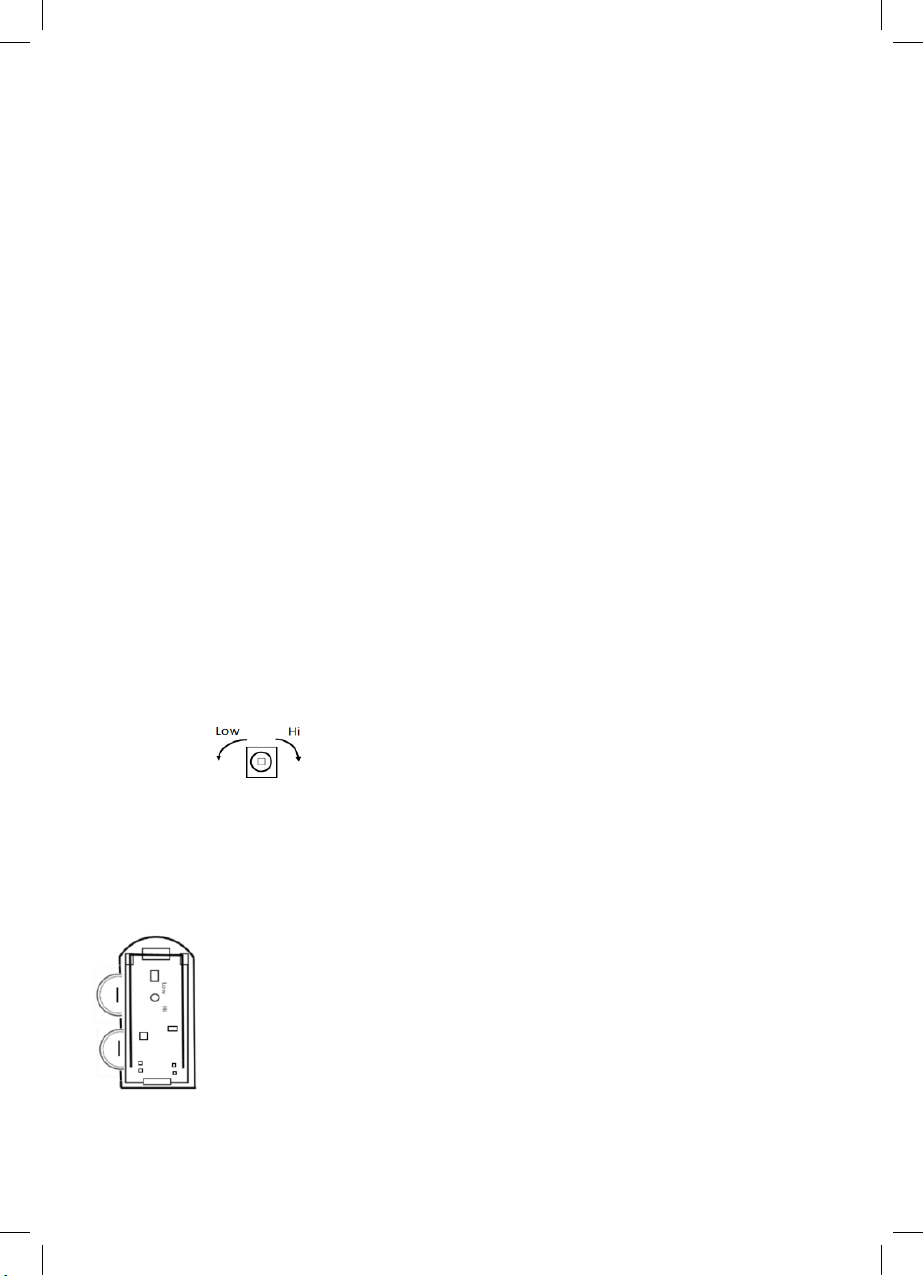

Shock sensor sensitivity setting

An LED test mode (see above) is included to aide in setting sensitivity

to desired level.

1. With sensor solidly mounted in the intended location tap mounting

surface with desired level of activation impact.

2. Adjust potentiometer until correct sensitivity is obtained

The potentiometer adjusts shock sensitivity from minimum Low

(CCW) to maximum Hi (CW). These setting are marked on the

PCB. In maximum sensitivity mode, the least amount of shock is

required to activate a shock alarm.

If potentiometer is set all the way Low (CCW) the shock portion of

the device is turned o and only the internal reed switch is active.

Battery Replacement

Low Battery trouble will be transmitted when the sensor battery

needs to be replaced.

NOTE: Replace both (2) batteries within 7 days following a low

battery trouble indication.

• Remove the cover from the sensor.

• Carefully slide out the old batteries.

• Insert the two (2) new batteries into

the battery holder slots.

• Observe Polarity shown on the lithium

coin-cell battery.

• Replace the cover on the sensor test

activate the device at least ve times

CAUTION: Use only approved 3.0V Lithium Coin-cell battery:

Panasonic or Varta model CR2032

BATTERY WARNING:

Risk of re, explosion and burns. Do not attempt to recharge

or disassemble. Do not incinerate or expose to heat above

212° F (100° C). Dispose of used batteries properly. Keep

away from children.

FCC AND IC COMPLIANCE STATEMENT:

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation.

This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment o and on,

the user is encouraged to try to correct the interference by one or more

of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This device complies with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) this

device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation

of the device.

Cet appareil est conforme avec Industrie Canada exempts de licence

standard RSS (s). Son fonctionnement est soumis aux deux conditions

suivantes: (1) cet appareil ne doit pas provoquer d’interférences et (2) cet

appareil doit accepter toute interférence, y compris celles pouvant causer

un mauvais fonctionnement de l’appareil.

In accordance with FCC requirements of human exposure to radio

frequency elds, the radiating element shall be installed such that a

minimum separation distance of 20 cm is maintained from the general

population.

FCC ID: 2ABBZ-RF-SHK-319 IC: 11817A-RFSHK319

This device complies with Part 15 of the FCC Rules. Operation is subject

to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation. Changes

or modications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This Class B digital apparatus complies with Canadian ICES-3B.

Cet appareil numérique de la classe B est conforme à la norme NMB-

003 du Canada.

Limited Warranty

THIS WIRELESS SENSOR IS WARRANTED TO BE FREE FROM

DEFECTS AND WORKMANSHIP FOR A PERIOD OF 2 YEARS FROM

DATE OF MANUFACTURE EXCLUDING BATTERIES. BATTERIES

USED WITH WIRELESS DEVICES ARE NOT WARRANTED.

MANUFACTURER HEREBY DISCLAIMS ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, WHETHER EXPRESS,

IMPLIED, STATUTORY OR OTHERWISE INCLUDING (BUT NOT LIMITED

TO) ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE WITH RESPECT TO THESE PRODUCTS AND

ANY RELATED SOFTWARE. MANUFACTURER FURTHER DISCLAIMS

ANY OTHER IMPLIED WARRANTY UNDER THE UNIFORM COMPUTER

INFORMATION TRANSACTIONS ACT OR SIMILAR LAW AS ENACTED

BY ANY STATE. (USA only) SOME STATES DO NOT ALLOW THE

EXCLUSION OF IMPLIED WARRANTIES, SO THE ABOVE EXCLUSION

MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER LEGAL RIGHTS

THAT VARY FROM STATE TO STATE. MANUFACTURER MAKES NO

REPRESENTATION, WARRANTY, COVENANT OR PROMISE THAT

ITS ALARM PRODUCTS AND/OR RELATED SOFTWARE (I) WILL NOT

BE HACKED, COMPROMISED AND/OR CIRCUMVENTED; (II) WILL

PREVENT, OR PROVIDE ADEQUATE WARNING OR PROTECTION

FROM, BREAK-INS, BURGLARY, ROBBERY, FIRE; OR (III) WILL WORK

PROPERLY IN ALL ENVIRONMENTS & APPLICATIONS.

NOTE: Elk Products is not responsible for any changes or

modications not expressly approved by the party responsible

for compliance. Such modications could void the user’s

authority to operate the equipment.

Elk Products, Inc.- 3266 Hwy 70 - Connelly Springs, NC 28612 http://www.elkproducts.com

11/22/2018

Loading...

Loading...