Page 1

EN

EWCM 4120-4150-4180

Compact controller for compressor plants

e

1 2

Page 2

Summary

INTRODUCTION - CHaracteristics ............................................................................................................................................................ 4

CONDITIONS OF USE................................................................................................................................................................................... 4

MECHANICAL ASSEMBLY............................................................................................................................................................................7

WIRING DIAGRAMS...................................................................................................................................................................................... 7

CONNECTION DIFFERENCES BETWEEN EWCM412/415/418 and EWCM4120/4150/4180....................................................... 13

BASIC FUNCTIONS .....................................................................................................................................................................................14

LEDs........................................................................................................................................................................................................14

Displays in particular states..............................................................................................................................................................15

Keys........................................................................................................................................................................................................ 16

User interface configuration............................................................................................................................................................17

Main display.........................................................................................................................................................................................19

Password and visibility....................................................................................................................................................................... 19

Accessing and using the menus ......................................................................................................................................................20

Machine state menu ..........................................................................................................................................................................20

Programming menu ...........................................................................................................................................................................21

CONFIGURING THE MACHINE.................................................................................................................................................................21

1) ANALOGUE INPUTS (AI3, AI4)....................................................................................................................................................21

3) HIGH/LOW VOLTAGE DIGITAL OUTPUTS (DO1…DO6)........................................................................................................ 25

4) PWM/OPEN COLLECTOR OUTPUTS AO1 AND AO2.............................................................................................................26

5) TRIAC TC OUTPUT.........................................................................................................................................................................29

6) LOW VOLTAGE ANALOGUE AO3 OUTPUT .............................................................................................................................30

Page 3

COMPRESSOR CONTROL.......................................................................................................................................................................... 31

Inverter compressor control............................................................................................................................................................32

Digital compressor control...............................................................................................................................................................34

Compressor timing.............................................................................................................................................................................36

Power stages........................................................................................................................................................................................37

Compressor switch-on policies .......................................................................................................................................................37

CONDENSATION CONTROL.....................................................................................................................................................................39

INVERTER COMPRESSOR CONTROL ..............................................................................................................................................40

DIGITAL FAN CONTROL.................................................................................................................................................................... 44

ADVANCED FUNCTIONS...........................................................................................................................................................................49

On/off device ......................................................................................................................................................................................49

Recording operating hours ..............................................................................................................................................................50

Real Time Clock (RTC).......................................................................................................................................................................50

ALARMS ........................................................................................................................................................................................................51

Alarms list with description and activation parameters............................................................................................................53

Alarm list with actions and notes ...................................................................................................................................................55

Alarms log ............................................................................................................................................................................................58

SERIAL CONFIGURATION..........................................................................................................................................................................59

PARAMETERS LIST ......................................................................................................................................................................................61

NAVIGATION MENU DIAGRAMS ............................................................................................................................................................69

ACCESSORY PRODUCTS............................................................................................................................................................................ 72

TECHNICAL DATA.......................................................................................................................................................................................73

Mechanical characteristics ...............................................................................................................................................................73

Electrical characteristics.................................................................................................................................................................... 73

Input/Output characteristics............................................................................................................................................................ 73

3

Page 4

INTRODUCTION - CHARACTERISTICS

The EWCM is a device which represents a family of controllers dedicated to managing the production room of a

refrigerator plant:

Configurable user interface.

Configurable navigation menu.

Alarms log.

Temperature control via inlet probe depending on configuration and installation.

Condensation control via outlet probe depending on configuration and installation.

NTC, 4…20 mA, 0…5V or 0.10V parameter-configurable inputs.

Parameter settings via keyboard or PC.

Copy card for uploading and downloading parameter maps.

Control of a single circuit with up to 4 compressors (or combination of compressors) whole or segmented with

up to 4 power stages/inverter compressor.

Condensation control with inverter fan or up to 4 digital fans.

CONDITIONS OF USE

Permitted use

This device is intended for controlling compressor plants.

For safety reasons, the instrument must be installed and used according to the instructions provided and in particular,

under normal conditions, parts bearing dangerous voltages must not be accessible. The device must be adequately

protected from water and dust as per the application, and must also only be accessible via the use of tools (with the

exception of the frontlet).

The device is ideally suited for use in household appliances and/or similar refrigeration equipment and has been

tested with regard to the aspects concerning European reference standards on safety. It is classified as follows:

4

Page 5

according to its manufacture: as an independently mounted or integrated automatic electronic control device

to be incorporated;

according to its automatic operating features, as a 1 B-type operated control type;

as a Class A device in relation to the category and structure of the software;

as a device with pollution grade 2;

as a device with class D fire resistance;

overvoltage category grade II

as a device made with class IIIa material.

Uses not permitted

Any use other than that expressly permitted is prohibited.

The relay contacts supplied are of the functional type and subject to fault (since they are electronically controlled

they are prone to short-circuit or remaining open): any protection devices specified in product standards or suggested

by common sense for obvious safety requirements must be installed externally to the instrument.

RESIDUAL RISKS AND RESPONSIBILITIES

Eliwell is not liable for damage due to:

unspecified installation/use and, in particular, in contravention of the safety requirements of established

legislation or specified in this document;

use on equipment which does not provide adequate protection against electrocution, water and dust in the

actual installation conditions;

use on equipment which allows toolfree access to dangerous components;

tampering with and/or alteration of the products;

installation/use on equipment which does not comply with established legislation and standards.

5

Page 6

DISCLAIMER

This document is the exclusive property of ELIWELL CONTROLS Srl and shall not be reproduced or distribuited

without authorisation of ELIWELL CONTROLS Srl.

Although great care has been exercised of this document, ELIWELL CONTROLS Srl, its employees or its vendors,

cannot accept any liability whatsoever connected with its use.

The same applies to any person or company involved in preparing and editing this document.

ELIWELL CONTROLS Srl reserves the right to make any changes or improvement without prior notice.

ELECTRICAL WIRING

Attention! Never work on electrical connections when the machine is switched on. The operation must be

carried out by qualified personnel.

To ensure proper connections, comply with the following:

using a power supply which does not correspond to the specifications given, can seriously damage the system;

use cables of suitable section for the terminals used.

Separate, as much as possible, the cables of probes and digital inputs from inductive loads and power

connections to prevent electromagnetic interference. Do not place the probe cables near other electrical

equipment (switches, meters, etc.)

Make connections as short as possible and do not wind them around electrically connected parts.

It is recommended to use screened wires for probe connections.

To avoid causing static discharges, do not touch the electronic components on the boards.

Eliwell supplies the high voltage cables to connect the device to loads, the power supply, probes, digital inputs, etc.

according to p/n - see the Accessories chapter.

The device must be connected to a suitable transformer that complies with the specifications provided in the

Technical Data chapter.

6

Page 7

MECHANICAL ASSEMBLY

76.4mm

70mm

28mm

35mm

29mm

71mm

67mm

59mm

The instrument is designed for panel mounting. Make a 29x71 mm hole and insert the instrument; secure it with the

special brackets provided. Do not mount the instrument in damp and/or dirt-laden areas; it is suitable for use in

places with ordinary or normal levels of pollution. Keep the area around the instrument cooling slots adequately

ventilated. The TTl serial port is located on the left side of the instrument.

70mm

67mm

29mm

71mm

76.4mm

59mm

WIRING DIAGRAMS

Circuit diagram key

35mm

28mm

12Va 12Va power supply

5Vc 5Vc power supply for 10A max ratiometric transducer

12Vc Auxiliary 12Vc power supply for AO1 or DO5 output

7

Page 8

DO1... DO6 2A - 230Va high voltage relay outputs

N Neutral

TC TRIAC 2A - 230Va high voltage output

AO1/AO2 PWM/Open collector analogue output for external fan module (to be used with 12Vc)

AO3 0/10 V, 4-20 mA, 0-20 mA low voltage analogue output

DO5 Open collector output (to be used with 12Vc)

DI1...DI5 Digital inputs voltage-free contact (closing current to 0.5mA ground)

AI1 (DI6)..AI2 (DI7) Digital inputs voltage-free contact (closing current to 0.5mA ground)

AI3..AI4 NTC */ voltage, current** / Digital Input configurable analogue inputs***

GND Ground

TTL (COM 1) TTL serial for connection to Copy Card/ParamManager/ DeviceManager or Televis

1 Outlet pressure switch ON/OFF (EWCM 4120 and EWCM 4180)

2 Inlet pressure switch ON/OFF

3 … 6 Block compressor 1… 4 ON/OFF

7 Remote ON/OFF

INPUT

8 Outlet probe (EWCM 4180)

9 Inlet probe

10 … 13 Compressor/power step 1_4 ON/OFF

14 TC high voltage condenser fan (EWCM 4120)

15 TC low voltage condenser fan (EWCM 4180)

16 Low voltage ON/OFF alarm (EWCM 4120)

OUTPUT

17 ON/OFF alarm (EWCM 4150 and EWCM 4180)

* SEMITEC 103AT type (10LΩ / 25°C).

** 4…20mA current input or 0…5V/0…10V voltage input or voltage-free digital input.

*** voltage-free digital input.

8

Page 9

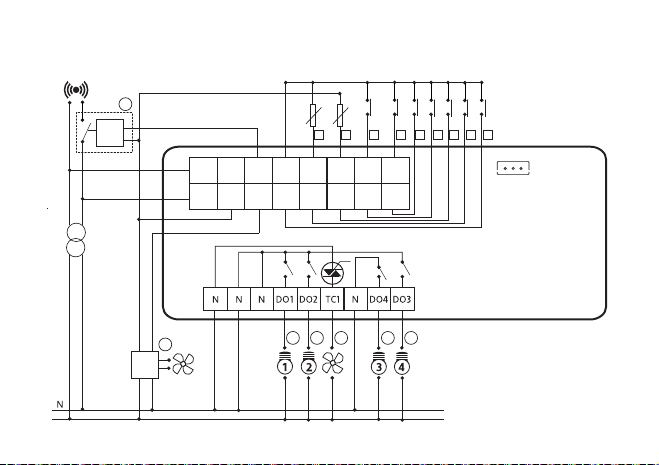

EWCM 4120

16

12 Vdc 35mA max.

12Vac 5Vdc

DO5 GND AI4 AI3

AO1 DI5 DI4 DI3 DI2 DI112Vac12Vdc

9

DI7 DI6

AI2 AI1

1 425

3

6

78

Not

used

EWCM 4120

15

L

1110

9

12

14

13

Page 10

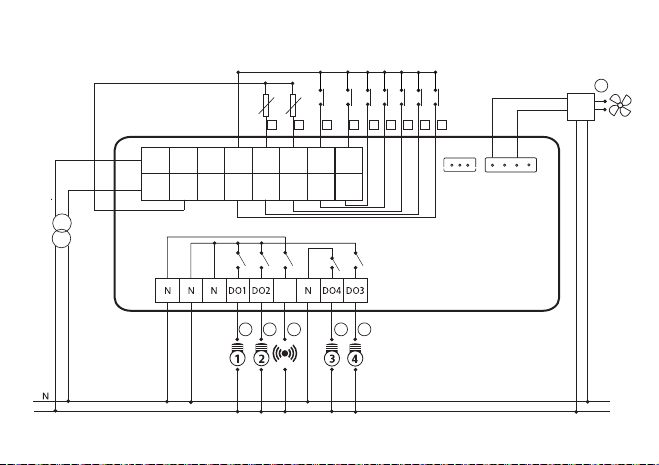

EWCM 4150

1 425

3

6

78

Not

used

AO3(I)

AO3(V)

GND

AO2

12Vac 5Vdc

12Vdc

DO5 GND AI4 AI3

AO1 DI5 DI4 DI3 DI2 DI112Vac

9

DI7 DI6

AI2 AI1

DO6

1110

L

12

17

13

10

EWCM 4150

Page 11

12Vac 5Vdc

12Vdc

EWCM 4180

DO5 GND AI4 AI3

AO1 DI5 DI4 DI3 DI2 DI112Vac

9

DI7 DI6

AI2 AI1

1 425

3

15

6

78

Not

used

AO3(I)

AO3(V)

GND

AO2

DO6

1110

L

12

17

13

11

EWCM 4180

Page 12

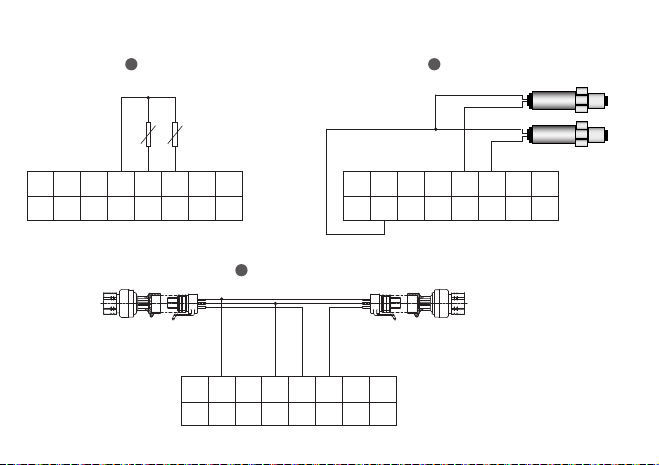

Examples of probe connections

EWPA 4/20mANTC

12Vac

5Vdc

DO5

AO1 DI5 DI4 DI3 DI2 DI112Vac 12Vdc

GND

AI4 AI3

DI7 DI6

AI2 AI1

12Vac

5Vdc

DO5

AO1 DI5 DI4 DI3 DI2 DI112Vac 12Vdc

GND

AI4 AI3

DI7 DI6

AI2 AI1

EWPA R 0/5V

5Vdc

DO5

AO1 DI5 DI4 DI3 DI2 DI112Vac 12Vdc

GND

12Vac

AI4 AI3

12

DI7 DI6

AI2 AI1

Page 13

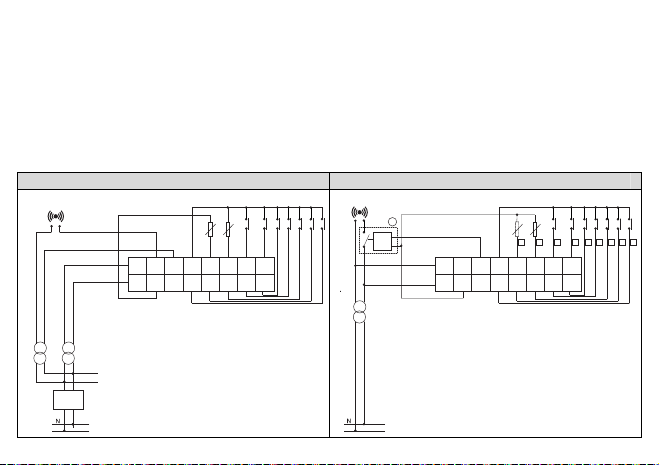

CONNECTION DIFFERENCES BETWEEN EWCM412/415/418 and EWCM4120/4150/4180

The main differences between EWCM412/415/418 and EWCM4120/4150/4180 are listed below:

The terminals of connectors EWCM412/415/418 are different from those of EWCM4120/4150/4180.

The alarm output on EWCM412 (12-24Va max 500mA output for use with 12Va insulated from power supply of

device) is replaced with an open collector output (with parameter configurable function) for use with 12Vc.

PLEASE NOTE: the terminals of the connector, to be used for this output, do not correspond between

EWCM412 and EWCM4120 (see diagram below).

The relays of EWCM4120/4150/4180 do not have a single common contact as on EWCM412/415/418; output

DO4 is separate from the other outputs (DO1, DO2 and DO3)

Connection EWCM412 Connection EWCM4120

A

12Vdc

GND GND ST2 ST1 ID7 ID612Vac ALL

TK1 ID5 ID4 ID3 ID2 ID112Vac

EWCM412

13

T2 T1

B

L

16

12 Vdc 35mA max.

12Vac 5Vac

L

DO5 GND AI4 AI3

AO1 DI5 DI4 DI3 DI2 DI112Vac12Vdc

EWCM 4120

9

DI7 DI6

AI2 AI1

1 425

3

6

78

Page 14

BASIC FUNCTIONS

The user has a display and 4 keys for programming the instrument and checking its status.

When the instrument is powered on for the first time it performs a lamp test, during which time the display and LEDs

flash for several seconds to check that they all function correctly. The instrument has two main menus, the “Machine

state” menu and the “Programming" menu.

EWCM4120 and EWCM4180 EWCM4150

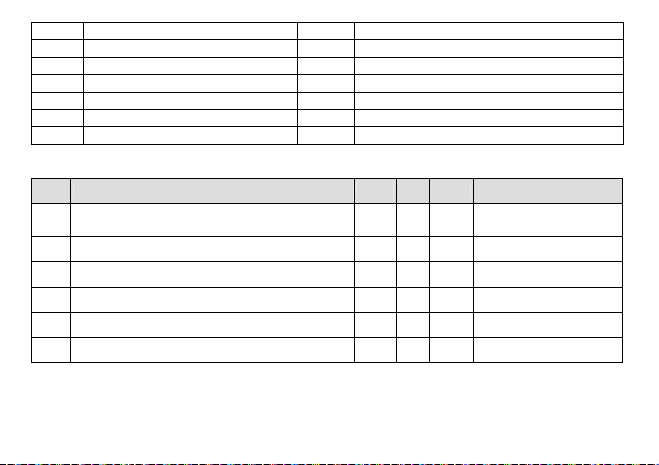

LEDs

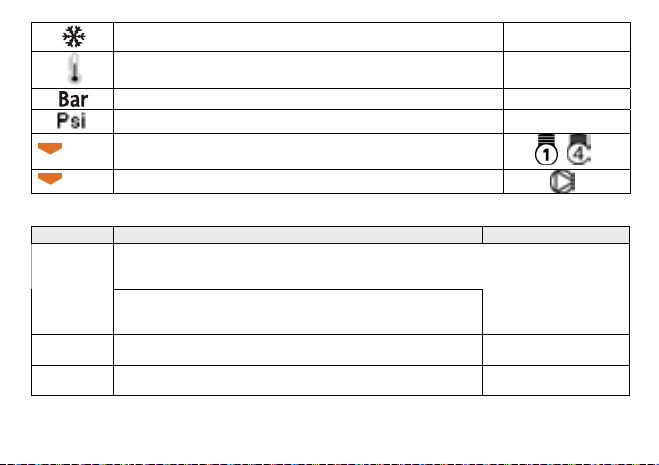

Symbol / icon Description Icon on front panel

EWCM4120-EWCM4180

(8) … (11)

Fan bar (configurable LEDs using parameters UI07…UI10)

EWCM4150

LEDs NOT configured (configurable LEDs using parameters UI07…UI10)

Programming menu

Alarm. If permanently on the alarm is active, if flashing the alarm is

silenced.

Heating. Heating mode

14

Page 15

Cooling. Cooling mode

Display of temperature values in °C/°F

Display of pressure values in Bar

Display of pressure values in Psi

Compressor ON (LED configurable using parameters UI00…UI03)

(1) ... (4)

LEDs NOT configured (Led configurable using parameters UI04…UI06)

(5) ... (7)

Displays in particular states

Status Display LEDs /icons

alarm

Remote

ON/OFF

ON/OFF

keyboard/local

Main display alternated with alarm code (if more than one alarm is

present simultaneously, the one with the lower index will be

displayed) If there is an

If the measurement on the main display is incorrect, the error code

will be displayed; If a further alarm is present, it will alternate between

“---“ and the error code.

Display "OFF" flashing All off

Display "OFF" continuous All off

Alarm icon permanently on

If alarm is silenced it will

flash

-

15

Page 16

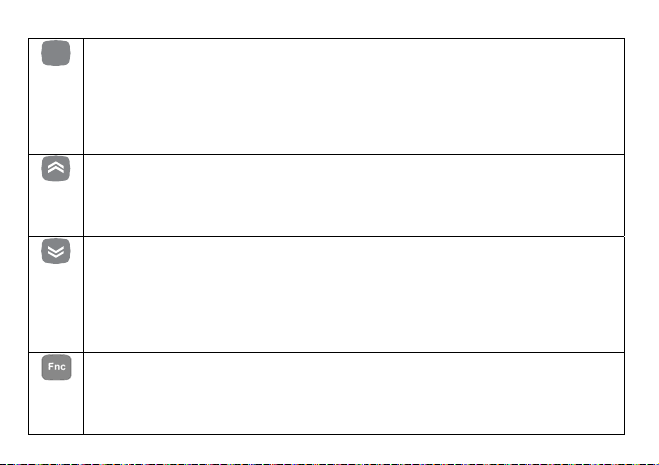

Keys

SET key used to:

set

SET function: access “machine state" menu.

access menu subfolders.

access parameter value.

Confirm parameter value and/or exit.

prg (Programming menu): press and hold (5 secs) to access the Parameters folders from the

main display.

UP key used to:

Scroll down the displayed folders and parameters.

Increase parameter value (if in parameter edit mode).

Band: press and hold (5 sec.) to enter the menu for viewing/editing the compressor plant

adjustment range.

DOWN key used to:

Scroll up the folders and parameters display.

Decrease the parameter value (if in parameter edit mode).

set: Press and hold (5 secs) to access the menu for viewing/editing the setpoint adjustment,

and the type of set point will be displayed. To edit the set point, use the "set" key to display

the value and the "Up" and "Down” keys to edit it.

Press “set” to confirm or “func” to exit (see Note).

FNC key used to:

Menu exit, parameter list, parameter value (without saving value) and return to the previous level.

disp: by holding down for some time (5 secs) access is provided to the menu for selecting the main

display. Using the “up” e “down” keys, only the values that have been configured as present in the

device will be displayed (flashing) and the selection is confirmed by pressing the “set” key.

16

Page 17

+

Press any key to silence the alarms; If there is an alarm, pressing a key once will silence it and will not activate the

corresponding function.

User interface configuration

The LEDs are configured using parameters UI00..UI10:

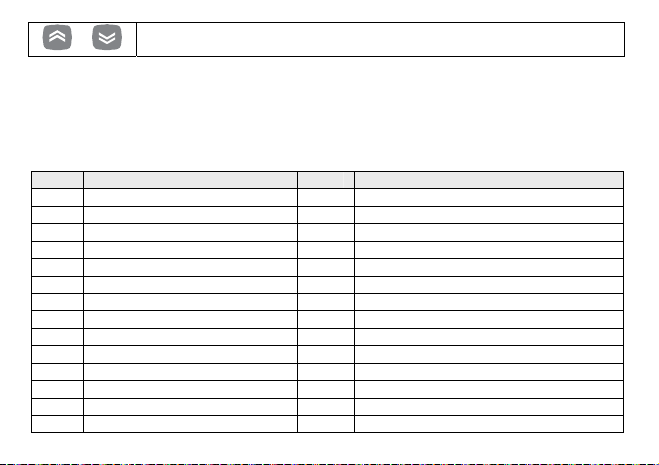

LED utilities table:

Value Description ON Flashing

0 LED disabled - -

1 _ 4 Compressor 1… 4 Active Interstep timing

5 Step 2 compressor 1 Active Interstep timing

6 Step 2 compressor 2 Active Interstep timing

7 Step 2 compressor 3 Active Interstep timing

8 Step 3 compressor 1 Active Interstep timing

9 Step 3 compressor 2 Active Interstep timing

10 Step 4 compressor 1 Active Interstep timing

11 …14 Fan 1 ... 4 ON Active Interstep timing

15 Alarm Active Silenced

16 … 22 Not used - -

23 Compressor inverter enabling Active 24 Fan inverter enabling Active 25 Inverter fan Active Interstep timing

If any alarms are present, they can be reset by simultaneously pressing the UP + DOWN

keys.

17 18

Page 18

26 Inverter compressors Active Interstep timing

27 Inverter fan bar ≥25% Active 28 Inverter fan bar ≥50% Active 29 Inverter fan bar ≥75% Active 30 Inverter compressor bar ≥25% Active 31 Inverter compressor bar ≥50% Active 32 Inverter compressor bar ≥75% Active -

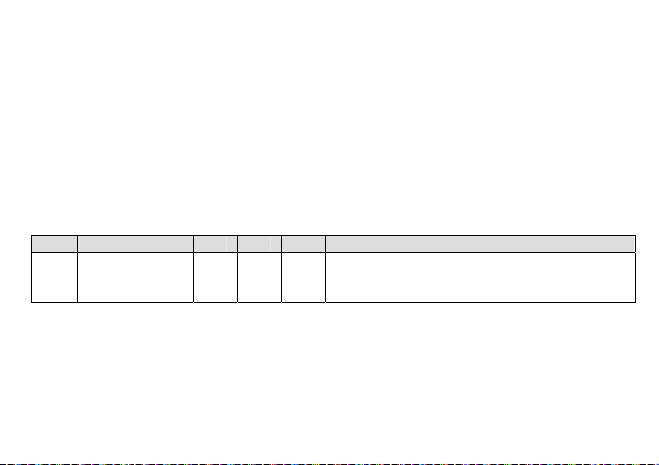

User interface configuration parameters:

Par. Description Min Max U.M. Notes

UI12 Select main set point display 0 1 num

UI13 Select main display 0 6 num

UI20 Installation password 0 255 num Default UI20= 1

UI21 Manufacturer password 0 255 num Default UI21=2

UI22 Unit of temperature measurement 0 1 num 0=°C, 1=°F

UI23 Unit of pressure measurement 0 1 num 0=Bar, 1=Psi

Parameters UI20 - UI21

In parameters UI20 and UI21 respectively, the installer (level 1) password and manufacturer (level 2) password must

be changed. See PASSWORD AND VISIBILITY chapter.

0=display Inlet Set

1= display Outlet Set

Page 19

Main display

Under normal operating conditions, it is possible to select which measurement to display on-screen (not in the

navigation menu or in the case of alarms).

Press and hold the “FNC” key to access the folder containing all of the available measurements. The only

measurements which will be displayed, flashing on-screen, are those which can be selected and which are present in

the device (for example The RTC will appear in the list only if it has been configured as present). The list is as follows:

AI01…AI04 (one of the probes available among those configured in the device)

RTC (clock)

Set point; In OFF, the set point displayed is the set point for the previous operating mode in OFF status.

The following procedure describes how to set the main display:

Press the “FNC” key for 5 seconds (value configurable from parameter UI19)

select the measurement to display by scrolling through the various options using the Up and Down keys

press the “set” key

Par. Description Min Max U.M. Notes

UI13 Main display 0 6 num

NOTE: Either the inlet setpoint or the outlet setpoint will be displayed, depending on parameter UI12 (select main set

point display).

Password and visibility

To view parameters visible for the given password, open folder PASS (in the Parameters menu PAR) and set the level1

value (set in parameter UI20) or level2 value (set in parameter UI21). The visibility of the parameters and the folders

during menu navigation can be configured by assigning appropriate values to each parameter and folder. This

operation can only be performed using suitable software (Parammanager or other communication SW).

0=analogue input 1, 1=analogue input 2, 2=analogue

input 3, 3=analogue input 4, 4= analogue input 5,

5= clock, 6= set point configured

19

Page 20

The visibility levels are:

Value 0 = Parameter or folder not visible.

Value 1 = installer level; These parameters can only be viewed by entering the Password 1 value (all parameters

specified as always visible and parameters that are visible at the installation level will be visible).

Value 2 = manufacturer level; These parameters can only be viewed by entering the Password 2 value (all

parameters specified as always visible, parameters that are visible at the installation level, and manufacturer

level parameters will be visible).

Value 3 = parameter or folder always visible.

Accessing and using the menus

Resources are organised into menus and viewed by briefly tapping the “set” key (“Machine state” menu) or by

keeping the “set” key pressed for more than 5 seconds (“Programming” menu). Press the "set" key once to view the

contents of any folder highlighted by the corresponding label. At this point it is possible to scroll through the

contents of any folder, editing it or using the functions envisaged for it. Either do not press any keys for 15 seconds

(time-out) or press the “fnc” key once, to cancel the parameter modifications and return to the previous screen.

WARNING:Not all of the parameters are visible if the 1 or 2 level password has not been previously entered.

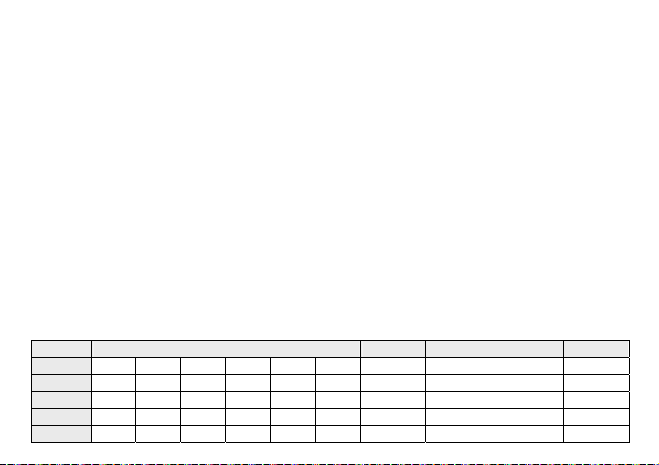

Machine state menu

From the states menu you can view values for each resource.

Some of the resources have “dynamic” visibility, e.g. if there are no alarms present then the AL folder will not be

displayed.

Folder Resources Visibility Description Edit

Ai AI01 AI02 AI03 AI04 Dynamic Analogue inputs //

di di01 di02 di03 di04 di05 // Dynamic Digital Input //

AO tC1 AO1 AO2 AO3 // // Dynamic Analogue outputs //

dO dO01 dO02 dO03 dO04 dO05 dO06 Dynamic Digital outputs //

CL HOUr dAtE YEAr Clock YES

20

Page 21

AL Er00 …. … … … Er99 Dynamic Alarms //

SP (1)* // // // // // set point(set) YES

Hr CP01 … CP04 Fn01 … Fn04 Dynamic

SC CP01 … CP04 Compressor selection //

As you will be able to see from the table, the setpoint SP and time can be modified and viewed.

(1) * The following type is initially indicated for the set point: SUCTion Set, DISCharge Set. Press the "set" key once

again to view/edit the set point value.

Programming menu

Menu Folder Subfolders Description

Parameters PAr CF Ui St CP Fn AL Pass CC OP Parameters

EU EU Eu00 … … … … … … … Eu99 Alarms log

EUR EUR Reset alarm history

Operating hours

Compressors / fans

YES

CONFIGURING THE MACHINE

1) ANALOGUE INPUTS (AI3, AI4)

The device has 2 analogue inputs which are configurable using the following parameters:

CF02* Type of analogue AI3 input CF07 Analogue AI4 input start of scale value

CF03* Type of analogue AI4 input CF10 Analogue AI3 input differential

CF04 Analogue AI3 input end of scale value CF11 Analogue AI4 input differential

CF05 Analogue AI3 input start of scale value CF14** Configuration of analogue AI3 input

CF06 Analogue AI4 input end of scale value CF15** Configuration of analogue AI4 input

See Parameters F04 … CF11 limits table

21

Page 22

* If inputs AI3 and AI4 are not set as DI, parameters CF25 and CF26 parameters must be set to 0. Failure to observe

this rule may result in malfunctions.

** If inputs AI3 and AI4 are set as DI, parameters CF14 and CF15 parameters must be set to 0.

*** The unit of measurement (U.M.) is selected based on parameters CF02 and CF03 and parameters UI22 (C°/F°) and

UI23 (Bar/Psi).

Inputs AI3 and AI4 are configurable as indicated in the following table (CF02 ... CF03):

Notes:

If an input is configured as NTC, the corresponding parameters are always displayed with the “thermometer” icon.

(UI22=0/1; U.M.= C°/F°)

If an input is configured as 4-20mA, 0-10V or 0-5V, the corresponding parameters are displayed with U.M. =Bar if

UI23=0 with U.M.=Psi if UI23=1.

Parameters CF04 ÷ CF07

Indicate the reading scale analogue limit values for inputs configured as 4-20mA, 0-10V, 0-5V. (Inputs 3 and 4 only)

If the input is not configured as input 4-20mA, 0-10V, 0-5V, the end of scale parameters lose meaning.

Value Type Description

0 None Probe not configured

1 DI Probe configured as potential-free contact digital input

2 NTC NTC probe range -50.0°C ÷ 99.9 °C

3 4-20mA Analogue input 4-20 mA

4 0-10V Analogue input 0-10 V

5 0-5V Analogue input 0-5 V

22

Page 23

Parameters CF10 ÷ CF11

Indicate the correction values to add to or subtract from the analogue inputs; by means of this parameter it is

possible to calibrate the temperature/pressure value read by the device. The value given by the instrument reading

“AIxx analogue input differential" will be used by the regulator connected to that probe and will be displayed onscreen. If the input is configured as a digital input, the correspon ding correction parameter must be set to 0

(otherwise the digital input will not function correctly).

Parameters CF14 ÷ CF15

Indicate the logical meaning of the analogue inputs. If the input is configured as a digital input, refer to parameters

CF23..CF26.

* If CF02=4-20mA, 0-10V, 0-5V then CF14 cannot be set to 2 or 3.

** If CF03=4-20mA, 0-10V, 0-5V then CF15 cannot be set to 1.

2) DIGITAL INPUTS (DI1, DI2, DI3 DI4 and DI5)

The EWCM32x74 device has 5 digital inputs for potential-free contacts which are configurable by means of user

parameters. If necessary the analogue inputs may also be configured as digital inputs.

Parameter Description

Value Description

0 Probe disabled

1 Inlet regulation probe *

2 Outlet regulation probe **

3 Not Used

CF16…CF20 DI1 …DI5 digital input configuration

CF23 …CF26* AI ...AI4 analogue input configuration if configured as digital input

* Set = 0 if AI1 is NOT configured as DI.

23

Page 24

Parameters CF16 ÷ CF20 and CF23 ÷ CF26

Indicate the logical meaning of the analogue inputs.

Value Description

± 0 Input disabled

± 1 Outlet pressure switch

± 2 Inlet pressure switch

± 3…± 6 Block compressor 1…4

± 7 Continuous compressor shut-down (inverter)

± 8…± 11 Fan 1..4 thermal switch

± 12 Continuous fan/shared fans thermal switch

± 13 Remote On/Off

± 14 General alarm

Polarity is defined below:

± 15 … ± 21 Not used

Value Type Description

+ Positive Active when contact closed

If multiple inputs are configured with the same value, only the input with the highest index is active (an OR logic is

- Negative Active when contact open

not executed)

24

Page 25

3) HIGH/LOW VOLTAGE DIGITAL OUTPUTS (DO1…DO6)

The device has 5 or 6 digital outputs (depending on model), which are configurable by means of user parameters.

The digital outputs are available as relay contacts (DO01…DO04 and DO06) or open collector low voltage outputs

(DO05). If necessary, the analogue outputs (Triac and PWM, AO1, AO2 and AO3) may also be configured as digital

outputs. See the following paragraph for the characteristics.

Parameter Description

CF45… CF49 DO1… …DO5 digital output configurations

CF50* Configuration of digital output DO6

* Parameter present in models with 5 relays (Triac not present in these models).

The relay output and open collector can be configured as shown in the table below:

Value Description

± 0 Output disabled

± 1…± 4 Compressor 1..4 switched on

± 5 Capacity step 1 compressor 1 relay

± 6 Capacity step 1 compressor 2 relay

± 7 Capacity step 1 compressor 3 relay

± 8 Capacity step 2 compressor 1 relay

± 9 Capacity step 2 compressor 2 relay

± 10 Capacity step 3 compressor 1 relay

± 11…± 14 Fan state 1..4

± 15 Alarm status

± 16…± 22 Not used

± 23 Compressor inverter enabling

± 24 Fan inverter enabling

25

Page 26

Polarity is defined below:

If multiple outputs are configured to run the same resource, the outputs will be activated in parallel.

4) PWM/OPEN COLLECTOR OUTPUTS AO1 AND AO2

The device has two outputs, configurable as PWM or open collector, which pilot the fans/continuous compressors

(via the CFS modules), if configured as PWM, or another resource via external relay if configured as open collector

(On/Off).

The AO1 output is always present whilst the AO2 output is present on models 4150 and 4180 only.

Parameter Description M.U. Min Max

CF34 Enable analogue output AO1 num 0 1

CF35 Enable analogue output AO2 num 0 1

CF37 Analogue AO1 output phase shift num 0 90

CF38 Analogue AO2 output phase shift num 0 90

CF40 Analogue AO1 output pulse length (1 unit=69.4 μs) num 5 40

CF41 Analogue AO2 output pulse length (1 unit=69.4 µs) num 5 40

CF43 Analogue AO1 output configuration num -24* 26*

CF44 Analogue AO2 output configuration num -24* 26*

CF51** Configuration of digital AO1 output num -24* 24*

CF52** Configuration of digital AO2 output num -24* 24*

* Values from 16 to 22 are not used.

** Parameters CF51 and CF52 represent the logic assignment of outputs AO01 and AO02 if configured as digital

outputs.

Value Type Description

+ Positive Active when contact closed

- Negative Active when contact open

26

Page 27

Note: Parameters CF37..CF41 have meaning only if the outputs have been configured as Triac outputs; The value to

enter represents the phase shift between voltage and current of the motor connected to the output (obtained from

cos indicated in the motor specifications).

The parameters for output AO2 are available only in models with this output.

Parameter CF34 ÷ CF35

Allow the Triac analogue output to be characterised in the following manner:

Parameters CF37 ÷ CF38

Indicate the phase shift values of the pulse output (for adaptation to inductive load) and are active if CF34=1 and

CF35=1.

Parameters CF40 ÷ CF41

Indicate the duration of the pulse output (1 unit=69.4 μs) and are active if CF34=1 and CF35=1.

Parameters CF43 ÷ CF44

Indicate the logical meaning of the Triac analogue outputs and are active if CF34=1 and CF35=1.

Value Description

0 Output configured as digital

1 Output configured as Triac (for pulse piloting)

27

Page 28

It is possible to pilot loads with output modulation (value 25-26) or loads with on/off type switching using the Triac as

a switch.

Value Description Type

0 Output disabled On/Off

1 _ 4 Compressor 1..4 switched on On/Off

5 Capacity step 1 compressor 1 relay On/Off

6 Capacity step 2 compressor 1 relay On/Off

7 Capacity step 3 compressor 1 relay On/Off

8 Capacity step 1 compressor 2 relay On/Off

9 Capacity step 2 compressor 2 relay On/Off

10 Capacity step 3 compressor 1 relay On/Off

11 … 14 Fan status 1..4 On/Off

15 Alarm status On/Off

16 … 22 Not used -

23 Compressor inverter enabling On/Off

24 Fan inverter enabling On/Off

25 Inverter fan status Proportional

Parameters CF51÷ CF52

26 Inverter compressor status Proportional

Indicate the logical meaning of outputs AO01 and AO02 configured as digital outputs and are active if CF34=0 and

CF35=0. For meaning see table entitled configuration of relay and open collector in high/low voltage digital outputs

(DO1 ... DO6).

28

Page 29

5) TRIAC TC OUTPUT

In certain models, the device has a high voltage Triac output which is typically used for piloting the fans/continuous

compressors.

The output can be configured for proportional operation (constant speed variation) or as ON/OFF; If configured as a

proportional output, the phase parameters and the pulse length of the Triac must be properly configured for better

adaptation to the load characteristics.

Parameter Description M.U. Min Max

CF33 Enable analogue TC output num 0 1

CF36 Analogue TC output phase shift num 0 90

CF39 Analogue TC output pulse length (1 unit=69.4 μs) num 5 40

CF42 Analogue TC output configuration num -24 26

Note: Parameters CF36 and CF39 have a meaning only if the outputs have been configured as Triac outputs.

Parameter CF33

Allows the Triac analogue output to be characterised in the following manner:

Value Type Description

0 None Output disabled

Parameter CF36

1 Triac Output configured as Triac

Indicate phase shift values to pilot Triac with phase cutting in the event of inductive loads; the value to enter

represents the phase shift angle between voltage and current of the motor connected to the output (obtained from

the cos indicated in the motor specifications).

Parameter CF39

Indicate pulse length to pilot Triac (1 unit = 69.4 μs).

29

Page 30

Parameter CF42

Indicate the logical meaning of Triac analogue outputs. It is possible to pilot loads with output modulation

(value 25-26) or loads with on/off type switching using the Triac as a switch. For meaning see table entitled

Configuration of Parameters CF43 ÷ CF44 in PWM/OPEN COLLECTOR OUTPUTS AO1 and AO2.

6) LOW VOLTAGE ANALOGUE AO3 OUTPUT

In certain models, the device has 1 low voltage analogue output configurable by means of the user parameters.

Depending on the application, the output may be available as 0-10V or 4-20mA

AO3 configuration

Parameter Description M.U. Min Max

CF27 Type of output analogue AO3 num 0 2

Parameter CF27

CF30 Configuration of analogue output AO3 num -24 26

Allows the Triac analogue output AO3 to be characterised in the following manner:

Value Type Description Notes

0 0-10V Analogue output - voltage Modulated piloting or on/off

1 4-20mA Analogue output - current Modulated piloting or on/off

Parameter CF30

2 0-20mA Analogue output - current Modulated piloting or on/off

Indicates the logical meaning of the analogue output. It is possible to pilot loads with output modulation

(value 25-26) or loads with on/off type switching using the output as switch 0-10V. For meaning see table

entitled Configuration of Parameters CF43 ÷ CF44 in PWM/OPEN COLLECTOR OUTPUTS AO1 AND AO2.

30

Page 31

COMPRESSOR CONTROL

The device can be configured to manage an inverter compressor or one or more homogenous digital compressors

(max. 4) by setting parameter CP22:

Parameter Description Min Max Notes

Number of compressor steps

CP22

per circuit

With digital compressors it is also possible to define the number of power stages by setting parameters CP23, CP24

and CP25:

Parameter Description Min Max Notes

CP23 Number of compressor steps 1 1 4

CP24 Number of compressor steps 2 1 3

CP25 Number of compressor steps 3 1 2

Regulation is proportional or Neutral Zone (ZN) as a function of the inlet probe (temperature or pressure control).

In the case of pressure regulation, probe AI3 must be used (high resolution probe).

In local or remote OFF the compressors are switched off.

The compressors and/or relative Power stages can be directly connected to the controller via the Triac output or relay

or indirectly connected via an external module (connected to controller via an PWM or analogue output):

Direct Triac TC output.

Indirect “PWM” output AO1, AO2 (needs external module for piloting the inverter compressor).

Indirect 4..20mA / 0..20mA / 0..10Vcc output AO3 (needs external module for piloting inverter compressor).

Relay output for piloting digital compressors (whole or segmented).

Digital Output DO5 (Open Collector) using an external relay.

0 4

31

0=inverter compressor.

≠0=CP22 represents the number of digital

compressors.

1=whole compressor

≠1= CP23 - 1 is the number of Power stages.

1= whole compressor

≠1= CP24 - 1 is the capacity step

1= whole compressor

2= the number of Power stages is 1

Page 32

One or more digital inputs can be configured as compressor block inputs:

Digital inputs DI1…DI7.

Analogue inputs AI3 …AI4 if configured as digital inputs.

It is also possible to configure a relay as compressor INVERTER enabling output.

Inverter compressor control

The operating mode depends on parameter ST02. Cold mode St02=1. Hot mode St02=0.

The inverter compressor control is proportional as a function of the inlet probe value. The following diagram

indicates the compressor speed as a function of the regulation probe in the case of regulation with lateral set point

(St01=1). In the case of central set point (St01=0), the proportional band is centred in the set point:

Speed

CP20

CP19

%

Cooling (St02 = 1)

CP00

CP07CP05

B

CP07 CP05

B

Heating (St02 = 0)

CP00

CP18

OFF

CP06

A

CP04

CP03

Keys

CP03

A Minimum cut-off

B Saturation cut-off

32

CP04

A

CP06

(°C/°F/Bar/Psi)

Page 33

Compressor

Inverter

Enabling

ON

OFF

Cooling

CP06

CP04

Setpoint

(CP00)

Setpoint

(CP00)

CP04

Heating

CP06

Regolator

probe

The digital inverter enabling output is activated in each case in which the analogue output has a value other than 0%.

The above drawing represents only the nominal case in which the cut-off hysteresis is enabled at the minimum.

Parameters CP08 (enable minimum cut-off) and CP09 (enable saturation cut-off) activate or deactivate the cut-off

function. Note that, if the minimum cut-off is disabled, the speed of the inverter compressor goes from 0 to the

minimum speed when the regulation probe reaches the set point from "below". If the regulation probe reaches the

set point from “above”, the speed will go from minimum speed to 0. Similarly if the saturation cut-off is disabled, the

speed of the inverter compressor goes from continuous regulation to maximum speed when the regulation probe

reaches Set point+Proportional Band from "below”. If the regulation probe reaches Setpoint+Proportional Band from

"above" there will be continuous regulation between maximum and minimum speed.

Regulation probe error: the inverter compressor will be piloted at the speed set by parameter CP21.

33 34

Page 34

Digital compressor control

The regulator calculates the number of refrigeration resources required by the system through a policy of assigning

resources selectable with parameter CP10 (Activation policy).

Activating or deactivating power steps must respect the activation and release times for resources CP15 and CP16

which are loaded on activation/release.

In alarm conditions, (e.g. due to the intervention of a compressor block) any reduction in power required is

calculated immediately. however, the power make-up must always keep to the time intervals described above,

particularly the activation time of the CP15 resources.

Proportional band: this occours if bit0 of parameter ST04 equals 0 (this occours for St04=0 and St04=2).

The operation depends on the parameter ST02: Cooling mode if St02=1 and Heating mode if St02=0.

The digital compressor control is stepped as a function of the inlet probe value.

The regulator activates a certain number of resources (power steps) to reach the Set point configured. The number of

resources required is linked to the difference between the value measured by the inlet probe and the set point;

Naturally, the greater this difference, the greater the number of resources required to reach the setpoint. The

temperature /pressure interval between activation of one power step and the next depends on the proportional band

and the number of resources present.

In the event of a regulation probe error, the number of active power steps is calculated as a percentage set at

parameter CP21 of the complete number of steps.

The following is an example of regulation with lateral set point (St01=1). In the case of central set point (St01=0) the

proportional band is deemed to be centred in the set point.

Page 35

Step

Cooling (St02 = 1) Heating (St02 = 0)

3

2

CP03

nr. of steps

CP03

nr. of steps

CP00

1

0

Neutral zone: this occurs if bit0 of parameter ST04 equals 1 (this occurs for St04=1 and St04=3).

CP03 CP03

CP00

(°C/°F/Bar/Psi)

The operation depends on the parameter ST02: Cooling mode if St02=1 and Heating mode if St02=0.

The main function of the regulator consists in activating/deactivating a number of resources (discrete power steps)

linked to the time in which the intake probe takes on values outside of the symmetric proportional band in

comparison to the set point value.

For the cooling mode, for example, when the value read by the intake probe exceeds the SET POINT+(BANDA)/2

threshold value, if the increasing interstep time (set with CP15) has already expired, an increase in power is

implemented and the CP15 time is recounted (increasing interstep time). If the value read by the intake probe

remains in this range, an additional power increase is activated for each “increasing interstep time” (set with CP15).

The operation is similar for switching off, with the times set by parameter CP16 (decreasing interstep time).

35

Page 36

No variation in power is required within the PROPORTIONAL BAND. Hysteresis is not included in this algorithm.

Set point

+1 +1 +1

-1

T inc. T inc.

T inc.

T dec.

Time

Regulator probe

Band

Set point

+1 +1 +1

-1

T inc. T inc.

T inc.

T dec.

Time

Regulator probe

Band

All interstep times are resynchronised upon the activation/deactivation of a new compressor combination.

In the case of an regulation probe error, the number of active steps is calculated as a percentage set for the CP21

parameter of the total number of steps.

Compressor timing

The switching on and off of a compressor (inverter or digital) must meet the following requirements:

Minimum time between switching off/on (parameter CP12). This is the minimum delay between switching off

Minimum time between switching off/on (parameter CP14). This is the minimum delay between switching on

Minimum time between switching off/on (parameter CP13). This is the minimum delay between switching on

and switching on;

and switching off;

and switching on again;

36 37

Page 37

The activation and deactivation of power steps for digital compressors must respect the activation and release times

for resources (parameters CP15 and CP16).

Power stages

For a segmented compressor in which the number of steps corresponds to the number of segments plus one, the

segmentation actuation mode depends on parameter CP11.

Parameter Description Min Max M.U.

CP11

For a whole compressor there are no power stages, so the compressor supplies either 0% or 100% of its power.

Example of compressor with 3 power stages (4 regulation power steps)

The compressors can supply 0%, 25%, 50%, 75% or 100% of their power.

Power ACC

Enable/disable sequence of relays associated to compressor

power stages in the suction section

0 2 Num

CP11=0 CP11=1 CP11=2

STG 1 STG 2 STG 3 STG 1 STG 2 STG 3 STG 1 STG 2 STG 3

100% ON ON ON ON

75% ON ON ON ON ON

50% ON ON ON ON ON

25% ON ON ON ON ON

0%

Compressor switch-on policies

The selection policy that the inlet regulator applies in the distribution of the refrigerator resources is defined by

parameter CP10. The policies available are saturation, balancing and fixed sequence.

Page 38

Parameter Description Min Max M./U. Notes

CP10 Activation Policy 0 2 Num 0= fixed sequence 1= balancing 2= saturation

The selection policies are based mainly on the hours of operation of the compressors.

They come into play when the regulator requests the activation/deactivation of a step. This request is then distributed

to the most suitable compressor according to the compressor selection policy selected using CP10.

Compressor saturation: The saturation policy distributes all resources equally over the smallest number of

compressors possible, so far as this is compatible with other requirements, such as: compressor safety timings. The

resulting allocation is intended to have the largest possible number of compressors switched off at any one time.

Compressor balancing: The balancing policy distributes all resources equally over the largest number of compressors

possible, so far as this is compatible with other requirements, such as compressor safety timings: The resulting

allocation is intended to have the greatest possible equalization of power output levels in the compressors at any one

time.

Fixed sequence compressors: The fixed sequence policy distributes all resources starting from the compressors with

the lowest index, so far as this is compatible with other requirements, such as compressor safety timings The resulting

allocation is such as to obtain, at any given time, a maximum delivery of the compressors with lower indexes.

Hours of use of compressors

The operating time of the compressors is stored every hour in EEPROM for the purpose of:

Managing the compressor switch-on policies;

Enabling the signalling of an alarm if the compressor operating hours exceed the maximum operating hours

threshold.

38

Page 39

Parameter Description Min Max M.U.

CP17 Maximum hours of use for compressor 0 6500 Hours*10

The hours of use of each single compressor can be reset from the State menu.

Selecting/deselecting compressors

Each individual compressor can be selected from the State menu. Deselection of a compressor entails the following:

The compressor availability is set to zero

Zero setting of all its possible alarms

Its alarms are not managed

Compressor block

Management of this alarm applies both to step compressors and to compressors with continuous regulation and is

active if the compressor is selected. The activation of this alarm blocks the compressors in use. In the case of step

compressors, the availability of another compressor is checked at the same time as the compressor block. If it is

available it will be selected depending on the policy (CP10) and immediately switched on.

CONDENSATION CONTROL

The device can be configured to manage an inverter fan or one or more homogenous digital fans (max. 4) by setting

parameter Fn25:

Parameter Description Min Max M.U Notes

-1 = no condensation.

Fn25 Number of fans per step for fan coil -1 4 Num

39

0 = continuous fan.

>0 = Fn25 represents the number of

digital fans.

Page 40

By setting parameter Fn25=-1 it is also possible to define that the fan is absent (no condensation) and the relative

regulator will not be actuated. If a probe is configured as a temperature probe or outlet pressure probe, the

condensation regulation is proportional or Neutral Zone (NZ). In the case of pressure regulation, the AI4 probe must

be used (low resolution probe). If no outlet probe has been configured, the fans will be piloted by default depending

on the operating mode (Heat or Cool). In local or remote OFF the fans are switched off.

The fan can be directly connected to the controller via the Triac output or relay or indirectly connected via an

external module (connected to controller via a PWM or analogue output):

• Direct Triac TC output

• Indirect “PWM” output AO1, AO2 (needs external module for piloting fan).

• Indirect 4..20mA / 0..20mA / 0..10Vcc output AO3 (needs external module for piloting fan).

• Relay outputs for piloting digital fans

• Digital Output DO5 (Open Collector) using an external relay.

One or more digital inputs can be configured as fan thermal switch:

• Digital inputs DI1…DI7.

• Analogue inputs AI3 …AI4 if configured as digital inputs.

It is possible to configure a relay as fan INVERTER enabling output.

INVERTER COMPRESSOR CONTROL

Pick-up

Each time the fan starts, the exchanger fan is supplied at the maximum voltage level, hence the fan runs at the

speed established by parameter Fn23 (max. pick-up speed) for a time equal to the value set via parameter Fn13

(pick-up time). After this time, the fan will continue at the speed set by the regulator. However if the regulator

wants to turn the ventilation off during the pick-up time, the fan will be switched off. The pick-up time will be

reloaded at the next start.

The speed specified by parameter Fn23 may be reached in one of two ways depending on the value of parameter

Fn12 (mode for reaching maximum pick-up speed):

40

Page 41

• 0 = the regulator immediately sets the output proportional to the speed specified by parameter Fn23 and

maintains this speed for the time specified by parameter Fn13.

• 1 = the regulator actuates the proportional output according to a ramp that allows the speed specified by

parameter Fn23 to be reached in the time specified by parameter Fn13.

If Fn13= 0, pick-up is disabled. The regulation may be at central set or side set depending on parameter St01.

The use of the interstep times Fn16 and Fn17 is enabled and they are loaded during the instrument switching on and

switching off phases. To prevent uncertainty, it is recommended to set the values to 0.

Regulation

The operating mode depends on parameter ST02. Cold mode St02 = 1. Hot mode St02 = 0.

If no condensation probe has been allocated (temperature or pressure), the fan ON/OFF switch will be controlled on

request from the compressor in cooling mode or in heating mode if Fn10 = 1, otherwise if Fn10 = 0 the fan is always

ON.

When the fan is ON it is piloted at the speed set by parameter Fn24. If however a condensation probe has been

allocated, the fan control is proportional as a function of the condensation probe value. The fan may be regulated

independently from the compressor or at the request of the compressor depending on parameter Fn10 (operation on

request by compressor): If Fn10=0 then condensation is controlled independently from the compressor, however if

Fn10=1 then the fan is OFF when all of the compressors available are OFF.

The minimum cut-off is bypassed for the time specified by parameter Fn14 on start-up of the compressor. If the

regulator requests the cut-off during this period the fan is piloted at the minimum speed set by parameter Fn20.

Note: The cut-off does NOT force the fans to be switched on but only prevents them from being switched off. The

following diagrams illustrates the fan speed and the digital inverter enabling output as a function of the regulation

probe in the case of regulation with lateral set point (St01=1). In the case of central set point (St01=0), the

proportional band is deemed to be centred in the set point:

41

Page 42

Parameters Fn08 (enable minimum cut-off) and Fn09 (enable saturation cut-off) activate or deactivate the cut-off

y

function. Note that if the minimum cut-off is disabled, the speed of the fan goes from 0 to the minimum speed when

the regulation probe reaches the set point from “below”. If the regulation probe reaches the setpoint from “above”,

the speed will go from minimum speed to 0.

Similarly, if the saturation cut-off is disabled, the fan speed goes from continuous regulation to maximum silent speed

when the regulation probe reaches the Set Point+Proportional Band from "below”.

If the regulation probe reaches Set point+Proportional Band from "above", there will be continuous regulation

between maximum silent speed and minimum speed.

Speed

%

Fn22

Fn21

Cooling (St02 = 1)

Fn00

Fn07Fn05

B

Fn07 Fn05

B

Heating (St02 = 0)

Fn00

Fn20

OFF

A

Fn06

Ke

Fn03

Fn04

Fn03

A Minimum cut-off

A

(°C/°F/Bar/Psi)

Fn04

06

B Saturation cut-off

42

Page 43

Fan

Inverter

Enabling

ON

OFF

The digital inverter enabling output is activated in each case in which the analogue output has a value other than 0%.

Cooling

Fn06

Fn04

Setpoint

(Fn00)

Setpoint

(Fn00)

Fn04

Heating

Fn06

The above drawing represents only the nominal case in which the cut-off hysteresis is enabled at the minimum.

Inverter preventilation (cold mode only)

If parameter Fn10=1 (if the compressor is OFF, the fan is OFF) and Fn15<>0, the preventilation is also active. Before

the compressor is switched on, the fan is switched on for a time equal to Fn15; the fan speed is proportional to the

value of the regulation probe. However, if during this period the regulator requests the switching off of the fan, the

fan will be piloted at the minimum speed set by parameter Fn20. This is to avoid the compressor switching on when

the condensation probe values are excessively high. If, at the end the preventilation, the regulator does not request

fans, the fan is switched off immediately. The preventilation is reset if the right parameter conditions are present and

if the inlet request is zeroed and then returns (even if the request is cancelled by its alarm or the outlet alarm).

In the event of a regulation probe error, the fan ON/OFF switch will be controlled on request from the compressor.

When the fan is ON it is piloted at the speed set by parameter Fn24.

43 44

Regolator

probe

Page 44

DIGITAL FAN CONTROL

Pick-up

On each activation request by the regulator, all of the exchanger fans are activated simultaneously for a time equal to

the value set using parameter Fn13 (pick-up time).

After this time has elapsed, the fans will be piloted at the speed set by the regulator. If, during the pick-up time, the

regulator wants to turn the ventilation off, the fans will be switched off. The pick-up time will be reloaded at the next

start. If Fn13= 0 the pick-up is disabled.

Activation and deactivation of power steps must respect the activation and release times for resources Fn16 and

Fn17, which are loaded at activation/release.

The use of the interstep times Fn16 and Fn17 is enabled in the case of a continuous fan and they are loaded during

the instrument switching on and switching off phases. To prevent uncertainty, it is recommended to set the values to 0.

Proportional band regulation: this occurs if bit1 of parameter ST04 equals 0 (this occurs for St04=0 and St04=1).

The operation depends on the parameter ST02: Cooling mode if St02=1 and Heating mode if St02=0.

If no condensation probe has been allocated (temperature or pressure), the fan ON/OFF switch will be controlled on

request from the compressor in cooling mode or in heating mode if Fn10=1, otherwise if Fn10=0 the fan is always

ON. During the ON phase, the number of fans switched on in respect to the number of those present depends on the

value set at parameter Fn24. If however a condensation probe has been configured, the fan control is by steps as a

function of the condensation probe value.

The regulator activates a certain number of resources (power steps) to reach the Set point configured (Fn00). The

number of resources required is linked to the difference between the value measured by the condensation probe and

the set point; The greater this difference, the greater the number of resources required to reach the set point. The

temperature/pressure interval between application of one power step and the next depends on the proportional

band and the number of resources present.

The fan may be regulated independently from the compressor or at the request of the compressor, depending on

parameter Fn10 (compressor operation on request).

Page 45

If Fn10=0 then the condensation control is independent of the compressor, if, however, Fn10=1 then the fan is off

when all of the compressors available are off.

The cut-off at minimum is bypassed for the time set at parameter Fn14 after the compressor is activated. If the

regulator requests the switching off of the fans during this time, the fans will be piloted at the minimum speed (1

step). The following is an example of regulation with lateral set point (St01=1). In the case of central set point

(St01=0), the proportional band is deemed to be centred in the set point:

Step

Cooling (St02 = 1)

3

2

Fn03

nr. of steps

Fn03

nr. of steps

Heating (St02 = 0)

Fn00

1

0

Fn03 Fn03

Fn00

Neutral zone regulation: this occurs if bit1 of parameter ST04 equals 1 (this occurs for St04=2 and St04=3).

The operation depends on the parameter ST02: Cooling mode if St02=1 and Heating mode if St02=0.

If a condensation probe has not been allocated (in temperature or in pressure) the fans are On OFF controlled on

request by the compressor in cooling mode or in heating mode if Fn10=1 otherwise, if Fn10=0, the fan is always ON.

45 46

(°C/°F/Bar/Psi)

Page 46

During the ON phase, the number of fans that are switched on in comparison to the number of those present is a

function of the value set for parameter Fn24.

If a condensation probe has been allocated, the fan control will be in steps with a neutral zone in function of the

value of the condensation probe and the set times.

Fan regulation can be done independently of the compressor or upon request of the compressor in function of the

parameter Fn10 (operation on compressor request): if Fn10=0 condensation control is independent of the

compressor, if Fn10=1 instead, if all of the available compressors are off, the fan is off.

The minimum cut-off is bypassed for time set for parameter Fn14 from switching on the compressor. During this

period, if the regulator requests the fans to switch off, they will be controlled at the minimum speed (one step).

The main function of the regulator with a neutral zone consists in activating/deactivating a number of resources

(discrete power steps) linked to the time in which the delivery probe takes on values outside of the symmetric

proportional band in comparison to the set point value.

For the cooling mode, for example, when the value read by the delivery probe exceeds the SET POINT+(BANDA)/2

threshold value, if the increasing interstep time (set with FN16) has already expired, an increase in power is

implemented and the FN16 time is recounted (increasing interstep time). If the value read by the delivery probe

remains in this range, an additional power increase is activated for each “increasing interstep time” (set with FN16).

The operation is similar for switching off, with the times set by parameter FN17 (decreasing interstep time). Within

the PROPORTIONAL BAND, no variation in power is required.

Hysteresis is not included in this algorithm.

The addition and removal of power steps must respect the activation and release times between resources Fn16 and

Fn17 that are loaded upon their activation/release. In case of Neutral Zone regulation, the position of the Setpoint is

always central, independently from the value of the parameter St01. An example is shown below:

Page 47

Set point

+1 +1 +1

-1

T inc. T inc.

T inc.

T dec.

Time

Regulator probe

Band

Set point

+1 +1 +1

-1

T inc. T inc.

T inc.

T dec.

Time

Regulator probe

Band

Digital fan preventilation (cold mode only)

If the parameter Fn10=1 (if the compressor is OFF, the fan is OFF) and Fn15<>0, the preventilation function is active.

Prior to switching on the compressor, the fans will be activated for a time equal to Fn15; the number of fans activated

is proportional to the value of the regulation probe but is not less than 1. This is to avoid the compressor switching

on when the condensation probe values are excessively high.

If, at the end the preventilation, the regulator does not request fans, the fans are switched off immediately. The

preventilation is reset if the right parameter conditions are present and if the inlet request is zeroed and then returns

(even if the inlet request is cancelled by its alarm or the outlet alarm). In the event of a regulation probe error, the

fan ON/OFF switches will be controlled on request from the compressor. During the ON phase, the number of fans

switched on in respect to the number of those present depends on the value set at parameter Fn24.

47 48

Page 48

Digital fans rotation

In the case of step fans, rotation of the fans can be controlled during activation and release by means of parameter

Fn11. If Fn11=0 (fixed sequence), the activation sequence is fan 1, fan 2, ....fan n; The sequence is inverted during

deactivation, e.g. fan n..., fan 2, fan 1.

If Fn11=1 (operating hours), during activation the fan which worked the least is selected, while during deactivation

the fan which has worked the most is selected. The aim is to balance out the operating hours between all fans.

Maximum fans stop time

Parameter Fn18 indicates the maximum time for which the fans (continuous or digital) may remain off. Once this

time has elapsed, fan pick-up is forced for the time specified by Fn26.

If, during the pick up time, the compressors are switched on, the minimum cut-off bypass will not be respected at the

end of the pick-up time, and in the absence of a request by the fan regulator the fans will immediately be switched

off.

If, during the pick up time, preventilation is activated due to the compressors being switched on, it will remain active

for any remaining time after the end of the pick up time.

The function is disabled if Fn18=0 or if Fn26=0.

The time the fans are off is reinitialised each time the device is switched on.

Fan operating hours

The operating time of the fans is stored every hour in EEPROM for the purpose of:

Managing the fan rotation function based on the operating duration.

Enabling the signalling of an alarm if the fan operating hours exceed the maximum operating hours threshold.

Parameter Fn19 enables the maximum number of fan operating hours to be set.

The hours of use of each individual fan can be zeroed from the State menu.

Page 49

Fans thermal switch

The intervention of the digital fan thermal protection is blocked for the correctly used fan.

If another fan is available it will be selected depending on the policy (Fn11) and immediately activated. The

contemporaneous intervention of the thermal protections of all of the digital fans causes an alarm which blocks the

machine.

In the case of fans with continuous control or digital fans in which a single common thermal fan has been configured,

the tripping of the thermal switch causes the machine to shut down.

ADVANCED FUNCTIONS

On/off device

The activation/deactivation of the device used for controlling resources may be carried out via keyboard or digital

input:

ON/OFF from keyboard: The device may be switched on or off using the keyboard from the Folder

Programming menu OP. This function is not active if the ON/OFF is configured via digital input (e.g. for DI5,

CF20=13). In OFF mode, the screen will display the word OFF.

ON/OFF via Digital Input: If a digital or analogue input is configured for this function, the device state

depends on the input state. In OFF mode, the word OFF will flash on-screen. ON/OFF via keyboard is not

active.

49

Page 50

Recording operating hours

The device records the operating hours of the compressors and fans; This data is visible in the Hr folder and is called

CP0n (nth compressor hours), Fn0n (nth fan hours).

For values lower than 9999 the entire value is displayed, for higher values the hours/100 are displayed and the

decimal point is activated. The maximum limit of recorded hours is 65535; once this value has been reached the

device will automatically reset the hour counter. The display is dynamic, e.g. only the hours of actually available

resources will be displayed. It is possible to set a maximum operating hours threshold, which generates an alarm as

soon as it is reached (for example, for compressor or fan maintenance)

The alarm does not cause the exclusion of the regulator resource, and is displayed on-screen with a code depending

on the resource that has exceeded the permitted operating hours. The alarm does not reset the operating hours.

The operating hours can be reset manually from the states menu, Hr folder; When displaying the hours of a

particular resource, press and hold the “set” key to zero the operating hours of the resource (and not those of

other resources).

Real Time Clock (RTC)

The device can be supplied with a clock which makes it possible to store the time at which alarm events occurred.

The parameter CF72 is used to activate/deactivate the clock.

The current time is set using the appropriate menu as shown in the navigation menu diagram; use the Set key to

confirm the value once the time and date have been modified. The value will only be saved on exiting the menu

(timeout or by pressing the Esc key).

Once the time is set, the instrument must be connected for several hours to fully charge the back-up battery.

The switch between legal/solar time is not automatic.

The device does not perform a real time control on the correctness of the date set; this means that it is

possible to set a non-existent date such as 30/02/2007 without the machine noticing.

50

Page 51

ALARMS

The alarms can be one of 3 types:

Automatic reset alarm: alarm active if the cause of the alarm is present, otherwise not.

Manual reset alarm: alarm active if the cause of the alarm is present, if the cause of the alarm has ceased the alarm

can only be reset manually (by simultaneously pressing the UP and DOWN keys).

Semi-automatic alarm: Behaves like an automatic alarm as long as the number of events in the unit of time is less

than a certain value, otherwise like a manual alarm. The unit of time can be programmed using parameter AL00, the

number of responses can be individually programmed for each semi-automatic alarm.

Alarm events are stored with a time resolution of T=(AL00/32) minutes; multiple events occurring in period T are

counted as one single event.

Manual reset performed while an alarm cause is present does not enable the alarm to be reset.

It is possible to force the semi-automatic alarm to be considered only as an automatic alarm or a manual reset alarm,

by setting the appropriate number of alarm responses:

If the number of responses=0, the alarm is managed as a manual reset alarm only. At the first response, the

alarm will become active and can be reset manually;

If the number of responses=33 the alarm is managed as an automatic alarm only. At the first response, the

alarm becomes active but automatically resets when the cause has ceased;

A bypass time is defined for semi-automatic alarms and can be set by parameter. It allows the alarm signal to be

delayed, for example to enable the system to stabilise.

If the bypass time = 0, the alarm response is immediate (see the following diagram).

Alarm signal

See special display diagram

51

Page 52

1 event

3=AL10210Counter

Manual

Time

AUTOMATIC

ON

Alarm

OFF

1

Events

0

1 event

1 event

Sampling

AUTOMATIC automatic reset

AL00/32 AL00/32 AL00/32 AL00/32

Manual manual reset

AL00/32 sampling time

Silence and reset alarms

Alarm silencing consists of the forced deactivation of the output configured as an alarm and is performed by pressing

any key (in the presence of an alarm). Silencing has no effect on the alarm state, it only affects the signal itself; The

alarm LED, which is a fixed light in the presence of an alarm, becomes a flashing light when silenced. Alarm reset

consists of zeroing all pending manual reset alarms.

Events no. of considered events. Event 3 = (AL10)

52 53

Page 53

This is done by simultaneously pressing the UP + DOWN keys. To reset a manual reset alarm which is still active, the

alarm must be first deactivated and then immediately re-entered. This causes a new entry to be stored in the alarms

log and resets the alarm relay (silenced by key).

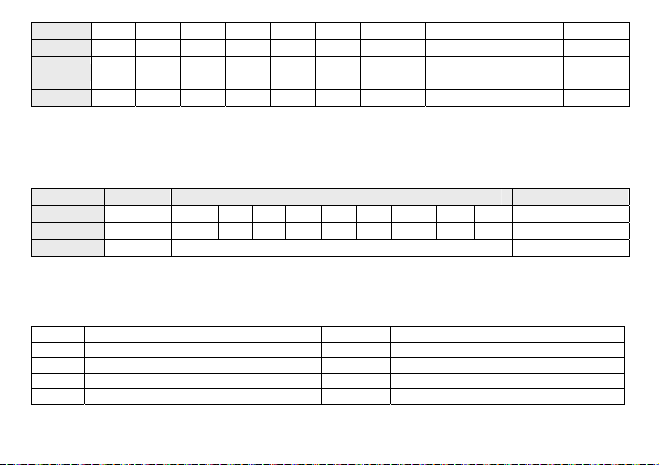

Alarms list with description and activation parameters

A= By-pass C= n° of responses

Code Description Type Cause (Set) Activation Hysteresis A 1) C 2) 3)

Er01 Low pressure switch - inlet inlet probe<= CP00

Er02 High pressure switch - inlet

Er03 Low pressu re switch - outlet outlet probe<= Fn00

Er04 High pr essure switch - outlet

Er05 Inlet probe maximum EVE inlet probe>set activation

Er06 Inlet probe minimum EVE Inlet probe<set activation

Er07 Outlet probe maximum EVE

Er08 Outlet probe minimum EVE

Er09 Block compressor 1 EVE Block compressor 1

Er10 Block compressor 2 EVE Block compressor 2

Er11 Block compressor 3 EVE Block compressor 3

Inlet

EVE

gas pressure switch

Outlet

EVE

pressure switch

Outlet probe>set

activation

Outlet probe<set

activation

inlet probe> CP00

outlet probe> Fn00

AL17 if St03=0

CP00+AL17 if St03=1

AL19 if St03=0

CP00-AL19 if St03=1

AL21 if St03=0

Fn00+AL21 if St03=1

AL23 if St03=0

Fn00-AL23 if St03=1

AL18 AL08 AL07

AL20 AL06 AL05

AL22 AL12 AL11

AL24 AL10 AL09

Er12 Block compressor 4 EVE Block compressor 4

Continuous compressor

Er13

shut-down

Continuous compressor

EVE

shut-down

AL02 AL01

AL04 AL03

AL14 AL13

Page 54

Code Description Type Cause (Set) Activation Hysteresis A 1) C 2) 3)

Er14 Fan thermal switch 1 EVE Fan thermal switch 1

Er15 Fan thermal switch 2 EVE Fan thermal switch 2

Er16 Fan thermal switch 3 EVE Fan thermal switch 3

Er17 Fan thermal switch 4 EVE Fan thermal switch 4

Continuous fan thermal

Er18

switch

shared fans thermal switch

Operating hours exceeded

Er19

Compr. 1

Operating hours exceeded

Er20

Compr. 2

Operating hours exceeded

Er21

Compr. 3

Operating hours exceeded

Er22

Compr. 4

Operating hours exceeded

Er23

Compr. Inverter

Operating hours exceeded

Er24

Fan 1

Operating hours exceeded

Er25

Fan 2