Page 1

Panel

Panel Mount Programmable Controller

Installation Manual

EN

Page 2

CONTENTS

1 Introduction ............................................................................................................................................................. 3

1.1 General description ......................................................................................................................................................................... 3

1.1.1 Specifications: ..................................................................................................................................................................................................................................... 4

1.2 Models and Features....................................................................................................................................................................... 4

2 Mechanical Installation ......................................................................................................................................... 5

3 Electrical connections ........................................................................................................................................... 6

3.1 General warnings.............................................................................................................................................................................. 6

3.1.1 Power supply ....................................................................................................................................................................................................................................... 6

3.1.2 Analogue Inputs-Probes ................................................................................................................................................................................................................... 6

3.1.3 Serial connections.............................................................................................................................................................................................................................. 6

3.2 Wiring diagrams................................................................................................................................................................................ 8

3.3 Analogue inputs................................................................................................................................................................................ 9

3.4 Connections..................................................................................................................................................................................... 10

3.4.1 Example: RS485 connection (Field)............................................................................................................................................................................................. 10

3.4.2 CAN connection example (Field) ................................................................................................................................................................................................10

3.4.3 Example: RS485 connection with FREE Smart network......................................................................................................................................................... 11

3.4.4 CANopen network connection example ................................................................................................................................................................................... 12

4 Technical Data....................................................................................................................................................... 14

4.1 General Technical Data................................................................................................................................................................. 14

4.2 I/O features...................................................................................................................................................................................... 14

4.3 Display............................................................................................................................................................................................... 15

4.4 Serials ................................................................................................................................................................................................ 15

4.5 Transformer..................................................................................................................................................................................... 15

4.6 Mechanical dimensions ................................................................................................................................................................ 15

4.7 Permitted use.................................................................................................................................................................................. 15

4.8 Improper Use .................................................................................................................................................................................. 15

4.9 Disclaimer......................................................................................................................................................................................... 15

5 User Interface ........................................................................................................................................................16

5.1 Keys and LEDs ................................................................................................................................................................................. 16

5.2 First power on................................................................................................................................................................................. 17

5.3 DIAGNOSTICS menu...................................................................................................................................................................... 17

5.3.1 BIOS parameters............................................................................................................................................................................................................................... 17

5.3.2 HMI Management ............................................................................................................................................................................................................................18

5.3.3 Probe values ......................................................................................................................................................................................................................................18

Note: for offset programming see the section on Analogue Inputs in the Connections chapter....................................................................................... 18

5.3.3.1 Date and time ........................................................................................................................................................................................................................ 18

5.4 Remote interface............................................................................................................................................................................ 18

5.4.1 Language............................................................................................................................................................................................................................................. 18

5.4.2 ........................................................................................................................................................................................................................................................ 18

5.4.3 HMI sel ................................................................................................................................................................................................................................................ 18

5.4.3.1 COM Setting ........................................................................................................................................................................................................................... 19

5.4.3.2 HMI Management ................................................................................................................................................................................................................. 19

6 Parameters.............................................................................................................................................................. 20

6.1 Table of parameters ......................................................................................................................................................................20

6.1.1 Table of parameters ........................................................................................................................................................................................................................ 20

7 Models and Accessories...................................................................................................................................... 34

7.1 Models .............................................................................................................................................................................................. 34

7.2 Accessories....................................................................................................................................................................................... 35

EN

Invensys Controls

An Invensys Company

Page 3

References

Cross references

Highlighting icons:

1 INTRODUCTION

To allow quick, easy reference, the guide has been designed with the following features:

References column

A column to the left of the text contains references

need quickly and easily.

Cross references:

words in italics are listed in the analytical index along with the page number where they are dealt with in more detail.

All

In the "on-line" (computer) manual, the words in italics are "hyperlinks" (i.e. mouse-clickable links), connecting up the

different parts of the manual and making it "navigable".

Some text passages are marked by icons in the references c

Important! : highlights information of which an incorrect understanding can i

Note / highlight: indicates further information on the subject concerned that the user should take into account.

Tip: a suggestion that could help the user to understand and make better use of the information

:

to subjects discussed in the text to help you locate the information you

olumn, which have the following meanings:

mpact negatively on the

system or result in risk to persons, instruments, data, etc.; users must read and take note of

these sections.

provided.

1.1 General description

The FREE Panel (EVP) is a fully programmable panel mounting solution with LCD display made by Eliwell,

suitable for managing a wide range of H

The EVP can be

FREE Smart or third-party controllers it guarantees high performance in terms of memory, connectivity and user interface

as well as

The EVP is designed for panel mounting, and can al

Programming of the EVP is managed via the FREE Studio development tool, which makes it possible to quickly and

reliably create and customise new programs for all types of application.

The use of several different programming languages in accordance with IEC61131-3 standard (industrial control

programming ), makes it possible to develop new algorithms or entire programmes totally unassisted, which can th

uploaded to FREE Evolution modules via PC, guaranteeing maximum confidentiality with appropriate security.

The EVP can be

manage a local menu created with the FREE Studio User Interface

mana

share network variables (binding)

WEB functionalities

The FREE Panel (EVP) also features WEB functionalities (the FREE Panel product is also designated FREE WEB) offeri

makers of machinery and systems integrators full remote access. Having a web-based connection in machines significantly

reduces support and maintenance costs by minimizing call-out charges. End users also benefit, as they can mo

own systems both locally and from distance, using the easy-to-understand graphics interface of any common browser via

smartphone, tablet or PC.

Main WEB functionalities

Web-based access.

Remote reading and support.

Local and remote system control, including alarms management.

Preventive and predictive maintenance.

Email alarm alerts.

Next generation system interface on PC, tablet and smartphone.

used as a system controller, with gateway functions; used in combination with the FREE Evolution and

straightforward programming, maintenance and servicing.

used to:

ge up to 10 remote menus, created with the FREE Studio User Interface a

respective FREE Evolution devices connected to the network

VAC/R and many other applications, from the simplest to the most complex.

so be wall-mounted using a special backplate, available as an accessory.

en be

nd uploaded from the

ng

nitor their

FREE Panel

3/38

Page 4

1.1.1 Specifications:

FREE Panel EVP 3300/C is equipped with serial CAN, RS485 and

ETHERNET, 3 inputs (1 on-board NTC + 1 remote

configurable NTC/DI +1 remote current/voltage configurable).

FREE Panel EVP 3500/C/R is equipped with serial CAN, RS485 and ETHERNET, 3 i

nputs (1 on-board humidity module + 1

on-board NTC + 1 remote configurable NTC/DI) .

The EVP comes with a built-in 128x64px graphical user terminal.

- - 24V~/c or 48Vc power supply.

1.2 Models and Features

<IMG INFO>

56,65

29,75

1

2

51

- -> See Appendix A - Models and Accessories, and Technical Data section.

FREE Panel

4/38

Page 5

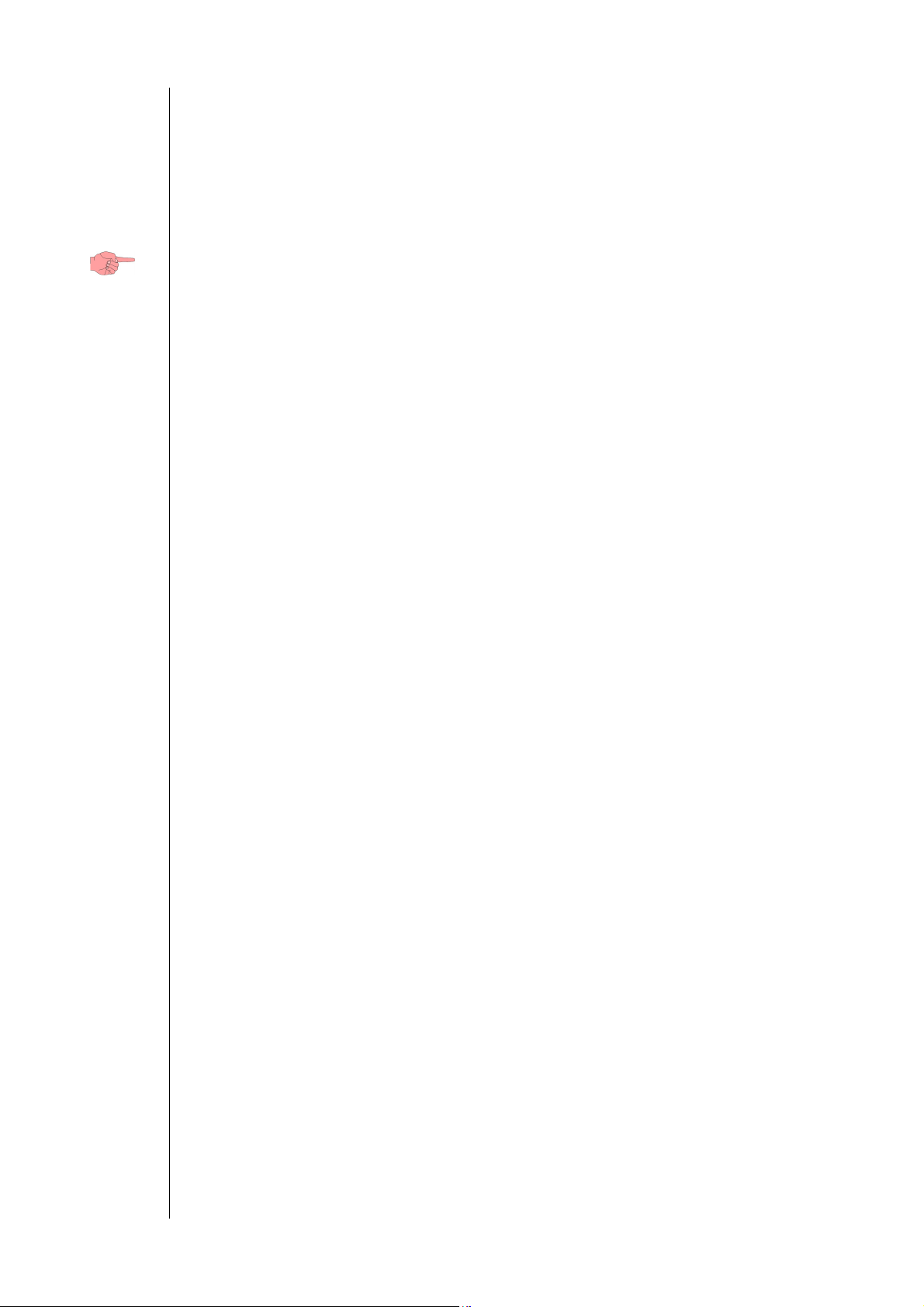

2 MECHANICAL INSTALLATION

IMPORTANT! Always make sure the device is switched OFF before touching connections.

operations must be carried out by qualified personnel.

All

Do not mount devices in extremely damp and/or dirt-laden areas; they are designed for use in places with ordinary or

normal levels of contamination.

Make sure the area near the cooling slots is ventilated.

Mounting the FREE Panel (EVP)

Designed for panel mounting.

Make a 138x68mm hole.

Remove the front panel (figure 1) and make 4 holes in the panel that the controller is to be mounted on (Figure 2, points

A/B/C/D) or two holes (Figure 2, points E/F) of dia. 2.7 mm at the specified spacing (Figure 2).

Insert the device, fixing it with the screws. Press the front of the remote terminal to close.

Figure 1

Cut out EVP

A

E

68

Figure 2

Cut out EVP

138

B

F

84

DC

90

150

(x 6)

2.7

FREE Panel

5/38

Page 6

3 ELECTRICAL CONNECTIONS

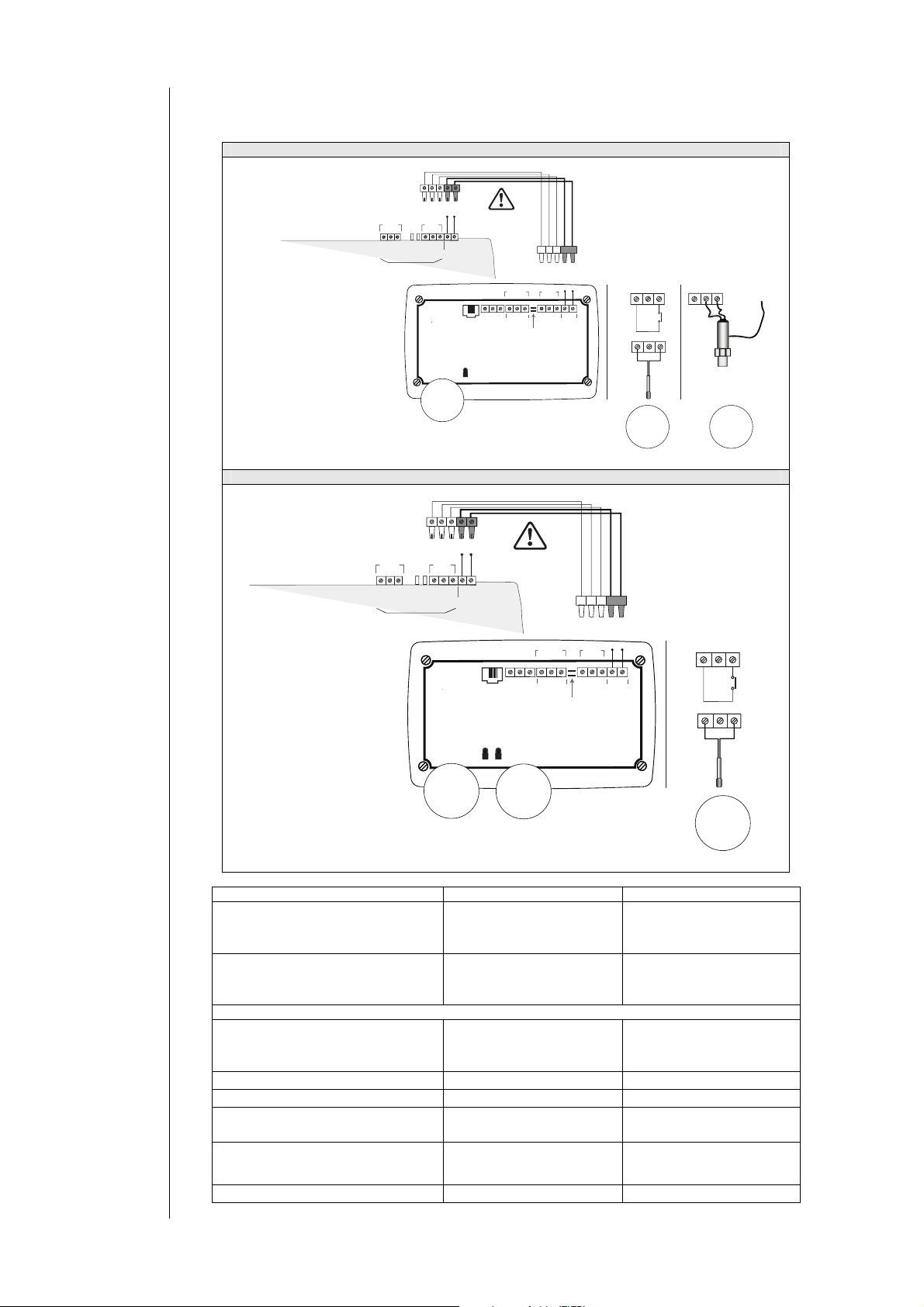

<IMG INFO>

30,7

43,9

1

2

51

-28,35

-1

<IMG INFO>

30,7

43,9

1

2

51

-28,35

-1

Temperature

obes

pr

Pressure probes

3.1 General warnings

Before proceeding with any operation, make sure the device is connected to a suitable external transformer. T

following rules must be followed when connecting cards to each other and to the application:

Loads that exceed the maximum limits stated in this manual must not be applied to outputs.

When connecting loads, follow the circuit diagrams carefully.

To avoid unwanted couplings, wire all SELV (safety extra voltage) users separately from high voltage

IMPORTANT!

Make sure the appliance is switched off before working on electrical connections.

by skilled personnel. To ensure proper connections,

3.1.1 Power supply

Important!

Make sure that the power supply is

3.1.2 Analogue Inputs-Probes

Probes have no connection polarity and can be exten

probes influences the electromagnetic compatibility (EMC) of the instrument: take great care with the wiring).

Important!

Pressure probes

Signal leads (temperature/pressure probes, digita

routed separately from power cables.

Use probes supplied by Eliwell. Contact Eliwell sales department for parts availability.

users.

Operations must be carried out

comply with the following:

Power supplies other than those specified can seri

ously damage the system.

Select cables of suitable section for the terminals used

Separate the cables of probes and digital inputs from inductive loads and high voltage connections to prevent

y electromagnetic interference. Do not place probe signal leads near other electrical equipment (switches,

an

meters, etc.)

Make connections as s

hort as possible and do not wind them around electrically connected parts.

To avoid electrostatic discharges, do not touch the electronic components on printed circuit boards.

The device must be connected to a suitable transformer th

Technical Data ch

apter.

at complies with the specifications indicated in the

of the correct voltage for the instrument.

ded using a normal two core cable (note that the extension of the

have a specific connection polarity, which must be observed.

l inputs, RS-485/CAN-BUS serials and the electronic supply) must be

he

3.1.3 Serial connections

On-board CAN as

On-board RS485 as

On-board ETHERNET seria

standard

standard

l as standard

Pay special attention when connecting serial lines: Do not connect instruments that communicate using RS485 seria

minals, or CAN instruments to RS485 terminals.

CAN ter

CAN

CAN

TE 1

NO

Use a shielded and "twisted pair" cable with two 0.5mm

2

conductors, plus braiding (ideally Belden cable model

3105A (characteristic impedance 120 Ohms) with PVC sleeve, 2 conductors plus braid, 22 AWG, nominal capacity

between conductors 36pF/m, nominal capacity between conductor and shielding 68pF/m).

Always follow regulations applicable to the routing and connection of cables. Make certain that data transmission

circuits are properly separated from power lines.

For connections

TERM jumpers (available on the terminal strip beside the CAN seria

over longer distances, it is better to end the line with resistors on both ends, inserting the two R

l as the default factory configuration).

NOTE 2

The maximum distance depends on the baud setting.

Kb/s (Kbaud) On-board

CAN

50 Kbaud 1000m

125 Kbaud 500m

250 Kbaud 250m

500 Kbaud 60m

NOTE 3

5-way terminal strip:

3-way ( “GS“, “H and “L”) serial CAN

2-way POWER supply

l to

Page 7

RS485

T

ETHERNE

RS485

INSTALLING THE

NOTE 1

Use a shielded and "twisted pair" cable with two 0.5mm

PVC sleeve, 2 conductors plus braid, 20 AWG, nominal capacity between conductors 89pF/m, nominal capacity between

conductor and shielding 161pF/m).

See EN 50174 standard on IT cabling for indications on how cables should be routed.

Make certain that data transmission circuits are properly separated from power lines.

An RS-485 network up to 1200m in length with a maximum of 256* devices can be

*Note: example of Evolution Modbus Slave with single Master supervisor.

This length can b

NOTE 2

Single terminal strip with 3 conductors: use all 3 conductors (“+”, “-“ for the signal and “GS” for the braid).

NOTE 3

Attach the 120 (Ohm) 1/4W resistors between the "+" and "-" terminals of the interface and the last controller in each

branch of the network.

NOTE 4

Maximum settable speed 57600 baud. Higher speeds are envisaged for local connection to FREE Studio Device and tests.

ETH

The Ethernet c

The connection allows:

connection of different controllers and/or applications exchanging variables and/or parameters (netw

connection of a supervision system using Modbus TCP/IP protocol

connection of an IEC 61131-3 Free Studio development system

NOTE: The Ethernet

of the input and output channels.

RS-485 NETWORK

e extended and the number of devices for each channel increased using appropriate repeater modules.

onnection allows the FREE PANEL to communicate on an Ethernet network using TCP/IP protocol.

connector shield is internally connected to the earth of the instrument and therefore to the reference

2

conductors, plus braiding (ideally Belden cable model 8762 with

connected straight to the controller.

ork).

FREE Panel

7/38

Page 8

3.2 Wiring diagrams

FREE EVOLUTION

EVD ● EVC

CAN: max distance depending on baud rate

R TERM

R TERM

POWER

CAN

GS H L POWER

CAN

AI1

NTC Sensor Built-in

OUT

Ethernet

RS485

GS - +

RS485

AI1

EVP3300/C

WARNING

WHILE CABLING

Remote

RS485

Probes

+-GS

AI2 AI3 G

RS485 CAN

EVP3300/C

RTERM

CAN

GS H L

24 Va/c

48 Vc

POWER

10m

POWER : max distance

Remote Probes

AI3 G

+12V External

Power Supply

example of

Transducer

Digital

input

NTC

AI2 G

AI2 G

Built-in Probe

RS485

R TERM

GS - +

RS485

FREE EVOLUTION

EVD ● EVC

EVP3500/C/RH

CAN: max distance depending on baud rate

CAN

R TERM

GS H L POWER

CAN

POWER

OUT

WARNING

WHILE CABLING

Remote

Probes

AI2 AI3 G

Ethernet

RS485

+-GS

RS485 CAN

RTERM

GS H L

EVP3500/C/RH

AI1

NTC Sensor Built-in

AI1

AI4

RH Sensor Built-in

AI4

Built-in Probes

Label Description

POWER

CAN

GS H L

24Va/c - 48Vc

suppl y

Isolated CAN seri

GS ground serial isolated

from G

e

pow r

al

cross – cabling: incorrect cabling irreversibly damages EVP and FREE Evolution

RS485

GS - +

Isolated RS485 se

GS ground serial isolated

from G

rial

Ethernet ETHERNET serial

Built-in AI1 NTC Sensor On-board NTC sensor

AI2 Remote Probes

G

AI3 Remote Probes

G

NTC, D.I. remote

Ground GND

4...20mA/0-10V/0-5V

Ground GND

Built-in AI4 RH Sensor On-board RH% sensor

CAN

AI2 AI3

10m

POWER : max distance

24 Va/c

48 Vc

POWER

Remote Probe

AI2 G

Digital

input

AI2 G

NTC

AI2

Notes

Pin POWER Vout on EVD/EVC

Max. distance 10m EVPEVD/EVC

R TERM termination resistors

for CAN

Apply 120 Ohm terminal

resistors

Probe not included

EVP3300/C

Probe not included

12V External power supply

EVP3500/C/RH

FREE Panel

8/38

Page 9

3.3 Analogue inputs

Inputs can be configured as specified in the table below.

Parameter Description

Cfg_AI1

Cfg_AI2

Cfg_AI3

The temperature and humidity measurement, as well as the corresponding precisions and tolerances, refer to the

application point of the probes inside the instruments.

If these same measurements are to be referred to air conditions outside of the instrument, e.g. ambient measurements,

account must be taken of offset (differential) parameters th

instrument itself.

The differentials e.g. Calibration parameters th

for on-board (built-in) sensors, 'compensation' parameters are

Factory values

for these

offsets assume

a typical

installation with wall mounted backplate in a non-ventilated environment and with the display

these conditions the following calibration values are obtained:

Compensation_AI1 = -12.0 °C

Compensation_AI4 = -10.5 °C

If the usage conditions require the backlight to be mainly ON, the values must be modified as follows:

Compensation_AI1 = -15.0 °C

Compensation_AI4 = -13.0 °C

For other mounting conditions, it is advisable to carry out calibration during installation, checking the temperature and

relative humidity differences between the external air and the internal probes and if necessary correcting the parameters

Com

In any case it is possible to achieve a precision of +- 1°C on the temperature measurement and +- 3%RH on the relative

humidity measurement.

Parameter Description

Calibration_AI1 Analogue input AI1 differential °C/10 or °F/10 -180 ... 180

Calibration_AI2 Analogue input AI2 differential °C/10 or °F/10 -180 ... 180

Calibration_AI3 Analogue input AI3 differential -1000 ... 1000

Calibration_AI4 Analogue input AI4 differential

Parameter Description

Compensation_AI1

Compensation_AI4

pensation_AI1/ Compensation_AI4

Type of input

analogue

AI1

Type of input

analogue

AI2

Type of input

analogue

AI3

Parameter Range Description

FullScaleMin_AI3 -9999…+9999 Analogue input AI3 start of scale value

FullScaleMax_AI3 -9999…+9999 Analogue input AI3 full scale value

Internal compensation AI1

difference between external air

temperature and measurement

Internal compensation AI4

difference between external

temperature and T measurement

read by RH sensor AI4 (this

temperature is used to calculate

the relative humidity based on

0 1 2 3 4 5

NTC

probe

(NK103)

NTC

probe

(NK103)

- - -

at can be set are

read by NTC sensor AI1

psychrometric charts)

Probe

configured

as voltagefree digital

input

Probe

configured

as voltagefree digital

input

at depend on the installation and usage conditions of the

also available

Values

NTC

probe

(103AT-2)

NTC

probe

(103AT-2)

Unit of Measure range

Unit of Measure range

°C/10 or °F/10 -1000 ... 1000

°C/10 or °F/10 -1000 ... 1000

- - -

- - -

4-20

mA

0-10

V

backlighting mainly OFF. In

0-5 V

-1000 ... 1000

FREE Panel

9/38

Page 10

3.4 Connections

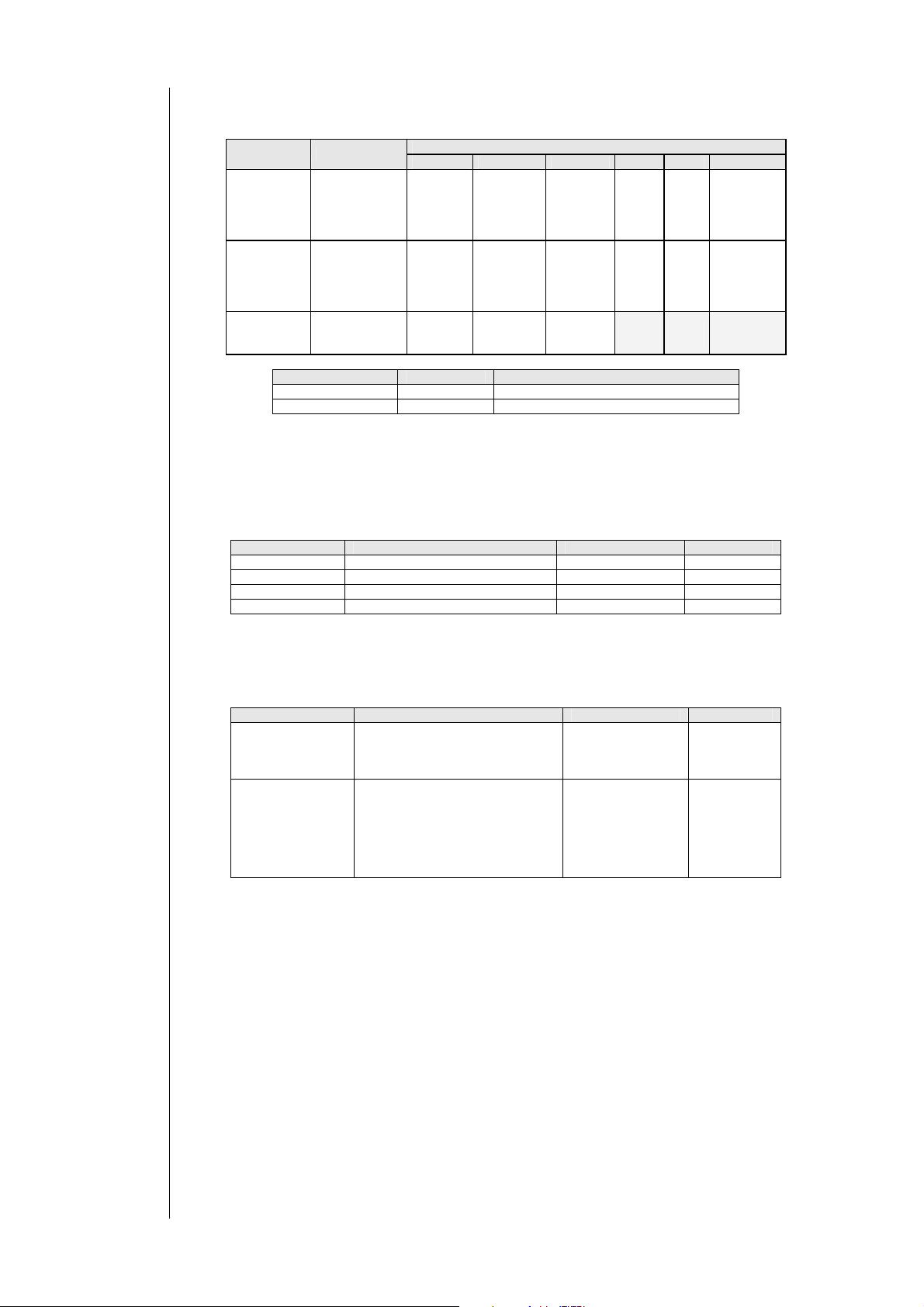

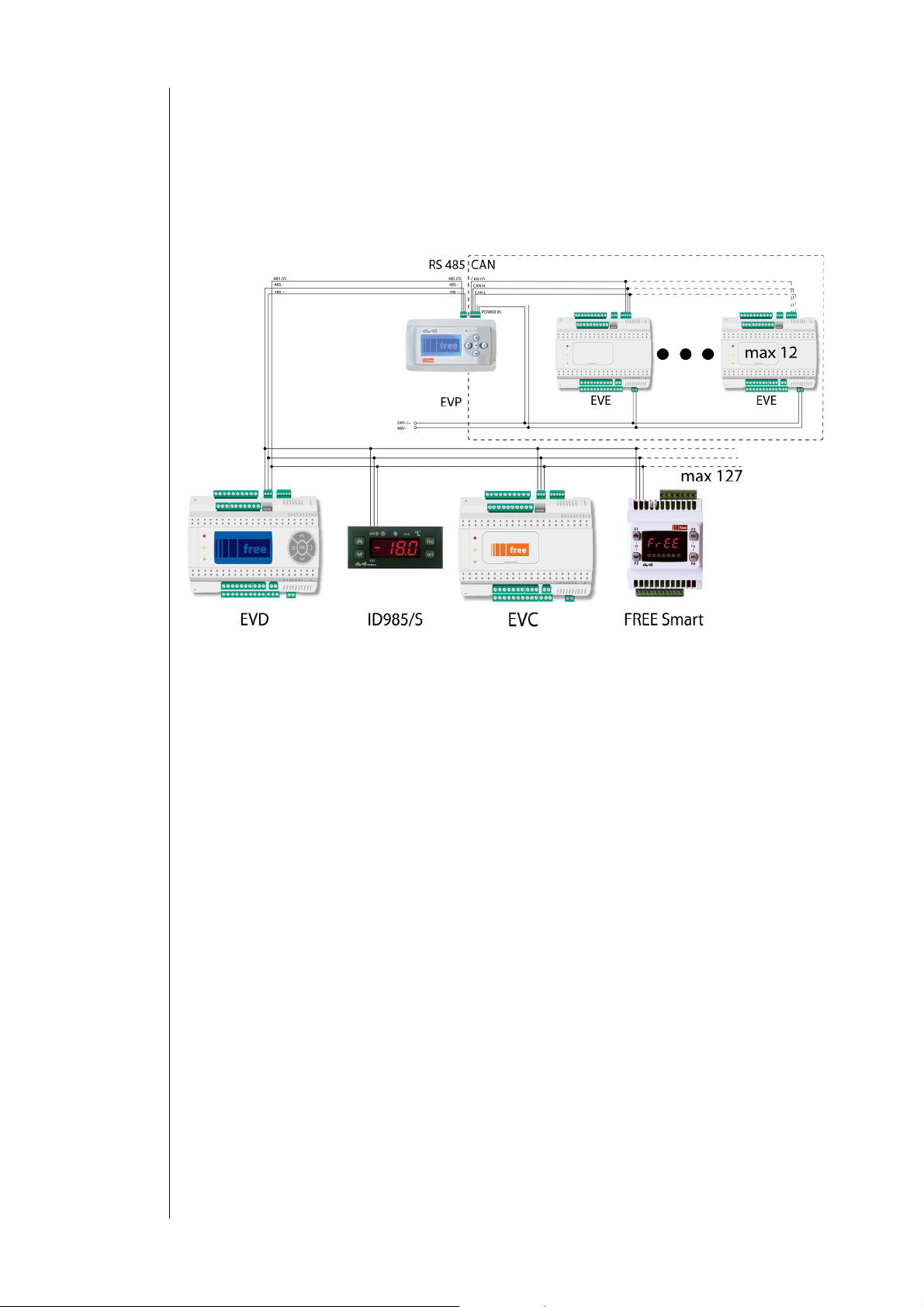

3.4.1 Example: RS485 connection (Field)

1 FREE Panel EVP

Max 127 FREE Evolution EVE expansion modules connected in RS485

o E

VP is in Modbus RTU Master mode

o EVEs are in Modbus RTU Slave mode

485 GS

485 -

485 +

Switch/Router

Ethernet

FREE Studio / Supervisor

POWER IN

EVP

24Va/c

CAN GS

CAN H

CAN L

48Va

POWER IN

<IMG INFO>

3.4.2 CAN connection example (Field)

1 FREE Panel EVP

Max 12 FREE Evolution EVE expansion modules connected in CAN

EVE

1

485 GS

485 -

485 +

max 127

EVE

127

max 12

24Va/c

48Va

EVP

EVE

EVE

FREE Panel

10/38

Page 11

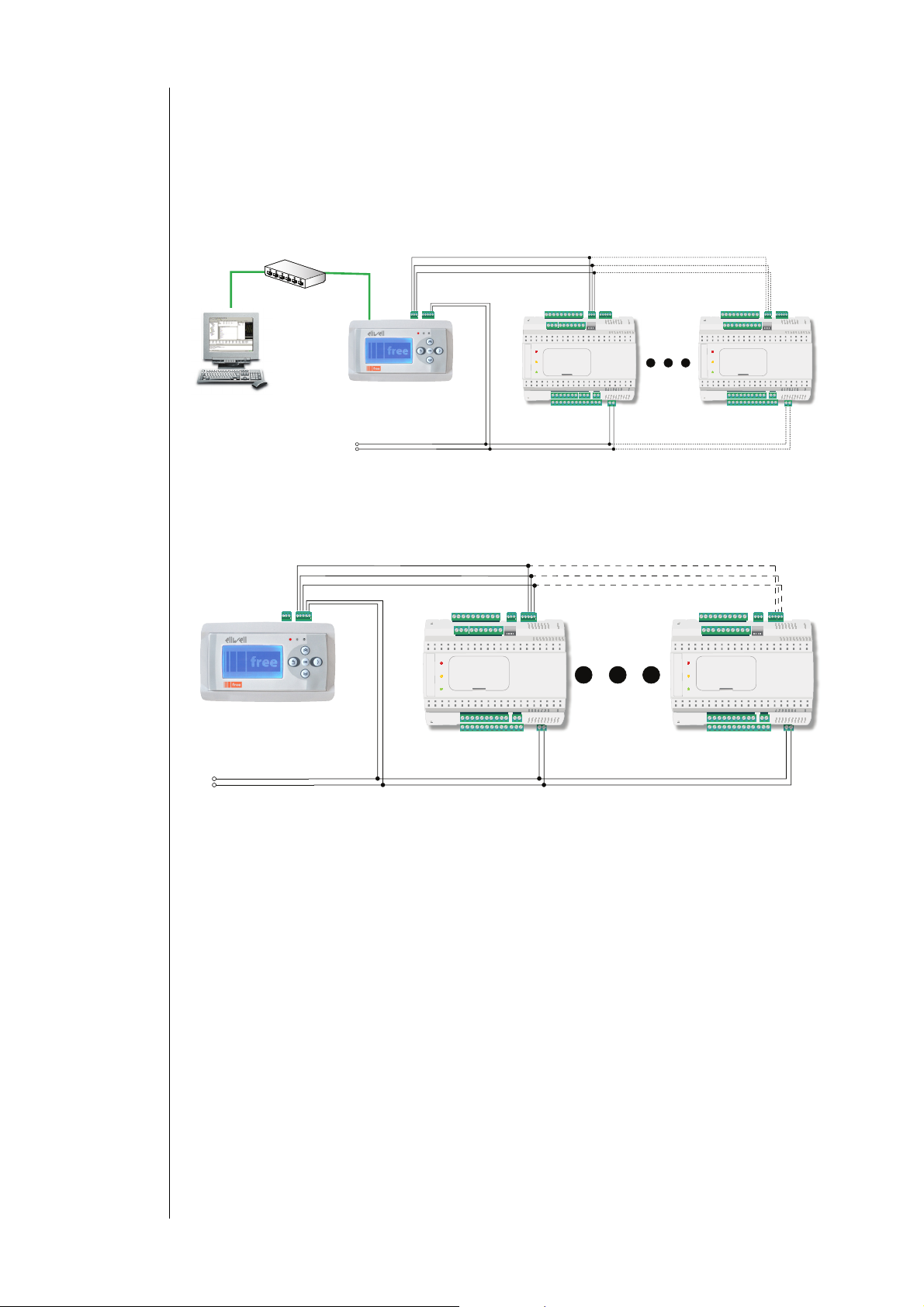

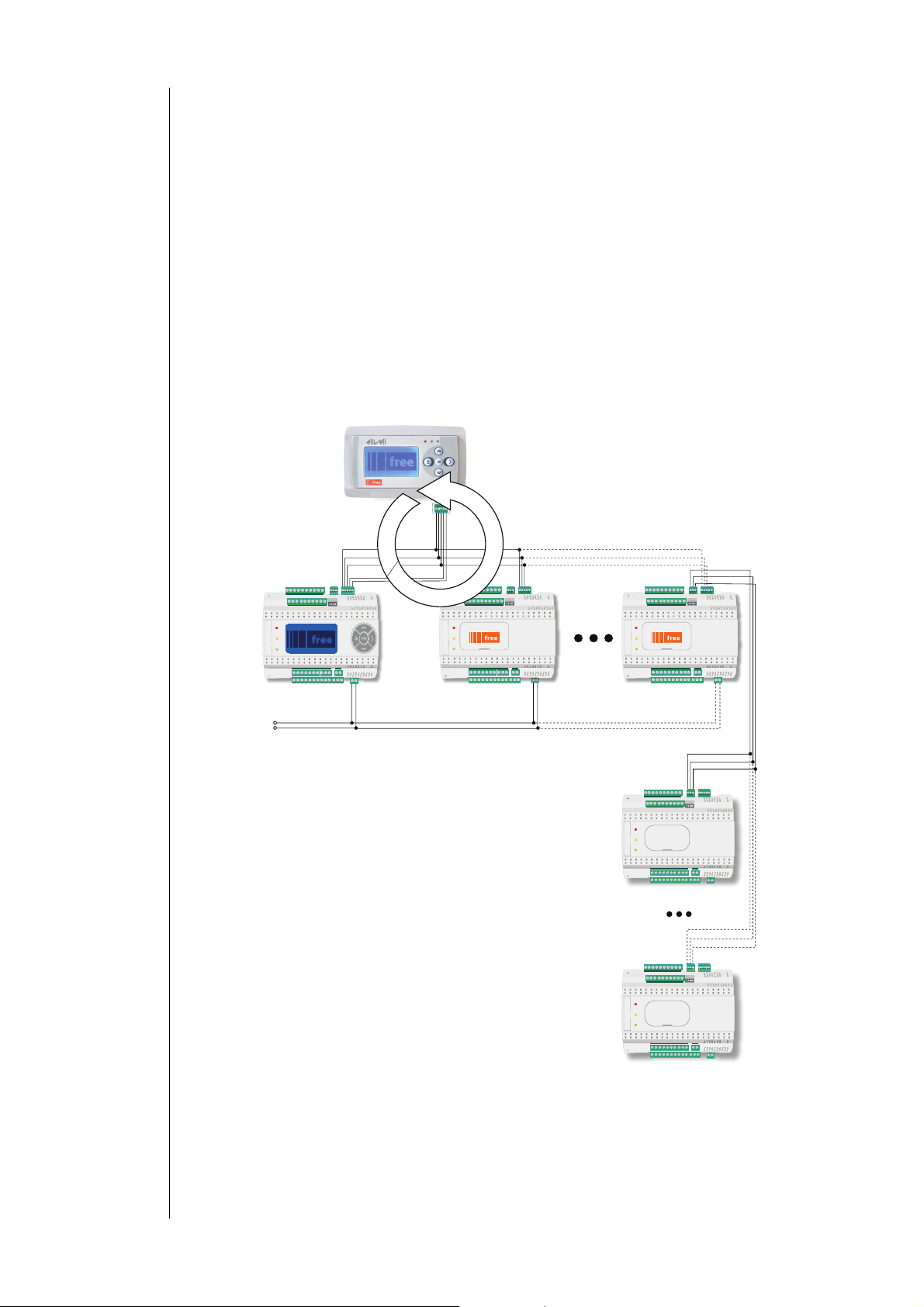

3.4.3 Example: RS485 connection with FREE Smart network

1 FREE Panel EVP

Max 127 FREE Evolution EVD/EVC or FREE Smart or Eliwell and/or third-party instruments equipped with

RS485 serial

CAN n

VP is in Modbus RTU Master mode

o E

o All devices equipped with RS485 are in

modules)

etwork – see CAN connection example

Modbus RTU Slave mode (including the FREE Evolution

FREE Panel

11/38

Page 12

3.4.4 CANopen network connection example

1 FREE Panel EVP

Max 10 FREE Evolution EVD/EVC

CAN n

etwork – see CAN connection example (Field)

HMI menu

EVP can be e

In this case EVP is programmed with the network menu, which can re

quipped with its own menu (named Network menu)

ad variables present in the Evolution controller

network

EVP can o

perate from the terminal of the individual controllers and download up to 10 remote menus from the respective

Evolution controllers

In this case the remote menu allows 'local' navigation of the individual Evolution controller

PLC

The variables of the various controllers are shared (bound together)

A PLC present on EVP can

use variables present in the network and share its own variables with other PLCs present on the

respective Evolution controllers

EVP

24Va/c

48Va

EVD

1

CAN GS

CAN H

CAN L

POWER OUT

POWER

CAN

POWER

Binding

CAN GS

CAN H

CAN L

485 GS

485 -

485 +

max 10

EVC

2

EVC

10

485 GS

485 -

485 +

EVE 1

485 GS

485 -

485 +

EVE 127

FREE Panel

12/38

Page 13

FREE WEB

E

P

BRIDG

The FREE Panel product is also designated FREE WEB

The Ethernet c

Evolution.

FREE WEB

REE Studio allows the creation and management of web pages internally of FREE WEB, i.e. a veritab

F

WEB functionalities allow complete local or remote access by way of an ordinary browser. Thanks to the web connection,

the system provides remote reading and support and remote diagnostics services, as well as e-mail alarm alerts.

Note. Connection to FREE WEB re

NOTE: refer to the section on Parameters / ETHERNET PASSIVE

BRIDGE

REE Studio allows monitoring of FREE Smart tools or third party tools, typically Modbus/RTU slaves, where FREE WEB (or

F

FREE Evolution with Plug-In ETH) is the Master Modbus/RTU.

In a FREE Studio project, more exactly, FREE WEB is u

for Modbus 0x03 and 0x10 commands.

E.g. from FREE Studio, set the connection with FREE Smart as Modbus/TCP, inserting the FREE WEB IP address and the

Modbus/RTU add

onnection also allows communication using HTTP protocol, i.e. access to a Web Server contained in FREE

le website in miniature.

mains possible by way of FREE Studio.

PLUG-IN folder

sed as a Modbus/TCP to Modbus/RTU protocol conversion element

ress of the Smart slave.

Trivial File Transfer Protocol)

TFTP (

TFT

Note. TFTP (Tr

network.

ivial File Transfer Protocol) can also be enabled for file transfer between PC and controller on an Ethernet

FREE Panel

13/38

Page 14

4 TECHNICAL DATA

4.1 General Technical Data

Standard Min. Max.

Supply voltage* 24V~/c ±20%

Power supply frequency 50Hz/60Hz --- ---

Power consumption 5W

Insulation class 2 --- --Ambient operating temperature 25°C -10°C +55°C

Ambient operating temperature of EVK1000 terminal 25°C -5°C +55°C

Ambient operating humidity (non-condensing) 30% 10% 90%

Storage temperature 25°C -20°C +85°C

Ambient storage humidity (non-condensing) 30% 10% 90%

* powered via FREE Evolution EVD/EVC or directly via a transformer

Note: power cable must not be longer than 10m

Classification

The product meets the requirements of the following

Type of disconnection or suspension for each circuit Microswitch disconnection

European Community Directives

and complies with the following harmonized

regulations

Use

Mounting on DIN Omega bar support

Type of action 1.B

Pollution class 2 (normal)

Over voltage category II

Nominal pulse voltage 2500V

Digital outputs refer to the label on the device

Fire resistance category D

Software class and structure A

PTI of materials used for insulation PTI 250V

Period of electrical stress on the insulating parts Long period

EN 60730-2-6 / EN 60730-2-9 / EN 60730-1

in terms of construction, as an independently mounted

temperature-sensitive automatic electronic controller

or

48Vc ±20%

Directive 2006/95/EC

Directive 89/108/EC

21V 60V

4.2 I/O features

Type and

Label

Analogue

inputs

AI1

AI2

configurable

AI3

configurable

AI4

*50mA maximum current @5V; **Clean contact.

Note: Also see Electrical Connections ch

probe Description Resolution Accuracy

On-

board

Remote

NOT

included

Remote

NOT

included

On-

board

NTC 0.1°C/°F

NTC 103AT 0.1°C/°F

NTC NK103 0.1°C/°F

D.I.** 20KΩ

4...20mA 1 digit

0-5V* 1 digit

0..10V 1 digit

On-board

%RH input

apter / Analogue Inputs paragraph for instructions on offsets and calibrations

0.01%RH

(0%=0pt,

100% =

1000pt)

0.5% f.s + 1

digit

0.5% f.s + 1

digit

0.5% f.s + 1

digit

1% f.s +1

digit

1% f.s +1

digit

1% f.s +1

digit

±3%

[20...80%]

±5% …] […

elsewhere

Measurement

range

10KΩ x x

–50…+110 °C

(-58...230°F)

-40…+150 °C

(-40...302°F)

0…1000 100Ω

0…1000 21KΩ

0…1000 21KΩ

0-100 %RH

Impedance

10KΩ

10KΩ

3500

3300

/C

/C

/RH

x x

x

x

Page 15

4.3 Display

backlit with LEDs +

3 LEDs

Note: LED and backlighting can b

Protection rating: The single-mould plastic front cover allows for water resistant panel mounting that is

Display:

Container: backplate + frame in PC+ABS UL94 V-0 plastic resin, front cover in transparent

Monochromatic LCD graphic display 128x64px backlit with LEDs

e controlled from IEC application

comparable to IP65 protection.

polycarbonate, polyester membrane keys

4.4 Serials

Serial Description Notes

CAN Open opto-isolated serial CAN

RS-485 Opto-isolated RS-485 Modbus RTU serial

ETHERNET Modbus TCP/IP ETHERNET port

max50m@500kpbs

200m@125kpbs

Note: 2 jumpers available for

CAN ter

Pay special attention when

connecting serial lines: do not

cable RS485 in

Pack includes MACADDRESS, in

12-digit alphanumeric format

minal resistance

CAN port or

vice versa

barcode and

4.5 Transformer

The instrument must be connected to a suitable current transformer with the following features:

Primary voltage: Depending on requirements of device and/or country of installation

Secondary voltage: 24V~/c - 48Vc ±20%

Power supply fre

Power: 5W min.

quency V~: 50/60Hz

4.6 Mechanical dimensions

Length (L) mm Depth (d)

Space required 160

Hole for panel mounting 68 / 138 (+0.2 mm /

mm

10 96

Height (H) mm Notes

-0.1 mm)

4.7 Permitted use

For safety reasons, the device must be installed and used according to the instructions provided. In particular, parts

carrying dangerous voltages must not be accessible in normal conditions.

The device must be adequately protected from water and dust with regard to the application, and must only be accessible

using tools (with the exception of the front panel).

The device is suitable for use in household and/or similar air conditioning appliances or installations and has been tested

for safety aspects in accordance with harmonized European reference standards.

4.8 Improper Use

Any use other than that expressly permitted is prohibited.

The relay contacts supplied are of the functional type and subject to fault (since they are electronically controlled they are

prone to short-circuiting or remaining open). Any protection devices specified in product standards or suggested by

common sense for obvious safety requirements must be installed externally to the device.

Eliwell is not liable for damage caused by:

Unspecified installation/use and, in particular, in contravention of the safety requirements of established legislation or

specified in this document;

Use on equipment which does not provide adequate protection against electrocution, water and dust in the actual

installation conditions;

Use on equipment in which dangerous components can be

Installation/use on equipment which does not comply with established legislation and standards.

accessed without the use of specific tools;

4.9 Disclaimer

This document is the exclusive property of Eliwell Controls srl and may not be reproduced or circulated unless expressly

authorized by Eliwell Controls srl itself.

Every care has been taken in preparing this document; however, Eliwell Controls srl cannot accept liability for any

damage resulting from its use.

FREE Panel

15/38

Page 16

5 USER INTERFACE

The interface, comprising the front cover of the controller, allows you to perform all operations needed to use the device.

EVP

DIA Menu

5.1 Keys and LEDs

The LEDs can be programmed from the IEC application.

The keys can be

following default settings.

EVP is factory configured with a default DIA

After uploading of an IEC application and/or a HMI menu from FREE Studio, the main display c

menu created with FREE Studio Interface.

In which case, to open the DIAGNOSTICS menu pr

To return to the IEC application menu open the ‘HMI Management’ p

See Remote Interface paragraph

programmed from the IEC application. By default, the device displays a short menu containing the

Key Key

Scroll up

1 UP

2 OK

3 > Moves cursor to right in Edit Mode

4 DOWN

5

Exit

Key combination

4+5

Return to previous page (e.g. 2/10 3/10)

Increase / modify a value

Go to the next label

Scroll down

Move to next level/menu (open folder,

value)

Enter/exit edit mode

Confirm operation

Scroll down

Move to the next page (e.g. 1/102/10)

Decrease / modify a value

Go to previous label

Exit menu page / go back to previous menu

Move cursor to left in Edit Mode

(press and hold) Exit Edit Mode without saving any changes

GNOSTICS (DIA) menu that appears when the instrument is powered on.

oceed as follows:

DOWN

Exit

Press once

(press and release)

subfolder, parameter,

Prolonged press (press and hold for

about 3 seconds)

Open DIAGNOSTICS menu

age, select and press the OK key

onsists of the application

Page 17

5.2 First power on

When the instrument is powered up for the first time, a few summary pages are displayed showing system status (SYSTEM

INFO)

The system will also search for the PLC application and the local menu…

If present, the menu will appear on the display

SYSTEM INFO

HW

BIOS

DATE

BOOT

EEPROM

NOR FLASH OK

NAND FLASH OK

SDRAM OK

BATRAM OK

RTC OK

searching …

PLC

HMI searching …

CON loaded

5.3 DIAGNOSTICS menu

The DIAGONISTICS menu, native to EVP, is used to manage system parameters (BIOS parameters), remote interfaces (HMI)

and to display I/

The DIA menu can be

To change the default language, o

O values and clock

displayed in 5 languages: English, Italian, German, Spanish and French.

pen BIOS Parameters > Display

EVP

BIOS parameters

HMI Management

Probe values

Date and time

5.3.1 BIOS parameters

Parameter configuration menu. See Parameters ch

Note: This menu is depopulated with respect to the parameters tab

FREE Studio device

Language c

BIOS parameters <

select language <

See parameter Display/Hmi_Language

hange example

OK key > Display 1/3 < OK key > Edit Mode < UP/DOWN key >

OK key > < key >

apter.

BIOS parameters

Display

Buzzer

CAN

Display

1/3

Language

Italiano

Display

1/3

Language

English

le contained in the corresponding chapter and in the

FREE Panel

17/38

Page 18

5.3.2 HMI Management

See Remote Interface paragraph

5.3.3 Probe values

Shows input values (read only)

EVP has 3 inputs. Example EVP3500/C/RH

Note: for offset programming see the section on Analogue Inputs in the Connections chapter

5.3.3.1 Date and time

Shows time (HH : MM : SS) and date (DD / MM / YY) of the internal clock

To edit the value press OK. Select the value that you want to modify

Press the OK key to enter Edit Mode. Use the UP and DOWN keys to modify value. Confirm with the OK key

Select ‘Update’ and press OK to update the clock

Probes values

1/3

Internal NTC External NTC Humidity sensor

27.3 - - - - - - - - - - - - - - 43.38

°C, °F °C, °F RH%

Probes values

2/3

Date and time

14 : 45 : 45

20 / 07 / 11

Update

Date and time

16 : 50 : 56

20 / 07 / 11

Update

Probes values

3/3

5.4 Remote interface

Language: 0

5.4.1 Language

This section is for setting the language

The number of languages and the order are established by the corresponding application/menu

See parameter HMI Management/Hmi_Language

5.4.2

o return to the menu of the IEC application, move the cursor onto this symbol and press the OK key

T

See HMI sel

5.4.3 HMI sel

This

section is for setting the menu to be shown on the display

default H

By

Network: this is the EVP ‘local’ menu (local HMI)

rem1…rem10: menus located on max 10 Evolution devices connected to the network that can be

MI menus are NOT present (only the DIA menu is available)

EVP EVP EVP

HMI sel: Network HMI sel: rem1 … HMI sel: rem10

of the remote menu, defined from the FREE Studio User Interface

EVP

HMI sel: Network

COM setting

HMI Management

‘uploaded’ to EVP

FREE Panel

18/38

Page 19

To move from one page to the next press the UP and DOWN keys

After selecting the desired menu move the cursor onto to view the menu

If OK the display

If the menu is not present, the following screen appears

5.4.3.1 COM Setting

This read-only page shows the configuration of the EVP serial ports

5.4.3.2 HMI Management

This page shows the configuration of the 10 remote pages

From these pages it is possible to ‘launch’ (run) the corresponding menu – if present

Move the cursor onto and press the OK key

Note: it will not be possible to launch the local (network) menu from this section

Note: in the example only one remote page is present

To ‘upload’ a remote page use

After selecting the desired menu move the cursor onto to view the menu

Press OK to upload or any other key to cancel

Note: the upload may take up to a minute

If there are no data to upload, the following screen displays

will show the selected menu (IEC application)

EVP

1/10

File: HMIREM.KBD

Id: 0 Id: 0 … Id: 0

Com: CAN Com: CAN Com: CAN

Addr: 125 Addr: 000 Addr: 000

Launch remote page

Please Wait

Warning

Upload failed

Press OK

EVP

CAN : 1 . 500000

485s : 1 . 38400.P81

ETH : 010.000.000.100

EVP

1/10

Upload remote page

Upload page?

The process cannot

be interrupted

Cancel OK

Upload remote page

Uploading…

80%

Attenzione

There are no remote

pages on the card

Press OK

EVP 10/10

FREE Panel

19/38

Page 20

FOLDER

x

LABEL

VAL PAR ADDRESS

RESET (Y/N)

R/W

DATA SIZE

CPL

RANGE

DEFAULT

U.M.

6 PARAMETERS

User-parameterization renders the FREE Panel EVP fully configurable.

Parameters can b

Keys on the EVP front panel

PC and FREE Studio software

The following sections provide a detailed analysis of each parameter, divided into categories (folders).

6.1 Table of parameters

The following table contains all the device configuration parameters available in FREE Studio Device and in the

DIAGNOSTICS (DIA) / BIOS Parameters men

Description of columns:

This indicates the label

A group of these parameters i

Refer also to the following table:

(x) if present (loaded to EVP)

The local menu - if present (uploaded to EVP) - is defined with the Network label

ndicates the label use

This i

Indicates the address of the modbus register containing the resource to be accessed.

Indicates whether the device MUST be rebooted after the parameter has been changed.

Y=YES the device MUST be rebooted to save the change.

N=NO the device DOES NOT need to be rebooted after changing the parameter

Indicates if resources are read/write, read-only or write-only:

Indicates the size of the data in bits.

When the field indicates “-1”, the value read by the register requires conversion, because the value represents a number

with a sign. In other cases the value is always positive or null.

To carry out the conversion, proceed as follows:

If the value in the register is between 0 and 32.767, the result is the value itself (zero and positive values)

If the value in the register is between 32.768 and 65.535, the result is the value of the register – 65.536 (negative

Describes the interval of values that can be

parameters (in

Indicates the factory setting for the standard model of the instrument.

Unit of measure for values converted according to the rules indicated in the CPL co

The unit of measure shown is an example only, as it may change depending on the application (e.g. parameters wit

in °C/bar could also have %RH)

e changed using:

of the FREE Studio Device folder containing the parameter in question

s available on the LCD display in the DIAGNOSTICS (DIA) menu

FOLDER EVP

ACKNOWLEDGEMENT x -

AI CALIBRATION x -

ANALOGUE INPUTS x -

All Parameters

HMI management

d to display the parameters

R The resource is read-only

W The resource is write-only

RW The resource can be bot

values)

dicated in the parameter label).

ON-BOARD RS485 x -

ON-BOARD CAN x x

ETHERNET x x

HMI management x x

HMI remote 1 (rem1) x (x)

HMI remote 10 (rem10)

u

EVP

DIA

(x)

lumn

Display x x

Buzzer:

… x (x)

h read and written to

assigned to the parameter. It can be correlated with other instrument

x x

h a U.M.

6.1.1 Table of parameters

(See next page)

FREE Panel

20/38

Page 21

EVP parameters

FOLDER

ACKNOWLEDGEMENT Par_TAB 15716 WORD Y RW

ACKNOWLEDGEMENT Par_POLI 15717 WORD Y RW

ACKNOWLEDGEMENT Par_PARMOD 15719 BOOL RW

AI CALIBRATION Gain_Ntc_AI1 15616 WORD RW Ai1 NTC calibration gain 0 … 65535 32768 num.

AI CALIBRATION Gain_Ntc_AI2 15617 WORD RW Ai2 NTC calibration gain 0 … 65535 32768 num.

AI CALIBRATION Gain_5V_AI3 15620 WORD RW Ai3 0-5V calibration gain 0 … 65535 32768 num.

AI CALIBRATION Gain_10V_AI3 15621 WORD RW Ai3 0-10V calibration gain 0 … 65535 32768 num.

AI CALIBRATION Gain_mA_AI3 15622 WORD RW Ai3 4-20mA calibration gain 0 … 65535 32768 num.

AI CALIBRATION Offs_Ntc_AI1 15650 WORD -1 RW Ai1 NTC calibration offset -32768 … 32767 0 num.

AI CALIBRATION Offs_Ntc_AI2 15651 WORD -1 RW Ai2 NTC calibration offset -32768 … 32767 0 num.

AI CALIBRATION Offs_5V_AI3 15654 WORD -1 RW Ai3 0-5V calibration offset -32768 … 32767 0 num.

AI CALIBRATION Offs_10V_AI3 15655 WORD -1 RW Ai3 0-10V calibration offset -32768 … 32767 0 num.

AI CALIBRATION Offs_mA_AI3 15656 WORD -1 RW Ai3 4-20mA calibration offset -32768 … 32767 0 num.

LABEL

ADDRESS

PAR. VALUE

DATA SIZE

CPL

R/W

RESET (Y/N)

Map code

Note: read/write parameter

Model Code

Note: read/write parameter

Parameter changed

Flag indicating change to default s

0= map not modified.

1= at least one parameter has been changed from the

original configuration.

DESCRIPTION

ettings.

RANGE

0 … 65535 0 num.

0 … 65535 1025 num.

0 … 1 0 num.

DEFAULT

U.M.

FREE Panel

21/38

Page 22

FOLDER

ANALOGUE

INPUTS

ANALOGUE

INPUTS

ANALOGUE

INPUTS

ANALOGUE

INPUTS

ANALOGUE

INPUTS

ANALOGUE

INPUTS

ANALOGUE

INPUTS

ANALOGUE

INPUTS

ANALOGUE

INPUTS

ANALOGUE

INPUTS Calibration_Ai3

ANALOGUE

INPUTS Calibration_Ai4

ANALOGUE

INPUTS

ANALOGUE

INPUTS

LABEL

Temp_UM 15725 WORD Y RW

Cfg_AI1 15726 WORD RW

Cfg_Ai2 15727 WORD RW

Cfg_Ai3 15728 WORD RW

Cfg_Ai4 15729 WORD RW

FullScaleMin_Ai3 15736 WORD -1 RW

FullScaleMAx_Ai3 15737 WORD -1 RW

Calibration_Ai1 15748 WORD -1 RW

Calibration_Ai2 15749 WORD -1 RW

Compensation_AI1

Compensation_AI4

ADDRESS

PAR. VALUE

15750 WORD -1 RW

15751 WORD -1 RW

15752 WORD -1 RW Internal compensation AI1 -1000 ... 1000 0 °C/10

15753 WORD -1 RW Internal compensation AI4 -1000 ... 1000 0 °C/10

DATA SIZE

CPL

RESET (Y/N)

R/W

DESCRIPTION

Temperature unit of measure

0 = °C;

1 = °F

Type of analogue input Ai1

0= NTC (NK103)

1= DI

2= NTC (103AT)

Type of analogue input Ai2

See Cfg_Ai1

Type of analogue input Ai3

3 = 4…20mA

4=0-10V

5=0-5V

Type of analogue input Ai4

See Cfg_Ai3

Analogue input Ai3 start of scale value

N.B.: Minimum full scale: for current probes, value at 4mA,

for 0-10V voltage probes, value at 0V, 10% for ( 0-5V) probes,

value at 10% (corresponding to 0.5V).

Analogue input Ai3 full scale value

N.B.: Maximum full scale for current probes, value at 20mA,

for 0-10V voltage probes, value at 10V, for (0-5V) probes,

value at 90% (corresponding to 4.5V).

Analogue input Ai1 differential -180 ... 180 0

Analogue input Ai2 differential -180 ... 180 0

Analogue input Ai3 differential -1000 ... 1000 0

Analogue input Ai4 differential -1000 ... 1000 0

RANGE

0 ... 1 0 num.

0 ... 2 2 num.

0 ... 2 2 num.

3 ... 5 3 num.

3 ... 5 3 num.

-9999…+9999 0

-9999…+9999 1000

DEFAULT

U.M.

°C/10

or

°F/10

°C/10

or

°F/10

FREE Panel

22/38

Page 23

FOLDER

RS485

ON BOARD

RS485

ON BOARD

RS485

ON BOARD

RS485

ON BOARD

RS485

ON BOARD

RS485

ON BOARD

ON-BOARD

CAN

ON-BOARD

CAN

LABEL

VAL PAR AdDRESS

Addr_RS485_OB 15774 WORD

Proto_RS485_OB 15775 WORD

Databit_RS485_O

Stopbit_RS485_O

Parity_RS485_OB 15778 WORD

Baud_RS485_OB 15779 WORD

Addr_CAN_

ud_CAN_

Ba

B 15776 WORD Y RW

B 15777 WORD Y RW

OB 15780 WORD Y RW

OB 15781 WORD Y RW

DATA SIZE

CPL

RESET (Y/N)

Y RW

Y RW

Y RW

Y RW

R/W

DESCRIPTION

On-board RS485 serial address

The actual address is determined by the sum of this value +

the value of the dip switch.

On-board RS485 protocol selection

2 = uNET

3 = Modbus/RTU

On-board RS485 data bit number

Fixed setting 8

On-board RS485 stop bit number

1= 1 stop bit

2= 2 stop bit

On-board RS485 protocol parity

0= NULL

1= ODD

2= EVEN

On-board RS485 protocol baudrate

0=9600 baud

1=19200 baud

2=38400 baud

3=57600 baud

4=76800 baud

5=115200 baud

On-board CAN serial address

The actual address is determined by the sum of this value +

the value of the dip switch.

On-board CAN protocol baudrate

2=500 Kbaud

3=250 Kbaud

4=125 Kbaud

5=125 Kbaud

6=50 Kbaud

RANGE

0 ... 255 1 num.

2 ... 3 2 num.

8 ... 8 8 num.

1... 2 1 num.

0 ... 2 2 num.

0 ... 5 2 num.

1 ... 127 1 num.

2 ... 6 2 num.

DEFAULT

U.M.

FREE Panel

23/38

Page 24

ON BOARD ETHERNET

WEB SERVER FUNCTI

The parameters

HTTP and

FREE WEB

HTTP HyperText Transfer Protocol.

An HTTP server generally listens on port 80 using TCP protocol.

TFTP Trivial File

Protocol using basic FTP functionalities. Typical use: transfer of small files between hosts on a network. TFTP USES

The parameters f

DHCP protocol

TFTP ports

allows the use of HTTP and TFTP servers

ONALITY: For more details refer to document 9IS24252_Web_ApplicationNotes

necessary for the configuration of ports and protocols are these:

value

Port_HTTP

Transfer Protocol.

or configuring the PORTS are:

value

Port_TFTP

value

EnableDHCP_ETH

HTTP port

HTTP communication Port number

Default

TFTP port

mmunication Port number

TFTP co

0 corresponds to port 69

Default

Enable DHCP

0 … 1 (False, True)

0 corresponds to port 80

PORT 69

0

False

0

FREE Panel

24/38

Page 25

DNS system

System for the conversion of host names, or network nodes, to IP addresses

Used by FREE Studio to send text e-mails (strings)

value value

PriDNS_1_ETH

PriDNS_2_ETH

PriDNS_3_ETH

PriDNS_4_ETH

Primary DNS server

(part 1)

Primary DNS server

(part 2)

Primary DNS server

(part 3)

Primary DNS server

(part 4)

194 SecDNS_1_ETH Secondary DNS server (part 1) 194

25 SecDNS_2_ETH Secondary DNS server (part 2) 25

2 SecDNS_3_ETH Secondary DNS server (part 3) 2

129 SecDNS_4_ETH Secondary DNS server (part 4) 130

FOLDER

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

LABEL

Port_TFTP 15772 WORD

Port_HTTP 15796 WORD Y RW

Port_ETH 15797 WORD Y RW

Ip_1_ETH 15798 WORD Y RW

Ip_2ETH 15799 WORD Y RW

Ip_3ETH 15800 WORD Y RW

Ip_4ETH 15801 WORD Y RW

ADDRESS

PAR. VALUE

DATA SIZE

CPL

RESET (Y/N)

Y RW

R/W

DESCRIPTION

TFTP port

mmunication Port number Default 0 corresponds to

TFTP co

port 69

HTTP port

HTTP communication Port number Default 0

port 80

Port

TCP/IP Modbus communication port. Port 502 for example

On-board Ethernet passive IP address (part 1) 0 … 255 10 num.

On-board Ethernet passive IP address (part 2) 0 … 255 0 num.

On-board Ethernet passive IP address (part 3) 0 … 255 0 num.

On-board Ethernet passive IP address (part 4) 0 … 255 100 num.

corresponds to

RANGE

0 … 65535 0 num.

0 … 65535 0 num.

0 … 65535 502 num.

DEFAULT

U.M.

FREE Panel

25/38

Page 26

FOLDER

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

LABEL

DefGtwy_1_ETH 15802 WORD Y RW

DefGtwy_2_ETH 15803 WORD Y RW

DefGtwy_3_ETH 15804 WORD Y RW

DefGtwy_4_ETH 15805 WORD Y RW

NetMsk_1_ETH 15806 WORD Y RW

NetMsk_2_ETH 15807 WORD Y RW

NetMsk_3_ETH 15808 WORD Y RW

NetMsk_4_ETH 15809 WORD Y RW

ADDRESS

PAR. VALUE

DATA SIZE

CPL

RESET (Y/N)

R/W

DESCRIPTION

Default Gateway (part 1) 0 … 255 192 num.

Default Gateway (part 2) 0 … 255 168 num.

Default Gateway (part 3) 0 … 255 0 num.

Default Gateway (part 4) 0 … 255 1 num.

Net mask (part 1) 0 … 255 255 num.

Net mask (part 2) 0 … 255 255 num.

Net mask (part 3) 0 … 255 255 num.

Net mask (part 4) 0 … 255 0 num.

RANGE

DEFAULT

U.M.

FREE Panel

26/38

Page 27

FOLDER

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

ETHERNET

ON BOARD

LABEL

PriDNS_1_ETH 15810 WORD Y RW

PriDNS_2_ETH 15811 WORD Y RW

PriDNS_3_ETH 15812 WORD Y RW

PriDNS_4_ETH 15813 WORD Y RW

SecDNS_1_ETH 15814 WORD Y RW

SecDNS_2_ETH 15815 WORD Y RW

SecDNS_3_ETH 15816 WORD Y RW

SecDNS_4_ETH 15817 WORD Y RW

EnableDHCP_ETH 15819 WORD Y RW

ADDRESS

PAR. VALUE

DATA SIZE

CPL

RESET (Y/N)

R/W

DESCRIPTION

Primary DNS server (part 1) 0 … 255 194 num.

Primary DNS server (part 2) 0 … 255 25 num.

Primary DNS server (part 3) 0 … 255 2 num.

Primary DNS server (part 4) 0 … 255 129 num.

Secondary DNS server (part 1) 0 … 255 194 num.

Secondary DNS server (part 2) 0 … 255 25 num.

Secondary DNS server (part 3) 0 … 255 2 num.

Secondary DNS server (part 4) 0 … 255 130 num.

Enable DHCP

RANGE

0 … 1

(False, True)

DEFAULT

False flag

U.M.

FREE Panel

27/38

Page 28

FOLDER

Display Hmi_Language 15819 WORD RW

Display Par_ContrLCD 15723 WORD Y RW

Display Par_BackLightTime 15724 WORD RW

Buzzer Buzzer_Mode 15990 WORD RW

LABEL

ADDRESS

PAR. VALUE

DATA SIZE

CPL

R/W

RESET (Y/N)

Display language

0 = Italian

1 = English

2 = French

3 = German

4 = Spanish

LCD Contrast

Allows adjustment of the LCD display co

Backlight switch-on time

Allows adjustment of LCD display s

Buzzer mode

0= always off

1= beep per key

DESCRIPTION

ntrast.

witch-on time.

RANGE

0 … 65535 0 num.

0 … 64 30 Num.

0 … 3600 10 sec

0 … 1 0 num.

DEFAULT

U.M.

FREE Panel

28/38

Page 29

FOLDER

HMI Management Hmi_Language 15989 WORD RW 0 … 65535 0 num.

HMI Management HmiList_Current 15820 WORD RW

NOTE: if HmiList_Current=11 the following folders/parameters are NOT USED

HMI remote 1 HmiList_ID_1 15821 WORD RW HMI remote 1 navigation ID list 0 ... 254 0 num.

HMI remote 1 HmiList_Res_1 15833 WORD RW

HMI remote 1 HmiList_Addr_1 15845 WORD RW

HMI remote 1 HmiList_Addr_2 15846 WORD RW HMI remote 1 navigation resource address for TCP (IP part 2) 0 ... 255 0 num.

HMI remote 1 HmiList_Addr_3 15847 WORD RW HMI remote 1 navigation resource address for TCP (IP part 3) 0 ... 255 0 num.

HMI remote 1 HmiList_Addr_4 15848 WORD RW HMI remote 1 navigation resource address for TCP (IP part 4) 0 ... 255 0 num.

HMI remote 1 HmiList_File_1 15893 15 byte RW HMI remote 1 navigation file (DOS 8.3 uppercase format) ******** string

HMI remote 2 HmiList_ID_2 15822 WORD RW HMI remote 2 navigation ID list 0 ... 254 0 num.

HMI remote 2 HmiList_Res_2 15834 WORD RW

HMI remote 2 HmiList_Addr_1 15849 WORD RW

HMI remote 2 HmiList_Addr_2 15850 WORD RW HMI remote 2 navigation resource address for TCP (IP part 2) 0 ... 255 0 num.

HMI remote 2 HmiList_Addr_3 15851 WORD RW HMI remote 2 navigation resource address for TCP (IP part 3) 0 ... 255 0 num.

HMI remote 2 HmiList_Addr_4 15852 WORD RW HMI remote 2 navigation resource address for TCP (IP part 4) 0 ... 255 0 num.

HMI remote 2 HmiList_File_2 15901 15 byte RW HMI remote 2 navigation file (DOS 8.3 uppercase format) ******** string

LABEL

ADDRESS

PAR. VALUE

DATA SIZE

CPL

R/W

RESET (Y/N)

Current HMI

0= HMI remote 1

1= HMI remote 2

2= HMI remote 3

3= HMI remote 4

4= HMI remote 5

5= HMI remote 6

6= HMI remote 7

7= HMI remote 8

8= HMI remote 9

9= HMI remote 10

10 = not used

11= Local HMI

HMI remote 1 navigation resource type

1=RTU (RS485 M

2=TCP (Modbus TCP)

3=CAN (C

HMI remote 1 navigation resource address for CAN, RTU and TCP

(IP part 1)

HMI remote 2 navigation resource type

1=RTU (RS485 M

2=TCP (Modbus TCP)

3=CAN (C

HMI remote 2 navigation resource address for CAN, RTU and TCP

(IP part 1)

odbus RTU)

ANopen)

odbus RTU)

ANopen)

DESCRIPTION

RANGE

0 … 11 11 num.

1 … 3 3 num.

0 ... 255 0 num.

1 … 3 3 num.

0 ... 255 0 num.

DEFAULT

U.M.

FREE Panel

29/38

Page 30

FOLDER

HMI remote 3 HmiList_ID_3 15823 WORD RW HMI remote 3 navigation ID list 0 ... 254 0 num.

HMI remote 3 HmiList_Res_3 15835 WORD RW

HMI remote 3 HmiList_Addr_1 15853 WORD RW

HMI remote 3 HmiList_Addr_2 15854 WORD RW HMI remote 3 navigation resource address for TCP (IP part 2) 0 ... 255 0 num.

HMI remote 3 HmiList_Addr_3 15855 WORD RW HMI remote 3 navigation resource address for TCP (IP part 3) 0 ... 255 0 num.

HMI remote 3 HmiList_Addr_4 15856 WORD RW HMI remote 3 navigation resource address for TCP (IP part 4) 0 ... 255 0 num.

HMI remote 3 HmiList_File_3 15909 15 byte RW HMI remote 3 navigation file (DOS 8.3 uppercase format) ******** string

HMI remote 4 HmiList_ID_4 15822 WORD RW HMI remote 4 navigation ID list 0 ... 254 0 num.

HMI remote 4 HmiList_Res_4 15836 WORD RW

HMI remote 4 HmiList_Addr_1 15857 WORD RW

HMI remote 4 HmiList_Addr_2 15859 WORD RW HMI remote 4 navigation resource address for TCP (IP part 2) 0 ... 255 0 num.

HMI remote 4 HmiList_Addr_3 15859 WORD RW HMI remote 4 navigation resource address for TCP (IP part 3) 0 ... 255 0 num.

HMI remote 4 HmiList_Addr_4 15860 WORD RW HMI remote 4 navigation resource address for TCP (IP part 4) 0 ... 255 0 num.

HMI remote 4 HmiList_File_4 15917 15 byte RW HMI remote 4 navigation file (DOS 8.3 uppercase format) ******** string

HMI remote 5 HmiList_ID_5 15825 WORD RW HMI remote 5 navigation ID list 0 ... 254 0 num.

HMI remote 5 HmiList_Res_5 15837 WORD RW

HMI remote 5 HmiList_Addr_1 15861 WORD RW

HMI remote 5 HmiList_Addr_2 15862 WORD RW HMI remote 5 navigation resource address for TCP (IP part 2) 0 ... 255 0 num.

HMI remote 5 HmiList_Addr_3 15863 WORD RW HMI remote 5 navigation resource address for TCP (IP part 3) 0 ... 255 0 num.

HMI remote 5 HmiList_Addr_4 15864 WORD RW

HMI remote 5 HmiList_File_5 15925 15 byte RW HMI remote 5 navigation file (DOS 8.3 uppercase format) ******** string

LABEL

ADDRESS

PAR. VALUE

DATA SIZE

CPL

R/W

RESET (Y/N)

HMI remote 3 navigation resource type

1=RTU (RS485 M

2=TCP (Modbus TCP)

3=CAN (C

HMI remote 3 navigation resource address for CAN, RTU and TCP

(IP part 1)

HMI remote 4 navigation resource type

1=RTU (RS485 M

2=TCP (Modbus TCP)

3=CAN (C

HMI remote 4 navigation resource address for CAN, RTU and TCP

(IP part 1)

HMI remote 5 navigation resource type

1=RTU (RS485 M

2=TCP (Modbus TCP)

3=CAN (C

HMI remote 5 navigation resource address for CAN, RTH and TCP

(IP part 1)

HMI remote 5 navigation resource address for TCP

(IP part 4)

odbus RTU)

ANopen)

odbus RTU)

ANopen)

odbus RTU)

ANopen)

DESCRIPTION

RANGE

1 … 3 3 num.

0 ... 255 0 num.

1 … 3 3 num.

0 ... 255 0 num.

1 … 3 3 num.

0 ... 255 0 num.

0 ... 255 0 num.

DEFAULT

U.M.

FREE Panel

30/38

Page 31

FOLDER

HMI remote 6 HmiList_ID_6 15826 WORD RW HMI remote 6 navigation ID list 0 ... 254 0 num.

HMI remote 6 HmiList_Res_6 15838 WORD RW

HMI remote 6 HmiList_Addr_1 15865 WORD RW

HMI remote 6 HmiList_Addr_2 15866 WORD RW HMI remote 6 navigation resource address for TCP (IP part 2) 0 ... 255 0 num.

HMI remote 6 HmiList_Addr_3 15867 WORD RW HMI remote 6 navigation resource address for TCP (IP part 3) 0 ... 255 0 num.

HMI remote 6 HmiList_Addr_4 15868 WORD RW HMI remote 6 navigation resource address for TCP (IP part 4) 0 ... 255 0 num.

HMI remote 6 HmiList_File_6 15933 15 byte RW HMI remote 6 navigation file (DOS 8.3 uppercase format) ******** string

HMI remote 7 HmiList_ID_7 15827 WORD RW HMI remote 7 navigation ID list 0 ... 254 0 num.

HMI remote 7 HmiList_Res_7 15839 WORD RW

HMI remote 7 HmiList_Addr_1 15869 WORD RW

HMI remote 7 HmiList_Addr_2 15870 WORD RW HMI remote 7 navigation resource address for TCP (IP part 2) 0 ... 255 0 num.

HMI remote 7 HmiList_Addr_3 15871 WORD RW HMI remote 7 navigation resource address for TCP (IP part 3) 0 ... 255 0 num.

HMI remote 7 HmiList_Addr_4 15872 WORD RW HMI remote 7 navigation resource address for TCP (IP part 4) 0 ... 255 0 num.

HMI remote 7 HmiList_File_7 15941 15 byte RW HMI remote 7 navigation file (DOS 8.3 uppercase format) ******** string

HMI remote 8 HmiList_ID_8 15828 WORD RW HMI remote 8 navigation ID list 0 ... 254 0 num.

HMI remote 8 HmiList_Res_8 15840 WORD RW

HMI remote 8 HmiList_Addr_1 15873 WORD RW

HMI remote 8 HmiList_Addr_2 15874 WORD RW HMI remote 8 navigation resource address for TCP (IP part 2) 0 ... 255 0 num.

HMI remote 8 HmiList_Addr_3 15875 WORD RW HMI remote 8 navigation resource address for TCP (IP part 3) 0 ... 255 0 num.

HMI remote 8 HmiList_Addr_4 15876 WORD RW HMI remote 8 navigation resource address for TCP (IP part 4) 0 ... 255 0 num.

HMI remote 8 HmiList_File_8 15949 15 byte RW HMI remote 8 navigation file (DOS 8.3 uppercase format) ******** string

LABEL

ADDRESS

PAR. VALUE

DATA SIZE

CPL

R/W

RESET (Y/N)

HMI remote 6 navigation resource type

1=RTU (RS485 M

2=TCP (Modbus TCP)

3=CAN (C

HMI remote 6 navigation resource address for CAN, RTH and TCP

(IP part 1)

HMI remote 7 navigation resource type

1=RTU (RS485 M

2=TCP (Modbus TCP)

3=CAN (C

HMI remote 7 navigation resource address for CAN, RTU and TCP

(IP part 1)

HMI remote 8 navigation resource type

1=RTU (RS485 M

2=TCP (Modbus TCP)

3=CAN (C

HMI remote 8 navigation resource address for CAN, RTU and TCP

(IP part 1)

odbus RTU)

ANopen)

odbus RTU)

ANopen)

odbus RTU)

ANopen)

DESCRIPTION

RANGE

1 … 3 3 num.

0 ... 255 0 num.

1 … 3 3 num.

0 ... 255 0 num.

1 … 3 3 num.

0 ... 255 0 num.

DEFAULT

U.M.

FREE Panel

31/38

Page 32

FOLDER

HMI remote 9 HmiList_ID_9 15829 WORD RW HMI remote 9 navigation ID list 0 ... 254 0 num.

HMI remote 9 HmiList_Res_9 15841 WORD RW

HMI remote 9 HmiList_Addr_1 15877 WORD RW

HMI remote 9 HmiList_Addr_2 15878 WORD RW HMI remote 9 navigation resource address for TCP (IP part 2) 0 ... 255 0 num.

HMI remote 9 HmiList_Addr_3 15879 WORD RW HMI remote 9 navigation resource address for TCP (IP part 3) 0 ... 255 0 num.

HMI remote 9 HmiList_Addr_4 15880 WORD RW HMI remote 9 navigation resource address for TCP (IP part 4) 0 ... 255 0 num.

HMI remote 9 HmiList_File_9 15957 15 byte RW HMI remote 9 navigation file (DOS 8.3 uppercase format) ******** string

HMI remote 10 HmiList_ID_10 15830 WORD RW HMI remote 10 navigation ID list 0 ... 254 0 num.

HMI remote 10 HmiList_Res_10 15842 WORD RW

HMI remote 10 HmiList_Addr_1 15881 WORD RW

HMI remote 10 HmiList_Addr_2 15882 WORD RW HMI remote 10 navigation resource address for TCP (IP part 2) 0 ... 255 0 num.

HMI remote 10 HmiList_Addr_3 15883 WORD RW HMI remote 10 navigation resource address for TCP (IP part 3) 0 ... 255 0 num.

HMI remote 10 HmiList_Addr_4 15884 WORD RW HMI remote 10 navigation resource address for TCP (IP part 4) 0 ... 255 0 num.

HMI remote 10 HmiList_File_10 15965 15 byte RW HMI remote 10 navigation file (DOS 8.3 uppercase format) ******** string

LABEL

ADDRESS

PAR. VALUE

DATA SIZE

CPL

R/W

RESET (Y/N)

HMI remote 9 navigation resource type

1=RTU (RS485 M

2=TCP (Modbus TCP)

3=CAN (C

HMI remote 9 navigation resource address for CAN, RTU and TCP

(IP part 1)

HMI remote 10 navigation resource type

1=RTU (RS485 M

2=TCP (Modbus TCP)

3=CAN (C

HMI remote 10 navigation resource address for CAN, RTU and

TCP (IP part 1)

odbus RTU)

ANopen)

odbus RTU)

ANopen)

DESCRIPTION

RANGE

1 … 3 3 num.

0 ... 255 0 num.

1 … 3 3 num.

0 ... 255 0 num.

DEFAULT

U.M.

FREE Panel

32/38

Page 33

Page 34

7 MODELS AND ACCESSORIES

7.1 Models

Model Mounting Dimensions Display

EVP3300/C Panel* 160x96x10mm

EVP3300/C/RH Panel* 160x96x10mm

--------------- (*) low voltage SELV: SAFETY EXTRA LOW VOLTAGE

(**) NOT INCLUDED - low voltage SELV: SAFETY EXTRA LOW VOLTAGE

/C indicates presence of RTC (Real Time Clock)

Accessories

Contact the Eliwell Sales Department for wall-mounting accessories.

Mak

slots, one at the bottom and one at the top, under the corresponding break-open removable doors, preventing the

opening of holes in walls with recessed-wall wiring.

Make all the necessary connections,

following the instructions for panel mounting (see Mounting chapter).

for Wall Mounting

e 4 holes of diameter 4.2mm in the wall at the specified spacing, to fix the backplate. Alternatively use the two side

then insert the EVP terminal (without front) in the backplate, which serves as a panel,

LCD

backlit

LCD

backlit

Accessories

On-board

Analogue

Inputs (*)

1x NTC

1 xNTC

1 x%RH

for Wall Mounting

Remote

Analogue

Inputs

(**)

1xNTC/DI

1x4…20mA/

0-5V/

0..10V

1xNTC/DI

Power supply Serials

CANopen

24V~/c - 48Vc

24V~/c - 48Vc

RS485

ETHERNET

TCP/IP

CANopen

RS485

ETHERNET

TCP/IP

Code EVA00WMRC0000

Backplate for wall mounting

Page 35

Dimensions of wall-mounting backplate

27

145

160

Ethernet

80

mm

90

57

R 1.5

90

83

59

7.2 Accessories

Note: the photos are intended to show the accessories and are by way of example only. The dimensions shown in the

figures are not to scale.

Name Code Description

Converters

and cables

SAR0RA00X701

USB/485 MINI KIT converter

+ USB cable

Documentation /

Notes

USB/CAN converter

Ethernet cable

230V~/24V 25VA transformer

Note: cable must be

than 10m

230V~/24V 35VA transformer

Note: cable must be

than 10m

no longer

no longer

Mounting on DIN rail

Cable

Transformer

EVA00USCA0000

Contact Eliwell

Sales Department

TF111202

TF111205

FREE Panel

35/38

Page 36

Temperature

probes

Name Code Description

SN8D6L4002

Name Code Description

SN691150

SN8DED11502C0

NTC probe NK103C1R1, 4m

Extended range

(polyester, 2-wire cable) IP65;

NTC probe 103AT, 1.5m (plastic

cap, 2-wire cable);

NTC temperature probe 5X20

1.5m TPE IP68

Documentation /

Notes

Instruction Sheet

SN8D6L4002 GB-I

Instruction Sheet

SN8D6L4002 GB-I

Instruction Sheet

SN8T6H1502 GB-I

Documentation /

Notes

Pressure

transducers

1

)

(

Code Description

Software Tools

Demo Case

Contact Eliwell

Sales Department

VAL00033K

Backplate

EVA00WMRC0000 Backplate for wall mounting

(1) Various items available. Contact the Sales Department

2

) Various lengths can be requested

(

GENERAL NOTES:

Eliwell can also

length.

supply a variety of different NTC probes depending on the cable type (PVC or silicon) and

Pressure transducer 4…20mA

male or female connector

Range fr

Depending on model

om -0.5/7bar to 0/50 bar

FREE Studio

Demo case

FREE Evolution

Instruction Sheet

9IS64173

EWPA

EN-IT-ES-DE-FR-RU

Documentation /

Notes

Contact Eliwell Sales

Department

FREE Panel

36/38

Page 37

Page 38

8 ANALITIC INDEX

(

(( 18

A

Accessories.......................................................................

Analogue inputs................................................................

35

9

Analogue Inputs-Probes..................................................6

B

BIOS parameters ............................................................17

BRIDGE ............................................................................ 13

C

CAN......................................................................................6

CAN connection example (Field)................................ 10

CANopen network connection example................... 12

COM Setting.................................................................... 19

Connections.....................................................................

10

Cross references ..............................................................3

D

Date and time................................................................. 18

DIA Menu......................................................................... 16

DIAGNOSTICS menu......................................................

Disclaimer ........................................................................

Display ..............................................................................

17

15

15

E

ELECTRICAL CONNECTIONS...........................................

6

ETHERNET ...........................................................................7

Example: RS485 connection (Field)............................ 10

Example: RS485 connection with FREE Smart

network ........................................................................ 11

F

First power on .................................................................

17

FREE WEB........................................................................ 13

G

General description...........................................................

General Technical Data ............................................

General warnings ..............................................................

3

14

6

H

Highlighting icons:............................................................3

HMI Management ..................................................18; 19

HMI sel.............................................................................. 18

I

I/O features ......................................................................

Improper Use.................................................................

14

15

INTRODUCTION................................................................