Page 1

Electronic controllers for refrigeration units

Controles electrónicos para unidades de refrigeración

Contrôleurs électroniques pour unités réfrigérantes

Controladores eletrônicos para unidades de refrigeração

EWP ///

Installation manual includes:

English, Spanish, French, and Portuguese

Page 2

Page 3

3

Electronic controllers for refrigeration units

STAND-BY (ESC)

Press and release

Returns to the previous menu level

Confirm parameter value

Press for at least 5 secs

Activates the Stand-by function

(when outside the menus)

UP

Press and release

Scrolls through menu items

Increases values

Press for at least 5 secs

Activates the Manual Defrost function

DOWN

Press and release

Scrolls through menu items

Decreases values

Press for at least 5 secs

Configurable function by user (par.H32)

SET (ENTER)

Press and release

Displays alarms (if active)

Opens the Machine Status menu

Press for at least 5 secs

Opens the Programming menu

Confirms commands

set

KEYS

EW

PL

US

902/961

EW

PL

US

971/974

ENGLISH

Page 4

4

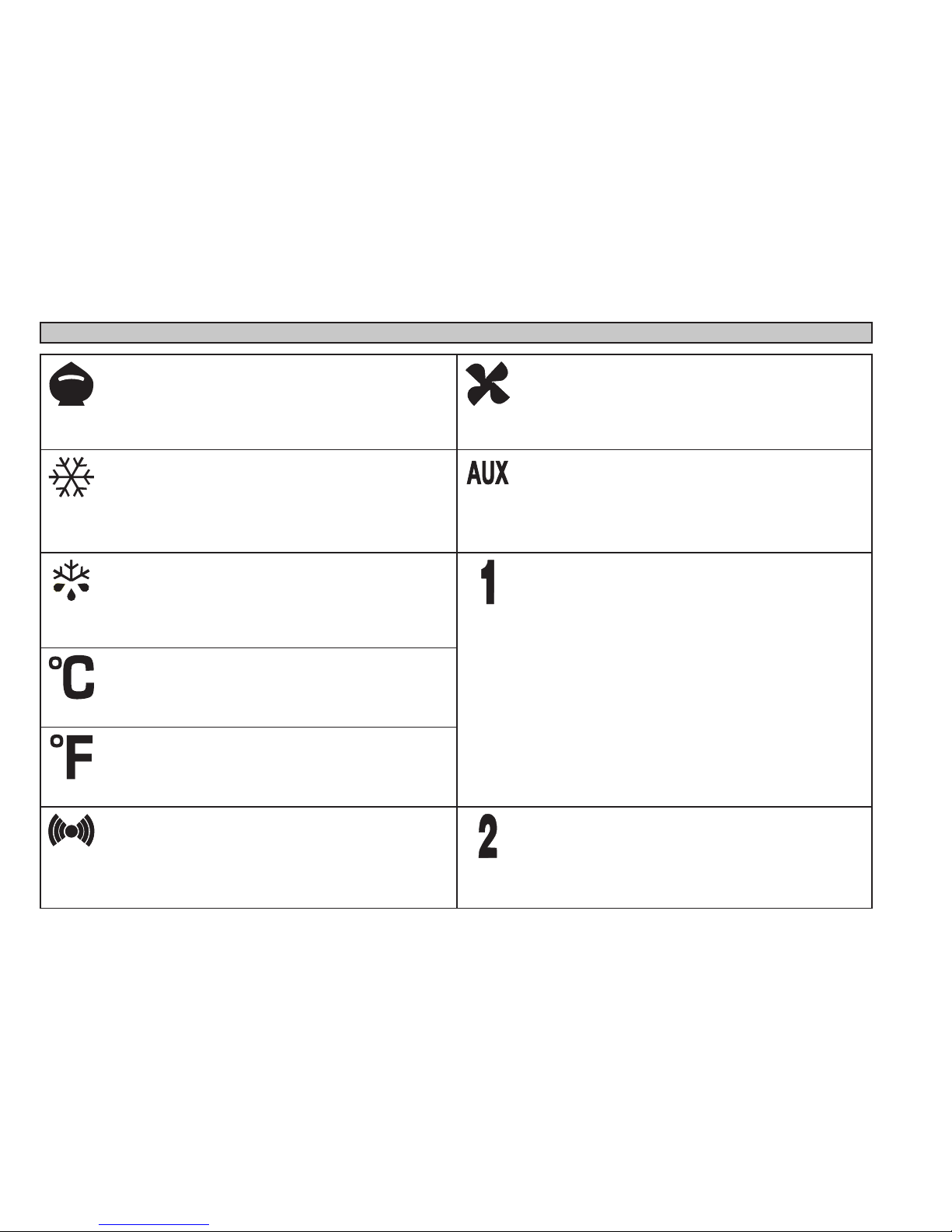

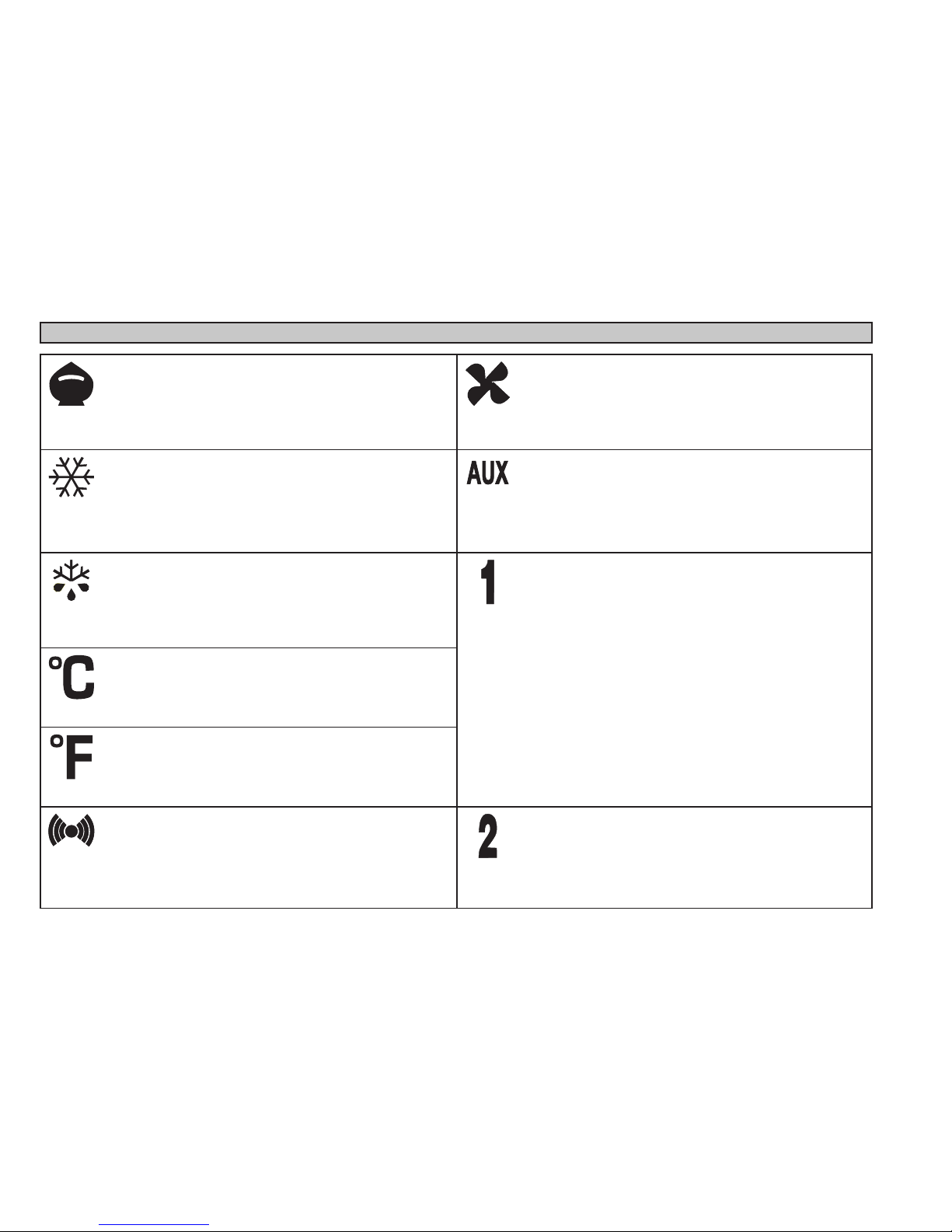

LEDs

Reduced SET / Economy

Flashing: reduced set active

Quick flashing: access to level 2 parameters

Off: otherwise

Compressor LED

Permanently on: compressor active

Flashing: delay, protection or

blocked start-up

Off: otherwise

Defrost LED

Permanently on: defrost active

Flashing: manual or D.I. activation

Off: otherwise

Fan LED

Permanently on: fans active

Off: otherwise

(only EWPlus 971 and EWPlus 974)

Alarm LED

Permanently on: alarm on

Flashing: alarm acknowledged

Off: otherwise

HEAT mode LED

Permanently on: compressor in HEAT mode

Off: otherwise

(only EWPlus 902 and EW Plus 961)

NOT USED

(only EWPlus 902 and EWPlus 961)

Aux LED

Permanently on: Aux active*

*depending on model

(only EWPlus 971 and EWPlus 974)

°C LED

Permanently on: °C setting (dro = 0)

Off: otherwise

°F LED

Permanently on: °F setting (dro = 1)

Off: otherwise

NOTE:

If the instrument is set in the COOL mode, in order to

use it in the HEAT mode it is necessary to re-program

the instrument by using the properly programmed

Copycard.

The same procedure should be followed to pass from

the HEAT mode to the COOL mode.

Page 5

5

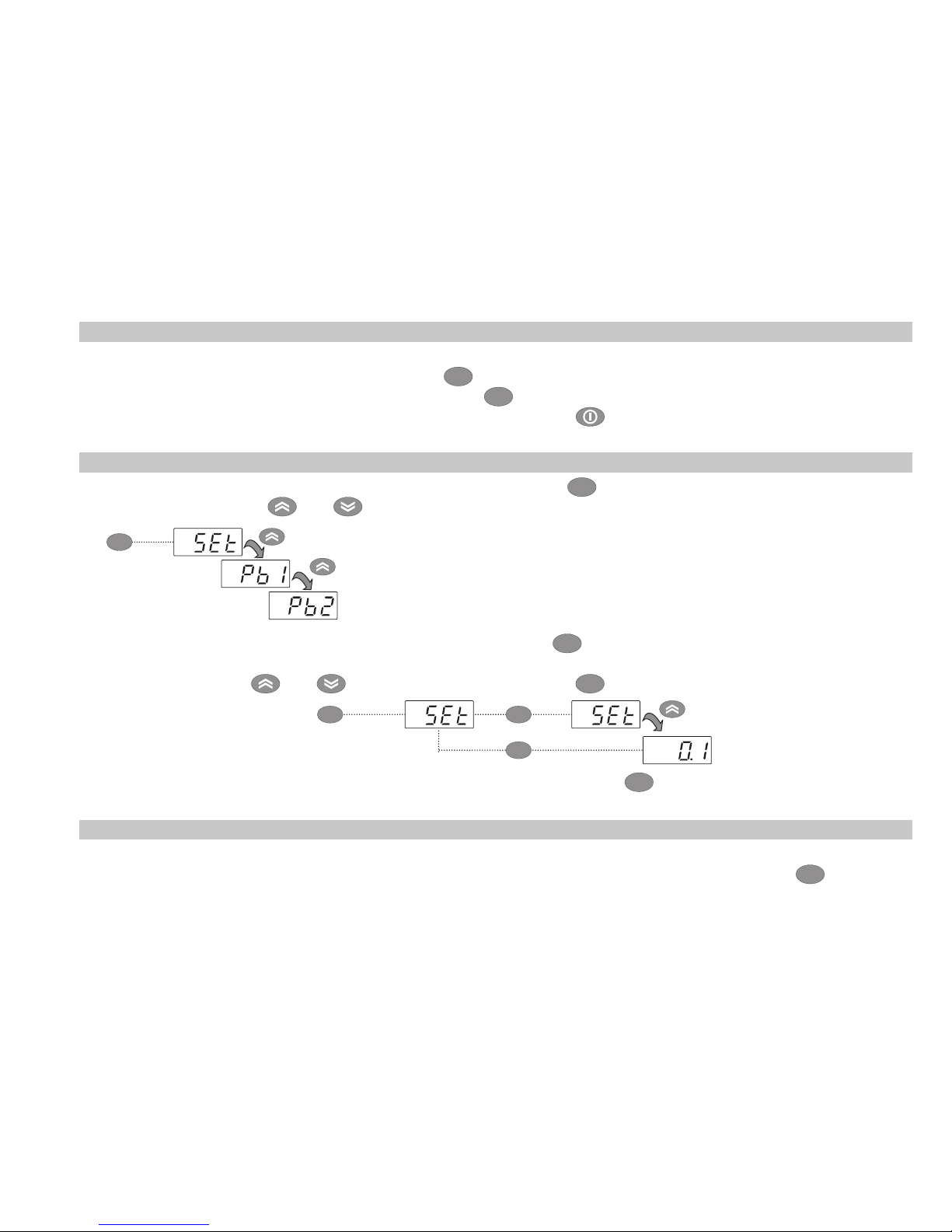

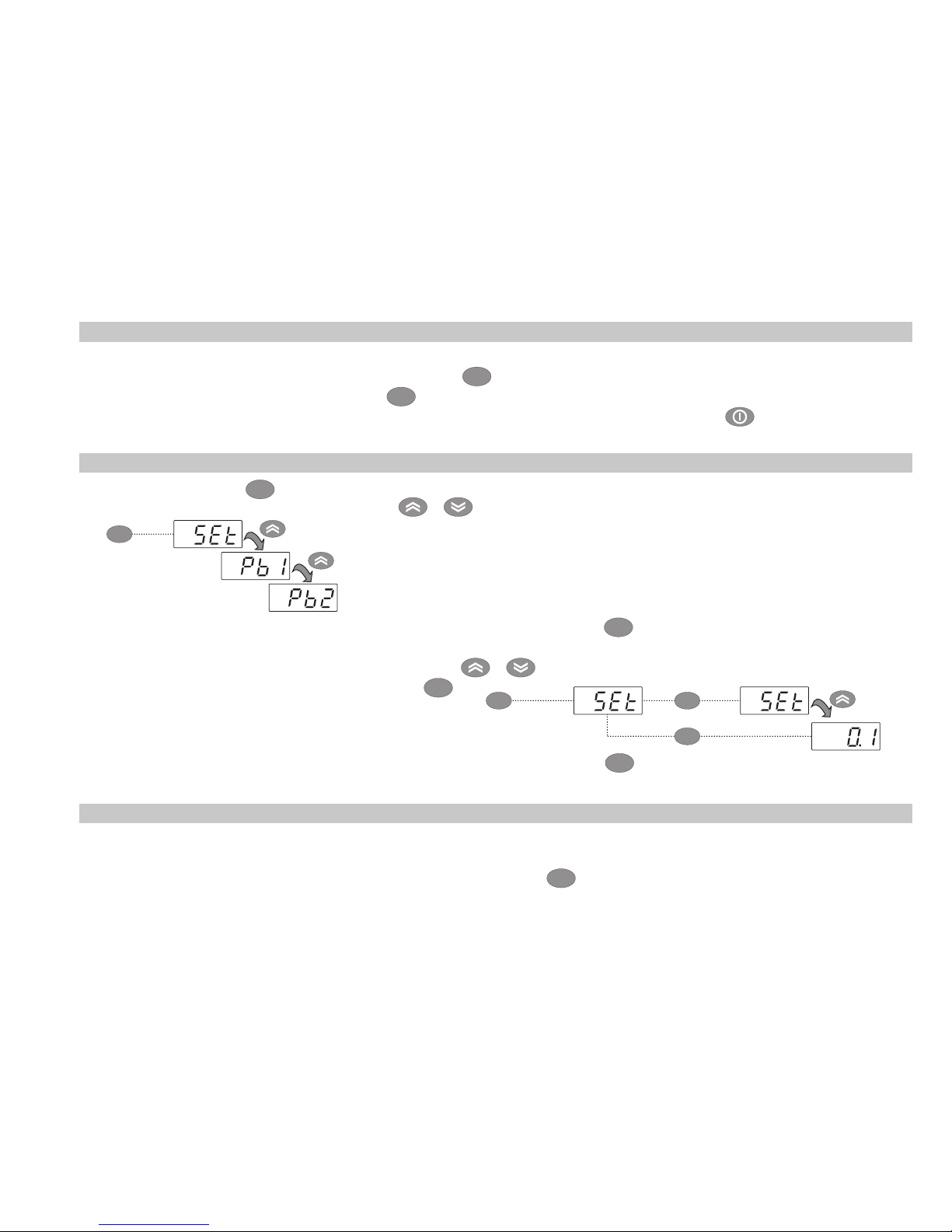

ACCESSING AND USING THE MENUS

Resources are organized into 2 menus which are accessed as explained below:

• ‘Machine Status’ menu: press and release the

set

key.

• ‘Programming’ menu: press for at least 5 secs the

set

key.

Either do not press any keys for 15 seconds (time-out) or press the key once, to confirm the last value

displayed and return to the previous screen.

MACHINE STATUS MENU

Access the “Machine Status” menu by pressing and releasing the

set

key. If no alarms are active, the “SEt” label

appears. By pressing the

and keys you can scroll all folders in the “Machine Status” menu:

- AL: alarms folder (only visible if an alarm is active);

- SEt: Set point setting folder;

- Pb1: probe 1 folder;

- Pb2: probe 2 folder **;

(** models EWPlus 971 and EWPlus 974 only)

Setting the Set point: To display the Set point value press the

set

key when the ‘SEt’ label is displayed.

The Set point value appears on the display. To change the Set point value, press the

and keys within 15 seconds. Press

set

to confirm the modification.

set

set set

Displaying the probes: When the Pb1 or Pb2* label is displayed, press

set

and the associated probe value

will appear (* Pb2 is only present on models EWPlus 971 and EWPlus 974).

SET POINT EDIT LOCK

It is possible to disable the keypad on this device. The keypad can be locked by programming the ‘LOC’

parameter. With the keypad locked you can still access the ‘Machine Status’ menu by pressing

set

to display

the Set point, but you cannot edit them. To disable the keypad lock, repeat the locking procedure.

set

Page 6

6

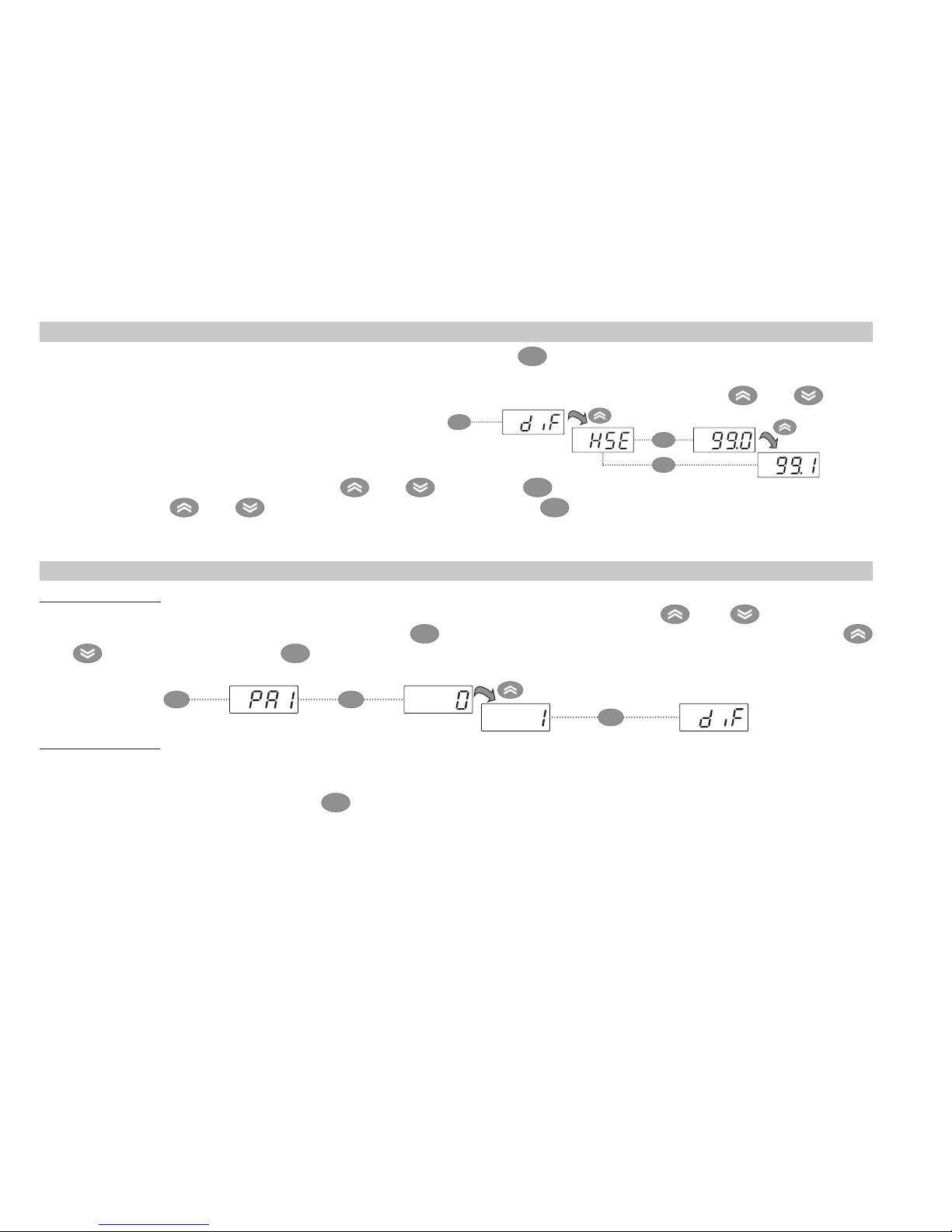

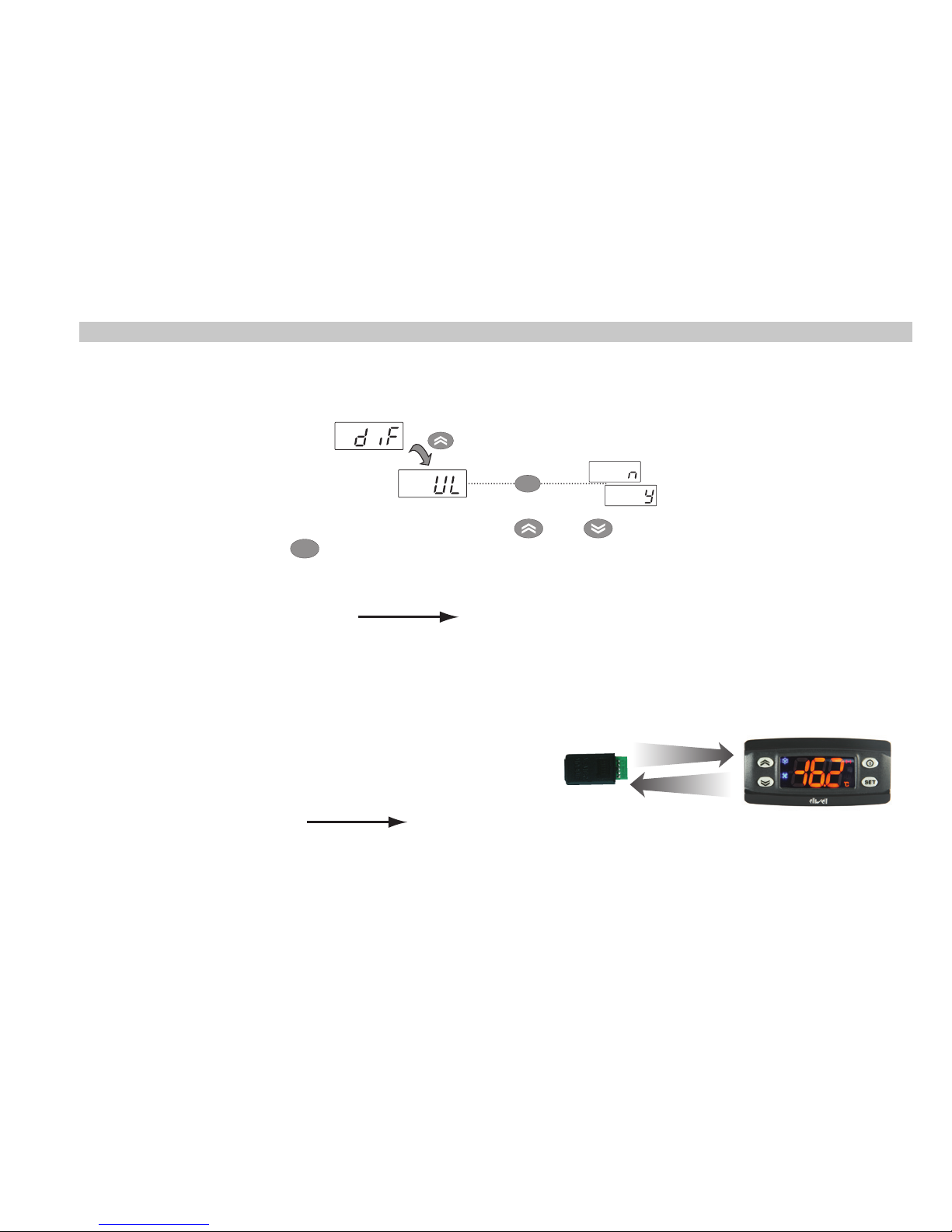

PROGRAMMING MENU

To access the ‘Programming’ menu press for at least 5 secs the

set

key. If specified, the ‘PA1’ for the level

1 parameters and the ‘PA2’ for the level 2 parameters access PASSWORD will be requested (see Par.

‘PASSWORD’) At the access, the display will show the first parameter (“diF”). By pressing the

and keys

you can scroll all parameters in the current level:

5 secs

Select the desired parameter using the and keys. Press

set

to see the current value of the selected

parameter. Press and to change the value and then press

set

to save it.

NOTE: It is strongly recommended that you switch the device off and on again each time the parameter

configuration is changed, in order to prevent malfunctioning of the configuration and/or ongoing timings.

PASSWORD

‘PA1’ Password: It allows access to the level 1 parameters. In the standard configuration the password is disabled

(value = 0). To enable it (value ≠ 0) enter the “Programming” menu by pressing the

and keys, scroll the

parameters until “PS1” label is displayed, press the

set

key to display the current value, change it by using the

and

keys and then press the

set

key to save it. If the password is already enabled, you will be required to enter

it to access the ‘Programming’ menu. To enter it:

set

setset

‘PA2’ Password: It allows access to the level 2 parameters. In the standard configuration the password is enabled

(valore ≠ 0). To change its value follow the steps like for ‘PA1’ and change the ‘PS2’ parameter value.

The visibility of the ‘PA2’ label will be:

1) If PA1 and PA2 ≠ 0: By pressing the

set

key for more than 5 seconds, “PA1” and “PA2” labels will be displayed

at the same level and it will be possible to access either the level 1 or the level 2 parameters.

2) Otherwise: The ‘PA2’ password is present between the level 1 parameters. If ‘PA2’ is enabled, you will be required

to enter it to access the level 2. To enter it follow the steps described for the ‘PA1’ password.

If the password is incorrect, the instruments display the PA1/PA2 label and you will have to repeat the entry

procedure.

set

set

set

Page 7

7

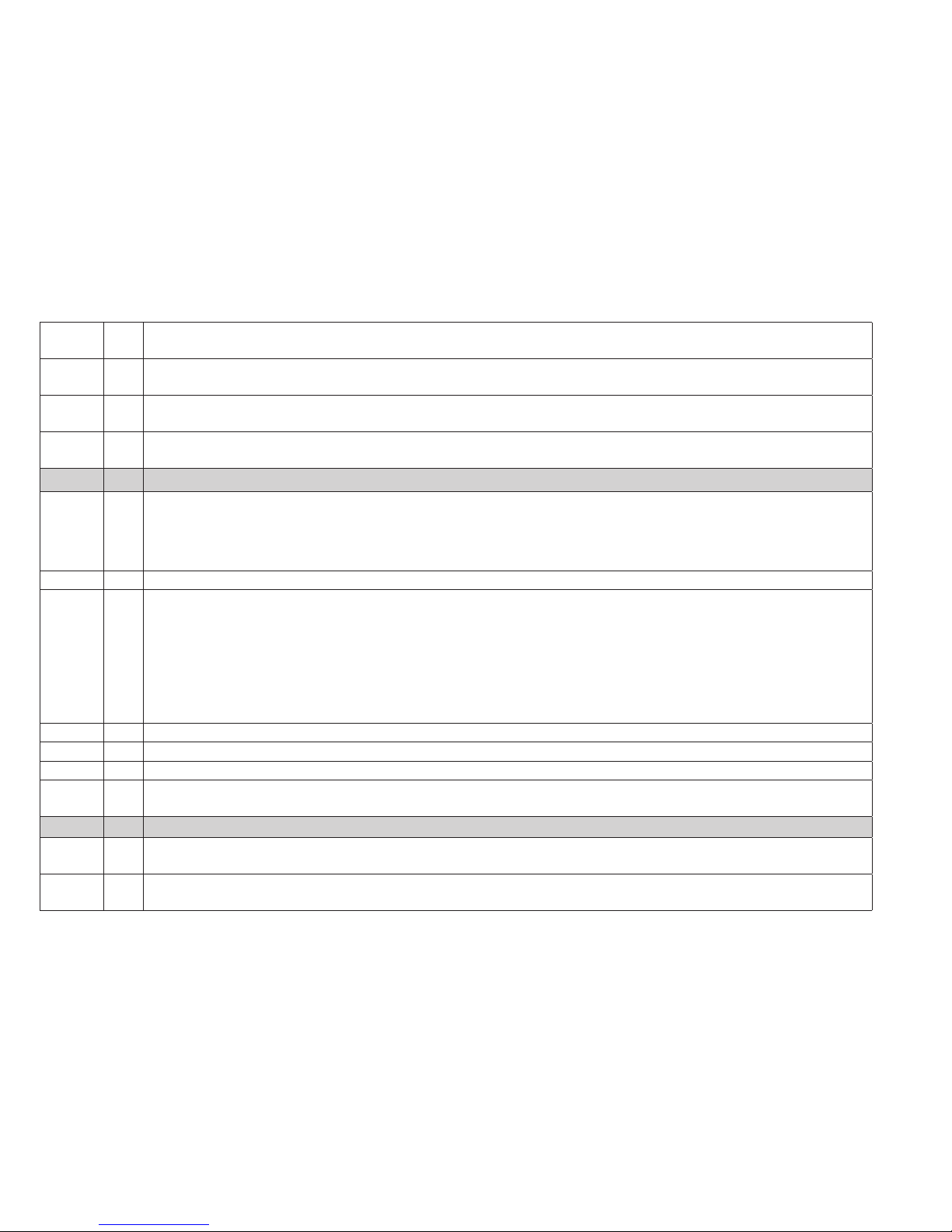

ALARMS

Label Fault Cause Effects Remedy

E1

Probe1 faulty

(cold room)

• Reading of out of range operating

values

• Probe faulty / short-circuited / open

• Display label E1

• Alarm icon permanently ON

• Min/max alarm regulator disabled

• Compressor operation according to

“Ont” and “OFt” parameters.

• Check probe type (NTC)

• Check the probe wiring

• Replace probe

E2

Probe2 faulty

(defrost)

• Reading of out of range operating

values

• Probe faulty / short-circuited / open

• Display label E2

• Alarm icon permanently ON

• The defrost cycle will end due to

Time-out (Parameter “dEt”)

• Check probe type (NTC)

• Check the probe wiring

• Replace probe

AH1

Probe1 HIGH

Temperature

alarm

Value read by Pb1 > HAL after time

of “tAO”.

(see “MAX/MIN TEMP. ALARMS “)

• Registration AH1 label in the AL folder

• No effect on regulation

• Wait until temperature value

read by probe1 returns below

HAL.

AL1

Probe1 LOW

Temperature

alarm

Value read by Pb1 < LAL after time

of “tAO”.

(see “MAX/MIN TEMP. ALARMS”)

• Registration AL1 label in the AL folder

• No effect on regulation

• Wait until temperature value

read by probe1 to come back

obove LAL

EA External alarm

• Digital input activated

(H11 = ±5)

• Registration EA label in the AL folder

• Alarm icon permanently ON

• Regulation blocked if EAL = y

• Check and remove the external

cause which generate alarm

on D.I.

OPd Door Open alarm

• Digital input activated

(H11 = ±4)

(for a longer time than tdO)

• Registration Opd label in the AL folder

• Alarm icon permanently ON

• Regulator blocked

• Close the door

• Delay function defined by OAO

Ad2

Defrosting

for time-out

• End of defrosting because of time

instead of because of reaching the

defrost end temperature detected

by the Pb2 probe.

• Registration Ad2 label in the AL folder

• Alarm icon permanently ON

• Wait until the next defrost for

automatic return

Page 8

8

MANUAL DEFROST CYCLE ACTIVATION

To manually activate the defrost cycle, hold down the key for 5 seconds.

If the defrost conditions are not satisfied:

- the parameter OdO ≠ 0 (EWPlus 902/961/971/974)

- the evaporator probe Pb2 temperature is higher than the defrost end temperature (EWPlus 971/974)

the display will flash 3 times, to indicate that the operation will not be carried out.

DIAGNOSTICS

Alarms are always indicated by the buzzer (if present) and the alarm icon .

To switch off the buzzer, press and release any key, the relative icon will continue to flash.

NOTES: If alarm exclusion times have been set (see ‘AL’ folder in the parameters table) the alarm will not be

signalled.

A probe 1 (Pb1) malfunction alarm will appear directly on the display with the

indication E1.

Models EWPlus 971/974: A probe 2 (Pb2) malfunction alarm will appear

directly on the display with the indication E2.

MECHANICAL ASSEMBLY

The instrument is designed for panel mounting. Make a hole of 2-13/16” x 1-1/8” (71x29mm), insert the instrument and fix it using the brackets provided. Do not mount the instrument in humid and/or dirty places; it is

suitable for use in ordinary polluted places. Ventilate the place in proximity to the instrument colling slits.

74 mm

32 mm

29 mm

71 mm

70 mm

59 mm

Page 9

9

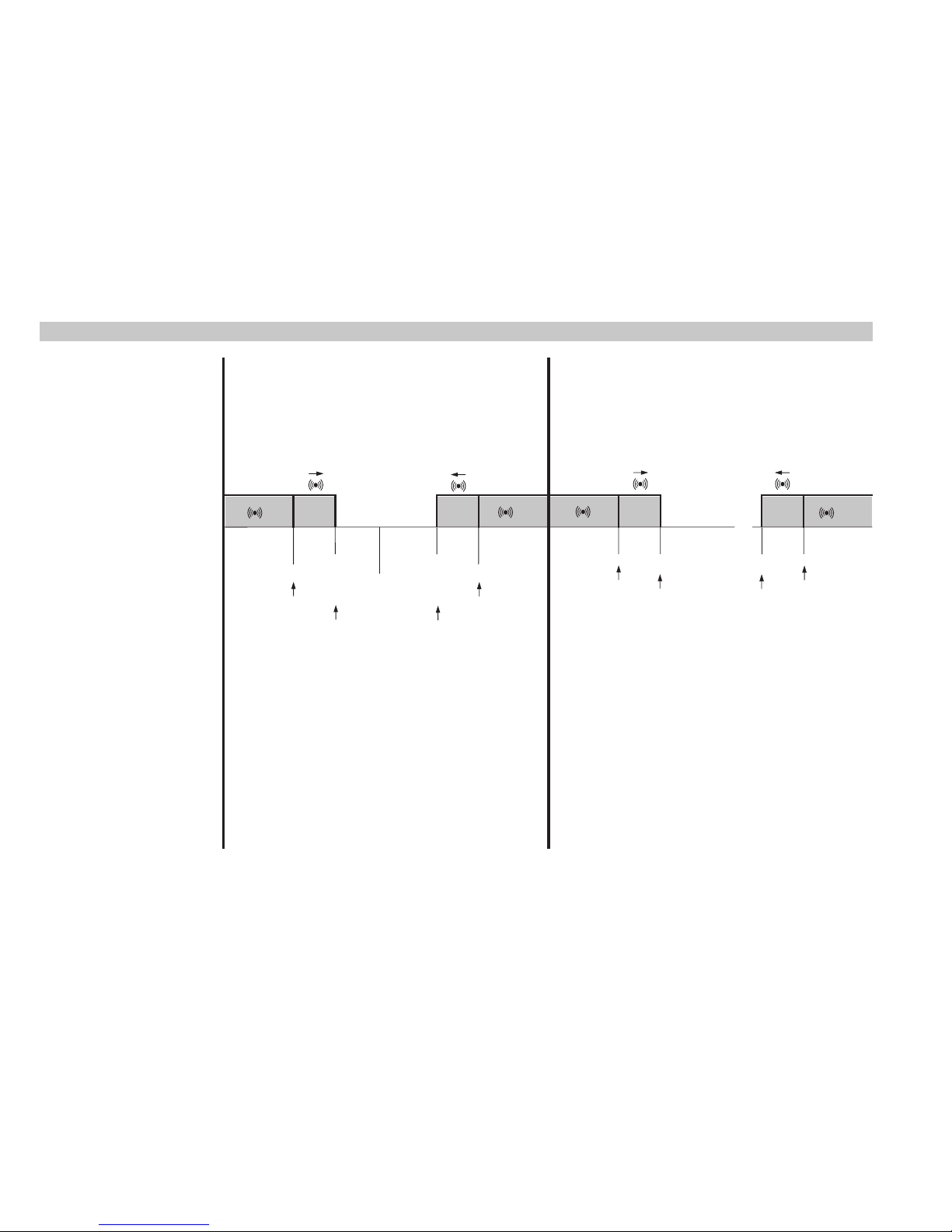

USING THE COPY CARD

The Copy Card is an accessory connected to the TTL serial port used for quick programming of the device

parameters (upload and download a parameter map to one or more devices of the same type). Upload (label

UL) and copy card formatting (label Fr) operations should be performed as explained below:

set

After the password ‘PA2’ has been putted in, press the and keys to scroll through to the required

function (e.g. UL). Press the

set

key to execute the upload. If the operation is successful, the display will show

‘y’, if not it will show ‘n’.

Upload (UL) This function uploads the programming parameters from the device.

UPLOAD: device

Copy Card

Format (Fr) This command is used to format the copy card, an operation which is necessary when using the

card for the first time. Important: when the copy card has been programmed, the parameter

‘Fr’ will delete all data that have been entered. This operation cannot be cancelled.

Download from reset:

Connect the copy card when the device is switched off. When

the device is switched on, the download from the copy card will

begin automatically. At the end of the lamp test, the display will

show ‘dLy’ if the operation was successful and ‘dLn’ if not.

DOWNLOAD: Copy Card

device

NOTES:

- After the parameters have been downloaded, the device uses the downloaded parameter map settings.

UPLOAD

DOWNLOAD

Page 10

10

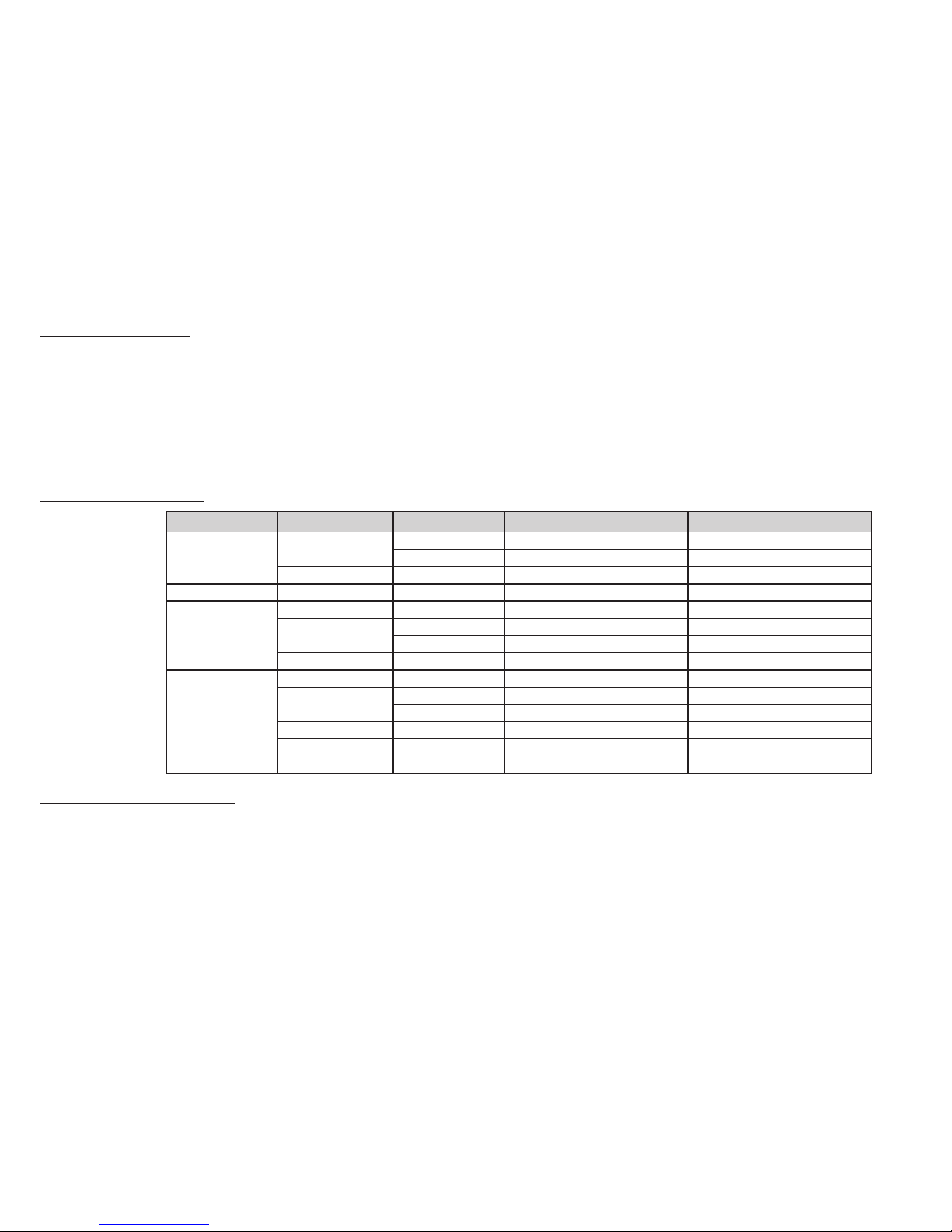

MAX/MIN TEMPERATURE ALARM

Relative Temperature

Value to Setpoint (Att=1)

Absolute Temperature

Value (Att=0)

Temp. ≤ Set + LAL *

Temp. ≥ Set + HAL **

Temp. ≥ Set + LAL + AFd or

≥ Set - ILALI + AFd (LAL < 0)

Temp. ≤ Set + HAL - AFd (HAL > 0)

Temp. ≤ LAL (LAL with sign)

Temp. ≥ HAL (HAL with sign)

Temp. ≥ LAL + AFd

Temp. ≤ HAL - AFd

Minimum temperature

alarm

Maximum temperature

alarm

Returning from

minimum temp. alarm

Returning from

maximum temp. alarm

* if LAL is negative, Set + LAL < Set

** if HAL is negative, Set + HAL < Set

Setpoint - LAL

AFd

Off

Setpoint + HAL

AFd

Setpoint - LAL + AFd

Setpoint + HAL - AFd

Setpoint

LAL

AFd

HAL

AFd

LAL + AFd

HAL - AFd

Page 11

11

CONDITIONS OF USE

Permitted use

For safety reasons the instrument must be installed and used according to the instruction provided and in

particular, under normal conditions, parts bearing dangerous voltage levels must not be accessible. The

device must be adequately protected from water and dust as per the application and must also only be

accessible via the use of tools (with the exception of the frontlet).

The device is ideally suited for use on household appliances and/or similar refrigeration equipment and has

been tested with regard to the aspects concerning European reference standards on safety.

Unpermitted use

Any other use other than that permitted is de facto prohibited. It should be noted that the relay contacts

provided are of a practical type and therefore subject to fault. Any protection devices required by product

standards or dictated by common sense due to obvious safety reasons should be applied externally.

TECHNICAL DATA

Classification: Control device (not safety) to integrate

Mounting: Panel mounting with 2-13/16” x 1-1/8” (71x29mm) drilling template

Control type: 1.B

Pollution rating: 2

Material class: IIIa

Overvoltage category class: II

Nominal impulsive voltage: 2500V

Temperature: Operating: –5 to +65°C (+23 to +149°F) - Storage: –30 to +85°C (–22 to +185°F)

Power Supply: 115Va or 230Va (

+

10% / -10%) 50/60 Hz

Consumption: 4VA max

Digital Output (relays): Please refer to the device label

Fire resistance class: D

Software class: A

NOTE: Check the power supply specified on the instrument label; for relay and power supply

capacities, contact Technical Service.

Page 12

12

Input Characteristics

Display Range: NTC: –50°C to +110°C (–58°C to +230°F)

(on display with 3 digit + sign)

Accuracy: Better than 0.5% of full-scale + 1 digit

Resolution: 0.1°C (0.1°F up to 199.9 ; 1°F beyond)

Buzzer: YES (it depends on the model)

Analogue Input: EWPlus 902/961: 1 NTC input - EWPlus 971/974: 2 NTC inputs

Digital Input: 1 voltage-free digital input

Output Characteristics

Digital Output:

Model Relay Type of load

Power Supply 115V

a Power Supply 230Va

EWPlus 902:

OUT1 - N.O.

Resistive 8A 8A

Motor 1/8 Hp 1/2 Hp

OUT1 - N.C. Resistive 6A 6A

EWPlus 961: Compressor Motor 16 FLA / 96 LRA 12 FLA / 72 LRA

EWPlus 971:

Compressor Motor 16 FLA / 96 LRA 12 FLA / 72 LRA

Defrost - N.O.

Resistive 8A 8A

Motor 1/8 Hp 1/2 Hp

Defrost - N.C. Resistive 6A 6A

EWPlus 974:

Compressor Motor 16 FLA / 96 LRA 12 FLA / 72 LRA

Defrost - N.O.

Resistive 8A 8A

Motor 1/8 Hp 1/2 Hp

Defrost - N.C. Resistive 6A 6A

Fan

Resistive 3A 3A

Motor 1.4 FLA / 7.5 LRA 1.4 FLA / 7.5 LRA

Mechanical Characteristics

Housing: PC UL94 V-0 resin plastic casing, polycarbonate glass

Dimensions: Front 2-15/16” x 1-1/4” (74x32mm), depth 2-15/16” (59mm) (excluding terminals)

Terminals: Screw terminals for cable with a diameter of 13 AWG

(2.5mm2)

Connectors: TTL for connection to Copy Card

Humidity: Operating / Storage: 10 to 90% RH (not condensing)

Page 13

13

Regulations

Electromagnetic compatibility: This device complies with Directive 2004/108/EC

Security: This device complies with Directive 2006/95/EC

Food safety: This device complies with standard EN 13485 as follows:

- suitable for storage

- application: air

- climate range A

- measurement class 1 in the range from -25°C to 15°C (-13°F to 59°F) (*)

(* exclusively using Eliwell NTC probes)

NOTE: The technical data included in this document, related to measurement (range, accuracy, resolution, etc.)

refer to the instrument itself, and not to its equipment such as, for example, sensors. This means, for example,

that sensor(s) error(s) shall be added to the instrument’s one.

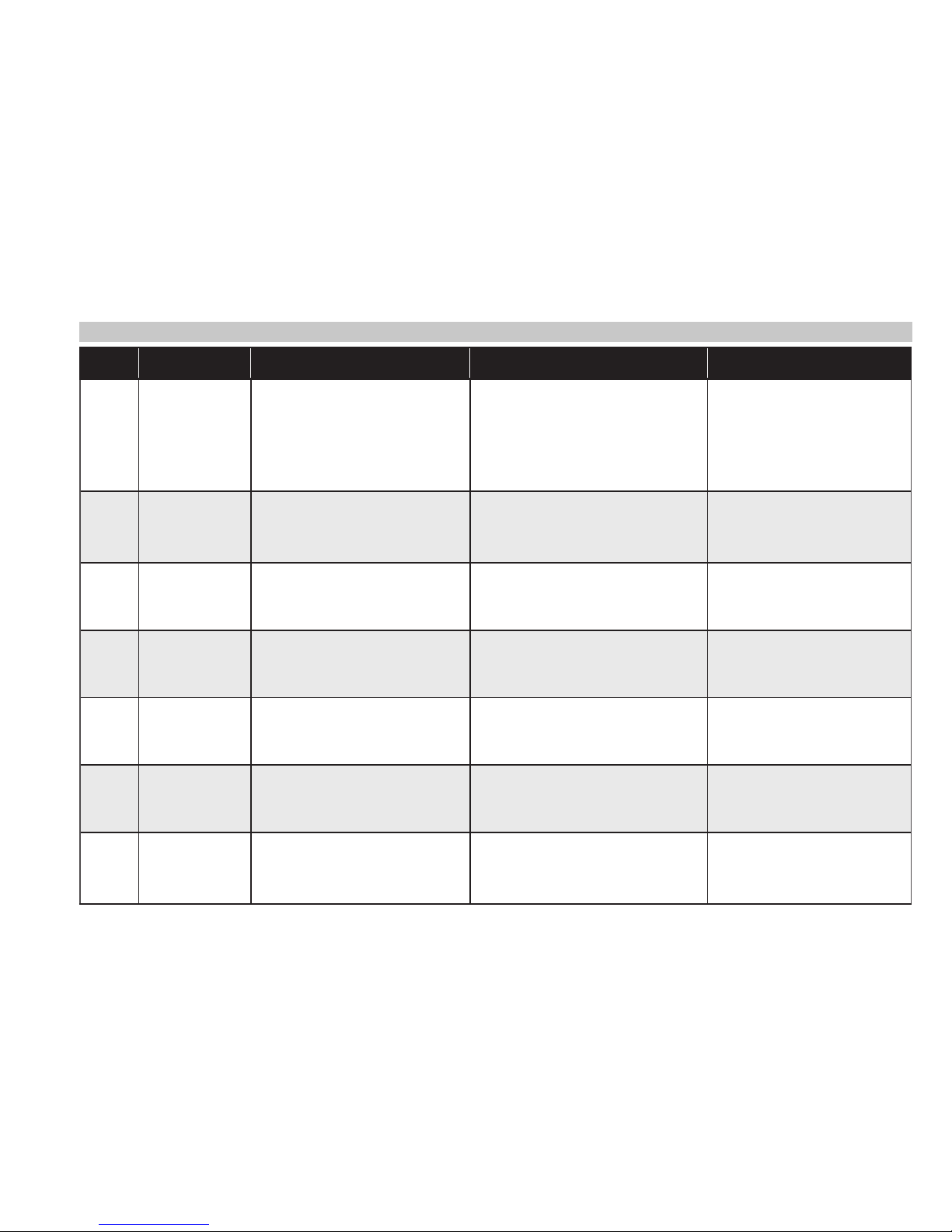

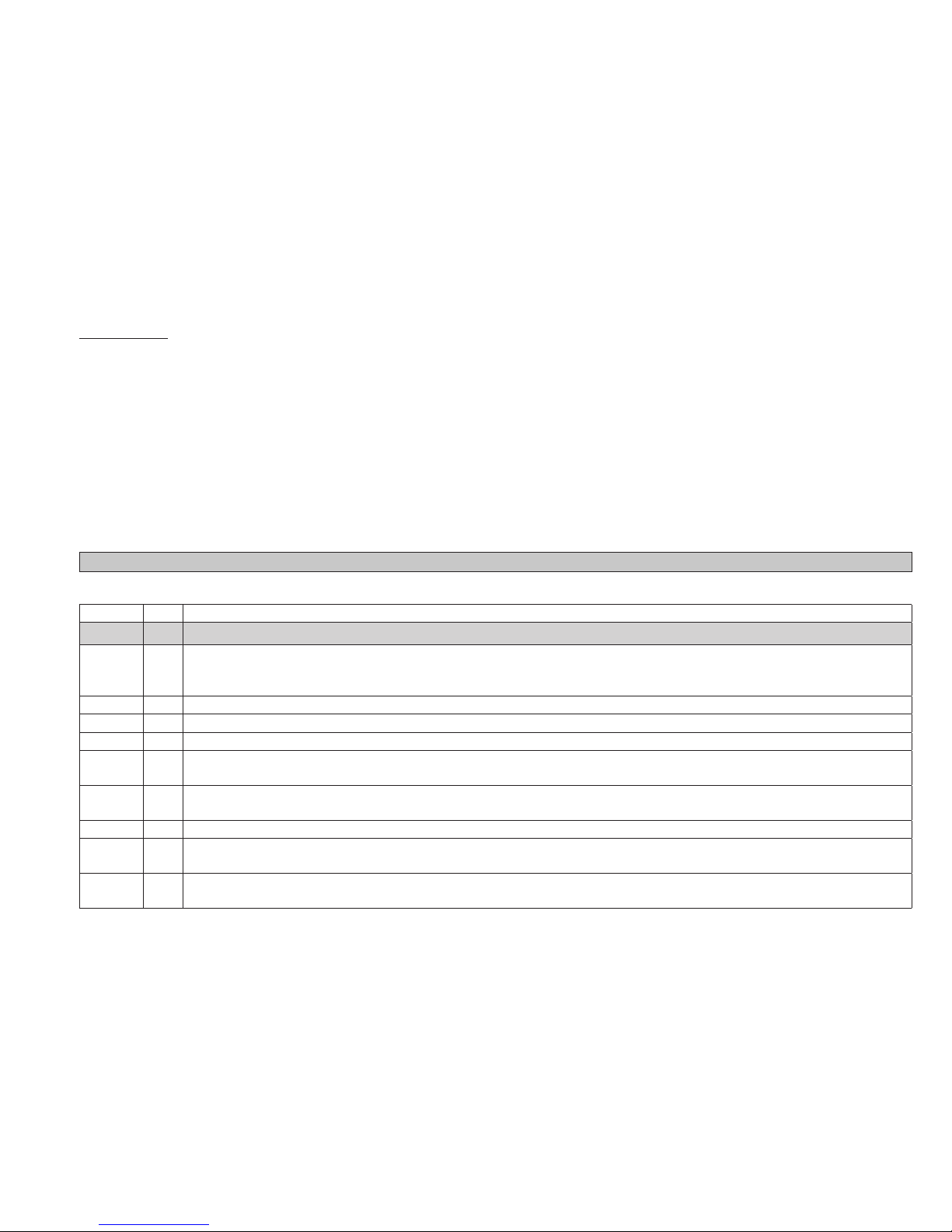

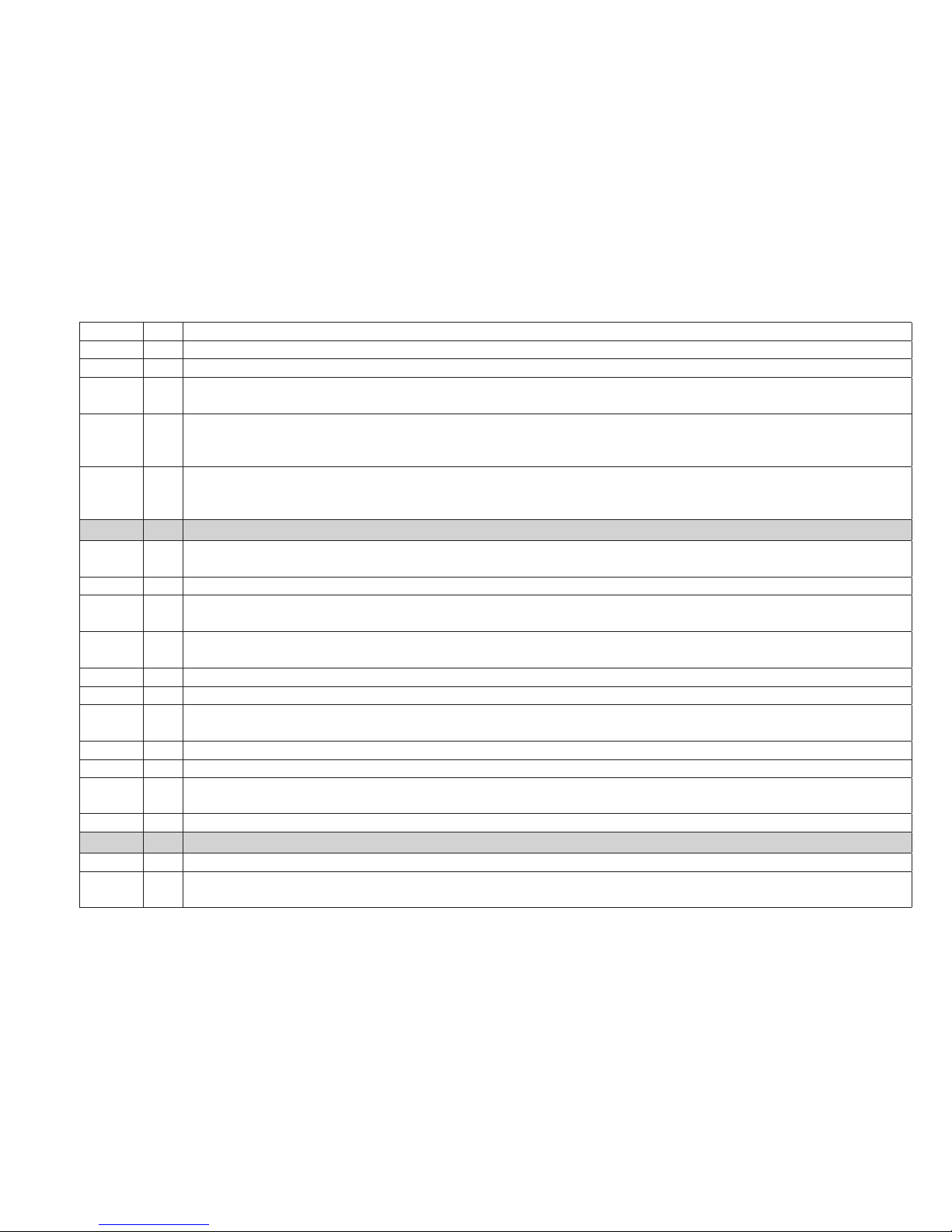

TABLE OF PARAMETERS

PAR.

Liv. DESCRIPTION

SEt Temperature SEtpoint.

COMPRESSOR

diF 1&2

diFferential. Relay compressor tripping differential. The compressor stops on reaching the Setpoint

value (as indicated by the adjustment probe), and restarts at temperature value equal to the Setpoint

plus the value of the differential. Note: diF ≠ 0.

HSE 1&2 Higher SEt. Maximum possible setpoint value.

LSE 1&2 Lower SEt. Minimum possible setpoint value.

HC 2 The regulator will go to HOT operating mode (set to ‘H’) or COLD operating mode (set to ‘C’)

OSP 2

Offset Set Point. Temperature Value to be added to the Set-Point if reduced set is enabled

(Economy function).

dOd 2

digital (input) Open door. Digital input that allow you to switch off loads.

Valid if H11 = ±4 (door switch). n = does not switch off loads; y = switch off loads.

dAd 2 digital (input) Activation delay. Delay time in activating the digital input.

Ont 2

ON time (compressor). Compressor activation time in the event of faulty probe. If OFt=1 and

Ont=0, the compressor is always off, while if OFt=1 and Ont>0 it operated in duty cycle mode.

OFt 2

OFF time (compressor). Compressor deactivation time if probe is faulty. If Ont=1 and

OFt=0, the compressor is always on, while if Ont=1 and OFt>0 it operated in duty cycle mode.

Page 14

14

dOn 2

delay (at) On compressor. Delay time in activating the compressor relay after switch-on of

instrument.

dOF 2

delay (after power) OFF. Delay after switch off; the indicated time must elapse between switch-off of

the compressor relay and the successive switch-on.

dbi 2

delay between power-on. Delay between switch-ons; the indicated time must elapse between

two successive switch-ons of the compressor.

OdO (!) 2

delay Output (from power) On. Delay time in activating the outputs after switch-on of the instrument

or after a power failure.

DEFROST

dty 1&2

defrost type. Type of defrosting.

0 = electric defrost - compressor off (OFF) during defrosting;

1 = reverse cycle defrost (hot gas); compressor on (ON) during defrosting;

2 = Free defrost; defrosting independently of compressor.

dit 1&2 defrost interval time. Interval between the start of two successive defrosting operations.

dCt 2

defrost Counting type. Selection of count mode for the defrosting interval.

0 = compressor operating hours (DIGIFROST® method);

Defrosting active only if compressor is on;

1 = Real Time - equipment operating hours; defrost counting is always active when the

machine is on and start everytime the instrument switch on;

2 = compressor stop. Each time the compressor stops a defrosting cycle is performed

according to parameter dtY.

dOH 2 defrost Offset Hour. Start-of-defrosting delay time from the call.

dEt 1&2 defrost Endurance time. Defrosting time-out; determines duration of defrosting.

dSt 1&2 defrost Stop temperature. Defrost stop temperature (defined by the evaporator probe).

dPO 2

defrost (at) Power On. Determines if at the start-up the instrument must enter defrosting (if

the temperature measured by the evaporator allows this operation). y = yes; n = no.

EVAPORATOR FAN

FPt 2

Fan Parameter type. Characterizes the ‘FSt’ parameter that can be expressed or as an absolute

temperature value or as a value related to Setpoint. 0 = absolute 1 = relative.

FSt 1&2

Fan Stop temperature. Fan lock temperature; if the value, read by the evaporator probe, is

higher than the set value, fans stop.

Page 15

15

FAd 2 FAn differential. Fan starting differential (see par. ‘FSt’).

Fdt 1&2 Fan delay time. Delay time in activating fans after a defrost operation.

dt 1&2 drainage time. Dripping time.

dFd 1&2

defrost Fan disable. Allows to select the evaporator probes exclusion during defrost.

y = yes (fan disable); n = no.

FCO 2

Fan Compressor OFF. Allows to select compressor fans lock OFF (switched off).

y = fans activated (with thermostat; based on the value read by the defrost probe, see par. “FSt”); n =

fans off; dc = not used.

Fod 2

Fan open door. Fans active when the door is open.

Allows you to select the option of stopping the fans when the door is open, and re-starting the

fans when door is closed (if they were active). n = fans stop; y = fans unchanged.

ALARMS

Att 2

Allow you to select if the parameters HAL and LAL will have absolute (Att=0) or relative (Att=1)

value.

AFd 2 Alarm Fan differential. Alarm differential.

HAL 1&2

Higher ALarm. Maximum temperature alarm. Temperature value (in relative value) which if

exceeded in an upward direction triggers the activation of the alarm signal.

LAL 1&2

Lower ALarm. Minimum temperature alarm. Temperature value (in relative value), which if

exceeded in a downward direction, triggers the activation of the alarm signal.

PAO 2 Power-on Alarm Override. Alarm exclusion time after instrument switch on, after a power failure.

dAO 2 defrost Alarm Override. Temperature alarm exclusion time after defrost.

OAO 2

Alarm signaling delay after digital input disabling (door close). Alarm is only for high-low

temperature alarms.

tdO 2 time out door Open. Alarm activation delay time open door.

tAO 1&2 temperature Alarm Override. Temperature alarm signal delay time.

dAt 2

defrost Alarm time. Alarm for defrosting ended due to time out.

n = alarm deactivated; y = alarm activated.

EAL 2 External Alarm Clock. External alarm to lock loads (n = don’t lock loads; y = lock loads).

COMMUNICATION

dEA 2 Device address in family (valid values from 0 to 14).

FAA 2

Device family (valid values from 0 to 14). The FAA and dEA values represent the network address of

the equipment and are indicated in the following format “FF.DD” (where FF=FAA and DD=dEA).

Page 16

16

DISPLAY

LOC 1&2

LOCk. Setpoint change shutdown. See related paragraph. There is still the possibility to enter

into parameters programming and modify these, including the status of this parameter to

permit keyboard shutdown. n = no; y = yes.

PS1 1&2 PAssword 1. When enabled (value ≠ 0) it constitutes the access key for level 1 parameters.

PS2 2 PAssword 2. When enabled (value ≠ 0) it constitutes the access key for level 2 parameters.

ndt 2 number display type. View with decimal point. y = yes; n = no.

CA1 1&2 CAlibration 1. Positive or negative temperature value added to the value read by probe 1.

CA2 1&2 CAlibration 2. Positive or negative temperature value added to the value read by probe 2.

ddL 1&2

defrost display Lock. Viewing mode during defrosting.

0 = shows the temperature read by the room probe;

1 = locks the reading on the temperature value read by room probe when defrosting

starts, and until the next time the Setpoint value is reached;

2 = displays the label “dEF” during defrosting, and until the next time the Setpoint value

is reached.

dro 2

display read-out. Select °C or °F for displaying the temperature read by the thermostat probe.

(0 = °C, 1 = °F).

PLEASE NOTE: the switch between °C and °F DO NOT modify setpoint, differential, etc.

(for example set=10°C become 10°F)

ddd 2

Selection of type of value to be displayed.

0 = Setpoint; 1 = cold room probe (Pb1); 2 = evaporator probe (Pb2).

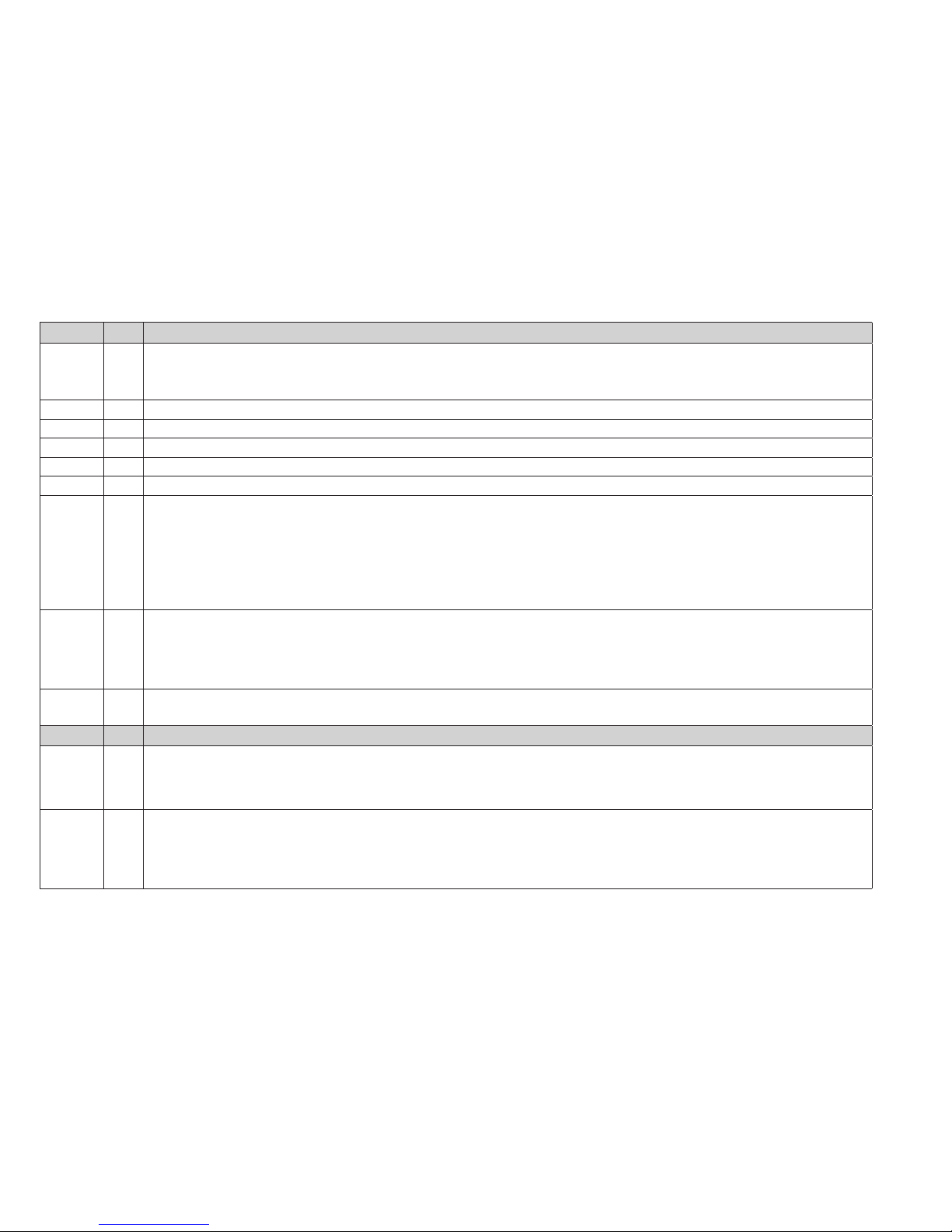

CONFIGURATION

H08 (!) 2

Stand-by operating mode. 0 = display switch off;

1 = display switch off, loads and alarms stopped;

2 = display with OFF label, loads and alarms stopped.

H11 (!) 2

Configuration of digital inputs/polarity. 0 = disabled; ±1 = defrosting; ±2 = reduced set;

±3 = not used; ±4 = door switch; ±5 = external alarm; ±6 = Stand-by (ON-OFF).

ATTENTION!:

the “+” sign indicates that the input is activated when the contact is closed.

the “-” sign indicates that the input is activated when the contact is open.

Page 17

17

H22 (!) 2

(Only EWPlus 971) Configurability of digital output 2 (B).

0 = Disabled; 1 = Compressor; 2 = Defrost; 3 = Fan; 4 = Alarm; 5 = AUX; 6 = Standby.

H23 (!) 2 (Only EWPlus 974) Configurability of digital output 3 (C). Same as H22.

H25 (!) 2 (Option) Enable/Disable the buzzer. 0 = Disabled; 4 = Buzzer; 1-2-3-5-6 = Not used.

H32 (!) 2

DOWN button configurability.

0 = disabled; 1 = defrost; 2 = not used; 3 = reduced set; 4 = stand-by.

H42 (!) 1&2 Evaporator probe present. n = not present; y = present.

reL 1&2 reLease firmware. Device version: read only parameter.

tAb 1&2 tAble of parameters. Reserved: read only parameter.

COPY CARD

UL 2 Up load. Programming parameter transfer from instrument to Copy Card.

Fr 2 Format. Erasing all data in the copy card.

(!) WARNING!

• If one or more of these parameters highlighted with (!) are modified, the controller must be switched off

and switched on again to ensure correct operation.

• Parameter H25 is present only in model with buzzer on board.

SUPERVISION

The device can be connected to:

• Telecontrol system TelevisSystem (°)

• ParamManager fast parameter setting software

The connection can be made via TTL serial port.

For connection to RS-485 bus use TTL/RS485 interface BusAdapter 150.

For connection to PC should be used:

• for TelevisSystem: PCInterface 1110/1120 with Televis license;

• for ParamManager: PCInterface 2150/2250 with ParamManager license;

(°) To configure the instrument for this purpose, use parameters “dEA” and “FAA” in the “Programming” menu.

NOTE: The instrument can be connected to TelevisSystem but the RVD function is not available.

Page 18

18

CONNECTIONS

EWPlus 902 TERMINALS

OUT1 regulator relay OUT1

N-L Power Supply (115Va or 230Va)

A TTL input

EWPlus 961 TERMINALS

Compressor relay

N-L Power Supply (115Va or 230Va)

A TTL input

EWPlus 961EWPlus 902

N

L

3 6 7 9

10

D.I.

Power Supply

4VA max

Pb1

4 5 11

(thermostat)

LOAD

OUT1

A

TTL

W

PLU

S

902

N

L

2 3 9

10

D.I.

Pb1

4 11

(A)

(thermostat)

A

TTL

W

PLU

S

961

Power Supply

4VA max

Page 19

19

CONNECTIONS

EWPlus 971 TERMINALS

Compressor relay

Defrost relay

N-L Power Supply (115Va or 230Va)

A TTL input

EWPlus 974 TERMINALS

Compressor relay

Defrost relay

Fans relay

N-L Power Supply (115Va or 230Va)

A TTL input

EWPlus 974EWPlus 971

N

L

2 3 6 7 8 9

10

D.I.

Pb1

4 5 11

Pb2

(A) (B)

(evaporator)

(thermostat)

A

TTL

W

PLU

S

971

Power Supply

4VA max

1

N

L

2 3 6 7 8 9

10

(C)

D.I.

Pb1

4 5 11

Pb2

(A) (B)

(evaporator)

(thermostat)

A

TTL

W

PLU

S

974

Power Supply

4VA max

Page 20

20

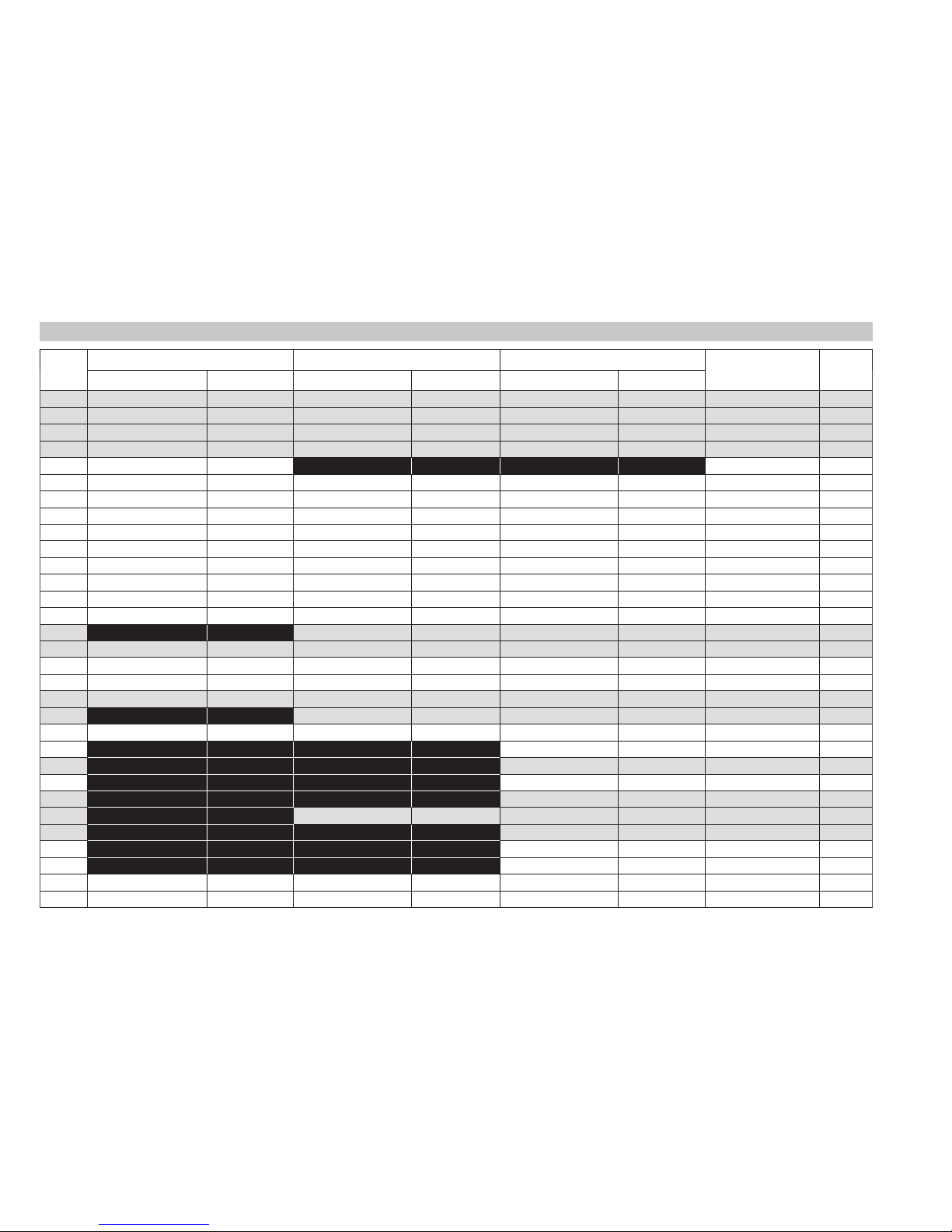

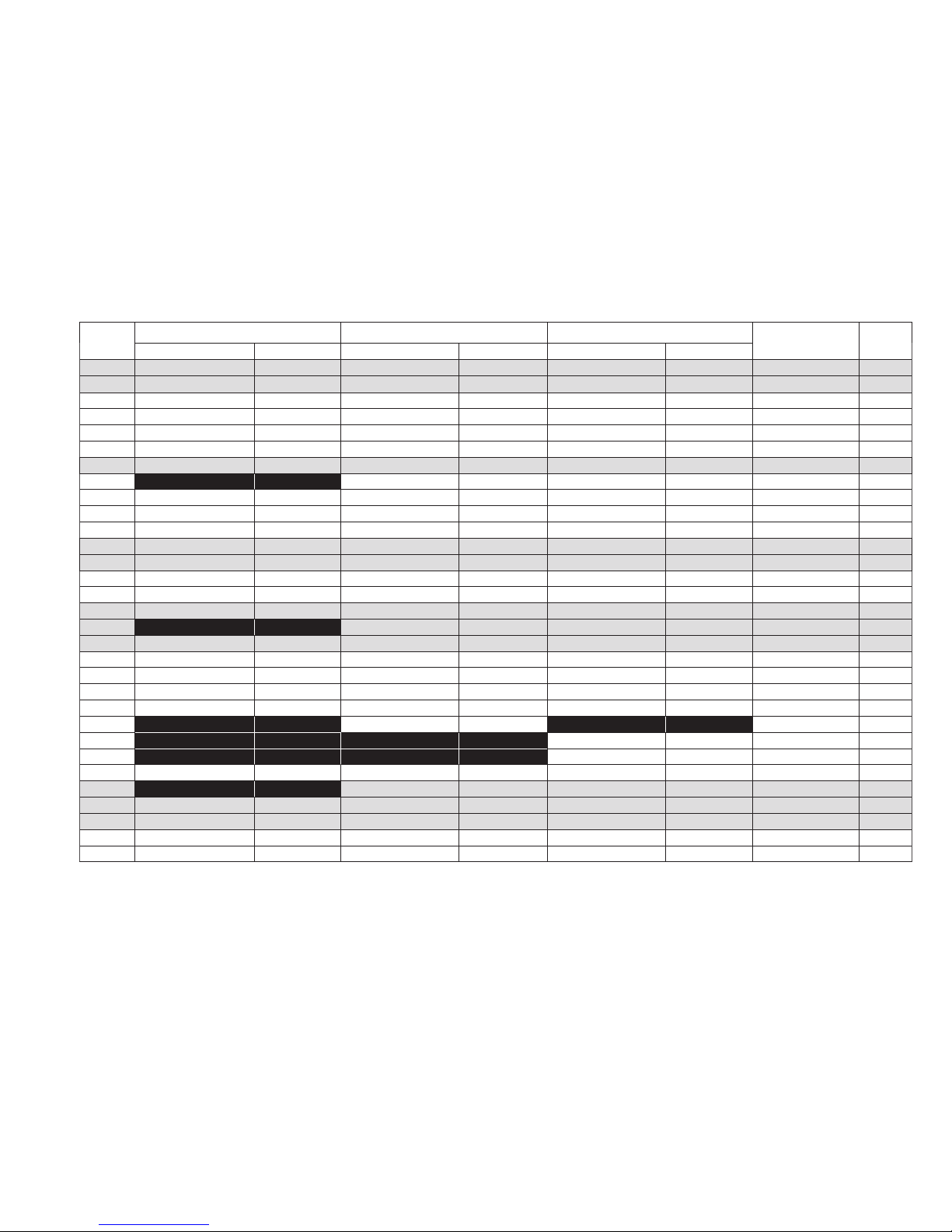

Parameters - Default setting

PAR

EWPlus 902/961 EWPlus 971 EWPlus 974

M.U. Level

RANGE DEFAULT RANGE DEFAULT RANGE DEFAULT

SEt -50,0 ... 99,0 32,0 -50,0 ... 99,0 32,0 -50,0 ... 99,0 32,0 °C/°F

diF 0,1 ... 30,0 2,0 0,1 ... 30,0 2,0 0,1 ... 30,0 2,0 °C/°F 1&2

HSE LSE ... 230 99,0 LSE ... 230 99,0 LSE ... 230 99,0 °C/°F 1&2

LSE -55,0 ... HSE -50,0 -55,0 ... HSE -50,0 -55,0 ... HSE -50,0 °C/°F 1&2

HC H/C C flag 2

OSP -30,0 ... 30,0 0,0 -30,0 ... 30,0 0,0 -30,0 ... 30,0 0,0 °C/°F 2

dOd n/y n n/y n n/y n flag 2

dAd 0 ... 255 0 0 ... 255 0 0 ... 255 0 min 2

Ont 0 ... 250 0 0 ... 250 0 0 ... 250 0 min 2

OFt 0 ... 250 1 0 ... 250 1 0 ... 250 1 min 2

dOn 0 ... 250 0 0 ... 250 0 0 ... 250 0 secs 2

dOF 0 ... 250 0 0 ... 250 0 0 ... 250 0 min 2

dbi 0 ... 250 0 0 ... 250 0 0 ... 250 0 min 2

OdO 0 ... 250 0 0 ... 250 0 0 ... 250 0 min 2

dty 0/1/2 0 0/1/2 0 flag 1&2

dit 0 ... 250 6 0 ... 250 6 0 to 250 6 hours 1&2

dCt 0/1/2 1 0/1/2 1 0/1/2 1 num 2

dOH 0 ... 59 0 0 ... 59 0 0 ... 59 0 min 2

dEt 1 ... 250 30 1 ... 250 30 1 ... 250 30 min 1&2

dSt -50,0 ... 150 45,0 -50,0 ... 150 45,0 °C/°F 1&2

dPO n/y n n/y n n/y n flag 2

FPt 0/1 0 flag 2

FSt -50,0 ... 150 100,0 °C/°F 1&2

FAd 1,0 ... 50,0 2,0 °C/°F 2

Fdt 0 ... 250 0 min 1&2

dt 0 ... 250 0 0 ... 250 0 min 1&2

dFd n/y y flag 1&2

FCO n/y y flag 2

Fod n/y n flag 2

Att 0/1 1 0/1 1 0/1 1 flag 2

AFd 1,0 ... 50,0 2,0 1,0 ... 50,0 2,0 1,0 ... 50,0 2,0 °C/°F 2

Page 21

21

PAR

EWPlus 902/961 EWPlus 971 EWPlus 974

M.U. Level

RANGE DEFAULT RANGE DEFAULT RANGE DEFAULT

HAL LAL ... 150,0 50,0 LAL ... +150,0 50,0 LAL ... 150,0 50,0 °C/°F 1&2

LAL -50,0 ... HAL -50,0 -50,0 ... HAL -50,0 -50,0 ... HAL -50,0 °C/°F 1&2

PAO 0 ... 10 0 0 ... 10 0 0 ... 10 0 hours 2

dAO 0 ... 999 0 0 ... 999 0 0 ... 999 0 min 2

0AO 0 ... 10 0 0 ... 10 0 0 ... 10 0 hours 2

tdO 0 ... 250 0 0 ... 250 0 0 ... 250 0 min 2

tAO 0 ... 250 0 0 ... 250 0 0 ... 250 0 min 1&2

dAt n/y n n/y n flag 2

EAL n/y n n/y n n/y n flag 2

dEA 0 ... 14 0 0 ... 14 0 0 ... 14 0 num 2

FAA 0 ... 14 0 0 ... 14 0 0 ... 14 0 num 2

LOC n/y n n/y n n/y n flag 1&2

PS1 0 ... 250 0 0 ... 250 0 0 ... 250 0 núm 1&2

PS2 0 ... 250 0 0 ... 250 0 0 ... 250 0 num 2

ndt n/y y n/y y n/y y flag 2

CA1 -12,0 ... 12,0 0,0 -12,0 ... 12,0 0,0 -12,0 ... 12,0 0,0 °C/°F 1&2

CA2 -12,0 ... 12,0 0,0 -12,0 ... 12,0 0,0 °C/°F 1&2

ddL 0/1/2 1 0/1/2 1 0/1/2 1 num 1&2

dro 0/1 1 0/1 1 0/1 1 flag 2

ddd 0/1/2 1 0/1/2 1 0/1/2 1 num 2

H08 0/1/2 2 0/1/2 2 0/1/2 2 num 2

H11 -6 ... +6 0 -6 ... +6 0 -6 ... +6 0 num 2

H22 0 ... 6 2 num 2

H23 0 ... 6 3 num 2

H25(!) 0 ... 6 4 num 2

H32 0 ... 4 0 0 ... 4 0 0 ... 4 0 num 2

H42 n/y y n/y y flag 1&2

rEL / / / / / / / 1&2

tAb / / / / / / / 1&2

UL / / / / / / / 2

Fr / / / / / / / 2

(!) WARNING!

Parameter H25 is present only in model with buzzer on board.

Page 22

22

ELECTRICAL WIRING

Attention! Never work on electrical connections when the machine is switched on.

The device is equipped with screw or removable terminals for connecting electric cables with a diameter of

13 AWG (2.5mm2) (one wire per terminal for power connections).

For the capacity of the terminals, see the label on the instrument. Do not exceed the maximum current allowed;

in case of higher loads, use an appropriate contactor. Make sure the power supply voltage complies with the

one required by the instrument. Probes have no connection polarity and can be extended using a regular

bipolar cable (note that the extension of the probes affects the EMC electromagnetic compatibility of the

instrument: pay extreme attention to wiring). Probe cables, power supply cables and TTL serial cables should

be separated from, and not placed near power cables.

RESPONSIBILITY AND RESIDUAL RISKS

In addition to the exclusions provided in the Warranty terms, Invensys Controls shall not be liable for any

damages deriving from:

- Installation and/or use other than that prescribed and, in particular, that does not comply with applicable

regulatory and safety standards, including the standards provided herein;

- Installation and/or use on boards which do not guarantee adequate protection against electric shock,

water, dust, or access to dangerous parts;

- Installation and/or use on boards that do not comply with applicable regulatory and safety standards;

- tampering with and/or alteration of the products.

DISCLAIMER

This manual and its contents remain the sole property of Robertshaw Controls Company, d/b/a Invensys

Controls, and shall not be reproduced or distributed without the written permission of an authorized

representative of Invensys Controls. Although considerable care has been exercised in the preparation of this

document, Invensys Controls, its employees, agents, vendors, and any other third parties cannot and do not

accept any liability whatsoever in connection with its use, preparation, editing, or any misprints and errors

contained herein. Invensys Controls reserves the right to make changes to this document at any time without

prior notice.

Page 23

23

WARRANTY ON EWPLUS 902/961/971/974 SERIES

Eighteen Months Limited Warranty

Invensys Controls warrants to the original contractor installer, or to the original consumer user, that each new

Eliwell Control will be free from defects in materials and workmanship under normal use and service for a

period of eighteen (18) months from the date of manufacture (the “Warranty Period”). If any Product fails within

the applicable Warranty Period, Invensys Controls shall, at its option, repair or replace the Product or credit

the purchase price, provided the Product is returned to Invensys Controls’ facility or designated agent within

the Warranty Period, with transportation or postage charges prepaid and proof of the date of purchase, and

the Product, upon examination by Invensys Controls, is found not to conform to the Warranty. Cost of Product

removal, labor, or reinstallation of new Product are not covered under this Warranty and are not the responsibility

of Invensys Controls. Warranty on Products, parts and/or components sold, but not manufactured by Invensys

Controls, shall be expressly limited to the warranty terms of the manufacturer of such products, parts and/or

components.

The above warranty does not apply to: i) batteries; ii) defects or damage that result from use of the Products in

other than their normal and customary manner; iii) defects or damage that result from use of the Products in

any manner other than in accordance with Invensys Controls’ recommendations and instructions; iv) defects or

damage which occur from misuse, alteration, accident, water, fire or neglect; and/or v) defects due to abuse or

damage such as burned contacts, stripped threads, split castings, improper installation or missing parts.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER

EXPRESS OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY, TITLE AND FITNESS

FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL INVENSYS CONTROLS BE LIABLE TO CONSUMER,

CONTRACTOR OR ANY THIRD PARTY FOR ANY CONSEQUENTIAL, INCIDENTIAL, SPECIAL, EXEMPLARY, OR

PUNITIVE DAMAGES ARISING FROM OR RELATING TO USE OF THE PRODUCT INCLUDING, BUT NOT LIMITED

TO, LOSS OF GOODWILL, LOSS OF PROFIT OR REVENUE, AND PROPERTY DAMAGE, REGARDLESS WHETHER

SUCH LOSS OR DAMAGE IS BASED IN CONTRACT, WARRANTY, TORT, NEGLIGENCE, STRICT LIABILITY,

INDEMNITY, PRODUCT LIABILITY, OR OTHERWISE AND EVEN IF INVENSYS CONTROLS HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGES.

Page 24

24

WARRANTY ON EWPLUS 902/961/971/974 SERIES (Cont.)

REPAIR, REPLACEMENT, OR CREDIT OF THE PURCHASE PRICE, AS PROVIDED HEREIN, SHALL CONSTITUTE

BUYER’S SOLE RIGHTS AND REMEDIES WITH RESPECT TO DEFECTS IN THE PRODUCTS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations

on how long an implied warranty lasts, so the above limitations or exclusions may not apply to you. This Warranty

gives you specific legal rights, and you may also have other rights which vary from state to state.

For Warranty returns, send controls, shipping prepaid and proof of date of purchase to:

Invensys Controls

Warranty Claims Department

515 S. Promenade

Corona, CA 91719

In Canada:

Invensys Controls

Warranty Claims Department

3505 Laird Road Unit #14

Mississauga, Ontario L5L 5Y7 Canada

Page 25

25

Controles electrónicos para unidades de refrigeración

STAND-BY (ESC)

Pulsar y soltar

Regresa a un nivel anterior respecto al

menú actual

Confirma el valor del parámetro

Pulsar durante al menos 5 s

Activa la función Stand-by

(cuando no estoy dentro del menú)

Subir

Pulsar y soltar

Recorre las opciones del menú

Aumenta los valores

Pulsar durante al menos 5 s

Activa la función de descarche manual

Bajar

Pulsar y soltar

Recorre las opciones del menú

Aumenta los valores

Pulsar durante al menos 5 s

Función configurable por el usuario

(par. H32)

SET (ENTER)

Pulsar y soltar

Muestras las alarmas (si las hay)

Entra en el menú Estado Máquina

Pulsar durante al menos 5 s

Entra en el menú Programación

Confirma los mandos

set

TECLAS

EW

PLUS

902/961

EW

PLUS

971/974

ESPAÑOL

Page 26

26

LED

SET Reducido / Economy

Intermitente: set reducido activado

Intermitente rápido: encendido con

parámetros de nivel 2

Off: en caso contrario

Led Compresor

Encendido fijo: compresor activado

Intermitente: retardo, protección o

activación bloqueada

Off: en caso contrario

Led Defrost (Descarche)

Encendido fijo: descarche activado

Intermitente: activación manual o desde E.D.

Off: en caso contrario

Led Ventilador

Encendido fijo: ventiladores activados

Off: en caso contrario

(sólo EWPlus 971 y EWPlus 974)

Led Alarma

Encendido fijo: presencia de una alarma

Intermitente: alarma silenciada

Off: en caso contrario

Led Estado HEAT

Encendido fijo: compresor en HEAT

Off: en caso contrario

(sólo EWPlus 902 y EWPlus 961)

NO UTILIZADO

(sólo EWPlus 902 y EWPlus 961)

Led Aux

Encendido fijo: salida Aux activada*

*según el modelo

(sólo EWPlus 971 y EWPlus 974)

Led °C

Encendido fijo: configuración en °C (dro = 0)

Off: en caso contrario

Led °F

Encendido fijo: configuración en °F (dro = 1)

Off: en caso contrario

Nota:

Si el instrumento está programado en modalidad Frío

(COOL), para poderlo utilizar en modalidad Calor

(HEAT) es necesario reprogramarlo con la Copy Card

debidamente configurada.

Lo mismo ocurre para pasar de Calor a Frío.

Page 27

27

ACCESO Y USO DE LOS MENÚS

Los recursos están agrupados en dos menús a los que se accede como se indica a continuación:

• Menú “Estado Máquina”: pulsar y soltar la tecla

set

.

• Menú “Programación”: pulsar la tecla

set

durante más de 5 segundos.

Esperar 15 segundos sin utilizar el teclado (tiempo máximo) o pulsar una vez la tecla para confirmar el

último valor que aparece en el display y regresar a la página anterior.

MENÚ ESTADO MÁQUINA

Pulsar y soltar la tecla

set

para entrar en el menú “Estado Máquina”. Si no hay ninguna alarma activada, se

visualiza la etiqueta “SEt”. Pulsar las teclas

y para recorrer las carpetas del menú “Estado Máquina”:

- AL: carpeta de alarmas (sólo se visualiza si hay alarmas activadas);

- SEt: carpeta de configuración

- Pb1: carpeta del valor de la sonda 1;

- Pb2: carpeta del valor de la sonda 2 **;

(** sólo modelos EWPlus 971 y EWPlus 974)

Configurar el Setpoint: Para ver el valor del Setpoint, pulsar la tecla

set

mientras se visualiza la etiqueta

“SEt”. El valor del Setpoint aparecerá en el display. Para modificar el valor del

Setpoint, pulsar las teclas y antes de que transcurran 15 s. Para confirmar la

modificación, pulsar

set

.

Ver las sondas: Desde las etiquetas Pb1 o Pb2*, pulsar la tecla

set

para ver el valor medido por la

sonda asociada (* Pb2 sólo se visualiza en los modelos EWPlus 971 y EWPlus 974).

BLOQUEO DE MODIFICACIÓN DEL SETPOINT

El instrumento permite desactivar el funcionamiento del teclado.

El teclado se puede bloquear programando el parámetro “LOC”. Aunque el teclado esté bloqueado, es

posible acceder al menú “Estado Máquina” pulsando la tecla

set

y ver el Setpoint. El valor no se podrá

modificar. Para desbloquear el teclado, repetir el procedimiento de bloqueo.

set

set

set set

Page 28

28

MENÚ DE PROGRAMACIÓN

Para entrar en el menú de “Programación”, pulsar durante más de 5 s la tecla

set

. Si está activada, el sistema

solicitará la CONTRASEÑA de acceso “PA1” para mostrar los parámetros de nivel 1 y “PA2” para mostrar los de

nivel 2 (ver apartado “CONTRASEÑA”). Al entrar en el menú, el display mostrará el primer parámetro (“diF”).

Pulsar las teclas

y para recorrer todos los parámetros del nivel actual:

5 sec

Seleccionar el parámetro deseado con las teclas y . Pulsar la tecla

set

para ver el valor actual del

parámetro. Utilizar las teclas y para modificar el valor y pulsar la tecla

set

para guardarlo.

NOTA: se recomienda apagar y volver a encender el instrumento siempre que se modifique la configuración de

los parámetros para evitar anomalías de funcionamiento en la configuración y/o los temporizadores activados.

CONTRASEÑA

Contraseña “PA1”: Autoriza el acceso a los parámetros de nivel 1. En la configuración estándar la contraseña

no está habilitada (valor = 0). Para habilitarla (valor ≠ 0) entrar en el menú Programación, pulsar las teclas y

para recorrer los parámetros hasta seleccionar la etiqueta “PS1”, pulsar

set

para ver el valor, modificarlo con

las teclas y y pulsar

set

para guardarlo. Si la contraseña está habilitada, el sistema la solicitará al entrar en

el menú “Programación”. Para introducirla, seguir la secuencia:

Contraseña “PA2”: Autoriza el acceso a los parámetros de nivel 2. En la configuración estándar está habilitada

(valor ≠ 0). Para modificar el valor, seguir las operaciones descritas para “PA1” y cambiar el valor del parámetro

“PS2”. La visibilidad de “PA2” es:

1) Si PA1 y PA2 ≠ 0: Pulsando la tecla

set

durante más de 5 s, “PA1” y “PA2” se visualizarán en el mismo nivel y será

posible acceder a los parámetros de nivel 1 o de nivel 2.

2) En los demás casos: La contraseña “PA2” se encuentra entre los parámetros de nivel 1. Si está habilitada, será

solicitada para acceder al nivel 2. Para introducirla, realizar las operaciones descritas para la contraseña “PA1”.

Si la contraseña introducida es incorrecta, el instrumento muestra la etiqueta PA1/PA2 y es necesario repetir la

secuencia de introducción.

set

setset

set

set

set

Page 29

29

ALARMAS

Etiqueta Avería Causa Efectos Soluciones

E1

Sonda1 averiada

(cámara)

• Lectura de valores fuera del rango de

funcionamiento

• Sonda averiada / en cortocircuito

/ abierta

• Visualización de etiqueta E1

• Icono de alarma fijo

• Desactivación del control de alarma de

máxima y mínima

• Funcionamiento del compresor según

los parámetros “Ont” y “OFt”.

• Controlar el tipo de sonda (NTC)

• Controlar el cableado de las

sondas

• Sustituir la sonda

E2

Sonda2 averiada

(descarche)

• Lectura de valores fuera del rango de

funcionamiento

• Sonda averiada / en cortocircuito

/ abierta

• Visualización de etiqueta E2

• Icono de alarma fijo

• El ciclo de descarche termina por tiempo

máximo (parámetro “dEt”)

• Controlar el tipo de sonda (NTC)

• Controlar el cableado de las

sondas

• Sustituir la sonda

AH1

Alarma de ALTA

temperatura de la

sonda 1

Valor leído por Pb1 > HAL transcurrido

un tiempo equivalente a “tAO”

(ver “ALARMAS DE TEMP. MÁX. Y MÍN.)

• Registro de etiqueta AH1 en carpeta AL

• Sin efecto sobre la regulación

• Esperar a que el valor de

temperatura leído por la sonda 1

descienda por debajo de HAL

AL1

Alarma de BAJA

temperatura de la

sonda 1

Valor leído por Pb1 > LAL transcurrido

un tiempo equivalente a “tAO”

(ver “ALARMAS DE TEMP. MÁX. Y MÍN.)

• Registro de etiqueta AL1 en carpeta AL

• Sin efecto sobre la regulación

• Esperar a que el valor de

temperatura leído por la sonda 1

descienda por debajo de LAL

EA Alarma exterior

• Activación de la entrada digital

(H11 = ±5)

• Registro de etiqueta EA en carpeta AL

• Icono de alarma fijo

• Bloqueo de la regulación si EAL = y

• Comprobar y eliminar la causa

externa que ha generado la

alarma en la E.D.

OPd

Alarma puerta

abierta

• Activación de la entrada digital

(H11 = ±4) (durante un periodo de

tiempo mayor que tdO)

• Registro de etiqueta Opd en carpeta AL

• Icono de alarma fijo

• Bloqueo del control

• Cerrar la puerta

• Función de retardo definida

por OAO

Ad2

Descarche por

tiempo máximo

• Fin de descarche por tiempo en

lugar de por temperatura de fin de

descarche medida por la sonda Pb2

• Registro de etiqueta dAt en carpeta AL

• Icono de alarma fijo

• Esperar el descarche sucesivo para

restablecimiento automático

Page 30

30

74 mm

32 mm

29 mm

71 mm

70 mm

59 mm

ACTIVACIÓN MANUAL DEL CICLO DE DESCARCHE

La activación manual del ciclo de descarche se obtiene manteniendo pulsada durante 5 s la tecla .

Si no se dan las condiciones de descarche necesarias:

- El parámetro OdO ≠ 0 (EWPlus 902/961/971/974)

- La temperatura de la sonda del evaporador Pb2 supera la temperatura final de descarche (EWPlus 971/974)

el display parpadeará 3 veces para indicar que el descarche no será efectuado.

DIAGNÓSTICO

En caso de alarma el zumbador (si lo hay) se activa y el icono de alarma se enciende.

Para silenciar el zumbador, pulsar y soltar una tecla cualquiera. El icono de alarma seguirá parpadeando.

NOTAS: Durante los tiempos de inhabilitación de alarmas (carpeta “AL” de la Tabla de Parámetros), la alarma

no es señalizada.

El aviso E1 de alarma por sonda 1 averiada (Pb1) aparece directamente

en el instrumento.

Modelos EWPlus 971/974: El aviso de alarma por sonda 2 averiada

(Pb2) aparece directamente en el instrumento.

INSTALACIÓN

El instrumento ha sido diseñado para la instalación en panel. Realice un orificio de 2-13/16” x 1-1/8”

(71x29mm), introduzca el instrumento y fíjelo con los soportes que se suministran. No instale el instrumento

en lugares excesivamente húmedos y/o sucios, es adecuado para el uso en ambientes con polución ordinaria

o normal. La zona próxima a las ranuras de refrigeración del instrumento ha de estar bien ventilada.

Page 31

31

CÓMO UTILIZAR LA COPY CARD

La Copy Card es un accesorio que, conectándolo a un puerto de serie de tipo TTL, permite programar de modo

rápido los parámetros del instrumento (cargar y descargar un mapa de parámetros en uno o más instrumentos

del mismo tipo). Para cargar (etiqueta UL) y formatear la Copy Card (etiqueta Fr), es necesario efectuar las

siguientes operaciones:

Introducir la contraseña “PA2” y recorrer las opciones con las teclas y para seleccionar la función

deseada (por ejemplo UL). Pulsar la tecla

set

para iniciar la descarga.

Si el proceso termina con éxito, el display mostrará “y”; en caso de error, mostrará “n”.

Cargar (UL) Esta operación sirve para cargar los parámetros de programación desde el instrumento.

CARGAR: instrumento

Copy Card

Formato: (Fr)

Este comando sirve para formatear la Copy Card. Se recomienda efectuar esta operación cuando la

Copy Card se utiliza por primera vez. Atención: si el parámetro “Fr” se utiliza cuando la Copy Card

ya está programada, todos los parámetros que contiene serán cancelados. Esta operación no se

puede anular.

Descarga mediante reset:

Conectar la Copy Card al instrumento mientras está apagado.

Al encenderlo, el proceso de descarga desde la Copy Card

se iniciará en automático. Una vez completado el test de las

lámparas, el display mostrará “dLy” si el proceso termina

con éxito y “dLn” en caso de error.

DESCARGA: Copy Card

instrumento

NOTAS: Una vez completado el proceso de descarga, el instrumento utilizará las configuraciones del nuevo

mapa que se acaba de cargar.

UPLOAD

DOWNLOAD

set

Page 32

32

ALARMA DE TEMPERATURA MÁX. Y MÍN.

Temperatura en Valor

Relativo al Setpoint (Att=1)

Temperatura en Valor

Absoluto (Att=0)

Temp. ≤ Set + LAL *

Temp. ≥ Set + HAL **

Temp. ≥ Set + LAL + AFd o

≥ Set - ILALI + AFd (LAL < 0)

Temp. ≤ Set + HAL - AFd (HAL > 0)

Temp. ≤ ( con signo)

Temp. ≥ HAL (HAL con signo)

Temp. ≥ LAL + AFd

Temp. ≤ HAL - AFd

Alarma de

temperatura mínima

Alarma de

temperatura máxima

Restablecimiento

tras alarma de

temperatura mínima

Restablecimiento tras

temperatura máxima

* si LAL es negativo, Set + LAL < Set

** si HAL es negativo, Set + HAL < Set

Setpoint - LAL

AFd

Off

Setpoint + HAL

AFd

Setpoint - LAL + AFd

Setpoint + HAL - AFd

Setpoint

LAL

AFd

HAL

AFd

LAL + AFd

HAL - AFd

Page 33

33

CONDICIONES DE USO

Uso permitido

Con el fin de lograr una mayor seguridad, el instrumento debe instalarse y utilizarse según las instrucciones

suministradas y en condiciones normales no deberán ser accesibles las piezas con tensiones peligrosas. El

dispositivo debe estar protegido adecuadamente contra el agua y el polvo según su aplicación y ser accesible

sólo con el uso de una herramienta (con excepción del frontal). El dispositivo es idóneo para equipos

refrigerantes de uso doméstico y/o similares y su seguridad se ha verificado según las normas armonizadas

europeas de referencia.

Uso no permitido

Está totalmente prohibido cualquier otro uso distinto del permitido. Se debe tener en cuenta que los

contactos de relé suministrados son de tipo funcional y pueden averiarse: los dispositivos de protección

previstos por la normativa del producto o bien sugeridos por el sentido común, según específicas exigencias

de seguridad, deben estar instalados fuera del instrumento.

DATOS TÉCNICOS

Clasificación: Dispositivo de funcionamiento (no de seguridad) para incorporar

Instalación: Sobre panel con plantilla de montaje 2-13/16” x 1-1/8” (71x29mm).

Tipo de acción: 1.B

Grado de contaminación: 2

Grupo de material: IIIa

Categoría de sobretensión: II

Tensión impulsiva nominal: 2500 V

Temperatura: Uso: –5 a +65°C (+23 a +149°F) - Almacenamiento: –30 a +85°C (–22 a +185°F)

Alimentación eléctrica: 115Va or 230Va (

+

10% / -10%) 50/60 Hz

Consumo: 4VA máx.

Salidas digitales (relé): Consultar la etiqueta del dispositivo

Grado de resistencia al fuego: D

Clase del software: A

Nota: Controle la alimentación declarada en la etiqueta del instrumento; consulte con el departamento

comercial para obtener información sobre las capacidades de los relés y la alimentación.

Page 34

34

Características de las entradas

Rango de visualización: NTC –50°C a +110°C (–58°C a +230°F)

(en el display con 3 dígitos + signo)

Precisión: Mejor del 0.5% del final de escala +1 dígito

Definición: 0.1°C (0.1°F hasta 199.9°C ; 1°F más allá)

Zumbador: SÍ (según el modelo)

Entradas analógicas: EWPlus 902/961: 1 entrada NTC - EWPlus 971/974: 2 entradas NTC

Entradas digitales: 1 entrada digital sin tensión

Características de las salidas

Salidas

digitales:

Modelo Relé Tipo de carga

Alimentación 115VA Alimentación 230VA

EWPlus 902:

OUT1 - N.A.

resistivo 8A 8A

motor 1/8 Hp 1/2 Hp

OUT1 - N.C. resistivo 6A 6A

EWPlus 961: compresor motor 16 FLA / 96 LRA 12 FLA / 72 LRA

EWPlus 971:

compresor motor 16 FLA / 96 LRA 12 FLA / 72 LRA

descarche - N.A.

resistivo 8A 8A

motor 1/8 Hp 1/2 Hp

descarche - N.C. resistivo 6A 6A

EWPlus 974:

compresor motor 16 FLA / 96 LRA 12 FLA / 72 LRA

descarche - N.A.

resistivo 8A 8A

motor 1/8 Hp 1/2 Hp

descarche - N.C. resistivo 6A 6A

ventiladores

resistivo 3A 3A

motor 1.4 FLA / 7.5 LRA 1.4 FLA / 7.5 LRA

Características mecánicas

Caja: Cuerpo plástico de resina PC UL94 V-0, cristal de policarbonato

Dimensiones: Frontal 2-15/16” x 1-1/4” (74x32mm), profundidad 2-15/16” (59mm) (bornes excluidos)

Bornes: De tornillo/extraíbles para cables con sección de 13 AWG

(2.5 mm2)

Conectores: TTL para conectar la Copy Card

Humedad: Funcionamiento / Almacenamiento: 10 a 90% HR (sin condensación)

Page 35

35

Normas

Compatibilidad Electromagnética: El dispositivo cumple los requisitos de la Directiva 2004/108/EC

Seguridad: El dispositivo cumple los requisitos de la Directiva 2006/95/EC

Seguridad alimentaria: El dispositivo cumple los siguientes requisitos de la Norma EN13485:

- idóneo para la conservación

- aplicacion: aire

- clase climática A

- clase de medición 1 en el rango de -25°C to 15°C (-13°F to 59°F) (*)

(*sólo y exclusivamente si se utilizan sondas Eliwell NTC)

NOTA: Las características técnicas inherentes a las medidas (rango, precisión, definición, etc.), que se incluyen en

el documento, se refieren al instrumento en sí mismo y no a los accesorios en dotación como, por ejemplo, las

sondas. Esto implica, por ejemplo, que el error introducido por la sonda se agrega al característico del instrumento.

TABLA DE PARÁMETROS

PAR. Niv. DESCRIPCIÓN

SEt

SEtpoint de regulación de la temperatura.

COMPRESOR

diF 1&2

diFferential. Diferencial de activación del relé del compresor; el compresor se apaga al alcanzar el valor

de Setpoint configurado (por indicación de la sonda Pb1) y se vuelve a encender cuando la temperatura

alcanza un valor equivalente al setpoint más el valor del diferencial. Nota: diF ≠ 0.

HSE 1&2

Higher SEt. Valor máximo de setpoint.

LSE 1&2

Lower SEt. Valor mínimo de setpoint.

HC 2

El control aplicará una modalidad de funcionamiento para CALOR (“H”) o para FRÍO (“C”)

OSP 2

Offset Set Point. Valor de temperatura que se ha de sumar algebraicamente al Set-Point si el set reducido

está habilitado (función Economy).

dOd 2

digital (input) Open door. Entrada digital que permite apagar los dispositivos. Válido si H11=±4

(microinterruptor de la puerta). n = no apagar los dispositivos; y = apagar los dispositivos.

dAd 2

digital (input) Activation delay. Tiempo de retardo para la activación de la entrada digital.

Ont 2

ON time (compressor). Tiempo de encendido del compresor por sonda averiada. Si OFt=1 y Ont=0, el

compresor permanece siempre apagado, si OFt=1 y Ont>0 funciona en modalidad duty cycle.

OFt 2

OFF time (compressor). Tiempo de apagado del compresor por sonda averiada. Si Ont=1 y OFt=0, el

compresor permanece siempre encendido, si Ont=1 y OFt>0 funciona en modalidad duty cycle.

Page 36

36

dOn 2 delay (at) On compressor. Tiempo de retardo para la activación del relé del compresor desde la llamada.

dOF 2

delay (after power) OFF. Tiempo de retardo tras el apagado; entre el apagado del relé del compresor

y el encendido sucesivo debe transcurrir el tiempo indicado.

dbi 2

delay between power-on. Tiempo de retardo entre encendidos; entre dos encendidos sucesivos del

compresor debe transcurrir el tiempo indicado.

OdO (!) 2

delay Output (from power) On. Tiempo de retardo para la activación de las salidas desde el

encendido del instrumento o tras un corte de corriente.

DESCARCHE

dty 1&2

defrost type. Tipo de descarche.

0 = descarche eléctrico - compresor apagado (OFF) durante el descarche;

1 = descarche con inversión de ciclo (gas caliente);

compresor encendido (ON) durante el descarche;

2 = descarche en modalidad Free; descarche independiente del compresor.

dit 1&2 defrost interval time. Intervalo de tiempo entre dos descarches sucesivos.

dCt 2

defrost Counting type. Selección del modo de cómputo del intervalo de descarche.

0 = horas de funcionamiento del compresor (método DIGIFROST®); Descarche activado SÓLO

con compresor encendido;

1 = Real Time - horas de funcionamiento del aparato; el cómputo de descarche permanece

siempre activado cuando la máquina está encendida y se inicia siempre al encenderla;

2 = parada compresor. Cada vez que el compresor se para se inicia un ciclo de descarche en

función del parámetro dty.

dOH 2 defrost Offset Hour. Tiempo de retardo para iniciar el primer descarche desde la llamada.

dEt 1&2

defrost Endurance time. Tiempo máximo de descarche; determina la duración máxima del descarche.

dSt 1&2

defrost Stop temperature. Temperatura de fin de descarche (determinada por la sonda del evaporador).

dPO 2

defrost (at) Power On. Determina si el instrumento debe iniciar el descarche al encenderlo (si la

temperatura medida lo permite). y = sí; n = no.

VENTILADORES EVAPORADOR

FPt 2

Fan Parameter type. Caracteriza el parámetro “FSt” que se puede expresar en valor absoluto de

temperatura o en valor relativo al Setpoint. 0 = absoluto; 1 = relativo.

FSt 1&2

Fan Stop temperature. Temperatura de bloqueo de los ventiladores; si el valor leído por la sonda

del evaporador supera el valor programado, los ventiladores se paran.

FAd 2 FAn differential. Diferencial de intervención para activación de los ventiladores (ver par. “FSt”).

Fdt 1&2 Fan delay time. Tiempo de retardo para la activación de los ventiladores tras un descarche.

Page 37

37

dt 1&2 drainage time. Tiempo de goteo.

dFd 1&2

defrost Fan disable. Permite seleccionar la desactivación de los ventiladores del evaporador durante

el descarche. y = sí (ventilador desactivado o apagado); n = no.

FCO 2

Fan Compressor OFF. Permite seleccionar el bloqueo de los ventiladores con el compresor OFF

(apagado). y = ventiladores activados (termostatación; en función del valor leído por la sonda de

descarche, ver el parámetro “FSt”); n = ventiladores apagados; dc = no utilizado;

Fod 2

Fan open door. Activación de los ventiladores si la puerta está abierta.

Permite seleccionar el bloqueo de los ventiladores con la puerta abierta y su activación al cerrarla (si

estaban activados). n = bloqueo ventiladores; y = ventiladores sin variación de estado.

ALARMAS

Att 2

Permite seleccionar si los parámetros HAL y LAL deben tener un valor absoluto (Att=0) o relativo

(Att=1).

AFd 2 Alarm Fan differential. Diferencial de alarmas.

HAL 1&2

Higher ALarm. Alarma de temperatura máxima. Valor de temperatura (en valor relativo) por encima

del cual se activa la señal de alarma.

LAL 1&2

Lower ALarm. Alarma de temperatura máxima. Valor de temperatura (en valor relativo) por debajo

del cual se activa la señal de alarma.

PAO 2

Power-on Alarm Override. Tiempo de desactivación de las alarmas al encender el instrumento tras

un corte de corriente.

dAO 2 defrost Alarm Override. Tiempo de desactivación de las alarmas de temperatura tras el descarche.

0AO 2

Retardo para la activación de la alarma tras la desactivación de la entrada digital (puerta cerrada).

Por alarma se entiende la alarma de alta y baja temperatura.

tdO 2 time out door Open. Tiempo de retardo para la activación de la alarma por puerta abierta.

tAO 1&2 temperature Alarm Override. Tiempo de retardo para la activación de la alarma de temperatura.

dAt 2

defrost Alarm time. Activación de alarma por fin de descarche por tiempo máximo.

n = no activar alarma; y = activar alarma.

EAL 2 External Alarm Clock. Una alarma externa bloquea los controles (n = no bloquear; y = bloquear).

COMUNICACIÓN

dEA 2 Índice del dispositivo dentro de la familia (valores válidos de 0 a 14).

FAA 2

Familia de dispositivo (valores válidos de 0 a 14). El par de valores FAA y dEA es la dirección de red

del dispositivo y posee el siguiente formato “FF.DD” (donde FF=FAA y DD=dEA).

Page 38

38

DISPLAY

LOC 1&2

LOCk. Bloqueo de modificación del Setpoint. Ver el apartado correspondiente. Es posible entrar

en la programación de parámetros y modificar incluso su estado para permitir el desbloqueo del

teclado. n = no; y = sí.

PS1 1&2

PAssword 1. Si está habilitada (valor distinto de 0), activa la contraseña de acceso a los parámetros

de nivel 1.

PS2 2

PAssword 2. Si está habilitada (valor distinto de 0), activa la contraseña de acceso a los parámetros

de nivel 2.

ndt 2 number display type. Visualización con punto decimal. y = sí; n = no.

CA1 1&2 Calibración 1. Valor de temperatura positivo o negativo que se suma al leído por la sonda 1.

CA2 1&2 Calibración 2. Valor de temperatura positivo o negativo que se suma al leído por la sonda 2.

ddL 1&2

Defrost display Lock. Modalidad de visualización durante el descarche.

0 = muestra la temperatura leída por la sonda de la cámara;

1 = bloquea la lectura en el valor de temperatura leído por la sonda de la cámara desde que se

activa el descarche y hasta que se alcanza el valor de Setpoint;

2 = muestra la etiqueta “dEF” durante el descarche y hasta que se alcanza el valor de Setpoint.

dro 2

Display read-out. Selecciona la unidad de visualización de la temperatura leída por la sonda en °C

o °F. (0 = °C, 1 = °F).

NOTA: al pasar de °C a °F y viceversa, NO se modifican los valores del setpoint, el diferencial,

etc. (por ejemplo set = 10 °C será 10 °F).

ddd 2

Selección del tipo de valor que ha de mostrar el display.

0 = Setpoint; 1 = sonda de la cámara (Pb1); 2 = sonda del evaporador (Pb2).

CONFIGURACIÓN

H08 (!) 2

Modalidad de funcionamiento en stand-by.

0 = apagar sólo el display;

1 = apagar el display, bloquear los controles y las alarmas;

2 = mostrar OFF en el display y bloquear los controles y las alarmas.

H11 (!) 2

Configuración de las entradas digitales y la polaridad.

0 = desactivado; ±1 = descarche; ±2 = set reducido; ±3 = no utilizado;

±4 = microinterruptor puerta; ±5 = alarma externa; ±6 = Stand-by (ON-OFF).

¡ATENCIÓN!: signo “+” indica que la entrada se activa con contacto cerrado.

signo “-” indica che la entrada se activa con contacto abierto.

Page 39

39

H22 (!) 2

(Solo EWPlus 971) Configuración salida digital 2 (B).

0=Deshabilitada; 1=Compressor; 2=Desescarghe; 3=Ventiladores; 4=Alarma; 5=AUX; 6=StandBy.

H23 (!) 2 (Solo EWPlus 974) Configuración salida digital 3 (C). Análogo a H21.

H25 (!) 2 (Opciòn) Activa/Desactiva el zumbador. 0 = Deshabilitada; 4 = Buzzer; 1-2-3-5-6 = No se utiliza.

H32 (!) 2

Configuración de la tecla DOWN.

0 = desactivada; 1 = descarche; 2 = no utilizada; 3 = set reducido; 4 = stand-by.

H42 (!) 1&2 Presencia de la sonda del evaporador. n = no presente; y = presente.

reL 1&2 reLease firmware. Versión de dispositivo: parámetro de solo lectura.

tAb 1&2 tAble of parameters. Reservado: parámetro de solo lectura.

COPY CARD

UL 2 Up Load. Envío de los parámetros de programación del instrumento a la Copy Card.

Fr 2 Format. Eliminación de todos los datos contenidos en la Copy Card.

(!) ¡ATENCIÓN!

• Cuando se modifica uno o más parámetros marcados con (!), es necesario apagar y volver a encender el

control para garantizar el funcionamiento correcto.

• El parámetro H25 sólo está presente en los modelos equipados con zumbador.

SUPERVISIÓN

El instrumento se puede conectar:

• al sistema de telegestión TelevisSystem (°)

• a un software de configuración rápida de los parámetros ParamManager

La conexión se efectúa a través de un puerto de serie TTL.

Para efectuar la conexión a la red RS-485, se debe utilizar la interfaz TTL/RS485 BusAdapter 150.

Para la conexión al PC, se debe utilizar:

• para TelevisSystem: PCInterface 1110/1120 con licencia Televis;

• para ParamManager: PCInterface 2150/2250 con licencia ParamManager;

(°) Para configurar el instrumento, se deben utilizar los parámetros “dEA” y “FAA” del menú “Programación”.

NOTA: El instrumento se puede conectar a TelevisSystem pero la función RVD no estará disponible.

Page 40

40

CONEXIONES

BORNES EWPlus 902

OUT1 relé del control OUT1

N-L Alimentación (115Va o 230Va)

A Entrada TTL

BORNES EWPlus 961

Relé del compresor

N-L Alimentación (115Va o 230Va)

A Entrada TTL

EWPlus 961EWPlus 902

N

L

3 6 7 9

10

D.I.

Alimentación

4VA máx

Pb1

4 5 11

(cámara)

CARGA

OUT1

A

TTL

W

PLU

S

902

N

L

2 3 9

10

D.I.

Pb1

4 11

(A)

(cámara)

A

TTL

W

PLU

S

961

Alimentación

4VA máx

Page 41

41

CONEXIONES

BORNES EWPlus 971

Relé del compresor

Relé de descarche

N-L Alimentación (115Va o 230Va)

A Entrada TTL

BORNES EWPlus 974

Relé del compresor

Relé de descarche

Relé de los ventiladores

N-L Alimentación (115Va o 230Va)

A Entrada TTL

EWPlus 974EWPlus 971

N

L

2 3 6 7 8 9

10

D.I.

Pb1

4 5 11

Pb2

(A) (B)

(descarche)

(cámara)

A

TTL

W

PLU

S

971

Alimentación

4VA máx

1

N

L

2 3 6 7 8 9

10

(C)

D.I.

Pb1

4 5 11

Pb2

(A) (B)

(descarche)

(cámara)

A

TTL

W

PLU

S

974

Alimentación

4VA máx

Page 42

42

Parámetros - Ajuste predefinido

PAR

EWPlus 902/961 EWPlus 971 EWPlus 974

U.M. Nivel

RANGO PREDEFINIDO RANGO PREDEFINIDO RANGO PREDEFINIDO

SEt -50,0 ... 99,0 32,0 -50,0 ... 99,0 32,0 -50,0 ... 99,0 32,0 °C/°F

diF 0,1 ... 30,0 2,0 0,1 ... 30,0 2,0 0,1 ... 30,0 2,0 °C/°F 1&2

HSE LSE ... 230 99,0 LSE ... 230 99,0 LSE ... 230 99,0 °C/°F 1&2

LSE -55,0 ... HSE -50,0 -55,0 ... HSE -50,0 -55,0 ... HSE -50,0 °C/°F 1&2

HC H/C C flag 2

OSP -30,0 ... 30,0 0,0 -30,0 ... 30,0 0,0 -30,0 ... 30,0 0,0 °C/°F 2

dOd n/y n n/y n n/y n flag 2

dAd 0 ... 255 0 0 ... 255 0 0 ... 255 0 min. 2

Ont 0 ... 250 0 0 ... 250 0 0 ... 250 0 min. 2

OFt 0 ... 250 1 0 ... 250 1 0 ... 250 1 min. 2

dOn 0 ... 250 0 0 ... 250 0 0 ... 250 0 sec 2

dOF 0 ... 250 0 0 ... 250 0 0 ... 250 0 min. 2

dbi 0 ... 250 0 0 ... 250 0 0 ... 250 0 min. 2

OdO 0 ... 250 0 0 ... 250 0 0 ... 250 0 min. 2

dty 0/1/2 0 0/1/2 0 flag 1&2

dit 0 ... 250 6 0 ... 250 6 0 ... 250 6 horas 1&2

dCt 0/1/2 1 0/1/2 1 0/1/2 1 núm. 2

dOH 0 ... 59 0 0 ... 59 0 0 ... 59 0 min. 2

dEt 1 ... 250 30 1 ... 250 30 1 ... 250 30 min. 1&2

dSt -50,0 ... 150 45,0 -50,0 ... 150 45,0 °C/°F 1&2

dPO n/y n n/y n n/y n flag 2

FPt 0/1 0 flag 2

FSt -50,0 ... 150 100,0 °C/°F 1&2

FAd 1,0 ... 50,0 2,0 °C/°F 2

Fdt 0 ... 250 0 min. 1&2

dt 0 ... 250 0 0 ... 250 0 min. 1&2

dFd n/y y flag 1&2

FCO n/y y flag 2

Fod n/y n flag 2

Att 0/1 1 0/1 1 0/1 1 flag 2

AFd 1,0 ... 50,0 2,0 1,0 ... 50,0 2,0 1,0 ... 50,0 2,0 °C/°F 2

Page 43

43

PAR

EWPlus 902/961 EWPlus 971 EWPlus 974

U.M. Nivel

RANGO PREDEFINIDO RANGO PREDEFINIDO RANGO PREDEFINIDO

HAL LAL ... 150,0 50,0 LAL ... 150,0 50,0 LAL ... 150,0 50,0 °C/°F 1&2

LAL -50,0 ... HAL -50,0 -50,0 ... HAL -50,0 -50,0 ... HAL -50,0 °C/°F 1&2

PAO 0 ... 10 0 0 ... 10 0 0 ... 10 0 horas 2

dAO 0 ... 999 0 0 ... 999 0 0 ... 999 0 min. 2

0AO 0 ... 10 0 0 ... 10 0 0 ... 10 0 horas 2

tdO 0 ... 250 0 0 ... 250 0 0 ... 250 0 min. 2

tAO 0 ... 250 0 0 ... 250 0 0 ... 250 0 min. 1&2

dAt n/y n n/y n flag 2

EAL n/y n n/y n n/y n flag 2

dEA 0 ... 14 0 0 ... 14 0 0 ... 14 0 núm. 2

FAA 0 ... 14 0 0 ... 14 0 0 ...14 0 núm. 2

LOC n/y n n/y n n/y n flag 1&2

PS1 0 ... 250 0 0 ... 250 0 0 ... 250 0 núm. 1&2

PS2 0 ... 250 0 0 ... 250 0 0 ... 250 0 núm. 2

ndt n/y y n/y y n/y y flag 2

CA1 -12,0 ... 12,0 0,0 -12,0 ... 12,0 0,0 -12,0 ... 12,0 0,0 °C/°F 1&2

CA2 -12,0 ... 12,0 0,0 -12,0 ... 12,0 0,0 °C/°F 1&2

ddL 0/1/2 1 0/1/2 1 0/1/2 1 núm. 1&2

dro 0/1 1 0/1 1 0/1 1 flag 2

ddd 0/1/2 1 0/1/2 1 0/1/2 1 núm. 2

H08 0/1/2 2 0/1/2 2 0/1/2 2 núm. 2

H11 -6 ... +6 0 -6 ... +6 0 -6 ... +6 0 núm. 2

H22 0 ... 6 2 num 2

H23 0 ... 6 3 num 2

H25 (!) 0 ... 6 4 núm. 2

H32 0 ... 4 0 0 ... 4 0 0 ... 4 0 núm. 2

H42 n/y y n/y y flag 1&2

rEL / / / / / / / 1&2

tAb / / / / / / / 1&2

UL / / / / / / / 2

Fr / / / / / / / 2

¡ATENCIÓN!

El parámetro H25 está presente sólo en los modelos equipados con zumbador.

Page 44

44

CONEXIONES ELÉCTRICAS

¡Atención! Trabaje en el cableado eléctrico sólo y únicamente con la máquina apagada.

El instrumento incorpora regletas de tornillo o extraíbles para conectar cables eléctricos con una sección máxima

de 13 AWG (2,5mm

2)

(un único cable por borne para las conexiones de potencia). Consulte la capacidad de los

bornes en la etiqueta del instrumento. No supere la corriente máxima permitida; en caso de cargas superiores,

utilice un contactor de potencia adecuada. Asegúrese de que el voltaje de la alimentación corresponda al

requerido por el instrumento. Las sondas no se caracterizan por ninguna polaridad de conexión y pueden

prolongarse utilizando un cable bipolar normal (téngase en cuenta que la prolongación de las sondas afecta al

comportamiento del instrumento desde el punto de vista de la compatibilidad electromagnética EMC). Realice las

conexiones con atención. Los cables de prueba, los cables de alimentación y los cables de la serie TTL deben estar

separados de los cables de energía, no colocados cerca de ellos.

RESPONSABILIDAD Y RIESGOS RESIDUALES

Además de las exclusiones previstas en las condiciones de la Garantía, Invensys Controls no se hará responsable

por daños derivados de:

- La instalación y/o el uso distintos de los indicados y, en particular, que no cumplan con las correspondientes

normas reglamentarias y de seguridad, inclusive las normas estipuladas en el presente;

- La instalación y/o el uso en tableros que no garanticen una protección adecuada contra descargas eléctricas,

agua, polvo o acceso a piezas peligrosas;

- La instalación y/o el uso en tableros que no cumplan con las correspondientes normas reglamentarias y de

seguridad;

- La manipulación y/o alteración de los productos.

EXIMENTE DE RESPONSABILIDAD

Este manual y su contenido son de propiedad exclusiva de Robertshaw Controls Company, que opera bajo

el nombre de Invensys Controls, y no podrán ser reproducidos ni distribuidos sin el permiso escrito de un

representante autorizado de Invensys Controls. Aunque se ha ejercido un considerable cuidado en la

elaboración de este documento, ni Invensys Controls ni sus empleados, distribuidores, vendedores u otros

terceros aceptan, ni pueden hacerlo, responsabilidad alguna en relación con su uso, elaboración, redacción,

erratas ni errores contenidos en el mismo. Invensys Controls se reserva el derecho de efectuar cambios en el

documento en cualquier momento, sin previo aviso.

Page 45

45

Garantía – Serie EWPLUS 902/961/971/974

Garantía Limitada por dieciocho meses

Invensys Controls garantiza al instalador o comprador original que cada control de Eliwell nuevo se encuentra libre

de defectos de material o mano de obra en condiciones normales de uso y servicio por el término de dieciocho (18)

meses a partir de la fecha de fabricación (el “Período de Garantía”). Si algún Producto demostrara estar defectuoso

dentro del Período de Garantía correspondiente, Invensys Controls reparará o reemplazará el mismo, a su criterio,

o reembolsará el precio de compra a condición de que el Producto sea devuelto a la planta de Invensys Controls

o al distribuidor designado, dentro del Período de Garantía, con los gastos de transporte o envío prepagados y

comprobante de la fecha de compra y se determine que el Producto, al ser examinado por Invensys Controls, no

responde a la Garantía. Los gastos ocasionados por el retiro del Producto, la mano de obra o reinstalación de un

Nuevo Producto no están cubiertos por la presente Garantía e Invensys Controls no se hace responsable por los

mismos. La Garantía de los Productos, piezas y/o componentes vendidos pero no fabricados por Invensys Controls,

se limitará expresamente a los términos de garantía del fabricante de tales productos, piezas y/o componentes.

La garantía precedente no se aplicará a: i) baterías; ii) defectos o daños originados por el uso de los Productos en

alguna otra forma que la normal y acostumbrada; iii) defectos o daños originados por el uso de los Productos de

manera diferente a la indicada en las recomendaciones e instrucciones de Invensys Controls; iv) defectos o daños

ocasionados por uso indebido, alteración, accidente, exposición al agua o al fuego o negligencia y/o v) defectos

debidos a abuso o daños tales como contactos quemados, roscas sin aislamiento, fundiciones rajadas, instalación

incorrecta o piezas faltantes.

LA GARANTIA PRECEDENTE REEMPLAZA Y EXCLUYE TODAS LAS DEMAS GARANTIAS, EXPRESAS O IMPLICITAS,

INCLUSIVE LAS GARANTIAS IMPLICITAS DE CALIDAD COMERCIAL, PROPIEDAD Y ADECUACION A UN FIN

DETERMINADO. EN NINGUN CASO SERA INVENSYS CONTROLS RESPONSABLE ANTE EL CONSUMIDOR,

CONTRATISTA O TERCEROS POR DAÑOS EMERGENTES, INCIDENTALES, POSIBLES, EJEMPLARES O PUNITIVOS

PROVENIENTES O RELACIONADOS CON EL USO DEL PRODUCTO INCLUSIVE, AUNQUE SIN CARACTER

TAXATIVO, LA PERDIDA DE CLIENTELA, EL LUCRO CESANTE Y DAÑOS MATERIALES, INDEPENDIENTEMENTE

DE QUE TAL PERDIDA O DAÑO OBEDEZCA AL CONTRATO, LA GARANTIA, UN ACTO ILICITO, NEGLIGENCIA,

RESPONSABILIDAD OBJETIVA, INDEMNIDAD, RESPONSABILIDAD DEL FABRICANTE U OTRO E INCLUSO SI

INVENSYS CONTROLS HA SIDO ADVERTIDA SOBRE LA POSIBILIDAD DE TALES DAÑOS.

Page 46

46

Garantía – Serie EWPLUS 902/961/971/974

LA REPARACION, REEMPLAZO O REEMBOLSO DEL PRECIO DE COMPRA, DE ACUERDO CON LO DISPUESTO

EN LA PRESENTE, CONSTITUIRAN LOS UNICOS DERECHOS Y RECURSOS DEL COMPRADOR RESPECTO DE

DEFECTOS EN LOS PRODUCTOS.

Algunos estados no permiten la exclusión ni limitación de daños incidentales o emergentes ni permiten la limitación

del plazo de duración de una garantía implícita, de modo que las limitaciones o exclusiones antedichas pueden no