Page 1

TelevisIn & TelevisOut

Data acquisition and alarm signalling modules.

Parametric controller to capture plant variables in real time and signal alarm conditions when connectd to a supervisor system, both

dedicated (Televis) or standard market ones (MODBUS protocol).

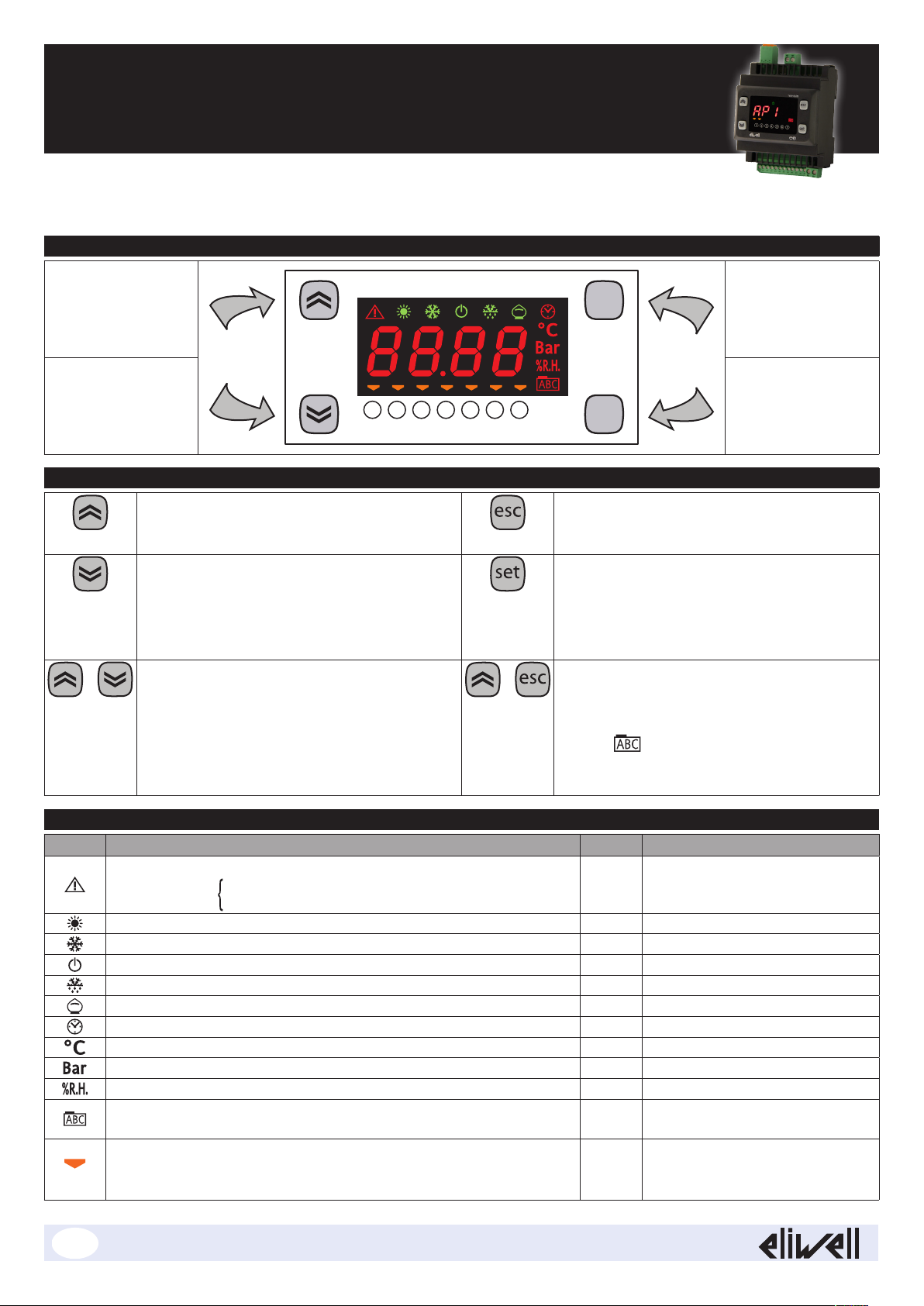

USER INTERFACE

DOWN

+

UP

1

UP

• Increase values

• Go to next label

DOWN

• Decrease values

• Go to previous label

ON/OFF

Pressing and holding these keys at the same time

for 5seconds or a remote command activates the

ON/OFF function.

In OFF mode, the screen shows the word OFF.

All alarms are disabled, including active and

communication ones.

Probe data capture remains active.

3

2

4 5 6 7

KEYS

+

esc

ESC

SET

set

ESC

• Exit without saving new settings

• Go back to previous level

SET (ENTER)

• Confirm value / exit and save new settings.

• Go to next level (access to folder, sub-folder,

parameter, value)

• Open State Menu

LOCK

Pressing and holding both keys together for

5seconds or a Supervisor command locks /

unlocks the keypad.

The icon

nothing will happen when a key is pressed, not

even the setpoint will be displayed.

blinks when the keypad is locked;

(ENTER)

LED

Icon Description Colour Note

Permanently on: alarm active and output set for this alarm

(1) ... (7)

Flashing:

alarm active and output not set for this alarm

Blinks when serial communication is on green

NOT USED green

ON when the device is powered on but not when it is OFF

NOT USED green

NOT USED green

NOT USED red

Temperature unit of measurement red

Pressure unit of measurement red

Units of measure for relative humidity red

Permanently on: during navigation

Flashing: keypad locked

Manages utilities connected to the device.

TelevisIn: indicates if Digital Inputs are active (ON)

TelevisOut: indicates if Digital Outputs are active (ON)

alarm silenced and output set for this alarm

red silenced from remote and/or DI

green

red

Amber

EN

Page 2

MECHANICAL INSTALLATION

The instrument is intended for DIN

SIDE VIEW

rail mounting.

For GUIDA DIN installation, follow

the steps described below:

• Move the two spring docking

devices to their standby position

(use a screwdriver to press against

the relative compartments)

• Then mount the controller on the

DIN RAIL, pressing on the spring

docking devices which will go to

the closing position.

REAR VIEW 3D VIEW

TECHNICAL SPECIFICATIONS (EN 60730-2-9)

Classification: electronic automatic control (not safety) device for incorporation

Mounting: Omega DIN rail.

Type of action: 1.C - 1.Y

Pollution class: 2

PTI of materials used for insulation: PTI 250V (device made with class IIIa material)

Overvoltage category: II

Nominal pulse voltage: 2500V

Temperature: Use: –20 … +55°C • Storage: -40 … +85°C

Power supply: SMPS 100-240 Va ±10% 50/60 Hz

Power consumption: 5W max

Fire resistance category: D

Software class: A

RTC battery life: In absence of external power, the clock battery will last 4 days.

FURTHER INFORMATION

TelevisIn Characteristics

Measurement range: NTC: –50.0...+110°C; PTC: –50.0...+150°C; PT1000: –50.0...+400°C (on display with 3 digits + sign)

Accuracy: NTC, PTC: ±0.5% e.o.s. + 1 digit

PT1000: ±1°C (-30°C ... 30°C) e ±1% e.o.s. (-50°C ... 400°C)

0-1V: ±2% e.o.s.

0-5V, 0-10V, 0...20mA, 4...20mA: ±1% e.o.s.

Impedance: 0-1V: 110kΩ; 0-5V: 110kΩ; 0-10V: 21kΩ; 0...20mA: 100Ω; 4...20mA: 100Ω

Resolution: NTC, PTC, PT1000: 0.1°C; 0-1V, 0-5V, 0-10V, 0...20mA, 4...20mA: 0,1

Analogue Inputs: PB1, PB2, PB5: NTC, PTC, PT1000 inputs or configurable DIs

PB3, PB4:

Digital Inputs: DI1, DI2: Multifunctional digital inputs

Digital Outputs: OUT1: SPST relay 2A max 250Va

DI, NTC, 0-1V, 0-5V, 0-10V, 0...20mA or 4...20mA configurable inputs

TelevisOut Characteristics

Digital Outputs: OUT1, OUT2, OUT3: SPST relay 2A max 250Va

OUT4: SPDT relay 2A max 250Va

OC outputs/Digital Inputs: OUT5/DI1: OC Analogue Output or voltage-free Digital Input

OUT6/DI2: OC Analogue Output or voltage-free Digital Input

The two analogue outputs are low voltage (SELV) Open Collector (OC) ones: PWM with

- Precision: 2%;

- Nominal range: 0…16.9Vc(12V~ rectified); closure 12Vc;

- Maximum current: 35mA (min load of 340Ohm @12Vc)

NOTA: ** Outputs OUT5 and OUT6 (typically connected to the device's auxiliary 12Vcoutput) cannot

deliver more than 70mA in total. Any other loads connected to the same 12Vc auxiliary output

must also be taken into account.

Mechanical Characteristics

Container: PC+ABS resin casing, UL94 V-0

Dimensions: 4 DIN-rail

Terminals: removable screw terminals with 2.5mm

2

cross-section.

Connectors: TTL for MFK / Device Manager connection (via DMI)

RS485 to connect to TelevisSystem/Modbus supervisor.

Humidity: Usage / Storage: 10...90% RH (non-condensing)

Regulations

Electromagnetic compatibility: The device complies with Directive 2004/108/EC

Safety: The device complies with Directive 2006/95/EC

Food Safety: The device complies with standard EN13485 as follows:

- suitable for storage

- application: air

- climate range: A

- measurement class 1 in the range from -25°C to 15°C (*)

(*with Eliwell probes only)

NOTE: The technical specifications stated in this document regarding the measurement (range, accuracy, resolution, etc.)

referstrictly to the instrument and not to any accessories provided, such as the probes.

This means, for example, that the error introduced by the probe must be added to the error of the instrument.

Page 3

SUPERVISION

Applications can

The connection to supervisor systems is via the RS-485 port and can use Televis or Modbus protocols.

The protocol to be used must be configured to ensure the proper function of TelevisIn and/or TelevisOut. The parameters to be set

are in the “Add” folder, under the “Installer” parameters (see section entitled “Password”), as listed below.

N.B.: 1) All communication parameters in the “Add” folder are not in the vectors.

2) A double terminal clip is provided as an RS485 connection accessory RS485

to connect two RS-485 in parallel.

COMMUNICATION PARAMETERS (Add)

PAR. Description UM Range Value

PtS Select protocol (t = Televis; d = ModBus). flag t/d t

dEA Device address: indicates the device address to the management protocol. num 0 ... 14 0

FAA Family address: indicates the device family to the management protocol. num 0 ... 14 0

Adr Modbus protocol controller address num 1 ... 250 1

Pty Sets Modbus parity bit (n = none; E = even; o = uneven). num n/E/o n

StP Sets Modbus stop bit: (1b = 1 BIT; 2b = 2 BIT). flag 1b/2b 1b

LOADING DEFAULT APPLICATIONS

The procedure for loading one of the default applications is:

• At power-on of the device, keep the

• Scroll through the various applications (“AP1”... “AP8”) using the

• Select the application you want using the

by pressing the

• If the operation is successful, the display will show “y”, if not it will show “n”.

• After a few seconds the instrument will return to the main display.

key or by timeout.

key pressed: the label “AP1” will appear.

and keys.

key (“AP3” in the example) or cancel the operation

RESET PROCEDURE

TelevisIn & TelevisOut can be RESET and the default factory settings restored in a simple and user-friendly way.

This is done by simply reloading one of the basic applications (see “Loading default applications”).

You may need to RESET the instrument in circumstances in which the normal operation of the instrument is compromised or if you

decide to restore the instrument to its default configuration (e.g. Application “AP1” values).

IMPORTANT! This operation resets the instrument to its initial state, returning all the parameters to their default values.

This means that all changes made to operating parameters will be lost.

TelevisIn (Connections and Default applications)

No. Label Description

–

+

}

TelevisIn

100-240V

}

Function Label Parameters AP1 AP2 AP3 AP4 AP5...AP8 Note

Input DI1 H11

Input DI2 H12

Input Pb1 / DI3 H41, H13** PTC

Input Pb2 / DI4 H42, H14** PTC

Input Pb3 / DI5 H43, H15** 4...20mA 4...20mA

Input Pb4 / DI6 H44, H16** 4...20mA

Input Pb5 / DI7 H45, H17** PTC

Output OUT1 H21

}

a

1-2-3 RS-485 Serial RS-485 (1 = “-”; 2 = “+” and 3 = “GND”)

6 C Common

7 OUT1

DI1 Digital Input 1

DI2 Digital Input 2

GND Ground

12V

PB1/DI3 Analogue input 1 configurable as: DI, NTC, PTC and PT1000

PB2/DI4 Analogue input 2 configurable as: DI, NTC, PTC and PT1000

PB3/DI5 Analogue input 3 configurable as: DI, NTC, V*** and I***

PB4/DI6 Analogue input 4 configurable as: DI, NTC, V*** and I***

PB5/DI7 Analogue input 5 configurable as: DI, NTC, PTC and PT1000

GND Ground

23-24 Power supply

NOTES

* Connect the terminal to one of the GND terminals.

** Analogue Inputs PB1...PB5 can also be configured

as DIs (H4x="DI")

*** The V and I configurable inputs (PB3 e PB4) are:

• V = 0-1V; 0-5V and 0-10V

• I = 0...20mA and 4...20mA

NO relay output OUT1 - high voltage (2A - 230V

c Auxiliary power supply 12Vc

Power supply 100-240V

DI

-

NTC

be configured

a

by users

a)

• Use sensor SEMITEC 103 AT with

NTC analogue inputs (10KOhm /

25°C).

• Digital inputs DI1/DI2 are low voltage digital inputs and the closing

current for ground is0.5mA.

Page 4

TelevisOut (Connections and Default applications)

Input/Output

DI1 / OUT5

H11

Input/Output

DI2 / OUT6

H12

Output

OUT1

H21

NO-LINK

Output

OUT2

H22

Output

OUT3

H23

Output

OUT4

H24

–

}

}

9

8

+

TelevisOut

100-240V

a

10 11

12

No. Label Description

1-2-3 RS-485 Serial RS-485 (1 = "-"; 2 = "+" and 3 = "GND")

6 C Common

7 OUT1

8 OUT2

9 OUT3

10 OUT4

11 OUT4

12 OUT4

OUT5/DI1

OUT6/DI2

GND Ground

12V

23-24 Power supply

NO relay output OUT1 - high voltage (2A - 230V

NO relay output OUT2 - high voltage (2A - 230V

NO relay output OUT2 - high voltage (2A - 230V

NC relay output OUT4 - high voltage (2A - 230V

Common relay output OUT4 - high voltage (2A - 230V

NO relay output OUT4 - high voltage (2A - 230V

Low voltage digital input 1, also configurable as Analogue Output

OUT5 - low voltage (SELV) OC: PWM

Low voltage digital input 2, also configurable as Analogue Output

OUT6 - low voltage (SELV) OC: PWM

c Auxiliary power supply 12Vc

Power supply 100-240V

NOTES

* Connect the terminal to one of the GND terminals.

** SELV: SAFETY EXTRA LOW VOLTAGE

Function Label Parameters AP1 AP2...AP8 Note

•

Digital inputs DI1/DI2 are low voltage digital inputs

Applications

can be configured

by users

and the closing current for ground is 0.5mA.

a)

a)

a)

a)

a)

a)

a

PASSWORDS

Password PA1: allows access to the “User” parameters. By default the password is disabled (PS1=0).

Password PA2: allows access to “Installer” parameters. By default the password is enabled (PS2=0).

(For more details, see the User Manual which can be downloaded from the Eliwell website).

The visibility of “PA2” is:

1) PA1 and PA2≠0: Press and hold

the “User” parameters (PA1) or the “Installer” parameters (PA2).

2) Otherwise: Password PA2 is at the end of the level1 parameters. If enabled, it will be required when accessing the “Installer”

parameters.

NOTE: If the value entered is incorrect, label PA1/PA2 will be shown again and the procedure must be repeated.

for longer than 5seconds to display PA1 and PA2. You can then decide whether to access

MACHINE STATE MENU

Press the once to open this menu.

Use the

The visibility of folders depends on the configuration:

• AL: alarms (always present, if there are no active alarms, the display readsd “----”)

• Pb: Pbx values (for configured inputs only) and dEP (dewpoint)

• di: DI state (configured inputs only)

• do: DO state (configured outputs only)

Pb, di and do are only visible if there is at least one configured input/output.

and keys to browse the menu. Press to access the parameters or values it contains.

PROGRAMMING MENU

To access the “Programming” menu hold down the key for more than 5 seconds. If enabled, the instrument will request an

access PASSWORD, either PA1 for “User” parameters or PA2 for “Installer” parameters (see “PASSWORD” section).

“User” parameters:

“Installer” parameters:

NOTE: It is strongly recommended that you switch the device off and on again each time parameter configuration is changed,

inorder to prevent the configuration and/or ongoing timings from malfunctioning.

When accessed the display will show the first parameter (e.g. “diF”). Press and to scroll through all

parameters in the current level. Select the desired parameter by pressing . Press and to change it

and

When accessed the display will show the first folder (e.g. “diF”).

(For the list of “Installer” parameters, see the User Manual which can be downloaded from the Eliwell website).

to save changes.

Page 5

COPY CARD / UNICARD

When connected to the serial port (TTL), the Copy Card/Unicard allows instrument parameters to be programmed rapidly.

EnterPA2 to access “Installer” parameters, scroll through the folders using

Press

• Upload (UL):

to select it, scroll through the parameters using and then press (e.g. UL) to select the function.

select UL and press . This function uploads the programming parameters from the instrument to the card.

and until folder FPr is displayed.

If the operation is successful, the display will show “y”, otherwise it will show “n”.

• Format (Fr): This command is used to format the copy card (which is necessary when using the card for the first time).

Important: the Fr parameter deletes all data present. This operation cannot be reversed.

• Download (dL):

NOTE: After the download, the instrument will use the newly uploaded map settings.

Important! Make sure the machine is switched off before working on the electrical connections.

The instrument is equipped with screw connectors to connect power cables with a maximum cross-section of 2.5mm

terminal). Make sure that the power supply is of the correct voltage for the device.

Temperature probes (NTC, PTC, PT1000) have no connection polarity and can be extended using a normal bipolar cable (note that

the extension of the probes influences the instrument's EMC electromagnetic compatibility: take great care with the wiring).

Ratiometric or pressure probes (4...20mA), have a connection polarity.

Probe cables, power supply cables and the RS485 serial cable should be routed separately from power cables.

This document is the exclusive property of ELIWELL CONTROLS SRL and may not be reproduced or circulated without the express

permission of ELIWELL CONTROLS. While all possible care has been taken to ensure the accuracy of this document, ELIWELL

CONTROLS SRL cannot accept liability for any damage resulting from its use. The same applies to any person or company involved

in preparing and editing this document. ELIWELL CONTROLS SRL reserves the right to make aesthetic or functional changes at any

time without notice.

ELIWELL CONTROLS SRL declines all liability for damage due to:

- installation/use other than expressly specified and, in particular, in conflict with the safety prescriptions set down in regulations

and/or specified in this document;

- use on panels that do not provide adequate protection against electric shocks, water or dust in the adopted mounting conditions;

- use on panels allowing access to dangerous parts without having to use tools;

- tampering with and/or modification of the product;

- installation/use on panels that do not comply with statutory laws and regulations.

Permitted use

For safety reasons, the device must be installed and used according to the instructions provided. In particular, parts carrying dangerous voltages must not be accessible in normal conditions. The device must be adequately protected from water and dust with

regard to the application, and must only be accessible using tools (with the exception of the front panel). The device is suitable for

use in household refrigeration appliances and/or similar equipment and has been tested for safety aspects in accordance with the

harmonized European reference standards.

Improper use

Any use other than that expressly permitted is prohibited. The relays provided are of a functional type and can be subject to failure:

any protection devices required by product standards, or suggested by common sense for obvious safety requirements, must be

installed externally to the controller.

Connect the Copy Card when the instrument is switched off. At power-on, data will automatically start

downloading from the USB key to the instrument. At the end of the lamp test, the display will show “dLy”

ifthe operation was successful and “dLn” if not.

ELECTRICAL CONNECTIONS

2

(one wire per

DISCLAIMER

LIABILITY AND RESIDUAL RISKS

CONDITIONS OF USE

Eliwell Controls s.r.l.

Via dell’Industria, 15 • Z.I. Paludi

32010 Pieve d’Alpago (BL) - ITALY

Telephone: +39 0437 986 111

Fax: +39 0437 989 066

www.eliwell.com

Technical Customer Support:

Technical helpline: +39 0437 986 300

E-mail: techsuppeliwell@invensys.com

Sales:

Telephone: +39 0437 986 100 (Italy)

+39 0437 986 200 (other countries)

E-mail: saleseliwell@invensys.com

code 9IS54225-1 - TelevisIn&Out - rel.05/12 - EN -

© Eliwell Controls s.r.l. 2012 - All rights reserved.

Loading...

Loading...