Page 1

RGF 300

Three-phase voltage regulator

Page 2

WARNING !

HIGH LEAKAGE CURRENT: first connect to earth !

The rgf300 is a voltage regulator for three phase motors which operates

connected to the three phase mains voltage. The regulator must be installed by

qualified personnel who will connect the electric supply, attach the cables in

their permanent positions and commission the plant.

Incorrect installation of the rgf300 voltage regulator or the fan connected to it

may cause damage to objects or people so ensure the instructions in this manual

and all required security measures are read and followed carefully.

When receiving the goods, check that the packing is intact; in the event of any damage

•

due to transportation, notify the forwarding agent according to legal requirements.

The rgf series of products shown in this manual has been manufactured to the highest

•

standards.

The manufacturer declines all responsibility for accident, loss or damage caused by the

•

use of these appliances. These must be correctly installed by qualified personnel in

conformity with their destined use and, whenever needed, must undergo correct

maintenance which should be carried out while ensuring the safety of people, domestic

animals and goods.

The purchaser must previously ascertain the suitability of the product for the use it is

•

intended for and assume all consequent risks and responsibility.

The rgf300 is a mains voltage regulator which uses the phase-cut principle completely

•

controlled over the three phases. It has been designed to vary the effective voltage on

three phase asynchronous motors for fans following a control signal (either mA, VDC or

Ohm). The appliance is manufactured for industrial use and therefore meets the EMC

standards that relate to industrial environments.

Using the appliance for purposes other than the ones described above will be considered

•

incorrect. In particular, the appliance may NOT be used to supply machine tools or any

other machines where the motor torque-speed characteristic is not quadratic.

If the equipment is intended for civil, commercial and/or light industrial use,

•

supplementary components and other types of equipment are required which can be

supplied on specific request from the purchaser. In this case, the purchaser must

provide a suitable design of the plant in which the applia nce is to be installed ( compliant

with EN 60555 - 2/3 standards regarding disturbance produced by electrical household

appliances and the like.

We decline all responsibility for any errors in the catalogues, publications or other

•

written documents. The information in this manual is not binding and we reserve the

right to make changes to the products without prior notice, at any time and in an y way

that we deem convenient for production purposes or useful for increasing functionality

and performance.

RGF 300

2/53

Page 3

SAFETY RULES !

This appliance has been designed to give excellent performance provided it is installed and used carefully in

a suitable electric environment by qualified personnel.

The following rules

Follow the instructions in this manual exactly and observe all safety measures in force.

•

Do NOT tamper with or disassemble the regulator's internal components; doing so will

•

INVALIDATE THE GUARANTEE and may cause unnecessary damage.

The regulator does not contain components that can be repaired by the user.

•

•

The regulator must be suitably and effectively earthed by the installer according to the standards in force;

earthing is essential for the EMC filt er to oper ate cor re ctly .

•

The user must be protected from the electric supply and the motor must be protected from possible

overloads in compliance with the standards in force.

DO NOT

•

DO NOT

•

circumstances.

•

Before supplying power to the unit, check carefully that the power and earth are correctly connected.

•

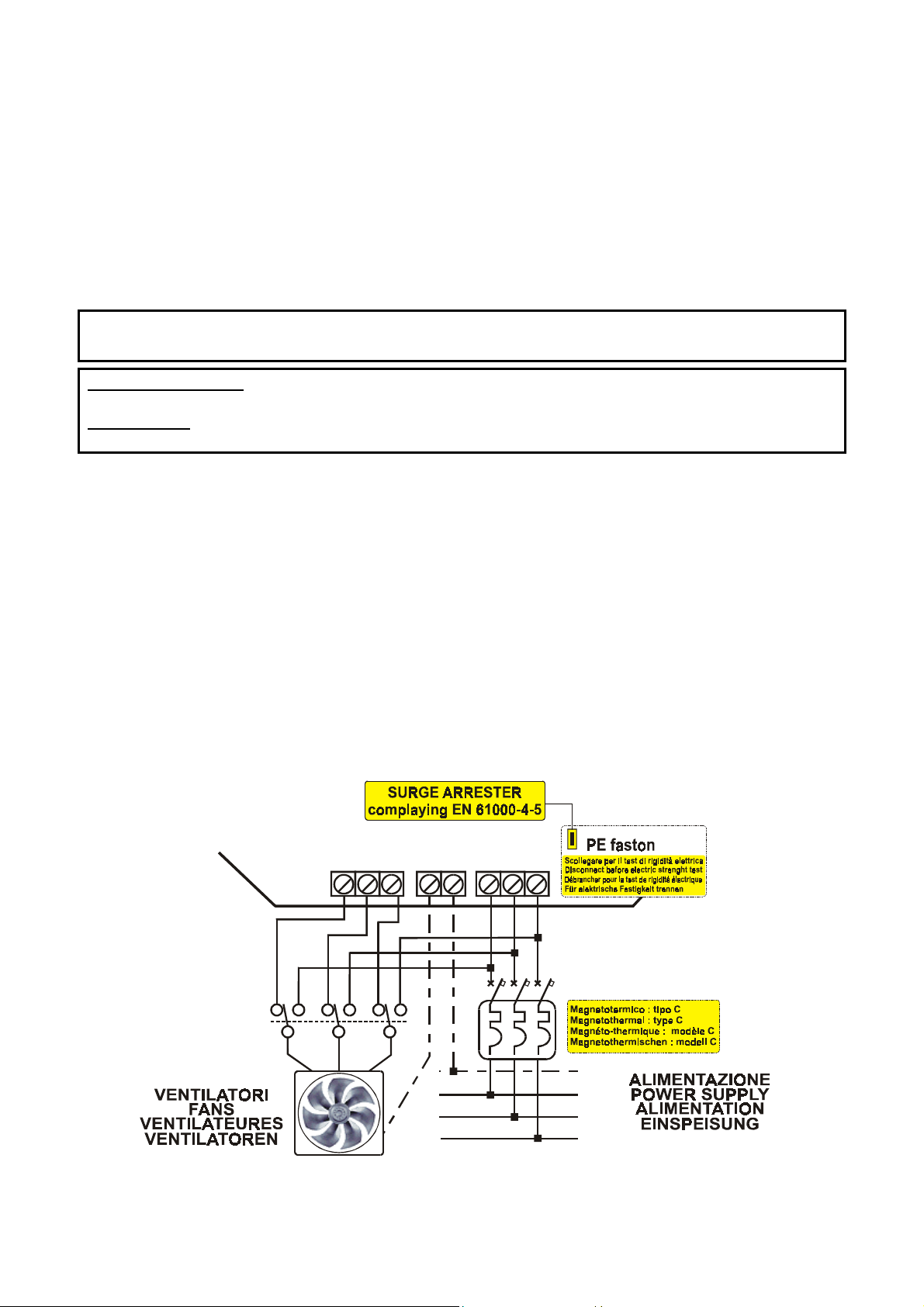

If the mains supply is "disturbed", which may be due to other electrical power components causing

irregularities in the supply (power contactors), it is recommended that supplementary three phase

SURGE ARRESTER

‘

•

Avoid repeatedly connecting and disconnecting the power supply to the regulator; a constant supply

keeps the regulator at working temperature and eliminates problems caused by condensate inside the

protection case.

•

Alternatively, use the remote terminal board contact 'MB' S2 = ON/OFF.

•

The S2 = ON/OFF contact on the MB terminal board does not cut the mains supply and therefore cannot

be used as a safety switch.

•

Install the regulator out of direct sunlight so that the container cannot get overheated and cause a

reduction in the maximum load current.

•

The appliance may operate at environmental temperatures up to 50°C. Do not install it where this

temperature may be exceeded or the integrity of the regulator will be compromised and the appliance

may make the user appliance operate at full load (100%) with all consequent effects.

•

The appliance must be stood vertically to encourage heat dissipation and to ensure there is a sufficient air

circulation and free space measuring

be grouped together on a single electric board, provide forced air circulation with a fan or cooling unit of

sufficient power.

•

Use the holes on the lower and power terminal board sides of the appliance, for entrance of the

connection cables. This will prevent water, dust etc. from getting in and will ensure the

level is maintained using adequately sized cables and sheaths of suitable quality.

Reassemble and check the cover of the external protection panel is properly closed.

•

DO NOT alter or damage the identification stickers on the equipment.

•

DO NOT force the trimmers to rotate beyond their set mechanical travel.

•

Only alter the trimmers intended for regulation.

•

Under no circumstances alter the trimmers marked with the spot of red paint.

•

must be obeyed

supply the regulator without the internal protection panel made from lexan.

touch the electrical parts of the circuit when the power supply is connected under any

’

filters are installed direc tly on the regulat or supp ly.

when installing the regulator :

150 mm

above and below the regulator. If several regulators are to

IP55

protection

WARNING !

HIGH LEAKAGE CURRENT: first connect to earth !

RGF 300

3/53

Page 4

1.0 P

RESENTATION

1.1 D

1.2 I

1.3 P

1.4 E

1.5

2.0 E

LECTRICAL CONNECTIONS

2.1 E

2.2 E

2.3 E

3.0 C

OMMISSIONING PROCEDURE

3.1 J

3.2 M

3.3 M

3.4 S

3.5 S

3.6 M

3.7 O

4.0 C

ONTROL TRIMMER

4.1 M

4.2 M

4.3 C

4.4 P

4.5 S

4.6 S

4.7 M

5.0 HELP

6.0

RGF

300

7.0

8.0 L

9.0 D

TROUBLESHOOTING

IABILITY AND RESIDUAL RISKS

ISCLAIMER

CONTENTS

……………………………………………………..….……………………………

ESCRIPTION

NSTALLATION AND MACHANICAL DIMENSIONS

RINCIPLE OF OP ERATION

1.3.1 O

1.3.2 A

LECTRIC MOTORS

1.4.1 M

RGF

300

LECTRICAL CONNECTIONS, POWER CARD

LECTRICAL CONNECTIONS, ANALOGUE INPUT SIGNALS

2.2.1 C

2.2.2 C

2.2.3 C

2.2.4 R

2.2.5 C

LECTRICAL CONNECTIONS

2.3.1 O

UMPERS

ASTER, VERSION

ASTER, VERSION

LAVE, VERSION

LAVE, VERSION

ASTER, VERSION X OR

PTIONAL MODULE FOR DOUBLE SET-POINT CONFIGURATION

AX

. O

IN

. O

UT-OFF REGULATION

ROPORTIONAL BAND REGULATION

4.4.1 V

4.4.2 V

ET-POINT RE GULATION (MODELS

4.5.1 D

OFT-START REGULATION

ANUAL REGULATION (HEAT-PUMP

I

ORTABLE DISPLAY UNIT

– P

EASY REFERENCE COMMISSIONING GUIDE

……………………………….……………………………………………………………

………………………………………………………………………………..

……………………………………………..

……………………………………………………………………

PERATING MODE

PPLICATION

…………………………………………………………………

……………………………………………………………………….

…………………………………………………………………………..

AGNETOTHERMAL PROTECTION

TECHNICAL DATA

….……………………………………………………………….

……..……………………………………………

…………………………………………………………………………

……..…………………………………………….

……...……………………………..

ONNECTION OF

ONNECTION OF

ONNECTION OF OTHER SENSORS AND CONTROL SIGNALS

EMOTE CONNECTION FOE A CURRENT (M

ONNECTION OF THE RGF

PERATING SELECTION

PRESSURE TRANSDUCERS

XSK

TEMPERATURE SENSORS

NTC

……………………………………

…………………………………….

………………………….

OR VOLTAGE (VDC) CONTROL SIGNAL

A)

MULTIDRIVER

FF INPUTS / OUTPUT

, ON-O

INPUTS / OUTPUT

………………………

………………………………………

………………………………………………………………

…………….…………………………………………………………

……………………………………………………………………………………..

M (4-20mA),

V (0-10VDC),

M (0-20mA),

V (0-10VDC),

Y (NTC °C),

FOR 1 OR 2 CONTROL

FOR 1 OR 2 CONTROL

FOR 1 OR 2 CONTROL

FOR 1 OR 2 CONTROL

FOR 1 OR 2 CONTROL

INPUTS ……………………………

INPUTS ……………………………

INPUTS ………………..………..….

INPUTS ……………………………..

INPUTS …………….………..

(SP1-SP2) …………….…...

…………………………………………………………………………………

UTPUT REGULATION

UTPUT R

………………………………..… T

………………….. T

………………..……..…. T

……..……... T

ERSIONS WITH

ERSIONS WITH

MASTER

SLAVE

REGULATOR OPERATION

REGULATOR OPERATION

M, V, X, Y) … T

ECADIC SET-POINT OPTION (MOD

………………...……. T

) ..………... T

. M, V, X, Y) P3 ………………………………..

RIMMER

RIMMER

RIMMER

RIMMER

RIMMER

RIMMER

RIMMER

P4 …………………………….

P5 ……………………………

P6 ……………………………

P2 ……………………………

………………………………

……………………………….

P3 …………………………..

P1 ….……………………….

P7 …………………………..

…………………………………………………………………

………………………………………………..

. . . ………………………………….…………………………………………....

……………………………….………………………………………

.

RGF 300

4/53

Page 5

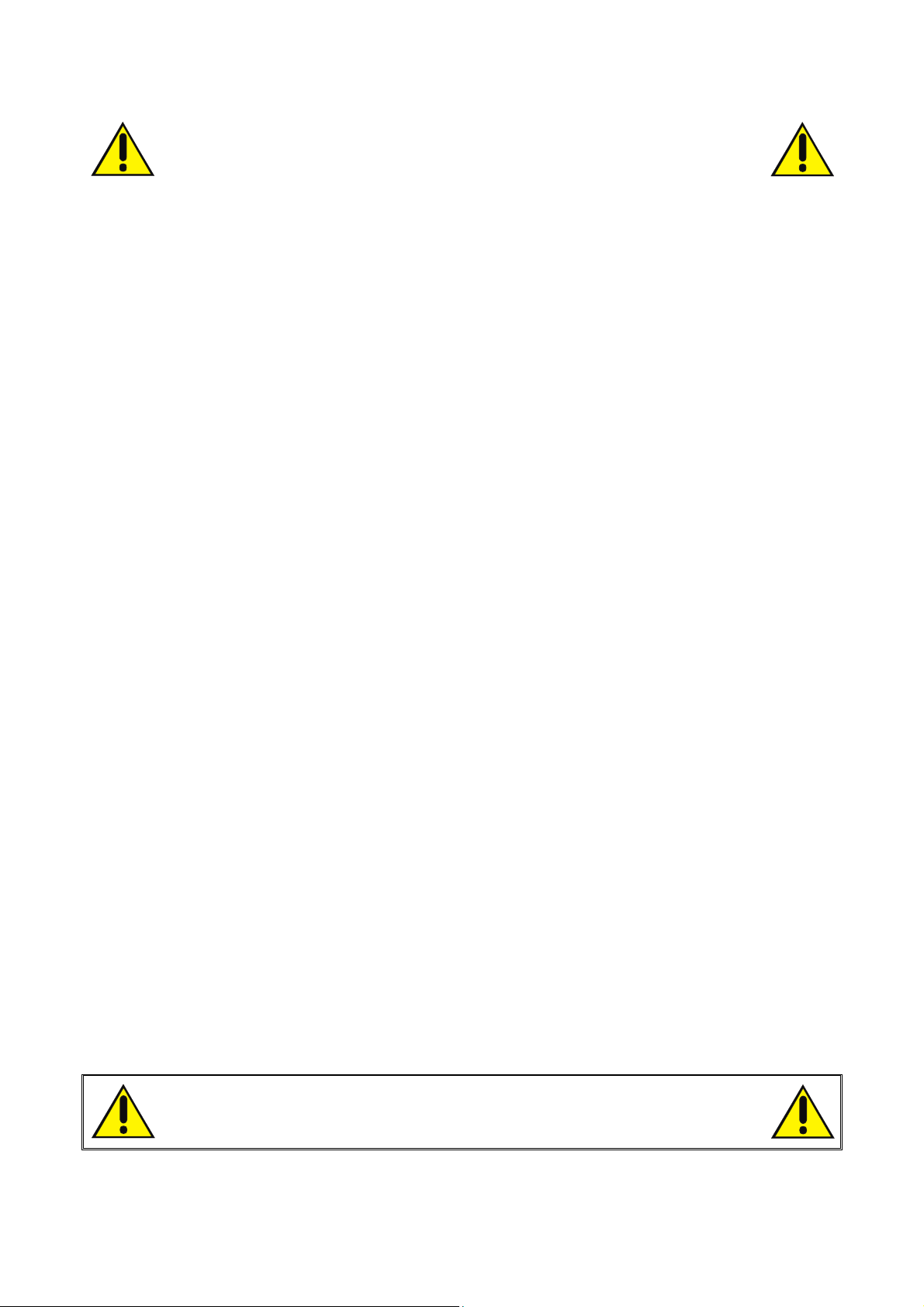

1.0 P

HANK YOU

T

RESENTATION

for choosing an

rgf300

series three phase voltage regulator, designed specifically to give the

maximum yield and greatest ease of use.

Like all our products, it has been built to the very highest quality standards using electronic components of

the utmost reliability which have undergone functional tests that guarantee use of the product for at least

30,000 hours

rgf300

The

of continuous operation without problem.

regulator is a power unit designed to meet requirements of quality and flexibility of use in plants

and machines in which proportional variation of the speed of rotation of the fans is essential.

The regulator is housed in a

during ordinary use (

120°C

GEWISS GW Plast

), increased mechanical impact resistance (

120°C

case (

fig. 1

) which guarantees high heat resistance

IK = 08

) and a protection level (

IP55

that allows the regulator to be installed out of doors.

Inside the case there is a lexan protection panel displaying instructions for use and commissioning of the

rgf300

The

.

12A rgf300

Vdc

mA

NTC

is shown in

fig. 1.

fig. 1

Before installing the device, you are invited to read this manual which describes the necessary

procedures for correct installation and commissioning of the machine.

)

rgf300

RGF 300

5/53

Page 6

Like all our products, the

subsequent modification

Since all these products are not used as "

machines, the standards' compatibility test was carried out under typical operating conditions.

The essential requirements of the directive are satisfied by conformity to "

industry.

rgf300

EEC/92/31

series bears CE marking as required by directive

on electromagnetic compatibility.

stand alone

" appliances but incorporated into other plants or

generic standards

3

89/336/ECC

IP 55

120°C

STOCK & WORK

- 20

°C

+85

°C

UR%

and its

" for heavy

- 20

+50

EN 50081-2

EN 55011

EN 55011

ENV 50140 (IEC 801-3)

ENV 50141

IEC 801-4

IEC 801-2

The tests and checks for conformity have been carried out according to the procedures described in the

product's technical documentation. The system used was formed by an

cable and relative controls, a power supply cable, a motor cable and a fan.

Responsibility for the f inal characteri stics of the syste m or plant rega rd ing th e EMC directiv e

rests with the installer. The equipment must be install ed in observance of the regulation s in

force using the information presented in this manual.

emission standard,

EN 50082-2

class B, for radiated disturbances

class A, for conducted disturbances

for susceptibility (on the power supply)

for conducted susceptibility on power lines

for fast transistors (bursts / high frequency disturbances)

for electrostatic discharge (

immunity standard, and in particular:

ESD

)

rgf300

fig. 2

voltage r egulator , a contr ol

RGF 300

6/53

Page 7

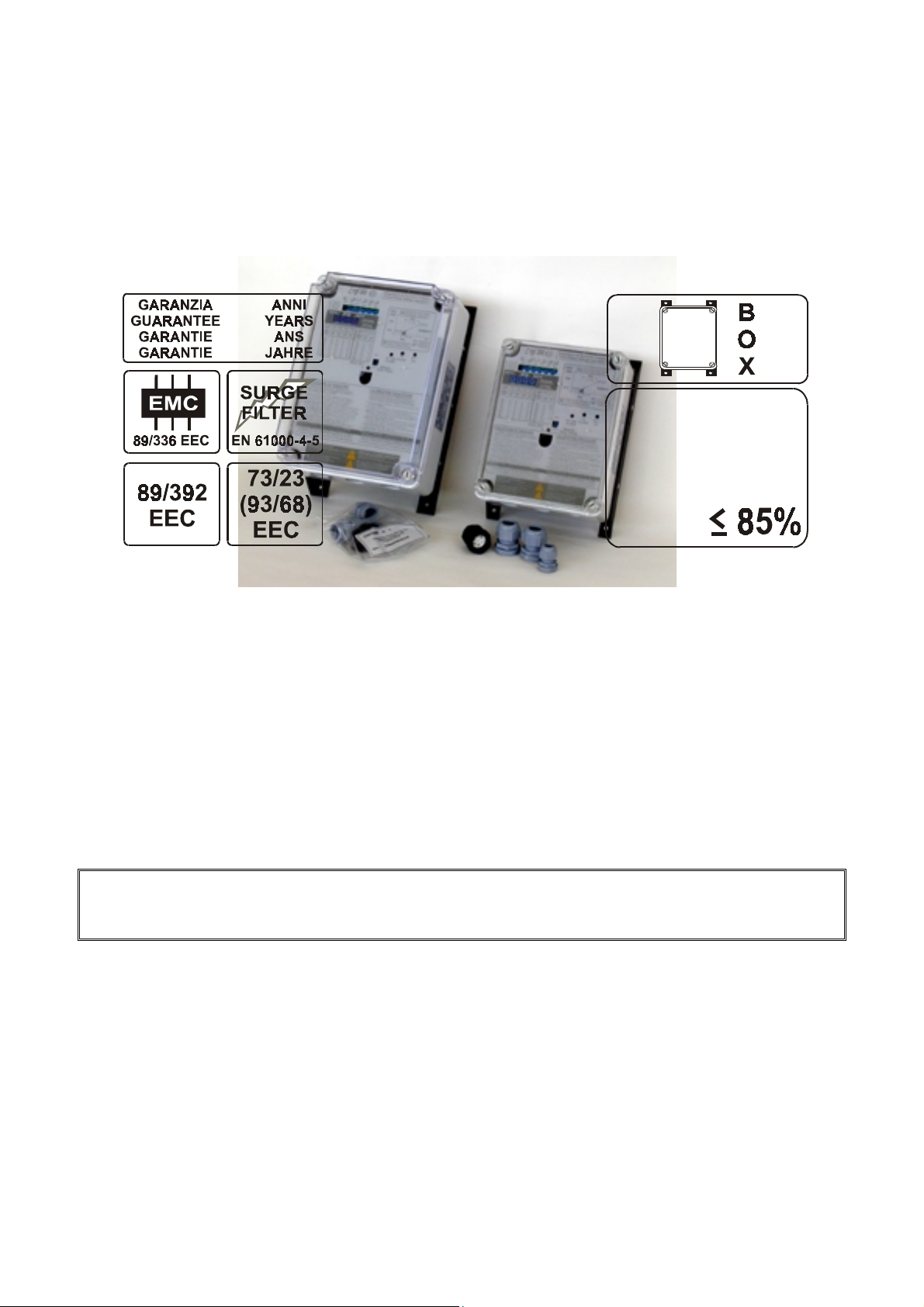

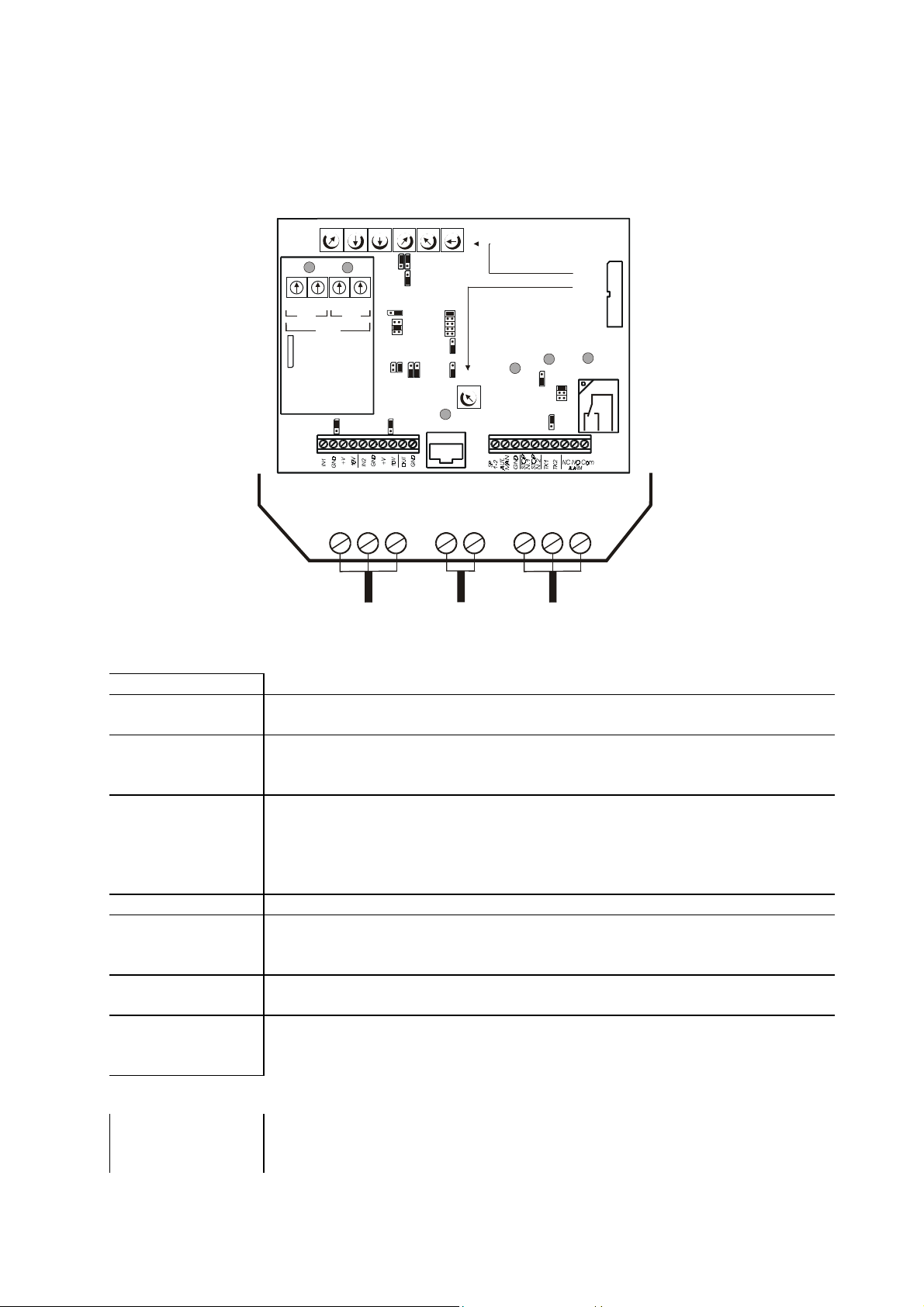

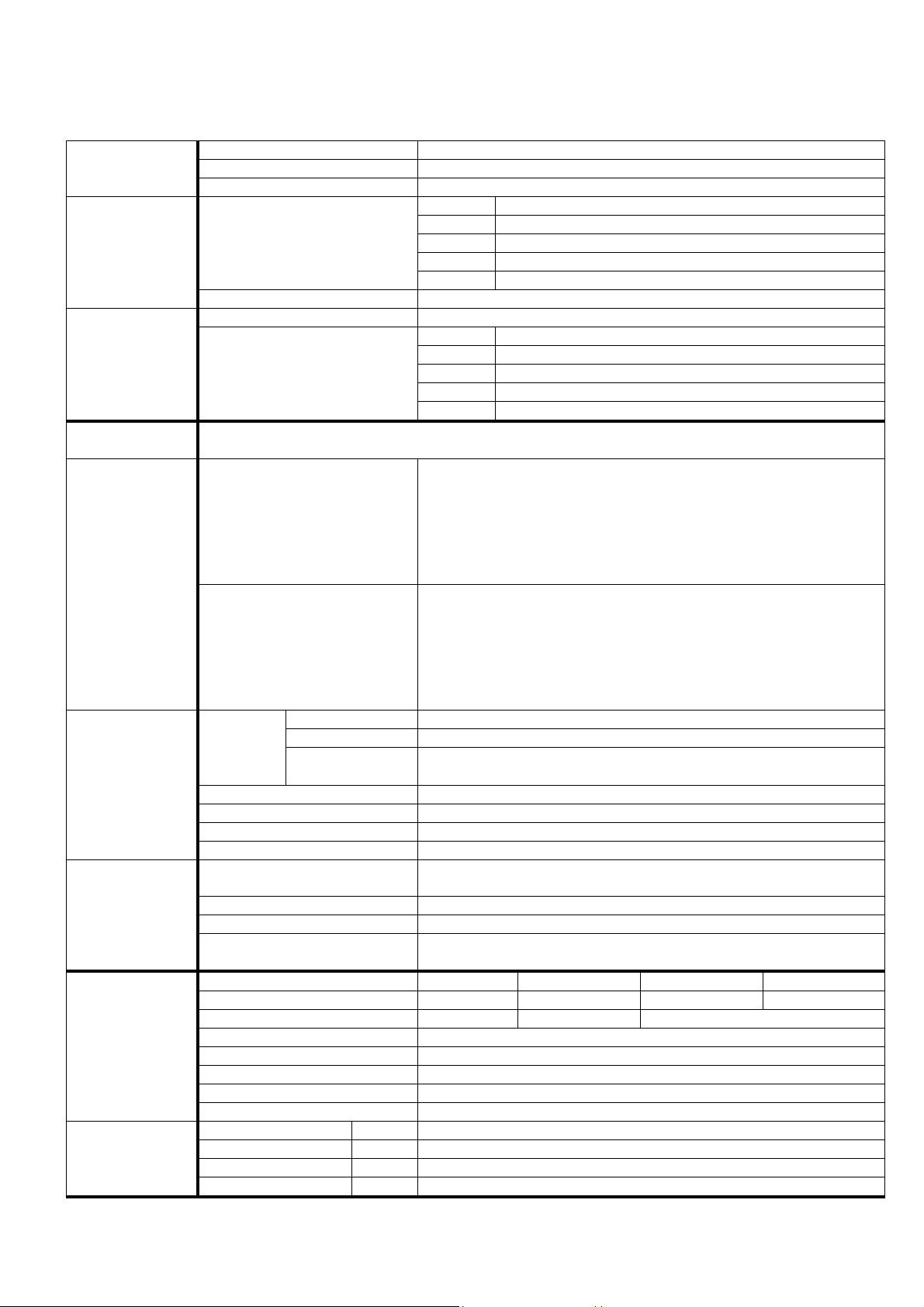

Fig. 3

represent the

22

1

2

3

4

5

6

7

rgf300

regulator with the general contents

21

20

19

8

9

10

fig. 3

18

17

16

15

14

13

12

11

CONTENTS of rgf300 regulator

Control Trimmer for work parameters regulation

1.

Reference table for Set-point rotary centesimal switch

3.

Terminal block for analog inputs/output signals

5.

Power card (lower)

7.

Terminal block for PE connection

9.

SURGE ARRESTER circuit / PE faston connection

11.

I

CN2 connector for HELP

13.

Control Trimmer for Manual mode (heat-pump) regulation

15.

Characteristic with function parameters

17.

Macrolon cover of the case

19.

Black anodized heat sink

21.

display unit

Double 10 positions rotary switch for Set-point (optional)

2.

Lexan internal panel for protection against direct contact

4.

Control card (upper)

6.

Terminal block for load connection (U-V-W)

8.

Terminal block for threephase power supply (R-S-T)

10.

SURGE ARRESTER

12.

Terminal block ON-OFF auxilary inputs/output sig nals

14.

Status LED

16.

Cover screws

18.

20.

GEWISS GW Plast 120°C case

Screws hole for wall installation

22.

circuit like EN 61000-4-5

RGF 300

7/53

Page 8

1.1 DESCRIPTION

rgf300

The

mounted inside the

The two cards represent the

series three-phase cutting regulators comprises two electronic cards on a vetronite support

GEWISS IP55 GW Plast

control

SP1

0

9

1

2

8

3

7

4

6

5

SW1 SW2 SW3 SW4

SP1

CN3

RGFPB10640

(OPTIONAL)

MA

control card

The

•

trimmers

!"

centesimal switch

•

relay

•

Leds

AC LINE ALARM

T.K. ALARM

RL1 ON

MANUAL

•

jumpers

•

flat cable

CN2

•

•

Inputs/output

signals terminal

boards

power card

The

•

power supply

terminal boards

contains the following regulation, connection and signalling components:

Marked "Pn"; used to set working parameters

Marked “SW”; used for the

on the transducer skale (only with

Marked "

Relay with commutation contact for external signalling of correct operation or

stop (see selection jumper

Marked "

RED Led DL1

RED Led DL2

GREEN Led DL3

YELLOW Led DL4

Marked

Marked

The flat allows connection to the control and power cards.

Check the flat is securely fixed during maintenance or commissioning.

Rapid connector to the portable

parameters

Terminal board MA

Terminal board MB

contains the following connection components:

'M1'

for three-phase input supply

'M2'

for three-phase output

‘M3’

120°C

section (upper) and

case.

power

section (lower).

P1

Mm MmMm

0

9

9

1

2

8

8

3

7

7

4

6

6

5

P3

J16

0

5

1

4

SP2

1

2

P2

2

3

7

P4

SP2

0

9

8

6

5

P3

1

J1

2

1

2

3

4

1 2

1

2

3

J8 J10

J9

1

J17

2

P6

P5

P1

1

2

3

4

5

1

2

1

2

P7

Mm

= soft-start

P2 Proportional Band

=

P3 Set-Point

=

P4

= max. output

P5

= min. output

P6

= cut-off

P7

= Set- H.P. mode

ALARM

ALARM

T.K .

AC LINE

1

J13

2

J15

MmMm

Mm

1

J2

2

1

J3

2

J4

J6

J5

J5

J7

1

J12

2

J11

MANUAL

CN 2

M2 M3 M1

fig. 4

simply

RL1"

J14

Dln"

to signal "regulator stop/fault"

to signal "external heat protection (

to signal commutation relay

to signal

'Jn'

; used to change preset operational modes

'FL'

for connection of the control analogue input signals

for connection of the ON-OFF inputs and outputs

U, V, W

for the

Earth / PE

connection

Set-Point parameter, with

PB 1064

).

HEAT PUMP

“

R,S,T

I

HELP

FL

RL1

ON

RL1

J14

1

2

3

1

2

MB

option)

T.K

)."

RL1

”

mode

10

unit for display of the

in the

N.O.

100

working po int s

position

rgf300

's wor k

RGF 300

8/53

Page 9

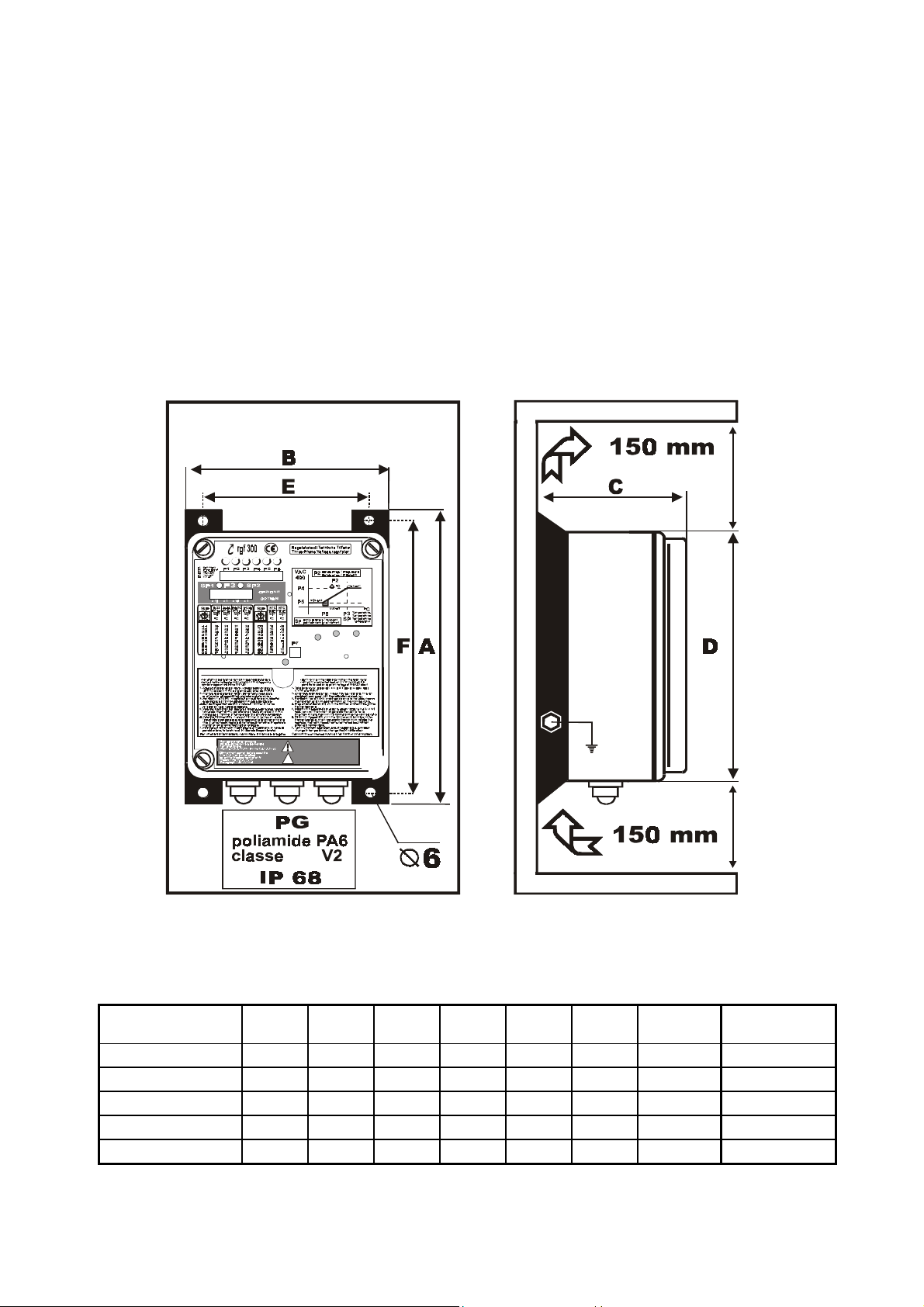

1.2 INSTALLATION AND MECHANICAL DIMENSIONS

rgf300

The

the side fins before connecting to the power supply.

The holes provided on the lower part of the regulator are for entry of the electric connection cables:

•

four pole line (

•

four pole line (

•

signal cable lines for the analogue inputs and digital outputs.

To make installation simpler, all regulators are also fitted with stuffing boxes in

IP68

The regulator is cooled by natural convection and so air must be able to pass freely below and above the

appliance.

Therefore ensure there is at least

regulator must always be securely assembled and fixed using the four (4) attachment screws on

three phase + Earth

three phase + Earth

) to power the regulator,

) to power the load,

PA6

polyamide, class V2,

, for use with the power and signal cables.

150 mm.

of free space above and below the regulator.

AC LINE

HELPi U NIT Heat - Pu mp

ALARM

ALARM

RL1ONT.K.

fig. 5

Mechanical Dimensions

MODELS A B C D E F kg.

rgf 312

rgf 320

rgf 325

rgf 340

rgf 360

286 201 130 255 181 255 4.0

351 237 181 317 185 320 5.5

351 237 201 317 172 320 8.0

416 318 178 397 275 385 11.0

460 318 228 397 260 410 17.0

Fixing

∅∅∅∅

screw holes

∅ 6

∅ 6

∅ 6

∅ 6

∅ 8

RGF 300

9/53

Page 10

Table 1

RGF 300

10/53

Page 11

1.3 PRINCIPLE OF OPERATION

rgf300

The

series appliances are voltage regulators that use the phase cutting principle totally controlled over

three phases.

The regulators, also referred to as speed controls, have been designed to change the average voltage on the

following types of equipment, according to a control signal:

•

asynchronous three phase motors connected to

•

electrical resistor device s with sec tio ned

fans, pumps, agitators, mixers

single / three phase

.

;

Regulation occurs as a result of cutting of the input sinusoid. Regulation does not generate any torque knock

or pulsation and is particularly quiet. Any voltage loss is contained within a maximum limit of 1%.

Fig. 6

shows a block diagram of regulator

rgf300

.

CONTROL CIRCUIT

POWER CIRCUIT

C

E

A

B

T

S

R

PE

A - Power circuit

B - Mains filter and EMC

protective devices

C - Power supply and synchronism

signals

D - Insulators for the control

signals of the power devices

E - Regulation and control circuit

F – Modulator for control of the

PE

F

D

fig. 6

W

V

U

power devices

The speed regulators are sized to withstand a starting current equal to more than twice the rated current;

therefore, when choosing a regulator, it is essential to take into consideration both the motor starting current

and the type of motor.

It is actually well-known that, while the starting current in axial fans is equal to 2 or 3 times the rated current,

the same current in centrifugal fans can have values around 7 or 8 times the rated current.

As far as the choice of motor is concerned, it is advisable to choose motors suited to the type of regulation.

As a general rule, the best suited are:

motors with high slipping resistive motors

•

defluxed motors

•

tropicalised motors

•

CLASS H motors

•

as these allow better performance to be obtained with speed changes, they are quieter and start with lower

current.

When choosing a motor, it is always advisable to contact your own supplier and order a motor which is

suitable for speed control by voltage change. Subsequently, practical trials should be carried out on the

motors or prototype machines in order to check their correct operation.

After choosing the motor, the speed regulator must be ordered according to

•

•

rated voltage

the

maximum power

,

required (load-Amperes) bearing in mind the

starting current

.

RGF 300

11/53

Page 12

After the motor characteristics have been checked, the following should be defined in order to identify the

type of operating mode and application.

1.3.1 Operating mode

rgf

The

•

controls allow two different types of operation depending on which type of input is available:

operation as

REGULATOR

(also called MASTER)

the phase cutting regulators is directly connected to one or more sensors; the phase cutting is a function of

the values selected for:

Set-Point P3

#"

Proportional band P2

#"

operation as

•

In this case, the

of the voltage by sending the control signal to the slave.

The incoming control signal to the

MASTER (mA – Vdc)

For a

MASTER (ohm)

For a

SLAVE (mA – Vdc)

For a

1.3.2 Application

It is generally possible to connect one or two sensors/control signals to all ‘

(trimmer or centesimal switch)

(trimmer)

POWER UNIT

rgf

is set up to be controlled by an external Master regulator which decides the phase cutting

(also called SLAVE)

rgf300

Active sensors with control in current (mA) or voltage (

Control signals in current (mA) or voltage (

regulators can be:

NTC

sensors with control in

°C/ohm ( 10 kohm @ 25 °C )

Vdc

)

MASTER’

and

Vdc

‘SLAVE’

)

models; with two (2) sensors-signals connected, the regulator automatically selects the greater or lesser

signal.

In the case of active sensors, this can be directly powered (

The principal applications are for measuring pressure (

cu.m/h

(

), superpressure (

mm.

), static pressure (Pa), supertemperature (

24Vdc / max. 40 mA

bar

), temperature (°C), humidity (

).

destratification

%RH

), delivery

) etc. i n plants and

machines.

MASTER SLAVE

fig. 7

RGF 300

12/53

Page 13

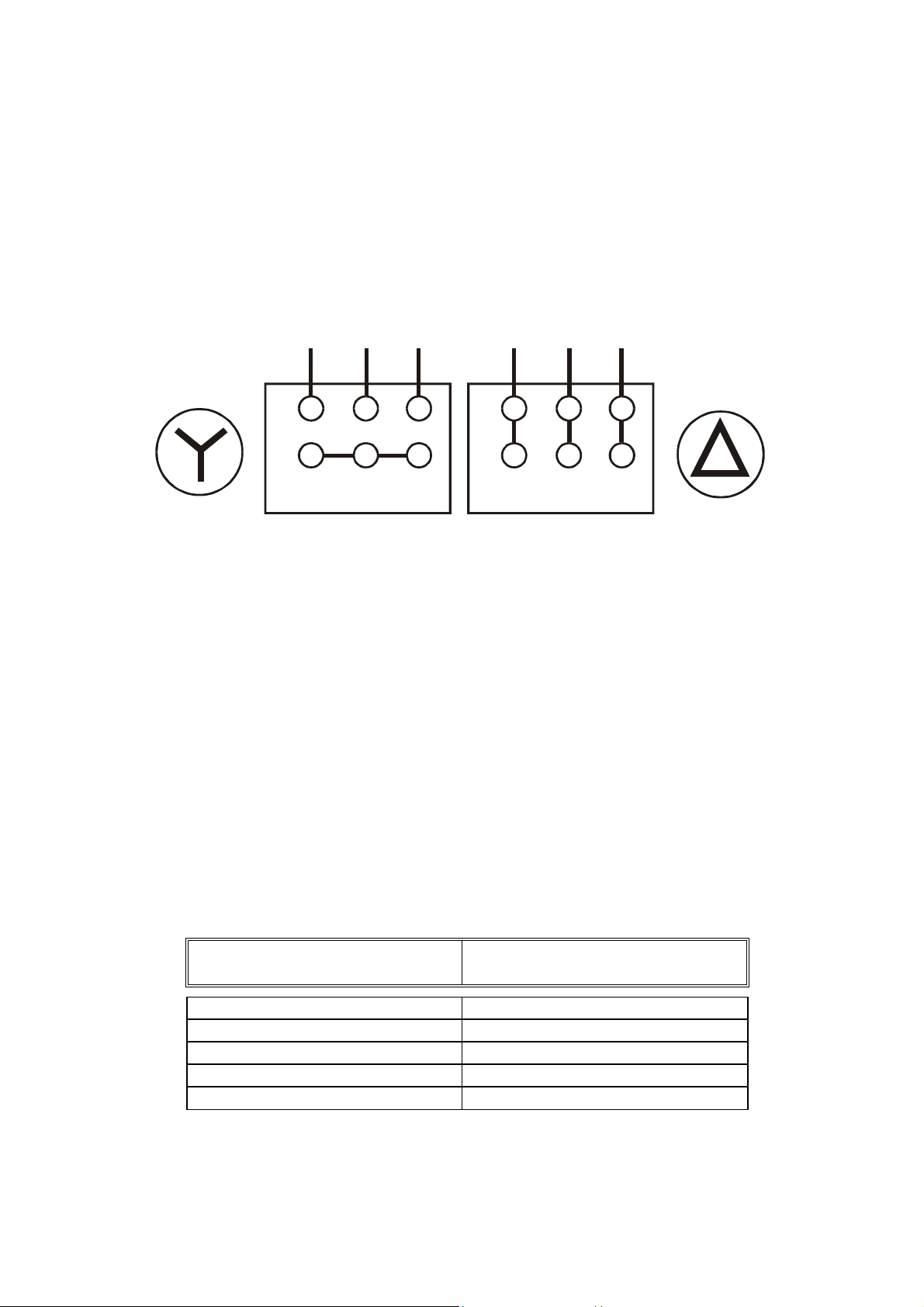

1.4 ELECTRIC MOTORS

Three phase asynchronous motors can be connected to the

rgf300

regulator in applications where the torquemotor speed characteristic is quadratic.

This mainly allows phase cutting application with axial and centrifugal fans used for control purposes.

The correct electrical connection and the supply voltage are given on the motor's specifications plate.

The sense of rotation of the motor can be altered by swapping the connections of two of the three supply

cables.

It is important to keep the motor power supply cable as short as possible to reduce the level of interference

and leakage currents to a minimum

(10 / 15 mt)

; if the cable has to be long, an auxiliary three-phase filter of

exactly the same power as the regulator must be installed on the regulator output.

The figure below shows the star and delta connection configurations.

U V W

Z X Y

ST AR CONNECTION DELT A CONNECTION

U V W

Z X Y

fig. 8

rgf300

The

current must never exceed the rated current as given on the

regulator can control several motors connected in parallel but the absorption of the motors' total

rgf300

's specification plate.

The speeds of the motors vary at the same time though any differences in behaviour during start up and at

low speeds are due to slight differences between the motors even if they are of the same type. However, if

the required speeds of the motors are different, motors must be used with different rated speeds. Bear in

mind though that motors with very different characteristics create different electrical situations and these

may cause problems on start up and at low speeds caused by different resistances of the stators which require

different voltages on start up and at low speeds.

1.4.1 Magnetothermal protection

rgf300

Installation of magnetothermal protections is the responsibility of the installer

devices must be protected by a magnetothermal switch fitted upstream of the cutting regulators.

.

It is advisable to fit an automatic magnetothermal protection with a 'C' intervention curve having the

following capacity:

magnetothermal

RGF 300 models

carrying capacity

rgf 312 20 A

rgf 320 30 A

rgf 325 36 A

rgf 340 60 A

rgf 360 80 A

Table 2

RGF 300

13/53

Page 14

1.5 rgf 300 TECHNICAL C

Voltage

UPPLY

S

Frequency

Overvoltage protection for installation Category II (

URRENT

C

Rated

Overload

Control circuits

OWER

P

O

PRINCIPLE

PERATING

Thermally dissipated

Totally controlled three-phase cutting, with compensation for inductive loads and motors, without need for

connection to NEUTRAL

POWER unit

M , V

PERATING

O

CHARACTERISTIC

(Vers.

)

Regulator

M , V , X , Y

(Vers.

Vers. M Two

Vers. V Two

Vers.

NPUT

I

SIGNALS

Control

Heat protection

Start/Stop

Automatic/Manual

Set-Point 1 / Set-Point 2

Transducer supply

UTPUT SIGNALS

O

Potentiometer supply Two

Auxiliary control

RL1

service relay

Version & Input M: 0-20 mA V: 0-10 Vdc X: +10/+60°C Y: -20/+20°C

Target value

DJUSTMENTS

A

AND

RESETTINGS

P

Proportional range

Minimum limit / Cut-Off Adjustable from

Maximum limit Adjustable from

Acceleration ramp Adjustable from 1” to

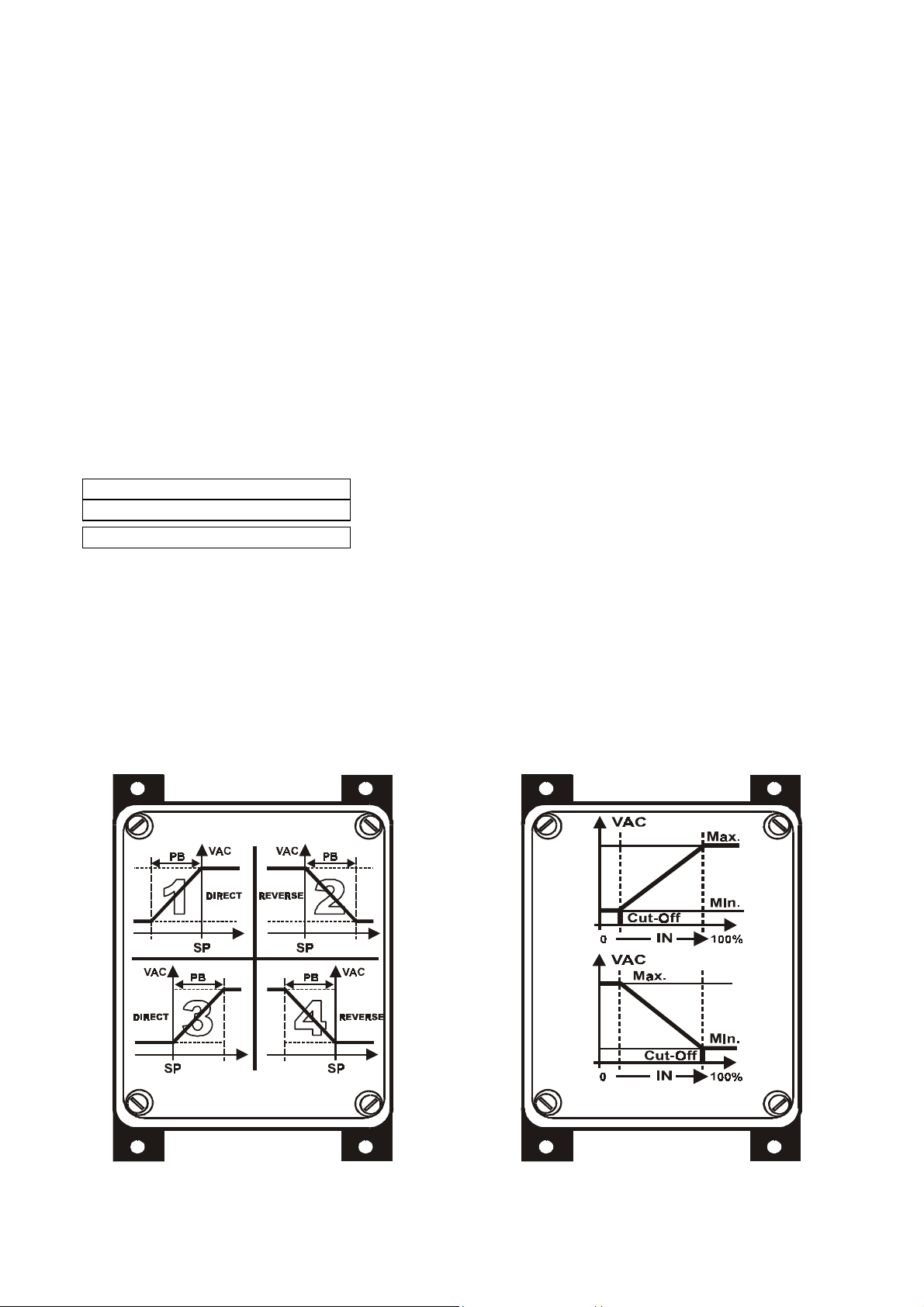

Direct/Reverse presetting Action mode of input prevailing over output :

Prevailing input presetting Selection mode for prevailing input :

INE ALARM

LED

SIGNALLING

AC L

LARM

T.K. A

RL1 ON Green

ANUAL MODE

M

ON Red

ON Red

ON Yellow

HARACTERISTICS

420V

50 Hz (60 Hz

RGF 312

RGF 320

RGF 325

RGF 340

RGF 360

200%

10VA

RGF 312 72 W @ 12A

RGF 320 120 W @ 20A

RGF 325 150 W @ 20A

RGF 340 240 W @ 40A

RGF 360 360 W @ 60A

The output voltage depends on the control signal prevailing between the

two available at the inputs, which is chosen by means of the preestablished mode, according to the specific appliance regulating curve.

The action can be :

DIRECT

REVERSE

Standard Config.

The output voltage changes to keep set to the target point, selected with

the Set-Point, the quantity measured by the transducer prevailing

between the two available at the inputs, which is chosen by means of the

)

X, Y

pre-established mode (greater or lesser in value).

The action mode, either

the controlled quantity, transducer characteristic and load action.

Standard

Two

25°C)

O

O

O

O

Two

from short circuit

0-10V / 1 mA

NO/NC

of :

Signals locked state due to absence of one supply phase

Signals locked state due to motor thermal protection NC contact opening

Signals

Signals “

AC

+/- 10 %

three-phase (

)

4 KV

12 A

20 A

25 A

40 A

60 A

up to

up to

up to

up to

up to

50°C

environment, over decrease by

50°C

environment, over decrease by

50°C

environment, over decrease by

50°C

environment, over decrease by

50°C

environment, over decrease by

of the rated current (max.

, with the output increasing as the input increases, or

,

with the output decreasing as the input increases.

: output increasing as the controlled variable increases

direct

: output increasing as the controlled variable increases

0-20 mA, Ri = 100 hom

analog inputs, priority to the greater std.

0-10 Vdc, Ri = 10 khom

kohm

analog inputs for the

, priority to the hottest sensor std.

N/OFF

input, motor protection NC thermal contact

N/OFF

N/OFF

N/OFF

: Off Vin=0 =

input

Off (Vin=0) =

input:

Start /

input for Set-point 1/2 commutation (Only with

+22Vdc (-10% / +20%) 40 mA

+10Vdc / 5 mA

stabilized outputs

analog output for cascade control of other

relay contact, free from potential, for separate or joint signalling

alarm signals absent / start enabling / voltage supply

0 ... 20 mA 0 … 10 Vdc +10 ... +60 °C -20 ... +20 °C

0.4 … 4 mA 0.3 … 3.5 Vdc 3 … 30 °C

0%

to

100%

100% to 0%

10”

RL1

service relay energised state

ANUAL

M

” operation state at fixed speed

230V

AC

and

500V

AC

on request)

)

0.6 A/°C

1.0 A/°C

1.2 A/°C

1.8 A/°C

2.5 A/°C

10”

every 3’)

reverse,

or

is chosen in consideration of

analog inputs, priority to the greater std.

NTC

sensors supplied (

N

O

(

Automatic /

IN

=24V

V

N

IN

O

V

(

) : Stop

=24V

)=Manual

10KΩΩΩΩ @

PB1064

)

non-stabilised outputs, protected

SLAVE

units

greater

Direct or Reverse

smaller

/

RGF 300

14/53

Page 15

ROTECTIONS

P

ASE

C

NSULATION

I

EMPERATURE

T

UMIDITY

H

NSTALLATION

I

LECTRICAL

E

CONNECTIONS

ECHNICAL

T

STANDARDS

RH < 85%

Continually checks presence of the three mains phases; when one phase

Mains surveillance

EMC integrated

mains filter

Overvoltage protection According to

is absent, it stops the appliance and switches on the “phase absent” alarm

signal LED (

According to

ISM

appliances directly connected to low voltage power mains

AC LINE ALARM

EN 55011 (CEI 110-6

EN 61000-4-5

RGF 312 286 x 201 x 130 mm 4.0 kg

RGF 320 351 x 237 x 181 mm 5.5 kg

Dimensions and Weight

RGF 325 351 x 237 x 201 mm 8.0 kg

RGF 340 416 x 318 x 178 mm 11.0 kg

RGF 360 460 x 318 x 220 mm

Materials

Degree of protection

GW-Plast 120°C

IP 55

and black anodised aluminium

Environmental pollution Strong pollution

Fire resistance Category D

Case Class

Control circuits

Working

Storing

Vertical wall-mounting only, with

SIGNAL

RGF 312

POWER

RGF 320

RGF 325

RGF 340

RGF 360

89/392/EEC

73/23/EEC

Directive

Directive

I

(use of earthed protection cable)

4000V

between control input and mains voltage components

-20 T 50

-30 T 85

N° 4

(from –20°C to + 50°C)

(from –30°C to + 85°C)

∅∅∅∅ 6

mm. holes (RGF350 with

Trailing cable with rated cross section

Trailing cable with rated cross section

Trailing cable with rated cross section

Trailing cable with rated cross section

Trailing cable with rated cross section

Trailing cable with rated cross section

CEI-EN 60204-1

: “ Safety of machinery”

(93/68)

89/336/EEC

Directive

EN 50081-2

EN 50082-2

EN 55011

EN 55011

ENV 50140 (IEC 801-3

ENV 50141

IEC 801-4

IEC 801-2

Generic standard for industrial environment emission

Generic standard for industrial environment immunity

class B, for radiated disturbance

class B, for conducted disturbance

for conducted susceptibility on the signal lines

for fast transients (burst / high-frequency disturbance)

for electrostatic discharge (

Table 3

)

) Class B:

: overvoltage Category

II (4 KV)

17.0 kg

N° 4 ∅∅∅∅ 8

slotted holes)

1.5 sq mm / 22-14 AWG Cu

2.5 sq mm / 20-12 AWG Cu

4.0 sq mm/ 24-10 AWG Cu

10 sq mm / 20-6 AWG Cu

10 sq mm / 20-6 AWG Cu

10 sq mm / 20-6 AWG Cu

) for susceptibility (on the supply)

ESD

)

RGF 300

15/53

Page 16

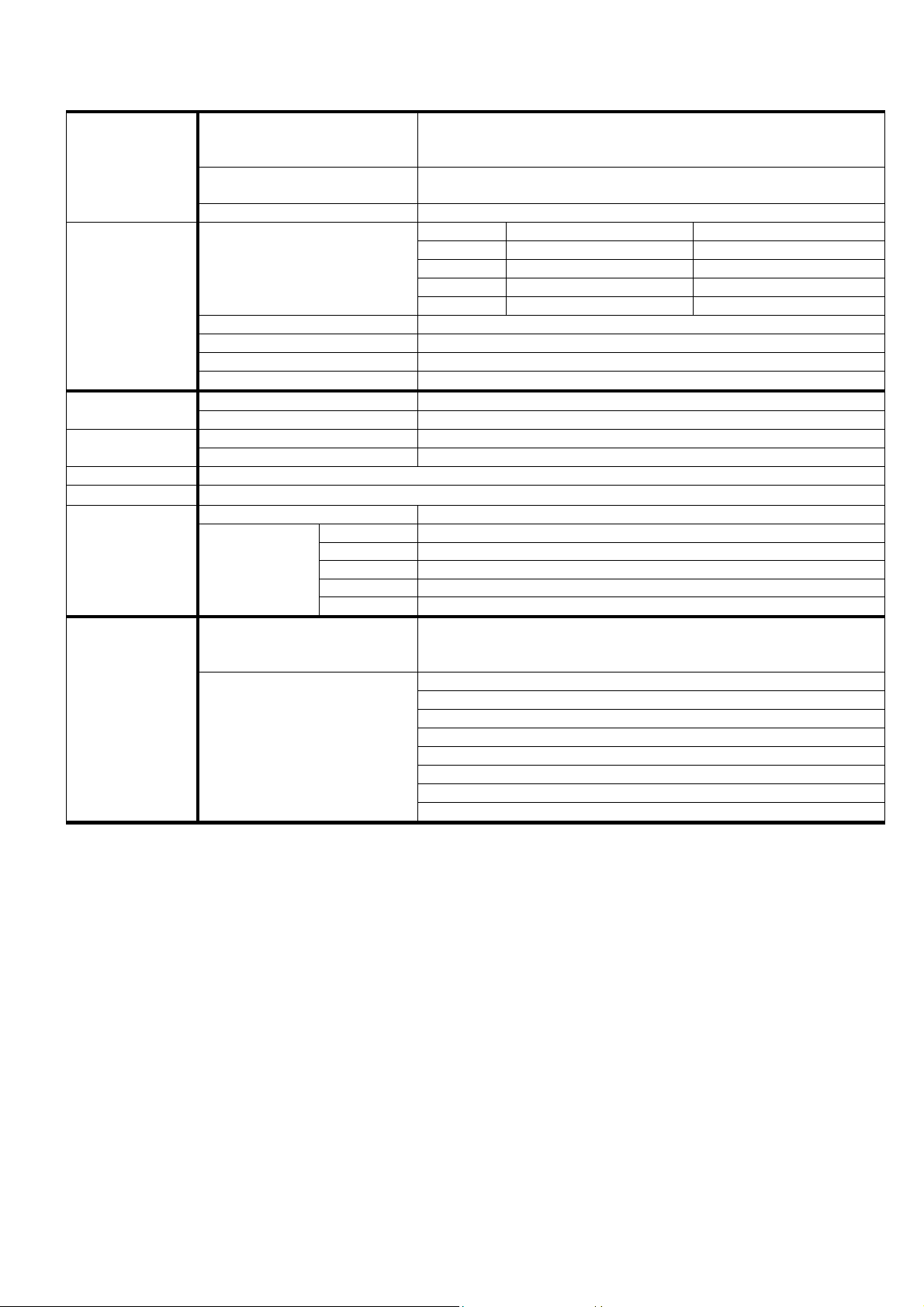

2.0 ELECTRICAL CONNECTIONS

2.1 POWER CARD ELECTRICAL CONNECTIONS

For supply and load connection, reference should be made to the diagrams shown in

section of the cables is adequate to the connected load .

The power cables (supply and load) must be installed separately from the control cables (analogue inputs and

ON-OFF inputs/outputs) keeping the maximum distance possible between the conductors.

Do not place power cables with signal cables in the same raceway. If the cables cross one another,

ensure it is at 90°.

ATTENTION : connect the earth conductor to the screw placed purposely beside the dissipator. Use

heat resistant cables able to withstand temperatures greater than 90°C.

SURGE ARRESTER : electric protection placed between the regulator supply and the earth to protect

the device from transitory mains excess voltage.

ATTENTION : disconnect the PE faston contact from the earth reference, in the '

STRENGTH TEST

’.

The

rgf300

regulators allows connection of three-phase loads

without requiring connec tion of the

This simplifies installation and facilitates the star or delta load configuration.

It is advisable to provide a by-pass switch to allow load activation even when the cutting regulators is faulty

emergency by-pass

(

).

When connecting the by-pass, the following precautions should be taken into consideration:

i) connection made through the by-pass switch must keep phase correspondence unaltered so as to

avoid destructive shortcircuits and maintain the motor's sense of rotation.

ii) before supplying the load with maximum voltage, supply to the regulator should be disconnected,

therefore:

it is advisable to use a three-position manual switch as a commutation device

••••

if automatic commutation is carried out by means of contactors, make sure there is some delay (at

••••

least 2 seconds) between regulator disconnection and load activation operations.

Electrical connection of the supply and load,

for

rgf300

regulators is shown in

BY-PASS

fig. 9

U V W PE R S T

PE

L1

L2

L3

fig. 8,

makin g sur e the

ELECTRIC

NEUTRAL

.

RGF 300

16/53

Page 17

fig. 9

RGF 300

17/53

Page 18

y

2.2 ELECTRICAL CONNECTIONS, ANALOGUE INPUT SIGNALS

The connections for the control analogue inputs are described below.

They can be connected to the MA terminal board, in particular:

MASTER

MASTER

SLAVE

version Control signals in current (mA) or voltage (

version Active sensors with control in current (mA) or voltage (

version

NTC

sensors with control in

°C ( 10 kohm @ 25 °C

Vdc

)

Vdc

)

)

By connecting the second sensor it is possible to obtain regulation control on the basis of the

SIGNAL VALUE

(STANDARD version) provided by one of the two sensors.

REATER

G

Warning :

terminal for supply to

There is also a control output available on the terminal board to pilot the

when two active type sensors with current or voltage output are connected, use the +V

+22 Vdc / 40mA (MA 3

for

IN 1

and

MA 7

rgf

IN 2

for

)

unit, single phase or three

phase, that executes regulation on differentiated loads using the same automatic regulation parameters of the

rgf300

main

.

CONNECTIONS

Trailing cable with rated cross section

1.5 sq mm / 22-14 AWG Cu

Alarm

Rela

RL1

0 - 20

mA

0-10

Vdc

RGF-MEIRGF-MEI

SLAVE

1 2 3 4 5 6 7 8 9 10

NC

NO

S1 S2 TK

S3

COM

SLAVE

SLAVE

ALARM - RELAY

NC NA Com

SLAVE

8

RL1

OFF

9

10

GENERAL ALARM

SELECTIONS

ON 1 ON 2 ON 3

ON 1

ON 1

ON 2

ON 2

ON 3

ON 3

rgf300rgf300

1 2 3 4 5 6 7 8 9 10

M

4 - 20

mA

1 2 3 4 5 6 7 8 9 10

V

0 - 10

Vdc

1 2 3 4 5 6 7 8 9 10

X

Y

NTC

4 - 20

mA

0 - 10

Vdc

NTC

1 2 3 4 5 6 7 8 9 10

M

V

X

Y

RGF-MEI

RGF-MEI

SLAVE

SLAVE

SLAVE

SLAVE

1 2 3 4 5 6 7 8 9 10

M

0 - 20

mA

1 2 3 4 5 6 7 8 9 10

V

0-10

Vdc

1 2 3 4 5 6 7 8 9 10

V

1 2 3 4 5 6 7 8 9 10

M

V

fig. 10

ON 1

ON 2

ON 3

rgf300

RGF 300

18/53

Page 19

One of the main applications of the

is modulated to keep temperature or pressure constant as a work point for one or more refrigerating circuits

(condensator or evaporator mode).

STANDARD

In the

Directions are given below for connection or calibration of

temperature sensors and other possible applications for

2.2.1 Connection of XSK pressure transducers (4-20 mA)

The table below lists the information necessary for calibration of the

referred to the Centesimal Commutators (

with the position of P2.

Set-Point SP /

condition, the fan reaches maximum voltage in output (P4) coinciding with the work

P3 for 4-20m A,

SP / P3 Trimmer Centesimal Switch

M0

m

Setting

Trimmer

0

m

0

m

0

m

(*)

analogue inputs, corresponding to the mA control signal generated by the

Fig. 11

regulation controls.

GND

OUT

GND

GND

c

mA V(*)

m 4 0.4 0.00 0.00 0.00 00 m 0.4 0.37 0.62 0.75

M

c

M

5 0.5 0.93 01.56 01.87 06

6 0.6 1.87 03.12 03.75 12

7 0.7 2.81 04.68 05.62 18

8 0.8 3.75 06.25 07.50 25

9 0.9 4.69 07.81 09.37 31

10 1.0 5.63 09.37 11.25 37

11 1.1 6.56 10.94 13.12 44

c 12 1.2 7.50 12.50 15.00 50 c 2.1 1.94 3.28 3.93

13 1.3 8.44 14.06 16.87 56

c

c

Column V gives the voltage values legible with a multi meter (

14 1.4 9.38 15.63 18.75 62

15 1.5 10.31 17.19 20.62 68

16 1.6 11.25 18.75 22.50 74

M

17 1.7 12.19 20.31 24.37 80

18 1.8 13.13 21.88 26.25 87

19 1.9 14.07 23.44 28.12 93

M 20 2.0 15.00 25.00 30.00 99

shows the connection of two pressure transducers plus the type of operation (standard) and the operating

10

PRESSURE TRANSDUCER

9

10V

+V

8

7

6

IN 2

10V

+V

5

4

3

2

IN 1

1

4-20mA

0-10Vdc

START

position

rgf300

series regulators is the control of voltage and speed of rotation of fans. This

rgf300

regulators with

direct or remote regulation

Com

.) or Trimmer (

Trim

.), and for calibration of the

setting with

0-15

bar

ACCURACY

+/- 3% FS

XSK 2

XSK 1

0-25

bar

0-30

bar

Tab. 4

N°

20Vdc

Set-point

active pressure sensors, NTC

.

Set-point (page 34

Proportional Band PB / P2 setting for

) with the position of P3

Proportional Band

4-20 mA pressure transducers

Mm

c

Mm

c

Mm

c

scale limit) on the IN/

4-20mA

Mm

START

position

c

Set.

Trim

mA

0-15

bar

0-25

bar

M 4.0 3.74 6.24 7.50

Gnd

terminals of the

transducer in regulation.

WARNING :

do not invert the transducer

cables (IN / +V) when

connection is made to terminals

1/3 and 5/7 as the transducer

may be damaged.

ATTENTION :

at standard configuration

P3/Set-point

fig. 11

max. output fan

=

.

0-30

bar

RGF 300

19/53

Page 20

2.2.2 Connection of NTC temperature sensors (10kohm @ 25 °C)

Two versions of

X

•

for scale

Y

•

for scale

NTC

temperature sensors are available for

+10 °C to +60 °C

- 20 °C to +20 °C

The table below lists the information necessary for calibration of the

P3

referred to the centesimal Commutators (

Proportional Band

with the position of P2.

Com

Setting of work point SP / Set-point P3 with NTC probe

rgf300

models:

Set-point (page 34

.) or Trimmer (

) with the position of

Trim

.), and for calibration of the

Proportional Band PB/P2

SP > Trimmer P3 SP > Centesimal switch with NTC probe

Mm

Mm

RIMMER

T

SETTING

Mm

c

Mm

c

Mm

START

c

c

position

m

X (°C)

10°/60°

Y (°C)

-20°/20°

6° -22° 00 10° -20° 3 °C

30 25° -8°

c

35° 0° 50 35° 00° 18 °C

START

position

CENTESIMAL

SETTING

10 15° -16°

20 20° -12°

40 30° -4°

60 40° 4°

70 45° 8°

80 50° 12°

N°

X (°C)

10° / 60°

Y (°C)

-20°/ 20°

Mm

START

position

c

RIMMER

T

SETTING

c

Mm

m

Mm

c

c

Mm

For X & Y

Skale

90 55° 16°

c

Connection of the two

Also shown is the type of operation (standard) and operating regulation controls.

Master X for scale +10 C° to +60 C° Master Y for scale -20 C° to +20 C°

M

64° 23°

NTC

99 60° 20°

sensors is shown in

Tab. 5

fig. 12

below.

c

M

30 °C

GND

OUT

10V

+V

10

9

8

7

NTC probe (10 kohm a 25 °C)

NTC

°C

T. C.

Airflow = 35"

NO-Air = 70"

ATTENTION :

at standard configuration

P3 / Set-point

output fan

max.

=

GND

IN 2

10V

+V

GND

IN 1

6

5

4

3

NTC 2

NTC 1

2

fig. 12

1

RGF 300

20/53

Page 21

2.2.3 Connection of other sensors and control signals

Active sensors with : 0-20 / 4-20 mA current output (M vers.), and

0-10 Vdc voltage output (V vers.)

Connection can usually be made to the

control signal (

If the sensors have an earth (

supply), they can be directly connected to and supplied by the

The diagram below shows the connection of two differential pressure transducers used to maintain constant

pressure / air delivery from a fan in a controlled air flow plant (laminar flow); also shown is the type of

operation (standard) and the operating regulation controls.

0-20 mA

) or voltage output (

Gnd

rgf300

) as well as a signal (IN) reference, and they accept a

regulator with one or two active sensors, with current output

0-10 Vdc

) with conductors having two or three wires.

+24Vdc

rgf300

regulator (

fig. 13

).

(max.

40 mA

GND

OUT

10V

+V

GND

IN 2

10V

+V

GND

IN 1

10

9

8

7

6

5

4

3

2

1

+

DIFFERENTIAL

4-20mA

0-10Vdc

- Refrigerant

- Water

and

- Air Oil

- Vapor

- General Purpose

+

Differential

Transducer

+

Differential

Transducer

fig. 13

_

_

RGF 300

21/53

Page 22

2.2.4 Remote connection for a current (mA) or voltage (Vdc) control signal

Connection of an external control unit (for SLAVE M, V)

If regulator control from an external unit is required, choose one of the following versions:

SLAVE M

SLAVE V

when the external control unit uses a current control signal (

when the external control unit uses a voltage control signal (

This configuration allows a grid of several regulators to be controlled via a single regulation control signal in

either mA or Vdc, even if the regulators are a mixture of single phase and three phase.

It is therefore possible to control totally and automatically several ventilation units and, if necessary, to

release one or more regulators from automatic regulation that, using a local manual control signal (only with

0-10 Vdc

control), are regulated to the requested voltage.

The number of inputs available for differentiated control is 2 with priority going to the greater value.

fig. 14

See

for the layout of the connections.

0-20 mA

0-10 Vdc

), or

).

GND

OUT

10V

+V

GND

IN 2

10V

+V

GND

IN 1

SLAVE 'M' MODE

10

9

8

7

AUT OM ATIC CONT R OL

0-20mA

1

2

6

5

4

3

AUT OM ATIC CONT R OL

0-20mA

1

2

2

1

mode

on off

mode

on off

SLAVE 'V' MODE

GND

OUT

10V

mode

set

CFI

on

off

+V

GND

IN 2

10V

mode

set

on

CFI

off

+V

GND

IN 1

10

9

8

7

6

5

4

3

2

1

MANUAL SPEED

MANUALE CONTROL

0-10Vdc

AUT OM ATIC CONT R OL

0-10Vdc

1

2

100%0%

mode

mode

on off

on

CFI

off

RGF 300

22/53

set

Page 23

fig. 14

RGF 300

23/53

Page 24

2.2.5 Connection of the rgf MULTIDRIVER control

In this configuration, the

MA 9 (OUT)

the

The control output controlled by jumper J6 allows a signal to be sent to several

The signal takes account of the work settings on the main

Using a single control / sensor, it is therefore possible to control several single or three phase regulation

units, that act both simultaneously and proportionally, starting from the transmitted regulation control

signals.

Each unit can be used singly with other work limits (

The electrical connection and controls available are shown in

GND

OUT

10V

+V

GND

IN 2

10V

+V

GND

IN 1

and

10

9

8

7

6

5

4

3

2

1

rgf300

MA 10 (GND)

regulator is able to guide other single or three phase

IN1 GND

1 2

300

terminals.

IN1 GND

1 2

100

MEI

mA

Vdc

NTC

MEI

mA

Vdc

NTC

MIN

IN1 GND

1 2

rgf300

MAX

and

fig. 15

.

OUTPUT

.

SLAVE

).

NTC

NTC

NTC

NTC

fig. 15

Connection of the

With this module it is also possible to increase the number of sensors (max. 16), which either use current (

20mA

), voltage (

Four sensors can be connected to this module; the control signal automatically selected is the one with the

greatest value

For more information, consult the user manual for regulator

rgfMEI

0-10Vdc

and as this module is supplied separately.

expansion module is also shown in

) or kohm (

NTC sensor

), that can be connected to the regulator.

fig. 15

rgfMEI

.

.

rgf

regulators through

(M or V) units.

mA - Vdc

mA - Vdc

mA - Vdc

mA - Vdc

0-

RGF 300

24/53

Page 25

2.3 ELECTRICAL CONNECTIONS, ON-OFF INPUTS/OUTPUT

This paragraph describes the connections to the auxiliary

S1 - S2 - S3

available on the ‘MB’ terminal board for which the electrical connection is made with

and

TK,

ON-OFF inputs / output

POTENTIAL

0-

cables.

Also described is the operation of the

CONNECTIONS

Trailing cable with rated cross section

RL1 ALARM

relay and its use based on jumper

1.5 sq mm / 22-14 AWG Cu

J14

.

2.3.1 Operating selection

The operating selection is obtained by activating the

1/3, 2/3, 4/5

board.

Fig. 16

In particular:

S1

S2

S3

shows an example of connection using switches and safety devices.

indicates a

normally open (NO)

switch for commutation from

indicates a NO contact for activation/inhibition of operation (

represents a NO contact to activate commutation from

Set-point 1

AUTOMATIC

remote ON-OFF

N.B. : this control is only operative if the RGFPB10640 optional card is present on the regulator

TK

indicates a

normally closed (NC

) safety device, e.g. a

which would halt operation if were open (only if

RL1

TK 2

TK 1

STOP 2

STOP 1

GND

AUT-MAN

SP1 - SP2

10

9

8

7

6

5

4

3

2

1

COM

NO

NC

TK

S2

S1

S3

RL1 ON

GENERAL

ALARM

OFF

REMOTE

OFF

CONTACT

OFF

CONTACT

OFF

J15=ON2

RL1

HEAT PROTECTION

).

9

8

7

COM

NO

NC

TK

10

6

5

S2

4

3

2

1

S1

S3

fig. 16

6/7

and

terminals on the 'MB' terminal

MANUAL

to

);

Set-point 2 (SP1 – SP2

to

positioned on the motor,

RL1 ON

GENERAL

ALARM

ON

REMOTE

ON

CONTACT

ON

CONTACT

ON

rgf

operation.

)

signal

RGF 300

25/53

Page 26

S1: AUT / MAN (MB 2 – MB 3 terminals)

S1 = OPEN operation with variable speed regulation (Led heat-pump = OFF)

S1 = CLOSED MANUAL operation at fixed speed (Led heat-pump = ON)

The S1 contact allows the regulation to be commutated from "AUTOMATIC OPERATION" (power

supplied according to the control signal) to "MANUAL OPERATION" with fixed supply power.

Activation of this function is displayed by the

Application example :

WINTER / SUMMER OPERATION

heat-pump Led

of heat pumps.

lighting up.

The fans, connected to the regulator, can be activated depending on the temperature or pressure detected; or,

by switching

0%)

, for the required time.

CALIBRATION

the P7 trimmer to the desired voltage; then open S1

This will reset the automatic speed regulation on the basis of the control signal.

S1= CLOSED

, voltage to the fans can be kept constant, equal to the value set with

: switch the S1 contact to

CLOSED ( Led hea t-pump = ON)

(Led heat-pump = OFF)

.

and regulate the position of

P4 (100% -

The operation described here can be achieved by means of electromechanical devices. However it is

extremely simple if the cutting regulators is controlled by an external regulator (e.g. Energy Light - type

Eliwell

S2: STOP (MB 4 – MB 5 term inals)

), which can automatically control the S1 contact.

S2 = OPEN Regulator operational

S2 = CLOSED Operation stop

With S2 = CLOSED operation of the cutting regulators is stopped via a remote contact.

This is useful, for example, to stop fans during defrosting or to link fan operation to activation of a central

unit (e.g. compressor) or an alarm (e.g. max./min. temperature).

S3: SP1 / SP2 (MB 1 – MB 3 terminals)

S3 = OPEN Automatic regulator operation with SET-POINT 1

S3 = CLOSED Automatic regulator operation with SET-POINT 2

S3

The

With S3 = OPEN, the regulator works with

contact allows the reference Set-point to be commutated from

SET-POINT 1

With S3 = CLOSED, the regulator works with

Activation of this function is displayed by the

.

SET-POINT 2

SP1

and

SP2

.

Leds lighting up on the optional

SP1

to

SP2.

RGFPB10640

card.

This function is useful, for example, for day / night or winter / summer operations.

Selection is made by means of an external contact in automatic or manual commutation mode.

N.B. : this control is only operative if the optional RGFPB10640 card is present on the regulator.

TK: TK1 – TK2 (MB 6 – MB 7 terminals)

TK = CLOSED Regular operation (Led TK

TK = OPEN Operation stop (Led TK

Intervention of an external safety device opens a

Led TK

ALARM

(ON)

is lighted up.

In plants with fans in parallel, individual protection devices must be used for each motor connected so as to

reduce the risk of a total stop.

To restore normal conditions (

For operation with

J15=2,

the configuration required is :

RESET

), see the position of jumper

ALARM

ALARM

0 V

= OFF )

= ON )

potential contact and halts operation of the regulator.

J13

.

MB 6/7 = NC

RGF 300

26/53

Page 27

RL1: ALARM relay (MB 8-9-10 terminals) with J14 selection jumper

RL1

The

of the operating status.

For the operation mode of this output relay, configure jumper

the table below:

relay is mounted on the

POWER SUPPLY

control card

. The relay has a commutation contact for external signalling

J14

so that all alarms are enabled, as shown in

T.K. STOP

FAN SPEED

J14 RL1

R S T

(S2)

U V W

ON ON ON Unable Unable O.K.

ON1

OFF OFF OFF Unable Unable K.O.

ON ON ON OFF Unable O.K.

ON2

OFF OFF OFF ON Unable K.O.

ON ON ON OFF ON O.K.

ON3

OFF OFF OFF ON OFF K.O.

Besides relay RL1 in rest conditions,

J 14

:

ON1 ( standard = factory selection).

ON2

ON3

RL1

OFF

8

ALARM - RELAY

NC NA Com

9

fig. 17

10

Table 6

shows the three positions for:

GENERAL ALARMS

SELECTIONS

ON 1 ON 2 ON 3

ON 1

ON 2

ON 3

fig. 17

ON 1

ON 2

ON 3

rgfrgf

ON 1

ON 2

ON 3

rgf

RGF

RGF 300

27/53

Page 28

3.0 COMMISSIONING PROCEDURE

Having carried out the electrical connections to the regulator, it is time to perform the configuration,

regulation and commissioning operations for the

It is important to remember that the settings of the

configuration or the operating mode of the regulator set in the factory (check the label on the right side of the

casing).

3.1 Jumpers

This paragraph describes the preset functions of the programming

of the following types The term "

Jumper

" refers to the moveable element which connects two (2) contacts.

2, 3, 6

10 contacts

and

rgf300

(see

regulator by following the procedure below.

jumpers (Jn

fig. 18

).

) are only to be modified to change the

jumpers

; the jumpers used on the card are

3 contacts

3 contatti

pos.

1

1 2 1 2

2 contacts

2 contatti

ON

pos.

1 2 1 2 3

fig. 18

For 2 contact jumpers, the function is activated when the

jumper

For 3 contact jumpers, there are two selection types:

•

position ‘1’ i.e. the middle jumper connected to jumper no. 1

•

position ‘2’ i.e. the middle jumper connected to jumper no. 2

For 6 contact jumpers (

J5

For 10 contact jumpers (J6), there are 5 selection types (pos.

The main jumpers on the

J1

J1 = ON1

J1 = ON2

J2

J2 = ON1

J2 = ON2

Selects the work field of the

P3

with control from active sensors for

P3

with control from active sensors for

Activates the standard

this control is only operative if the RGFPB10640 card is present on the regulator)

(

Set-point (P3

Set-point (P3

J14

and

), there are 3 selection types (pos.

1, 2, 3, 4, 5

rgf300

cutting regulators

Set-point P3

control card

:

4-20mA

0-10 Vdc

Set-point

), with trimmer mounted on the

or the auxiliary, optional, double digital

PB 1018/3

), with double digital commutators in 99 positions, mounted on the

RGFPB10640;

it also inhibits operation of P3 (standing) when in the

J3

J3 = ON1

J3 = ON2

Selects the operation of the regulator at the

Set-point (P3

Il

Set-point (P3

) corresponds to the minimum control value of the fan

) corresponds to the maximum control value of the fan

The standard position is ON2.

Set-point

3 contacts

3 contatti

pos.

2

6 contacts

6 contatti

pos.

is present (position ON).

1, 2, 3

fig. 18

);

shows position 1.

).

are described below.

NTC (ohm

or

) sensors for

basic regulation card

SLAVE

:

configuration,

1

°C

Set-point

J2 = ON2

:

RGF 300

28/53

Page 29

J4

J5

J5 = ON1

J5 = ON2

J5 = ON3

J6

J6 = ON1

J6 = ON2

J6 = ON3

J6 = ON4

J6 = ON5

J7

J7 = ON1

J7 = ON2

J8 = ON

J9 = ON

J10

J10 = ON1

J10 = ON2

J11

J11 = ON1

J11 = ON2

J12

J12 = ON1

J12 = ON2

Selects the operating mode of output

Selects the work field of the

P2

scale for control input with

P2

scale for control input with active sensors from

P2

scale for control input with activ e sensor s from

Selects the type of output control sig nal from the

0-10 V

10-0 V

Control signal with

Signal to indicate the shift of the input signal from the

signal proportional to the power output (for

signal proportional to the power output (for

OFFSET

Proportional Band

(for

Input signal (greater or lesser) (for

Selects the size of the value in % C (of control) to display on the portable unit:

displays control signal %C with

displays control signal %C without

Selection

J 8

If

is

Selection

J 8

If

is

Selection

J 9

If

is

Selection

J 9

If

is

DIRECT

for '

ON,

the voltage supplied to the fans increases with the inc rea se in input si g n al.

REVERSE

for ‘

ON,

the voltage supplied to the fans increases with the decrease in input signal.

REVERSE

for ‘

ON,

the voltage supplied to the fans increases with the decrease in input signal.

DIRECT

for '

ON,

the voltage supplied to the fans increases w ith the inc rease in in put signal.

' operation with

‘ operation with

‘ operation with

' operation with

MA 9/10

NTC (ohm

J4 = 1

J4 = 1

) sensors for °C (range

)

)

OFFSET

OFFSET (0 – 100%)

J3 = ON1

J3 = ON2

J3 = ON1

J3 = ON2

in combination with jumper

°C, mA, Vdc

in

:

3 – 30 °C)

4-20 mA

0-10 Vdc

rgf300

(range

(range

on terminal

0.3 – 3.5 Vdc

J4 = 2)

J4 = 1

)

Set-point

(for

J6.

0.4 – 4 mA

MA 9/10

J4 = 1

)

The selection of one excludes the other.

In the versions with

Selects the

selects

selects

Selects the input signal priority:

selects the

selects the

•

In the version with

with the greater °C value

Selects the type of input for use of the portable unit :

displays the voltage signal in

displays the current signal in

•

In the version with

work field of the sensor (

MASTER

SLAVE

MASTER

LESSER

GREATER

NTC

sensor, the operation of J8 and J9 with

SLAVE

or

mode for the

mode for the

value

value

NTC

NTC

operating mode:

rgf300

rgf300

sensor, selecting

V (0-10 Vdc)

mA (0-20

4-20 mA)

and

sensor, selecting

X = +10 to +60 °C

J11=ON1

J12=ON1

and

is the equivalent of selecting the sensor

is equivalent to automatic setting of the

Y = -20 to +20 °C

J3 ON1/ON2,

)

)

)

:

is inverted.

RGF 300

29/53

Page 30

J13

J13 = ON1

J13 = ON2

J14

J14 = ON 1

J14 = ON 2

J14 = ON 3

J15

J15 = ON 1

J15 = ON 2

J16

J16 = ON 1

J16 = ON 2

J17

J17 = ON 1

J17 = ON 2

Selects the

RESET

operating mode of the TK contact (terminal board

MB 6/7

):

when selected, if the TK protection intervenes, the regulator must be switched off and on

again to reset the system after the cause has been eliminated (

MANUAL RESET

).

when selected, if the TK protection intervenes, the system restarts automatically after

the contact has been reset (

AUTOMATIC RESET

).

The standard position is ON2

Selects the operation of the

when selected the relay is activ e (

when selected the relay is activ e (

and with open remote

STOP

when selected the relay is activ e (

with open remote

STOP

The standard position is ON3

.

RL1

relay:

position ON

position ON

), in the absence of alarms (

), in the absence of alarms (

control signal

position ON

), in the absence of alarms (

control signal and with

.

supply

Alarm Led = OFF

Alarm Led = OFF

Alarm Led = OFF

of voltage to the load in course.

Selects the operation of the heat protection:

when selected, the TK heat protection contact is excluded.

when selected, the TK heat protection contact must be connected to the terminal board

The standard position is ON1

Selects the type of input on the

.

IN 1

channel:

when selected, the input is activated for control signals in mA.

when selected, the input is activated for control signals in

Selects the type of input on the

IN 2

channel:

Vdc

ohms (NTC

and

sensor)

when selected, the input is activated for control signals in mA.

when selected, the input is activated for control signals in

Vdc

ohms (NTC

and

sensor)

)

)

),

WARNING !

• Check the position of jumpers 'Jn' during commissioning.

If the rgf300regulator work mode is altered (MASTER / SLAVE), refer to fig.s 19, 20, 21, 22 and 23 which

give the standard work configurations of the jumpers.

• The regulator is already set for the operations indicated on the label on the side of the casing; if modifications

are required, describe and indicate the modifications made on the TECHNICAL ASSISTANCE MODULE.

WARNING !

• The configuration with NTC temperature sensors is not compatible with other configurations.

It is not therefore possible to alter the position of the jumpers to pass from operation with NTC sensors to

operation with active sensors or control signals in mA or Vdc, nor to change the °C work field/scale of the rgf

regulator.

RGF 300

30/53

Page 31

3.2 MASTER, version M (4-20 mA), for 1 or 2 control INPUTS

P1 P2 P3 P4 P5 P6

= Soft-Start

MmmMmMmMmMmM

1

1

CN3

J1

J4

J5

J8

J9

1

J17J16

2

2

1 2

1

2

3

J10

1

2

1

2

J2

2

1

J3

2

J6

J7

1

2

HEAT

PUMP

J12J11

1

2

3

4

5

1

2

1

2

Mm

P7

P1

= Proportional Ba nd

P2

= Set-Point

P3

= max. output

P4

= min. output

P5

= Cut-off

P6

= MANUAL (mode H .P.)

P7

AC LINE

ALARM

ALARM

J13

J15

T.K.

1

2

J14

1

2

RL 1

ON

1

2

3

FL

RL1

CN2

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

fig. 19

3.3 MASTER, version V (0-10 Vdc), for 1 or 2 control INPUTS

P1 P2 P3 P4 P5 P6

= Soft-Start

MmmMmM

1

J1

2

CN3

1 2

J4

J5

J8

J9

1

J17J16

2

mM

1

J2

2

1

J3

2

1

J6

2

3

J10

1

1

2

2

HEAT

1

PUMP

2

mMmM

1

2

3

4

5

1

J7

2

P7

1

2

Mm

J12J11

P1

= Proportional Band

P2

= Set-Point

P3

= max. output

P4

= min. output

P5

= Cut-off

P6

= MANUAL (mode H.P.)

P7

AC LINE

ALARM

ALARM

J13

J15

T.K.

1

2

J14

1

2

RL 1

ON

1

2

3

FL

RL1

CN2

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

fig. 20

RGF 300

31/53

Page 32

3.4 SLAVE, version M (0-20 mA), for 1 or 2 control INPUTS

P1 P2 P4 P5 P6

= Soft-Start

Mm

MmM

m

J1

mM

1

2

1 2

1

2

1

2

J4

1

2

J5

3

J10

J8

1

2

J9

1

2

1

J17J16

2

mMmM

J2

J3

1

2

3

J6

4

5

1

J7

2

1

1

2

2

J12J11

HEAT

PUMP

P7

Mm

P1

=

P2 Set - 100% output

=

P3 standing

= max. output

P4

= min. output

P5

= Cut-off

P6

= MANUAL (mode H.P.)

P7

T.K.

AC LINE

ALARM

ALARM

J13

J15

1

2

J14

1

2

RL 1

ON

1

2

3

FL

RL1

CN2

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

fig. 21

3.5 SLAVE, version V (0-10 Vdc), for 1 or 2 control INPUTS

P1 P2 P4 P5 P6

= Soft-Start

Mm

m

M

mM

1

J1

2

1 2

mM

J4

J5

J10

J8

J9

1

2

1

J17J16

2

mMmM

1

J2

2

1

J3

2

1

J6

2

3

J7

1

1

2

2

J11

HEAT

PUMP

1

2

J12

1

2

3

4

5

1

2

Mm

P7

P1

=

P2 Set - 100% output

=

P3 standing

= max. output

P4

= min. output

P5

= Cut-off

P6

= MANUAL (mode H.P.)

P7

T.K.

AC LINE

ALARM

ALARM

J13

J15

1

2

J14

1

2

RL 1

ON

1

2

3

FL

RL1

CN2

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

fig. 22

RGF 300

32/53

Page 33

3.6 MASTER, version X or Y (NTC °C), for 1 or 2 control INPUTS

P1 P2 P3 P4 P5 P6

= Soft-Start

MmmM mM

CN3

1

2

J17J16

J1

J4

J8

1

2

J5

J9

mM

1

2

1

2

1 2

1

2

3

J10

1

2

1

2

mMmM

J2

J3

1

2

3

J6

4

5

1

J7

2

1

1

2

2

J12J11

HEAT

PUMP

P7

Mm

P1

= Proportional Band

P2

= Set-Point

P3

= max. output

P4

= min. output

P5

= Cut-off

P6

= MANUAL (mode H.P.)

P7

AC LINE

ALARM

ALARM

J13

J15

T.K.

1

2

J14

1

2

RL 1

ON

1

2

3

FL

RL1

CN2

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

fig. 23

rgf300

The

MASTER X

MASTER Y

version for temperature control inputs with

with temperature scale

with temperature scale

+10 to +60 °C

-20 to +20 °C.

The scale limit values for the Trimmer with P3 Set-point calibration are inverted compared to the

current (mA) and voltage (

Vdc

) scales for the active sensors.

NTC

sensors is available in two °C scales:

WARNING !

• The configuration with NTC temperature sensors is not compatible with other configurations.

It is not therefore possible to alter the position of the jumpers to pass from operation with NTC sensors to

operation with active sensors or control signals in mA or Vdc, nor to change the °C work field/scale of the

rgf regulator.

RGF 300

33/53

Page 34

3.7 Optional module for dual Set-point configuration (SP1 – SP2)

rgf300

The

using the

Insert the card in the

When the card is positioned, with

99

position

regulator can be used in versions

optional

module card

CN3

RGFPB10640

connector on the

J2=ON2

digital commutators

.

Activating the contact on terminal board

commutation is shown by the lighting up of the

MASTER M, V, X, Y

for double control Set-points.

rgf300

regulator (see the position in

, Tri mme r P3 is disabled (

MB 1/ 3

, it is possible to change the regulator's work point. The

SP1

and

SP2 Leds

with a

standing

reference dual Set-point

fig. 25

).

) and substituted by two pairs

on the card above the centesimal

commutator for setting of the Set-points.

Fig. 26

shows the

mA (bar/°C

RGFPB10640

card and the reference table for inputs in:

for pressure transducers) and

°C

(for

NTC

sensors) in the different work ranges.

SP1

0

9

8

7

6

0

9

1

1

2

2

8

3

3

7

4

5

7

4

6

5

SW1 SW2 SW3 SW4

SP1

P3

CN3

RGFPB10640

(OPTIONAL)

SP2

0

9

8

6

0

9

1

1

2

2

8

3

3

7

4

4

6

5

5

SP2

fig. 24

MA MB

P1 P2 P3 P4 P5 P6

MmmMmMmMmMmM

1

1

SP1 SP2

0

0

0

9

9

1

1

2

8

8

3

7

7

4

4

6

6

5

5

SW1 SW2 SW3 SW4

SP1 SP2

0

9

9

1

2

2

8

8

3

3

7

7

4

6

6

5

5

P3

CN3

J1

1

2

3

4

J4

J5

2

1 2

J2

2

1

J3

2

J6

1

2

3

J7

PB10640

(optional)

1

2

J9

J8

1

1

2

2

J10

1

J17J16

2

J12J11

HEAT

PUMP

CN2

1 2 3 4 5 6 7 8 9 10

1

2

3

4

5

1

2

1

2

P7

Mm

P1 = Soft-Start

P2 = Proporti onal Band

P3 = (standing for J2=2)

P4 = max. output

P5 = min. output

P6 = Cut-off