Page 1

INTRODUCTION

This section is designed to get you up and running in the shortest possible

time. It contains basic information on the EWRC300 – 500LX.

Should you need more detailed information, please refer to the remainder

of the manual.

Out of the box, the EWRC300 – 500LX is set up for standard Electrical

Defrost applications.

It can be altered for Hot Gas or Off Cycle applications if needed.

INPUTS / OUTPUTS DEFAULT SETTINGS

Output relays (default settings)

• Out (relay) 1 = Compressor (or liquid line valve)

• Out (relay) 2 = Defrost

• Out (relay) 3 = Evaporator fan

• Out (relay) 4 = Alarm (EWRC500LX only)

• Out (relay) 5 = Light (EWRC500LX only)

Note: It is possible to change the function of each relay, see parameters

H21 to H25

Probe Inputs

• Pb1 = Regulation Probe

• Pb2 = Defrost Termination Probe

• Pb3 = Not required (except in special applications)

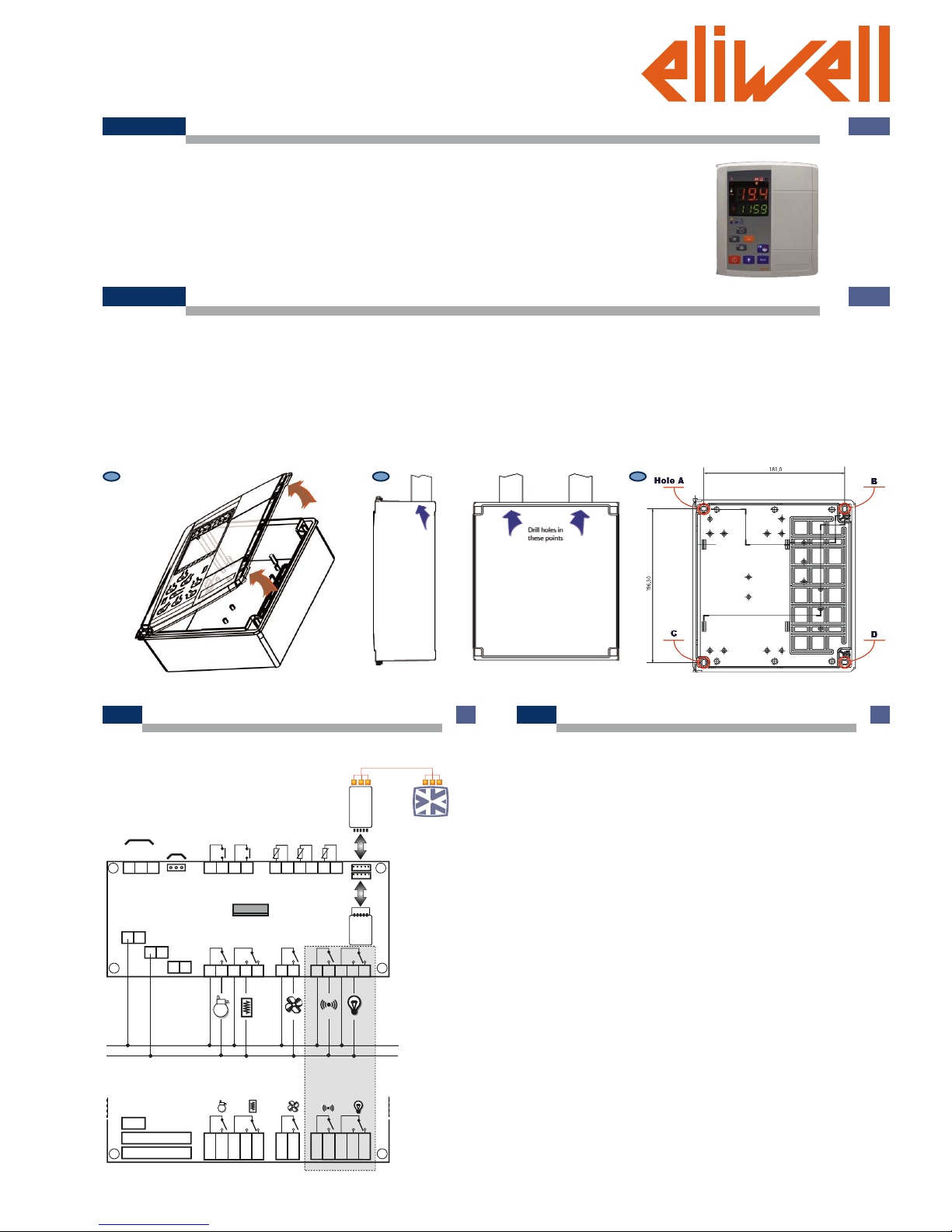

MECHANICAL ASSEMBLY

a) Remove the coverplate on the right side of the door, pressing lightly on

the points indicated by the arrows in Figure 1 and open the door.

b) Drill holes in the backplate at the top or bottom to pass the wires through.

See the example in figure 2.

c) Screw the backplate to the wall using 4 screws (not supplied) to match the

holes illustrated in Figure 3.

d) Shut the door by securing it with the 2 screws provided.

Replace the screw caps removed earlier from the door (see point a).

e) The door lock (an optional accessory) can be installed in 3 different

positions on the door, the holes to be drilled are indicated on the back.

Each position on the door represents a different position where the

disconnector can be mounted.

N.B.: to make it easier to wall mount the backplate, remove the door by pressing lightly on the left side (the side that the door is attached by). You will

also have to separate the base from the keypad by disconnecting the keypad

cable.

11

11

22

22

33

33

EWRC 300-500 LX

CCCCoooolllldddd FFFFaaaacccceeee FFFFaaaammmmiiiillllyy

yy • Quick Start

WIRING DIAGRAM

GND

485+

485-

RS-485

RS-485/TTL

Keyboard

Line

Neutral

Ground

EWRC 300-500 LX

19 20 21 22 23 24

Pb2

Pb1

Pb3

11 12 13 14

DI2

DI1

1 2 3

Line

Neutral

Ground

230V

230V

Removable

Connectors

Faston

LINE

NEUTRAL

Copy

Card

Bus

Adapter

RS 485

TTL

TTL

EWRC500LX only

Page 2

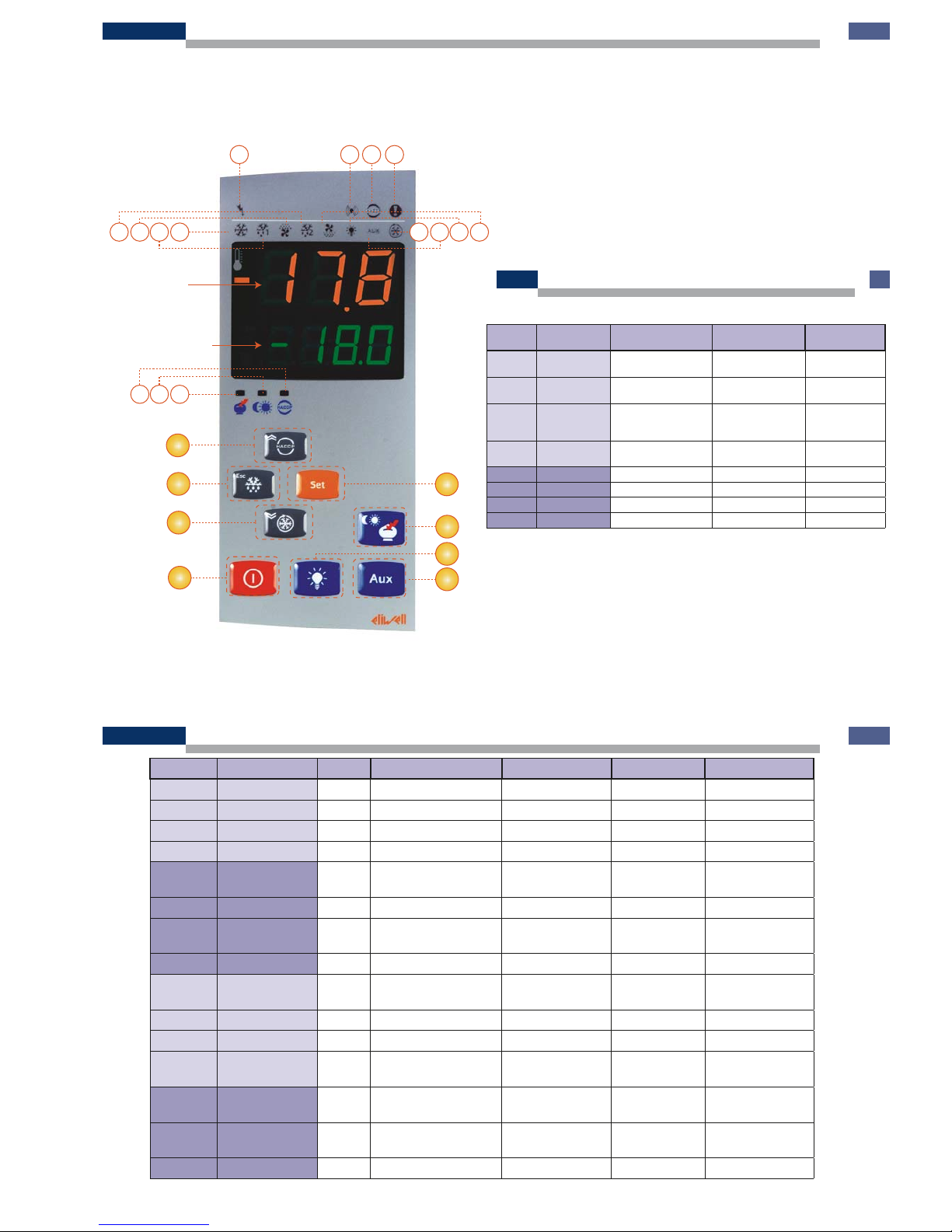

DISPLAY

Top Display 3 figures with + /- sign shows:

• Process Value

• parameters’ labels,

• alarms, functions

Bottom Display 4 figures shows:

• parameters’ value,

• function state / other

A

B

C

D

F

E

H

G

43

21

5678

131415

11 10 9

TOP DISPLAY

12

BOTTOM DISPLAY

Nr. LED color ON BLINK OFF Note

1 POWER red Power ON / Power OFF

2 ALARM red Alarm Silenced No Alarm

3 HACCP red HACCP Alarm Not Viewed No Alarm HACCP models

3 PANIC red Panic Alarm / No Alarm

5 COMPRESSOR yellow Compressor ON delay

Compressor

OFF

6 DEFROST 1 yellow defrost drip No defrost

7

EVAPORATOR

FANS

yellow Fans ON forced ventilation Fans OFF

8 DEFROST 2 yellow defrost drip No defrost

9

CONDENSER

FANS

yellow Fans ON / Fans OFF

10 LIGHT yellow Light ON / Light OFF

11 AUX yellow AUX ON / AUX OFF

12 DCC green

Deep Cooling Cycle

ON

/

Deep Cooling

Cycle OFF

13 ENERGY SAVING yellow Energy Saving ON /

Energy Saving

OFF

14

NIGHT AND

DAY

yellow Night and Day ON /

Night and Day

OFF

RTC models

15 HACCP yellow HACCP Menu / Other Menu HACCP models

Nr. KEY press and release

press approx

3 sec

Note

AUP

Scroll

Increase Values

HACCP menu H31

B ESC

Exit

Function Menu

manual defrost H32

C SET

Change SetPoint

Set Date / time

Enable Functions

Confi guration Menu

D DOWN

Scroll

Decrease Values

/ H33

E ENERGY SAVING Enable Energy Saving Night and Day Menu H37

F POWER Switch On / Off device drip H34

G LIGHT Switch On / Off Light forced ventilation H35

H AUX Aux / H36

LEDS

KEYS

Page 3

PARAMETERS

These are the most commonly used parameters. Their factory default values will suit normal electrical defrost applications. You can alter them to better

suit your particular application if you need to.

FOLDER LABEL DESCRIPTION RANGE DEFAULT M.U. Note

SEt Regulation SetPoint 0 °C/°F CutOut

CPr diF Differential 0 ... 30.0 2.0 °C/°F Related to SetPoint

CPr HSE Higher Set point adjustment limit LSE ... HdL 50.0 °C/°F

Minimum User can adjust

SetPoint

CPr LSE Lower Set point adjustment limit LdL ... HSE -50.0 °C/°F

Maximum User can adjust

SetPoint

CPr dOF Compressor Antishort cycle 0 ... 255 0 min Minutes

dEF dtY Defrost Mode 0 ... 2 0 num Electrical Defrost (1=HotGas)

dEF dit Interval between defrost 0 ... 255 6 h/min/sec Hours

dEF dCt defrost interval Counting mode 0 ... 3

3= RTC

models / 1

num

Time elapses since start of

last defrost

dEF dEt Maximum duration of Defrost 1 ... 255 30 h/min/sec Minutes

dEF dSt Defrost termination temperature -302.0 ... 1472.0 6.0 °C/°F

dEF dPO Execute a Defrost at Power On n/y n fl ag

FAn FSt Evaporator Fan Stop temperature -302.0 ... 1472.0 6.0 °C/°F

FAn Fdt Fan delay after defrost 0 ... 255 0 min Minutes

FAn dt Drip time 0 ... 255 0 min Minutes

FAn dFd Fan Stop during defrost n/y y fl ag

ALr HAL Maximum alarm threshold LAL ... 1472.0 50.0 °C/°F

ALr LAL Minimum alarm threshold -302.0 ... HAL -50.0 °C/°F

ALr dAO defrost Alarm Override 0 ... 999 60 min

Alarm delay after

defrost

ALr tAO Temperature Alarm Override 0 ... 255 0 min Temperature alarm delay

diS LOC Lock keyboard n/y n fl ag

diS PA1 Password 1 (USr) 0 ... 999 0 num

diS ndt number display type n/y y fl ag

diS CA1 Offset Probe 1 -30.0 ... 30.0 0.0 °C/°F Regulation Probe

diS CA2 Offset Probe 2 -30.0 ... 30.0 0.0 °C/°F Defrost termination Probe

diS ddL Lock display during defrost 0 ... 2 2 num Display shows “DEF”

CnF H00 Probe Type 0/1 1 fl ag

0=PTC; 1=NTC

depending on model

CnF H42 Defrost termination Probe presence n/y y fl ag Always present

HOW TO CHANGE THE SET POINT

• Press and release the SET button.

• The Top Display shows SET, the bottom display shows the value

• Use the UP & DOWN buttons to adjust the Set Point’s value

• Press ESC for display to return to normal

HOW TO ENTER THE USER LEVEL (USR) AND ALTER PARAMETER VALUES

• Press & Hold the SET button for 3 seconds until the display changes to

show USr

• Press & release SET to enter USr (User Level).

• The first parameter is displayed. Top display shows the parameter label,

Bottom display shows parameter value.

• Using the UP & DOWN buttons, go to the desired parameter

• Press & release SET, then using the UP & DOWN buttons, adjust the para-

meter’s value.

• Press ESC several times to return to normal display

ALL OTHER PARAMETERS ARE CONTAINED IN INSTALLER LEVEL (InS)

Entering Installer Level (InS):

You should only need to do this for more advanced applications. Here the

parameters are arranged in folders (Compressor / Defrost / Fans etc)

• Press & Hold the SET button for 3 seconds until the display changes to

show Usr

• Use the UP or DOWN button to display InS

• Press & release SET to enter InS (InStaller Level).

• The first parameter folder is displayed

• Keep pressing SET until you see the folder you want

• Press the UP or DOWN button, the first parameter is displayed. Top

display shows the parameter label, Bottom display shows parameter value.

• Using the UP & DOWN buttons, go to the desired parameter

• Press & release SET, then using the UP & DOWN buttons, adjust the parameter’s value.

• ress ESC several times to return to normal display

FOR MORE DETALED INFORMATION READ ON Technical Sheet p/n

9IS44058

cod. 9IS44112-1 - GB - rel. 07/08 © Eliwell Controls s.r.l. 2008 All rights reserved.

Eliwell Controls s.r.l.

Via dell’Industria, 15 • Zona Industriale Paludi • 32010 Pieve d’Alpago (BL) ITALY

Telephone +39 0437 986 111 • Facsimile +39 0437 989 066

Sales +39 0437 986 100 (Italy) • +39 0437 986 200 (other countries) • E-mail saleseliwell@invensyscontrols.com

Technical helpline +39 0437 986 300 • E-mail techsuppeliwell@invensyscontrols.com

www.eliwell.it

Loading...

Loading...