Eliwell EWRC 300 NT, EWRC 500 NT, WRC 500 NT HACCP, EWRC 500 NT 4DIN, EWRC 500 NT 4DIN HACCP User Manual

...Page 1

EWRC 300/500/5000 NT

Controllers for static and ventilated cold rooms

9MA10258.01

www.eliwell.com

USER

MANUAL

Page 2

This documentation contains the general description and/or technical characteristics of the product

contained herein. This documentation is not intended and must not be used to determine the

appropriateness or reliability of these products related to the user’s specific applications. Every user or

integration specialist must perform their own complete and appropriate risk assessment, evaluations and

tests on the products relating to the specific use or application.

Schneider Electric nor any of its associates or branches shall be held liable or prosecutable for the

improper use of the information contained herein. Users may send us comments and suggestions to

improve or correct this publication.

You hereby accept to not reproduce, other than for personal, non-commercial use, all or part of this

document in any form without the written authorisation of Eliwell. You also accept to not create any

hypertext links to this document or the relative contents. Eliwell shall not grant any rights or licence for

personal and non-commercial use of the document and the relative contents, with the exception of a nonexclusive licence to consult the material “as-is”, at your own risk. All other rights are reserved.

During the installation and use of this product, you must comply with local, national and international

safety laws. For safety reasons and to ensure compliance with the data of the documented system,

component repairs must be performed exclusively by the manufacturer.

When the devices are used for applications with technical safety requirements, comply with the most

relevant instructions. Improper use of Eliwell software (or any other approved software) with Eliwell

hardware products may constitute a risk for personal safety and many cause damage to the equipment.

Failure to comply with these instructions may constitute a risk for personal safety and may cause damage

to the equipment.

© 2018 Eliwell. All rights reserved.

2

9MA10258.01 07/2018

Page 3

CONTENTS

1. INTRODUCTION ............................................................................................................9

1.1. GENERAL DESCRIPTION ...................................................................................................................................9

1.2. MODELS ............................................................................................................................................................... 9

2. TECHNICAL SPECIFICATIONS ............................................................................ 10

2.1. TECHNICAL DATA

(EN 60730-2-9:2010, EN 61439-1:2011 / 61439-2:2011 / EN 60204-1:2006) ........................................10

2.2. ELECTRICAL SPECIFICATIONS .........................................................................................................................10

2.3. FURTHER INFORMATION ..................................................................................................................................11

2.3.1. INPUT CHARACTERISTICS .............................................................................................................................................................11

2.3.2. OUTPUT CHARACTERISTICS .........................................................................................................................................................11

2.3.3. MECHANICAL CHARACTERISTICS ..............................................................................................................................................12

3. MECHANICAL INSTALLATION ............................................................................ 13

3.5. INSTALLATION PROCEDURE ...........................................................................................................................15

4. ELECTRICAL CONNECTIONS .............................................................................. 20

4.1.1. WIRING GUIDELINES ......................................................................................................................................................................20

4.1.2. RULES FOR SCREW-TYPE TERMINAL BOARDS .........................................................................................................................21

4.1.3. ANALOGUE INPUTS-PROBES .......................................................................................................................................................22

4.1.4. SERIAL CONNECTIONS ..................................................................................................................................................................23

4.1.5. RS-485 CONNECTION ...................................................................................................................................................................23

4.1.6. TTL CONNECTION .........................................................................................................................................................................23

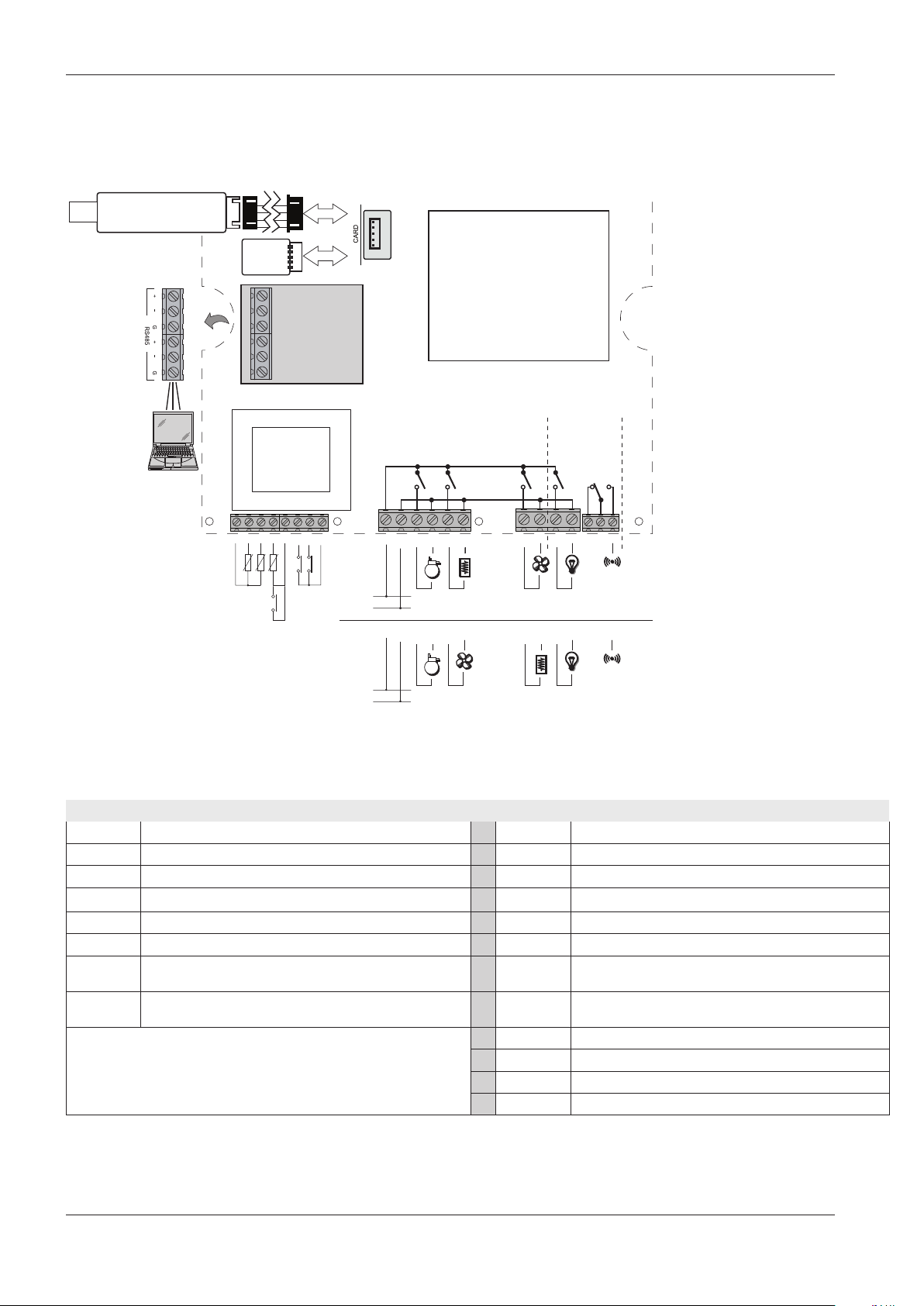

4.2. WIRING DIAGRAM ..............................................................................................................................................24

4.2.1. TERMINALS .......................................................................................................................................................................................24

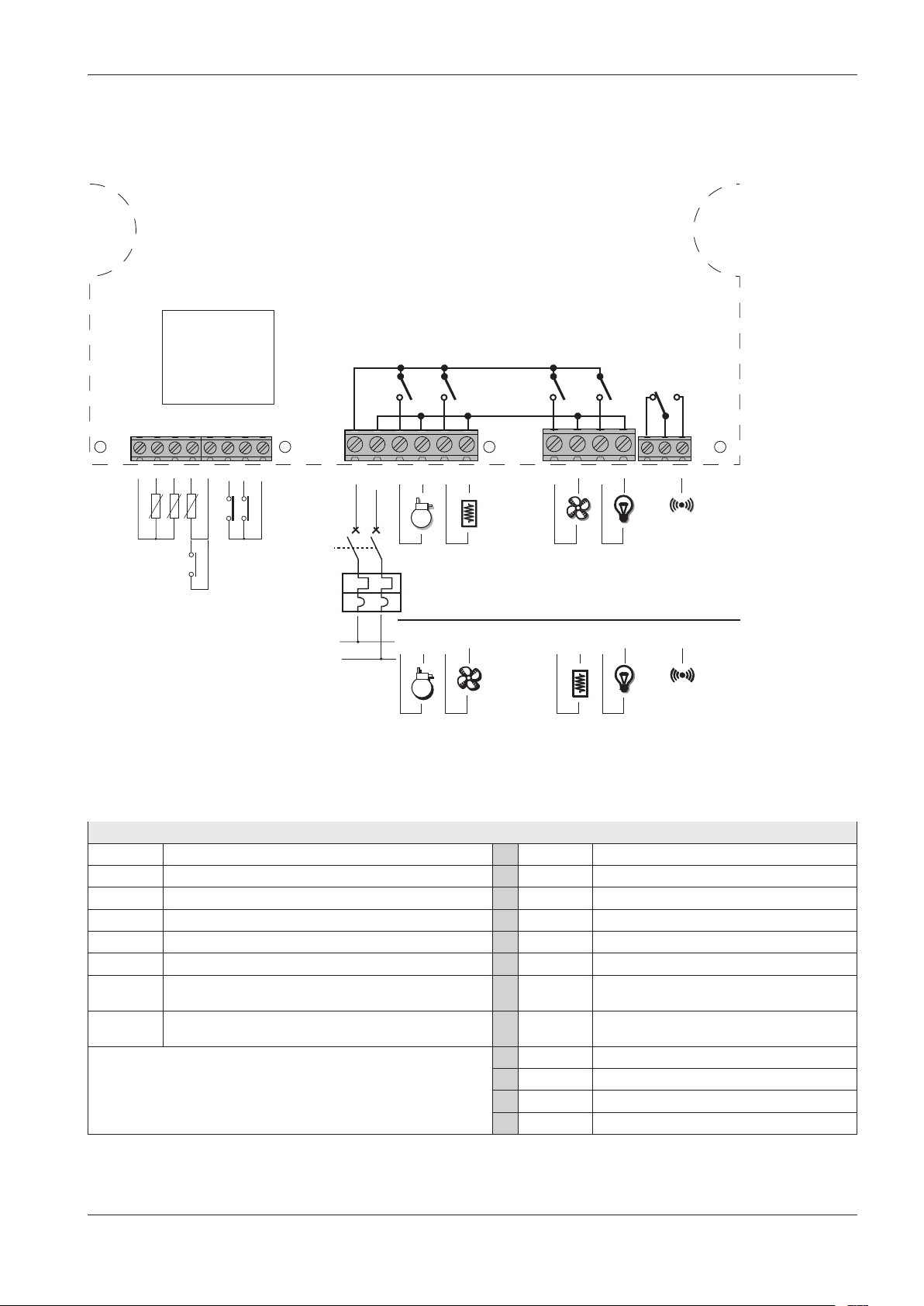

4.3. WIRING DIAGRAM FOR MODELS WITH MAGNETOTHERMAL SWITCH INSTALLED .........................25

4.3.1. TERMINALS .......................................................................................................................................................................................25

5. USER AND START-UP INTERFACE ....................................................................... 26

5.1. DISPLAY .................................................................................................................................................................26

5.1.1. KEYS ....................................................................................................................................................................................................26

5.1.2. ICONS .................................................................................................................................................................................................27

5.1.3. PRELIMINARY CONFIGURATIONS ...............................................................................................................................................28

5.1.4. OPERATION IN DEFAULT CONFIGURATION .............................................................................................................................28

5.1.5. NAVIGATION ....................................................................................................................................................................................29

5.1.6. FUNCTIONS MENU AND KEY-ENABLED FUNCTIONS ...........................................................................................................30

5.1.7. PASSWORDS .....................................................................................................................................................................................31

5.1.8. SETPOINT PROGRAMMING ..........................................................................................................................................................32

5.1.9. VIEWING PROBE VALUES ...............................................................................................................................................................33

5.1.10. HOW TO MODIFY THE DATE AND TIME ..................................................................................................................................34

5.1.11. DISPLAYING ALARMS ..................................................................................................................................................................35

5.1.12. SYSTEM ALARMS EXAMPLE ........................................................................................................................................................36

5.1.13. MODIFYING A PARAMETER .......................................................................................................................................................37

9MA10258.01 07/2018

3

Page 4

6. FUNCTIONS AND REGULATORS ........................................................................ 39

6.1. SETTINGS ............................................................................................................................................................. 39

6.1.1. PROBE SETTING AND CALIBRATION ..........................................................................................................................................39

6.1.2. DISPLAY SETTINGS ..........................................................................................................................................................................39

6.2. FUNCTIONS .........................................................................................................................................................40

6.2.1. UPLOAD, DOWNLOAD, FORMAT ................................................................................................................................................40

6.2.2. UNICARD ...........................................................................................................................................................................................41

6.3. BOOT LOADER FIRMWARE ..............................................................................................................................42

6.4. COMPRESSOR .....................................................................................................................................................43

6.4.1. COMPRESSOR CONFIGURATION ...............................................................................................................................................43

6.4.2. SECOND COMPRESSOR CONFIGURATION .............................................................................................................................43

6.4.3. COMPRESSOR OPERATING CONDITIONS ................................................................................................................................43

6.5. COMPRESSOR/GENERAL PROTECTIONS .................................................................................................... 44

6.5.1. COMPRESSOR SAFETY TIMINGS .................................................................................................................................................45

6.6. DEFROST/DRIPPING ...........................................................................................................................................46

6.6.1. DEFROST TYPE AND ACTIVATION ...............................................................................................................................................46

6.6.2. AUTOMATIC DEFROSTING ...........................................................................................................................................................47

6.6.3. MANUAL DEFROST .........................................................................................................................................................................47

6.6.4. EXTERNAL DEFROST ......................................................................................................................................................................48

6.6.5. DEFROST WITH REMOTE START/STOP .......................................................................................................................................49

6.7. DEFROST MODE .................................................................................................................................................50

6.7.1. DEFROST WITH ELECTRIC HEATERS ...........................................................................................................................................50

6.7.2. INVERSE DEFROST ..........................................................................................................................................................................51

6.7.3. DOUBLE EVAPORATOR DEFROST ...............................................................................................................................................52

6.8. EVAPORATOR FANS ........................................................................................................................................... 54

6.8.1. EVAPORATOR FAN OPERATING CONDITIONS ........................................................................................................................54

6.8.2. FAN OPERATION IN TEMPERATURE CONTROL MODE .........................................................................................................55

6.8.3. FAN OPERATION IN DUTY-CYCLE MODE ..................................................................................................................................56

6.8.4. FAN OPERATION IN DEFROST .....................................................................................................................................................57

6.8.5. FAN FUNCTION DURING DRIPPING ...........................................................................................................................................58

6.8.6. POST-VENTILATION ........................................................................................................................................................................58

6.9. DEEP COOLING CYCLE - DCC .........................................................................................................................59

6.10. PREHEAT .............................................................................................................................................................59

6.11. PRESSURE SWITCH ...........................................................................................................................................60

6.11.1. AUXILIARY OUTPUT (AUX/LIGHT) ..............................................................................................................................................61

6.12. DOOR/EXTERNAL ALARM MANAGEMENT ............................................................................................... 62

6.13. DEMISTING HEATERS (FRAME HEATERS) ................................................................................................... 64

6.14. CONDENSER FANS .......................................................................................................................................... 65

6.15. STAND-BY ...........................................................................................................................................................66

6.16. PUMP DOWN.....................................................................................................................................................66

6.16.1. SERVICE STOPPAGE ......................................................................................................................................................................66

4

9MA10258.01 07/2018

Page 5

7. PARAMETERS ...................................................................................................... 67

7.1. HOW TO MODIFY THE USER PARAMETERS ................................................................................................ 67

7.2. HOW TO EDIT THE INSTALLER PARAMETERS ..............................................................................................67

7.3. PARAMETER TABLE ............................................................................................................................................68

7.3.1. PARAMETER H60..............................................................................................................................................................................78

8. ALARMS ............................................................................................................... 79

8.1. ALARMS AND SIGNALS TABLE ........................................................................................................................ 79

8.2. ALARM CAUSE/EFFECT TABLE ....................................................................................................................... 80

8.3. DESCRIPTION OF ALARMS ............................................................................................................................... 82

8.3.1. PROBE ALARM..................................................................................................................................................................................82

8.3.2. MINIMUM AND MAXIMUM TEMPERATURE ALARM ................................................................................................................83

8.3.3. END OF DEFROST DUE TO TIMEOUT ALARM ..........................................................................................................................84

8.3.4. EXTERNAL ALARM ...........................................................................................................................................................................85

8.3.5. DOOR OPEN ALARM ...................................................................................................................................................................... 85

8.3.6. PRESSURE SWITCH INPUT ALARM ...............................................................................................................................................86

8.3.7. PANIC ALARM ..................................................................................................................................................................................87

8.3.8. LEAK DETECTOR ALARM ...............................................................................................................................................................87

9. MODBUS MSK 554 FUNCTIONS AND RESOURCES ......................................... 89

9.3.1. DATA FORMAT (RTU) .......................................................................................................................................................................89

9.3.2. NETWORK .........................................................................................................................................................................................89

9.3.3. MODBUS COMMANDS AVAILBLE AND DATA AREAS ............................................................................................................90

9.3.4. ADDRESS CONFIGURATION.........................................................................................................................................................90

9.3.5. PARAMETER VISIBILITY AND VALUES ..........................................................................................................................................91

9.3.6. MODBUS TABLES ............................................................................................................................................................................91

9.3.7. PARAMETER/VISIBILITY TABLE ......................................................................................................................................................93

9.3.8. PARAMETER/VISBILITY H60 TABLE ..............................................................................................................................................98

9.3.9. FOLDER VISIBILITY TABLE ..............................................................................................................................................................100

9.3.10. CLIENT TABLE .................................................................................................................................................................................100

10. ADVANCED FUNCTIONS - NIGHT AND DAY ................................................... 102

10.1. DAY/NIGHT REGULATOR OPERATION .......................................................................................................102

10.2. OPERATION WITH DEFROST GROUP..........................................................................................................103

10.3. DAY/NIGHT REGULATOR DURING A BLACKOUT ..................................................................................... 103

10.4. OPENING FOLDER NAD - DAY/NIGHT ........................................................................................................104

11. ADVANCED FUNCTIONS - HACCP .................................................................. 105

11.1. DISPLAYING HACCP ALARMS .......................................................................................................................106

9MA10258.01 07/2018

5

Page 6

SAFETY INFORMATION

Important information

Read these instructions carefully and visually inspect the equipment to familiarise yourself with the device before attempting

to install it, put it into operation, overhaul or service it. The following warning messages may appear anywhere in this

documentation or on the equipment to warn of potential dangers or to call attention to information that can clarify or simplify

a procedure.

The addition of this symbol to a danger warning label indicates the existence of an electrical danger that could

result in personal injury should the user fail to follow the instructions.

This is the safety warning symbol. It is used to warn the user of the potential dangers of personal injury.

Observe all the safety warnings that follow this symbol to avoid the risk of serious injury or death.

DANGER

DANGER indicates a dangerous situation that, unless avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially dangerous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a potentially dangerous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

NOTICE used in reference to procedures not associated with physical injuries.

6

9MA10258.01 07/2018

Page 7

NB

The electrical panel (device) must be installed and repaired only by qualified staff. Neither Schneider Electric nor Eliwell

accept any responsibility for any consequences resulting from the use of this material.

A qualified person is someone who has specific skills and knowledge regarding the structure and the operation of electrical

equipment and who has received safety training on how to avoid the inherent dangers.

Product related information

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Disconnect all power from all equipment including connected devices prior to removing any covers or doors, or

installing or removing any accessories, hardware, cables or wires.

• Always use a properly rated voltage sensing device to confirm the power is off where and when indicated.

• Before powering the device back up, fit back and fix all the covers, hardware components and wiring.

• Check the earthing connections on all earthed devices.

• Use only the specified voltage when operating this equipment and any associated products.

• Comply with all standards regarding accident protection and local applicable safety directives.

Failure to follow these instructions will result in death or serious injury.

This equipment is designed to operate outside all hazardous locations and is not to be used in applications which generate

(or could potentially generate) hazardous environments. Install this equipment only in areas and applications known to be

free from dangerous atmospheres at all times.

DANGER

POTENTIAL FOR EXPLOSION

• Install and use this equipment in non-hazardous locations only.

• Do not install or use this equipment in applications which could generate hazardous atmospheres, such as

applications which use flammable refrigerants.

Failure to follow these instructions will result in death or serious injury.

For information regarding the use of control equipment in applications capable of generating hazardous materials, please

contact the relevant national regulatory bodies or certifying authorities.

WARNING

UNINTENDED EQUIPMENT OPERATION

• The equipment signal cables (probes, digital inputs, communication, and the relative power supplies) must be laid

separately from the power cables.

• Every end application of this device must be tested individually and completely in order to check its proper

operation before putting it in service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

9MA10258.01 07/2018

7

Page 8

Permitted use

The device must be installed and used in accordance with the instructions provided. In particular, parts carrying dangerous

voltages must not be accessible under normal conditions.

It must be adequately protected from water and dust with regard to the application, and must only be accessible using tools

or a keyed locking mechanism (with the exception of the front panel).

The device is suitable for use in household refrigeration appliances and/or similar equipment and has been tested in

accordance with the harmonized European reference standards.

Prohibited use

Any use other than that expressly permitted is prohibited.

The relay contacts provided are mechanical and subject to failure; any protection devices required by product standards, or

suggested by good practice in view of obvious safety requirements, must be installed externally of the device.

Liability and residual risks

The liability of Schneider Electric and Eliwell is limited to the correct and professional use of the product according to the

directives referred to herein and in the other supporting documents, and does not cover any damage (including but not limited

to) the following causes:

• unspecified installation/use and, in particular, in contravention of the safety requirements of the legislation in force in the

country of installation and/or specified in this document;

• use on equipment which does not provide adequate protection against electrocution, water and dust in the actual

installation conditions;

• use on devices which allow access to dangerous parts without the aid of a keyed or tooled locking mechanism;

• tampering with and/or modification of the product;

• installation/use on equipment that does not comply with the regulations in force in the country of installation.

Disposal

The equipment (or product) must be subjected to separate waste collection in compliance with the local legislation on

waste disposal.

Date of production

The date of production is shown on the device label, indicating the week and year of production (WW-YY).

8

9MA10258.01 07/2018

Page 9

1. INTRODUCTION

1.1. GENERAL DESCRIPTION

The Coldface EWRC 300/500/5000 NT series controls the temperature of a static or ventilated cold room. The instrument

controls positive or negative cold rooms and is capable of managing a double evaporator and condenser fan.

Coldface has 3 or 5 configurable relays, depending on the model, and 2(3) configurable digital inputs for door switches or

other devices. Models are available with clock with yearly calendar and HACCP event logging.

The instrument can be connected to TelevisSystem / Modbus via the RS-485 plug-in module (optional).

The container lets you install one or more electromechanical devices, depending on the model.

This summary document contains basic information about the standard

EWRC 300/500/5000 NT models. For further information and custom configurations, refer to the complete user manual

code 9MA0258, available to download from the website www.eliwell.com.

1.2. MODELS

• EWRC 300 NT - Versions with 3 configurable relays for controlling al the accessory loads in the room.

• EWRC 500 NT - Versions with 5 configurable relays for controlling all the accessory loads in the room.

• EWRC 500 NT HACCP - Versions with 5 configurable relays for controlling all the accessory loads in the room, HACCP

function with clock and yearly calendar.

• EWRC 500 NT 4DIN - Versions with 5 configurable relays for controlling all the accessory loads in the room, plus door

for installation of magnetothermal switch or accessories on a DIN rail.

• EWRC 500 NT 4DIN HACCP - Versions with 5 configurable relays for controlling all the accessory loads in the room,

HACCP function with clock and yearly calendar, plus door for installation of magnetothermal switch or accessories on a

DIN rail.

• EWRC 500 NT BREAKER - Versions with 5 configurable relays for controlling all the accessory loads in the room, plus

door and magnetothermal switch installed.

• EWRC 500 NT 4DIN BREAKER HACCP - Versions with 5 configurable relays for controlling all the accessory loads in

the room, HACCP function with clock and yearly calendar, plus door and magnetothermal switch installed.

• EWRC 5000 NT HACCP - Version with larger container, with 5 configurable relays for controlling all the accessory loads

in the room, HACCP function with clock and yearly calendar, plus door for installation of components on a DIN rail

.

9MA10258.01 07/2018

9

Page 10

2. TECHNICAL SPECIFICATIONS

2.1. TECHNICAL DATA

(EN 60730-2-9:2010, EN 61439-1:2011 / 61439-2:2011 / EN 60204-1:2006)

Front panel protection rating IP65

Classification: Electronic automatic control device (not safety device) for stand-alone

installation

Installation: wall

Type of action: 1.B

Pollution class: 2

Panel use: Internal use

Panel type: Fixed panel

Maximum installation site altitude: 2000 m (2187 yd)

Weight: < 2 kg (< 4.41 lb)

Material class: IIIa

Over-voltage category: II

Nominal pulse voltage: 2500 Vac

Operating temperature: -5…50°C (23°F...122°F) (EN 60730-2-9:2010)

Storage temperature: -20…85°C (-20°F...185°F)

Operating humidity: 10…90% non-condensing

Storage humidity: 10…90% non-condensing

Power supply: 230 Vac ±10 % 50/60 Hz

Power consumption: 11 VA max

Magnetothermal switch: EWRC 500 BREAKER: Two-pole (2P)

Control: EWRC NT electronic controller

Connection: device on external flexible cable, Y type connection

Digital outputs (relay): refer to the label on the device

Fire resistance category: D

Software class: A

Ball test temperature: 100°C (212°F)

Clock backup: Up to four days in the absence of an external power supply.

(HACCP models only)

2.2. ELECTRICAL SPECIFICATIONS

Rated voltage (Un): 230 Vac

Rated operating voltage (Ue): 230 Vac

Rated insulation voltage (Ui): 230 Vac

Rated impulse withstand voltage (Uimp): EWRC 500 BREAKER

Rated panel current (InA): EWRC 500 BREAKER

Rated circuit current (InC): EWRC 500 BREAKER

Conditioned short circuit current (Icc): < 4.5 kA

Rated frequency (fn): 50/60 Hz

(1)

EWRC 500 BREAKER RCAS / RCAR

(1)

: 4 kV (EN 61439-2:2011)

(1)

: 16 A (EN 61439-2:2011)

(1)

: 16 A (EN 61439-2:2011)

10

9MA10258.01 07/2018

Page 11

2.3. FURTHER INFORMATION

RCSU

RCH300

OUT1

12(8) A

12FLA - 72LRA

12(8) A

12FLA - 72LRA

12(8) A

12FLA - 72LRA

OUT2

8 A

8FLA - 48LRA

8 A

8FLA - 48LRA

8 A

8FLA - 48LRA

8A resistive

OUT4--

8 A

8FLA - 48LRA

8 A

8FLA - 48LRA

NO 8 A, NC 6 A resistive

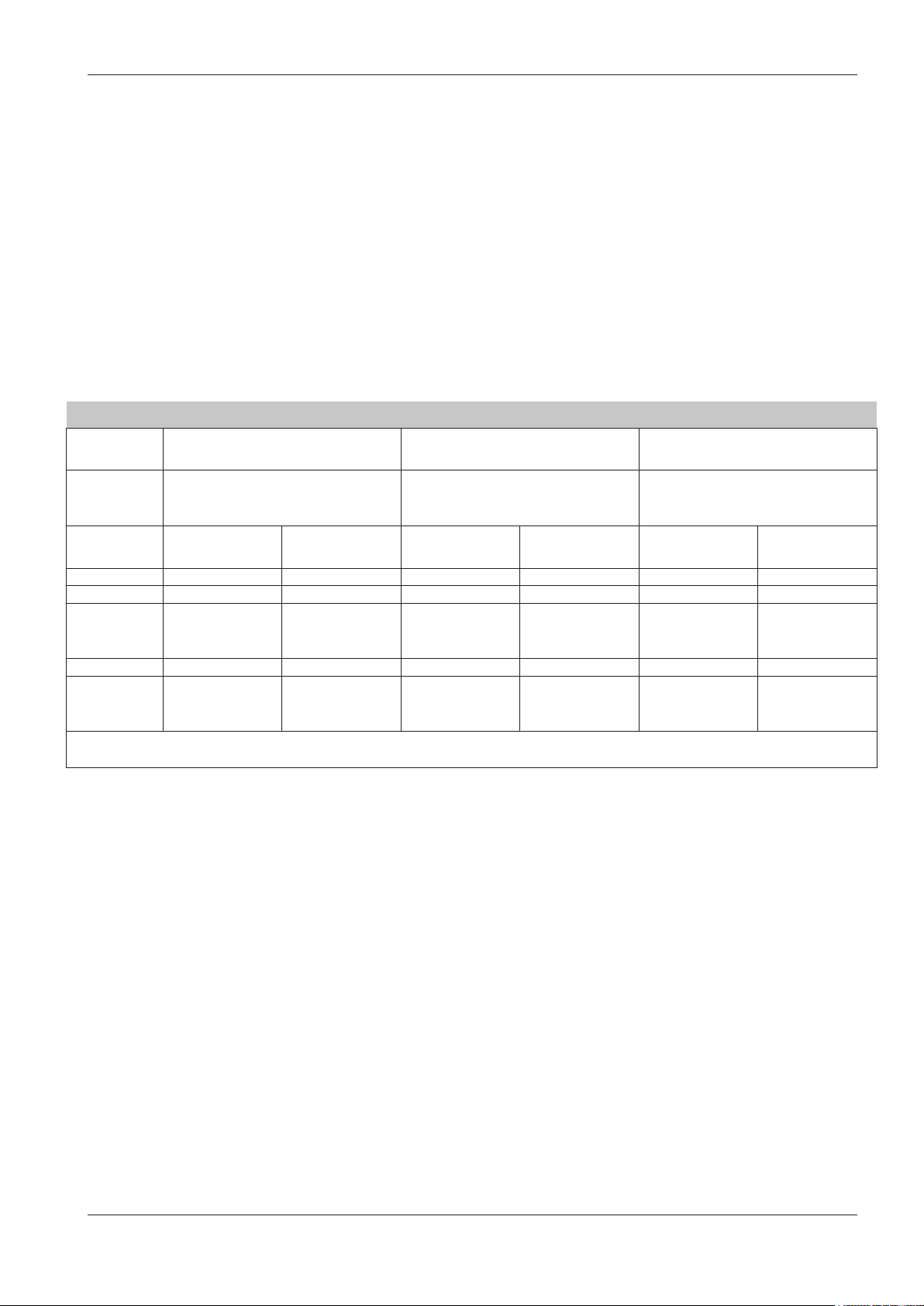

NOTE. Maximum common flow rate 16 A for models EWRC 500 BREAKER RCA

/ RCA

Maximum common flow rate 18 A for all other models

2.3.1. INPUT CHARACTERISTICS

Measurement range: NTC: -50.0...110°C (-58°F...230°F); (on 3-digit display with +/- sign)

PTC: -55.0...150°C (-67°F...302°F); (on 3-digit display with +/- sign)

Accuracy: better than 0.5% integral scale + 1 digit

Resolution: 0.1°C (0.1°F)

Buzzer: only on models where this is provided

Analogue inputs: 3(2) configurable NTC/PTC inputs

Digital inputs: 2(3) multi-function, voltage-free digital inputs (DI)

2.3.2. OUTPUT CHARACTERISTICS

RELAY OUTPUTS

MODEL EWRC 300 NT EWRC 500/5000 NT EWRC 500 NT

CODE

STANDARD

OUT3 8(4) A

OUT5 - - NO 8(4) A, NC 6(3) A

RCSH

RCAH

EN60730

max 250 Vac

UL60730

max 240 Vac

4.9FLA - 29.4LRA 8(4) A

EN60730

max 250 Vac

RCAU

UL60730

max 240 Vac

8 A resistive

4.9FLA - 29.4LRA

NO 8 A, NC 6 A resistive

NO 4.9FLA - 29.4LRA

S

RCSP

RCAP

EN60730

max 250 Vac

12(8) A 12FLA - 72LRA

NO 8(4) A, NC 6(3) A

R

NO 4.9FLA - 29.4LRA

UL60730

max 240 Vac

9MA10258.01 07/2018

11

Page 12

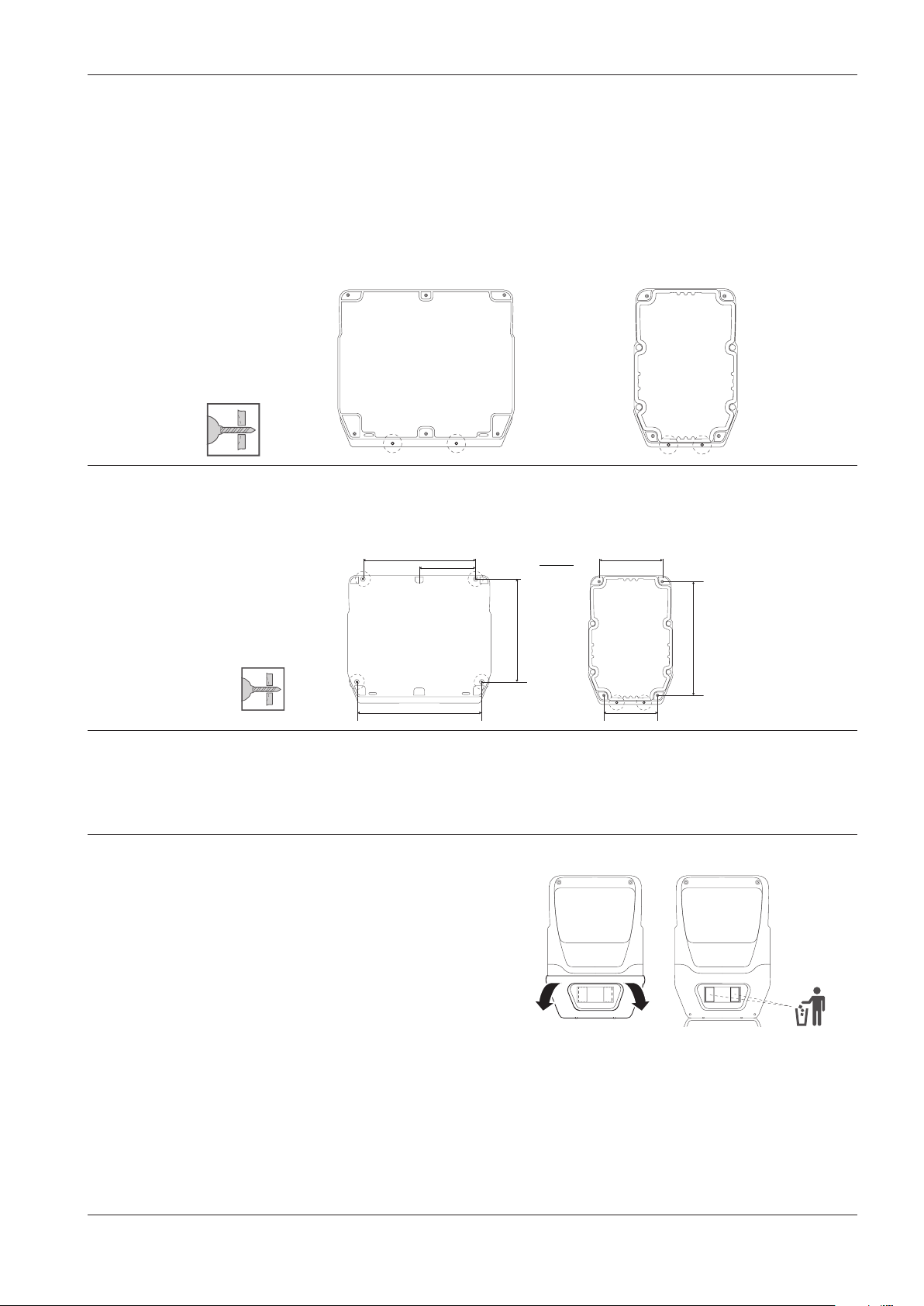

2.3.3. MECHANICAL CHARACTERISTICS

Casing: PC+ABS

Dimensions:

front panel 213 x 318 mm, depth 102 mm

front panel 221 x 318 mm, depth 107 mm

front panel 420 x 360 mm, depth 147 mm

Terminals: screw

See “4.1.2. Rules for screw-type terminal boards” page 21

Connectors: TTL for UNICARD / CopyCard / Device Manager connection (via DMI)

Humidity: Operation / Storage: 10...90% RH (non-condensing)

NOTE: The technical specifications stated in this document regarding the measurement (range, accuracy, resolution, etc.)

refer strictly to the instrument and not to any accessories provided, such as the probes.

EWRC 300/500

EWRC 500 BREAKER

EWRC 5000

12

9MA10258.01 07/2018

Page 13

3. MECHANICAL INSTALLATION

3.1. Before starting

Before starting to install your system, read this chapter carefully. Caution must be exercised concerning compliance with all

safety information, other electrical requirements or laws which may apply to your machine or process when using this equipment.

WARNING

REGULATORY INCOMPATIBILITY

Make sure that all equipment used and the systems designed comply with all applicable local, regional and national laws.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

3.2. Disconnection from the power supply

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Disconnect all power from all equipment including connected devices prior to removing any covers or doors, or

installing or removing any accessories, hardware, cables or wires.

• Always use a properly rated voltage sensing device to confirm the power is off where and when indicated.

• Before powering the device back up, fit back and fix all the covers, hardware components and wiring.

• Check the earthing connections on all earthed devices.

• Use only the specified voltage when operating this equipment and any associated products.

• Comply with all standards regarding accident protection and local applicable safety directives.

Failure to follow these instructions will result in death or serious injury.

3.3. Operating environment

Flammable refrigerant gases

This equipment is designed to operate outside all hazardous locations and is not to be used in applications which generate

(or could potentially generate) hazardous environments. Install this equipment only in areas and applications known to be

free from dangerous atmospheres at all times.

DANGER

POTENTIAL FOR EXPLOSION

• Install and use this equipment in non-hazardous locations only.

• Do not install or use this equipment in applications which could generate hazardous atmospheres, such as

applications which use flammable refrigerants.

Failure to follow these instructions will result in death or serious injury.

For information regarding the use of control equipment in applications capable of generating hazardous materials, please

contact the relevant national regulatory bodies or certifying authorities.

9MA10258.01 07/2018

13

Page 14

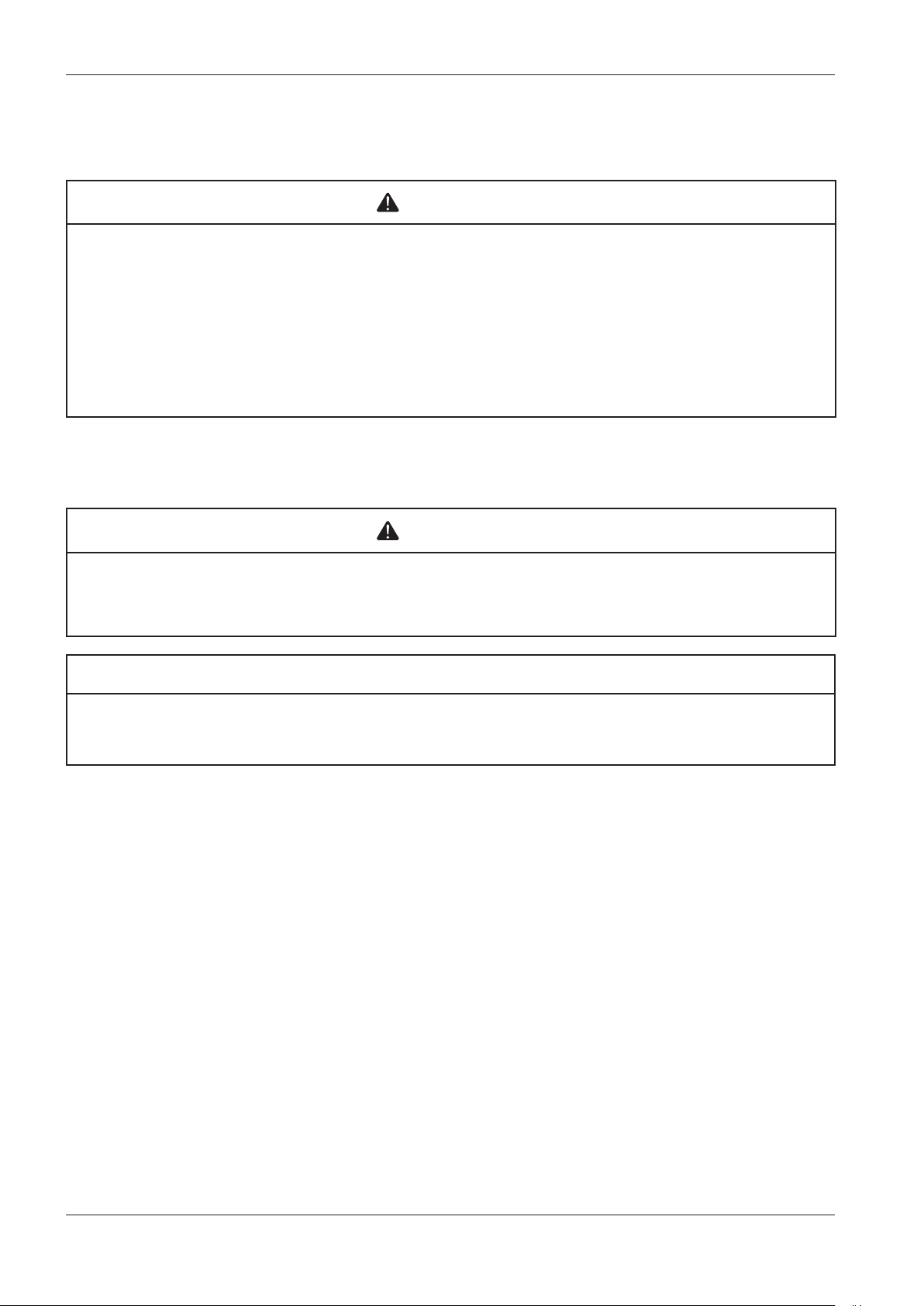

WARNING

UNINTENDED EQUIPMENT OPERATION

Install and use the equipment in compliance with the conditions described in the Technical Specifications chapter.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

3.4. Comments concerning installation

WARNING

UNINTENDED EQUIPMENT OPERATION

• Use appropriate safety interlocks where personnel and/or equipment hazards exist.

• Do not use this equipment in safety-critical machine functions unless the equipment is otherwise designated as

functional safety equipment and conforming to applicable regulations and standards.

• Do not disassemble, repair, or modify this equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The devices are designed for wall mounting.

When handling the equipment, use caution to avoid damage caused by electrostatic discharge. In particular, the unshielded

connectors and in certain cases the open circuit boards are vulnerable to electrostatic discharge.

WARNING

UNINTENDED EQUIPMENT OPERATION DUE TO ELECTROSTATIC DISCHARGE

• Keep the equipment in the protective packaging until ready for installation.

• The equipment must only be installed in type-approved casing and/or in points that prevent unauthorised access and

provide protection from electrostatic discharge.

• When handling sensitive equipment, use an antistatic bracelet or equivalent earthed protective device against

electrostatic discharge.

• Before handling the equipment, always discharge the static electricity from the body by touching an earthed surface

or type-approved antistatic mat.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

14

9MA10258.01 07/2018

Page 15

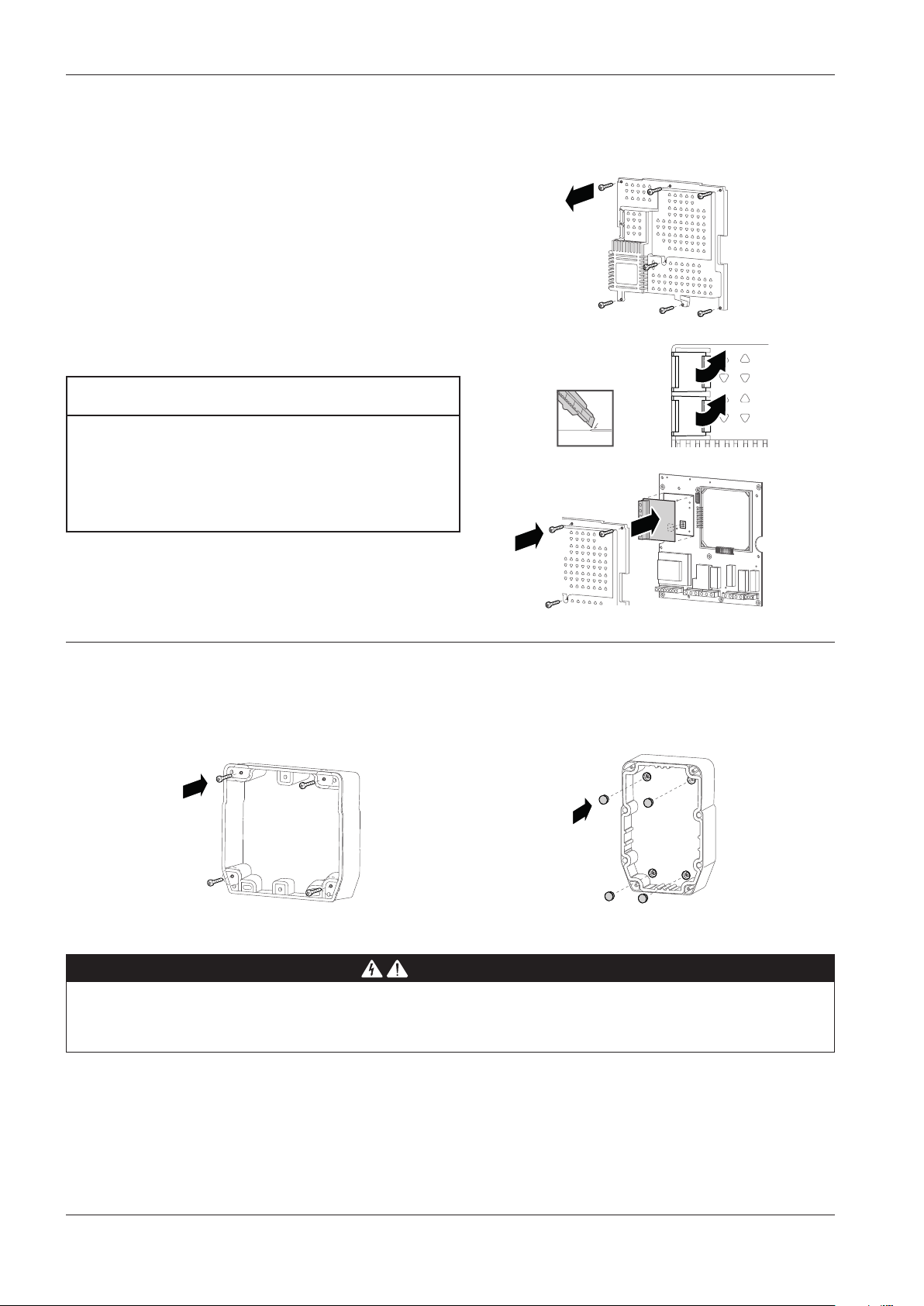

3.5. INSTALLATION PROCEDURE

360 / 14,17 87/ 3,42

NOTE: procedural steps that are common to all models. ONLY the EWRC 5000 model is used as an example.

1) Remove the cover and drill the holes for the cable clamps (at least one for power cables and one for signalling

cables) on the bottom of the panel.

NOTE: for the 300/500 models, use the drilling template provided.

2) Drill the wall fixing holes on the back of the panel, in the areas marked on the back.

mm / in

343 / 13,5

171,5/ 6,75

321,5 / 12,66

UM [mm]

in.

116/ 4,57

A

CD

B

235 / 12,66

EWRC300/500: distance between holes A-B 116 mm (4.57 in.); holes C-D 87 mm (3.42 in.); holes A-C 235 mm (9.25 in.)

Hinges are available for mounting on special compartments for opening the cover both right and left.

Screw on the respective anchoring screws taking care that the hinges are fitted well and lie flush so that they do not

interfere with the compression of the seal.

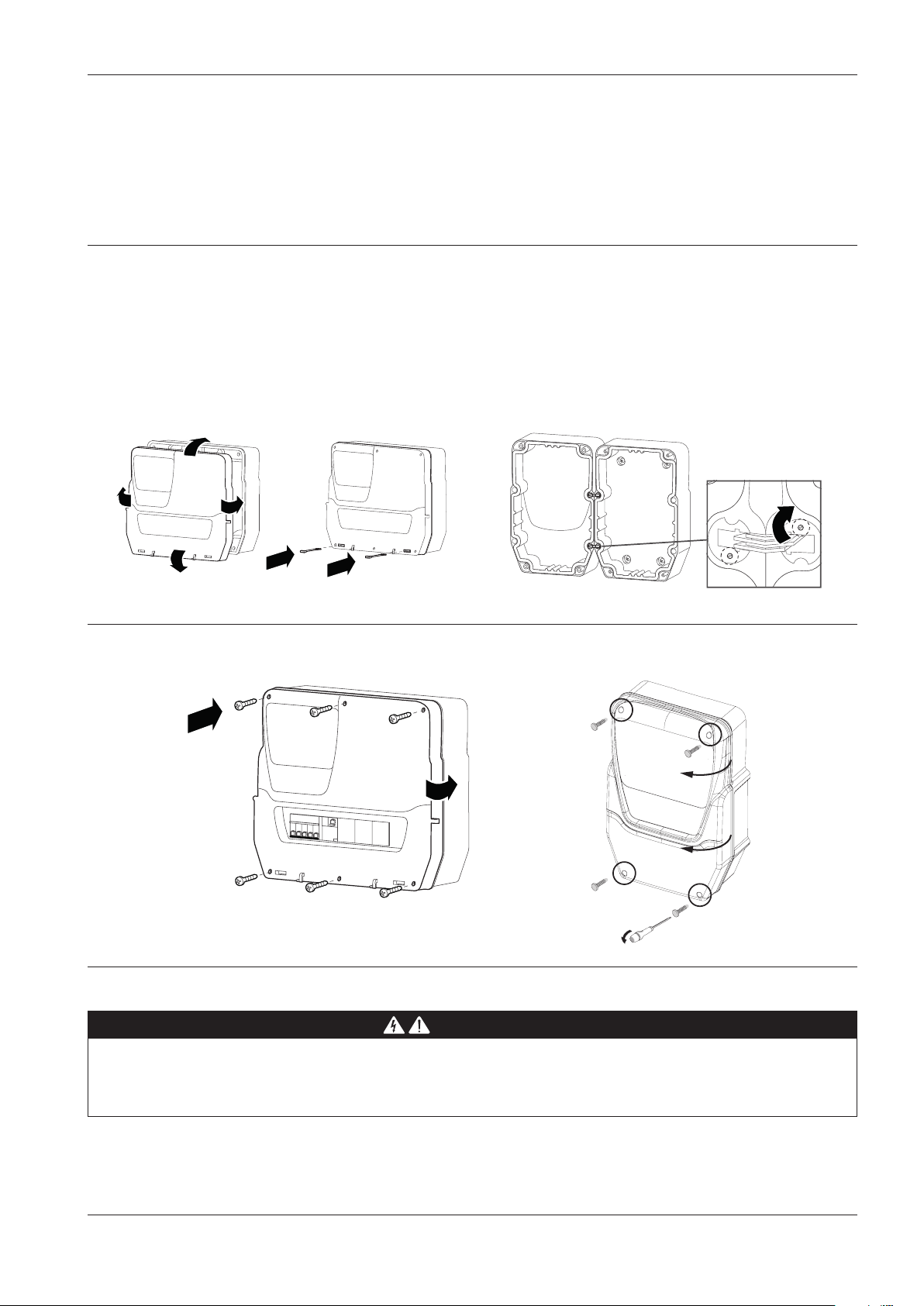

3) Optional. Fir the panel.

NOTE: on models 300/500 with front door two more DIN spaces

can be created: open the door with both hands as shown in the

figure, then remove the factory-fitted push-through tabs.

9MA10258.01 07/2018

15

Page 16

4) Optional. Install the plug-in RS-485 module for

communication with the supervisor.

EWRC 5000 only:

1) Remove the seven screws securing the plastic protecting

the board.

2) Remove the protective element, then use a box cutter to

remove the two terminal covers.

3) Connect the RS-485 plug-in module (optional) using the

specific spacers, then replace the cover and secure it

using the screws.

NOTICE

INOPERABLE DEVICE

Fit the plug-in RS-485 module in the plug-in connector

aligning the four posts with the holes in the control board.

Failure to follow these instructions can result in

equipment damage.

5) Fix the back of the panel to the wall using four screws (not supplied) suited to the wall thickness.

NOTE: TDI20 screw caps (not provided) can be fitted to 300/500 models at the wall mounting points so that the IP

rating is not altered.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

For models with magnetothermal switch, before connecting make sure that switch is in the OFF position.

Failure to follow these instructions will result in death or serious injury.

16

9MA10258.01 07/2018

Page 17

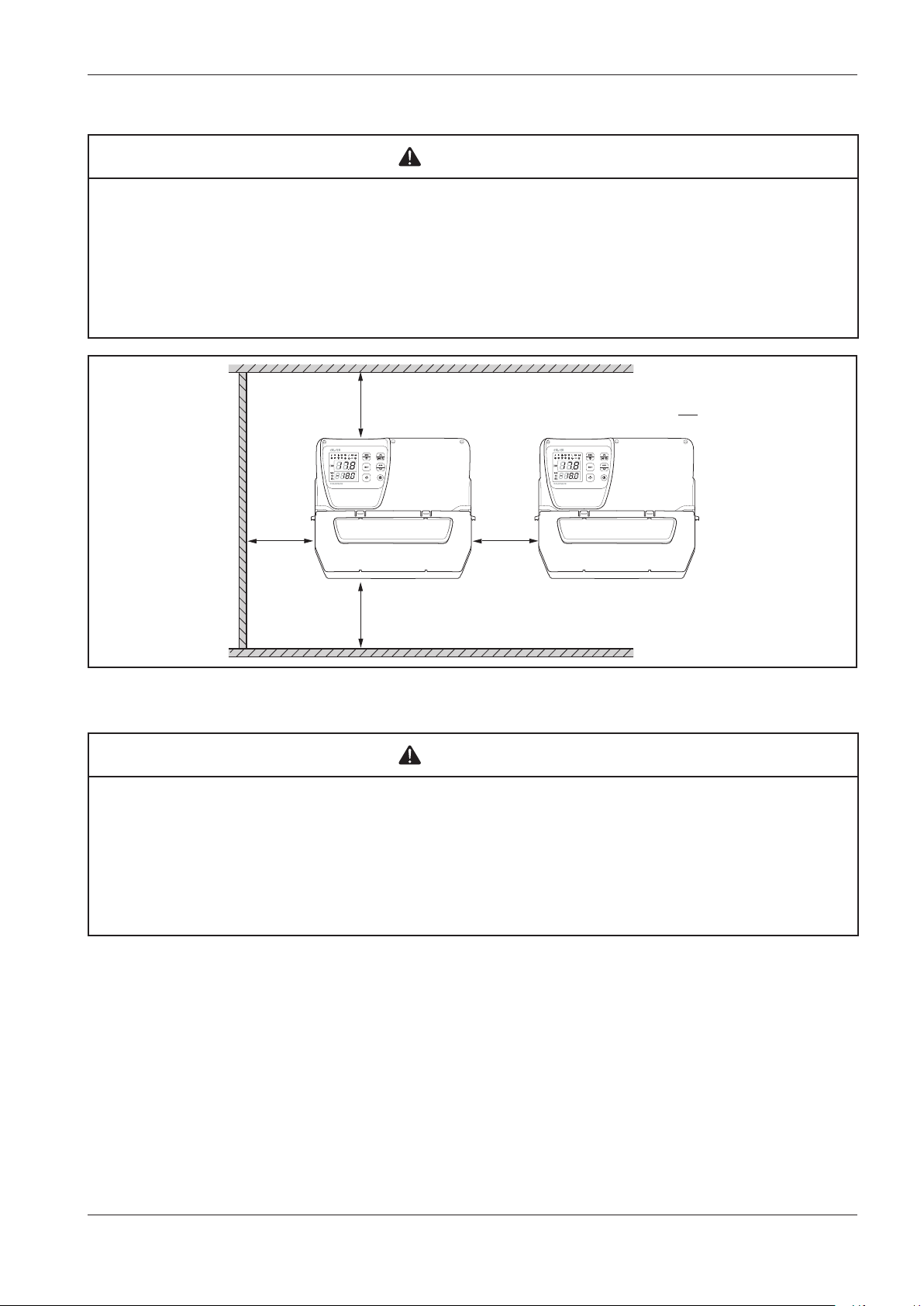

6) Make the electrical connections referring to the wiring diagrams shown page 24 and page 25. Use suitable

cable/pipe clamps.

NOTE: only models with magnetothermal switch. Connect the switch to the electronic board power supply using the

accessory cable provided in the packaging.

7) Fit the hinges to secure the cover.

EWRC 5000

Place the panel cover on the base making it stick to the

perimeter seal. Then, while holding the cover in place, fit

the two hinges provided into the corresponding holes and

press them until you hear them click as they are locked

into place.

8) Close the cover and secure it with the screws provided.

EWRC 300/500

Fit the hinges provided into their housings on the right

or left side of the panel and tighten the corresponding

screws to secure them.

DANGER

RISK OF ELECTRIC SHOCK, EXPLOSION OR EXPOSURE TO ACCESSIBLE PARTS

The final application must disallow access to parts at hazardous voltage, as the instrument offers no intrinsic

protection against this risk.

Failure to follow these instructions will result in death or serious injury.

9MA10258.01 07/2018

17

Page 18

9) DIN rail-mounted models with window only. Close access to

inside the panel from the front window using the dedicated

DIN plugs.

For EWRC NT 500 models with the plastic knockout

removed and no internal magnetothermal switch, the end

user is responsible for ensuring that the open parts of the

box are not accessible.

10) EWRC 5000 only. Fit the door: align the front door with the

two hooks at the bottom of the panel and push it towards the

right until you hear it click as it locks into place.

1

11) Close the door

2

18

9MA10258.01 07/2018

Page 19

WARNING

UNINTENDED EQUIPMENT OPERATION

• Place the devices dissipating the most heat in the top of the cabinet and ensure suitable ventilation.

• Do not place this equipment near or above any devices which could cause overheating.

• Install the device in a point that guarantees the minimum distances from all structures and adjacent equipment as

indicated in this document.

• Install all equipment in conformity with the technical specifications given in the respective documentation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

mm

in.

25

9.84

25

9.84

25

9.84

25

9.84

Fig. 1. Distance valid for all models

WARNING

UNINTENDED EQUIPMENT OPERATION

• Place the devices dissipating the most heat in the top of the cabinet and ensure suitable ventilation.

• Do not place this equipment near or above any devices which could cause overheating.

• Install the device in a point that guarantees the minimum distances from all structures and adjacent equipment as

indicated in this document.

• Install all equipment in conformity with the technical specifications given in the respective documentation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

9MA10258.01 07/2018

19

Page 20

4. ELECTRICAL CONNECTIONS

4.1. Wiring practices

The following information describes the guidelines for wiring and the associated best practices to follow when using the device.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Disconnect all power from all equipment including connected devices prior to removing any covers or doors, or

installing or removing any accessories, hardware, cables or wires.

• Always use a properly rated voltage sensing device to confirm the power is off where and when indicated.

• Before powering the device back up, fit back and fix all the covers, hardware components and wiring.

• Check the earthing connections on all earthed devices.

• Use only the specified voltage when operating this equipment and any associated products.

• Comply with all standards regarding accident protection and local applicable safety directives.

Failure to follow these instructions will result in death or serious injury.

This equipment is designed to operate outside all hazardous locations and is not to be used in applications which generate (or could

potentially generate) hazardous environments. Install this equipment only in areas and applications known to be free from dangerous

atmospheres at all times.

DANGER

POTENTIAL FOR EXPLOSION

• Install and use this equipment in non-hazardous locations only.

• Do not install or use this equipment in applications which could generate hazardous atmospheres, such as

applications which use flammable refrigerants.

Failure to follow these instructions will result in death or serious injury.

For information regarding the use of control equipment in applications capable of generating hazardous materials, please contact the

relevant national regulatory bodies or certifying authorities.

4.1.1. Wiring guidelines

The following regulations must be complied with for wiring:

• Make connections as short as possible and do not wind them around electrically connected parts.

• Check that the operating conditions and surroundings comply with the specification values.

• Use wires of the correct diameter and suited to the voltage and current requirements.

• Use copper conductors (obligatory).

WARNING

UNINTENDED EQUIPMENT OPERATION

• The equipment signal cables (probes, digital inputs, communication, and the relative power supplies) must be laid

separately from the power cables.

• Every end application of this device must be tested individually and completely in order to check its proper operation

before putting it in service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

20

9MA10258.01 07/2018

Page 21

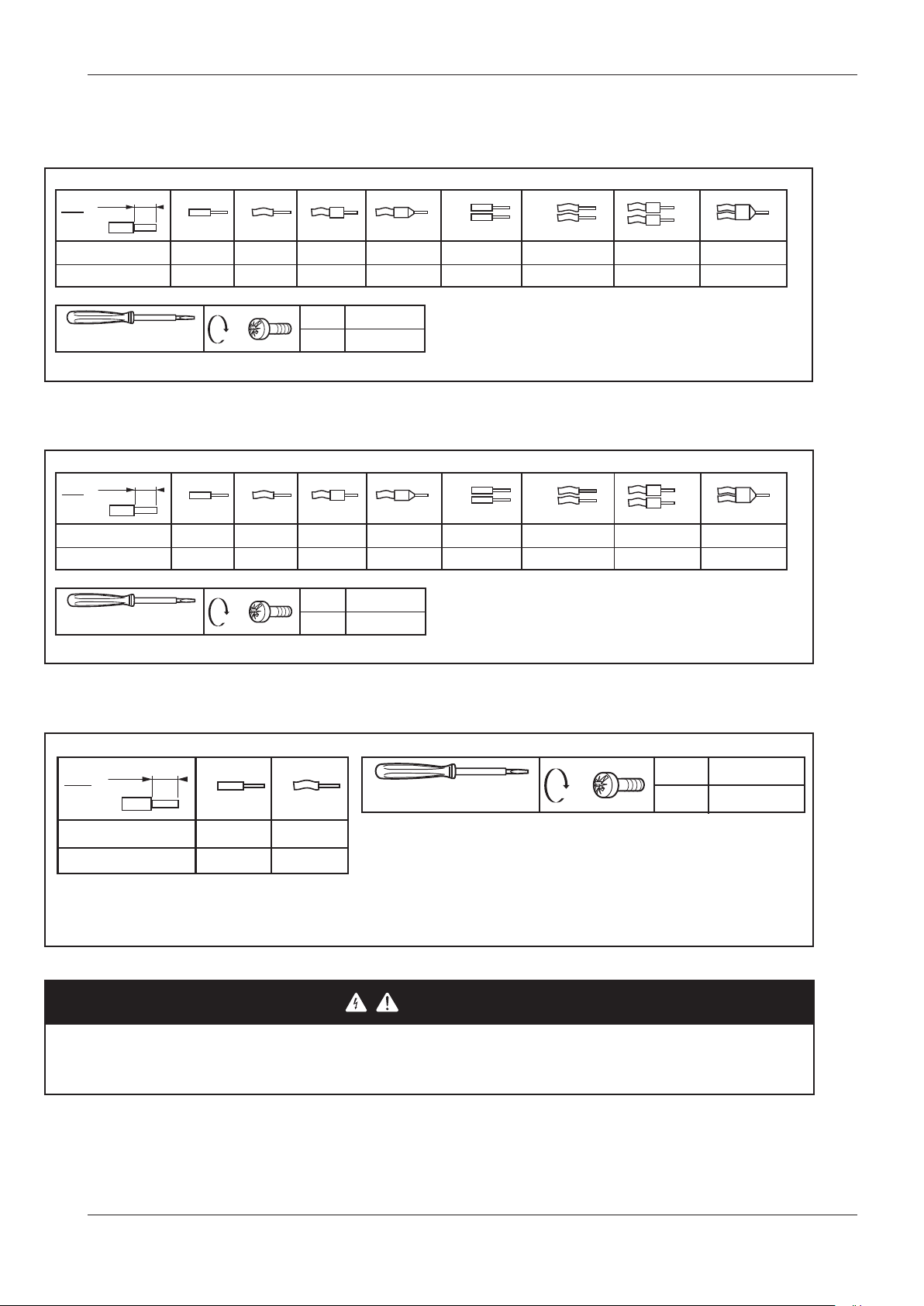

4.1.2. Rules for screw-type terminal boards

The table below illustrates the types of cables and wire sections for a screw-type terminal board with5.08 (0.197 in.) spacing:

7

mm

0.28

in.

2

mm

AWG

Ø 3,5 mm (0.14 in.)

The table below illustrates the types of cables and wire sections for a screw-type terminal board with7.62 (0.30 in.) spacing:

7

mm

0.28

in.

mm

AWG

2

0.2…2.5

24…14

0.2…4

24…12

0.2…2.5

24…14

C

0.2…2.5

24…14

0.25…2.5

22...14

N•m

lb-in

Fig. 2. Spacing 5.08 mm (0.197 in.)

0.25…2.5

22...14

0.25…2.5

22...14

0.5...0.6

4.42...5.31

0.25…2.5

22...14

2 x 0.2…0.75

2 x 24…18

2 x 0.2…1.5

2 x 24…16

2 x 0.2…0.75

2 x 24…16

2 x 0.2…1.5

2 x 24…16

2 x 0.25…0.75

2 x 22…18

2 x 0.25…0.75

2 x 22…18

2 x 0.5...1.5

2 x 20...16

2 x 0.5...1.5

2 x 20...16

0.5...0.6

Ø 3,5 mm (0.14 in.)

The table below illustrates the types of cables and wire sections for the magnetothermal switch:

mm

in.

14

0.55

mm

2

AWG

C

1…25

18…4

Fig. 4. Cable types and tightening torque for the magnetothermal switch

N•m

4.42...5.31

lb-in

Fig. 3. Spacing 7.62 mm (0.3 in.)

Ø 6 mm (0.24 in.)

1…16

18…6

DANGER

C

LOOSE WIRING CAN RESULT IN ELECTRIC SHOCK

Tighten the connections in compliance with the technical specifications for pairs.

Failure to follow these instructions will result in death or serious injury.

N•m

lb-in

2

17.7

9MA10258.01 07/2018

21

Page 22

Specific considerations for handling

When handling the equipment, use caution to avoid damage caused by electrostatic discharge. In particular, the unshielded

connectors and in certain cases the open circuit boards are vulnerable to electrostatic discharge.

WARNING

UNINTENDED EQUIPMENT OPERATION DUE TO ELECTROSTATIC DISCHARGE

• Keep the equipment in the protective packaging until ready for installation.

• The equipment must only be installed in type-approved casing and/or in points that prevent unauthorised access and

provide protection from electrostatic discharge.

• When handling sensitive equipment, use an antistatic bracelet or equivalent earthed protective device against

electrostatic discharge.

• Before handling the equipment, always discharge the static electricity from the body by touching an earthed surface

or type-approved antistatic mat.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

4.1.3. Analogue Inputs-Probes

The temperature probes do not feature any connection polarity and can be extended using normal bipolar cable.

WARNING

UNINTENDED EQUIPMENT OPERATION DUE TO CONNECTIONS

• The equipment signal cables (probes, digital inputs, communication, and the relative power supplies) must be laid

separately from the power cables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

NOTICE

INOPERABLE DEVICE

Before switching on the electrical power, check all the wiring connections.

Failure to follow these instructions can result in equipment damage.

NOTE: The NTC temperature probes do not feature any connection polarity and can be extended using normal bipolar cable.

22

9MA10258.01 07/2018

Page 23

4.1.4. Serial connections

The controller can be connected to TelevisSystem / Modbus remote control systems by a direct RS-485 connection using

the RS-485 optional plug-in module.

4.1.5. RS-485 connection

• Use a “twisted pair” shielded cable with two conductors with cross-section 0.5 mm2 (AWG 20), plus sheath, such as, for

example, a Belden cable version 3105A (typical impedance 120 Ω) with PVC sheath, rated capacity between conductors

36 pF/m, rated capacity between conductor and sheath 68 pF/m. Alternatively, use a “twisted pair” shielded cable with

two conductors with cross-section 0.5 mm

PVC sheath, rated capacity between conductors 89 pF/m, rated capacity between conductor and sheath 161 pF/m. For

laying wires, comply with the indications given in standard EN 50174 on information technology wiring.

• Follow the applicable regulations for laying and connecting the cables. Extra care must be taken in separating data

transmission circuits from power lines.

• The length of the RS-485 network which can be connected directly to the controller is 1200 m. This length can be

extended and the number of devices for each channel increased using appropriate repeater modules.

• Input impedance: 1/8 unit load.

• Single terminal board with 3 conductors: use all 3 conductors (“+” and “-” for the signal and “GND” for the braiding).

• Attach the 120 Ω 1/4W resistors between the “+” and “-” terminals on the interface and the last controller in each branch

of the network.

• The RS-485 physical level can be used for Modbus SL communication

Concurrent communication of different protocols on the same serial port is NOT permitted.

2

(AWG 20), plus sheath, such as, for example, a Belden cable version 8762 with

Pay special attention when connecting serial lines. Incorrect wiring may cause the equipment to stop working.

NOTICE

INOPERABLE DEVICE

Do not communicate simultaneously via Modbus and Televis protocols on the same serial port.

Failure to follow these instructions can result in equipment damage.

4.1.6. TTL connection

Use a 5-wire TTL cable up to 3 m (118 in.) in length.

An Eliwell-supplied TTL cable is recommended. Contact Eliwell Sales Office for item availability.

9MA10258.01 07/2018

23

Page 24

4.2. WIRING DIAGRAM

UNICARD

COPY CARD

GND GND GND+ +

Pb1 Pb2

Yellow cable

+

+

Pb3/DI3

RS-485

OPTIONAL

DI2 DI1

230 Vac

230 Vac

EWRC 300/500/5000 NT

DISPLAY

EWRC 500NT/

5000 NT

1615141312111091 2 3 4 5 6 7 8

H23

only

COM

18 19 20 2117

18 19 20 2117161514131211109

H24 H25

NONC

RCSU

RCSH

RCH300

RCSP

RCAP

OUT1 OUT2 OUT3 OUT4 OUT5

18 A max

L

N

L

N

H22 H23 H24 H25

H21

H22

H21

4.2.1. TERMINALS

TERMINALS

1, 5, 8 GND 9, 10 LINE/NEUTRAL. Power supply

2 Analogue input Pb1 11 NO OUT1

3 Analogue input Pb2 12 NEUTRAL

4 Analogue input Pb3 / Digital input DI3 13 NO OUT2

6 Digital input DI2 14 NEUTRAL

7 Digital input DI1 15 NO OUT3

CARD

RS-485

TTL for connection to UNICARD / CopyCard /

TelevisSystem

Modulo plug-in for connection to

TelevisSystem / Modbus (optional)

16 NEUTRAL

17 NO OUT4

18 NEUTRAL

19 NC OUT5

20 OUT5 Common terminal

21 NO OUT5

24

9MA10258.01 07/2018

Page 25

4.3. WIRING DIAGRAM FOR MODELS WITH MAGNETOTHERMAL

H21

H24 H25

H23

H22

SWITCH INSTALLED

EWRC 500 NT BREAKER

OUT1 OUT2 OUT3 OUT4 OUT5

COM

NONC

18 19 20 2117

GND GND GND+ + +

Pb1 Pb2

+

DI2 DI1

H21

H22 H23 H24 H25

1615141312111091 2 3 4 5 6 7 8

RCAU

Pb3/DI3

16 A max

230 Vac

L

N

18 19 20 2117161514131211

RCAP

4.3.1. TERMINALS

TERMINALS

1, 5, 8 GND 9, 10 LINE/NEUTRAL. Power supply

2 Analogue input Pb1 11 NO OUT1

3 Analogue input Pb2 12 NEUTRAL

4 Analogue input Pb3 / Digital input DI3 13 NO OUT2

6 Digital input DI2 14 NEUTRAL

7 Digital input DI1 15 NO OUT3

CARD

RS-485

TTL for connection to UNICARD / CopyCard /

TelevisSystem

Modulo plug-in for connection to

TelevisSystem / Modbus (optional)

16 NEUTRAL

17 NO OUT4

18 NEUTRAL

19 NC OUT5

20 OUT5 Common terminal

21 NO OUT5

9MA10258.01 07/2018

25

Page 26

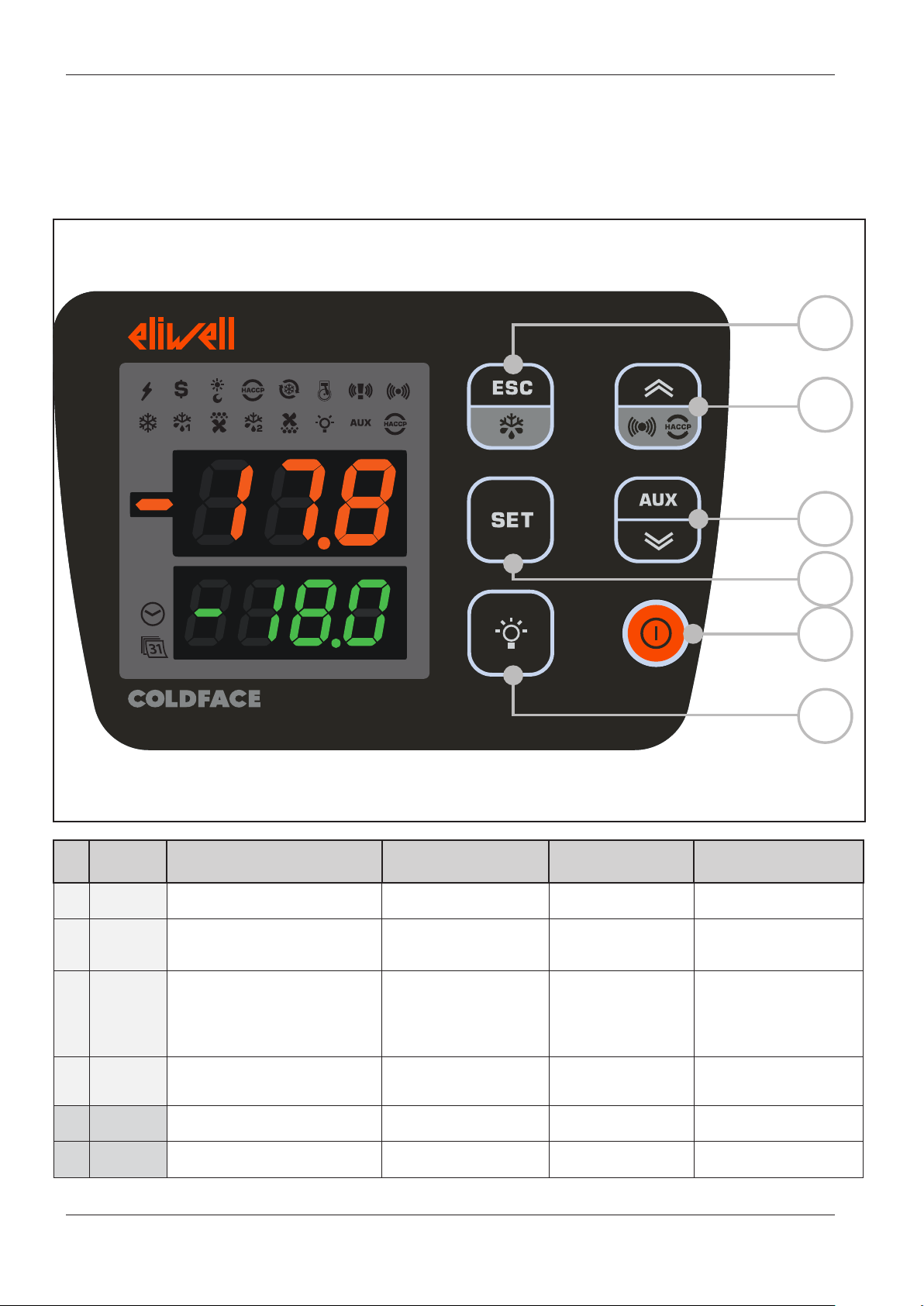

5. USER AND START-UP INTERFACE

5.1. DISPLAY

5.1.1. KEYS

A

B

%RH

No. KEY press and release

A

B

C SET

D

E ON/OFF /

F LIGHT Switch light On/Off Switch light On/Off /

ESC

Defrost

p UP

Alarms

q DOWN

AUX

• Functions Menu

• Alarms Menu (always visible)

• Display setpoint / probe values /

time (Models with clock only)

• Confirm values

• Access value edit mode

(upper display blinking)

system INFO

See Technical Support

press and hold for about

3 seconds

• Manual defrost

• Return to Main Menu

/

Access Parameters menu

Activate auxiliary function

Switch On/Off

device

NAVIGATION MENU Notes

• Increase values

• Confirm values

• Move right

• Decrease values

• Output

• Scroll

• Scroll

/

C

D

E

F

Configurable - see parameter H33

HACCP alarms

only on foreseen models

and if present

Time only visible on models with clock

Configurable - see parameter H32

Configurable - see parameter H34

Configurable - see parameter H35

26

9MA10258.01 07/2018

Page 27

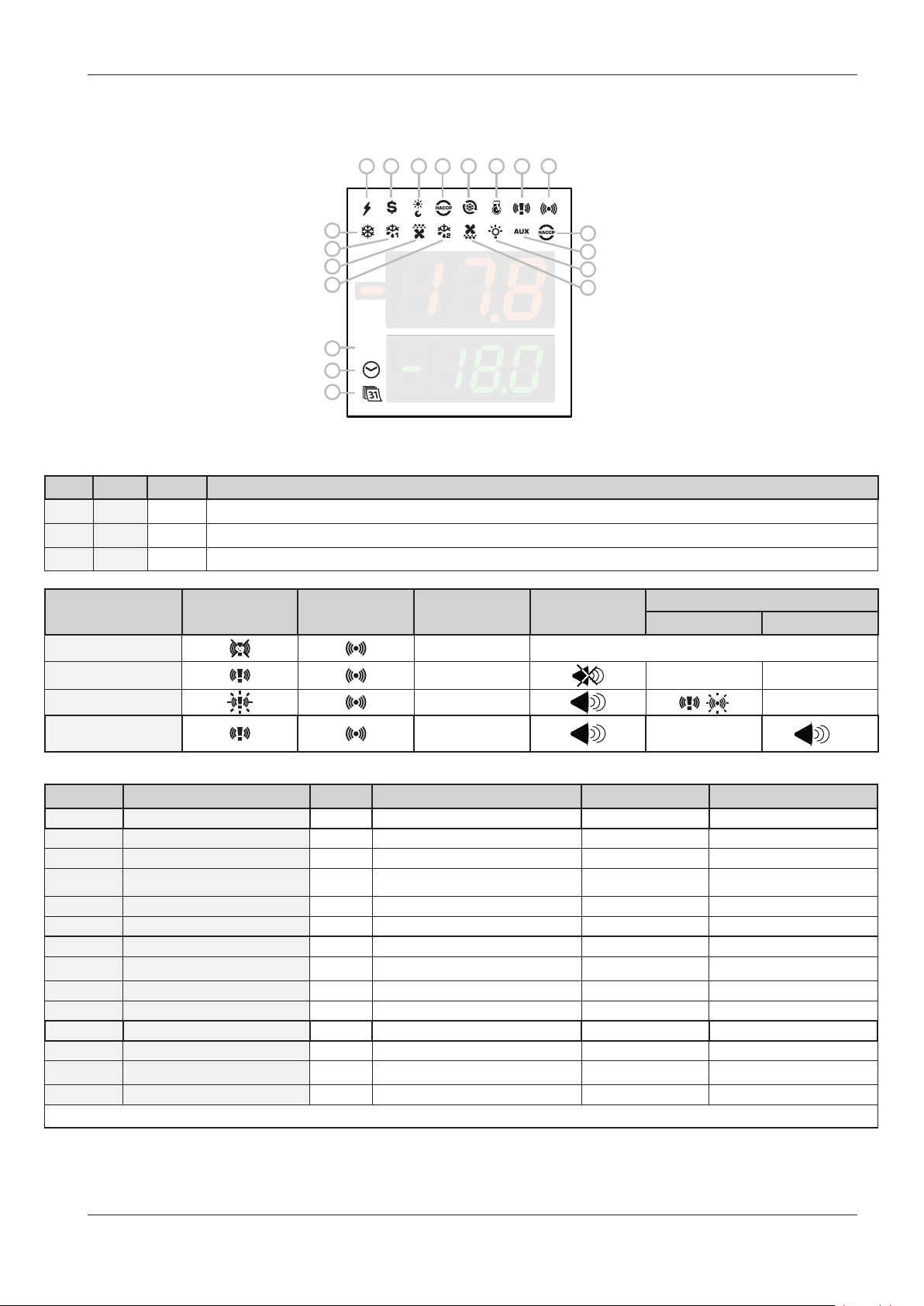

5.1.2. ICONS

1

2 3 4 5 6 7 8

9

10

11

12

17

%RH

18

19

13

14

15

16

Icons have the following meaning:

No. ICON colour description

17 %RH amber not used

18 TIME amber access in case of time display or editing

19 DATA amber access in case of date display or editing

Alarms ICON 7 ICON 8

ALARM Red See “8.2. ALARM CAUSE/EFFECT TABLE” page 80

PANIC

Colour

Buzzer

Red --- ---

OFF

Icon Buzzer

LEAK DETECTOR

LEAK DETECTOR

PANIC +

Red

Red ---

...

(1) = As long as the Panic alarm persists it will not be possible to mute the buzzer from the keypad.

No. Icon colour ON

BLINKING

OFF

1 POWER SUPPLY green Power supply ON / Power supply OFF

2 ENERGY SAVING amber Energy saving ON / Energy saving OFF

3 NIGHT & DAY amber Night & Day ON / Night & Day OFF

4 HACCP amber HACCP menu / /

5 DEEP COOLING (DCC) amber Drip cooling cycle ON /

Drip cooling cycle OFF

6 PUMP DOWN amber Compressor Pump Down ON / Compressor Pump Down OFF

9 COMPRESSOR amber Compressor ON Delay Compressor OFF

10 DEFROST 1 amber Defrost Dripping

No defrost

11 EVAPORATOR FANS amber Fans ON Forced ventilation Fans OFF

12 DEFROST 2 amber Defrost Dripping

No defrost

13 HACCP ALARM red HACCP alarm Not displayed No alarm

14 AUXILIARY (AUX) amber AUX ON / AUX OFF

15 LIGHT amber Light ON / Light OFF

16 CONDENSER FANS amber Fans ON / Fans OFF

ON: function/alarm ON; OFF: function/alarm OFF

---

(1)

9MA10258.01 07/2018

27

Page 28

5.1.3. PRELIMINARY CONFIGURATIONS

After making the electrical connections, simply power up the device to start operation.

At first start-up, Eliwell recommends that you:

1. make sure the instrument is powered (green POWER SUPPLY icon on)

2. make sure the display is working: when the controller is powered up it performs a lamp test, during which time the

display and icons will blink for several seconds to ensure that they all function correctly

3. make sure there are no active alarms (ALARM / HACCP ALARM icon off and labels E1, E2, E3 not displayed).

4. configure the main parameters listed in the USER menu to suit your requirements, as described below

5.1.4. OPERATION IN DEFAULT CONFIGURATION

The instrument is configured for negative cold. For positive cold, disable the evaporator probe Pb2 (set H42=n) and relay

OUT3 (set H23=6) to prevent continuous ventilation.

COMPRESSOR

The compressor is active if the cold room temperature measured by Pb1 exceeds the value of SEt + diF. The compressor

stops if the cold room temperature detected by Pb1 falls below the SEt value. The instrument includes compressor on/off

protection.

DEFROST

Defrost is by means of electric heaters (parameter dty = 0) and the time counter is always active with the instrument

switched on (dCt=1).

Manual defrost

Manual defrost is activated by pressing and holding the ESC key (A)

If conditions are not right for defrosting, (e.g. the evaporator probe temperature is higher than the defrosting end temperature) or parameter OdO≠0, the display will blink three times to indicate that the operation will not be performed.

Default Defrost settings

dit = 6 hours. interval between 2 defrost cycles

dSt = 6.0 °C. defrosting end temperature. set by Pb2

The Defrost cycle may terminate due to a timeout based on the parameter dEt (default 30 min).

EVAPORATOR FANS

The OUT3 relay is configured as the fan relay and is activated when required, according to the delay and parameter settings.

Default fan settings

dt = 0 min. dripping time

dFd = Y. Fans off during defrosting

LIGHT (EWRC 500/5000)

The light is activated by pressing and holding the LIGHT key (F)

As digital input DI1 is configured as door switch, relay OUT4 (light) is activated when the door is opened. The light also

switches on with the instrument in stand-by.

ALARM relay (EWRC 500/5000)

Relay OUT5 is configured as alarm relay and is activated in the case of alarms, according to delays and parameter settings.

28

9MA10258.01 07/2018

Page 29

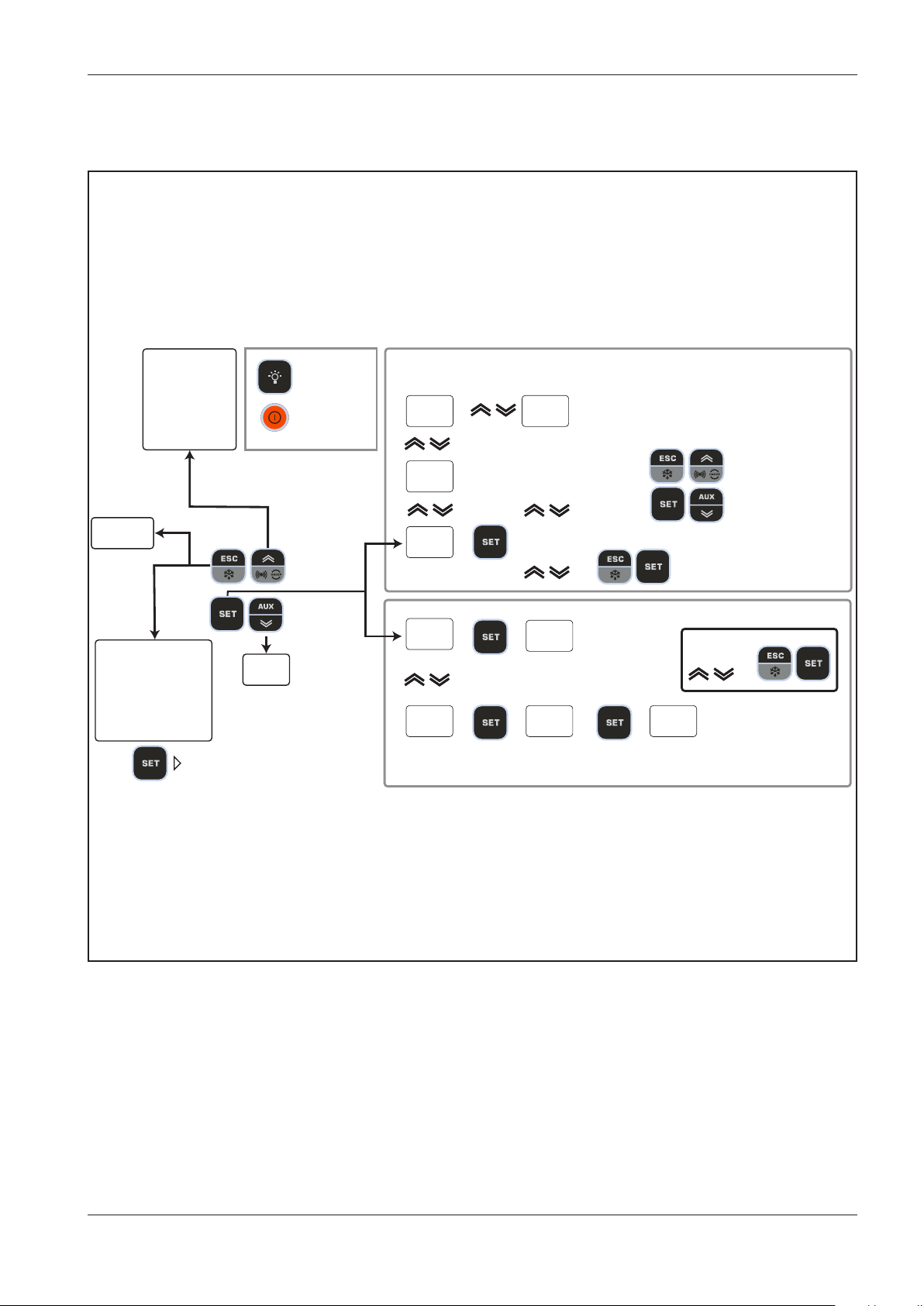

5.1.5. NAVIGATION

Display alarms

if active

Display HACCP alarms

if function active

1 sec

Manual

defrost

3 sec

1 sec

Functions Menu

LOC keypad lock

rHC reset HACCP alarms

rSE activate reduced Set

rPA Pressure switch alarms

rEd disable HACCP

function ON / OFF

Info

System

Turns light on/o

Turns instrument

on / o

1 sec

3 sec

display probe

value

Pb1

-20.6

rtc

18.55

SET

-18.9

USr

inS

display probe

value

Pb2

-20.6

set time and date

modify SetPoint

value

diF

2.0

CPr

- - -

conrm with

SetPoint & Probes

Parameters

modify

value

diF

2.0

conrm with

9MA10258.01 07/2018

29

Page 30

5.1.6. FUNCTIONS MENU AND KEY-ENABLED FUNCTIONS

The Functions menu is used to perform a number of manual functions such as putting the device into stand-by, clearing

pressure switch interventions and clearing HACCP alarms, etc.

Access the Functions menu by pressing the ESC key.

The following table lists the functions, which are all OFF by default.

Display Function description

The UP/ESC/ON-OFF/LIGHT keys and the functions

LOC

OFF

Keypad lock

The DOWN key may be used to view the Setpoint only;

programmed via keys are locked

the value cannot be modified

Only function visible if keypad locked (On)

rEd

OFF

rPA

OFF

rSE

Disables

HACCP alarm

recording

Reset pressure switch

alarm

Reduced set Reduced set

NOTE: the function reverts to OFF status when you exit the

Disables HACCP alarm recording

Clears pressure switch alarm

Functions Menu

OFF

rHC

Reset HACCP alarms

Clears HACCP alarms

May be protected by Password PA3

OFF

All models have the UP key set to display the Alarms Menu.

All models also allow the setting of other keys to activate a specific function as identified by the client.

The parameters for configuring the two keys are:

• H32 = DOWN key configuration

• H33 = ESC key configuration

• H34 = ON/OFF key configuration

• H35 = LIGHT key configuration

The values that can be set apply to these keys and the functions that can be activated are:

Value of

H32/H33/H34/H35

0 = disabled

1 = defrost

2 = Auxiliary

3 = Activate reduced set

4 = Reset HACCP alarms

5 = Disable HACCP alarms

6 = Light

7 = Stand-by

8 = NOT USED

9 = Evaporator fans ON

30

10 = Activate / disable Frame Heater relay

11 = Enable/disable Night And Day functions

12 = deep cooling cycle

13 = Clear voltage drop errors

(Reset Power Failure)

14 = Service stoppage

15 = Activate economy set + Night And Day

Function enabled

9MA10258.01 07/2018

Page 31

5.1.7. PASSWORDS

Password PA1 is disabled by default.

Password “PA1”: allows access to User parameters.

To enable (PA1≠0): press and hold SET for more than 3 seconds. The label USr appears. Press SET again.

Scroll through the parameters using UP and DOWN until you find label PA1, press SET to display its value, change it using

UP and DOWN and save by pressing SET or ESC.

Example with password enabled (PA1≠0): it will be requested before access to the User parameters is granted.

Display description

-17.8

-18.0

USr

PA1

PA1

0

PA1

12

diF

2.0

Press SET for 3 seconds

Label PA1 appears

Press SET

Use UP and DOWN keys to enter the password

In the example the password is 12

Press SET

User menu accessed

The first User parameter appears

If the value entered is incorrect, label PA1 will be shown

again and the procedure must be repeated

Password “PA2”: allows access to Installer parameters.

The example is the same. Note. Password PA2 is set by default to 15

Display description

-17.8

Press SET for 3 seconds

-18.0

USr

Use ‘UP’ and ‘DOWN’ to search for InS

Label USr appears

PA1

9MA10258.01 07/2018

31

Page 32

Display description

inS

Press SET

PA2

PA2

Use UP and DOWN keys to enter the password

0

PA2

In the example the password is 15

Press SET

15

Installer menu accessed

CPr

---

5.1.8. SETPOINT PROGRAMMING

By way of example, we will change the Setpoint value from -18.0 degrees centigrade to -20.0 degrees centigrade.

If the value entered is incorrect, label PA2 will be shown

again and the procedure must be repeated

the first CPr folder appears

Display description

-17.8

Press and release the SET key

-18.0

SEt

-18.0

SEt

-20.0

-17.8

-20.0

The upper display will show SEt, the lower display will

indicate the current setpoint value

Press and release the SET key once more

The upper display will show SEt blinking

Use the UP & DOWN keys to adjust the setpoint value

Press the ESC key several times to return to the normal

display

(or press the SET key to confirm, followed by ESC to exit)

The new Setpoint value is saved and appears on the

lower display

32

9MA10258.01 07/2018

Page 33

5.1.9. VIEWING PROBE VALUES

Display description

-17.8

-20.0

SEt

-20.0

rtc

5.28

Pb1

7.8

Pb2

Press and release the SET key

The upper display will show SEt, the lower display

will indicate the current setpoint value

Use the DOWN key to view the value of probe Pb1

The time is displayed in HACCP models

Use the DOWN key again to view the value of

probe Pb1

Use the DOWN key again to view the value of

probe Pb2

7.8

If H43 is not 0 (probe 3 present)

Pb3

Use the DOWN key again to view the value of

probe Pb3

-18.6

-17.8

Press the ESC key to return to the normal display

Normal display

-20.0

9MA10258.01 07/2018

33

Page 34

5.1.10. How to modify the date and time

Function only available in HACCP models

Display description

-17.8

-20.0

SEt

-20.0

rtc

5.28

rtc

5.28

rtc

Press and release the SET key

The upper display will show SEt, the lower display

will indicate the current setpoint value

Use the DOWN key to display the time

The CLOCK icon will be on

Press and release the SET key.

The CLOCK icon will be on

The hour value will begin to blink

Use the UP & DOWN keys to adjust the hour value

The CLOCK icon will be on

Press and release the SET key

17.28

The CLOCK icon will be on

rtc

17.28

rtc

Use the UP & DOWN keys to adjust the hour value

The hour value has been changed

The minute value begins to blink

Repeat this procedure to adjust the date value

(DAY.MONTH) and YEAR

31.05

In this case the DATA icon (31) is on

rtc

Press the ESC key several times to return to the

normal display

2014

34

9MA10258.01 07/2018

Page 35

5.1.11. Displaying Alarms

Display description

-17.8

Press and release the UP key.

The upper display will show ALr.

-18.0

ALr

nOnE

The lower display will show

a. nOnE if no alarms active

b. SYSt if system alarms present

ALr

SYSt

HACCP models ONLY

ALr

HACP

The lower display will show HACP if HACCP alarms are present

The upper display will show ALr.

NOTE: parameter H50 must = 1

9MA10258.01 07/2018

35

Page 36

5.1.12. System Alarms example

Let us suppose two alarms have occurred,

• one HIGH TEMPERATURE on the cold room probe

• one HIGH TEMPERATURE on probe 3 (parameter H43 different from 0)

Display description

-17.8

-18.0

ALr

SYSt

ALr

HA1

ALr

HA3

Press and release the UP key.

The upper display will show ALr.

The lower display will indicate SYSt

Press and release the SET key.

The upper display will show ALr.

The lower display will show

HA1 HIGH TEMPERATURE alarm on the cold room probe

Use the UP & DOWN keys to view other alarms, if present

In the example, the lower display will indicate HA3 HIGH TEMPERATURE alarm on probe 3

(see para. H43)

Press the ESC key several times to return to the normal display

36

9MA10258.01 07/2018

Page 37

5.1.13. Modifying a parameter

The User parameters USr are not divided into subfolders.

They are always visible by default (access password PA1 is not enabled by default).

The same parameters are also visible in the respective folders ‘Compressor’, ‘Fans’, etc. within the Installer parameters

menu InS. The password is enabled (PA2=15) by default.

NOTE: It is advisable to switch the device off and on again each time the configuration of the parameters is

changed, so as to prevent malfunctions affecting the configuration and/or the current timings.

How to modify a user parameter

Instructions are provided below on how to modify a User parameter

The same procedure applies to Installer (inS) level parameters.

Let us take the dit parameter as our example.

There are no sub-folders at User level. At Installer level the parameter is in the folder containing dEF defrost parameters.

We will now show how to change the value from 6 hours to 8 hours.

Display description

Press and hold the SET key for approx. 3 seconds

-17.8

-20.0

The folder for USr parameters will appear

USr

diF

2.0

Press and release the SET key to access the first

Use the UP & DOWN keys to find the parameter that you

Press and release the SET key.

parameter

The first User parameter appears

wish to modify

Press and release the SET key.

diT

The dit label will blink

6

diT

8

Use the UP & DOWN keys to adjust its value

Press and release the SET key

to confirm the modification.

9MA10258.01 07/2018

37

Page 38

How to modify an Installer parameter

Instructions are provided below on how to modify the same User parameter but via the Installer menu

Let us take the dit parameter as our example.

At Installer level the parameter is in the folder containing dEF defrost parameters.

We will now show how to change the value from 8 h to 6 h.

Display description

Press and hold the SET key for approx. 3 seconds

-17.8

-20.0

The folder for USr parameters will appear

USr

Use the UP & DOWN keys to search for the inS folder

Press and release the SET key.

inS

CPr

---

dEF

---

dit

8

dit

Press and release the SET key to access the first

parameter

The first folder appears

Use the UP & DOWN keys to search for the dEF folder

Press and release the SET key.

The first parameter in the dEF folder will appear

Use the UP & DOWN keys to find the parameter you want

to change

Press and release the SET key.

The dit label will blink

Use the UP & DOWN keys to adjust its value

38

6

Press and release the SET key

to confirm the modification.

9MA10258.01 07/2018

Page 39

6. FUNCTIONS AND REGULATORS

This chapter describes the various functions of the devices.

NOTE: some functions may not be available in certain models.

6.1. SETTINGS

6.1.1. PROBE SETTING AND CALIBRATION

EWRC 300/500/5000 NT have 3 configurable NTC/PTC inputs (Pb1...Pb3).

The temperature probes (Pb1...Pb3) must all be the same type and should be configured via parameter H00, visible at User

level (USr) or inside folder CnF, Installer level (inS)

• H00 = 0 if using PTC probes

• H00 = 1 if using NTC probes (Default)

After installation, the values read by the probes can be corrected/calibrated using the following parameters:

• CA1: probe 1 offset. Positive or negative value to be added to the value read by Pb1 (Range: -30.0...30.0)

• CA2: probe 2 offset. Positive or negative value to be added to the value read by Pb2 (Range: -30.0...30.0)

• CA3: probe 3 offset. Positive or negative value to be added to the value read by Pb3 (Range: -30.0...30.0)

6.1.2. DISPLAY SETTINGS

At User level (Usr) or inside the diS folder at Installer level (inS) you will find the parameters used to set the temperature

readout, decimal point usage, unit of measure and display during defrost.

• ndt: (USr/inS) enables/disables decimal point display

(with resolution of one-tenth of a degree; e.g.: 10.0°C)

Display with decimal point is only possible within the range of values from -99.9°C to 99.9°C

• ndt = y displays read values with decimal point (default);

• ndt = n displays read values without decimal point

NOTE: enabling/disabling the decimal point only affects the on-screen display of values.

The controller will continue to perform calculations with decimal point.

• ddL: (USr/inS) sets the type of display during and up to the end of defrost

• ddL = 0 displays the probe value (default)

• ddL = 1 continues to display the value read by the probe at the start of defrosting

• ddL = 2 displays the fixed label dEF

• dro: (inS) sets temperature display to °C or °F.

• dro = 0 display in °C (default)

• dro = 1 display in °F

NOTE: switching between °C and °F DOES NOT modify the values of temperature parameters

(e.g. setpoint=10°C becomes 10°F).

This means that the maximum and minimum limits of parameters as absolute values

are the same for both units of measure and hence the ranges are different.

• ddd: (inS) establishes the value to be shown on the upper display.

All other display and adjustment modes are the same.

• ddd = Set displays the Setpoint value

• ddd = Pb1 displays the values read by Pb1 (default)

• ddd = Pb2 displays the values read by Pb2

• ddd = Pb3 displays the values read by Pb3

9MA10258.01 07/2018

39

Page 40

6.2. FUNCTIONS

6.2.1. UPLOAD, DOWNLOAD, FORMAT

Description

The Unicard/CopyCard must be connected to the (TTL serial port and allows the rapid programming of instrument

parameters.

DOWNLOAD from reset operating mode: at power-on, if the Unicard/CopyCard is inserted in the device, the controller

automatically downloads data.

After connecting the Unicard/CopyCard with the instrument switched off and on completion of the lamp test, one of the

following labels will be displayed:

• dLY if the operation was successful

• dLn if the operation was not successful

After about 5 seconds, the display will show the probe or set point value, depending on the default settings.

NOTE: once the download has been completed successfully, the controller will start to work with the new map loaded.

Operating mode: access “Installer” parameters by entering the password “PA2” if enabled (PA2≠0), scroll through the folders

using UP & DOWN until the folder “FPr” appears. Select it using SET, scroll through the parameters using UP & DOWN and