Page 1

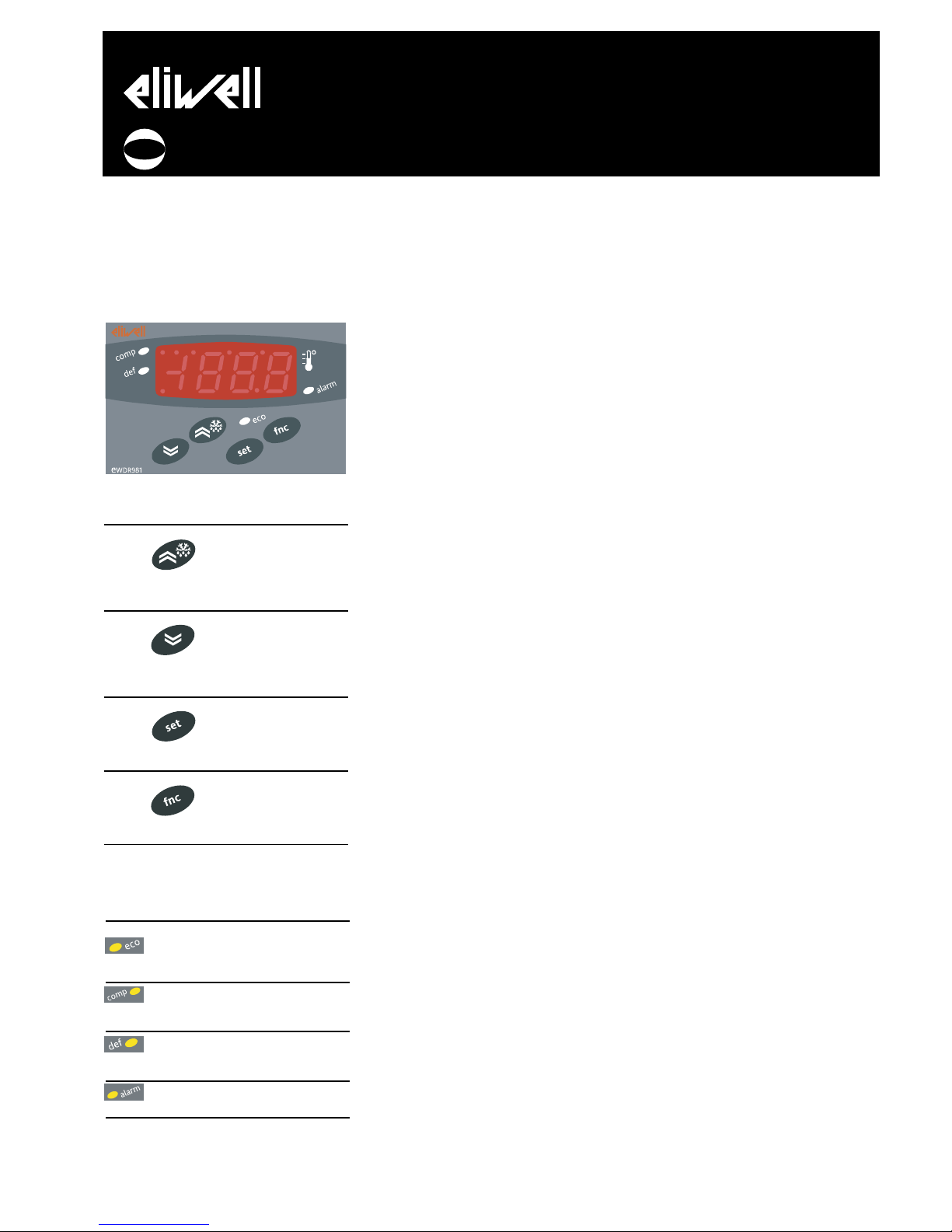

USER INTERFACE

The user interface has a 4 LED display to

indicate status and alarms and four buttons

for controlling instrument status and programming.

KEYS

UP Increase in value of

parameter

Menu scrolling and

activation of defrost

function

(Parameter programmable

H31)

DOWN Decrease in value of

parameter

Menu scrolling and

activation of associated

function

(Parameter programmable

H32)

set Access to different levels of

menu

Alarm display, set

point and probes

Access to programming of

parameters

fnc Exit current level of

menu

Confirmation of value of parameter

(Parameter programmable

H33)

SIGNAL LED

The status of the external devices, functions

and controllers is described by the device

LEDs.

DISPLAY

This is used to display the inputs, the set

point, the parameters and related values,

alarms, functions and the status of the

device.

DESCRIPTION OF MENU

Access to both menus is controlled by

the ‘set’ button. If it is pressed and

immediately released, the ‘machine

status menu‘ is displayed. Hold the same

button down for 5 seconds to access the

‘parameter programming menu‘.

When one of the two menus has been

accessed, you can navigate between the

level 1 folders using the ‘UP’ and ‘DOWN’

buttons. The folders are opened by

pressing the ‘set’ button once. You can

now scroll through the contents of each

folder, modify it or use its functions.

You can exit each level of both menus in

three ways: using the ‘fnc’ button, if a

new value is confirmed by pressing the

‘set’ button or, when the time-out has

elapsed (15 seconds inactivity on the

device).

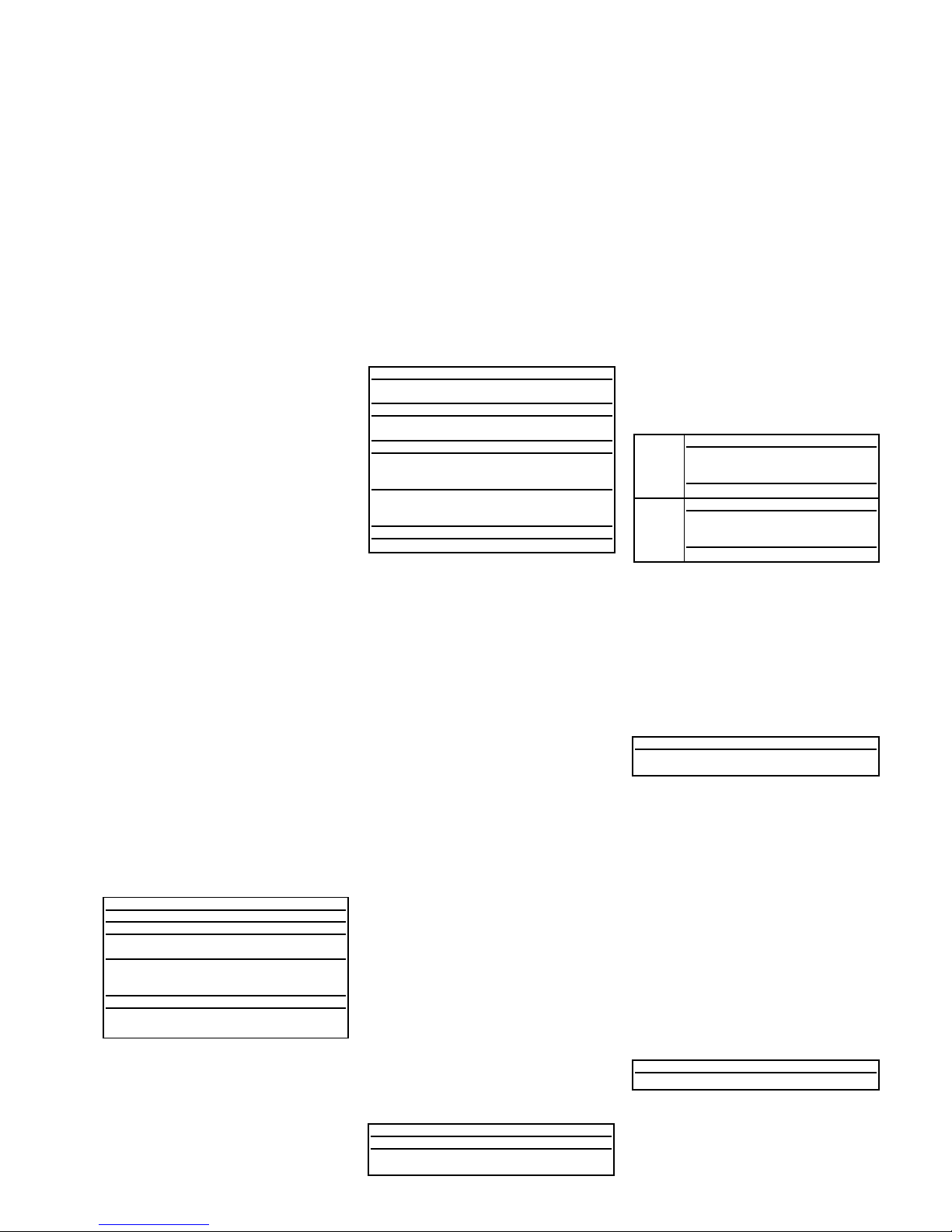

MACHINE STATUS MENU

The ‘machine status menu’ contains the

folders and basic information on the

device:

-AL: alarm folder

-SEt: Set point setting folder

-Pb1: ‘probe 1 value’ folder

-Pb3: ‘probe 3 value’ folder

If no alarms are present, the “SEt” label

is displayed. From here, you can scroll

down the other menu items using the

UP’ and ‘DOWN’ buttons.

Each folder can be accessed by pressing

the ‘set’ button once. Values are

modified using the ‘UP’ and ‘DOWN’

buttons and the ‘set’ button that

confirms the selected value and takes

you back to the higher level.

Setting the set point

Access the ‘machine status menu’. If no

alarms are present, the “SEt” label is

displayed. By pressing and immediately

releasing the ‘set’ button, the set point

value can be set using the UP’ and

‘DOWN’ buttons. Press and release the

‘set’ button again or press the ‘fnc’

button to go back to the main menu

level. The set point setting folder is also

closed when the time-out elapses.

Alarm on

If an alarm condition exists when the

Machine Status menu is accessed the

“ALfolder label appears.

PARAMETER PROGRAMMING MENU

Access the menu by pressing the ‘set’

button for at least 5 seconds.

The menu structure enables all

parameter folders to be divided into two

levels.

All the level 1 folders can be accessed

by entering the password ‘PA1’.

Scroll down the level 1 folders using the

‘UP’ and ‘DOWN’ buttons. Press and

release the ‘set’ button next to the

selected label to access the parameters.

Scroll through the labels in the folder

using the ‘UP’ and ‘DOWN’ buttons,

press ‘set’ to display the current value of

the selected parameter, use the ‘UP’ and

‘DOWN’ buttons and set the required

value by pressing ‘set’.

To access the level 2 folders in the ‘Cnf’

folder, select the ‘PA2’ label, enter the

password ‘PA2’ and confirm with the ‘set’

button. All the parameters that cannot

be changed at level 1 are in this level.

NOTE: Level 1 parameters will only be

displayed if you quit the ‘parameter

programming menu’ and repeat the

steps for manipulation of level 1

folders.

The steps to follow for manipulation of

level 2 parameters are the same as those

NOTE: It is strongly recommended

that the instrument is switched off

and on again each time parameter

configuration is changed in order to

prevent malfunctioning of the

configuration and/or ongoing timings.

PASSWORD

The passwords “PA1and “PA2” are used

to access level 1 and level 2 parameters.

To change them and assign them the

desired value, access the ‘parameter

programming menu’ in the “diS” label

folder.

The password is requested:

- PA1 when entering the ‘parameter

programming menu’;

- PA2 in the “Cnf” folder containing the

level 1 parameters.

USING COPY CARD

The Copy card function can be used to

upload and download parameter maps

of one or more of the same type of

instrument.

The accessory is connected to the device

using the special TTL serial port on the

instrument. The Copy card can be used

for the following functions:

EWDR 981

electronic controllers for refrigeration units

cod. 9IS43091

rel. 3/05

GB

LED Description Indication

reduced set point Lights up when

inserted LED set point is dis-

played, blinking

when reduced set

point is inserted

compressor LED ‘on’ with LED on.

Blinking for delay,

protection or activation blocked

defrost LED ‘on’ during defrost-

ing. Blinking when

activated manually

or by digital input

alarm LED ‘on’ if alarm is pre-

sent. Blinking for

silenced

alarm decimal point ‘on’ to indicate of

voltage when on

stand-by and display ‘off’

Page 2

Upload (UL): The upload function reads

the instrument parameters and writes

them onto the Copy card

Download(dL): The download function

writes the parameter map that is on the

copy card at that time onto the

instrument memory.

NOTE:

Upload = instrument—-> Copy card

Download = Copy card —> instrument

The operations are performed by

accessing the folder with the ‘FPr’ label

and selecting the ‘UL’, ’dL’ or ‘Fr’

commands. The operation is confirmed

by pressing the ‘set’ button. If the

operation is successful, a “y” is displayed

whereas if it is unsuccessful an “n” will

be displayed.

Formatting the copy card

This function is necessary when using the

copy card for uploading for the first

time or when using the copy card on

device models that are not compatible.

NOTE: formatting deletes all the data

on the Copy card and cannot be

undone.

Download from reset

Once the copy card has been connected

the instrument is switched on. When the

lamp test is over, one of the following

two labels will be displayed for 5

seconds:

- dLY if the operation is successful

- label DLn if operation fails The display

will then go into default position (probe

or set point).

NOTE: after downloading, the

instrument will begin to work with

the new parameter map that has just

been downloaded.

ADVANCED FUNCTIONS

DOOR SWITCH INPUT

This is a clean contact digital input with

programmable polarity. The door switch

input functions are controlled by the

values of the following parameters:

Parameter H11 is used to configure the

door switch input with values between

-8 and +8. Positive and negative values

are present in order to select the

polarity assigned to the input and:

NOTE: the sign “-” indicates that the

input is activated when the contact is

closed.

The ‘+’ sign indicates that the input is

activated when the contact is open

LIGHT CONTROLLER

Controls the light relay. The function can

be started in two different ways. If you

press the light button the light relay is

switched on if it was off and is switched

off if it was on.

The light status is recorded by the

device as soon as the button is pressed

so that when power is restored after a

black-out the device can continue to

operate in the same way as before the

power failure.

The following parameters control how

the light works:

The configuration of these parameters

controls the status of the light relay by

using the digital input as well as the

normal button.

The parameter dSd automatically

switches on the light relay when the

digital input is enabled and switches it

off when the digital input is disabled

following the delay set by parameter dLt.

Parameter H06 activates the light button

and enables the relay when the door is

open even when the instrument is

powered but is ‘off’.

The dedicated button always deactivates

the light relay even if the digital input is

on or during the dLt delay only if the

parameter OFL=Y.

DIAGNOSTICS

PROBE ALARMS

When one of the probes is outside the

nominal operating range or the probe is

open or has shorted, an alarm is

generated if at least one of these

conditions persists for at least 10

seconds.

If at least one of these 3 alarms is

signalled the alarm LED and relay are

enabled. When activated code E1

appears on the display.

If several alarms are activated at the

same time, they are displayed alternately

for 2 seconds each. An error condition

in the room probe leads to:

- E1 code appears on display

- activation of compressor as indicated

by Ont and OFt

- deactivation of maximum and

minimum alarm controller.

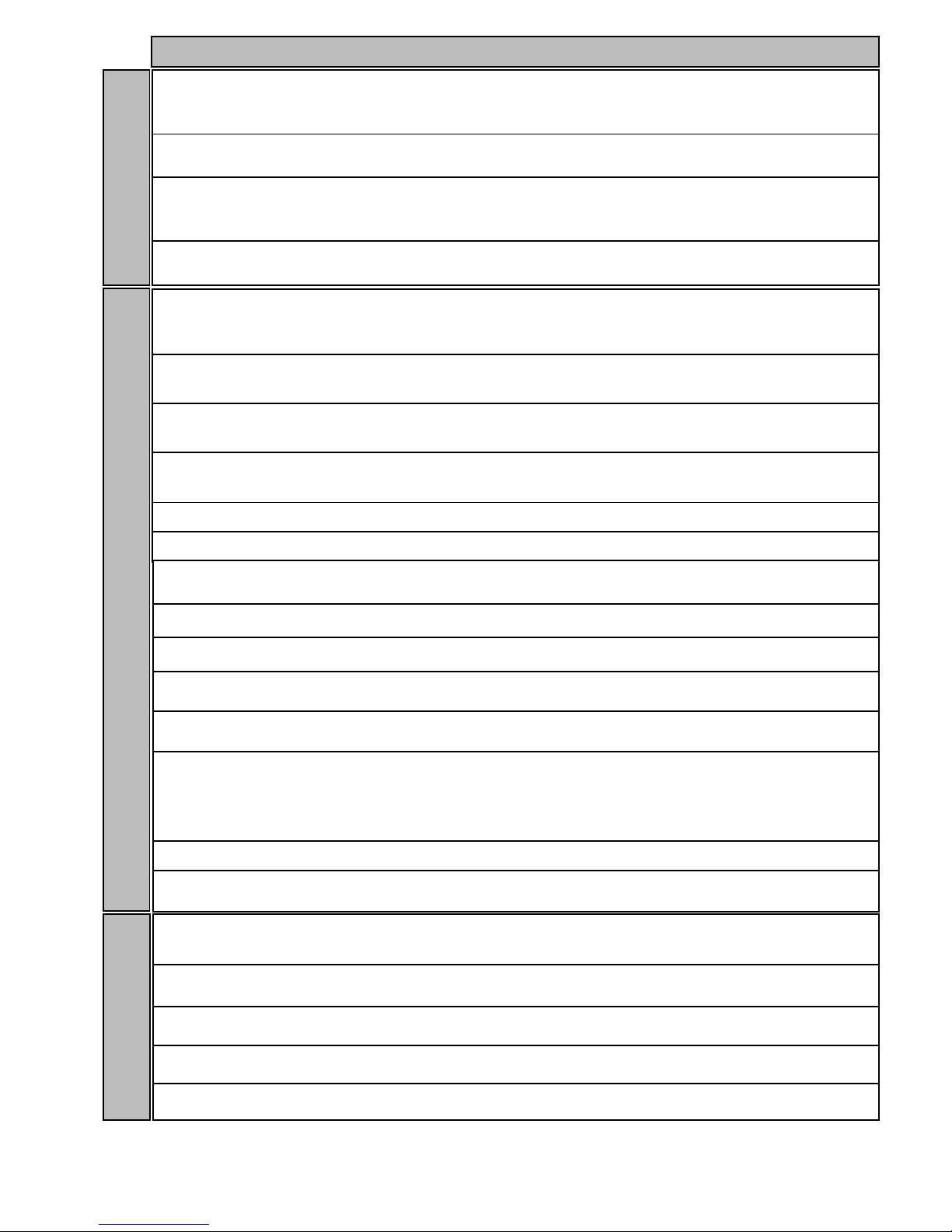

MINIMUM AND MAXIMUM

TEMPERATURE

ALARM

The alarm is regulated on the room

probe. The temperature limits are

defined by parameters HAL and LAL. The

limits refer to the set point if parameter

Att=1 and are absolute if Att=0.

NOTE: If the alarms are relative, the

parameter HA1 is set to positive

values and LA1 to negative values.

ALARM WITH THRESHOLD REFERRING

TO PROBE 3

An alarm is associated with probe 3 that

refers to a threshold that is reset at a

specified differential.

By setting parameter PbA=3 probe 3 will

signal a high or low temperature alarm

for exceeding the set value.

The alarm is handled in the same way as

the other temperature alarms and

standard signal delays are used.

EXTERNAL ALARM

It is set if the digital input is enabled

with the delay specified by parameter

dAd and remains enabled until the next

time the digital input is deactivated. The

alarm consists of an alarm LED that

remains on, activation of a buzzer and

deactivation of all the device loads (if

specified by the EAL parameter).

If an external alarm is present the EA

label is displayed in the AL folder.

It is reset the next time the digital input

is deactivated and the buzzer can be

manually silenced.

Par Description

dOd Digital input switches off loads

dAd D.I. activation delay

OAO Alarm signal delay after dis-

disabling the digital input (door closed)

tdO Time out door open. Time out

signal after activation of D.I.

(door open)

H11 Digital output configurability/polarity 1

H21...H25 Digital output configurability 1...5

Par Description

H06 Button/aux input/door switch light active

when instrument off

dSd Enabling light relay by door switch

dLt Delay Light Relay

deactivation delay

OFL Light switch always disables light relay

OAO Alarm signal delay after

disabling the digital input

(door closed)

tdO Time out door open.

Time out signal after activation of D.I.

(door open)

H11 Digital output configurability/polarity 1

H21...H25 Digital output configurability 1...5

Signal Description

E1 Faulty room probe

E3 Faulty display probe

EWDR 981 2/8

Att=0

absolute

Maximum temperature alarm

room probe temperature ≥ HAL

Minimum temperature alarm

room probe temperature ≤ LAL

Att=1

relative

Maximum temperature alarm

room probe temperature ≥ Set + HAL

Minimum temperature alarm room

probe temperature ≤ Set + LAL

Signal Description

AH3 High temperature alarm

AL3 Low temperature alarm

Signal Description

EA External alarm

Page 3

OPEN DOOR ALARM

This alarm is generated when the door is

open for longer than the value specified

in parameter tdO. The door open alarm

is signalled in the alarm folder (AL) and

the LED and alarm relay are switched on.

The OPd label is also displayed.

The relay can be deactivated by pressing

the silencing button. The LED continues

to flash intermittently and the OPd label

remains in the alarm menu until the

door is closed.

MECHANICAL

ASSEMBLY

The EWDR 981 is designed to be wallmounted (removable brackets) or

mounted on DIN rail (Omega 3). The

unit operates correctly with an ambient

temperature range of between -5 and 55

°C. Units must not be installed in

excessively humid and/or dirty locations.

TECHNICAL DATA

Casing: plastic 4 Din modules

Dimensions: front 70x85 mm, depth

61mm.

Mounting: on DIN rail (Omega 3) or

wall-mounted.

Connections: on screw terminal block for

≤ 2.5mm

2

conductors

(only one conductor per terminal block

for power connections)

Operating temperature: -5...55°C.

Storage temperature: -30...85°C.

Operating and storage ambient humidity:

10...90 % RH (non-condensing).

Display: 3 digits + sign

Analogue inputs: 2 NTC/PTC inputs

(parameter configurable)

Digital inputs: 2 voltage-free parameterconfigurable digital inputs.

Serial: TTL for Copy Card

Digital outputs: 1 on relay:

16A 1hp 250V SPDT;

Configurable 12Vc/24mA output

Resolution: 1 or 0.1°C.

Accuracy: better than 0.5% of bottom

scale +1 digit

Consumption: 5VA

Power supply: 230Va

ELECTRICAL

CONNECTIONS

Warning! Always switch off machine

before working on electrical

connections.

The instrument has screw terminal blocks

for connecting cables with a maximum

diameter of 2.5 mm

2

(only one conductor

per terminal block for power

connections): for terminal capacity, see

the label on the instrument.

The relay outputs are voltage free.

Do not exceed the maximum current

allowed. For higher loads, use a suitable

contactor.

Make sure that the power voltage

complies with the device voltage.

Probes have no connection polarity and

can be extended using an ordinary

bipolar cable (note that if probes are

extended this affects the electromagnetic

compatibility (EMC) of the instrument:

special care must be used when wiring).

The TTL serial cable must be kept

separate from the power cables.

EWDR 981 3/8

CONDITIONS OF USE

PERMITTED USE

For safety reasons the instrument must

be installed and used in accordance with

the instructions supplied.

Users must not be able to access parts

with dangerous voltage levels under normal operating conditions. The device

must be suitably protected from water

and dust depending on the specific

application and only be accessible using

special tools (except for the front keypad).

The device is ideally suited for household use and/or similar use in the refrigeration sector and has been tested with

regard to safety in accordance with the

European harmonized reference standards. It is classified as follows:

• as an automatic electronic control

device to be independently mounted as

regards its construction;

• as a 1 B type operated control device

as regards its automatic operating features;

• as a Class A device as regards the category and structure of the software.

UNPERMITTED USE

The use of the unit for applications

other than those described above is forbidden. It should be noted that the relay

contacts supplied with the device are

functional and therefore exposed to

potential faults. Any protection devices

required to comply with product

requirements or dictated by common

sense due to obvious safety reasons

should be installed externally.

RESPONSIBILITY AND RESIDUAL RISKS

Eliwell shall not be liable for any damages deriving from:

- installation/use other than that prescribed and, in particular, which does not comply

with the safety standards specified in the regulations and/or those given herein;

- use on boards which do not guarantee proper protection against electric shock, water

or dust when assembled;

- use on boards which allow dangerous parts to be accessed without the use of tools;

- tampering with and/or alteration of the product;

- installation/use on boards that do not comply with the standards and regulations in

force.

Signal Description

OPd Open door alarm

Page 4

PAR. DESCRIPTION

RANGE DEFAULT VALUE LEVEL U.M.

SEt Set point with range falling between the minimum

LSE set point and the maximum HSE set point. The

set point value is in the machine status menu

menu

LSE...HSE 0.0 °C/°F

diF When the compressor stops when it reaches the

set point value, it restarts at a value corresponding

to the set point plus the value of the differential It

must not be 0

0.1...30.0 2.0 1-2 °C/°F

HSE Maximum set point value

LSE...302 50.0

1-2 °C/°F

LSE Minimum set point value

-58.0...HSE -50.0 1-2 °C/°F

OSP Offset point. Value to be added to set point if

reduced set point is activated Economy function).

-30.0...30.0 0 2 °C/°F

Cit Minimum compressor ON time. Minimum time for

activating a compressor before deacti vation Not

active if=0

0...250 0 2 min

CAt Maximum compressor ON time. Maximum time for

activating a compressor before deacti vation Not

active if=0

0...250 0 2 min

Ont (1) Compressor activation time if probe is faulty. If set

to 1 with OFt=0 the compressor always remains on

whereas if OFt>0 it operates in duty cycle mode

(see Duty Cyclediagram)

0...250 0 1-2 min

OFt (1) Compressor shut-down time if probe is faulty. If set

to 1 with Ont=0 the compressor always remains off

whereas if OFt>0 it operates in duty cycle mode

(see Duty Cyclediagram)

0...250 1 1-2 min

dOn Delay in activating compressor relay after start-up

0...250 0 1-2 sec

dOF Delay after shut-down; between compressor relay

shut-down and subsequentstart-up the specified

time must elapse.

0...250 0 1-2 min

dbi Delay between switch-ons; the specified time must

elapse between two subsequent switch-ons

0...250 0 1-2 min

OdO Delay in activating outputs after start-up of instru-

ment or after a power failure.

Not active if=0

0...250 0 1-2 min

dty Type of defrost.

0 = electrical defrosting;

1 = cycle reversing defrosting (hot gas);

2 = Free mode defrosting (compressor disabled).

0/1/2 0 1-2 num

dit Period of time elapsing between the start of two

defrosts 0=function disabled

0...250 6h 1-2 hours/min/sec

dt1 Unit of measurement for defrost times (par. dit)

0=”dit” expressed in hours

1=”dit” expressed in minutes

2=”dit” expressed in seconds

0/1/2 0 2 num

NOTE: At level 1 the folders will only display all the level 1 parameters. At level 2 the folders will only display all the level

2 parameters. The symbol 1-2 indicates the parameters that are displayed at both menu levels

Defrosting controller-dEF label Compressor controller-CP label

dt2 Unit of measurement for duration of defrosting

(dEt parameter)

0= “dEt” parameter expressed in hours

1= “dEt” parameter expressed in minutes

2= “dEt” parameter expressed in seconds

0/1/2 1 2 num

dCt Selection of defrosting time count mode.

0=compressor operating hours DIGIFROST®

method). Defrosting active only if compressor is

on.

1 = device operating hours; defrost counting is

always active when the machine is on

2=compressor stop Each time the compressor

stops a defrosting cycle

defrost cycle is performed according to par. dtY

3=disabled

0/1/2/3 1 1-2 flag

dOH Delay between start of first defrosting operation

and start-up of instrument.

0...59 0 1-2 min

dEt Defrosting time-out; determines maximum dura-

tion of defrosting.

1...250 30min 1-2 min/sec

EWDR 981 4/8

Page 5

PAR. DESCRIPTION

RANGE DEFAULT VALUE* LEVEL** U.M.

dPO Determines when instrument starts up if

the defrosting cycle must be activated (if the

temperature on the evaporator allows this)

y=defrosting activated at start-up

n=defrosting not activated at start-up

n/y n 1-2 flag

tcd minimum time for each compressor state

before defrosting “Ontime if >0; “Offtime if >0

-31...31 0 2 min

Cod Compressor “Off” time before defrost cycle.

The compressor is not turned on if a defrost cycle

is expected in the time indicated by the parameter.

0=Function excluded

0...60 0 2 min

Defrosting controller-dEF label

NOTE: At level 1 the folders will only display all the level 1 parameters. At level 2 the folders will only display all the

level 2 parameters. The symbol 1-2 indicates the parameters that are displayed at both menu levels

Alarms-AL label

Att Determines if “LAL” and “HAL” are expressed as

absolute values or as a differential related to the

set point

0=absolute value

1=value related to set point

0/1 0 2 flag

AFd Alarm differential

1.0...50.0 2.0 1-2 °C/°F

HAL (2) Maximum alarm. Temperature limit (whose

absolute or relative value status is regulated by

“Att”) above which the alarm is activated.

LAL...150.0 50.0 1-2 °C/°F

LAL (2) Minimum alarm. Temperature limit (whose

absolute or relative value status is regulated by

“Att”) below which the alarm is activated.

-50.0...HAL -50.0 1-2 °C/°F

PAO (3) Alarm exclusion time after start-up of instrument

following a power failure

0...10 0 1-2 hours

dAO Alarm exclusion time after defrosting

0...999 0 1-2 min

EWDR 981 5/8

OAO High and low temperature alarm delay after

disabling digital input

(door closed)

0...10 0 2 hours

tdO Time out after alarm signal when digital input is

disabled (door open)

0...250 0 2 min

tAO (3) Temperature alarm delay time

0...250 0 1-2 min

EAL External alarm to lock controllers

n=does not lock,

y=locks

n/y n 2 flag

AOP Polarity of alarm output:

0 = alarm active and output disabled;

1 = alarm active and output enabled

0/1 1 2 flag

PbA Configuration of temperature alarm on

probe 1 and/or 3:

0=on probe 1 (thermostat control)

1=on probe 3 (display)

2=on probe 1 and 3 (thermostat control and display)

3=on probe 1 and 3 (thermostat control and display)

on external threshold

0/1/2/3 0 2 num

SA3 Probe 3 alarm set point

-50.0...150.0 50 2 °C/°F

dA3 Probe 3 alarm differential

-30.0...30.0 2.0 2 °C/°F

dt Dripping time

0...250 0 1-2 min

Light & digital inputs

Lit Label

dLt Light relay disabling delay after closing

door if “dSd”=y

0...31 0 2 min

OFL Light relay disabled even if disabling delay

“dLt” is active

n/y n 2 flag

dAd Delay in activating digital input

0...255 0 2 min

dOd Digital input switches off loads

n/y n 2 flag

dSd Light relay enable from door switch.

n = door open, light does not turn on;

y = door open, light turns on (if it was off)

n/y y 2

flag

Page 6

PAR. DESCRIPTION

RANGE DEFAULT VALUE* LEVEL** U.M.

NOTE: At level 1 the folders will only display all the level 1 parameters. At level 2 the folders will only display all the

level 2 parameters. The symbol 1-2 indicates the parameters that are displayed at both menu levels

EWDR 981 6/8

LOC Keyboard locked. Parameters can still be

programmed.

n= keyboard not locked

y= keyboard locked

n/y n 1-2 flag

PA1 Contains the password for level 1 parameters.

Enabled if not 0

0...250 0 1 num

PA2 Contains the password for level 2 parameters.

Enabled if not 0

0...250 0 2 num

ndt Display with decimal point.

n= without decimal point (only whole numbers)

y= with decimal point

n/y n 1-2 flag

CA1 Temperature value to be added to that read

by probe 1 as specified by parameter CAI

-12.0...12.0 0 1-2 °C/°F

CA2 Temperature value to be added to that read

by probe 2 as specified by parameter CAI

-12.0...12.0 0 1-2 °C/°F

CA3 Temperature value to be added to that read

by probe 3 as specified by parameter CAI

-12.0...12.0

0

1 °C/°F

Display - diS label

CAI Intervention of offset on display, thermostat

control or both:

0 = only modifies the temperature displayed

1 = adds to the temperature used by controllers

not the temperature displayed that remains

unchanged.

2= adds to temperature displayed that is

also used by controllers.

0/1/2

2

2 num

LdL Minimum value that can be displayed

-55.0...140

-50.0

2 °C/°F

HdL Maximum value that can be displayed

-50.0...302

140.0

2 °C/°F

ddL display during defrosting:

0= displays temperature read by thermostat

control probe

1= displays temperature read entering

defrost cycle until set point is reached

2= displays “dEF” label during defrosting until

set point is reached (or when Ldd expires)

0/1/2 1 1-2 flag

Ldd Time out for unlocking display (with ddL=2) if

defrosting lasts too long

0...255

0

1-2 min

dro (4) Select °C or °F to display temperature:

0= °C 1= °F

0/1

0

1-2 flag

ddd Value to be displayed:

0 = Set point

1 = probe 1 (thermostat control)

2 = disabled

3 = probe 3 (display)

0/1/2/3

1

2 num

H00 Selects probe, PTC or NTC 0= PTC 1= NTC

0/1

1

1-2 flag

H02 Quick activation time for functions with configured

buttons. Not possible for aux

(time expected = 1 second)

0...15

5

2 sec

H11 (5) Configuration of digital inputs/polarity:

0= disabled 1 = defrost

2 = reduced set point 3 = auxiliary

4 = door switch 5= external alarm

6= disabled

7= stand-by (On/Off) 8= maintenance request

-8...8

4

2 num

H08 Stand-by operating mode

0= only display switched off;

1= display on and controls locked;

2= display off and controls locked

0/1/2

2

2 num

H06 Button/input aux/door switch light active when

instrument is off

n/y

y

2 flag

H12 (5) Configuration of digital inputs/polarity

Same as H11

-8...8

0

2 num

Configuration- CnF label

Page 7

PAR. DESCRIPTION

RANGE DEFAULT VALUE* LEVEL** U.M.

Configuration- CnF label

EWDR 981 7/8

H21 Digital output configurability (C):

0= disabled 1= compressor

2= defrosting 3= fans

4= alarm 5= auxiliary

6= stand-by 7= light

8= buzzer 9= defrosting on 2nd

evaporator

0...9

1

2 num

H31 UP button configurability

0=disabled 1=defrosting

2=auxiliary 3=reduced set point

4=disabled 5=disabled

6=light 7=stand-by

8= maintenance request

H32 DOWN button configurability

Same as H31(0=disabled default)

0...8

0

2 num

H33 ESC button configurability

Same as H31(0=disabled default)

0...8

0

2 num

0...8

1

2 num

H41 Presence of control probe:

n= not present y= present

n/y

y

2 num

H43 Presence of display probe:

n= not present y= present (display probe)

n/y

y

2 flag

PA2*** in the CnF folder when you enter the correct password you can access level 2 parameters from label PA2 by pressing the “set” button

rEL Device version. Read only parameter

/

/

1 /

tAb Parameter table; Reserved; Read only parameter

/

/

1 /

Copy Card

Fpr label

UL Transfer of parameter map from instrument to

Copy Card

dL Transfer of parameter map from Copy Card to

instrument

Fr (6) Formatting. Cancels all data in the Copy Card

/

/

1 /

/

/

1 /

/

/

1 /

NOTES:

(1) See Duty Cycle diagram

(2) If relative values are present (par. Att=1) parameter HAL is set to positive values and the parameter LAL is set to negative values (-LAL)

(3) Refers exclusively to high and low temperature alarms

(4) when changing from °C to °F or vice versa the set points, differentials, etc. are NOT converted (for example, “set=10 °C becomes set=10°F”)

(5) CAUTION: positive or negative values change polarity, Positive values: active input when contact is closed; Negative values: active input when contact is open.

(6) If the Fpr parameter is used, the data previously stored on the Copy Card will be permanently lost. This operation cannot be undone

* Value: to be compiled manually by user with any custom settings (if different from default settings)

** Level: indicates the visibility level of parameters accessed using a password (see relevant paragraph)

*** PA2 is visible at level 1 in the CnF folder

whereas it can be modified at level 2 in the diS folder

H25 Digital output configuration. (E) Same as H11.

0...9

4

2 num

if alarm(s)

present

AL

Pb1

SEt

set

alarms

Pb1 value

SEt value

set

change SEt

value

show alarms

press and release

(quickly/single press)

Pb3

Pb3 value

is present

MACHINE STATUS MENU

Ont, OFt parameters programmed for

Duty Cycle

Ont OFt Compressor output

00OFF

0>0OFF

>0 0 ON

>0 >0 dc

OUT

On

Off

OFtOnt

Ont

The error condition for probe 1

(compressor) causes the following:

- E1 code appears on display

- the controller is activated as indicated by

the “Ont” and

“OFt” parameters if programmed for

Duty Cycle

DUTY CYCLE DIAGRAM

Page 8

CP

dEF

AL

level 1 par

level 1 par

level 1 par

PA1›0

set PA1 value

diS

CnF

Fpr

level 1 par

level 1 par

level 1 par

level 2 par

level 2 par

level 2 par

level 2 par

level 2 par

CP

dEF

diS

CnF

PA2›0

set PA2 value

level 2

level 1

change

par value

scroll

parameters

press for 5 sec

level 2 par

Lit

AL

PA2

PROGRAMMING MENU

EWDR 981 8/8

The technical characteristics in this

document concerning measurements (range,

accuracy, resolution, etc.) refer to the

instrument in the strictest sense and not to

any accessories provided such as probes,

for example. This means that an error

introduced by the probe is added to any

error that is in the instrument.

Minimum temperature alarm

Maximum temperature alarm

LAL

AFd

HAL

AFd

1

set+ LAL

AFd

Off

set+HAL

AFd

set

2

Temperature lower than or equal to LAL (LAL with sign)

Temperature lower than or equal to set point+LAL (set-|LAL|)

(LAL only negative)

Temperature higher than or equal to HAL (HAL with sign)

Maximum temperature alarm

back swing

Minimum temperature alarm

back swing

Temperature higher than or equal to LAL+AFd

Temperature lower than or equal to HAL-AFd

Temperature expressed as an absolute value (par “Att0)

Abs(olute)

Temperature expressed in relation to set point

(par “Att”=0) reL(ative)

if Att=reL(ative) LAL must be negative: therefore set

point+LAL<set point because set point+(-|LAL|)=set point-|LAL|

MIN/MAX ALARM MENU

WIRING DIAGRAM

TERMINALS

1-2 Probe input 1 (room probe)

1-4 Probe input 3 (display or 2nd evaporator probe)

5-6 Digital input 1

5-7 Digital input 2

8-9 Auxiliary output 12Vc/20mA (E) see par. H25

(alarm default)

13-14 Power supply 230Va

A TTL input for Copy Card

20-21-22* N.O. relay output (C) see par. H21 (compressor default)

19-22* N.C. relay output (C) see par. H21 (compressor default)

EWDR 981

1

245678910 11 12

13

14 19 20 21

22

TTL

A

(C)

AUX OUT

12VC/20mA

P

o

w

e

r

S

u

p

p

ly

Pb1

Pb3

D.I.1

D.I.2

(E)

Eliwell & Controlli s.r.l.

Via dell'Industria, 15 Zona Industriale Paludi

32010 Pieve d'Alpago (BL) ITALY

Telephone +39 0437 986111

Facsimile +39 0437 989066

Internet http://www.eliwell.it

Technical Customer Support:

Email: techsuppeliwell@invensys.com

Telephone +39 0437 986300

Climate Controls Europe

An Invensys Company

3/05 eng

cod. 9IS43091

* Relay characteristics

Relay output (C) 16A 1hP 250Va

DISCLAIMER

This document is the exclusive property of

Eliwell and cannot be reproduced and

circulated unless expressly authorized by

Eliwell.

Although Eliwell has taken all possible

measures to guarantee the accuracy of this

document, it declines any responsibility for any

damage arising out of its use.

The same applies to any person or company

involved in preparing and writing this

document. Eliwell reserves the right to make

any changes or improvements without prior

notice and at any time.

Temperature higher than or equal to set point+HAL (HAL only positive)

Temperature higher than or equal to set point + LAL + AFd

set point -|LAL|+AFd

Temperature lower than or equal to set point+HAL-AFd

Loading...

Loading...