Electronic controllers for refrigeration units

ID

PLUS

902/961/971/974

EN

CONTENTS EN

IDPLUS 902/961 USER INTERFACE (KEYS AND LEDS) .......................................................................................... 4

IDPLUS 971/974 USER INTERFACE (KEYS AND LEDS) .......................................................................................... 6

IDPLUS 902/961 CONNECTIONS .............................................................................................................................. 8

IDPLUS 902/961 APPLICATIONS ............................................................................................................................... 9

IDPLUS 971 CONNECTIONS ...................................................................................................................................... 10

IDPLUS 971 APPLICATIONS ........................................................................................................................................ 11

IDPLUS 974 CONNECTIONS ...................................................................................................................................... 12

IDPLUS 974 APPLICATIONS ........................................................................................................................................ 13

LOADING DEFAULT APPLICATIONS ........................................................................................................................ 14

SETPOINT MODIFICATION LOCK ............................................................................................................................. 14

INSTRUMENT ON/OFF ................................................................................................................................................ 14

ACCESSING AND USING THE MENUS ..................................................................................................................... 14

MANUAL DEFROST CYCLE ACTIVATION ................................................................................................................ 15

MECHANICAL INSTALLATION - DIMENSIONS ....................................................................................................... 15

TROUBLESHOOTING ................................................................................................................................................... 15

ALARMS .......................................................................................................................................................................... 16

PASSWORDS ................................................................................................................................................................. 18

USING THE COPYCARD .............................................................................................................................................. 18

MACHINE STATUS MENU ........................................................................................................................................... 19

PROGRAMMING MENU ............................................................................................................................................... 19

MAX/MIN TEMPERATURE ALARMS........................................................................................................................... 20

LIABILITY AND RESIDUAL RISKS ................................................................................................................................ 20

DISCLAIMER ................................................................................................................................................................... 21

ELECTRICAL CONNECTIONS ..................................................................................................................................... 21

CONDITIONS OF USE ................................................................................................................................................. 21

TECHNICAL DATA (EN 60730-2-9) ............................................................................................................................ 22

FURTHER INFORMATION (INPUT, OUTPUT AND MECHANICAL FEATURES - APPLICABLE REGULATIONS) 22

DESCRIPTION OF IDPLUS 902/961 FAMILY ............................................................................................................ 24

TABLE OF USER MENU PARAMETERS (IDPLUS 902/961) ..................................................................................... 25

TABLE OF INSTALLER MENU PARAMETERS (IDPLUS 902/961) .......................................................................... 26

DESCRIPTION OF IDPLUS 971 FAMILY .................................................................................................................... 30

TABLE OF USER MENU PARAMETERS (IDPLUS 971) ............................................................................................. 31

TABLE OF INSTALLER MENU PARAMETERS (IDPLUS 971) ................................................................................... 32

DESCRIPTION OF IDPLUS 974 FAMILY .................................................................................................................... 37

TABLE OF USER MENU PARAMETERS (IDPLUS 974) ............................................................................................. 38

TABLE OF INSTALLER MENU PARAMETERS (IDPLUS 974) ................................................................................... 39

STANDBY (ESC)

Press and release

Returns to the previous menu level

Confirms parameter value

Press for at least 5 sec

Activates the Standby function

(when outside the menus)

UP

Press and release

Scroll menu items

Increases values

Press for at least 5 sec

Activates the Manual Defrost function

DOWN

Press and release

Scroll menu items

Decrease values

Press for at least 5 sec

Function can be configured by the user

(par. H32)

SET (ENTER)

Press and release

Displays alarms (if active)

Opens Machine Status menu

Press for at least 5 sec

Opens Programming menu

Confirm commands

KEYS

set

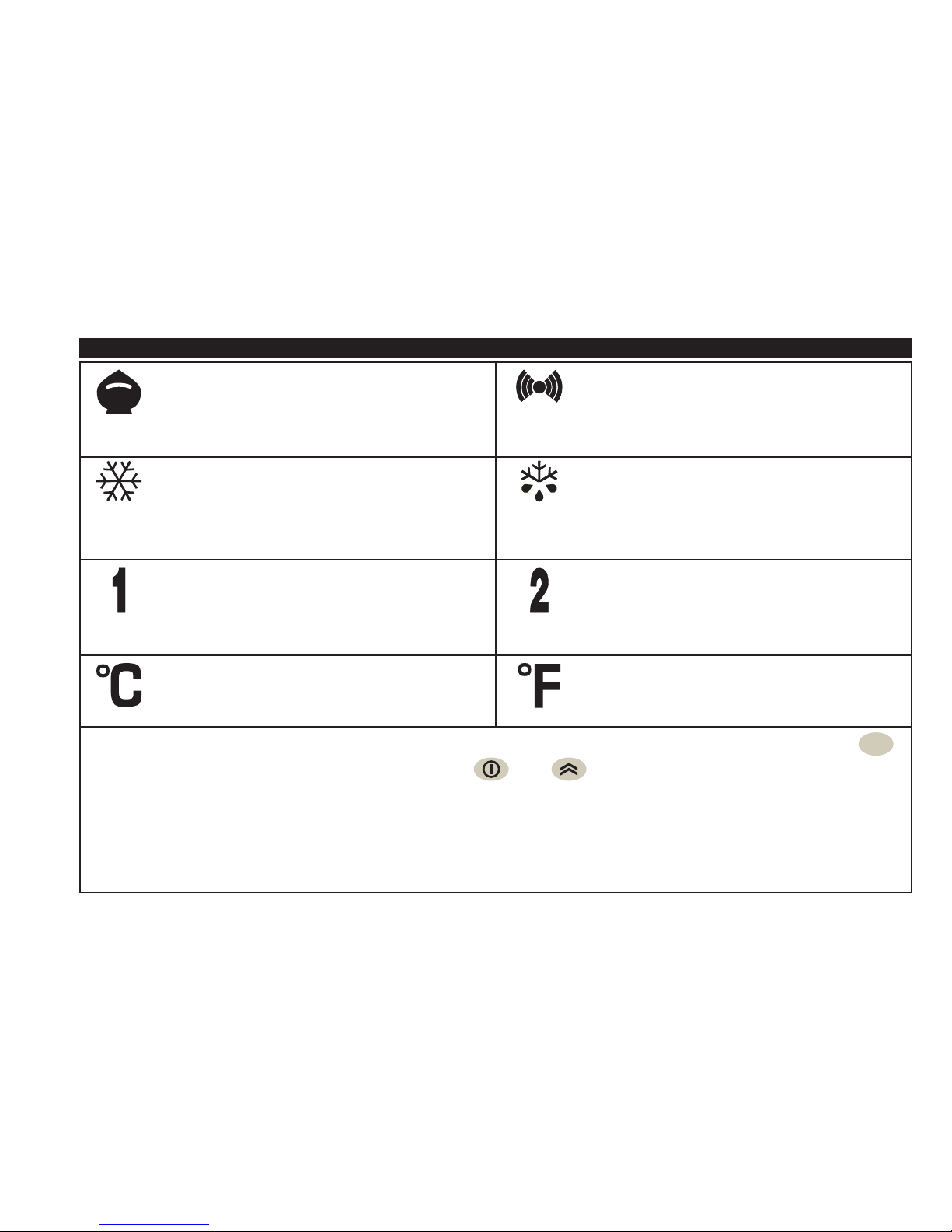

IDPlus 902/961 USER INTERFACE

ID

PLUS

902/961

* When switched on, the device performs a Lamp Test; the display and LEDs will flash for several

seconds to check that they all function correctly.

* To activate the LOC function: - enter the “Basic Commands” menu by pressing the key

set

.

- press keys and within 2 seconds.

If the LOC function is Active and you try to enter the “Programming” menu, the text LOC

appears. If this happens, the parameters are still displayed but cannot be edited.

To disable the keypad lock, repeat the aforementioned procedure.

Reduced SET / Economy LED

Flashing: economy Setpoint active

Quick flashing: access to level2 parameters

Off: otherwise

Compressor LED

Permanently on: compressor active

Flashing: a delay, a protection or a

locked start-up

Off: otherwise

Defrost LED

Permanently on: defrost active

Flashing: manual or D.I. activation

Off: otherwise

Alarm LED

Permanently on: alarm active

Flashing: alarm acknowledged

Off: otherwise

HEAT status LED

Permanently on: compressor in HEAT

Off: otherwise

NOT USED

°C LED

Permanently on: °C setting (dro = 0)

Off: otherwise

°F LED

Permanently on: °F setting (dro = 1)

Off: otherwise

LEDs

Standby (ESC)

Press and release

Returns to the previous menu level

Confirms parameter value

Press for at least 5 sec

Activates the Standby function

(when outside the menus)

UP

Press and release

Scroll menu items

Increases values

Press for at least 5 sec

Activates the Manual Defrost function

DOWN

Press and release

Scroll menu items

Decrease values

Press for at least 5 sec

Function can be configured by the user

(par.H32)

SET (ENTER)

Press and release

Displays alarms (if active)

Opens Machine Status menu

Press for at least 5 sec

Opens Programming menu

Confirm commands

KEYS

set

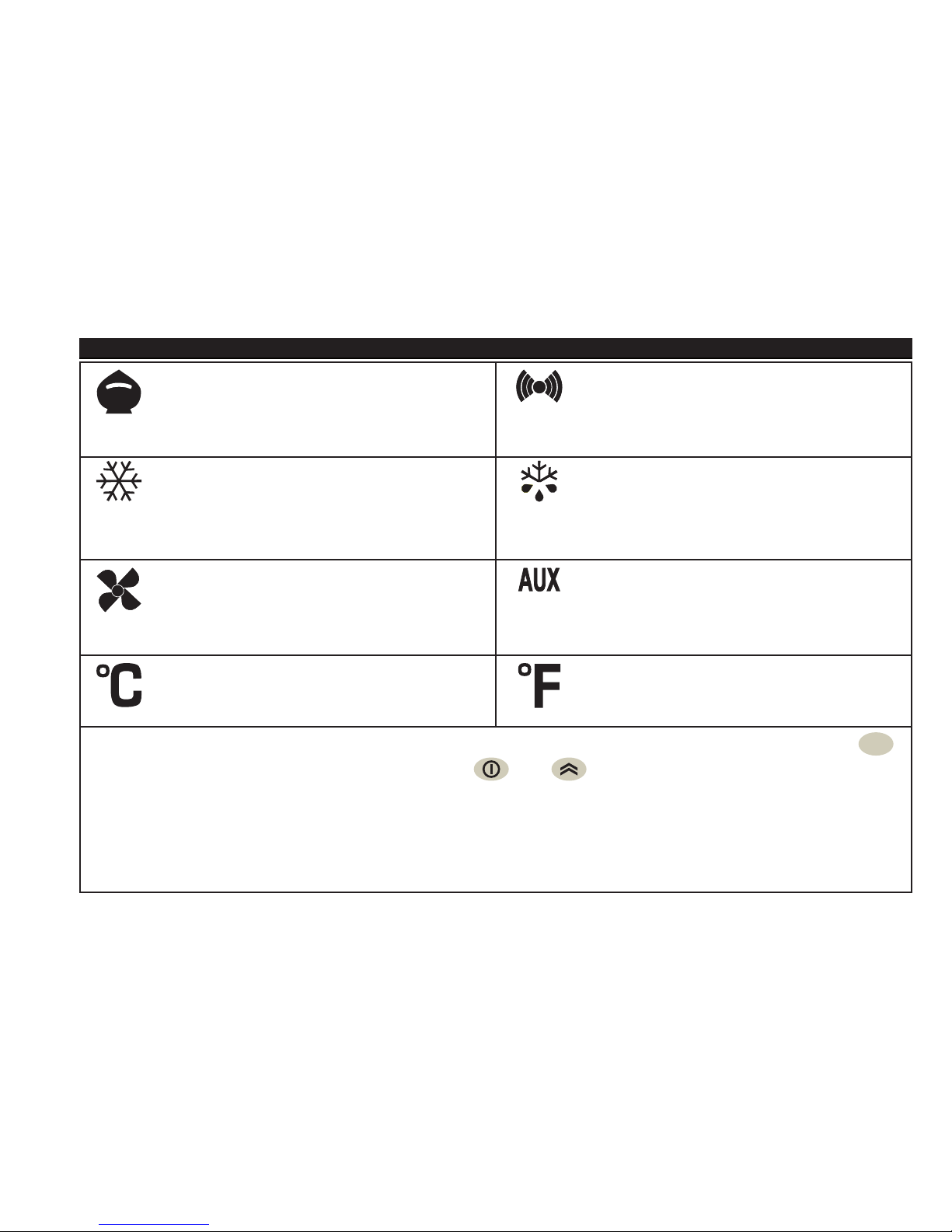

ID

PLUS

971/974

IDPlus 971/974 USER INTERFACE

Reduced SET / Economy LED

Flashing: economy Setpoint active

Quick flashing: access to level2 parameters

Off: otherwise

Compressor LED

Permanently on: compressor active

Flashing: a delay, a protection or a

locked start-up

Off: otherwise

Alarm LED

Permanently on: alarm active

Flashing: alarm acknowledged

Off: otherwise

°C LED

Permanently on: °C setting (dro =0)

Off: otherwise

°F LED

Permanently on: °F setting (dro =1)

Off: otherwise

LEDs

Defrost LED

Permanently on: defrost active

Flashing: manual or D.I. activation

Off: otherwise

Fans LED

Permanently on: fans active

Off: otherwise

Aux LED

Permanently on: Aux output active

Flashing: manual or D.I. activation of

Deep Cooling

* When switched on, the device performs a Lamp Test; the display and LEDs will flash for several

seconds to check that they all function correctly.

* To activate the LOC function: - enter the “Basic Commands” menu by pressing the key

set

.

- press keys and within 2 seconds.

If the LOC function is Active and you try to enter the “Programming” menu, the text LOC

appears. If this happens, the parameters are still displayed but cannot be edited.

To disable the keypad lock, repeat the aforementioned procedure.

IDPLUS 902/961 CONNECTIONS

IDPlus 902: TERMINALS IDPlus 961: TERMINALS

OUT1

OUT1 relay 2-3-4: 12Va or 5-6-7: 230Va

1-2: Compressor relay

Supply

6-7: models 12Va or 3-4: models 230Va

Supply

6-7: models 12Va or 3-4: models 230Va

N-L 230V

a power supply N-L 230Va power supply

10-9 Probe Pb1 10-9 Probe Pb1

10-11 Digital Input 1/ Pb3 probe 10-11 Digital Input 1/ Pb3 probe

TTL TTL Input TTL TTL Input

version with Pb3

(H11=0 and H43=y)

version with D.I.1

(H11≠0 and H43=n)

Pb3

9

10

Pb1

11

8

D.I.1

9

10

Pb1

11

8

Probe

connections

MODELS 12V~/c

2 3 4 5 6 7

ID

PLUS

902

Load

N

L

8 9 10 11

TTL

Power

Supply

MODELS 12V~/c

D

PLUS

961

1

2

6 7

N

L

8 9 10 11

TTL

Power

Supply

MODELS 230V~

D

PLUS

961

N

L

1

2

3 4

8 9 10 11

TTL

Power

Supply

MODELS 230V~

3 4 5 6 7

D

PLUS

902

Load

N

L

8 9 10 11

TTL

Power

Supply

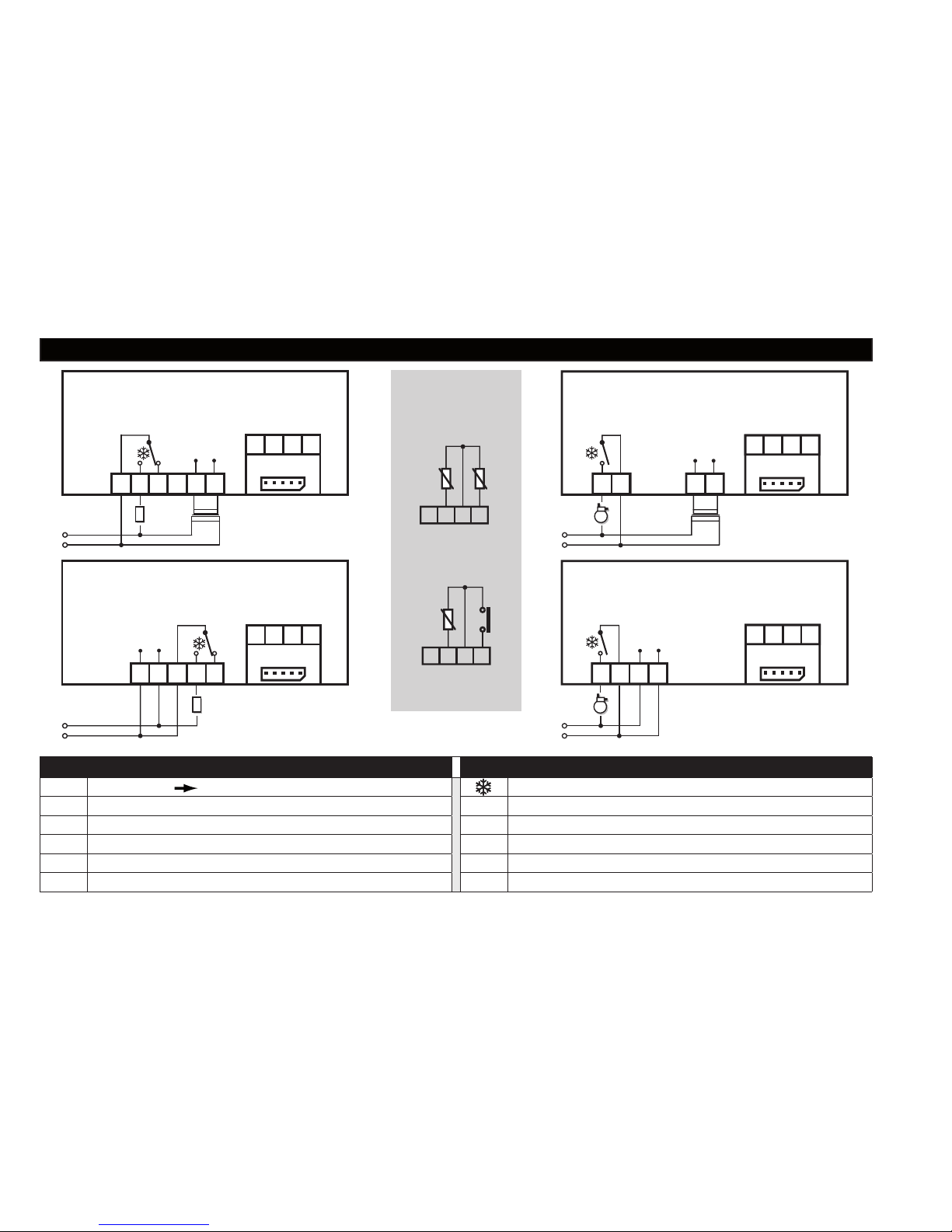

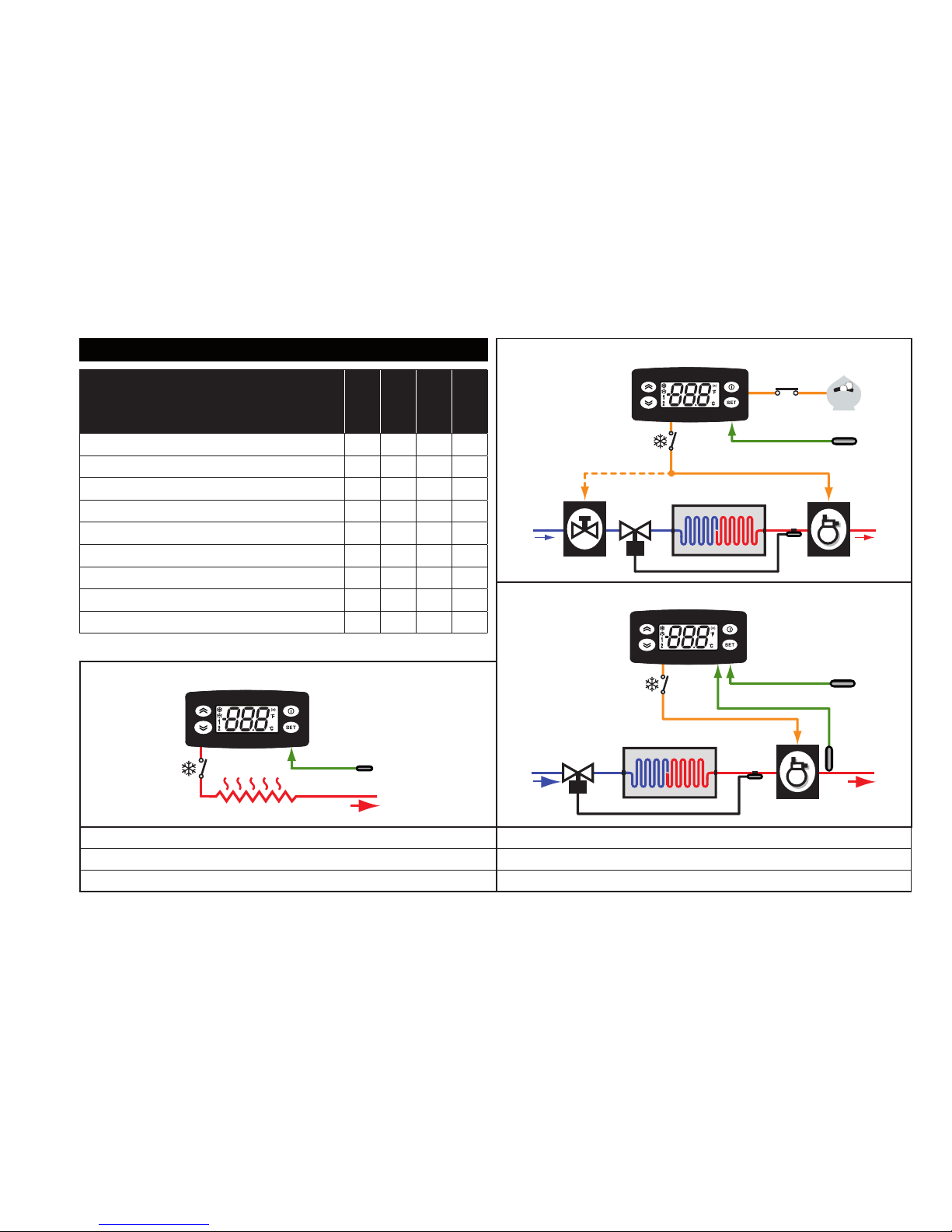

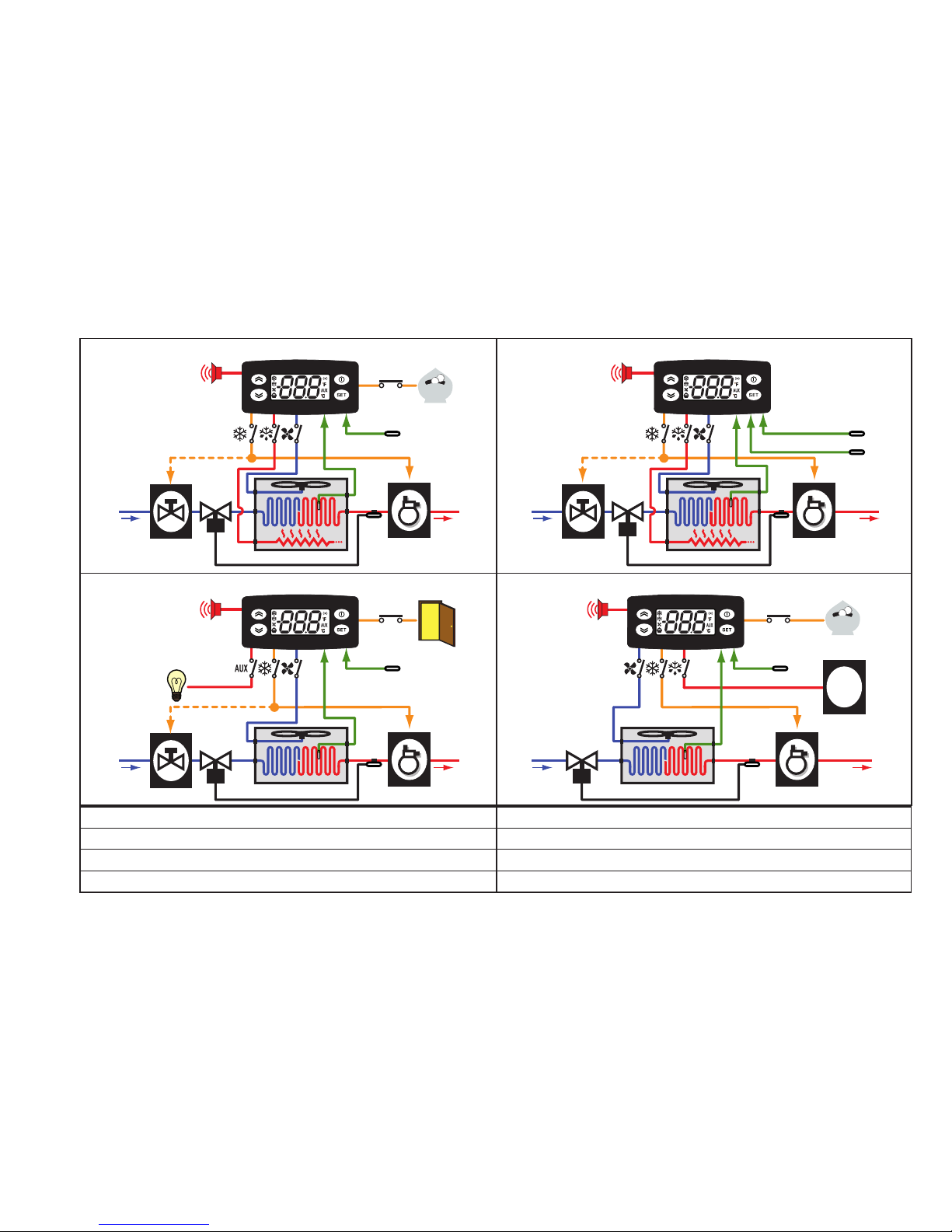

F = Functions

H = Inputs and Outputs

R = Relay Output

APP.1APP.2APP.3APP.

4

Cold application X X X

Hot application X

F - Timed defrost X X

F - Alarm on Pb1 X X X X

F - Overheating X

H - Pb1 present X X X X

H - Pb3 / D.I.1 enabled D.I. D.I. Pb3

R - Compressor/Filling X X X

R - Heating elements X

Pb1

Ambient

Resistor

Pb1

Ambient

Evaporator

T.E.V.

Compressor

Pb3

Application settings

Application 1&2

Application 3

Application 4

Pb1

Ambient

Evaporator

T.E.V.

Compressor

D.I.1

1€

1€

Valve

Ambient = Ambient Valve = Valve

Evaporator = Evaporator Compressor = Compressor

Resistor = Resistor T.E.V. = Thermostatic Expansion Valve

IDPLUS 971 CONNECTIONS

IDPlus 971: TERMINALS

1-2: Compressor relay TTL TTL Input or Digital Input 2

Defrost relay 2-3-4: 12Va or 5-6-7: 230Va

10-9 Probe Pb1

Supply

6-7: models 12Va or 3-4: models 230Va

10-8 Probe Pb2

N-L 230V

a power supply 10-11 Digital Input 1/ Pb3 probe

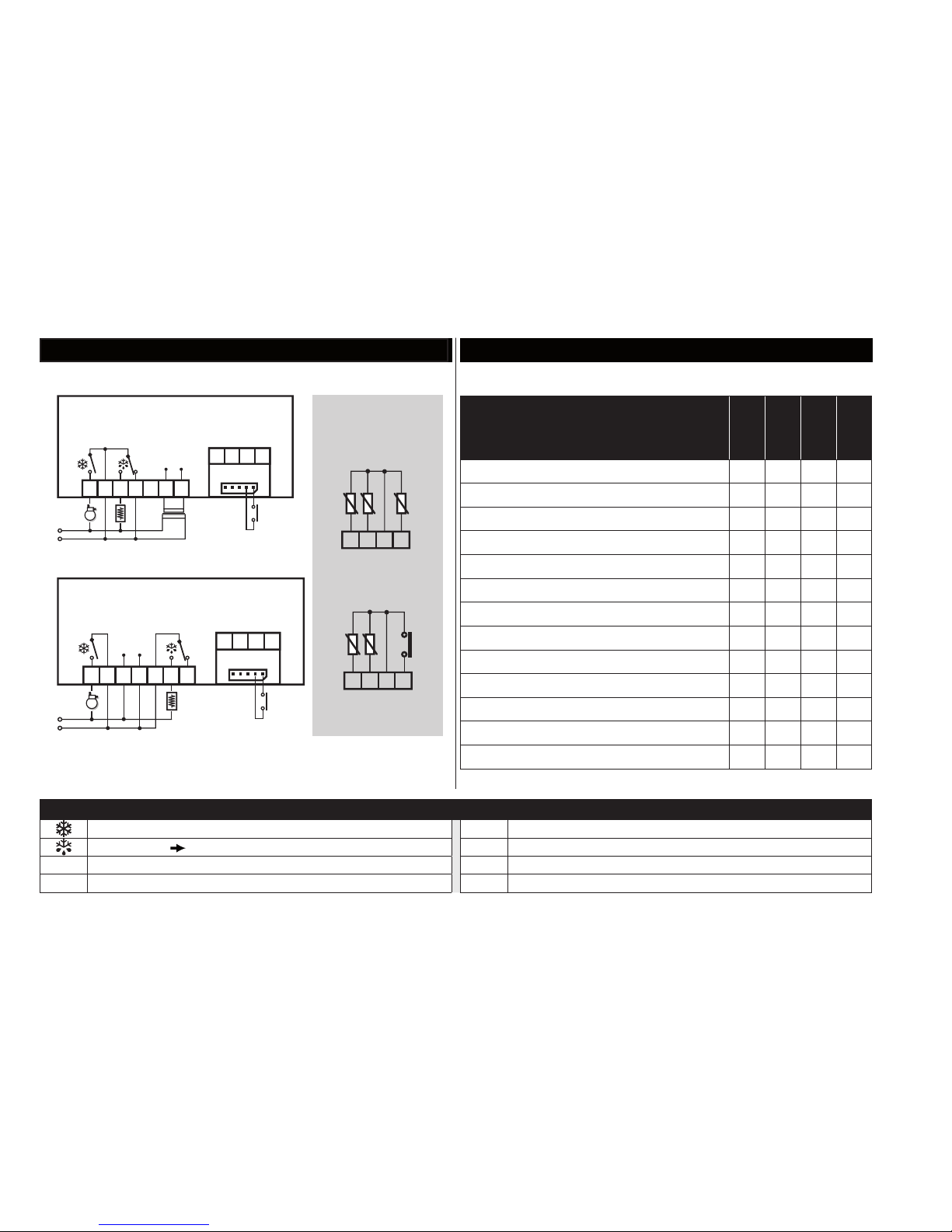

F = Functions

H = Inputs and Outputs

R = Relay Output

APP.1APP.2APP.3APP.

4

Cold application X X X X

F - End defrost by time X X

F - End defrost by temperature X X

F - Alarm on Pb1 X X X X

F - Compressor OFF X

H - Pb1 present X X X X

H - Pb2 present X X

H - Pb3 / D.I.1 enabled D.I. D.I. D.I. D.I.

H - Buzzer X

R - Compressor X X X X

R - Heating elements X X

R - Fans X

R - Alarm X

Application settings

version with Pb3

(H11=0 and H43=y)

version with D.I.1

(H11≠0 and H43=n)

Pb3

9

10

Pb1

11

8

Pb2

D.I.1

9

10

Pb1

11

8

Pb2

Probe

connections

D

PLUS

971

1

2

3

4

5 6

7

8 9 10 11

N

L

TTL

D.I.2

MODELS 12V~/c

max. 17A

Power

Supply

MODELS 230V~

D

PLUS

971

1

2

3

4

5 6

7

8 9 10 11

N

L

TTL

D.I.2

Power

Supply

Application 3

Application 1 Application 2

Application 4

Evaporator

T.E.V.

Pb1

Ambient

Valve

D.I.1

1€

1€

Compressor

Pb2

Evaporator

T.E.V.

Pb1

Ambient

Valve

D.I.1

1€

1€

Compressor

Evaporator

T.E.V.

Pb1

Ambient

Valve

D.I.1

Compressor

Pb2

Evaporator

T.E.V.

Pb1

Ambient

Valve

D.I.1

1€

1€

Compressor

External Alarm

Internal

Buzzer

Ambient = Ambient Valve = Valve

Evaporator = Evaporator Compressor = Compressor

Internal Buzzer = Internal Buzzer T.E.V. = Thermostatic Expansion Valve

External Alarm = External Alarm

IDPLUS 974 CONNECTIONS

IDPlus 974: TERMINALS

0-2: Fans relay 10-9 probe Pb1

1-2: Compressor relay 10-8 probe Pb2

Defrost relay 2-3-4: 12Va or 5-6-7: 230Va

10-11 Digital Input 1/ Pb3 probe

Supply

6-7: models 12Va or 3-4: models 230Va

TTL TTL Input or Digital Input 2

N-L 230V

a power supply

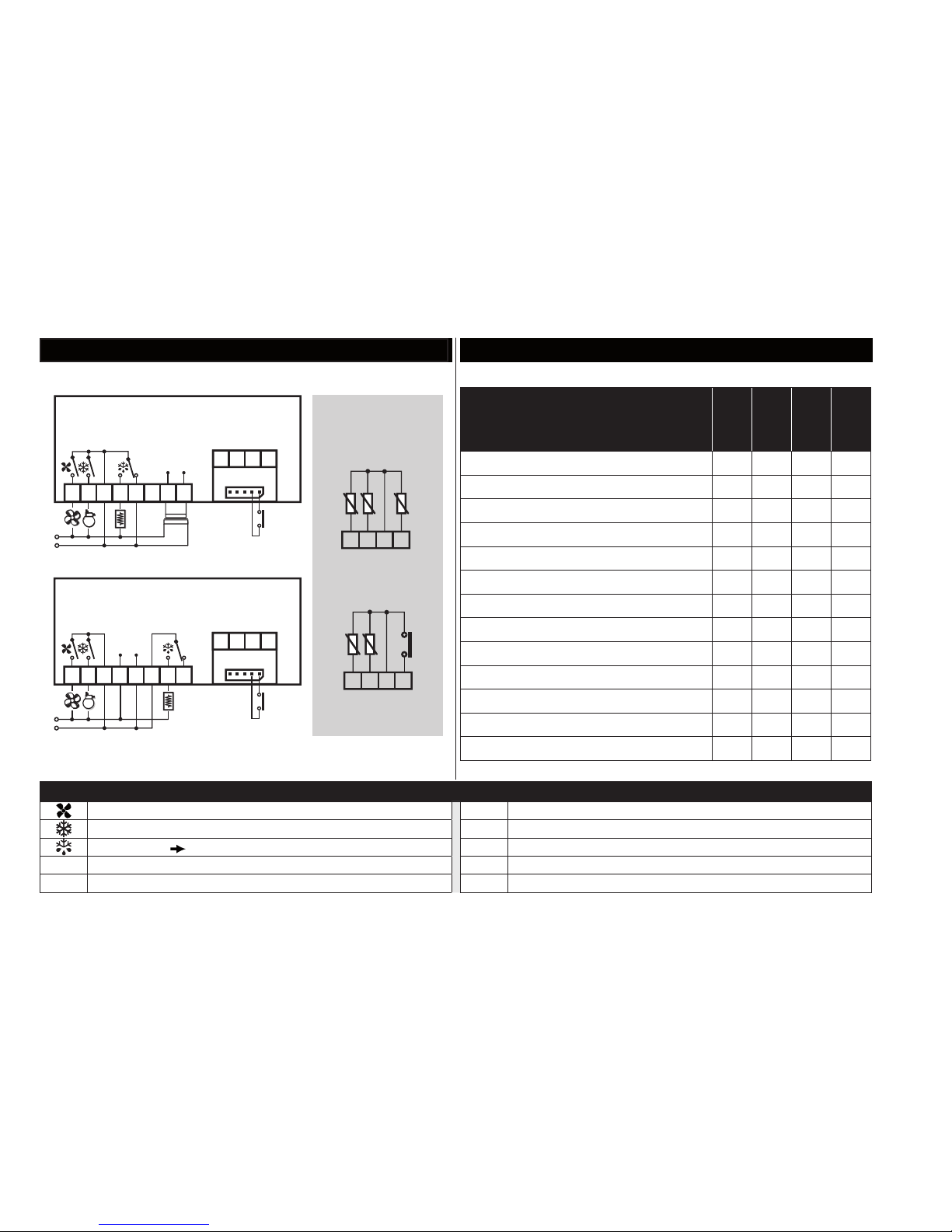

F = Functions

H = Inputs and Outputs

R = Relay Output

APP.1APP.2APP.3APP.

4

Cold application

X X X X

F - End defrost by temperature

X X X X

F - HACCP

X

F - Alarm on Pb1

X X X X

H - Pb1 present

X X X X

H - Pb2 present

X X X X

H - Pb3 / D.I.1 enabled

D.I. Pb3 D.I. D.I.

H - Buzzer

X X X X

R - Compressor

X X X X

R - Heating elements

X X

R - Fans

X X X X

R - Auxiliary

X

R - Reversing valve

X

Application settings

version with Pb3

(H11=0 and H43=y)

version with D.I.1

(H11≠0 and H43=n)

Pb3

9

10

Pb1

11

8

Pb2

D.I.1

9

10

Pb1

11

8

Pb2

Probe

connections

D

PLUS

974

1

2

3

4

5 6

7

8 9 10 11

N

L

TTL

0

D.I.2

MODELS 12V~/c

max. 17A

Power

Supply

D

PLUS

974

1

2

3

4

5 6

7

8 9 10 11

N

L

TTL

0

D.I.2

MODELS 230V~

max. 17A

Power

Supply

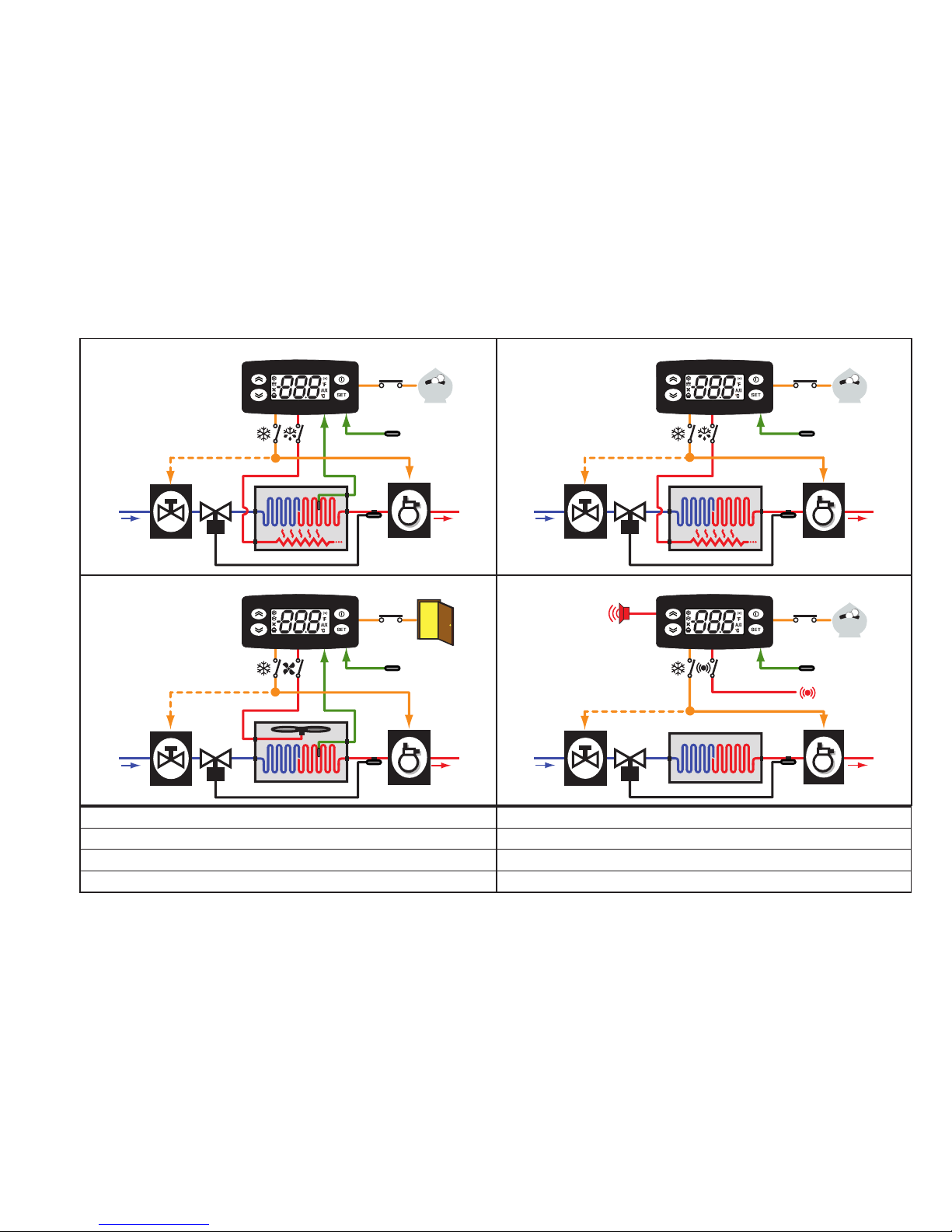

Application 3

Application 1 Application 2

Application 4

Ambient = Ambient Valve = Valve

Evaporator = Evaporator T.E.V. = Thermostatic Expansion Valve

Compressor = Compressor AUX = AUX

Reversing valve = Reversing valve Internal Buzzer = Internal Buzzer

Internal

Buzzer

Evaporator

T.E.V.

Pb1

Ambient

Valve

D.I.1

Compressor

Pb2

Internal

Buzzer

Evaporator

T.E.V.

Pb1

Ambient

Valve

D.I.1

1€

1€

Compressor

Pb2

Internal

Buzzer

Evaporator

T.E.V.

Pb1

Pb3

Ambient

HACCP

Valve

Compressor

Pb2

Internal

Buzzer

Evaporator

T.E.V.

Pb1

Ambient

D.I.1

Compressor

Pb2

1€

1€

Reversing

Valve

The keypad can be locked by entering the “Basic Commands” menu using

set

and pressing and

within 2 seconds, or by programming the “LOC” parameter (see “diS” folder). If the keypad is locked, the “Basic

Commands” menu can be accessed and the Setpoint displayed, but the value cannot be modified.

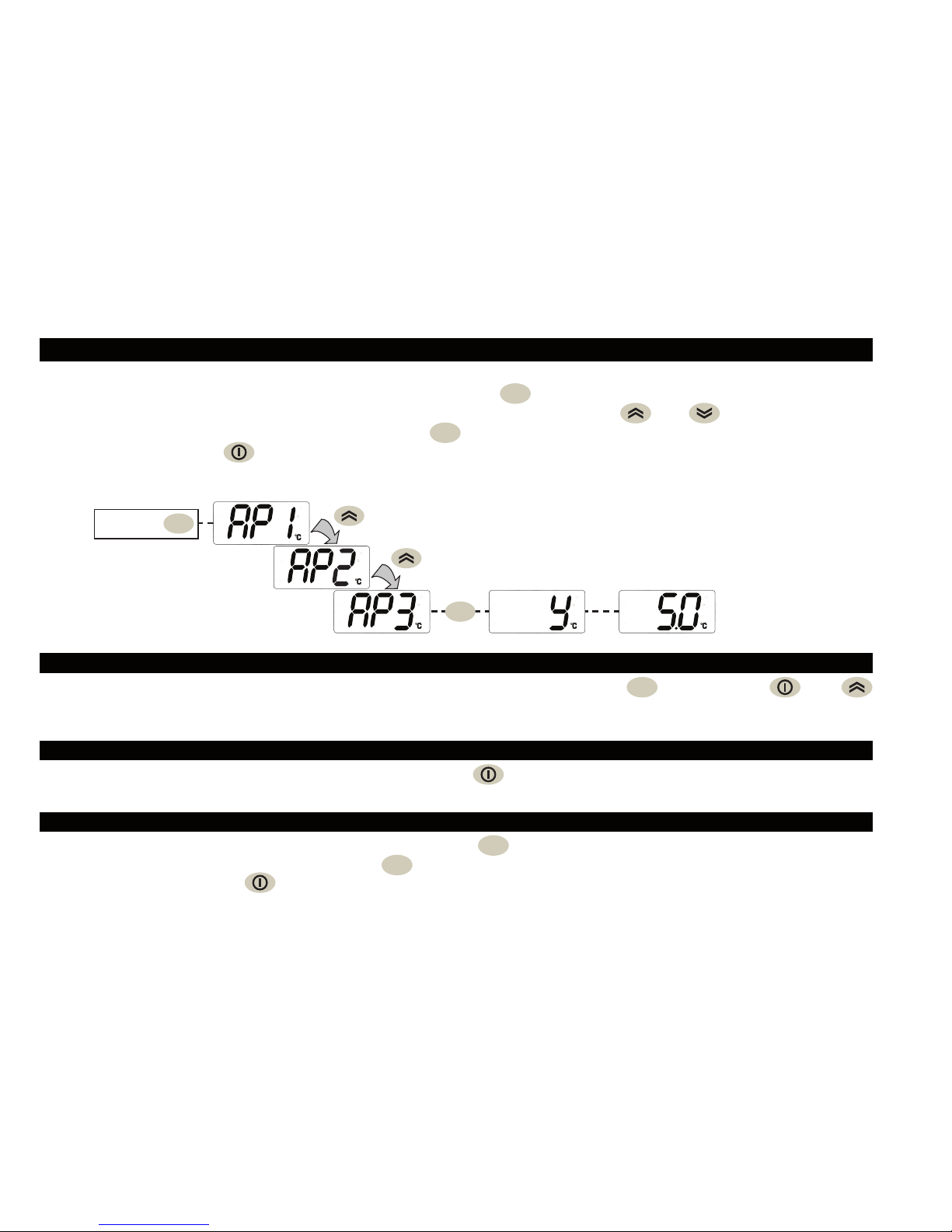

LOADING DEFAULT APPLICATIONS

The procedure used to load one of the default applications is:

• when the instrument switches on, press and hold the

set

key: the label “AP1” will appear;

• scroll through the various applications (AP1-AP2-AP3-AP4) using the

and keys;

• select the desired application using the key

set

(“AP3” in the example) or cancel the procedure by

pressing the key

; alternatively wait for the timeout;

• if the operation is successful, the display will show “y”, otherwise “n” will appear;

• after a few seconds the instrument will return to the main display.

set

Power-on +

set

ACCESSING AND USING THE MENUS

Resources are organised into menus. Press and release the

set

key to access the “Machine Status” menu.

To access the “Programming” menu, press the

set

key for more than 5 seconds. If no keys are pressed for over 15

seconds (Timeout), or if the

key is pressed, the last value to appear on the display is confirmed.

LOCK SETPOINT MODIFICATION

The instrument can be switched off by pressing the key for longer than 5 seconds. In this condition, the

adjustment algorithms and defrost cycles are disabled and the text “OFF” will appear on the display.

INSTRUMENT ON/OFF

MOUNTING - DIMENSIONS

74mm

32mm

29mm

71mm

70mm

67mm

The device is designed for panel mounting. Drill a 29x71 mm hole and insert the instrument; secure it with the

special brackets provided. Do not install the instrument in damp and/or dirty places; in fact, it is suitable for use

in places with ordinary or normal levels of pollution.

Keep the area around the instrument cooling slots adequately ventilated.

Alarms are always indicated by the buzzer (if present) and the alarm icon

.

To switch off the buzzer, press and release any key; the corresponding icon will continue to flash.

N.B.: If alarm exclusion times have been set (see “AL” folder) the alarm will not be signalled.

In the event of an alarm caused by a malfunctioning ambient probe (Pb1), the indication “E1” will appear on the

display. For a malfunctioning evaporator probe (Pb2), the indication “E2” will appear (IDPlus 971/974 only).

Finally, for a malfunctioning Pb3 probe, the indication “E3” will appear on the display.

DIAGNOSTICS

Hold down the key for longer than 5 seconds. It is only activates if the temperature conditions are fulfilled.

Otherwise, the display will flash three times to indicate that the operation will not be performed.

MANUAL DEFROST CYCLE ACTIVATION

ALARMS

Label Fault Cause Effects Remedy

E1

Cold room

probe1 faulty

• measured values are outside operating

range

• Probe faulty/short-circuited/open

• Display label E1

• Alarm icon permanently on

• Disable max/min alarm controller

• Compressor operation based on parameters

“Ont” and “OFt”.

• check probe type (par. H00)

• check probe wiring

• replace probe

E2

Defrost probe2

faulty

only on IDPlus

971/974

• measured values are outside operating

range

• probe faulty/short-circuited/open

• Display label E2

• Alarm icon permanently on

• The Defrost will end due to Timeout (dEt)

• The evaporator fans will be: on if the

compressor is ON, or running in accordance with

the FCO parameter if the compressor is OFF

• check probe type (par. H00)

• check probe wiring

• replace probe

E3 Probe3 faulty

• measured values are outside operating

range

• probe faulty/short-circuited/open

• Display label E3

• Alarm icon permanently on

• check probe type (par. H00)

• check probe wiring

• replace probe

AH1

Alarm for HIGH

Pb1 temperature

value read by Pb1 > HAL after time of

“tAO” (see “MAX/MIN TEMP. ALARMS)

• Recording of label AH1 in folder AL

• No effect on regulation

Wait until value read by Pb1 returns

below HAL

AL1

Alarm for LOW

Pb1 temperature

value read by Pb1 < LAL after time of

“tAO” (see “MAX/MIN TEMP. ALARMS)

• Recording of label AL1 in folder AL

• No effect on regulation

Wait until value read by Pb1 returns

above LAL

EA External alarm

Digital input activated

(H11 = ±5)

• Recording of label EA in folder AL

• Alarm icon permanently on

• Regulation locked if rLO = y

check and remove the external cause

which triggered the alarm on the D.I.

OPd Door open alarm

digital input activation

(H11 = ±4)

(for longer than tdO)

• Recording of label Opd in folder AL

• Alarm icon permanently on

• Controller locked

• close the door

• delay function defined by OAO

Ad2

Defrost due to

timeout

end of defrost cycle due to timeout rather

than due to defrost end temperature being

recorded by Pb2

• Recording of label Ad2 in folder AL

• Alarm icon permanently on

wait for the next defrost cycle for

automatic return

Label Fault Cause Effects Remedy

COH

Over Heating

alarm

Pb3 value set by parameter SA3 exceeded

• Recording of label COH in folder AL

• Alarm icon permanently on

• Regulation locked (Compressor)

• wait for the temperature to return

to a value of SA3 (Setpoint) minus

dA3 (differential)

nPA

General pressure

switch alarm

Activation of pressure alarm by general

pressure switch

If the number N of pressure switch activations is:

N < PEn:

• Recording of folder nPA in folder AL, with the

number of pressure switch activations

• Regulation locked (Compressor and Fans)

• check and remove the cause which

triggered the alarm on the D.I.

(Automatic Reset)

PAL

General pressure

switch alarm

Activation of pressure alarm by general

pressure switch

If the number N of pressure switch activations is:

N = PEn:

• Display label PAL

• Recording of label PA in folder AL

• Alarm LED steady

• Regulation locked (Compressor and Fans)

• Switch the device off and back

on again

• Reset alarms by entering the

functions folder and selecting the

rAP function (Manual Reset)

HC n

Max/Min Pb3

value when out

of range (SLH...

SHH)

Logs the Max/Min value recorded by Pb3

when it exceeds range SLH...SHH.

“n” represents the sequential number of

times the range is exceeded.

• Recording of folder “HC n” in folder AL

• Alarm LED steady

• No effect on regulation

NB: “n” can assume the values 1 to 8.

If n > 8, folder HC8 will flash and the

system will overwrite folders where n=1

tC n

Pb3 out-of-range

dwell time

(SLH...SHH)

Stores the dwell time of the Pb3 value outside

range SLH...SHH. n” represents the sequential

number of times the range is exceeded.

• Recording of folder “tC n” in folder AL

• Alarm LED steady

• No effect on regulation

NB: “n” can assume the values 1 to 8.

If n > 8, folder HC8 will flash and the

system will overwrite folders where n=1

bC n

Value recorded

by Pb3 on return

from bOt

Logs the value recorded by Pb3 on return

from a blackout. “n” represents the sequential

number of blackouts that have occurred.

• Recording of folder “bC n” in folder AL

• No effect on regulation

NB: “n” can assume the values 1 to 8.

If n > 8, folder bC8 will flash and the

system will overwrite folders where n=1

bt n

Pb3 out-of-range

dwell time

during bOt

Stores the out-of-range dwell time of the

Pb3 value during a blackout.

“n” represents the sequential number of

blackouts that have occurred.

• Recording of folder “bt n” in folder AL.

The value contained will be 0 if the value of

Pb3 has remained within the range, ≠ 0 if the

value has gone outside of the range

• No effect on regulation

N.B.: “n” can assume the values

1 to 8.

If n > 8, folder bC8 will flash and

the system will overwrite folders

where n=1

NOTE: to delete folders “HC n”, “tC n”, “bC n” and “bt n” from folder AL, start function rES in folder FnC.

Password “PA1”: used to access User parameters. The password is not enabled by default (PS1=0).

To enable it (PS1≠0): press and hold

set

for longer than 5 seconds, scroll through the parameters using and

until you see the label PS1, press

set

to display the value, modify it using and , then save it by pressing

set

or . If enabled, it will be required in order to access the User parameters.

Password “PA2”: used to access Installer parameters. The password is enabled by default (PS2=15).

To modify it (PS2≠15): press

set

and hold for longer than 5 seconds, scroll through the parameters using and

until you see the label PA2, press

set

, set the value to “15” using and , then confirm using

set

.

Scroll through the folders until you find the label diS and press

set

to enter. Scroll through the parameters using

and until you see the label PS2, press

set

to display the value, modify it using and , then save it by

pressing

set

or . The visibility of “PA2” is as follows:

1) PA1 and PA2 ≠ 0: Press and hold

set

for longer than 5 seconds to display “PA1” and “PA2”. It will then be

possible to decide whether to access the User (PA1) or the Installer (PA2) parameters.

2) Otherwise: The password “PA2” is amongst the level1 parameters. If enabled, it will be required when

accessing the Installer parameters; to enter it, proceed as instructed for password “PA1”.

If the password entered is incorrect, the label PA1/PA2 will be displayed again and the procedure will need to be

repeated.

PASSWORD

The Copy Card is connected to the serial port (TTL) and allows rapid programming of the instrument parameters.

Access Installer parameters by entering “PA2”, scroll through the folders using

and until folder FPr appears.

Select it using

set

, scroll through the parameters using and , then select the function using

set

(e.g. UL).

• Upload (UL): Select UL and press

set

. This function uploads the programming parameters from the instrument to

the card. If the procedure is a success, “y”, will appear on the display, otherwise “n” will appear.

• Format (Fr): This command is used to format the copy card, (recommended when using the card for the first time).

Important: the Fr parameter deletes all data present. This operation cannot be cancelled.

• Download: Connect the Copy Card when the instrument is switched off. At power-on, data is downloaded from the

copy card to the instrument automatically. At the end of the lamp test, the display will show “dLy” if the

operation was successful and “dLn” if not.

NOTE: After downloading, the instrument works with the settings of the new map just downloaded.

USING THE COPY CARD

PROGRAMMING MENU

To access the “Programming” menu, press the

set

key for more than 5 seconds. If specified, an access PASSWORD

will be requested: “PA1” for User parameters and “PA2” for Installer parameters (see “PASSWORD” paragraph).

User parameters: When accessed, the display will show the first parameter (e.g. “diF”). Press

and to scroll

through all the parameters on the current level. Select the desired parameter by pressing

set

. Press and to

modify it and

set

to save the changes.

Installer parameters: When accessed, the display will show the first folder (e.g. “CP”). Press

and to scroll

through the folders on the current level. Select the desired folder using

set

. Press and to scroll through the

parameters in the current folder and select the parameter using

set

. Press and to modify it and

set

to save

the changes.

NOTE

: Make sure you switch the instrument off and on again each time the parameter configuration is changed, in

order to prevent malfunctioning in the configuration and/or timing in progress.

MACHINE STATUS MENU

Access the Machine Status menu by pressing

set

and releasing the key. If no alarms are active, the “SEt” label

appears. Use the keys

and to scroll through all the folders in the menu:

- AL: alarms folder (only visible if an alarm is active);

- SEt: Setpoint setting folder;

- Pb1: probe 1 - Pb1 folder;

- Pb2: probe 2 - Pb2* folder(IDPlus 971/974 models only);

- Pb3: probe 3 - Pb3** folder;

* folder displayed if Pb2 present (H42 = y)

** folder displayed if Pb3 present (H11 = 0 and H43 = y)

Setting the Setpoint: To display the Setpoint value press the

set

key when the “SEt” label is displayed.

The Setpoint value appears on the display. To change the Setpoint value, press the

and

keys within 15 seconds. Press

set

to confirm the modification.

Displaying the probes: When labels Pb1, Pb2 or Pb3 are present, press the

set

key to view the value measured

by the corresponding probe (NOTE: the value cannot be modified).

set

MAX/MIN TEMPERATURE ALARMS

Temperature as a

value relative to Setpoint (Att=1)

Temperature as an

Absolute value (Att=0)

Temp. ≤ Set + LAL *

Temp. ≥ Set + HAL **

Temp. ≥ Set + LAL + AFd or

≥ Set - ILALI + AFd (LAL < 0)

Temp. ≤ Set + HAL - AFd (HAL > 0)

Temp. ≤ LAL (LAL with sign)

Temp. ≥ HAL (HAL with sign)

Temp. ≥ LAL + AFd

Temp. ≤ HAL - AFd

Minimum alarm

Maximum alarm

Returning from minimum

temperature alarm

Returning from maximum

temperature alarm

* if LAL is negative, Set + LAL < Set

** if HAL is negative, Set + HAL < Set

Setpoint - LAL

AFd

Off

Setpoint + HAL

AFd

Setpoint - LAL + AFd

Setpoint + HAL - AFd

Setpoint

LAL

AFd

HAL

AFd

LAL + AFd

HAL - AFd

LIABILITY AND RESIDUAL RISKS

ELIWELL CONTROLS SRL declines any liability for damage due to:

- installation/uses different from those specified and, in particular, not complying with the safety regulations

and/or instructions given in this document;

- use on panels that do not provide adequate protection against electric shocks, water or dust when

assembled;

- use on panels allowing access to dangerous parts without the use of tools;

- tampering with and/or modifying the product;

- installation/use on panels not complying with current standards and regulations.

DISCLAIMER

This document is the exclusive property of ELIWELL CONTROLS SRL and may not be

reproduced or circulated unless expressly authorised by ELIWELL CONTROLS SRL itself.

Every care has been taken in preparing this document; nevertheless ELIWELL CONTROLS SRL cannot

accept liability for any damage resulting from its use. The same applies to any person or company involved

in preparing and editing this document. ELIWELL CONTROLS SRL reserves the right to make aesthetic or

functional changes at any time without notice.

ELECTRICAL CONNECTIONS

Attention! Make sure the machine is switched off before working on the electrical connections.

The instrument is equipped with screw or disconnectable terminal blocks for connecting electrical cables with a

max. diameter of 2.5 mm

2

(one wire per terminal for power connections): for the terminal ratings, see the label

on the instrument. Do not exceed the maximum permissible current; in case of higher loads, use a suitably rated

contactor. Make sure the power supply voltage complies with that required by the instrument.

Probes have no connection polarity and can be extended using a normal bipolar cable (note that the extension

of the probes influences the electromagnetic compatibility - EMC - of the instrument: take great care with the

wiring).

Probe cables, power supply cables and the TTL serial cable should be routed separately from power cables.

CONDITIONS OF USE

Permitted use

For safety reasons, the instrument must be installed and used according to the instructions supplied and, in

particular, parts under dangerous voltages must not be accessible in normal conditions. The device must be

adequately protected from water and dust with regard to its application, and must only be accessible using tools

(except for the front panel). The device is suitable for use in household refrigeration appliances and/or similar

equipment and has been tested for safety aspects in accordance with the harmonised European reference

standards.

Improper use

Any use other than that expressly permitted is prohibited. The relay contacts provided are of a functional

type and subject to failure: any protection devices required by product standards, or suggested by common

sense for obvious safety requirements, must be installed externally to the instrument.

Classification: operation (not safety) device for incorporation

Mounting: panel mounting with 71x29 mm (+0.2/-0.1 mm) drilling template

Type of action: 1.B

Pollution class: 2

Material class: IIIa

Overvoltage category: II

Rated impulse voltage: 2500V

Temperature: Use: -5 … +55°C - Storage: -30 … +85 °C

Power supply: 12Va/c (

±10%) 50/60 Hz or 230Va (±10%) 50/60 Hz

Consumption: 4.5W max

Digital outputs (relay): refer to the label on the device

Fire resistance category: D

Software class: A

NOTE: check the power supply specified on the instrument label; contact our Sales Office for power supply

and relay ratings.

TECHNICAL DATA (EN 60730-2-9)

FURTHER INFORMATION

Input Characteristics

Display range: NTC: -50.0°C ... +110°C; PTC: -55.0°C ... +140°C; PT1000: -55.0°C ... +150°C

(on display with 3 digits + sign)

Accuracy: NTC, PTC, PT1000 (-55,0°C...+70°C): Better than 0.5% of full scale +1 digit

PT1000 (+70,0°C...+150°C): Better than 0.6% of full scale +1 digit

Resolution: 0.1 °C

Buzzer: YES (depending on model)

Analogue inputs: IDPlus 902/961: 1 NTC (default)/PTC/PT1000 (can be selected using parameter H00)

IDPlus 971/974: 2 NTC (default)/PTC/PT1000 (can be selected using parameter H00)

Digital inputs: IDPlus 902/961: 1 voltage-free digital input;

IDPlus 971/974: 2 voltage-free digital inputs

N.B.: - D.I.1 can also be configured as a probe input (H11=0 and H43=y)

- D.I.2, if activated, should be connected to terminals 1-2 of the TTL (IDPlus 971/974)

Output Characteristics

Digital outputs: IDPlus 902: 1 OUT1 relay: N.O. 8(4)A - N.C. 6(3)A max 250Va

IDPlus 961: 1 Compressor relay: UL60730 (A) 2Hp (12FLA - 72LRA) max 240Va

IDPlus 971: 1 Defrost relay: N.O. 8(4)A - N.C. 6(3)A max 250Va

1 Compressor relay: UL60730 (A) 2Hp (12FLA - 72LRA) max 240Va or

IDPlus 974: 1 Defrost relay: N.O. 8(4)A - N.C. 6(3)A max 250Va

1 Compressor relay: UL60730 (A) 2Hp (12FLA - 72LRA) max 240Va or

1 Fans relay: 5(2)A max 250Va

Mechanical Characteristics

Casing: PC+ABS UL94 V-0 resin casing, polycarbonate window, thermoplastic resin keys

Dimensions: front panel 74x32 mm, depth 59 mm (without terminals)

Terminals: screw/disconnectable terminals for cables with a diameter of 2.5mm

2

Connectors: TTL for connection of Copy Card + D.I.2 (IDPlus 971/974 models only)

Humidity: Use / Storage: 10…90% RH (non-condensing)

Regulations

Electromagnetic compatibility: The device conforms to Directive 2004/108/EC

Safety: The device conforms to Directive 2006/95/EC

Food Safety: The device complies with standard EN 13485 as follows:

- suitable for storage

- application: air

- climate range A

- measurement class 1 in the range from -25°C to 15°C (*)

(* exclusively using Eliwell probes)

NOTE: The technical specifications given in this document regarding measurement (range, accuracy, resolution,

etc.) refer to the instrument and not to any accessories provided, such as the probes. This means, for example, that

the error introduced by the probe must be added to the typical error of the instrument.

IDPlus 902/961 devices are controllers with 1 relay output, 1 temperature regulation sensor

and 1 multifunctional Digital/Temperature input.

Temperature control and compressor start/stop, plus natural defrost on compressor stop.

Heating function: the controller can also be used as a simple ON/OFF thermostat for heating

applications.

The Digital input (D.I.) can be used for:

- Energy saving

- Defrost activation

- door switch

- Standby

- external alarm

- Deep Cooling

- pressure switch

- HACCP alarms

DESCRIPTION OF IDPLUS 902/961 FAMILY

TABLE OF USER MENU PARAMETERS (IDPLUS 902/961)

PAR. DESCRIPTION RANGE APP1 APP2 APP3 APP4 M.U.

SEt Temperature control SEtpoint LSE ... HSE 0,0 0,0 0,0 -2,0 °C/°F

diF Compressor relay activation differential 0,1 ... 30,0 2,0 2,0 2,0 0,1 °C/°F

HSE Maximum value that can be assigned to the Setpoint LSE ... 302 99,0 140 140 5,0 °C/°F

LSE Minimum value that can be assigned to the Setpoint -58.0 ... HSE -50,0 -55,0 -55,0 -10,0 °C/°F

dit Interval between the start of two consecutive defrost cycles 0 ... 250 6 8 hours

dEt Defrost timeout 1 ... 250 30 30 min

HAL Maximum temperature alarm LAL ... 150 50,0 150 150 50,0 °C/°F

LAL Minimum temperature alarm -50.0 ... HAL -50,0 -50,0 -50,0 -50,0 °C/°F

SA3 Probe 3 alarm Setpoint -50.0 ... 150 70,0 °C/°F

LOC Basic commands modification lock n/y n n n n flag

PS1 PAssword 1 for access to QUICK menu parameters 0 ... 250 0 0 0 0 num

CA1 Calibration1. Value to be added to the value read by probe 1 -12,0 ... 12,0 0,0 0,0 0,0 0,0 °C/°F

CA3 Calibration3. Value to be added to the value read by probe 3 -12,0 ... 12,0 0,0 °C/°F

ddL Display mode during defrost 0/1/2 0 0 num

Ldd Display lock disabling timeout. 0 = function disabled 0 ... 255 30 30 min

H43 Probe 3

present. n = not present; y = present n/y y flag

rEL firmware rELease. Reserved: read-only parameter / / / / / /

tAb tAble of parameters. Reserved: read-only parameter / / / / / /

Notes: ** The USER menu parameters also include “PA2”, which can be used to access the Installer menu

*** For the complete list of parameters, see: APPENDIX A: Table of Installer menu parameters

PAR. DESCRIPTION RANGE App1 App2 App3 App4 M.U.

SEt Temperature control SEtpoint. LSE ... HSE 0,0 0,0 0,0 -2,0 °C/°F

COMPRESSOR (“CP” folder)

diF diFferential. Compressor relay activation differential. 0,1...30,0

2,0 2,0 2,0 0,1

°C/°F

HSE Higher SEt. Maximum value that can be assigned to the Setpoint. LSE...302 99,0 140 140 5,0 °C/°F

LSE Lower SEt. Minimum value that can be assigned to the Setpoint. -58.0...HSE -50,0 -55,0 -55,0 -10,0 °C/°F

OSP

Temperature value to be added to the Setpoint if reduced set enabled

(Economy function).

-30,0...30,0 3,0 3,0 0,0 0,0 °C/°F

Hc Control mode. “H” = Hot, “C” = Cold. C/H C C H C flag

Ont

Controller on time for faulty probe.

if Ont = 1 and OFt = 0, the compressor remains on;

if Ont =1 and OFt>0 it runs in duty cycle mode.

0 ... 250 0 0 0 0 min

OFt

Controller off time for faulty probe.

if OFt = 1 and Ont = 0, the controller remains off;

if OFt = 1 and Ont > 0, it operates in duty cycle mode.

0 ... 250 1 1 1 1 min

dOn Compressor relay activation delay after request. 0 ... 250 0 0 0 0 secs

dOF Delay after switching off and subsequent activation. 0 ... 250 0 0 0 0 min

dbi Delay between two consecutive compressor activations. 0 ... 250 0 0 0 0 min

OdO

(!)

Delay in activating outputs after the instrument is switched on or after a power failure.

0 = not active.

0 ... 250 0 0 0 0 min

dcS Deep Cooling cycle Setpoint. -58,0...302 0,0 0,0 0,0 0,0 °C/°F

tdc Deep Cooling cycle duration. 0 ... 255 0 0 0 0 min*10

dcc Defrost activation delay after a Deep Cooling cycle. 0 ... 255 0 0 0 0 min

DEFROST (“dEF” folder)

dit Interval between the start of two consecutive defrost cycles. 0 ... 250 6 0 0 8 hours

dCt

Selection of count mode for the defrost interval.

0 = compressor running time;

1 = appliance running time;

2 = A defrost cycle is run at each compressor stop.

0/1/2 1 1 1 1 num

TABLE OF INSTALLER MENU PARAMETERS (IDPLUS 902/961)

PAR. DESCRIPTION RANGE App1 App2 App3 App4 M.U.

dOH Delay for start of first defrost after request. 0 ... 59 0 0 0 0 min

dEt Defrost timeout; determines the maximum defrost duration. 1 ... 250 30 1 1 30 min

dPO Determines whether the instrument must enter defrost mode at start-up. n/y n n n n flag

ALARMS (“AL” folder)

Att

Can be used to select absolute (Att=0) or relative (Att=1) values for HAL and LAL

parameters.

0/1

0 0 0 0

num

Afd Alarm differential. 1,0 ... 50,0 2,0 2,0 2,0 2,0 °C/°F

HAL Maximum temperature alarm. LAL...302 50,0 150 150 50,0 °C/°F

LAL Minimum temperature alarm. -58.0...HAL -50,0 -50,0 -50,0 -50,0 °C/°F

PAO Alarm exclusion time after re-activation following a power failure. 0 ... 10 0 0 0 0 hours

dAO Temperature alarm exclusion time after defrost. 0 ... 999 0 0 0 0 min

OAO Alarm signalling delay after disabling of digital input. 0 ... 10 0 0 0 0 hours

tdO Delay in door open alarm activation. 0 ... 250 0 0 0 0 min

tAO Time delay for temperature alarm indication. 0 ... 250 0 0 0 0 min

rLO An external alarm locks the controllers. n = does not lock; y = locks. n/y n n n n flag

SA3 Probe 3 alarm Setpoint. -58,0...302 0,0 0,0 0,0 70,0 °C/°F

dA3 Probe 3 alarm differential. 1,0 ... 50,0 1,0 1,0 1,0 10,0 °C/°F

LIGHTS & DIGITAL INPUTS (“Lit” folder)

dOd

Digital input for switching off utilities.

0 = disabled; 1 = disables fans;

2 = disables the compressor; 3 = disables fans and compressor.

0/1/2/3

0 0 0 0

num

dAd Activation delay for digital input. 0 ... 255 0 0 0 0 min

dCO Compressor deactivation delay after door opened. 0 ... 255 1 1 1 1 min

PRESSURE SWITCH (“PrE” folder)

Pen Number of errors allowed per maximum/minimum pressure switch input. 0 ... 15

0 0 0 0

num

PEI Minimum/maximum pressure switch error count interval. 1 ... 99 1 1 1 1 min

PEt Delay in activating compressor after pressure switch deactivation. 0 ... 255 0 0 0 0 min

PAR. DESCRIPTION RANGE App1 App2 App3 App4 M.U.

COMMUNICATION (“Add” folder)

PtS Communication protocol selection. t = Televis; d = Modbus. t/d t t t t flag

dEA Index of the device inside the family (valid values from 0 to 14). 0 ... 14 0 0 0 0 num

FAA Device family - valid values from 0 to 14. 0 ... 14 0 0 0 0 num

Pty Modbus parity bit. n = none; E = even; o = odd. n/E/o n n n n num

StP Modbus stop bit. 1b/2b 1b 1b 1b 1b flag

DISPLAY (‘diS’ folder)

LOC

Basic commands modification lock. It is still possible to enter parameter programming

mode and modify them. y = yes; n = no.

n/y

n n n n

flag

PS1 PAssword1: if PS1≠0 is the access key to "User" parameters. 0 ... 250 0 0 0 0 num

PS2 PAssword2: if PS2≠0 is the access key to "Installer" parameters. 0 ... 250 15 15 15 15 num

ndt Display with decimal point. y = yes; n = no. n/y y y y y flag

CA1 Calibration 1. Temperature value to be added to the Pb1 value. -12,0...12,0 0,0 0,0 0,0 0,0 °C/°F

CA3 Calibration 3. Temperature value to be added to the Pb3 value. -12,0...12,0 0,0 0,0 0,0 0,0 °C/°F

ddL

Display mode during defrost.

0= display temperature recorded by Pb1;

1= lock recorded Pb1 value at the start of the defrost cycle; 2= display the “dEF” label.

0/1/2 0 0 0 0 num

Ldd Timeout value for display unlock - dEF label 0 ... 255 30 30 30 30 min

dro

Select the unit of measurement used when displaying the temperature recorded by the

probes. (0 = °C, 1 = °F).

NOTE: switching between °C and °F or vice-versa DOES NOT modify the SEt,

diF values, etc. (e.g. Setpoint=10°C becomes 10°F)

0/1 0 0 0 0 flag

ddd

Selects type of value to display.

0 = Setpoint; 1 = probe Pb1; 2 = probe Pb2; 3 = probe Pb3

0/1/2/3 1 1 1 1 num

HACCP (“HCP” folder)

SHH Maximum HACCP alarm signals threshold. -55,0...150

0,0 0,0 0,0 0,0

°C/°F

SLH Minimum HACCP alarm signals threshold. -55,0...150 0,0 0,0 0,0 0,0 °C/°F

drA

Minimum time spent in critical range for the event to be recorded. After this a HACCP

alarm will be triggered and logged.

0 ... 99 0 0 0 0 min

drH HACCP alarm reset time after last reset. 0 ... 250 0 0 0 0 hours

PAR. DESCRIPTION RANGE App1 App2 App3 App4 M.U.

H50

Enable HACCP and alarm relay functions. 0 = HACCP alarms NOT enabled;

1 = HACCP alarms enabled and alarm relay NOT enabled;

2 = HACCP alarms enabled and alarm relay enabled.

0/1/2 0 0 0 0 num

H51 HACCP alarm exclusion time. 0 ... 250 0 0 0 0 min

CONFIGURATION (“CnF” folder)

H00 Probe type selection. 0 = PTC; 1 = NTC; 2 = PT1000. 0/1/2

1 1 1 1

num

H11

Configuration of digital input 1/polarity. 0 = disabled; ±1 = defrost; ±2 = economy

Setpoint; ±3 = not used; ±4= door switch; ±5 = external alarm; ±6= Standby;

±7= pressure switch; ±8= Deep Cooling; ±9= disable HACCP alarm logging.

NOTE: • the “+” sign indicates that the input is active if the contact is closed.

• the “-” sign indicates that the input is active if the contact is open.

-9 ... +9 2 2 0 0 num

H21

(IDPlus 961 only). Configurability of digital output 1 (

).

0= disabled; 1= compressor; 2= defrost; 3= fans; 4= alarm; 5= AUX; 6= Standby.

0 ... 6 1 1 1 1 num

H22

(IDPlus 902 only). Configurability of digital output 1 (

). Same as H21.

0 ... 6 1 1 1 1 num

H31

Configurability of UP key.

0 = disabled; 1 = defrost; 2 = not used; 3 = economy Setpoint; 4 = Standby;

5 = reset HACCP alarms; 6 = disable HACCP alarms; 7 = Deep Cooling.

0 ... 7 1 0 0 1 num

H32 Configurability of DOWN key. Same as H31. 0 ... 7 0 0 0 0 num

H43 Probe Pb3 present. n = not present; y = present. n/y n n n y flag

reL Device version. Read-only parameter. / / / / / /

tAb tAble of parameters. Reserved: read-only parameter. / / / / / /

COPY CARD (“FPr” folder)

UL Programming parameter transfer from instrument to Copy Card. / /

/ / /

/

Fr

Format Copy Card. Erase all data contained in the Copy Card.

NOTE: if parameter “Fr” is used, the data entered will be permanently lost.

This operation cannot be cancelled.

/ / / / / /

FUNCTIONS (“FnC” folder)

rAP Reset pressure switch alarms / / / / / /

rES Reset HACCP alarms / / / / / /

NOTE

: If one or more parameters marked with (!) are modified, the controller MUST be switched off and then switched on again to ensure correct operation.

IDPlus 971 devices are controllers with 2 relay outputs, 2 temperature sensors (regulation

and evaporator), a multifunctional Digital/Temperature input and a digital input.

The relay output can be used to control:

- compressor

- defrost heating elements

- evaporator fans

- AUX output

- temperature alarm

- Standby

The second probe can be used to control the defrost cycle and the evaporator fans.

The Digital inputs (D.I.1 and D.I.2) can be used for:

- Energy saving

- Defrost activation

- AUX management

- door switch

- Standby

- external alarm

- Deep Cooling

- pressure switch

- HACCP alarms

DESCRIPTION OF IDPLUS 971 FAMILY

ID Plus 971: TABLE OF USER MENU PARAMETERS

PAR. DESCRIPTION RANGE APP1 APP2 APP3 APP4 M.U.

SEt Temperature control SEtpoint LSE ... HSE 0,0 0,0 0,0 0,0 °C/°F

diF Compressor relay activation differential 0,1 ... 30,0 2,0 2,0 2,0 2,0 °C/°F

HSE Maximum value that can be assigned to the Setpoint LSE ... 302 99,0 99,0 99,0 99,0 °C/°F

LSE Minimum value that can be assigned to the Setpoint -58.0 ... HSE -50,0 -50,0 -50,0 -50,0 °C/°F

dty Type of defrost 0/1/2 0 0 num

dit Interval between the start of two consecutive defrost cycles 0 ... 250 6 6 6 6 hours

dEt Defrost timeout 1 ... 250 30 30 30 30 min

dSt End defrost temperature -50,0 ... 150 8,0 8,0 °C/°F

FSt Fans stop temperature -50,0 ... 150 50,0 °C/°F

Fdt Fan activation delay after a defrost cycle 0 ... 250 0 min

dt Coil drainage time 0 ... 250 0 min

dFd To select or exclude the fans n/y y flag

HAL Maximum temperature alarm LAL ... 150 50,0 50,0 50,0 50,0 °C/°F

LAL Minimum temperature alarm -50.0 ... HAL -50,0 -50,0 -50,0 -50,0 °C/°F

dOd Enable utility switch-off on activation of door switch 0/1/2/3 0 num

dCO Compressor deactivation delay after door opened 0 ... 255 1 min

LOC Basic commands modification lock n/y n n n n flag

PS1 PAssword 1 for access to QUICK menu parameters 0 ... 250 0 0 0 0 num

CA1 Calibration1. Value to be added to the value read by probe 1 -12,0 ... 12,0 0,0 0,0 0,0 0,0 °C/°F

CA2 Calibration2. Value to be added to the value read by probe 2 -12,0 ... 12,0 0,0 0,0 °C/°F

ddL Display mode during defrost 0/1/2 0 0 0 0 num

Ldd Display lock disabling timeout. 0 = function disabled 0 ... 255 30 30 30 30 min

H42 Evaporator probe present. n = not present; y = present n/y y y flag

rEL firmware rELease. Reserved: read-only parameter / / / / / /

tAb tAble of parameters. Reserved: read-only parameter / / / / / /

Notes: ** The USER menu parameters also include “PA2”, which can be used to access the Installer menu

*** For the complete list of parameters, see: APPENDIX A: Table of Installer menu parameters

TABLE OF USER MENU PARAMETERS (IDPLUS 971)

PAR. DESCRIPTION RANGE App1 App2 App3 App4 M.U.

SEt Temperature control SEtpoint. LSE ... HSE 0,0 0,0 0,0 0,0 °C/°F

COMPRESSOR (“CP” folder)

diF diFferential. Compressor relay activation differential. 0,1...30,0

2,0 2,0 2,0 2,0

°C/°F

HSE Higher SEt. Maximum value that can be assigned to the Setpoint. LSE...302 99,0 99,0 99,0 99,0 °C/°F

LSE Lower SEt. Minimum value that can be assigned to the Setpoint. -58.0...HSE -50,0 -50,0 -50,0 -50,0 °C/°F

OSP

Temperature value to be added to the Setpoint if reduced set enabled

(Economy function).

-30,0...30,0 3,0 3,0 0,0 3,0 °C/°F

Hc Control mode. “H” = Hot, “C” = Cold. C/H C C C C flag

Ont

Controller on time for faulty probe.

If Ont = 1 and OFt = 0, the compressor remains on;

if Ont =1 and OFt >0 it runs in duty cycle mode.

0 ... 250 0 0 0 0 min

OFt

Controller off time for faulty probe.

If OFt = 1 and Ont = 0, the controller remains off;

if OFt = 1 and Ont >0, it operates in duty cycle mode.

0 ... 250 1 1 1 1 min

dOn Compressor relay activation delay after request 0 ... 250 0 0 0 0 secs

dOF Delay after switching off and subsequent activation 0 ... 250 0 0 0 0 min

dbi Delay between two consecutive compressor activations 0 ... 250 0 0 0 0 min

OdO

(!)

Delay in activating outputs after the instrument is switched on or after a power failure.

0 = not active.

0 ... 250 0 0 0 0 min

dcS Deep Cooling cycle Setpoint. -58,0...302 0,0 0,0 0,0 0,0 °C/°F

tdc Deep Cooling cycle duration. 0 ... 255 0 0 0 0 min*10

dcc Defrost activation delay after a Deep Cooling cycle. 0 ... 255 0 0 0 0 min

DEFROST (“dEF” folder)

dtY

Type of defrost.

0 = electrical defrost; 1 = reverse cycle defrost;

2 = defrost independent of compressor.

0/1/2 0 0 0 0 num

dit Interval between the start of two consecutive defrost cycles. 0 ... 250 6 6 6 6 hours

TABLE OF INSTALLER MENU PARAMETERS (IDPLUS 971)

PAR. DESCRIPTION RANGE App1 App2 App3 App4 M.U.

dCt

Selection of count mode for the defrost interval.

0 = compressor running time; 1 = appliance running time;

2 = A defrost cycle is run at each compressor stop

0/1/2 1 1 1 1 num

dOH Delay for start of first defrost after request 0 ... 59 0 0 0 0 min

dEt Defrost timeout; determines the maximum defrost duration 1 ... 250 30 30 30 30 min

dSt Defrost end temperature - determined by the evaporator probe -50,0...150 8,0 50,0 8,0 50,0 °C/°F

dPO Determines whether the instrument must enter defrost mode at start-up n/y n n n n flag

FANS (“FAn” folder)

FSt

Fans stop temperature -58,0...302

50,0 50,0 50,0 50,0 °C/°F

FAd Fan activation differential 1,0 ... 50,0 2,0 2,0 2,0 2,0 °C/°F

Fdt Fan activation delay after a defrost cycle 0 ... 250 0 0 0 0 min

dt Coil drainage time 0 ... 250 0 0 0 0 min

dFd

Allows evaporator fan exclusion to be selected or not selected during defrosting.

y = yes (fans excluded); n = no

n/y y y y y flag

FCO

Selects or deselects fan deactivation at compressor OFF.

0 = fans off; 1 = fans active; 2 = duty cycle

0/1/2 0 0 0 0 num

FOn Fans ON time in day duty cycle 0 ... 99 0 0 0 0 min

FOF Fans OFF time in day duty cycle 0 ... 99 0 0 0 0 min

Fnn Fans ON time in night duty cycle 0 ... 99 0 0 0 0 min

FnF Fans OFF time in night duty cycle 0 ... 99 0 0 0 0 min

ESF Night mode activation. n = no; y = yes n/y n n n n flag

ALARMS (“AL” folder)

Att

Can be used to select absolute (Att=0) or relative (Att=1) values for HAL and LAL

parameters

0/1

0 0 0 0

num

Afd Alarm differential 1,0 ... 50,0 2,0 2,0 2,0 2,0 °C/°F

HAL Maximum temperature alarm LAL...302 50,0 50,0 50,0 50,0 °C/°F

LAL Minimum temperature alarm -58.0...HAL -50,0 -50,0 -50,0 -50,0 °C/°F

PAO Alarm exclusion time after re-activation following a power failure 0 ... 10 0 0 0 0 hours

dAO Temperature alarm exclusion time after defrost 0 ... 999 0 0 0 0 min

PAR. DESCRIPTION RANGE App1 App2 App3 App4 M.U.

OAO Alarm signalling delay after disabling of digital input 0 ... 10 0 0 0 0 hours

tdO Delay in door open alarm activation 0 ... 250 0 0 0 0 min

tAO Time delay for temperature alarm indication 0 ... 250 0 0 0 0 min

dAt Alarm signalling end of defrost due to timeout n/y n n n n flag

rLO External alarm locks controllers. n = does not lock; y = locks n/y n n n n flag

SA3 Probe 3 alarm Setpoint -58,0...+302 0,0 0,0 0,0 0,0 °C/°F

dA3 Probe 3 alarm differential 1,0 ... 50,0 1,0 1,0 1,0 1,0 °C/°F

LIGHTS & DIGITAL INPUTS (“Lit” folder)

dOd

Digital input for switching off utilities. 0=disabled;

1=disables fans; 2=disables the compressor; 3=disables fans and compressor

0/1/2/3

0 0 2 0

num

dAd Activation delay for digital input 0 ... 255 0 0 0 0 min

dCO Compressor deactivation delay after door opened 0 ... 255 1 1 1 1 min

PRESSURE SWITCH (“PrE” folder)

Pen Number of errors allowed per maximum/minimum pressure switch input 0 ... 15

0 0 0 0

num

PEI Minimum/maximum pressure switch error count interval 1 ... 99 1 1 1 1 min

PEt Delay in activating compressor after pressure switch deactivation 0 ... 255 0 0 0 0 min

COMMUNICATION (“Add” folder)

PtS Communication protocol selection. t = Televis; d = Modbus t/d t t t t flag

dEA Index of the device inside the family (valid values from 0 to 14) 0 ... 14 0 0 0 0 num

FAA Device family - valid values from 0 to 14 0 ... 14 0 0 0 0 num

Pty Modbus parity bit. n = none; E = even; o = odd n/E/o n n n n num

StP Modbus stop bit 1b/2b 1b 1b 1b 1b flag

DISPLAY (“diS” folder)

LOC

Basic commands modification lock. It is still possible to enter parameter programming

mode and modify them. y = yes; n = no

n/y

n n n n

flag

PS1 PAssword1: if PS1≠0 is the access key to User parameters 0 ... 250 0 0 0 0 num

PS2 PAssword2: if PS2≠0 is the access key to Installer parameters 0 ... 250 15 15 15 15 num

ndt Display with decimal point. y = yes; n = no n/y y y y y flag

CA1 Calibration 1. Temperature value to be added to the Pb1 value -12,0...+12,0 0,0 0,0 0,0 0,0 °C/°F

PAR. DESCRIPTION RANGE App1 App2 App3 App4 M.U.

CA2 Calibration 2. Temperature value to be added to the Pb2 value -12,0...+12,0 0,0 0,0 0,0 0,0 °C/°F

CA3 Calibration 3. Temperature value to be added to the Pb3 value -12,0...+12,0 0,0 0,0 0,0 0,0 °C/°F

ddL

Display mode during defrost.

0= display the temperature recorded by Pb1;

1 = lock recorded value of Pb1 at defrost start; 2 = display the “dEF” label

0/1/2 0 0 0 0 num

Ldd Timeout value for display unlock - dEF label 0 ... 255 30 30 30 30 min

dro

Select the unit of measurement used when displaying the temperature recorded by the

probes. (

0 = °C, 1 = °F).

NOTE: switching between °C and °F or vice-versa DOES NOT modify the SEt, diF

values, etc. (e.g. Setpoint=10°C becomes 10°F)

0/1 0 0 0 0 flag

ddd

Selects the type of value to display.

0 = Setpoint; 1 = probe Pb1; 2 = probe Pb2; 3 = probe Pb3

0/1/2/3 1 1 1 1 num

HACCP (“HCP” folder)

SHH Maximum HACCP alarm signals threshold -55,0...150

0 0 0 0

°C/°F

SLH Minimum HACCP alarm signals threshold -55,0...150 0 0 0 0 °C/°F

drA

Minimum time spent in critical range for the event to be recorded. After this a HACCP

alarm will be triggered and logged

0 ... 99 0 0 0 0 min

drH HACCP alarm reset time after last reset 0 ... 250 0 0 0 0 hours

H50

Enable HACCP and alarm relay functions.

0= HACCP alarms NOT enabled;

1 = HACCP alarms enabled and alarm relay NOT enabled;

2 = HACCP alarms enabled and alarm relay enabled

0/1/2 0 0 0 0 num

H51 HACCP alarm exclusion time 0 ... 250 0 0 0 0 min

CONFIGURATION (“CnF” folder)

H00 Probe type selection.

0 = PTC; 1 = NTC; 2 = PT1000 0/1/2

1 1 1 1

num

H11

Configuration of digital input 1/polarity.

0 = disabled; ±1 = defrost; ±2 = economy Setpoint; ±3= AUX;

±4= door switch; ±5 = external alarm; ±6= Standby; ±7= pressure switch; ±8=

Deep Cooling; ±9= disable HACCP alarm logging.

NOTE: • the “+” sign indicates that the input is active if the contact is closed.

• the “-” sign indicates that the input is active if the contact is open.

-9 ... +9 2 2 4 2 num

H12 Configuration of digital input 2/polarity. Same as H11 -9 ... +9 0 0 0 0 num

PAR. DESCRIPTION RANGE App1 App2 App3 App4 M.U.

H21

Configurability of digital output 1 (

).

0 = disabled; 1 = compressor; 2 = defrost; 3 = fans;

4 = alarm; 5 = AUX; 6 = Standby

0 ... 6 1 1 1 1 num

H22

Configurability of digital output 2 (

). Same as H21.

0 ... 6 2 2 3 4 num

H25

Enable/Disable buzzer.

0=Disabled; 4=Enabled; 1-2-3-5-6-7-8=not used

0 ... 8 0 0 0 4 num

H31

Configurability of UP key.

0 = disabled; 1 = defrost; 2 = AUX; 3 = economy Setpoint; 4 = Standby;

5 = reset HACCP alarms; 6 = disable HACCP alarms; 7 = Deep Cooling.

0 ... 7 1 1 1 1 num

H32 Configurability of DOWN key. Same as H31 0 ... 7 0 0 0 0 num

H42 Evaporator probe present. n = not present; y = present n/y y n y n flag

H43 Probe 3 present. n = not present; y = present n/y n n n n flag

reL Device version. Read-only parameter / / / / / /

tAb tAble of parameters. Reserved: read-only parameter / / / / / /

COPY CARD (“FPr” folder)

UL Programming parameter transfer from instrument to Copy Card / /

/ / /

/

Fr

Format Copy Card. Erase all data contained in the Copy Card.

NOTE: If parameter “Fr” is used, the data entered will be permanently lost.

This operation cannot be cancelled.

/ / / / / /

FUNCTIONS (“FnC” folder)

rAP Reset pressure switch alarms / / / / / /

rES Reset HACCP alarms / / / / / /

NOTE: If one or more parameters marked with (!) are modified, the controller MUST be switched off and then switched on again to ensure correct operation.

IDPlus 974 devices are controllers with 3 relay outputs, 2 temperature sensors (regulation

and evaporator), a multifunctional Digital/Temperature input and a digital input.

Relay outputs 2 and 3 can be used to control:

• compressor

• defrost heating elements

• evaporator fans

• AUX output

• alarm

• Standby

The second probe can be used to control the defrost cycle and the evaporator fans.

The Digital inputs (D.I.1 and D.I.2) can be used for:

• Energy Saving

• Defrost activation

• AUX management

• door switch

• Standby

• external alarm

• Deep Cooling

• pressure switch

• HACCP alarms

DESCRIPTION OF IDPLUS 974 FAMILY

TABLE OF USER MENU PARAMETERS (IDPLUS 974)

PAR. DESCRIPTION RANGE APP1 APP2 APP3 APP4 M.U.

SEt Temperature control SEtpoint LSE ... HSE 0,0 0,0 0,0 0,0 °C/°F

diF Compressor relay activation differential 0,1 ... 30,0 2,0 2,0 2,0 2,0 °C/°F

HSE Maximum value that can be assigned to the Setpoint LSE ... 302 99,0 99,0 99,0 99,0 °C/°F

LSE Minimum value that can be assigned to the Setpoint -58.0 ... HSE -50,0 -50,0 -50,0 -50,0 °C/°F

dty Type of defrost 0/1/2 0 0 1 num

dit Interval between the start of two consecutive defrost cycles 0 ... 250 6 6 6 6 hours

dEt Defrost timeout 1 ... 250 30 30 30 30 min

dSt End defrost temperature -50,0 ... 150 8,0 8,0 8,0 8,0 °C/°F

FSt Fans stop temperature -58,0 ... 302 50,0 50,0 50,0 50,0 °C/°F

Fdt Fan activation delay after a defrost cycle 0 ... 250 0 0 0 0 min

dt Coil drainage time 0 ... 250 0 0 0 0 min

dFd To select or exclude the fans n/y y y y y min

HAL Maximum temperature alarm LAL ... 150 50,0 50,0 50,0 50,0 °C/°F

LAL Minimum temperature alarm -50.0 ... HAL -50,0 -50,0 -50,0 -50,0 °C/°F

LOC Basic commands modification lock n/y n n n n flag

PS1 PAssword 1 for access to QUICK menu parameters 0 ... 250 0 0 0 0 num

CA1 Calibration1. Value to be added to the value read by probe 1 -12,0 ... 12,0 0,0 0,0 0,0 0,0 °C/°F

CA2 Calibration2. Value to be added to the value read by probe 2 -12,0 ... 12,0 0,0 0,0 0,0 0,0 °C/°F

CA3 Calibration3. Value to be added to the value read by probe 3 -12,0 ... 12,0 0,0 0,0 0,0 °C/°F

ddL Display mode during defrost 0/1/2 0 0 0 0 num

Ldd Display lock disabling timeout. 0 = function disabled 0 ... 255 30 30 30 30 min

SHH Maximum HACCP alarm signals threshold -55,0 ... 150 10,0 °C/°F

SLH Minimum HACCP alarm signals threshold -55,0 ... 150 -10,0 °C/°F

drA Minimum time spent in critical range before alarm occurs 0 ... 99 10 min

drH HACCP alarm reset time after last reset 0 ... 250 24 hours

H50 enable HACCP and alarm relay functions 0/1/2 1 num

H51 HACCP alarm exclusion time 0 ... 250 0 min

H42 Evaporator probe present. n = not present; y = present n/y y y y y flag

H43 Probe 3 present. n = not present; y = present n/y n y n n flag

rEL firmware rELease. Reserved: read-only parameter / / / / / /

tAb tAble of parameters. Reserved: read-only parameter / / / / / /

Notes: * The USER menu parameters also include: PA2, which can be used to access the Installer menu

** To reset the HACCP alarms, use the rES function in the FnC folder for Installer parameters

*** For the complete list of parameters, see: APPENDIX A: Table of Installer menu parameters

PAR. DESCRIPTION RANGE APP1 APP2 APP3 APP4 M.U.

SEt Temperature control SEtpoint LSE ... HSE 0,0 0,0 0,0 0,0 °C/°F

COMPRESSOR (“CP” folder)

diF diFferential. Compressor relay activation differential 0,1...30,0

2,0 2,0 2,0 2,0

°C/°F

HSE Higher SEt. Maximum value that can be assigned to the Setpoint LSE...302 99,0 99,0 99,0 99,0 °C/°F

LSE Lower SEt. Minimum value that can be assigned to the Setpoint -58,0...HSE -50,0 -50,0 -50,0 -50,0 °C/°F

OSP

Temperature value to be added to the Setpoint if reduced set enabled

(Economy function)

-30,0...30,0 3,0 0,0 0,0 3,0 °C/°F

Hc Control mode. “H” = Hot, “C” = Cold C/H C C C C flag

Ont

Controller on time for faulty probe.

If Ont = 1 and OFt = 0, the compressor remains on;

if Ont=1 and OFt>0 it runs in duty cycle mode

0 ... 250 0 0 0 0 min

OFt

Controller off time for faulty probe.

If OFt = 1 and Ont = 0, the controller remains off;

if OFt = 1 and Ont>0, it operates in duty cycle mode

0 ... 250 1 1 1 1 min

dOn Compressor relay activation delay after request 0 ... 250 0 0 0 0 secs

dOF Delay after switching off and subsequent activation 0 ... 250 0 0 0 0 min

dbi Delay between two consecutive compressor activations 0 ... 250 0 0 0 0 min

OdO

(!)

Delay in activating outputs after the instrument is switched on or after a power failure.

0 = not active

0 ... 250 0 0 0 0 min

dcS Deep Cooling cycle Setpoint -58,0...302 0,0 0,0 0,0 0,0 °C/°F

tdc Deep Cooling cycle duration 0 ... 255 0 0 0 0 min*10

dcc Defrost activation delay after a Deep Cooling cycle 0 ... 255 0 0 0 0 min

DEFROST (“dEF” folder)

dtY

Type of defrost.

0 = electrical defrost;

1 = reverse cycle defrost;

2 = defrost independent of compressor

0/1/2 0 0 0 1 num

dit Interval between the start of two consecutive defrost cycles 0 ... 250 6 6 6 6 hours

TABLE OF INSTALLER MENU PARAMETERS (IDPLUS 974)

PAR. DESCRIPTION RANGE APP1 APP2 APP3 APP4 M.U.

dCt

Selection of count mode for the defrost interval.

0 = compressor running time; 1 = appliance running time;

2 = A defrost cycle is run at each compressor stop

0/1/2 1 1 1 1 num

dOH Delay for start of first defrost after request 0 ... 59 0 0 0 0 min

dEt Defrost timeout; determines the maximum defrost duration 1 ... 250 30 30 30 30 min

dSt Defrost end temperature - determined by probe Pb2 -50,0...150 8,0 8,0 8,0 50,0 °C/°F

dPO Determines whether the instrument must enter defrost mode at start-up n/y n n n n flag

FANS (“FAn” folder)

FSt

Fans stop temperature -58,0...302

50,0 50,0 50,0 50,0 °C/°F

FAd Fan activation differential 1,0 ... 50,0 2,0 2,0 2,0 2,0 °C/°F

Fdt Fan activation delay after a defrost cycle 0 ... 250 0 0 0 0 min

dt Coil drainage time 0 ... 250 0 0 0 0 min

dFd

Allows evaporator fan exclusion to be selected or not selected during defrosting.

y = yes (fans excluded); n = no

n/y y y y y flag

FCO

Selects or deselects fan deactivation at compressor OFF.

0 = fans off; 1 = fans active; 2 = duty cycle

0/1/2 0 0 0 0 num

FOn Fans ON time in day duty cycle 0 ... 99 0 0 0 0 min

FOF Fans OFF time in day duty cycle 0 ... 99 0 0 0 0 min

Fnn Fans ON time in night duty cycle 0 ... 99 0 0 0 0 min

FnF Fans OFF time in night duty cycle 0 ... 99 0 0 0 0 min

ESF Night mode activation. n = no; y = yes n/y n n n n flag

ALARMS (“AL” folder)

Att

Can be used to select absolute (Att=0) or relative (Att=1) values for HAL and LAL

parameters

0/1

0 0 0 0

num

Afd Alarm differential 1,0 ... 50,0 2,0 2,0 2,0 2,0 °C/°F

HAL Maximum temperature alarm LAL...302 50,0 50,0 50,0 50,0 °C/°F

LAL Minimum temperature alarm -58,0...HAL -50,0 -50,0 -50,0 -50,0 °C/°F

PAO Alarm exclusion time after re-activation following a power failure 0 ... 10 0 0 0 0 hours

dAO Temperature alarm exclusion time after defrost 0 ... 999 0 0 0 0 min

PAR. DESCRIPTION RANGE APP1 APP2 APP3 APP4 M.U.

OAO Alarm signalling delay after disabling of digital input 0 ... 10 0 0 0 0 hours

tdO Delay in door open alarm activation 0 ... 250 0 0 0 0 min

tAO Time delay for temperature alarm indication 0 ... 250 0 0 0 0 min

dAt Alarm signalling end of defrost due to timeout n/y n n n n flag

rLO External alarm locks controllers. n = does not lock; y = locks n/y n n n n flag

SA3 Probe 3 alarm Setpoint -58,0...302 0,0 0,0 0,0 0,0 °C/°F

dA3 Probe 3 alarm differential 1,0 ... 50,0 1,0 1,0 1,0 1,0 °C/°F

LIGHTS & DIGITAL INPUTS (“Lit” folder)

dOd

Digital input for switching off utilities. 0=disabled;

1=disables fans; 2=disables the compressor; 3=disables fans and compressor

0/1/2/3

0 0 0 0

num

dAd Activation delay for digital input 0 ... 255 0 0 0 0 min

dCO Compressor deactivation delay after door opened 0 ... 255 1 1 1 1 min

AuP Aux output activation when door opened. n = not linked; y = linked n/y n n y n flag

PRESSURE SWITCH (“PrE” folder)

Pen Number of errors allowed per maximum/minimum pressure switch input 0 ... 15

0 0 0 0

num

PEI Minimum/maximum pressure switch error count interval 1 ... 99 1 1 1 1 min

PEt Delay in activating compressor after pressure switch deactivation 0 ... 255 0 0 0 0 min

COMMUNICATION (“Add” folder)

PtS Communication protocol selection. t = Televis; d = Modbus t/d t t t t flag

dEA Index of the device inside the family (valid values from 0 to 14) 0 ... 14 0 0 0 0 num

FAA Device family - valid values from 0 to 14 0 ... 14 0 0 0 0 num

Pty Modbus parity bit. n = none; E = even; o = odd n/E/o n n n n num

StP Modbus stop bit 1b/2b 1b 1b 1b 1b flag

DISPLAY (“diS” folder)

LOC

Basic commands modification lock. It is still possible to enter parameter programming

mode and modify them. y = yes; n = no

n/y

n n n n

flag

PS1 PAssword1: if PS1≠0 is the access key to User parameters 0 ... 250 0 0 0 0 num

PS2 PAssword2: if PS2≠0 is the access key to Installer parameters 0 ... 250 15 15 15 15 num

ndt Display with decimal point. y = yes; n = no n/y y y y y flag

PAR. DESCRIPTION RANGE APP1 APP2 APP3 APP4 M.U.

CA1 Calibration 1. Temperature value to be added to the Pb1 value -12,0...+12,0 0,0 0,0 0,0 0,0 °C/°F

CA2 Calibration 2. Temperature value to be added to the Pb2 value -12,0...+12,0 0,0 0,0 0,0 0,0 °C/°F

CA3 Calibration 3. Temperature value to be added to the Pb3 value -12,0...+12,0 0,0 0,0 0,0 0,0 °C/°F

ddL

Display mode during defrost. 0 = display the temperature recorded by Pb1;

1 = lock recorded value of Pb1 at defrost start; 2 = display the “dEF” label

0/1/2 0 0 0 0 num

Ldd Timeout value for display unlock - dEF label 0 ... 255 30 30 30 30 min

dro

Select the unit of measurement used when displaying the temperature recorded by the

probes. (0 = °C, 1 = °F).

NOTE: switching between °C and °F or vice-versa DOES NOT modify the SEt,

diF values, etc. (e.g. Setpoint=10°C becomes 10°F)

0/1 0 0 0 0 flag

ddd

Selects the type of value to display.

0 = Setpoint; 1 = probe Pb1; 2 = probe Pb2; 3 = probe Pb3.

0/1/2/3 1 1 1 1 num

HACCP (“HCP” folder)

SHH Maximum HACCP alarm signals threshold. -55,0...150

0 10 0 0

°C/°F

SLH Minimum HACCP alarm signals threshold. -55,0...150 0 -10 0 0 °C/°F

drA

Minimum time spent in critical range for the event to be recorded. After this a HACCP

alarm will be triggered and logged.

0 ... 99 0 10 0 0 min

drH HACCP alarm reset time after last reset. 0 ... 250 0 24 0 0 hours

H50

Enable HACCP and alarm relay functions. 0= HACCP alarms NOT enabled;

1 = HACCP alarms enabled and alarm relay NOT enabled;

2 = HACCP alarms enabled and alarm relay enabled.

0/1/2 0 1 0 0 num

H51 HACCP alarm exclusion time. 0 ... 250 0 0 0 0 min

CONFIGURATION (“CnF” folder)

H00 Probe type selection. 0 = PTC; 1 = NTC; 2 = PT1000. 0/1/2

1 1 1 1

num

H11

Configuration of digital input 1/polarity.

0 = disabled; ±1 = defrost; ±2 = economy Setpoint; ±3= AUX;

±4= door switch; ±5 = external alarm; ±6= Standby; ±7= pressure switch;

±8= Deep Cooling; ±9= disable HACCP alarm logging.

NOTE: • the “+” sign indicates that the input is active if the contact is closed.

• the “-” sign indicates that the input is active if the contact is open.

-9 ... +9 2 0 4 2 num

PAR. DESCRIPTION RANGE APP1 APP2 APP3 APP4 M.U.

H12 Configuration of digital input 2/polarity. Same as H11 -9 ... +9 0 0 0 0 num

H21

Configurability of digital output 1 (

).

0 = disabled; 1 = compressor; 2 = defrost; 3 = fans;

4 = alarm; 5 = AUX; 6 = Standby

0 ... 6 1 1 1 1 num

H22

Configurability of digital output 2 (

). Same as H21

0 ... 6 2 2 5 2 num

H23

Configurability of digital output 3 (

). Same as H21

0 ... 6 3 3 3 3 num

H25

Enable/Disable buzzer.

0 = Disabled; 4=Enabled; 1-2-3-5-6-7-8= not used

0 ... 8 0 0 0 0 num

H31

Configurability of UP key.

0 = disabled; 1 = defrost; 2 = AUX; 3 = economy Setpoint; 4 = Standby;

5 = reset HACCP alarms; 6 = disable HACCP alarms; 7 = Deep Cooling.

0 ... 7 1 1 1 1 num

H32 Configurability of DOWN key. Same as H31 0 ... 7 0 0 0 0 num

H42 Evaporator probe present. n = not present; y = present n/y y y y y flag

H43 Probe 3 present. n = not present; y = present n/y n y n n flag

rEL Device version. Read-only parameter / / / / / /

tAb tAble of parameters. Reserved: read-only parameter / / / / / /

COPY CARD (“FPr” folder)

UL Programming parameter transfer from instrument to Copy Card / /

/ / /

/

Fr

Format Copy Card. Erase all data contained in the Copy Card.

NOTE: If parameter “Fr” is used, the data entered will be permanently lost.

This operation cannot be cancelled.

/ / / / / /

FUNCTIONS (“FnC” folder)

rAP Reset pressure switch alarms / / / / / /

rES Reset HACCP alarms / / / / / /

NOTE

: If one or more parameters marked with (!) are modified, the controller MUST be switched off and then switched on again to ensure correct operation.

Eliwell Controls s.r.l.

Via dell'Industria, 15 • Z.I. Paludi

32010 Pieve d'Alpago (BL) ITALY

Telephone +39 0437 986 111

Fax +39 0437 989 066

www.eliwell.it

Technical Customer Support:

Technical helpline +39 0437 986 300

email: techsuppeliwell@invensys.com

Sales

Telephone: +39 0437 986 100 (Italy)

+39 0437 986 200 (other countries)

email: saleseliwell@invensys.com

code 9IS54157 - IDPlus 902/961/971/974 - EN - rel. 07/11

© Eliwell Controls s.r.l. 2010-2011 All rights reserved.

Loading...

Loading...