Page 1

QUICK START

EWRC 300/500/5000 NT

Controllers for static and ventilated cold rooms

English

Page 2

EWRC 300/500/5000 NT 2 - EN

English

NB

The electrical panel (equipment) must be installed and repaired only by qualified staff. Eliwell accepts no

responsibility for any consequences resulting from the use of this material.

A qualified person is someone who has specific skills and knowledge regarding the structure and the

operation of electrical equipment and who has received safety training on how to avoid the inherent

dangers.

Product related information

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Turn off all devices, including connected devices, before removing any covers or doors, or

installing/uninstalling accessories, hardware, cables, or wires.

• Always use a properly rated voltage sensing device to conrm the power is off where and when

indicated.

• Replace and secure all covers, accessories, hardware, cables, and wires and conrm that a

proper ground connection exists before applying power to the unit.

• Use only the specied voltage when operating this equipment and any associated products.

• Comply with all the standards regarding accident protection and the local applicable safety

directives.

Failure to follow these instructions will result in death or serious injury.

DANGER

POTENTIAL FOR EXPLOSION

• Install this device only in areas known to be free from dangerous surroundings.

• Install and use this equipment in non-hazardous locations only.

Failure to follow these instructions will result in death or serious injury.

WARNING

UNINTENDED EQUIPMENT OPERATION

• The signal cables (probes, digital inputs, communication, and relative power supplies) must be

laid separately from the power cables.

• Every implementation of this device must be tested individually and completely in order to check

its proper operation before putting it in service.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

Page 3

3 - EN EWRC 300/500/5000 NT

English

INTRODUCTION

The Coldface EWRC 300/500/5000 NT series controls the temperature of a static or ventilated cold

room. The instrument controls positive and negative cold rooms and is capable of managing a double

evaporator and condenser probes.

Coldface has 3 or 5 configurable relays, depending on the model, and 2(3) configurable digital inputs

for door switches or other devices. Models are available with clock with yearly calendar and HACCP

event logging.

It is possible to connect the instrument to TelevisSystem / Modbus via the optional RS485 plug-in

module.

The container lets you install one or more electromechanical devices, depending on the model.

This summary document contains basic information about the standard

EWRC 300/500/5000 NT models. For further information and different configurations, refer to

the complete user manual cod. 9MA*0258 which is available to download free of charge from

www.eliwell.com.

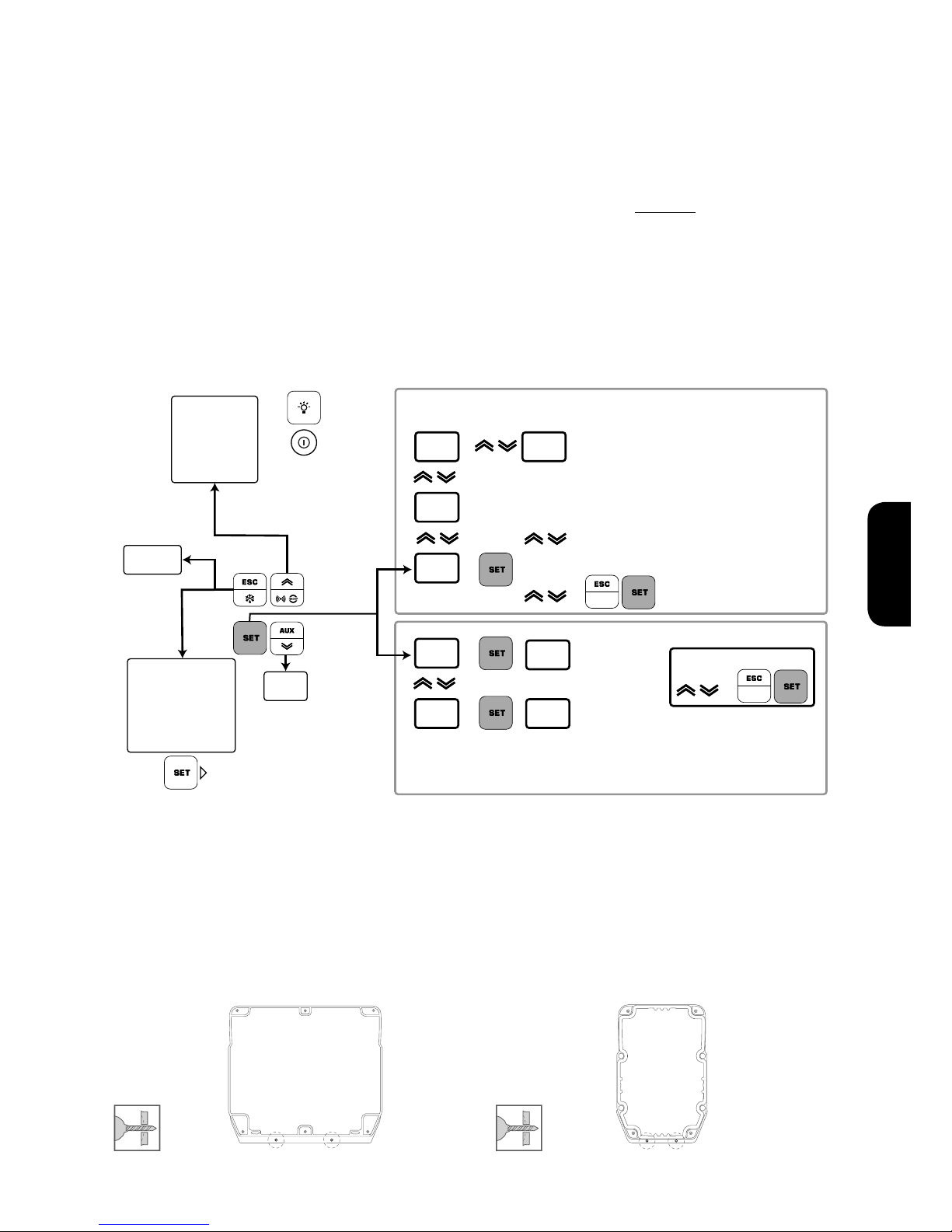

INSTALLATION PROCEDURE

NOTE: procedural steps that are common to all models. Only the EWRC 5000 model is used as an

example.

1) Remove the cover and drill the holes for the cable clamps (at least one for power cables and one

for signalling cables) on the bottom of the panel.

NOTE: for the 300/500 models, use the drilling template provided.

Manual

defrost

Display HACCP alarms

if function active

Display alarms

if active

Functions Menu

Info

System

LOC keypad lock

rEd disable HACCP

rPA Pressure switch

rSE active Set reduced

rHC reset HACCP alarms

SET

-18.9

rtc

18.55

Pb1

-20.6

set time

and date

display probe

value

display probe

value

modify SetPoint

value

conrm with

1 sec

1 sec

1 sec

3 sec

3 sec

function ON / OFF

Pb2

-20.6

inS

USr

see manual

diF

2.0

CPr

- - -

modify value

conrm with

Turns light

on/o

Turns instrument

on/o

Parameters

SetPoint & Probes

NAVIGATION DIAGRAM

Page 4

EWRC 300/500/5000 NT 4 - EN

English

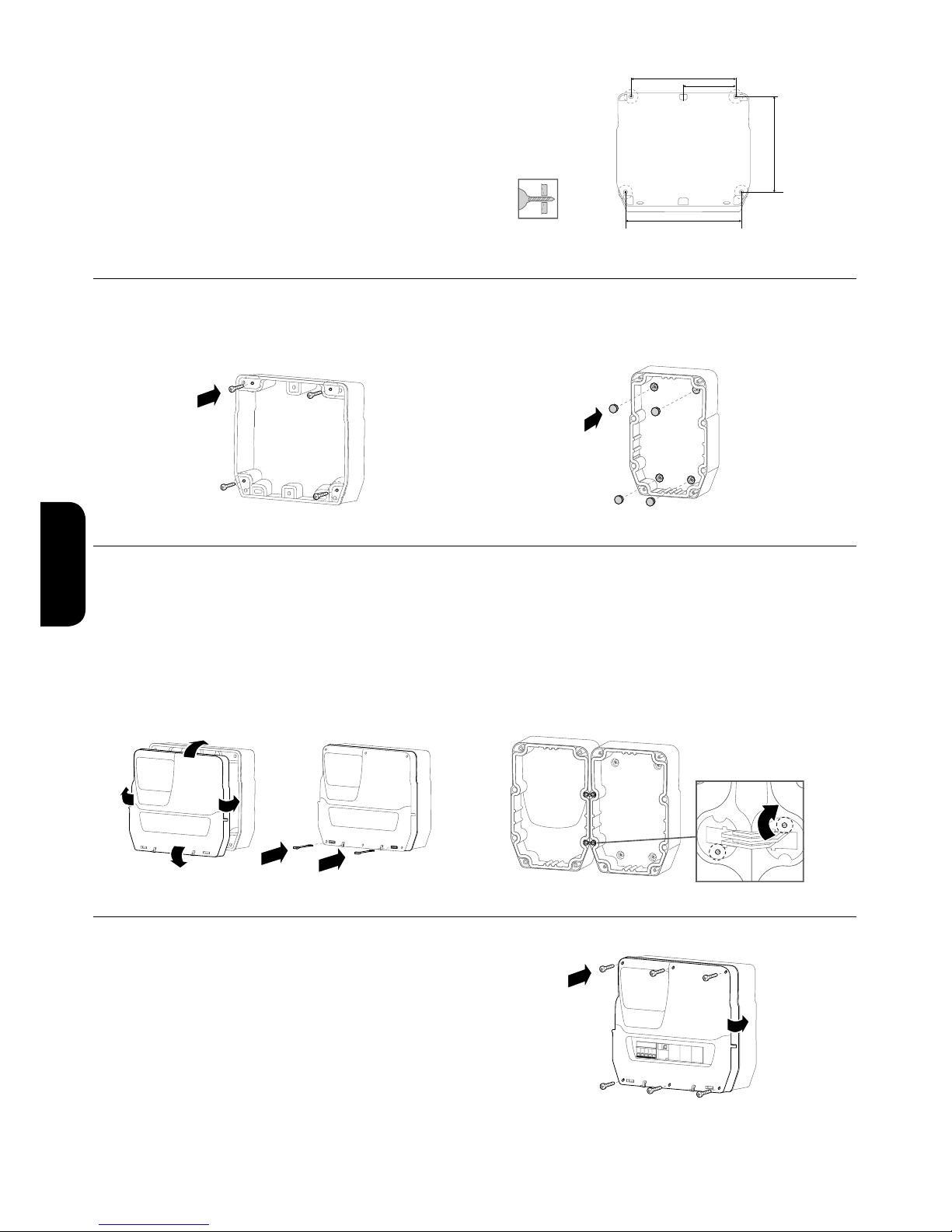

2) Drill the wall fixing holes on the back of the

panel, in the areas marked on the back.

321,5 / 12,66

mm / in

343 / 13,5

171,5/ 6,75

360 / 14,17

3) Fix the back of the panel to the wall using four screws (not supplied) suited to the wall thickness.

NOTE: apply TDI20 screw caps (not provided) on 300/500 models.

4) Fit the hinges to secure the cover.

EWRC 5000

Place the panel cover up against the wall, making it

stick to the perimeter seal. Then, while holding the

cover in place, fit the two hinges provided into the

corresponding holes and press them until you hear

them click into place.

EWRC 300/500

Fit the hinges provided into their housings on

the right or left side of the panel and tighten the

corresponding screws to secure them.

5) Close the cover and secure it with the screws

provided.

Page 5

5 - EN EWRC 300/500/5000 NT

English

ELECTRICAL CONNECTIONS

Output relay (default settings)

• OUT1 relay 1 = Compressor

(or liquid line valve)

• OUT2 relay 2 = Defrost

• OUT3 relay 3 = Evaporator fan

• OUT4 relay 4 = Light (EWRC 500/5000 only)

OUT1-4 common-line max 18 A

• OUT5 relay 5 = Alarm/AUX (EWRC 500/5000 only)

Probe inputs (default settings)

• Pb1 = Cold room NTC probe

• Pb2 = Defrost end NTC probe

• Pb3 = Not configured

Use parameter H00 to switch between NTC/PTC probe

types. SWITCH THE INSTRUMENT OFF AND ON

AGAIN after the change.

Digital Inputs (default settings)

• DI1 = Door switch

• DI2 = 300/500 model: not configured;

5000 mode: external alarm

• DI3 = not configured

Serial ports

• TTL for connecting to UNICARD / Copy Card

• TTL for connecting to TelevisSystem

• RS485 available ONLY with the optional plug-in

module for connecting to TelevisSystem / Modbus.

• Probe and digital inputs, OUT5 relay: 5.01 pitch screw terminals: electrical cables with a maximum section

of 2.5 mm

2

.

• Power supply and relay OUT1..OUT4: 7.62 pitch screw terminals: electrical cables with a maximum section

of 4 mm2.

5.08 mm (0.197 in.) pitch

7.62 mm (0.30 in.) pitch

DANGER

RISK OF ELECTRIC SHOCK, EXPLOSION OR EXPOSURE TO ACCESSIBLE PARTS

The final application must disallow access to parts at hazardous voltage, as the instrument offers no intrinsic

protection against this risk.

Failure to follow these instructions will resultin death or serious injury.

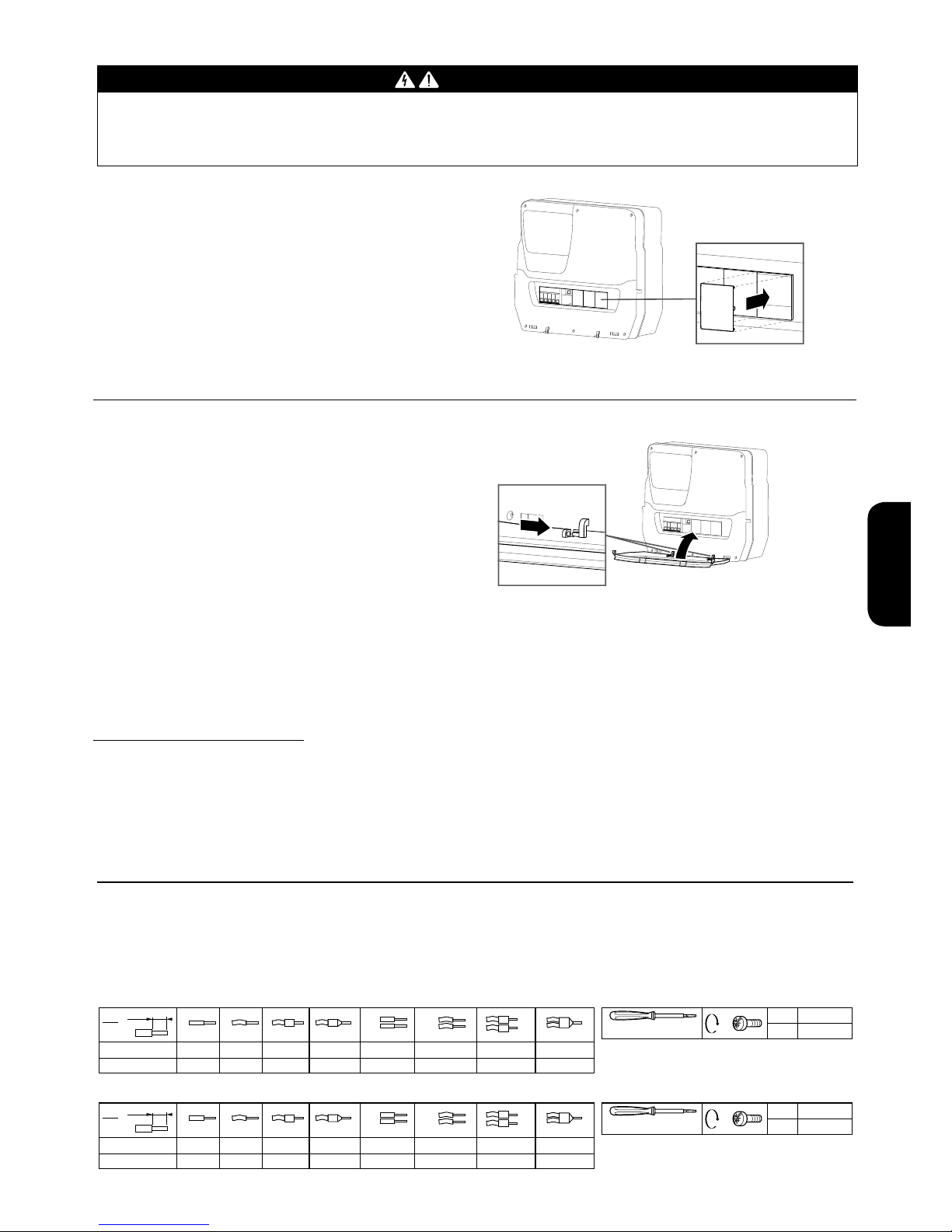

6) DIN rail-mounted models with window only.

Use the dedicated plugs (code 1602149)

to prevent access to the inside of the panel

through the front window.

For EWRC NT 500 models with the plastic

knockout removed and no internal circuit

breaker, the end user is responsible for

ensuring that the open parts of the box are

not accessible.

7) EWRC 5000 only. Fit the door: align the front

door with the two hooks at the bottom of the

panel and push it towards the right until it

clicks into place.

8) Close the door.

1

2

Ø 3,5 mm (0.14 in.)

mm

2

AWG

0.2…2.5

24…14

0.2…2.5

24…14

0.25…2.5

22...14

2 x 0.25…0.75

2 x 22…18

2 x 0.2…0.75

2 x 24…18

2 x 0.2…0.75

2 x 24…18

2 x 0.5...1.5

2 x 20...16

mm

in.

7

0.28

C

0.5...0.6

4.42...5.31

N•m

lb-in

0.25…2.5

22...14

Ø 3,5 mm (0.14 in.)

mm

2

AWG

0.2…4

24…11

0.2…2.5

24…14

0.25…2.5

22...14

2 x 0.25…0.75

2 x 22…18

2 x 0.2…1.5

2 x 24…16

2 x 0.2…1.5

2 x 24…16

2 x 0.5...1.5

2 x 20...16

mm

in.

7

0.28

C

0.5...0.6

4.42...5.31

N•m

lb-in

0.25…2.5

22...14

Page 6

EWRC 300/500/5000 NT 6 - EN

English

18 19 20 2117

EWRC 300/500/5000 NT

GND GND GND+ +

1615141312111091 2 3 4 5 6 7 8

PB1 PB2

DI2 DI1

UNICARD

COM

NONC

N

L

EWRC 500NT/

5000 NT

only

OUT1 OUT2 OUT3 OUT4 OUT5

H21

230 Vac

H22 H23 H24 H25

COPY CARD

Yellow cable

DISPLAY

RS485

OPTIONAL

ELIWELL

ELIWELL

18 A max

+

+

PB3/DI3

MODELS WITH DOOR AND INTERNAL CIRCUIT BREAKER

EWRC 500 NT BREAKER | EWRC 500 NT 4-DIN

Versions with a door on the front panel allow direct

access to the switch or to the upper part of the device

installed on the internal DIN rail.

To open the door, use both hands as shown in the

figure. Use your thumbs to apply gentle pressure at the

top to release the side tabs. Simultaneously with the

index finger gently pull the door toward you.

In versions provided with the miniature circuit breaker,

the installer must connect it to the power supply of the

electronic board through the wiring harness included

in the packaging.

The figure below shows the wiring diagram.

Versions with a door always have the omega DIN rail

installed.

You can mount up to a maximum of 4 DIN modules,

including 2DIN miniature circuit breaker when present.

It is easy to enlarge the window on the DIN housing

from 2 to 4 DIN, using the knockouts as shown in the

figure at the top right.

Cable types and wire sections for the circuit breaker

Ø 3,5 mm (0.14 in.)

mm

2

AWG

1…35

18…2

1…25

18…2

mm

in.

14

0.55

C

3.5

31

N•m

lb-in

Page 7

7 - EN EWRC 300/500/5000 NT

English

18 19 20 2117

EWRC 500 NT BREAKER

GND GND GND+ + +

1615141312111091 2 3 4 5 6 7 8

PB1

PB2 DI2 DI1

COM

NONC

OUT1 OUT2 OUT3 OUT4 OUT5

H21

H22 H23 H24 H25

N

L

230 Vac

16 A max

+

PB3/DI3

DANGER

RISK OF ELECTRIC SHOCK, EXPLOSION OR EXPOSURE TO ACCESSIBLE PARTS

Prevent access to parts at hazardous voltages, as the instrument offers no protection against this risk.

Failure to follow these instructions will resultin death or serious injury.

For EWRC NT 500 models with plastic knockout removed and no thermal-magnetic breaker installed: the end user

is responsible for ensuring that open parts of the box cannot be accessed.

DISPLAY

3-FIGURE UPPER DISPLAY

plus the - sign

Display:

• Operating value

• parameters label

• alarms, functions

if Upper display

blinking

it means that the value of the

Lower Display can be modified

4-FIGURE LOWER DISPLAY

Display:

• parameters value

• probe value

• function state

HACCP models

• time

B

A

C

F

E

D

%RH

Page 8

EWRC 300/500/5000 NT 8 - EN

English

1

%RH

2 3 4 5 6 7 8

17

18

19

9

10

11

12

13

14

15

16

No. LED COLOUR ON

FLASHING

OFF

1 POWER SUPPLY green Power supply ON / Power supply OFF

2 ENERGY SAVING amber Energy saving ON / Energy saving OFF

3 NIGHT & DAY amber Night & Day ON / Night & Day OFF

4 HACCP amber HACCP menu / /

5 DEEP COOLING (DCC) amber Drip cooling cycle ON /

Drip cooling cycle OFF

6 PUMP DOWN amber Compressor Pump Down ON / Compressor Pump Down OFF

9 COMPRESSOR amber Compressor ON delay Compressor OFF

10 DEFROST 1 amber defrost coil drainage

No defrost

11 EVAPORATOR FANS amber Fans ON forced ventilation Fans OFF

12 DEFROST 2 amber defrost coil drainage

No defrost

13 HACCP ALARM red HACCP alarm Not displayed No alarm

14 AUXILIARY (AUX) amber AUX ON / AUX OFF

15 LIGHT amber Light ON / Light OFF

16 CONDENSER FANS amber Fans ON / Fans OFF

ON: function/alarm ON; OFF: function/alarm OFF

LED

ALARMS

No. LED colour description

17 RH amber not used

18 TIME amber access in case of time display or editing

19 DATA amber access in case of date display or editing

Alarms LED 7 LED 8

Colour

Buzzer

Off

LED Buzzer

ALARM Red See “ALARMS TABLE” page 13

PANIC

Red --- ---

LEAK DETECTOR

Red

...

---

PANIC +

LEAK DETECTOR

Red ---

(1)

(1) = As long as the Panic alarm persists it will not be possible to mute the buzzer from the keypad.

KEYS

No. KEY press and release

press and hold for about

3seconds

NAVIGATION MENU Notes

A

ESC

Defrost

• Functions Menu

• Manual defrost

• Return to Main Menu

• Output

B

p UP

Alarms

• Alarms Menu (always visible) /

• Scroll

• Increase values

HACCP alarms

only on foreseen models

and if present

C SET

• Display SetPoint / probe values /

time (Models with clock)

• Conrm values

• Access value edit mode

(upper display blinking)

Access Parameters menu

• Conrm values

• Move right

display time

Models with clock only

D

q DOWN

AUX

system INFO

See Technical Support

Activate auxiliary function

• Scroll

• Decrease values

E ON/OFF / Switch On/O device /

F LIGHT / Switch light On/O /

Page 9

9 - EN EWRC 300/500/5000 NT

English

USER INTERFACE

How to modify the SetPoint

• Press and release the SET key. The upper display will show SEt, the lower display will indicate the

current SetPoint value

• Press and release the SET key once more. The upper display will show SEt blinking

• Use the UP & DOWN keys to adjust the Setpoint value

• Press the ESC key several times (or keep it pressed) to return to the normal display

How to read the probe value

• Press and release the SET key. The upper display will show SEt, the lower display will indicate the

current SetPoint value

• Press and release the DOWN key. If the RTC clock is present, the time will be shown in the lower display

• Press and release the DOWN key once more. The upper display will show Pb1, the lower display will

indicate the value read by the room probe

• Press and release the DOWN key once more to read the value of probe Pb2 and Pb3 if configured

• Press the ESC key to return to the normal display.

How to modify the User Parameters

The ‘User’ parameters are the most useful ones. This document describes them in the Parameter

Table section.

1) Press and hold the SET key for 3 seconds until the display shows USr

2) Press and release the SET key again. The upper display will show the first parameter, the lower display

will indicate the current parameter value

3) Using the UP & DOWN keys, find the parameter that you wish to modify

4) Press and release the SET key again. The upper display will show the name of the blinking parameter

5) Use the UP & DOWN keys to adjust the parameter value.

6) Press and release SET to save the parameter value

7) Return to step 3) or press ESC several times to return to the normal display

USER PARAMETERS TABLE

This section describes the most commonly used parameters, which are always visible (the access password PA1 is not enabled by default).

For a description of all other parameters, see the user manual.

NOTE: the user parameters are NOT divided into sub-folders and are always visible. The same parameters are also visible in the respective fold-

ers ‘Compressor’, ‘Fans’, etc. (indicated also here to make the groupings clearer) in the password-protected Installer parameters menu.

PAR. DESCRIPTION M.U. RANGE DEFAULT

SEt Temperature control SEtpoint °C/°F -58.0...302 0.0

COMPRESSOR (CPr)

diF

Activation differential

N.B.: diF cannot be equal to 0.

°C/°F 0 ... 30.0 2.0

HSE

Maximum value that can be assigned to the setpoint.

NOTE: The two setpoints are interdependent: HSE cannot be less than LSE and vice-versa.

°C/°F LSE ... HdL 50.0

LSE

Minimum value that can be assigned to the setpoint.

NOTE: The two setpoints are interdependent: LSE cannot be greater than HSE and vice

versa.

°C/°F LdL ... HSE -50.0

OSP

Temperature value to be added algebraically to the Setpoint if reduced set enabled (Economy function).

Enabling can take place via key, function or digital input configured specifically for this purpose.

°C/°F

-30.0 ...

30.0

0.0

Cit

Minimum activation time of compressor before possible deactivation.

If Cit = 0 not active.

min 0 ... 255 0

CAt

Maximum activation time of compressor before possible deactivation.

If CAt = 0 not active.

min 0 ... 255 0

Ont

Controller switch-on time in the event of faulty probe.

- if Ont = 1 and OFt = 0, the compressor stays on permanently (ON),

- if Ont > 0 and OFt > 0, it operates in Duty Cycle mode.

min 0 ... 255 10

OFt

Controller switch-off time in the event of faulty probe.

- if OFt = 1 and Ont = 0, the compressor stays off permanently (OFF),

- if Ont > 0 and OFt > 0, it operates in Duty Cycle mode

min 0 ... 255 10

Page 10

EWRC 300/500/5000 NT 10 - EN

English

PAR. DESCRIPTION M.U. RANGE DEFAULT

dOn

Delayed start. The parameter indicates that a protection is active on the general compressor relay

actuations. At least the indicated time must elapse between the request and the actual activation of the

compressor relay.

sec 0 ... 255 2

dOF

Delay time after power-off: the delay time indicated must elapse between deactivation of the compressor

relay and the next power-on.

min 0 ... 255 0

dbi

Delay between switch-ons; the delay time indicated must elapse between two consecutive compressor

power-ons.

min 0 ... 255 2

OdO

Delay in activating outputs after the instrument is switched on or after a power failure.

0 = Not active

min 0 ... 255 0

dS2 DEFROST (dEF)

dtY

Defrost mode

0 = Electric defrost (OFF Cycle defrost), i.e. compressor not running during defrost);

NOTE: electrical defrost + air defrost, when the fans are connected in parallel to the defrost output relay

1 = cycle inversion defrost (hot gas, or compressor on during defrost);

2 = “Free” mode defrost (independent from the compressor)

num 0 ... 2 0

dit

Interval between defrost cycles

Interval between the start of two consecutive defrost cycles.

0 = Function disabled (defrost NEVER performed).

hours/mins/

secs

0 ... 255 6 hours

dCt

Defrost interval count mode

0 = Compressor running time (DIGIFROST® method);

defrost active ONLY when the compressor is on.

N.B.: compressor running time is counted separately from the evaporator probe (count active also when

evaporator probe missing or faulty).

1 = Appliance running time; defrost counting is always active when the machine is on and starts at each

power-on;

2 = Compressor stopped. Every time the compressor stops, a defrost cycle is performed according to

parameterdtY;

3 = With RTC. Defrost at specific times set by parameters dE1...dE8, F1...F8

num 0 ... 3 1

dOH

Defrost cycle enabling delay from request

Delay preceding start of first defrost after call.

min 0 ... 59 0

dEt

Defrost timeout

Determines the maximum defrost time on Evaporator 1.

hours/mins/

secs

1 ... 255 30 min

dSt

Defrost end temperature

Defrost 1 end temperature (determined by evaporator probe 1).

°C/°F

-302.0 ...

1472.0

6.0

dPO

Defrost enabling request from power-on

Determines whether or not the instrument must defrost at power-up

(provided that the temperature measured at the evaporator will allow defrost).

n (0) = No, no defrost at power-on; y (1) = Yes, defrost at power-on.

flag n/y n

FANS (FAn)

FSt

Fans lockout temperature; if the value read is greater than FSt, the fans will be stopped. The value may

be positive or negative.

°C/°F -58.0...302 0.0

FAd Fans activation differential °C/°F 0.1 ... 25.0 0.1

Fdt Fans activation delay after a defrost cycle min 0 ... 250 0

dt dripping time. Dripping time. min 0 ... 250 0

dFd

Operating mode of evaporator fans during defrost.

n (0) = no (depending on the FCO parameter); y (1) = yes (fan off).

flag n/y y

FCO Evaporator fans operating mode. The status of the fans will be:

With the compressor ON, the fans are thermostat-controlled. With the compressor OFF, it depends on FCO

FCO=0, fans OFF

FCO=1-2, fans thermoregulated

FCO=3-4, fans in duty cycle

Dutycycle: controlled by way of parameters “FOn” and “FOF”.

num 0 ... 4 1

ALARMS (ALr)

AFd Alarms cut-in differential. °C/°F 0.1 ... 25.0 1.0

HAL

Probe 1 maximum alarm. Temperature value (intended either as distance from setpoint or as an absolute

value based on Att) above which the probe will trigger activation of the alarm signal.

°C/°F LA1...302 5.0

LAL

Probe 1 minimum alarm. Temperature value (intended as distance from setpoint or as an absolute value

based on Att) beneath which the probe will trigger activation of the alarm signal.

°C/°F -58.0...HA1 -5.0

PAO

Alarm exclusion time after device is switched on following a power failure.

This parameter refers to high/low temperature alarms LAL and HAL only.

hours 0 ... 10 3

Page 11

11 - EN EWRC 300/500/5000 NT

English

PAR. DESCRIPTION M.U. RANGE DEFAULT

dAO Temperature alarm exclusion time after defrost. min 0 ... 250 60

tAO

Delay preceding temperature alarm signal.

This parameter refers to high/low temperature alarms LAL and HAL only.

min 0 ... 250 0

DISPLAY parameters (diS)

LOC

LOCk. Setpoint edit lock. The parameter programming menu can still be accessed, and the settings

changed, which means also that the status of this parameter can be changed so as to unlock the keypad.

n (0) = No; y (1) = Yes.

flag n/y n

PA1 PAssword 1. When enabled (PA1 ≠ 0) this password provides access to level1 parameters (User). num 0 ... 250 0

ndt

Display values with decimal point.

n (0) = No (integers only); y (1) = Yes (displayed with decimal point).

flag n/y y

CA1

Calibration of probe Pb1.

Positive or negative temperature value added to the value read by Pb1. This sum is used for both

temperature display and temperature regulation purposes.

°C/°F -30.0...30.0 0.0

CA2

Calibration of probe Pb2.

Positive or negative temperature value added to the value read by Pb2. This sum is used for both

temperature display and temperature regulation purposes.

°C/°F -30.0...30.0 0.0

ddL

Display mode during defrost.

0 = Displays the temperature read by the probe.

1 = Locks the reading at the temperature value registering via the probe when the defrost cycle starts

and until the next time the SEt is reached.

2 = Displays the label dEF during defrosting and until the SEt is reached (or until Ldd has elapsed)

num 0/1/2 1

CONFIGURATION (CnF)

If one or more parameters in the folder are changed, the controller MUST be switched off and switched on again.

H00

Selection of type of probe used (Pb1 ... Pb3).

(0) = PTC

(1) = NTC

num

0/1

(PTC/NTC)

1 (NTC)

H23*

Configuration of digital output 3 (OUT 3).

num 0 ... 13 3

0 = disabled

1 = compressor

2 = defrost 1

3 = evaporator fans

4 = alarm

5 = AUX

6 = stand-by

7 = light

8 = buzzer output

9 = defrost 2

10 = compressor 2

11 = frame heater

12 = condenser fans

13 = compressor pump down

H42

Evaporator probe (Pb2) present

n (0) = not present

y (1) = present

num n/y y

rEL Firmware version release (e.g. 1,2,...). Read only. See Technical Support. / / /

tAb Map code. Read only. See Technical Support. / / /

COPY CARD parameters (FPr).

UL Upload. Transfers programming parameters from the instrument to a Copy Card / UNICARD. / / /

dL Download. Transfers programming parameters from a Copy Card / UNICARD to the instrument. / / /

Fr

Formatting. Deletes data on the Copy Card / UNICARD.

NOTE: If parameter “Fr” is used, the data entered will be permanently lost. This operation

cannot be reversed.

/ / /

* H23 Installer (inS) level for the EWRC5000 model

IT IS POSSIBLE TO EDIT OTHER PARAMETERS AVAILABLE IN THE INSTALLER (inS) LEVEL OF THE INSTRUMENT

How to edit the installer level parameters

Procedure applies only to more advanced applications. In this case the parameters are arranged in

folders (Compressor / Defrost / Fans etc)

1) Press and hold the SET key for 3 seconds until the display shows USr

2) Use the UP & DOWN keys to select the inS parameter section

3) Press and release the SET key again. The display will show the first folder

4) Press and release the SET key again. The upper display will show the first parameter in the folder, the

lower display will indicate the current parameter value

5) Use the UP & DOWN keys to find the parameter that you want to modify

The procedure proceeds in a similar manner to that described for the User parameters (points 4-7)

Page 12

EWRC 300/500/5000 NT 12 - EN

English

OPERATION IN DEFAULT CONFIGURATION

The instrument is configured for negative cold. For positive cold, disable the evaporator probe Pb2

(setH42=n) and set relay OUT3 (parameter H23=6) to prevent continuous ventilation.

COMPRESSOR

The compressor is active if the cold room temperature measured by Pb1 exceeds the value of SEt +

differential diF. The compressor stops if the cold room temperature detected by Pb1 falls below the SEt

value. The instrument includes compressor on/off protection*

DEFROST

Defrost is by means of electric heaters (parameter dty = 0) and the time counter is always active with the

instrument switched on (dCt=1).

Manual defrost

Manual defrost is activated by pressing and holding the ESC key (A).

If conditions are not right for defrosting, (e.g. the evaporator probe temperature is higher than the

defrosting end temperature) or the parameter OdO≠0, the display will blink three times to indicate that

the operation will not be performed.

Default Defrost settings

dit = 6 hours. interval between 2 defrost cycles

dSt = 6.0°C. Defrosting end temperature. Set by Pb2.

The Defrost cycle may terminate due to a timeout based on the parameter dEt (default 30 min).

EVAPORATOR FANS

The OUT3 relay is configured as the fan relay and is activated when required, according to the delay and

parameter settings*.

Default fan settings

dt = 0 min. dripping time

dFd = Y. Fans off during defrosting.

LIGHT (EWRC 500/5000)

The light is activated by pressing and holding the LIGHT key (F).

Since digital input D.I. 1 is configured as door switch, relay OUT4 (light) is activated when the door is

opened. The light also switches on with the instrument in standby*.

ALARM RELAY (EWRC 500/5000)

Relay OUT5 is configured as alarm relay and is activated in the case of alarms, according to delays and

parameter settings. *FOR MORE INFORMATION READ the manual, code 9MA*0258

SUPERVISION

EWRC 300/500/5000 NT can be connected to:

• TelevisSystem or third-party remote control systems via Modbus protocol

• DeviceManager fast parameter configuration software

The connection is direct RS-485 using the optional RS485/TTL plug-in module (not included). See the

Wiring diagram.

NOTE: if using the TTL port to communicate, disconnect the RS-485 port and vice-versa.

*FOR MORE INFORMATION READ the manual, code 9MA*0258

Page 13

13 - EN EWRC 300/500/5000 NT

English

ALARMS AND TROUBLESHOOTING

How to display the alarms

1) Press and release the UP key. The upper display will always show the label ALr. The lower display will

show:

• nOnE if no alarms active

• SYS to indicate system alarms - see Alarms Table

• HACP to indicate HACCP alarms - see HACCP alarms

2) Using the UP & DOWN keys, find the type of alarm that you want to check

System alarms

The upper display will show the label ALr, the lower display will indicate the alarm code - see Alarms

Table

• Using the UP & DOWN key, scroll the other alarms

• Press the ESC key to return to the previous alarm code, press the ESC key several times (or keep it

pressed) to return to the normal display

HACCP ALARMS • AVAILABLE ONLY FOR HACCP MODELS

The instrument logs high and low temperature alarms for the cold room probe, as well as any power

failures. The alarm types and the duration and start time of the alarm itself will be displayed in the alarms

folder ALr. It is possible to disable the recording of alarms and/or resetting of HACCP alarms. See

Functions Menu.

FOR MORE INFORMATION READ the manual, code 9MA*0258

ALARMS TABLE

This section lists alarms associated with the default conguration of the instrument.

For a description of alarms relating to custom congurations, refer to the user manual or contact Eliwell Technical Support.

Label Cause Eects Problem solving

E1*

Pb1 room probe faulty

• Measured values are outside operating

range

• Probe faulty/short-circuited/open

• Label E1 displayed

• Maximum and minimum alarm regulator

disabled

• Compressor operation based on

parameters “Ont” and “OFt” if set for duty

cycle.

• Check probe type NTC/PTC (see H00)

• Check probe wiring

• Replace probe

E2*

Pb2 defrost probe faulty

• Measured values are outside operating

range

• Probe faulty/short-circuited/open

• Label E2 displayed

• The Defrost cycle will end due to timeout (Parameter “dEt”)

• Check probe type NTC/PTC (see H00)

• Check probe wiring

• Replace probe

LA1

Pb1 LOW temperature alarm

• Value read by Pb1 < LAL after time of

tAO.

• Recording of label LA1 in folder ALr

• No eect on regulation

• Wait for the temperature value read by Pb1

to come back above LAL+AFd

HA1

Pb1 HIGH temperature alarm

• value read by probe Pb1 > HAL after

time of “tAO”.

• Recording of label HA1 in folder ALr

• No eect on regulation

• Wait until temperature value read by Pb1

returns below HAL-AFd.

TECHNICAL SUPPORT

Have the following information available when contacting Eliwell Technical Support:

• IdF firmware version (e.g. 554)

• rEL firmware version release (e.g. 1,2,...)

• tAb map code

• rC instrument model (e.g. 300 or 500)

To obtain this information:

• Press and release the DOWN / INFO key

• Press and release the DOWN key once more to display other information about the instrument.

• Press the ESC key to return to the normal display.

Page 14

EWRC 300/500/5000 NT 14 - EN

English

This section lists alarms associated with the default conguration of the instrument.

For a description of alarms relating to custom congurations, refer to the user manual or contact Eliwell Technical Support.

Label Cause Eects Problem solving

Ad2

End of defrost cycle due to timeout rather than due to defrost end

temperature being read by the defrost

probe

• Recording of label Ad2 in folder ALr • Wait for the next defrost cycle for automatic

return

OPd

• Digital input is activated

(set as door switch)

See para. H11/H12/H13

• Depends on delay set by parameter tdO

• Recording of label OPd in folder ALr

• Regulator locked (see para. dOA/PEA)

• Close door

• Depends on delay set by parameter OAO

E10**

**Models with clock only

Clock alarm: clock faulty or unpowered

for a long time

Functions associated with clock not

controlled

Contact Eliwell Technical Support

ALL ALARMS

• Alarm icon on continuously

• Buzzer (if present) and alarm relay (OUT5) activated, except Ad2

• Press any key to mute the alarm. The LED changes from a steady light to a blinking light.

NOTE: the buzzer is deactivated while the alarm relay remains active

*E1 - E2: If simultaneous they will be shown alternately on the display at a frequency of 2 seconds

TECHNICAL DATA (EN 60730-2-9:2010, EN 61439-1:2011 / 61439-2:2011 / EN 60204-1:2006)

DESCRIPTION

Front panel

IP65

Classification

Electronic automatic control device (not safety device) for stand-alone installation

Installation

wall

EWRC300/500: spacing

holes A-B 116 mm (4.57 in); holes C-D 87 mm (3.42 in); holes A-C 235 mm (9.25 in)

Hinges are available for mounting on special compartments for opening the cover both right

and left.

Screw on the respective anchoring screws taking care that the hinges are fitted well and lie flush

so that they do not interfere with the compression of the seal

wall

EWRC5000: See Mechanical Installation paragraph

Type of action

1.B

Pollution class

2 (IEC 60664-1:2007)

Panel type

Fixed panel

Maximum installation site altitude

2000 m (2187 yd)

Weight

< 2 kg (< 4.41 lb)

Panel use

Internal use

Material class

IIIa

Over voltage category

II (IEC 60664-1:2007)

Nominal pulse voltage

2500 V

Operating temperature

-5 ... 50 °C (EN 60730-2-9:2010)

Power supply

230 Va ± 10 % 50/60Hz

Control

EWRC NT electronic controller

Power consumption

11 VA max

Digital outputs (relay)

refer to the label on the device

Fire resistance category

D

Software class

A

Connection

device on external flexible cable, Y type connection

Ball test temperature

100 °C ( 212 °F)

Page 15

15 - EN EWRC 300/500/5000 NT

English

DESCRIPTION

EWRC 500 BREAKER

Circuit breaker

Two-pole (2P)

ELECTRICAL SPECIFICATIONS

DESCRIPTION

Rated voltage (Un)

230 Vac

Rated operating voltage (Ue)

230 Vac

Rated insulation voltage (Ui)

230 Vac

Conditioned short circuit current (Icc)

< 4.5 kA

Rated frequency (fn):

50/60 Hz

EWRC 500 BREAKER

:

Rated impulse withstand voltage (Uimp)

4 kV

Rated panel current (InA)

16 A

Rated circuit current (InC)

16 A

FURTHER INFORMATION

DESCRIPTION

Container

PC+ABS

Dimensions

EWRC 300/500: front panel 213 x 318 mm, depth 102 mm

EWRC 500 BREAKER: front panel 221 x 318 mm, depth 107 mm

EWRC 5000: front panel 420 x 360 mm, depth 147 mm

Connections

screw-on terminals (see wiring diagram)

with internal housing for magnetothermal switch, remote control switch, contactor, etc. on DIN rail

Storage temperature

-20 ... 85 °C

Operating humidity

10...90% RH non-condensing

Storage humidity

Display range

–50…110 (NTC) / –55…150 °C (PTC) without decimal point, on 2 displays:

(upper display) 3 digit + sign/ (lower display) 4 digit

Analogue Inputs

3(2) NTC inputs selectable with parameter H00

Digital Inputs

2(3) voltage-free digital inputs configurable with parameter H11/H12/H13

Relay outputs

EWRC 300

• OUT1 SPST 2 HP 12(12) A 250 Vac

• OUT2 SPST 1 HP 8(8) A 250 Vac

• OUT3 SPST 1/2 HP 8(4) A 250 Vac

common-line max 18 A

EWRC 500/5000

• OUT1 SPST 2 HP 12(12) A 250 Vac

• OUT2 SPST 1 HP 8(8) A 250 Vac

• OUT3 SPST 1/2 HP 8(4) A 250 Vac

• OUT4 SPST 1 HP 8(8) A 250 Vac

• OUT5 SPDT 1/2 HP 8(4) A 250 Vac

common-line max 18 A

Buzzer

only on models where this is provided

Serial ports

• 1 TTL port for connection to Unicard / Copy Card

• 1 TTL port for connection to TelevisSystem

• 1 RS-485 serial port for connection to TelevisSystem

/ Modbus

(use with optional plug-in module)

Note: if using the TTL port to communicate, disconnect the RS-485 port and vice-versa.

Accuracy

better than 0.5% of full scale +1 digit

Resolution

1 or 0.1 °C

Clock backup

Up to four days in the absence of an external power supply

Page 16

Eliwell Controls s.r.l.

Via dell’Industria, 15 • Z.I. Paludi

32016 Alpago (BL) ITALY

T +39 0437 986 111

www.eliwell.com

Technical Customer Support

T +39 0437 986 300

E techsuppeliwell@schneider-electric.com

Sales

T +39 0437 986 100 (Italy)

T+39 0437 986 200 (other countries)

E saleseliwell@schneider-electric.com

9IS54389 - EN - rel. 09/17

© Eliwell Controls s.r.l. 2014-17 All rights reserved.

Food safety

The device complies with Standard EN13485 as follows:

- suitable for storage

- application: air

- climate range A

- measurement class 1 in the range -25 °C to 15 °C (-13 °F to 59 °F) (only when using Eliwell probes)

Permitted use

This equipment is used to control cold rooms in commercial refrigeration sectors.

For safety reasons, the equipment must be installed and used in accordance with the instructions provided.

Prohibited use

Any use other than that described in the previous paragraph, “Permitted use”, is strictly forbidden.

The relays supplied are electromagnetic and are subject to wear. The protection devices required by international or

local laws must be installed outside the equipment.

LIABILITY AND RESIDUAL RISKS

The liability of Eliwell Controls srl is limited to the correct and professional use of the product according to the

directives referred to herein and in the other supporting documents, and does not cover any damage (including but

not limited to) the following causes:

unspecified installation/use and, in particular, in defiance of safety requirements of established legislation and/or

specified in this document;

installation/use on equipment which does not comply with established legislation and technical standards

tampering with and/or modification of the product.

DISCLAIMER

This document is the exclusive property of Eliwell and cannot be reproduced or circulated unless expressly

authorised by Eliwell. All possible care has been taken to ensure the accuracy of this document; nevertheless,

Eliwell Controls srl cannot accept liability for any damage resulting from its use. The same applies to any person or

company involved in the creation and preparation of this document. Eliwell reserves the right to make aesthetic or

functional changes at any time without notice.

DISPOSAL

The equipment (or product) must be subjected to separate waste collection in compliance with

the local legislation on waste disposal.

Loading...

Loading...